Discover the Best Timing Belt Supplier: Save Costs Today (2025)

Introduction: Navigating the Global Market for timing belt supplier

In today’s interconnected marketplace, sourcing a reliable timing belt supplier can pose significant challenges for international B2B buyers. Factors such as varying quality standards, fluctuating prices, and the complexities of cross-border logistics often complicate the procurement process. This guide is designed to equip you with the knowledge needed to navigate these challenges effectively. We will explore the different types of timing belts available, their applications across various industries, and how to thoroughly vet potential suppliers to ensure quality and reliability.

Additionally, we’ll provide insights into cost considerations and the importance of establishing long-term supplier relationships, particularly for buyers in Africa, South America, the Middle East, and Europe, including regions like Australia and Spain. By leveraging this comprehensive resource, you will be empowered to make informed purchasing decisions that not only meet your operational needs but also enhance your competitive edge in the global market.

This guide aims to demystify the sourcing process, offering actionable insights that facilitate smoother transactions and foster successful partnerships with timing belt suppliers worldwide. Whether you are a seasoned procurement professional or new to the B2B landscape, our goal is to provide you with the tools necessary to thrive in your sourcing endeavors.

Understanding timing belt supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM (Original Equipment Manufacturer) | Manufactured to original specifications, often with brand reputation | Automotive, Industrial Machinery | Pros: High reliability, compatibility; Cons: Higher price, limited customization. |

| Aftermarket Suppliers | Offer similar quality to OEM but at lower costs, often with variations | Automotive, Home Appliances | Pros: Cost-effective, diverse options; Cons: Variable quality, potential compatibility issues. |

| Custom Timing Belt Suppliers | Provide bespoke solutions tailored to specific requirements | Specialized Machinery, Aerospace | Pros: Perfect fit for unique applications; Cons: Longer lead times, potentially higher costs. |

| Specialty Material Suppliers | Focus on specific materials like rubber, polyurethane, or reinforced composites | Heavy Machinery, Construction | Pros: Enhanced performance characteristics; Cons: Limited availability, specific use cases. |

| Global Suppliers | Operate on an international scale, offering a wide range of products | Diverse Industries Worldwide | Pros: Broad selection, competitive pricing; Cons: Longer shipping times, potential tariffs. |

What Are OEM Timing Belt Suppliers and Their Benefits?

OEM (Original Equipment Manufacturer) suppliers produce timing belts that adhere strictly to the original specifications set by the equipment manufacturers. These belts are typically recognized for their reliability and compatibility with specific machinery. For B2B buyers, opting for OEM timing belts ensures that they receive a product that meets industry standards and is backed by the manufacturer’s reputation. However, this comes at a premium price, and customization options may be limited.

How Do Aftermarket Timing Belt Suppliers Compare?

Aftermarket suppliers provide timing belts that offer similar quality to OEM products, but often at a more competitive price. These suppliers cater to various industries, including automotive and home appliances. The primary advantage for B2B buyers is the cost savings and the availability of a broader range of options. However, buyers must be cautious as the quality can vary significantly among different aftermarket brands, which may lead to compatibility issues.

What Makes Custom Timing Belt Suppliers Unique?

Custom timing belt suppliers specialize in creating bespoke timing belts tailored to specific applications. This is particularly advantageous for industries such as aerospace or specialized machinery where standard belts may not fit. While these suppliers can ensure a perfect fit for unique requirements, B2B buyers should be prepared for longer lead times and potentially higher costs associated with custom manufacturing.

Why Consider Specialty Material Suppliers for Timing Belts?

Specialty material suppliers focus on timing belts made from specific materials, such as rubber, polyurethane, or reinforced composites. These materials can enhance the performance characteristics of the belts, making them suitable for heavy machinery or construction applications. B2B buyers looking for specific performance metrics may find these suppliers beneficial, but they might encounter limited availability and a narrower range of use cases.

How Do Global Timing Belt Suppliers Operate?

Global suppliers operate on an international scale, providing a wide array of timing belt products across various industries. Their extensive networks allow for competitive pricing and a broad selection of products. However, B2B buyers should consider potential downsides, such as longer shipping times and the possibility of tariffs, which could impact overall costs and delivery schedules.

Related Video: SolidWorks Tutorial: Timing Belt Design and Assembly

Key Industrial Applications of timing belt supplier

| Industry/Sector | Specific Application of Timing Belt Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine Timing Systems | Ensures precise timing for engine performance and efficiency | Quality of materials, compatibility with existing systems, supplier certifications |

| Manufacturing | Conveyor Systems | Enhances productivity by providing reliable motion control | Durability under load, resistance to wear, lead times for delivery |

| Agriculture | Agricultural Machinery | Improves equipment reliability for planting and harvesting | Customization for specific machinery, climate resistance, availability of replacement parts |

| Food Processing | Packaging and Sorting Machines | Increases efficiency and reduces downtime in production lines | Compliance with food safety standards, hygiene materials, flexibility in sizes |

| Textile Industry | Looms and Spinning Machines | Maintains consistent speed and quality in fabric production | Precision engineering, sourcing from reputable suppliers, support for maintenance |

How Are Timing Belts Used in Automotive Applications?

In the automotive sector, timing belts are crucial for synchronizing the rotation of the crankshaft and camshaft, ensuring that the engine’s valves open and close at the correct times during each cylinder’s intake and exhaust strokes. This precision is vital for maximizing engine efficiency and performance. International buyers should consider sourcing timing belts that meet OEM specifications, ensuring compatibility with various engine models. Additionally, it’s important to assess the supplier’s ability to provide timely deliveries, as delays can disrupt production schedules.

What Role Do Timing Belts Play in Manufacturing?

In manufacturing, timing belts are integral to conveyor systems that transport materials and products through assembly lines. They help maintain consistent speed and positioning, crucial for high-volume production. Buyers from regions like Africa and South America may seek suppliers who can provide belts that withstand harsh operating conditions, such as high temperatures or heavy loads. Furthermore, understanding the supplier’s lead times and after-sales support is essential to minimize downtime and maximize productivity.

How Are Timing Belts Applied in Agriculture?

In the agricultural sector, timing belts are used in various machinery, such as tractors and harvesters, to ensure smooth operation of critical components. They help in maintaining the synchronization of moving parts, which is vital for efficient planting and harvesting processes. Buyers should focus on suppliers that offer customized solutions tailored to specific agricultural machinery, considering factors like climate resistance and the availability of quick replacement parts to reduce operational disruptions.

Why Are Timing Belts Important in Food Processing?

In food processing, timing belts are utilized in packaging and sorting machines to facilitate the efficient movement of products along production lines. Their reliability directly impacts production rates and product quality. Buyers must ensure that the timing belts comply with food safety standards, using materials that are hygienic and resistant to contaminants. Additionally, flexibility in sizes and configurations can be a significant advantage in adapting to various production needs.

What Is the Significance of Timing Belts in the Textile Industry?

In the textile industry, timing belts are essential in looms and spinning machines, where they maintain a consistent speed necessary for high-quality fabric production. The precise operation of these machines is critical to prevent defects and ensure uniformity in textile products. International buyers should prioritize suppliers who specialize in precision-engineered timing belts and can provide ongoing support for maintenance and customization, ensuring sustained operational efficiency in their production processes.

Related Video: TIMING BELTS & PULLEYS PT. 4: TIMING BELT TENSION | MECH MINUTES | MISUMI USA

3 Common User Pain Points for ‘timing belt supplier’ & Their Solutions

Scenario 1: Quality Assurance in Sourcing Timing Belts

The Problem: B2B buyers often encounter difficulties in ensuring the quality of timing belts sourced from suppliers. Poor-quality belts can lead to unexpected machinery failures, increased downtime, and significant repair costs. For buyers in regions like Africa and South America, where local manufacturing might be limited, relying on international suppliers poses risks regarding product authenticity and durability.

The Solution: To mitigate quality concerns, buyers should implement a multi-step vetting process for timing belt suppliers. This includes requesting product samples and certificates of compliance with international standards such as ISO 9001 or TS16949. Engaging in supplier audits or using third-party inspection services can further ensure adherence to quality benchmarks. Additionally, fostering long-term relationships with suppliers can facilitate better communication and transparency, ensuring that any issues are addressed proactively.

Scenario 2: Understanding Timing Belt Specifications

The Problem: Many buyers struggle with the complex specifications of timing belts, including dimensions, materials, and load capacities. This challenge is particularly pronounced for buyers in the Middle East and Europe, where diverse applications require precise matching of timing belts to specific machinery. Misunderstandings in specifications can result in ordering incorrect products, leading to costly delays and operational inefficiencies.

The Solution: Buyers should invest time in understanding the technical specifications relevant to their applications. This can be achieved through collaboration with engineering teams to define exact requirements and by utilizing suppliers who offer comprehensive technical support. Creating a checklist of required specifications—such as belt width, pitch, and material type—can streamline the selection process. Moreover, leveraging digital tools like CAD software or supplier platforms that visualize components can aid in making informed decisions.

Scenario 3: Managing Supply Chain Disruptions

The Problem: Global supply chain disruptions have become a common issue, particularly for industries relying on imported timing belts. Buyers from Europe and the Middle East are often faced with delays in delivery schedules, which can halt production lines and impact overall business operations. Navigating these disruptions while maintaining inventory levels is a significant pain point for many organizations.

The Solution: To effectively manage supply chain risks, buyers should adopt a proactive inventory management strategy. This includes maintaining safety stock levels and diversifying the supplier base to avoid dependency on a single source. Implementing just-in-time (JIT) inventory practices can help minimize excess stock while ensuring timely access to required materials. Additionally, establishing clear communication channels with suppliers regarding lead times and potential disruptions can facilitate better planning and contingency strategies. Buyers may also consider utilizing technology solutions, such as supply chain management software, to enhance visibility and responsiveness throughout the procurement process.

Strategic Material Selection Guide for timing belt supplier

When selecting materials for timing belts, international B2B buyers must consider various factors, including the specific properties of the materials, their advantages and disadvantages, and their compatibility with different applications. Below, we analyze four common materials used in timing belt manufacturing, providing insights tailored for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Rubber Timing Belts?

Rubber is one of the most widely used materials for timing belts due to its excellent elasticity and flexibility. Key properties include:

- Temperature Rating: Typically effective in a range from -30°C to 100°C.

- Corrosion Resistance: Generally resistant to water and some chemicals, but can degrade with exposure to oils and solvents.

Pros & Cons: Rubber timing belts are durable and cost-effective, making them suitable for a variety of applications. However, they may not perform well in high-temperature environments or when exposed to certain chemicals.

Impact on Application: Rubber belts are commonly used in automotive and industrial applications where flexibility and noise reduction are important. Buyers should ensure that the specific rubber compound is compatible with the media it will encounter.

Considerations for International Buyers: Compliance with standards such as ASTM D2000 is crucial. Buyers from regions like Europe may prefer belts that meet specific EU regulations regarding material safety.

How Do Polyurethane Timing Belts Compare?

Polyurethane timing belts are known for their strength and wear resistance. Their key properties include:

- Temperature Rating: Can operate effectively at temperatures up to 80°C, with some specialized formulations reaching 120°C.

- Corrosion Resistance: Excellent resistance to oils, chemicals, and abrasion.

Pros & Cons: The durability and chemical resistance of polyurethane belts make them ideal for harsh environments. However, they can be more expensive and may require more complex manufacturing processes.

Impact on Application: These belts are often used in applications such as conveyor systems and robotics, where high load-bearing capacity is required. Buyers should assess the specific application to determine if polyurethane is the right choice.

Considerations for International Buyers: Compliance with international standards like DIN 2215 is essential. Buyers should also consider the availability of specific formulations in their region.

What Advantages Do Steel Reinforced Timing Belts Offer?

Steel-reinforced timing belts provide additional strength and stability. Key properties include:

- Temperature Rating: Generally effective in temperatures up to 100°C.

- Corrosion Resistance: Steel reinforcement can be susceptible to corrosion if not properly treated.

Pros & Cons: These belts offer superior tensile strength and are ideal for high-torque applications. However, they can be heavier and more costly than other options, and the manufacturing process is more complex.

Impact on Application: Steel-reinforced belts are commonly used in high-performance automotive engines and industrial machinery. Buyers should consider the weight and torque requirements of their specific applications.

Considerations for International Buyers: Buyers should ensure that the belts meet relevant standards such as JIS B 1301 for industrial belts. Additionally, they should be aware of the potential for corrosion in humid environments.

What Are the Benefits of Composite Timing Belts?

Composite timing belts, often made from a blend of materials, offer a balance of properties. Key properties include:

- Temperature Rating: Varies widely depending on the composite materials used, typically ranging from -20°C to 80°C.

- Corrosion Resistance: Varies; some composites may offer better resistance to specific chemicals than others.

Pros & Cons: The versatility of composite belts makes them suitable for a wide range of applications. However, their performance can vary significantly based on the specific materials used in the composite.

Impact on Application: Composite belts are used in various industries, including automotive and manufacturing, where specific performance characteristics are required. Buyers should evaluate the composition to ensure it meets their needs.

Considerations for International Buyers: Compliance with standards such as ISO 9001 can be important. Buyers should also consider the specific environmental conditions of their operational regions.

Summary Table of Material Selection for Timing Belts

| Material | Typical Use Case for timing belt supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Automotive, general industrial | Cost-effective and flexible | Limited high-temperature performance | Low |

| Polyurethane | Conveyor systems, robotics | High durability and chemical resistance | Higher cost and complex manufacturing | Medium |

| Steel Reinforced | High-performance engines, industrial machinery | Superior tensile strength | Heavier and more expensive | High |

| Composite | Various industries | Versatile and adaptable | Variable performance based on composition | Medium |

This strategic material selection guide provides international B2B buyers with essential insights into the materials used for timing belts, enabling informed decisions based on specific application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for timing belt supplier

What Are the Key Manufacturing Processes for Timing Belt Suppliers?

Understanding the manufacturing processes of timing belts is crucial for international B2B buyers looking to source high-quality products. The production of timing belts typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage utilizes specific techniques to ensure the final product meets stringent performance standards.

How Is Material Prepared for Timing Belt Production?

The first step in the manufacturing process is the preparation of raw materials. Timing belts are primarily made from synthetic rubber and reinforced with materials such as fiberglass or polyester.

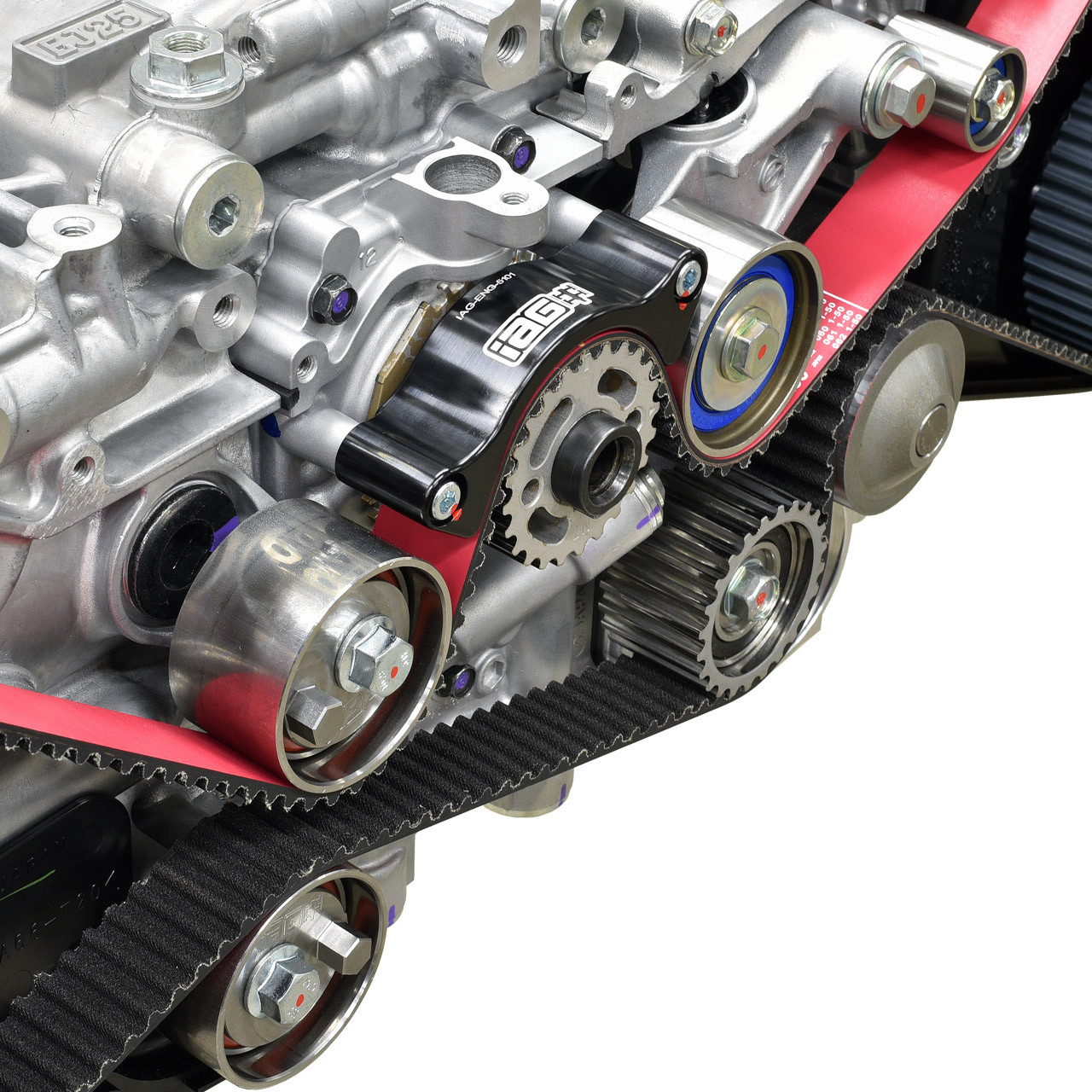

A stock image related to timing belt supplier.

-

Material Selection: Suppliers must select high-quality rubber compounds that offer durability, flexibility, and resistance to wear. The choice of reinforcements also plays a vital role in the belt’s strength and longevity.

-

Compounding: The selected materials are mixed in specific ratios to create a compound that meets the required mechanical properties. This process often includes adding various chemicals to enhance properties like heat resistance and tensile strength.

-

Pre-forming: The compounded material is then shaped into sheets or strips, ready for the next manufacturing stage.

What Techniques Are Used in the Forming Process?

The forming process is where the actual shape of the timing belt is created.

-

Extrusion: The prepared rubber compound is extruded into the desired profile. This technique ensures uniform thickness and consistency, which are critical for the belt’s performance.

-

Molding: In some cases, belts may be molded to incorporate specific features such as grooves or teeth, which are essential for synchronizing movement in machinery.

-

Curing: After forming, the belts undergo a curing process (vulcanization) to enhance their durability. This involves heating the rubber to create cross-links between the polymer chains, resulting in a strong, elastic material.

How Are Timing Belts Assembled and Finished?

Once the belts are formed, they proceed to the assembly and finishing stages.

-

Toothing and Reinforcement: If not already integrated, the toothing is added at this stage. Reinforcement materials, such as fiberglass cords, are also embedded to provide additional strength.

-

Trimming and Sizing: The belts are then trimmed to specific lengths and widths to meet customer specifications. This precision is crucial for ensuring compatibility with machinery.

-

Finishing Treatments: Finally, the belts may undergo additional treatments, such as surface coating, to improve wear resistance and reduce friction. This step enhances the overall performance and lifespan of the product.

What Quality Assurance Measures Are Essential for Timing Belt Suppliers?

Quality assurance (QA) is paramount in the production of timing belts, as these components are critical in various machinery and automotive applications. B2B buyers must ensure that their suppliers adhere to internationally recognized standards and implement effective QC measures.

Which International Standards Should B2B Buyers Look For?

Timing belt suppliers should comply with several international quality standards to ensure product reliability:

-

ISO 9001: This is the most widely recognized quality management standard. It ensures that the supplier follows consistent quality processes and focuses on customer satisfaction.

-

CE Marking: In Europe, products must have CE marking to indicate conformity with health, safety, and environmental protection standards.

-

API Certification: For suppliers involved in automotive applications, certification from the American Petroleum Institute (API) can further validate quality and performance.

What Are the Key QC Checkpoints in Timing Belt Manufacturing?

Quality control is integrated at various stages of the manufacturing process, commonly known as IQC (Incoming Quality Control), IPQC (In-Process Quality Control), and FQC (Final Quality Control).

-

IQC: Raw materials are inspected upon arrival to ensure they meet specified standards. This includes testing for physical properties and chemical composition.

-

IPQC: During manufacturing, periodic checks are made to monitor the production process. This includes verifying dimensions, material properties, and the integrity of the curing process.

-

FQC: Final inspection occurs after the belts are completed. This step involves a thorough examination of the finished product, including functional tests and visual inspections for defects.

How Can B2B Buyers Verify Supplier Quality Control?

International buyers should take specific steps to verify the quality control measures of potential suppliers:

-

Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes and quality assurance practices. This is essential for understanding their operational capabilities.

-

Quality Reports: Requesting detailed quality reports, including test results and certifications, can help assess the reliability of the supplier’s products.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s QC processes and the quality of the finished products.

What Nuances Should International Buyers Consider Regarding QC and Certification?

When sourcing timing belts from suppliers in different regions, B2B buyers must be aware of the nuances in quality assurance and certification practices:

-

Regional Standards: Different regions may have specific regulations and standards. For example, suppliers in Europe are often required to meet stricter environmental and safety standards than those in other regions.

-

Cultural Differences: Understanding the cultural context of suppliers can impact communication and expectations regarding quality. Establishing clear quality benchmarks and open lines of communication is essential.

-

Documentation: Ensure that all certifications and quality control documentation are up to date and easily accessible. This transparency builds trust and facilitates smoother transactions.

In conclusion, B2B buyers from Africa, South America, the Middle East, and Europe should prioritize understanding the manufacturing processes and quality assurance practices of timing belt suppliers. By doing so, they can make informed decisions, ensuring they partner with reliable suppliers that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘timing belt supplier’

Introduction

Sourcing a reliable timing belt supplier is crucial for businesses that depend on precision and efficiency in their manufacturing processes. This guide provides a step-by-step checklist to help international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigate the procurement process effectively. By following these actionable steps, you can ensure that you select a supplier that meets your specific needs and quality standards.

Step 1: Define Your Technical Specifications

Before engaging potential suppliers, clearly outline your technical specifications for timing belts. This includes dimensions, material requirements, load capacity, and application context. A well-defined specification helps eliminate misunderstandings and ensures that suppliers can meet your exact needs.

- Consider industry standards: Familiarize yourself with relevant industry standards (e.g., ISO or ANSI) to ensure compliance.

- Assess your application: Different applications may require specific belt types (e.g., synchronous or serpentine), so identify what suits your operations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential timing belt suppliers. Use industry directories, trade shows, and online platforms to compile a list of candidates.

- Check online reviews: Look for feedback from other B2B buyers to gauge the supplier’s reputation.

- Evaluate their experience: Prefer suppliers with a proven track record in your industry or similar applications.

Step 3: Verify Supplier Certifications

Ensure that your potential suppliers have the necessary certifications that guarantee quality and compliance with industry standards. This step is critical to mitigate risks associated with sourcing inferior products.

- Request documentation: Ask for certificates such as ISO 9001 for quality management or ISO/TS 16949 for automotive components.

- Inquire about quality control processes: Understanding their quality assurance measures can provide insights into their operational standards.

Step 4: Request Samples for Testing

Before making a bulk order, request samples of the timing belts. Testing samples is essential to validate their performance under actual working conditions.

- Conduct thorough testing: Evaluate the samples for durability, elasticity, and compatibility with your machinery.

- Assess supplier response time: A prompt response to sample requests indicates a supplier’s commitment to customer service.

Step 5: Negotiate Pricing and Terms

Once you have vetted suppliers and tested their products, enter negotiations regarding pricing, payment terms, and delivery schedules. This step is vital for establishing a mutually beneficial relationship.

- Consider total cost of ownership: Evaluate not just the price per unit but also shipping costs, duties, and potential tariffs.

- Establish payment terms: Discuss favorable terms such as net payment periods or early payment discounts to improve cash flow.

Step 6: Evaluate After-Sales Support

Assess the level of after-sales support offered by your supplier. Reliable after-sales service can significantly impact your operational efficiency and long-term partnership.

- Inquire about warranty policies: Understand the warranty terms and what they cover to safeguard your investment.

- Check for technical support: Ensure that the supplier can provide timely assistance in case of issues with the products.

Step 7: Finalize the Agreement

Once you’ve completed the above steps and are satisfied with your chosen supplier, finalize the agreement. Ensure all terms discussed are documented clearly in a contract.

- Include performance metrics: Define performance expectations and penalties for non-compliance to protect your interests.

- Establish communication channels: Set up regular check-ins to maintain a strong relationship and facilitate open communication.

By following this checklist, B2B buyers can effectively navigate the sourcing process for timing belt suppliers, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for timing belt supplier Sourcing

What Are the Key Cost Components in Timing Belt Supplier Sourcing?

When evaluating suppliers for timing belts, understanding the cost structure is crucial. The primary components contributing to the overall cost include:

-

Materials: The type and quality of raw materials directly influence pricing. High-performance materials may incur higher costs but can provide better durability and efficiency.

-

Labor: Labor costs vary based on location. Suppliers in regions with lower wage standards may offer more competitive pricing, but it’s essential to consider the trade-off in quality and expertise.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce these costs.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. However, these costs are often amortized over large production runs.

-

Quality Control (QC): Implementing rigorous QC measures is essential for ensuring product reliability. Suppliers that invest in quality assurance may charge a premium, but this can lead to lower defect rates and longer-lasting products.

-

Logistics: Shipping costs, including freight and insurance, can vary significantly based on distance and shipping methods. Incoterms also play a role in determining who bears these costs.

-

Margin: Supplier profit margins can vary widely. Understanding a supplier’s pricing strategy can offer insights into their financial health and reliability.

How Do Price Influencers Impact Timing Belt Sourcing Decisions?

Several factors can influence the pricing of timing belts, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs. Negotiate MOQs that align with your inventory needs to optimize costs.

-

Specifications and Customization: Custom specifications can increase costs due to the need for specialized materials or manufacturing processes. Clearly define your requirements to avoid unexpected price hikes.

-

Materials and Quality Certifications: Suppliers offering higher quality materials or certifications (such as ISO 9001) may charge more. However, investing in certified products can reduce the risk of failures and associated costs in the long run.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can affect pricing. Established suppliers with a history of reliability may charge more but can provide peace of mind.

-

Incoterms: Understanding Incoterms is critical for international transactions. They determine responsibility for shipping, insurance, and tariffs, impacting the total landed cost of goods.

What Are the Best Practices for Negotiating Pricing with Timing Belt Suppliers?

International B2B buyers should adopt strategic approaches to negotiate effectively:

-

Research Market Prices: Conduct thorough market research to understand standard pricing. This knowledge can serve as leverage during negotiations.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost associated with the product over its lifecycle, including maintenance and replacement costs.

-

Establish Long-term Relationships: Building long-term partnerships with suppliers can lead to better pricing and terms. Suppliers are often more willing to negotiate with repeat customers.

-

Be Transparent About Expectations: Clearly communicate your needs regarding quality, delivery schedules, and payment terms. This transparency can foster trust and lead to more favorable agreements.

-

Consider Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, exploring local suppliers can reduce logistics costs and simplify communication.

What Should Buyers Keep in Mind Regarding Indicative Prices?

While exploring potential suppliers, it’s essential to remember that prices are often indicative and can fluctuate based on market conditions, demand, and raw material costs. Always request detailed quotations that include all cost components to ensure clarity and avoid surprises. Engaging multiple suppliers can also provide a comparative analysis, helping you make an informed decision that aligns with your budget and quality requirements.

Alternatives Analysis: Comparing timing belt supplier With Other Solutions

Understanding Alternatives to Timing Belt Suppliers

When it comes to sourcing timing belts for various applications, international B2B buyers often explore multiple solutions to ensure they make informed decisions. Evaluating alternatives not only helps in understanding the market better but also allows buyers to select the most efficient, cost-effective, and reliable option for their specific needs. In this section, we will compare timing belt suppliers against two viable alternatives: chain drives and direct drive systems.

Comparison Table of Timing Belt Supplier and Alternatives

| Comparison Aspect | Timing Belt Supplier | Chain Drive | Direct Drive |

|---|---|---|---|

| Performance | High, smooth operation; good for moderate loads | High, suitable for heavy loads; more noise | Very high; immediate response and torque |

| Cost | Moderate; competitive pricing | Generally lower initial cost but higher long-term maintenance | Higher initial investment; lower maintenance costs |

| Ease of Implementation | Relatively easy; requires tensioning and alignment | More complex; requires precise installation | Easiest; minimal components involved |

| Maintenance | Moderate; requires periodic checks | High; needs regular lubrication and adjustments | Low; minimal upkeep required |

| Best Use Case | Automotive and industrial machinery | Heavy machinery, construction equipment | Robotics, high-performance applications |

What Are the Pros and Cons of Chain Drives?

Chain drives are a robust alternative to timing belts, particularly in applications requiring high torque and load-bearing capabilities. Pros include their strength and durability, making them ideal for heavy machinery and construction equipment. They can handle significant loads without slipping, which is critical in demanding environments. However, cons involve higher maintenance needs, as chain drives require regular lubrication and adjustments to prevent wear and tear. Additionally, they tend to be noisier than timing belts, which may not be suitable for all applications, especially in environments where noise reduction is essential.

How Do Direct Drive Systems Compare?

A stock image related to timing belt supplier.

Direct drive systems offer a compelling alternative to traditional timing belts, particularly in applications requiring immediate torque response and high precision. The pros of direct drive systems include minimal mechanical losses and reduced maintenance requirements since they consist of fewer components. This design allows for a more compact setup and eliminates the need for tensioning or alignment adjustments. However, the cons include a higher initial investment, which may not be feasible for all buyers, particularly those in cost-sensitive markets. Additionally, direct drives may not be suitable for all load types, limiting their application scope compared to timing belts.

How Can B2B Buyers Choose the Right Solution?

Choosing the right solution among timing belt suppliers, chain drives, and direct drive systems largely depends on the specific application requirements and operational constraints. B2B buyers should consider factors such as load capacity, noise tolerance, maintenance capabilities, and budget constraints. For example, automotive industries may prefer timing belts for their smooth operation, while heavy machinery manufacturers might lean towards chain drives for their durability. In contrast, industries focusing on robotics may find direct drives to be the most efficient choice due to their precision and minimal maintenance needs. Ultimately, the decision should align with the long-term operational goals of the business, ensuring maximum efficiency and cost-effectiveness.

Essential Technical Properties and Trade Terminology for timing belt supplier

What Are the Essential Technical Properties of Timing Belts for B2B Buyers?

When sourcing timing belts, understanding their technical properties is crucial for ensuring compatibility and performance in various applications. Here are some key specifications that buyers should consider:

What Material Grades Are Commonly Used for Timing Belts?

Material Grade: Timing belts are typically made from materials like neoprene, polyurethane, or rubber composites. Neoprene is known for its durability and resistance to oil and heat, while polyurethane offers flexibility and wear resistance. The choice of material directly impacts the belt’s lifespan and operational efficiency.

How Important Is Tolerance in Timing Belt Specifications?

Tolerance: This refers to the allowable deviation from specified dimensions, such as thickness and length. Precise tolerances are essential for ensuring that the timing belt fits correctly within a system, preventing slippage and mechanical failure. A high-quality timing belt with tight tolerances enhances the overall performance of machinery.

What Role Does Tooth Profile Play in Timing Belt Efficiency?

Tooth Profile: The design of the teeth on a timing belt (e.g., trapezoidal or round) affects how well it meshes with pulleys. The right tooth profile minimizes wear and noise while maximizing power transmission. Understanding this property helps buyers select belts that meet their specific operational needs.

Why Is Load Capacity a Critical Specification for Timing Belts?

Load Capacity: This measures the maximum load a timing belt can handle without failure. It is essential for buyers to assess the load requirements of their applications to avoid premature wear or breakage. A timing belt with insufficient load capacity can lead to costly downtimes and maintenance issues.

What Is the Significance of Belt Length in Timing Belt Applications?

Belt Length: The length of the timing belt must match the distance between the pulleys it operates on. Incorrect belt length can lead to installation difficulties and operational inefficiencies. Buyers should ensure accurate measurements when specifying belt lengths for their machinery.

What Are the Common Trade Terms Used by Timing Belt Suppliers?

In addition to technical properties, familiarity with industry terminology can facilitate smoother transactions and negotiations. Here are some common terms to know:

What Is an OEM in the Timing Belt Industry?

OEM (Original Equipment Manufacturer): This term refers to companies that produce components that are used in the manufacturing of a product. For timing belts, OEM suppliers guarantee that their belts meet specific standards and are compatible with the machinery for which they are designed.

How Does MOQ Affect Timing Belt Purchases?

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to ensure they can meet supplier requirements while managing their inventory effectively. This term often impacts pricing and supply chain decisions.

What Is an RFQ and Why Is It Important?

RFQ (Request for Quotation): An RFQ is a formal process in which a buyer requests pricing and terms from suppliers. For timing belts, issuing an RFQ can help buyers compare options and negotiate favorable terms, ensuring they get the best quality for their budget.

What Are Incoterms and How Do They Affect Timing Belt Transactions?

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in shipping and freight. Understanding Incoterms is essential for international buyers, as they clarify who is responsible for costs, risks, and logistics in the supply chain, impacting overall pricing and delivery.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing timing belts, ultimately enhancing their operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the timing belt supplier Sector

What Are the Current Market Dynamics and Key Trends in the Timing Belt Supplier Sector?

The timing belt supplier sector is currently experiencing significant shifts driven by global manufacturing trends and technological advancements. Key drivers include the increasing demand for efficient automotive and industrial machinery, which directly impacts the need for high-performance timing belts. The rise of electric vehicles (EVs) is reshaping this landscape, prompting suppliers to innovate and adapt their product lines to meet the unique requirements of EV powertrains. Additionally, advancements in materials science are leading to the development of timing belts that offer greater durability, reduced weight, and improved performance under extreme conditions.

Emerging technologies such as Industry 4.0 are reshaping sourcing strategies. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly leveraging digital platforms and supply chain analytics to optimize sourcing decisions. The shift towards just-in-time inventory systems is also notable, as companies seek to reduce holding costs while maintaining flexibility in their supply chains. Buyers should focus on suppliers who offer transparent pricing models and robust logistics solutions to navigate these dynamic market conditions effectively.

How Is Sustainability Influencing Sourcing Decisions in the Timing Belt Sector?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the timing belt sector. The environmental impact of manufacturing processes, including waste generation and carbon emissions, is under scrutiny, prompting companies to seek suppliers that prioritize eco-friendly practices. This includes the use of recycled materials and energy-efficient production methods, which not only reduce environmental footprints but also appeal to a growing consumer base that values sustainability.

Moreover, ethical supply chains are gaining importance, particularly in regions where labor practices may be a concern. Buyers should look for suppliers with certifications that demonstrate compliance with international labor standards and environmental regulations. Green certifications, such as ISO 14001 for environmental management systems, can serve as indicators of a supplier’s commitment to sustainability. By partnering with responsible suppliers, B2B buyers can enhance their brand reputation while contributing to global sustainability efforts.

What Is the Historical Context of the Timing Belt Supplier Industry?

The timing belt supplier industry has evolved considerably since its inception, driven by technological advancements and changing market demands. Initially, timing belts were made from simple rubber compounds, primarily serving the automotive sector. However, as machinery became more sophisticated and the demand for precision increased, manufacturers began to innovate with materials such as polyurethane and reinforced composites.

Over the decades, the introduction of advanced manufacturing techniques, such as injection molding and laser cutting, has transformed the production processes, leading to more efficient and reliable products. The rise of automation and digital technologies has further propelled the industry’s growth, enabling suppliers to offer customized solutions that meet specific customer needs. Understanding this evolution can help B2B buyers appreciate the complexities of the supply chain and the importance of partnering with suppliers who are forward-thinking and adaptable to future market changes.

Frequently Asked Questions (FAQs) for B2B Buyers of timing belt supplier

-

How do I choose the right timing belt supplier for my business needs?

When selecting a timing belt supplier, consider factors such as their industry reputation, product quality, and customer service. Look for suppliers with ISO certifications, as this indicates adherence to international quality standards. Additionally, assess their capacity to meet your specific requirements, including product range, customization options, and lead times. Request samples to evaluate the product quality firsthand, and seek testimonials or case studies from other B2B clients in your region to gauge reliability. -

What are the common types of timing belts available for industrial applications?

Timing belts come in various types, including rubber, polyurethane, and reinforced options. Rubber timing belts are widely used for general purposes, while polyurethane belts offer enhanced durability and resistance to wear and tear. Reinforced belts, often with steel cords, are designed for high-load applications. Assess your operational needs, such as load capacity, speed requirements, and environmental conditions, to determine the best timing belt type for your specific application. -

What minimum order quantities (MOQ) should I expect from timing belt suppliers?

The MOQ for timing belts can vary significantly based on the supplier and the complexity of the product. Many suppliers may require a MOQ of 100 to 500 units for standard products, while custom orders may have higher MOQs. It’s essential to discuss your purchasing needs upfront with potential suppliers to understand their MOQ policies and explore options for smaller initial orders or trial runs, especially if you are testing a new product line. -

What payment terms are typically offered by timing belt suppliers?

Payment terms can vary by supplier, but common practices include net 30, net 60, or upfront payments for first-time buyers. Some suppliers may offer discounts for early payments or bulk orders. It’s advisable to negotiate favorable terms that align with your cash flow needs. Consider using letters of credit for international transactions to mitigate risk and ensure secure payments, especially when dealing with suppliers from different regions. -

How can I ensure the quality of timing belts from international suppliers?

To ensure quality, request certifications such as ISO 9001 from your suppliers, which indicate compliance with international quality standards. Consider conducting factory audits or third-party inspections to verify production processes and quality control measures. Additionally, request product samples for testing and establish clear quality assurance protocols, including specifications and testing methods, to maintain consistent quality throughout your supply chain. -

What logistics considerations should I keep in mind when sourcing timing belts internationally?

When sourcing timing belts from international suppliers, factor in shipping costs, delivery times, and customs regulations. Choose a reliable logistics partner familiar with international shipping to manage transportation efficiently. Consider the Incoterms (International Commercial Terms) that dictate responsibilities for shipping, insurance, and tariffs. Additionally, plan for potential delays due to customs clearance and ensure your supply chain can accommodate these factors without disrupting operations. -

Can timing belts be customized to meet specific application requirements?

Yes, many timing belt suppliers offer customization options to meet unique application needs. Customizations can include specific lengths, widths, tooth profiles, materials, and additional features such as coatings for enhanced performance. Discuss your requirements with potential suppliers to see if they can accommodate your specifications and provide prototypes for testing before committing to larger orders. This will ensure that the belts perform optimally in your intended applications. -

What are the most common applications for timing belts in various industries?

Timing belts are widely used across various industries, including automotive, manufacturing, and robotics. In automotive applications, they synchronize engine components, while in manufacturing, they are utilized in conveyor systems and machinery for power transmission. Robotics often employs timing belts for precision movement and control. Understanding the specific needs of your industry will help you choose the right timing belts that meet performance standards and operational requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for timing belt supplier

In the increasingly competitive landscape of timing belt suppliers, strategic sourcing emerges as a critical component for international B2B buyers. By thoroughly evaluating potential suppliers, assessing their capabilities, and understanding regional market dynamics, businesses can secure quality products that meet their operational needs. This proactive approach not only reduces costs but also mitigates risks associated with supply chain disruptions.

How Can Strategic Sourcing Enhance Your Supply Chain?

Adopting a strategic sourcing mindset enables buyers from Africa, South America, the Middle East, and Europe to leverage global supplier networks effectively. Engaging with suppliers who demonstrate innovation, reliability, and compliance with international standards can lead to long-term partnerships that drive mutual growth. Moreover, understanding local regulations and market conditions can help in selecting suppliers that align with specific regional requirements.

What Should International B2B Buyers Consider Next?

As you navigate the selection process, focus on building relationships with suppliers that prioritize sustainability and technological advancements in their products. This forward-thinking approach will not only enhance your supply chain resilience but also position your business favorably in the market.

In conclusion, the future of sourcing timing belts is bright for those who embrace strategic methodologies. Engage with potential suppliers today to explore opportunities that will propel your business forward in this dynamic global marketplace.