Discover the Best Torque Wrench Manufacturer for Your Needs (2025)

Introduction: Navigating the Global Market for torque wrench manufacturer

In today’s competitive landscape, sourcing the right torque wrench manufacturer can pose significant challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With a myriad of options available, businesses often struggle to identify suppliers that offer both quality and cost-effectiveness. This comprehensive guide delves into the essential aspects of selecting a torque wrench manufacturer, covering various types of torque wrenches, their applications across different industries, and the critical process of supplier vetting.

International buyers will benefit from insights on evaluating manufacturing capabilities, understanding market trends, and comparing costs effectively. This guide not only highlights the importance of quality standards and certifications but also emphasizes the value of building long-term relationships with suppliers. By addressing common pain points and providing actionable strategies, this resource empowers businesses to make informed purchasing decisions tailored to their specific needs.

As you navigate the complexities of the global market for torque wrenches, this guide serves as a vital tool in your procurement strategy, ensuring you can confidently select a manufacturer that aligns with your operational goals and quality expectations. Whether you are in Brazil seeking reliable suppliers or in Europe looking for innovative solutions, this guide is designed to enhance your sourcing process and drive business success.

Understanding torque wrench manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Beam Torque Wrench | Simple mechanical design, visual reading scale | Automotive repairs, assembly lines | Pros: Cost-effective, easy to use. Cons: Less precise than other types. |

| Click Torque Wrench | Audible click at preset torque, ergonomic handle | Maintenance in manufacturing, aerospace | Pros: High accuracy, user-friendly. Cons: Requires calibration, can be expensive. |

| Digital Torque Wrench | Digital display, memory functions for multiple settings | Precision engineering, quality control | Pros: Very precise, easy to read. Cons: Battery-dependent, higher price point. |

| Adjustable Torque Wrench | Adjustable settings, versatile for different torque levels | General construction, heavy machinery | Pros: Flexible usage, suitable for various tasks. Cons: More complex operation. |

| Torque Angle Wrench | Measures both torque and angle, often used in conjunction | Automotive assembly, high-tension applications | Pros: Ensures precise tightening, enhances safety. Cons: Can be cumbersome, requires training. |

What Are the Characteristics of Beam Torque Wrenches?

Beam torque wrenches are characterized by their simple mechanical design, featuring a beam and a scale for torque measurement. They are particularly suitable for automotive repairs and assembly lines where cost-effectiveness is a priority. When purchasing a beam torque wrench, consider the ease of reading the scale and the overall durability of the tool. While they are affordable and easy to use, they may lack the precision required for high-stakes applications.

How Do Click Torque Wrenches Stand Out?

Click torque wrenches are distinguished by their audible click that signals when the preset torque is reached, making them user-friendly and effective for maintenance in manufacturing and aerospace sectors. Key purchasing considerations include the wrench’s calibration and ergonomic design. While they offer high accuracy and ease of use, buyers should be aware of the need for periodic calibration and the potential for higher costs compared to simpler models.

What Makes Digital Torque Wrenches a Preferred Choice?

Digital torque wrenches feature a digital display and often include memory functions for storing multiple settings. They are ideal for precision engineering and quality control applications where exact measurements are critical. Buyers should consider the readability of the display and battery life when selecting a digital torque wrench. Although they provide exceptional precision and ease of use, their reliance on batteries and higher price point can be drawbacks.

Why Choose Adjustable Torque Wrenches for Versatility?

Adjustable torque wrenches offer the flexibility to set varying torque levels, making them suitable for general construction and heavy machinery applications. When considering an adjustable torque wrench, buyers should evaluate the ease of adjustment and the range of torque settings available. Their versatility is a significant advantage, but the complexity of operation may require additional training for effective use.

What Are the Benefits of Torque Angle Wrenches?

Torque angle wrenches are unique in that they measure both torque and angle, making them essential for automotive assembly and high-tension applications. Key considerations for buyers include the ease of use and the accuracy of both torque and angle measurements. While these wrenches enhance safety and ensure precise tightening, they can be cumbersome and may require specialized training to operate effectively.

Related Video: How to use a Torque Wrench PROPERLY

Key Industrial Applications of torque wrench manufacturer

| Industry/Sector | Specific Application of Torque Wrench Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Assembly of vehicle components | Ensures precise fastening, enhancing safety and performance | Calibration standards, torque range, and durability |

| Oil & Gas | Maintenance of drilling equipment | Reduces equipment failure and downtime | Resistance to harsh environments and torque accuracy |

| Construction | Installation of structural steel connections | Guarantees structural integrity and safety compliance | Load capacity, portability, and ease of use |

| Aerospace | Assembly of aircraft components | Critical for safety and regulatory compliance | Lightweight materials, precision, and certification |

| Manufacturing | Production line fastening processes | Increases efficiency and reduces rework | Automation compatibility and torque accuracy |

How is Torque Wrench Used in the Automotive Industry?

In the automotive sector, torque wrenches are essential for the assembly of vehicle components, such as engines, transmissions, and suspension systems. These tools ensure that fasteners are tightened to the manufacturer’s specifications, preventing issues such as component failure or safety hazards on the road. For international buyers, particularly from regions like Africa and South America, sourcing torque wrenches that meet local automotive standards and regulations is crucial. Additionally, factors such as calibration accuracy and the ability to withstand high usage rates should be prioritized to ensure long-term reliability.

What Role Does Torque Wrench Play in Oil & Gas Operations?

In the oil and gas industry, torque wrenches are vital for the maintenance and assembly of drilling equipment. Proper torque application prevents leaks and equipment failures, which can lead to costly downtimes and safety incidents. Buyers from the Middle East, known for its extensive oil reserves, must consider the specific torque requirements dictated by the harsh environmental conditions. Therefore, sourcing wrenches that offer high durability and resistance to corrosion is essential for optimizing operational efficiency and safety.

How is Torque Wrench Utilized in Construction Projects?

In construction, torque wrenches are critical for the installation of structural steel connections. These tools ensure that bolts are tightened to the correct specifications, which is vital for maintaining the structural integrity of buildings and bridges. For buyers in Europe, where regulatory compliance is stringent, selecting torque wrenches that are certified for accuracy and load capacity is imperative. Additionally, ease of use and portability are key considerations, especially for projects that require frequent tool transport across job sites.

Why is Torque Wrench Important in Aerospace Manufacturing?

The aerospace industry requires the highest precision in fastening aircraft components. Torque wrenches are used to ensure that fasteners are tightened to exact specifications, which is crucial for safety and compliance with regulatory standards. International buyers, particularly in regions like Europe, should prioritize sourcing wrenches that are lightweight and made from advanced materials to reduce overall aircraft weight. Certification for aerospace applications is also critical, as it ensures that the tools meet the industry’s stringent quality and safety standards.

How Does Torque Wrench Enhance Efficiency in Manufacturing?

In the manufacturing sector, torque wrenches are utilized in production line fastening processes, ensuring that components are assembled correctly and efficiently. This reduces the risk of rework and enhances overall productivity. B2B buyers from Africa and South America should look for wrenches that are compatible with automated systems, as automation is increasingly becoming a standard in manufacturing. Furthermore, accuracy in torque application is vital to maintaining quality control, making it essential to choose reputable manufacturers with proven track records in producing reliable tools.

Related Video: Norbar Industrial Torque Wrench – New Generation

3 Common User Pain Points for ‘torque wrench manufacturer’ & Their Solutions

Scenario 1: Ensuring Accurate Torque Settings for Critical Applications

The Problem:

B2B buyers often face challenges ensuring that torque wrenches deliver precise torque settings, especially in industries where safety and performance are paramount, such as automotive and aerospace. Incorrect torque application can lead to catastrophic failures, causing significant financial loss and jeopardizing safety. Buyers may struggle with varying specifications across different projects and equipment, leading to confusion and potential misuse of torque tools.

The Solution:

To overcome this challenge, buyers should prioritize sourcing torque wrenches that feature a calibration certificate and are compliant with international torque standards such as ISO or ASME. When selecting a manufacturer, inquire about their calibration processes and whether they provide traceable calibration records. Additionally, consider investing in digital torque wrenches with built-in torque measurement capabilities, which can provide real-time feedback during application. Regular training for staff on proper torque application techniques, including the importance of calibration, will further ensure that all torque settings are accurate. Establish a routine inspection schedule for torque tools to maintain their accuracy over time.

Scenario 2: Navigating Different Torque Wrench Types and Applications

The Problem:

International B2B buyers often encounter confusion when trying to select the appropriate type of torque wrench for various applications. With several options available—manual, digital, and click-type—understanding the differences and knowing which tool is best suited for specific tasks can be overwhelming. This confusion can lead to incorrect tool usage, impacting productivity and increasing the risk of equipment damage.

The Solution:

Buyers should conduct a thorough assessment of their specific torque requirements based on the applications they handle. Create a detailed matrix that outlines the torque specifications, types of fasteners, and environmental conditions for each application. Engage with manufacturers to provide insights on the best tools for each scenario. For example, manual torque wrenches may be suitable for low-torque applications, while digital models can be ideal for high-torque, precision tasks. Manufacturers can also offer tailored recommendations based on industry needs, ensuring that buyers make informed choices. Furthermore, consider implementing a standardized tool selection protocol within your organization to streamline the decision-making process for future purchases.

Scenario 3: Managing Maintenance and Tool Lifespan

The Problem:

B2B buyers often overlook the importance of regular maintenance for torque wrenches, which can lead to premature tool failure and increased operational costs. Lack of maintenance can result in inaccuracies and a decline in tool performance, especially if tools are used in demanding environments like construction sites or manufacturing facilities. Buyers may also face difficulties in sourcing reliable service providers for tool maintenance and repairs.

The Solution:

To effectively manage maintenance, buyers should develop a comprehensive maintenance schedule tailored to the specific usage and environment of their torque wrenches. This should include routine checks for wear and tear, proper cleaning, and recalibration as needed. Collaborate with torque wrench manufacturers to understand their recommended maintenance practices and service intervals. Many manufacturers offer maintenance programs or can connect buyers with authorized service centers for repairs. Additionally, consider integrating a tool tracking system to monitor the usage and maintenance history of each torque wrench, ensuring proactive management of the tool lifespan. This not only extends the life of the equipment but also ensures consistent performance and accuracy, ultimately saving costs in the long run.

Strategic Material Selection Guide for torque wrench manufacturer

What Are the Key Materials Used in Torque Wrench Manufacturing?

Torque wrenches are critical tools in various industries, requiring careful material selection to ensure optimal performance and longevity. Below, we analyze four common materials used in the manufacturing of torque wrenches, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Steel: The Standard Choice for Torque Wrenches

Key Properties: Steel is known for its high tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications. Depending on the alloy used, steel can also exhibit good corrosion resistance.

Pros & Cons: The primary advantage of steel is its strength and ability to handle high torque loads. However, it can be susceptible to rust if not properly treated, which may require additional coatings or finishes. The cost of steel is generally moderate, but manufacturing complexity can increase with the need for heat treatment or special coatings.

Impact on Application: Steel torque wrenches are ideal for automotive and industrial applications where high torque is required. However, they may not be suitable for environments with high humidity or corrosive substances unless adequately protected.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM or DIN for steel grades. In regions like Africa and South America, where environmental conditions may vary, selecting the right steel alloy is crucial for ensuring product longevity.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight, with excellent corrosion resistance and a good strength-to-weight ratio. It performs well in moderate temperature ranges and is often anodized for additional protection.

Pros & Cons: The main advantage of aluminum is its lightweight nature, making it easier to handle and reducing fatigue during use. However, it is generally less durable than steel and may not withstand extreme torque loads as effectively. The manufacturing process for aluminum can be more complex, leading to higher costs.

Impact on Application: Aluminum torque wrenches are suitable for applications where weight is a concern, such as in aerospace or portable tool kits. They are also ideal for environments prone to corrosion, such as marine applications.

Considerations for International Buyers: Buyers should look for aluminum that meets specific international standards (e.g., JIS) for quality assurance. In Europe, aluminum products often need to comply with strict environmental regulations regarding material sourcing and recycling.

Composite Materials: The Future of Torque Wrench Manufacturing?

Key Properties: Composite materials combine various elements to enhance strength, reduce weight, and improve resistance to environmental factors. They can be engineered for specific applications, offering tailored performance characteristics.

Pros & Cons: The main advantage of composites is their versatility and ability to resist corrosion and wear. However, they can be more expensive to manufacture and may require specialized knowledge for production. Their performance under extreme conditions can also vary, which may limit their use in certain applications.

Impact on Application: Composites are becoming popular in specialized applications, such as in the aerospace industry, where weight savings are critical. They can also be used in environments where traditional metals would corrode.

Considerations for International Buyers: Buyers should verify that composite materials meet relevant international standards. In regions like the Middle East, where high temperatures can affect material performance, understanding the specific properties of composites is essential.

Stainless Steel: The Corrosion-Resistant Alternative

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to maintain structural integrity at elevated temperatures. It is often used in environments where exposure to moisture and chemicals is common.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to rust, making it ideal for long-term use. However, it is generally more expensive than regular steel and can be more challenging to machine, which may increase manufacturing costs.

Impact on Application: Stainless steel torque wrenches are suitable for applications in the food and pharmaceutical industries, where hygiene and corrosion resistance are paramount. They can also be used in marine environments due to their resistance to saltwater corrosion.

Considerations for International Buyers: Buyers must ensure compliance with standards such as ASTM A276 or AISI for stainless steel grades. In regions like Europe, understanding local regulations regarding material safety and environmental impact is essential.

Summary Table of Material Selection for Torque Wrench Manufacturers

| Material | Typical Use Case for torque wrench manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty automotive and industrial applications | High strength and durability | Susceptible to rust without treatment | Medium |

| Aluminum | Aerospace and portable tool kits | Lightweight and corrosion-resistant | Less durable under extreme torque | High |

| Composite | Specialized aerospace applications | Versatile and resistant to wear | Higher manufacturing complexity | High |

| Stainless Steel | Food and pharmaceutical industries | Excellent corrosion resistance | More expensive and difficult to machine | High |

This guide provides a comprehensive overview of material selection for torque wrench manufacturing, enabling international B2B buyers to make informed decisions based on specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for torque wrench manufacturer

What Are the Main Stages of Manufacturing Torque Wrenches?

The manufacturing process for torque wrenches typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring the final product meets the necessary performance and quality standards.

-

Material Preparation:

The first step involves selecting high-quality materials, often steel alloys, which are known for their strength and durability. Suppliers need to ensure that the raw materials are sourced from reputable vendors and meet international standards. This stage may also include processes such as heat treatment to enhance the material’s properties. -

Forming:

In this stage, the prepared materials are shaped into the components of the torque wrench. Techniques like forging, casting, or machining are commonly used. Forging is particularly advantageous as it improves the grain structure of the metal, resulting in greater strength. Advanced CNC (Computer Numerical Control) machines often perform precise machining to achieve the desired dimensions and tolerances. -

Assembly:

The assembly process involves combining various components, such as the handle, ratchet mechanism, and the measuring dial. This stage may require specialized tools and fixtures to ensure components fit together accurately. Skilled labor is essential here, as improper assembly can affect the wrench’s calibration and performance. -

Finishing:

Finally, the torque wrenches undergo finishing processes, including surface treatment and coating. These treatments not only enhance the aesthetic appeal but also improve corrosion resistance and overall durability. Techniques such as anodizing or powder coating are commonly employed in this stage.

How Is Quality Assurance Implemented in Torque Wrench Manufacturing?

Quality assurance (QA) is integral to the manufacturing of torque wrenches. It ensures that products meet specific standards and perform reliably under various conditions. Key components of QA include adherence to international standards, rigorous testing, and systematic checkpoints throughout the manufacturing process.

-

International Standards Compliance:

Many torque wrench manufacturers adhere to international quality management standards such as ISO 9001. This certification demonstrates a commitment to maintaining quality across all aspects of production, from design to delivery. Additionally, industry-specific standards like CE (Conformité Européenne) and API (American Petroleum Institute) may apply, especially for wrenches used in critical applications like oil and gas. -

Quality Control Checkpoints:

The manufacturing process typically includes several quality control (QC) checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet required specifications.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, random checks are conducted to monitor the quality of components and assembly.

– Final Quality Control (FQC): After assembly, each torque wrench is subjected to rigorous testing to verify its performance and accuracy. -

Common Testing Methods:

Torque wrenches undergo various tests to ensure they function correctly. Common testing methods include:

– Calibration Testing: Ensures that the wrench accurately measures torque settings.

– Durability Testing: Evaluates the wrench’s ability to withstand repeated use without degradation.

– Functional Testing: Confirms that the wrench operates as intended under specified loads.

How Can B2B Buyers Verify Supplier Quality Control?

International B2B buyers must be diligent in verifying the quality control measures of potential torque wrench suppliers. Here are some actionable steps to ensure product quality:

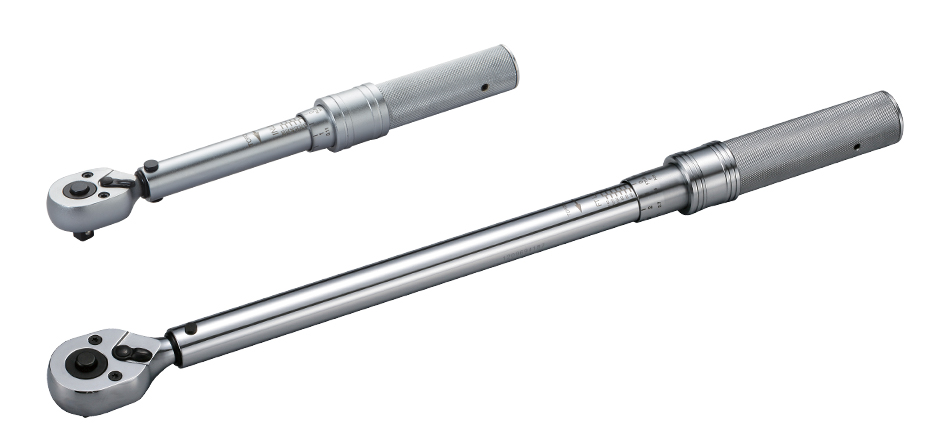

A stock image related to torque wrench manufacturer.

-

Conduct Supplier Audits:

Regular audits of suppliers can reveal their manufacturing practices and quality control systems. Buyers should assess the suppliers’ facilities, review their quality management certifications, and evaluate compliance with international standards. -

Request Quality Reports:

Suppliers should provide detailed quality reports that outline their testing methods, results, and adherence to standards. This documentation can offer insights into the supplier’s commitment to quality assurance. -

Third-Party Inspections:

Engaging third-party inspection services can add an extra layer of assurance. These organizations can conduct independent evaluations of the manufacturing processes and product quality before shipment.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances regarding quality control when sourcing torque wrenches:

-

Understanding Regional Standards:

Different regions may have varying standards and regulations. For instance, CE marking is essential for products sold in the European market, while other regions might prioritize different certifications. Buyers should familiarize themselves with the relevant standards for their market. -

Cultural and Communication Barriers:

When dealing with suppliers from diverse regions, language and cultural differences can impact quality expectations and communication. Establishing clear specifications and maintaining open lines of communication can help mitigate misunderstandings. -

Logistical Considerations:

Quality assurance extends beyond manufacturing. Buyers should also consider logistics, including how products are handled during shipping. Damage during transport can affect product integrity, so ensuring proper packaging and handling protocols is vital.

Conclusion

Understanding the manufacturing processes and quality assurance measures for torque wrenches is critical for B2B buyers. By being informed about the stages of production, quality control standards, and verification practices, international buyers can make educated decisions when sourcing these essential tools. This knowledge not only helps in selecting reliable suppliers but also ensures that the torque wrenches meet the necessary performance and safety standards for their intended applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘torque wrench manufacturer’

A stock image related to torque wrench manufacturer.

In today’s competitive marketplace, sourcing the right torque wrench manufacturer is crucial for ensuring quality and reliability in your operations. This practical sourcing guide provides a step-by-step checklist tailored for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. Follow these steps to streamline your procurement process and make informed decisions.

Step 1: Define Your Technical Specifications

Before reaching out to manufacturers, it’s essential to outline your specific requirements. Determine the type of torque wrenches you need, including features such as torque range, measurement units (metric or imperial), and whether you require electronic or mechanical models.

– Consider applications: Different applications may require specific torque settings or precision levels.

– Document your needs: Having a clear set of specifications helps in communicating effectively with potential suppliers.

Step 2: Conduct Market Research for Potential Manufacturers

Start by identifying potential torque wrench manufacturers that align with your technical specifications. Utilize online platforms, industry directories, and trade shows to gather a list of candidates.

– Focus on region: Look for manufacturers who have experience serving your specific region, as they may understand local market dynamics better.

– Check reviews and ratings: Customer feedback can provide insights into the reliability and quality of the manufacturer.

Step 3: Verify Supplier Certifications and Standards

Ensure that the manufacturers you consider hold relevant certifications that meet international standards, such as ISO 9001 or ISO 6789. This step is crucial for ensuring product quality and consistency.

– Request documentation: Ask suppliers to provide proof of their certifications.

– Check compliance: Ensure that their products comply with safety and performance standards applicable in your country.

Step 4: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Assess experience: Look for manufacturers with a proven track record in producing torque wrenches.

– Review past projects: Understanding their previous work can provide insights into their capabilities and reliability.

Step 5: Request Samples and Conduct Quality Testing

Always request samples of the torque wrenches before making a bulk order. This allows you to assess the quality and performance of the products firsthand.

– Perform tests: Check for accuracy, durability, and ease of use during your testing phase.

– Involve your team: Engage your technical team in the testing process to ensure the product meets your operational requirements.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a manufacturer, it’s time to discuss pricing, payment terms, and delivery schedules. Clear communication at this stage can help avoid misunderstandings later on.

– Be transparent about needs: Clearly outline your expectations regarding delivery times and payment terms.

– Consider long-term relationships: Establishing good terms can lead to better pricing and service in future transactions.

Step 7: Establish a Clear Communication Channel

Post-purchase, maintaining a communication line with your supplier is vital for addressing any issues that arise. Establishing regular check-ins can help build a strong partnership.

– Schedule follow-ups: Regular updates can ensure that both parties are aligned on expectations.

– Provide feedback: Sharing your experiences can help the manufacturer improve their products and services.

By following this checklist, international B2B buyers can streamline their sourcing process, ensuring they select a torque wrench manufacturer that meets their specific needs while fostering long-term business relationships.

Comprehensive Cost and Pricing Analysis for torque wrench manufacturer Sourcing

What Are the Key Cost Components in Sourcing Torque Wrenches?

When sourcing torque wrenches, understanding the cost structure is crucial for B2B buyers. The primary components that contribute to the overall cost include:

-

Materials: This is often the largest portion of the cost, influenced by the type of steel or alloy used. High-quality materials ensure durability and precision, which are critical for torque wrenches.

-

Labor: The labor cost varies significantly based on the manufacturing location. Countries with lower labor costs may offer cheaper products, but this can affect quality and service levels.

-

Manufacturing Overhead: This includes utilities, rent, and indirect labor. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers.

-

Tooling: The initial setup costs for manufacturing specific designs or customizations can be substantial. This is especially relevant for buyers requiring unique specifications.

-

Quality Control (QC): Investing in rigorous QC processes ensures the final product meets safety and performance standards. While this adds to costs, it ultimately protects the buyer from defective products.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location and the chosen Incoterms. Understanding these costs is essential for accurate budgeting.

-

Margin: Manufacturers typically add a profit margin on top of their costs. This margin can vary based on competition and market demand.

How Do Price Influencers Affect Torque Wrench Costs?

Several factors influence the pricing of torque wrenches, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts, making it essential for buyers to assess their needs accurately. Negotiating favorable MOQs can lead to significant cost savings.

-

Specifications and Customization: Custom specifications can increase costs due to additional tooling and manufacturing processes. Clear communication of requirements can help streamline this process and control costs.

-

Material Quality and Certifications: Products with certifications (such as ISO or ANSI) may come at a premium but provide assurance of quality. Buyers should weigh the benefits of certified products against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better service and product guarantees.

-

Incoterms: The choice of Incoterms can significantly impact logistics costs. Buyers must understand their responsibilities and the costs associated with shipping, insurance, and customs duties.

What Are Effective Buyer Tips for Negotiating Torque Wrench Prices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, effective negotiation and cost-efficiency strategies are vital:

-

Negotiate Terms: Always negotiate prices, payment terms, and delivery schedules. Suppliers may have flexibility, especially for larger orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, repair, and operational costs over the product’s lifespan. This holistic view can guide purchasing decisions.

-

Be Aware of Pricing Nuances: Prices can vary based on regional economic conditions, currency fluctuations, and trade tariffs. Staying informed about these factors will aid in making better purchasing decisions.

-

Research Supplier Backgrounds: Conduct due diligence on potential suppliers to ensure they meet your quality and reliability standards. This can prevent costly mistakes down the line.

-

Test Samples Before Bulk Orders: Request samples before committing to large orders. This can help ensure that the product meets your specifications and quality expectations.

Disclaimer on Indicative Pricing

It is important to note that prices for torque wrenches can vary widely based on the factors discussed above. This analysis provides indicative insights, but actual prices may differ based on market conditions and specific supplier negotiations. Always seek detailed quotations and terms from multiple suppliers to ensure the best deal.

Alternatives Analysis: Comparing torque wrench manufacturer With Other Solutions

In the realm of torque measurement and application, understanding the alternatives to traditional torque wrench manufacturers is crucial for international B2B buyers. Each solution presents unique advantages and challenges, which can significantly influence decision-making based on specific operational needs and budget constraints.

Comparison Table of Torque Wrench Manufacturer and Alternatives

| Comparison Aspect | Torque Wrench Manufacturer | Digital Torque Wrench | Torque Angle Gauge |

|---|---|---|---|

| Performance | High accuracy for torque applications | Enhanced accuracy with digital readouts | Effective for torque applications but requires manual calculation |

| Cost | Varies widely based on brand and features | Generally higher due to technology | Typically lower cost but less sophisticated |

| Ease of Implementation | Requires training for proper use | User-friendly with digital displays | Simple to use but requires understanding of torque angles |

| Maintenance | Regular calibration needed | Minimal, but battery replacement necessary | Low maintenance but accuracy can degrade without care |

| Best Use Case | Precision assembly and high-stakes applications | Automotive and aerospace industries | General mechanics and DIY projects |

What Are the Pros and Cons of Digital Torque Wrenches?

Digital torque wrenches provide enhanced features that traditional torque wrenches may lack. They offer precise digital readouts, reducing the risk of human error in torque application. This technology is particularly advantageous in industries such as automotive and aerospace, where accuracy is paramount. However, digital torque wrenches tend to be more expensive and require batteries, which can lead to potential operational delays if not managed properly. Additionally, while they are user-friendly, they still necessitate some training for effective use.

How Do Torque Angle Gauges Compare?

Torque angle gauges are a cost-effective solution for measuring torque in applications where a specific angle is critical. They are particularly useful in automotive assembly processes where torque settings must be applied in conjunction with angle measurements. While they are less expensive than both traditional and digital torque wrenches, they require manual calculations, which can introduce error if not performed carefully. Furthermore, while maintenance is low, the accuracy of torque angle gauges can degrade if not stored properly, which is a consideration for long-term use.

Conclusion: How Should B2B Buyers Choose the Right Torque Measurement Solution?

When selecting the right torque measurement solution, B2B buyers should assess their specific operational needs, budget constraints, and the level of accuracy required for their applications. For industries where precision is non-negotiable, investing in a reputable torque wrench manufacturer or a digital torque wrench may be warranted. Conversely, for simpler tasks or lower budgets, a torque angle gauge could provide sufficient accuracy without the higher costs associated with advanced technologies. By carefully evaluating these factors, international buyers from regions such as Africa, South America, the Middle East, and Europe can make informed decisions that align with their operational goals and financial capabilities.

Essential Technical Properties and Trade Terminology for torque wrench manufacturer

What Are the Essential Technical Properties of Torque Wrenches?

When sourcing torque wrenches, understanding their critical technical properties is vital for making informed purchasing decisions. Here are some essential specifications:

1. Material Grade: Why Is It Important?

Torque wrenches are commonly made from high-grade steel or alloy materials. The material grade determines the wrench’s strength, durability, and resistance to wear. For B2B buyers, selecting the right material is crucial as it impacts the longevity of the tool and its effectiveness in high-stress applications. High-grade materials ensure that the wrench can withstand high torque levels without deforming or breaking, which is essential for maintaining safety and operational efficiency.

2. Torque Range: How Does It Affect Performance?

The torque range indicates the minimum and maximum torque values that a wrench can apply. Understanding this range is essential for buyers, as it ensures that the tool meets the specific needs of their applications. A torque wrench with an appropriate torque range minimizes the risk of over-tightening, which can lead to equipment failure or damage. Buyers should assess their requirements carefully to select a wrench that covers the necessary torque specifications.

3. Accuracy and Tolerance: Why Do They Matter?

Accuracy is a critical property of torque wrenches, often expressed as a percentage of the reading. Tolerance refers to the allowable deviation from the specified torque value. For international B2B buyers, high accuracy and low tolerance are non-negotiable, especially in industries like automotive and aerospace, where precision is essential. A tool that offers consistent and reliable torque measurements enhances productivity and reduces the likelihood of costly errors.

4. Drive Size: What Should Buyers Consider?

The drive size of a torque wrench affects compatibility with sockets and other tools. Common drive sizes include 1/4”, 3/8”, 1/2”, and 3/4”. Buyers must consider the types of fasteners they will be working with to select an appropriate drive size. Choosing the right size ensures better torque application and prevents damage to both the tool and the fastener.

5. Calibration: How Does It Impact Quality Assurance?

Calibration refers to the process of adjusting the wrench to ensure its accuracy. A calibrated wrench provides confidence in torque applications, which is critical in industries where compliance with safety standards is mandatory. B2B buyers should prioritize manufacturers that offer calibration services or certification to guarantee that their tools meet industry standards.

What Are Common Trade Terms in the Torque Wrench Industry?

Understanding industry jargon is essential for effective communication and negotiation. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of torque wrenches, buyers should look for OEMs to ensure they receive high-quality products that meet specific industry standards. This term is critical when sourcing products for resale or integration into larger systems.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory and budget constraints effectively. Suppliers may set MOQs based on production costs, which can affect pricing and availability. Buyers should negotiate MOQs that align with their purchasing capabilities.

3. RFQ (Request for Quotation): What Should Buyers Include?

An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of goods. When preparing an RFQ for torque wrenches, buyers should include specifications, quantities, and delivery timelines. This process helps streamline procurement and ensures that buyers receive competitive offers from multiple suppliers.

4. Incoterms: How Do They Affect Shipping and Delivery?

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping and delivery. Familiarity with Incoterms is crucial for B2B buyers, as they dictate who bears the costs and risks at various stages of transportation. Understanding these terms can help buyers negotiate better shipping arrangements and avoid unexpected costs.

By grasping these technical properties and trade terminologies, international B2B buyers can make more informed decisions when sourcing torque wrenches, ensuring they select products that meet their operational needs while also optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the torque wrench manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Torque Wrench Manufacturing Sector?

The torque wrench manufacturing sector is experiencing significant growth driven by various global factors. The increasing demand for precision tools in industries such as automotive, aerospace, and construction is a primary driver. With the rise of electric and hybrid vehicles, the need for high-torque applications has surged, necessitating advanced torque tools. Additionally, the expansion of manufacturing capabilities in developing regions, particularly in Africa and South America, has opened new markets for torque wrench manufacturers.

Current B2B technology trends are also reshaping the sector. The adoption of Industry 4.0 technologies, such as IoT and AI, is enhancing the functionality of torque wrenches, allowing for real-time monitoring and data collection. This advancement is crucial for international buyers looking to improve operational efficiency and reduce downtime. Moreover, e-commerce platforms are facilitating direct sourcing from manufacturers, enabling buyers from regions like Europe and the Middle East to access a broader range of products and competitive pricing.

Emerging trends include a growing emphasis on customization and modular designs, which cater to specific industry needs. As buyers seek tools that can adapt to various applications, manufacturers are responding by offering customizable torque wrenches with interchangeable heads and settings. This flexibility is particularly appealing to B2B buyers who prioritize versatility and efficiency in their operations.

How Is Sustainability and Ethical Sourcing Impacting the Torque Wrench Manufacturing Sector?

Sustainability has become a critical concern in the torque wrench manufacturing sector, driven by increasing regulatory pressures and consumer demand for environmentally responsible practices. The environmental impact of manufacturing processes, particularly in terms of waste generation and resource consumption, is under scrutiny. Manufacturers are now adopting cleaner production methods, such as utilizing renewable energy sources and optimizing resource use, to minimize their carbon footprint.

Ethical sourcing is equally important for B2B buyers, particularly those in Europe and North America, where regulations around supply chain transparency are tightening. Buyers are increasingly prioritizing suppliers who demonstrate commitment to ethical practices, including fair labor standards and responsible sourcing of raw materials. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential criteria for evaluating suppliers.

Furthermore, the use of ‘green’ materials in production is gaining traction. Manufacturers are exploring the integration of recycled materials and eco-friendly coatings in their torque wrenches, appealing to buyers who are looking to enhance their sustainability credentials. By choosing suppliers who prioritize sustainability, international buyers can mitigate risks associated with regulatory compliance and enhance their brand reputation in increasingly eco-conscious markets.

What Is the Historical Evolution of the Torque Wrench Manufacturing Sector?

The torque wrench has a rich history that dates back to the early 20th century when it was first introduced as a solution to the problem of accurate fastening. Initially, torque wrenches were primarily mechanical devices used in automotive and aviation industries. Over the decades, advancements in materials and technology have led to the development of digital and electronic torque wrenches, which provide greater precision and ease of use.

In recent years, the focus has shifted towards integrating smart technologies, allowing for enhanced functionalities such as torque tracking and connectivity with other industrial systems. This evolution reflects the broader trends in manufacturing, where digital transformation is reshaping traditional practices. For B2B buyers, understanding this historical context is essential as it highlights the continuous innovation within the sector, ensuring that they can leverage the latest technologies to optimize their operations.

Frequently Asked Questions (FAQs) for B2B Buyers of torque wrench manufacturer

-

How do I choose the right torque wrench for my industry needs?

Selecting the right torque wrench involves understanding your specific application requirements. Consider factors such as torque range, accuracy, and type (click, beam, or digital). Evaluate the materials being worked on and ensure compatibility with the wrench’s specifications. For industrial applications, focus on durability and calibration options. It’s advisable to consult with manufacturers about your specific use case to ensure you select a tool that meets your operational demands. -

What are the typical minimum order quantities (MOQ) when sourcing torque wrenches?

Minimum order quantities can vary significantly among torque wrench manufacturers. Generally, you may encounter MOQs ranging from 50 to 500 units, depending on the manufacturer’s production capabilities and your specific requirements. For international buyers, it’s crucial to communicate your needs clearly, as some manufacturers might offer flexibility for first-time orders or smaller businesses. Always inquire about bulk discounts as well. -

What payment terms should I expect when purchasing from a torque wrench manufacturer?

Payment terms can vary widely based on the manufacturer’s policies and your business relationship. Common terms include 30% upfront and 70% upon delivery, or payment in full before shipping. For international transactions, consider using secure payment methods like letters of credit or escrow services to protect your investment. Clarifying payment terms upfront can help avoid misunderstandings and ensure a smooth transaction. -

How can I ensure the quality of torque wrenches from international suppliers?

To ensure quality, request certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, ask for product samples to assess performance firsthand. Establishing clear quality assurance protocols, including inspection processes before shipment, can also mitigate risks. Engaging third-party inspection services can provide further assurance of product quality and compliance with your specifications. -

What customization options are available when ordering torque wrenches?

Many torque wrench manufacturers offer customization options, including branding, specific torque settings, and unique designs tailored to your operational needs. Customization may also extend to packaging and instruction manuals in different languages. Discuss your requirements with the manufacturer during the initial stages of the negotiation to understand what is feasible and the associated costs. -

What logistics considerations should I keep in mind when importing torque wrenches?

When importing torque wrenches, consider shipping methods, lead times, and customs regulations in your country. It’s essential to evaluate the total landed cost, including shipping, tariffs, and potential storage fees. Work with logistics partners experienced in international trade to navigate these complexities. Additionally, ensure that the manufacturer provides necessary documentation for customs clearance to avoid delays. -

How do I vet a torque wrench manufacturer before placing an order?

To vet a manufacturer, conduct thorough research by checking their reputation, customer reviews, and industry certifications. Request references from previous clients, especially those in your region or industry. Visiting the manufacturing facility or participating in virtual tours can also provide insight into their operations. Ensure they have a reliable supply chain and can meet your delivery schedules consistently. -

What are the common warranty terms for torque wrenches, and why are they important?

Warranty terms typically range from one year to a lifetime, depending on the manufacturer and product type. A strong warranty indicates the manufacturer’s confidence in their product quality and can protect your investment against defects. Always review warranty coverage details, including what is included and any conditions that apply. Understanding warranty terms can help you make informed decisions and ensure you receive support in case of product issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for torque wrench manufacturer

What Are the Key Takeaways for Strategic Sourcing of Torque Wrenches?

In today’s competitive landscape, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must prioritize strategic sourcing to enhance their procurement processes for torque wrenches. Understanding the nuances of supplier reliability, product quality, and compliance with local standards can significantly impact operational efficiency and cost management. Buyers should focus on establishing long-term partnerships with manufacturers that offer innovation and customization, ensuring that their specific needs are met with precision.

How Can Strategic Sourcing Enhance Competitive Advantage?

The value of strategic sourcing extends beyond mere cost savings; it serves as a catalyst for driving innovation and fostering sustainability in supply chains. By engaging with manufacturers who prioritize sustainable practices, businesses can not only enhance their brand reputation but also comply with increasingly stringent regulations in various markets. Leveraging technology and data analytics in sourcing decisions will further empower buyers to make informed choices that align with their strategic objectives.

What’s Next for International Buyers in the Torque Wrench Market?

As we look ahead, the torque wrench market is poised for growth, driven by advancements in technology and increasing demand for precision tools. International B2B buyers should actively seek out suppliers who are not only responsive to current trends but also forward-thinking in their approach. This is an opportune time to reassess sourcing strategies, embrace digital transformation, and cultivate partnerships that will yield mutual benefits. Engage with manufacturers today to secure a competitive edge in your operations and ensure the highest standards in your torque wrench procurement process.