Discover Top Auto Engine Manufacturers: Your Complete Guide (2025)

Introduction: Navigating the Global Market for auto engine manufacturer

In an increasingly interconnected world, sourcing high-quality auto engines has emerged as a significant challenge for international B2B buyers. Whether you are operating in Africa, South America, the Middle East, or Europe, the complexities of selecting the right auto engine manufacturer can impact your business’s efficiency and profitability. This comprehensive guide delves into the diverse landscape of auto engine manufacturing, providing insights into various types of engines, their applications, and the critical factors to consider when vetting suppliers.

As the automotive industry evolves, understanding the nuances of engine technology and market trends becomes essential for making informed purchasing decisions. This guide empowers B2B buyers by outlining key considerations such as cost analysis, supplier reliability, and the importance of compliance with regional regulations. From navigating supply chain challenges to leveraging technological advancements, we equip you with actionable strategies to enhance your procurement process.

By focusing on the unique needs of buyers in regions like Saudi Arabia and Germany, we aim to bridge the gap between manufacturers and buyers, fostering partnerships that thrive on transparency and mutual benefit. With this guide, you will gain the knowledge and tools necessary to navigate the global market effectively, ensuring that you make the best choices for your business’s engine requirements.

Understanding auto engine manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Internal Combustion Engines | Utilizes fuel combustion for power; widely used and established. | Automotive, heavy machinery, generators | Pros: High power output, established technology. Cons: Environmental regulations, fuel dependency. |

| Electric Engines | Powered by electric motors; increasing adoption in various sectors. | Electric vehicles, renewable energy systems | Pros: Eco-friendly, lower operating costs. Cons: Limited range, charging infrastructure needed. |

| Hybrid Engines | Combines internal combustion and electric power sources. | Automotive, public transportation | Pros: Fuel efficiency, reduced emissions. Cons: Complex technology, higher initial costs. |

| Diesel Engines | Known for high torque and fuel efficiency; typically used in trucks. | Freight transport, industrial machinery | Pros: Long lifespan, better fuel economy. Cons: Emissions regulations, noise levels. |

| Specialty Engines | Custom-designed for specific applications; varied fuel types. | Aerospace, marine, and specialized vehicles | Pros: Tailored performance, unique applications. Cons: Higher costs, longer lead times. |

What Are the Characteristics of Internal Combustion Engines for B2B Buyers?

Internal combustion engines (ICE) are the most traditional type of engine found in vehicles and machinery. They operate by burning fuel within the engine itself, generating power through combustion. For B2B buyers, particularly in sectors like automotive and heavy machinery, ICEs offer high power outputs and a well-established technology base. However, it is crucial to consider the increasing environmental regulations and the dependency on fossil fuels, which may affect long-term operational costs and compliance.

How Do Electric Engines Benefit B2B Applications?

Electric engines are rapidly gaining traction across various industries due to their eco-friendliness and lower operating costs. These engines are powered by electric motors, making them suitable for electric vehicles and renewable energy systems. B2B buyers should weigh the benefits of reduced emissions against the limitations of range and the need for adequate charging infrastructure. As sustainability becomes a priority, investing in electric engines may enhance a company’s green credentials while offering potential savings in the long run.

Why Consider Hybrid Engines for Diverse Applications?

Hybrid engines integrate both internal combustion and electric power sources, providing a balanced solution for B2B applications. They are particularly popular in the automotive and public transportation sectors due to their fuel efficiency and reduced emissions. While the initial costs may be higher, the long-term savings on fuel and potential tax incentives for environmentally friendly technologies can make them an attractive option for buyers looking to innovate while maintaining operational efficiency.

What Are the Advantages of Diesel Engines in Freight Transport?

Diesel engines are renowned for their high torque and fuel efficiency, making them the preferred choice for freight transport and industrial machinery. B2B buyers in these sectors appreciate the long lifespan and better fuel economy of diesel engines, which can lead to lower operational costs over time. However, buyers must also navigate stringent emissions regulations and potential noise issues, which can impact their decision-making process.

How Do Specialty Engines Cater to Unique B2B Needs?

Specialty engines are designed for specific applications, such as aerospace, marine, and other specialized vehicles. These engines can utilize various fuel types and provide tailored performance characteristics that meet unique operational demands. While they offer significant advantages in terms of customization and efficiency, B2B buyers should be prepared for higher costs and longer lead times associated with the development and procurement of these specialized solutions.

Related Video: Car Engine Parts & Their Functions Explained in Details | The Engineers Post

Key Industrial Applications of auto engine manufacturer

| Industry/Sector | Specific Application of auto engine manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | High-performance engines for passenger vehicles | Enhanced vehicle performance and fuel efficiency | Compliance with local regulations, availability of parts, and after-sales service support. |

| Agriculture | Engines for agricultural machinery | Increased productivity and reliability in farming tasks | Durability in harsh conditions and access to technical support for maintenance. |

| Construction | Engines for heavy construction equipment | Improved operational efficiency and reduced downtime | Engine compatibility with equipment, fuel type, and service network availability. |

| Marine | Marine engines for vessels | Superior reliability and performance in marine environments | Compliance with maritime regulations and availability of spare parts for maintenance. |

| Power Generation | Engines for generators and power plants | Reliable power supply and operational efficiency | Fuel efficiency, emissions standards, and local support infrastructure. |

What Are the Key Applications of Auto Engine Manufacturers in the Automotive Industry?

In the automotive sector, auto engine manufacturers provide high-performance engines designed for passenger vehicles. These engines enhance vehicle performance and fuel efficiency, addressing the growing demand for eco-friendly and economical transportation solutions. International buyers, especially from Europe and South America, must consider compliance with local emissions regulations and the availability of engine parts to ensure smooth operations and maintenance. Additionally, robust after-sales service support is crucial for minimizing downtime and maximizing vehicle longevity.

How Do Auto Engine Manufacturers Serve the Agricultural Sector?

Auto engine manufacturers play a vital role in the agricultural sector by supplying engines for various agricultural machinery, such as tractors and harvesters. These engines are designed for increased productivity and reliability, crucial for farmers looking to optimize their operations. Buyers in Africa and South America should prioritize engines that demonstrate durability in challenging environmental conditions, as well as access to technical support for maintenance and repairs. This ensures that machinery remains operational during critical farming periods.

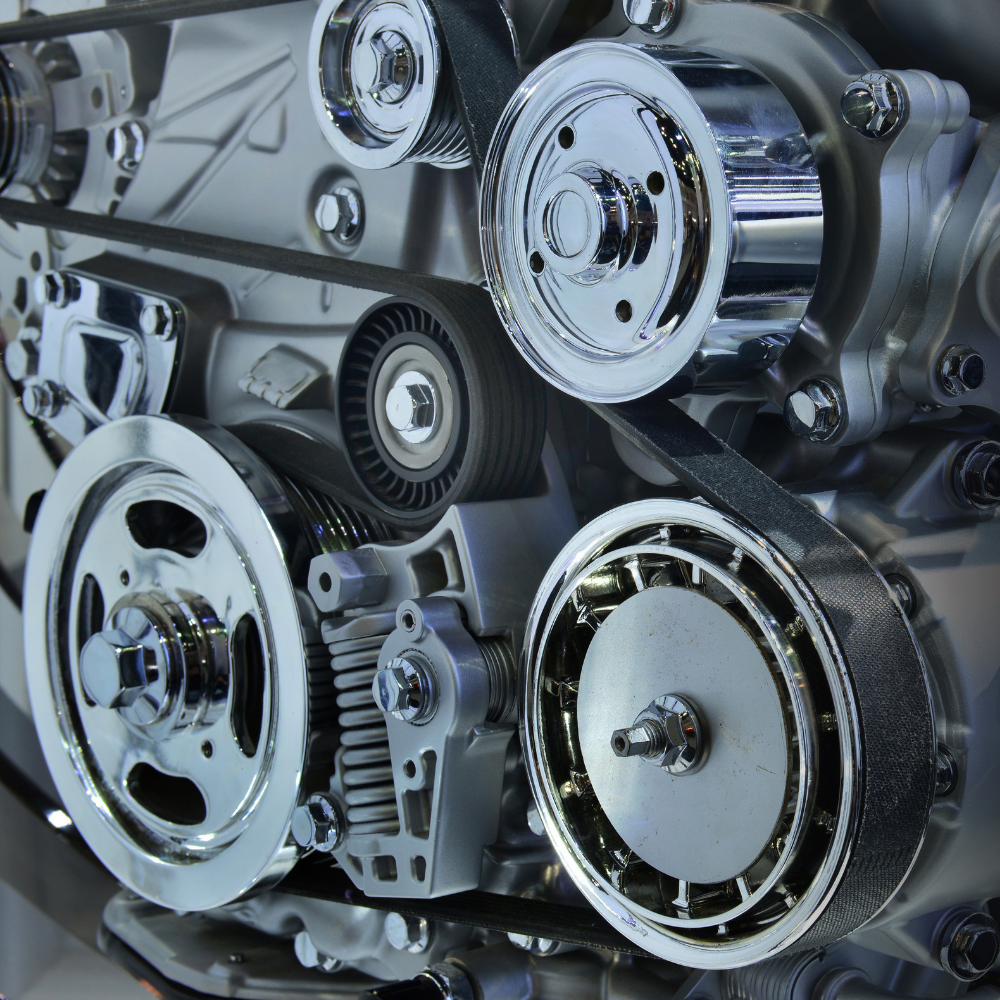

A stock image related to auto engine manufacturer.

What Are the Benefits of Auto Engines in the Construction Industry?

In the construction industry, auto engine manufacturers provide engines for heavy construction equipment like excavators and bulldozers. These engines improve operational efficiency and reduce downtime, which is essential for meeting project deadlines. Buyers from the Middle East and Europe should consider engine compatibility with existing equipment and the type of fuel used. Additionally, the availability of a service network is crucial for ensuring timely maintenance and repairs, which can significantly impact project timelines and costs.

How Are Marine Engines Beneficial for the Maritime Sector?

Marine engines supplied by auto engine manufacturers are critical for vessels operating in various maritime environments. These engines are designed for superior reliability and performance, essential for ensuring safety and efficiency at sea. International buyers, particularly from regions with significant maritime activities, must ensure that the engines comply with maritime regulations. Furthermore, access to spare parts and maintenance services is necessary to keep vessels operational and reduce the risk of costly downtime.

What Is the Role of Auto Engines in Power Generation?

Auto engine manufacturers also cater to the power generation sector by providing engines for generators and power plants. These engines are crucial for ensuring a reliable power supply and operational efficiency. Buyers should look for engines that offer high fuel efficiency and meet local emissions standards, especially in regions like Europe where environmental regulations are stringent. Additionally, understanding the local support infrastructure for maintenance is vital for ensuring uninterrupted power generation and minimizing operational risks.

Related Video: FANUC Industrial Robots | AUDI Case Study

3 Common User Pain Points for ‘auto engine manufacturer’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Engine Procurement

The Problem:

B2B buyers in regions like Africa and South America often face significant challenges in ensuring the quality of auto engines sourced from manufacturers. Limited access to reliable suppliers, coupled with varying standards in production quality, can lead to costly mistakes. For instance, a buyer may invest in a bulk order of engines that don’t meet the required specifications, resulting in operational disruptions and potential losses. This issue is particularly acute in markets where local regulations may not align with international quality standards.

The Solution:

To mitigate quality assurance challenges, buyers should adopt a rigorous supplier evaluation process. Begin by researching manufacturers with a proven track record in your region and beyond. Utilize online platforms that provide reviews and ratings of auto engine manufacturers, focusing on their compliance with international quality certifications such as ISO 9001. Establish direct communication with potential suppliers to inquire about their quality control measures and request samples for testing. Additionally, consider partnering with third-party inspection agencies that specialize in automotive components to perform on-site audits and product evaluations before finalizing any orders. This proactive approach not only ensures the quality of engines but also fosters long-term relationships with reliable suppliers.

Scenario 2: Addressing Supply Chain Disruptions in Engine Delivery

The Problem:

Supply chain disruptions can severely impact B2B buyers, especially those in the Middle East and Europe, who rely on timely deliveries of auto engines. Factors such as geopolitical tensions, natural disasters, or unexpected demand spikes can lead to delays, affecting production schedules and customer commitments. A buyer may find themselves in a situation where promised engines are late, causing a domino effect on their own operations and customer satisfaction.

The Solution:

To combat supply chain disruptions, buyers should implement a diversified sourcing strategy. Instead of relying on a single manufacturer, identify multiple suppliers across different regions. This approach mitigates risk by allowing buyers to shift orders as needed in response to supply chain issues. Additionally, leveraging technology such as predictive analytics can help anticipate potential disruptions by analyzing market trends and historical data. Establishing clear communication channels with suppliers is also crucial; regular updates on production timelines and shipping schedules can help buyers manage their inventory more effectively. Consider using just-in-time inventory practices to reduce stock holding costs while ensuring that backup options are available to meet urgent demands.

Scenario 3: Overcoming Technical Compatibility Issues with Auto Engines

The Problem:

Technical compatibility is a common pain point for B2B buyers, particularly in Europe and the Middle East, where various engine models must align with existing vehicle systems. A buyer may encounter difficulties when integrating new engines with older vehicle models or different brands, leading to performance issues and increased operational costs. This situation is exacerbated when dealing with manufacturers that do not provide comprehensive technical documentation or support.

The Solution:

To address compatibility issues, buyers should prioritize detailed compatibility assessments before making procurement decisions. Engage with manufacturers that offer extensive technical support and documentation, including installation guides, schematics, and maintenance protocols. Conduct thorough compatibility testing with existing systems, and if possible, request pilot runs or trials of the engines to evaluate performance in real-world conditions. Additionally, consider collaborating with engineering consultants who specialize in automotive systems to assist in the integration process. This investment in technical compatibility not only reduces the risk of operational disruptions but also enhances the overall performance and longevity of the vehicle systems.

Strategic Material Selection Guide for auto engine manufacturer

What Are the Key Properties of Aluminum in Auto Engine Manufacturing?

Aluminum is widely used in the automotive industry, particularly in engine components, due to its excellent strength-to-weight ratio. Its temperature rating can withstand up to 400°C, making it suitable for high-performance applications. Additionally, aluminum exhibits good corrosion resistance, which is essential for engines exposed to various environmental conditions.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which contributes to fuel efficiency and overall vehicle performance. However, it can be more expensive than steel and may require specialized manufacturing processes, such as casting or extrusion, which can increase production complexity.

Impact on Application: Aluminum is compatible with various engine media, including oil and coolant, and is often used in cylinder heads and engine blocks.

Considerations for International Buyers: B2B buyers from regions like Europe and the Middle East should ensure that their aluminum sourcing complies with standards such as DIN 1725 and ASTM B221. Additionally, the availability of recycled aluminum can be a significant factor in sustainability discussions, particularly in markets that prioritize eco-friendly practices.

How Does Steel Compare as a Material for Engine Components?

Steel remains a cornerstone material in auto engine manufacturing due to its durability and high strength. It can withstand extreme pressures and temperatures, often rated up to 800°C for certain grades. Steel’s corrosion resistance can be enhanced through coatings, making it versatile for various applications.

Pros & Cons: The key advantage of steel is its robustness, which translates to longer-lasting engine components. However, its weight can negatively impact fuel efficiency compared to lighter materials like aluminum. Additionally, the manufacturing processes for steel can be more complex and energy-intensive.

Impact on Application: Steel is commonly used for crankshafts, camshafts, and other critical components where strength is paramount.

Considerations for International Buyers: Buyers in regions such as South America and Africa should be aware of the different steel grades and their compliance with standards like ASTM A36 and JIS G3101. The cost of steel can vary significantly based on local market conditions and tariffs.

What Role Does Magnesium Play in Engine Manufacturing?

Magnesium is increasingly being adopted in automotive applications due to its exceptional lightweight properties, making it an attractive alternative to aluminum. It can handle temperatures up to 200°C and has good corrosion resistance when treated properly.

Pros & Cons: The main advantage of magnesium is its low density, which significantly reduces the overall weight of engine components. However, it is more expensive than aluminum and steel, and its manufacturing processes can be complex due to its flammability during machining.

Impact on Application: Magnesium is particularly suitable for components like transmission cases and engine covers, where weight savings are critical.

Considerations for International Buyers: Buyers from Europe and the Middle East should ensure compliance with standards such as ASTM B93 and EN 1753. Additionally, the availability of magnesium alloys can vary by region, impacting sourcing decisions.

What Are the Benefits of Composite Materials in Engine Applications?

Composite materials, particularly carbon fiber and glass fiber, are gaining traction in automotive engine manufacturing due to their high strength-to-weight ratios and excellent fatigue resistance. They can withstand temperatures up to 150°C, making them suitable for certain engine components.

Pros & Cons: The primary advantage of composites is their lightweight nature, which can lead to significant fuel efficiency improvements. However, they can be costly and require specialized manufacturing techniques, which may not be readily available in all regions.

Impact on Application: Composites are often used in non-structural components, such as engine covers and housings, where weight reduction is beneficial.

Considerations for International Buyers: B2B buyers in Africa and South America should consider local manufacturing capabilities and compliance with standards such as ASTM D7264 and ISO 13003 when sourcing composite materials.

Summary Table of Material Selection for Auto Engine Manufacturing

| Material | Typical Use Case for auto engine manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Cylinder heads, engine blocks | Lightweight, good corrosion resistance | Higher cost, complex manufacturing | Medium |

| Steel | Crankshafts, camshafts | High strength and durability | Heavier, more complex processes | Low |

| Magnesium | Transmission cases, engine covers | Extremely lightweight | Higher cost, flammability risks | High |

| Composites | Engine covers, housings | Excellent weight savings | High cost, specialized manufacturing | High |

In-depth Look: Manufacturing Processes and Quality Assurance for auto engine manufacturer

What Are the Main Stages in Auto Engine Manufacturing?

Manufacturing an auto engine involves a series of well-defined stages, each critical to the overall quality and performance of the final product. Here are the primary stages:

-

Material Preparation: This initial phase includes sourcing high-quality raw materials, such as aluminum and steel, which are essential for engine components. Buyers should ensure that suppliers utilize materials compliant with international standards to guarantee durability and performance.

-

Forming: In this stage, materials undergo processes like casting, forging, or machining to create engine parts. Techniques such as die casting are commonly used for producing complex shapes with high precision. It is crucial for B2B buyers to understand the forming techniques employed by their suppliers, as these directly affect the quality and reliability of the engine.

-

Assembly: The assembly stage involves the integration of various components, such as the engine block, cylinder head, and crankshaft. Manufacturers often employ advanced automation technologies, including robotics, to enhance precision and reduce labor costs. Buyers should inquire about the assembly processes to assess the efficiency and skill of the workforce.

-

Finishing: The final stage focuses on surface treatment and quality checks. Processes such as painting, coating, and polishing are applied to enhance the engine’s aesthetics and protect against corrosion. This stage is vital for ensuring the product meets the visual and functional expectations of international markets.

What Quality Assurance Practices Are Essential for Auto Engine Manufacturers?

Quality assurance (QA) is integral to the manufacturing process, ensuring that each engine meets rigorous standards. Here are key aspects of QA that B2B buyers should consider:

-

International Standards Compliance: Many auto engine manufacturers adhere to international standards such as ISO 9001, which outlines criteria for quality management systems. Compliance with these standards indicates a commitment to quality and continuous improvement. Additionally, industry-specific certifications like CE (European Conformity) and API (American Petroleum Institute) are critical for ensuring safety and performance.

-

Quality Control Checkpoints: Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected for compliance with specifications before entering production.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps identify defects early in the process.

– Final Quality Control (FQC): A thorough inspection is conducted before the product is shipped, ensuring it meets all specifications and standards. -

Common Testing Methods: Various testing methods, such as non-destructive testing (NDT), fatigue testing, and performance testing, are employed to validate the quality of engine components. Buyers should request details on the testing methods used by potential suppliers to ensure thorough evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is crucial for B2B buyers looking to ensure product reliability. Here are some actionable steps:

-

Conduct Audits: Regular audits of suppliers can provide insight into their manufacturing processes and quality control measures. Buyers should establish a schedule for these audits, focusing on both process adherence and outcome effectiveness.

-

Request Quality Reports: Suppliers should provide comprehensive quality reports that detail their QC practices, testing outcomes, and compliance with relevant standards. These reports can offer valuable insights into a supplier’s commitment to quality.

-

Utilize Third-Party Inspection Services: Engaging independent third-party inspectors can add an additional layer of assurance. These inspectors can validate supplier claims and ensure compliance with international standards.

What Are the Nuances of Quality Control for International B2B Buyers?

B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must navigate various nuances when assessing quality control:

-

Cultural Differences: Understanding the cultural context in which a supplier operates can influence quality expectations. Communication styles, work ethics, and local standards may vary significantly, affecting how quality is perceived and managed.

-

Regulatory Compliance: Different regions have specific regulatory requirements that impact manufacturing and quality control. For instance, European buyers must be aware of CE marking requirements, while Middle Eastern buyers may focus on compliance with local standards. Researching these regulations is crucial for successful sourcing.

-

Supply Chain Transparency: Buyers should demand transparency throughout the supply chain, from raw material sourcing to final delivery. This transparency helps identify potential risks and ensures that all aspects of the manufacturing process adhere to agreed-upon standards.

-

Adaptability to Market Needs: The ability of suppliers to adapt their quality control measures to meet the specific needs of diverse markets is essential. Buyers should assess whether suppliers have the flexibility to adjust their processes in response to changing demands or standards in their respective regions.

Conclusion: Prioritizing Quality in Auto Engine Manufacturing

In conclusion, international B2B buyers must prioritize both manufacturing processes and quality assurance when sourcing auto engines. Understanding the main stages of production, the importance of compliance with international standards, and effective verification methods are crucial for making informed purchasing decisions. By focusing on these elements, buyers can ensure that they partner with reputable manufacturers capable of delivering high-quality engines that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘auto engine manufacturer’

This guide aims to provide international B2B buyers with a structured approach to sourcing auto engine manufacturers. By following these steps, you can ensure a comprehensive evaluation of potential suppliers, mitigate risks, and ultimately secure high-quality engines that meet your specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications required for your auto engines. This includes engine type, performance metrics, compliance with local regulations, and any unique features necessary for your vehicles. A well-defined specification helps you communicate your needs effectively and allows suppliers to respond accurately.

- Performance Requirements: Specify horsepower, torque, and fuel efficiency.

- Regulatory Compliance: Ensure the engine meets environmental and safety standards relevant to your region.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential auto engine manufacturers. Utilize trade directories, industry reports, and referrals from industry peers to compile a list of reputable suppliers. Understanding the market landscape will help you identify which manufacturers are best suited to meet your specific requirements.

- Industry Reputation: Look for suppliers with positive reviews and a proven track record in the auto industry.

- Geographic Considerations: Consider suppliers that are strategically located to reduce shipping costs and lead times.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that potential suppliers possess the necessary certifications and comply with international quality standards. This step is crucial to ensure that the engines you procure are reliable and adhere to safety regulations.

- ISO Certifications: Check for ISO 9001 or ISO/TS 16949 certifications, which indicate quality management systems.

- Environmental Compliance: Ensure suppliers meet emissions standards relevant to your target markets.

Step 4: Request and Analyze Quotes

Once you have shortlisted potential suppliers, request detailed quotes that outline pricing, payment terms, and delivery schedules. Analyzing quotes helps you compare not just costs but also value, ensuring you understand what is included in the pricing.

- Breakdown of Costs: Look for clarity on unit prices, shipping, and any additional fees.

- Payment Terms: Evaluate terms to ensure they align with your cash flow needs.

Step 5: Conduct Supplier Audits

If possible, conduct an audit of the shortlisted suppliers. This may involve visiting their production facilities or reviewing their operations through virtual means. Supplier audits provide insights into their manufacturing processes and quality control measures.

- Production Capacity: Assess if the supplier can meet your volume demands.

- Quality Control Processes: Ensure they have robust quality assurance measures in place.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to establish favorable terms and conditions. This includes pricing, delivery timelines, warranties, and after-sales support. Strong negotiations can lead to better deals and foster a long-term partnership.

- Warranties and Support: Clarify the extent of warranties offered and the support available post-purchase.

- Flexibility in Terms: Discuss the possibility of adjusting terms based on your business needs.

Step 7: Establish a Clear Communication Plan

Finally, establish a communication plan with your chosen supplier. Clear communication is vital for addressing any issues that may arise during production and delivery. Regular updates will help build a strong relationship and ensure that both parties remain aligned.

- Regular Check-ins: Schedule periodic meetings to discuss progress and address concerns.

- Point of Contact: Designate specific contacts to streamline communication between your team and the supplier.

By following this structured sourcing checklist, B2B buyers can confidently navigate the complexities of procuring auto engines, ensuring they partner with manufacturers who meet their operational and quality standards.

Comprehensive Cost and Pricing Analysis for auto engine manufacturer Sourcing

What Are the Key Cost Components in Auto Engine Manufacturing?

When sourcing auto engines, understanding the various cost components is crucial for accurate budgeting and negotiations. The primary cost components include:

-

Materials: The quality and type of materials directly impact the engine’s performance and cost. Common materials include aluminum, steel, and specialized alloys. Fluctuations in raw material prices can significantly alter overall costs.

-

Labor: Labor costs vary by region, reflecting local wage standards and expertise. In countries like Germany, skilled labor may drive higher costs, whereas labor in parts of Africa or South America may be lower but could lack certain technical skills.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses. Efficient manufacturing processes can help mitigate overhead costs, making it essential to consider suppliers with lean production practices.

-

Tooling: Initial tooling costs can be substantial, especially for customized engine designs. It’s critical to assess whether the supplier can absorb these costs or if they will be passed on to you.

-

Quality Control (QC): Implementing rigorous QC measures is vital for ensuring engine reliability. While it may increase costs, it can save money long-term by reducing warranty claims and recalls.

-

Logistics: Shipping costs, including freight and insurance, should not be overlooked. Understanding the supplier’s location and the associated logistics can help in estimating total costs accurately.

-

Margin: Suppliers will add a profit margin to their costs. This margin can vary based on market conditions, demand, and the supplier’s positioning in the market.

How Do Price Influencers Affect Auto Engine Sourcing?

Several factors can influence pricing, making it essential for buyers to understand these variables:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Negotiating lower MOQs can be beneficial for smaller operations, while larger buyers can leverage their volume for better pricing.

-

Specifications and Customization: Custom-engineered solutions will typically incur higher costs. Buyers should clearly define specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: Engines made from high-grade materials or those that meet international quality standards (e.g., ISO certifications) will cost more. However, investing in quality can lead to significant savings over time.

-

Supplier Factors: The supplier’s reputation, financial stability, and location can all impact pricing. Established suppliers with a track record of reliability may charge a premium but provide better overall value.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is critical as they dictate responsibilities regarding shipping, insurance, and tariffs. Misunderstandings can lead to unexpected costs.

What Are the Best Buyer Tips for Cost-Efficiency in Auto Engine Sourcing?

To optimize sourcing strategies and enhance cost-efficiency, consider the following tips:

-

Negotiate Wisely: Build strong relationships with suppliers. Engage in open discussions about costs, payment terms, and potential discounts for long-term partnerships.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Assess maintenance, fuel efficiency, and potential downtime to gain a comprehensive understanding of long-term costs.

-

Understand Pricing Nuances: Different regions may have varying pricing structures influenced by local economic conditions, regulations, and market demand. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with these nuances to make informed decisions.

-

Conduct Market Research: Stay updated on industry trends, material costs, and competitor pricing to negotiate effectively. Engage local industry networks to gain insights into the best suppliers and pricing strategies.

Conclusion

Navigating the complexities of cost and pricing in auto engine manufacturing requires a thorough understanding of the various components and influencing factors. By leveraging this knowledge, international B2B buyers can make informed decisions, negotiate better deals, and ultimately enhance their sourcing efficiency. Always remember that indicative prices can fluctuate based on market conditions and should be validated with suppliers during negotiations.

Alternatives Analysis: Comparing auto engine manufacturer With Other Solutions

Understanding Alternatives in Auto Engine Manufacturing

In the competitive landscape of automotive manufacturing, selecting the right engine solution is critical for international B2B buyers. With advancements in technology and diverse regional needs, it is essential to explore viable alternatives to traditional auto engine manufacturing. This analysis will compare the traditional auto engine manufacturing process with two emerging alternatives: electric vehicle (EV) propulsion systems and hybrid engine technologies. Each solution offers unique advantages and challenges, making it crucial for buyers to evaluate them based on their specific requirements.

Comparison Table of Auto Engine Manufacturing and Alternatives

| Comparison Aspect | Auto Engine Manufacturer | Electric Vehicle Propulsion | Hybrid Engine Technology |

|---|---|---|---|

| Performance | High torque, reliable power output | Instant torque, quieter operation | Balanced power and efficiency |

| Cost | High initial investment, lower long-term maintenance | Higher upfront costs, potential savings in fuel | Moderate costs, fuel savings over time |

| Ease of Implementation | Complex supply chain, skilled labor needed | Requires infrastructure changes, skilled technicians | Integrates well with existing systems, less disruption |

| Maintenance | Regular servicing, parts availability | Lower maintenance, fewer moving parts | Requires both fuel and electric system maintenance |

| Best Use Case | Traditional vehicles, high-performance applications | Urban transport, eco-conscious markets | Versatile, suitable for various driving conditions |

What Are the Advantages and Disadvantages of Electric Vehicle Propulsion?

Electric vehicle propulsion systems are gaining traction as a sustainable alternative to traditional auto engines. One of the key advantages is their performance; EVs deliver instant torque, providing a responsive driving experience and quieter operation. Additionally, EVs have fewer moving parts, leading to lower maintenance costs over time. However, the initial investment for EV technology can be significantly higher than conventional engines, and the lack of charging infrastructure in some regions can hinder widespread adoption. Buyers in Africa or South America, for instance, must consider the availability of charging stations when evaluating EV solutions.

How Does Hybrid Engine Technology Compare?

Hybrid engine technology combines traditional internal combustion engines with electric propulsion, offering a balanced approach to performance and efficiency. This solution allows for reduced fuel consumption and lower emissions, making it appealing for eco-conscious markets. The integration of hybrid systems can be less disruptive, as they can be adapted to existing vehicle designs. However, hybrid engines require maintenance for both the combustion and electric components, which can complicate service logistics. Buyers in the Middle East, known for their diverse driving conditions, may find hybrids to be versatile options for urban and rural applications.

How Can B2B Buyers Choose the Right Engine Solution?

When selecting the appropriate engine solution, B2B buyers should assess their specific operational needs, budget constraints, and market trends. Factors such as performance requirements, cost of ownership, ease of implementation, and maintenance considerations should guide decision-making. For instance, businesses in Europe may prioritize sustainability and opt for EVs, while those in regions with established fuel infrastructures might lean towards hybrids or traditional engines. Ultimately, understanding the unique advantages and challenges of each alternative will empower buyers to make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for auto engine manufacturer

What Are the Key Technical Properties for Auto Engine Manufacturers?

When sourcing components for auto engines, understanding essential technical properties is crucial for ensuring product quality and performance. Here are some critical specifications every B2B buyer should be familiar with:

-

Material Grade

Material grade refers to the classification of materials based on their properties and performance characteristics. For auto engines, common materials include aluminum, steel, and cast iron. Selecting the right material grade impacts the engine’s weight, durability, and thermal efficiency. Buyers should prioritize suppliers who provide detailed information about material certifications and compliance with international standards. -

Tolerance

Tolerance defines the permissible limit of variation in a physical dimension. In auto engine manufacturing, precise tolerances are vital for components like pistons and cylinder heads, where even minor deviations can lead to performance issues or engine failure. B2B buyers should ensure that their suppliers can meet the specified tolerances to maintain engine reliability and efficiency. -

Heat Resistance

Heat resistance indicates a material’s ability to withstand high temperatures without losing its mechanical properties. This property is particularly important for engine components exposed to extreme heat, such as exhaust manifolds and turbochargers. Buyers should look for materials that not only offer high heat resistance but also have good thermal conductivity to enhance engine performance. -

Corrosion Resistance

Corrosion resistance is the ability of a material to resist degradation due to chemical reactions with its environment. In regions with high humidity or exposure to road salt, such as parts of Europe and South America, selecting corrosion-resistant materials is essential. This property prolongs the life of engine components, reducing maintenance costs and enhancing reliability. -

Fatigue Strength

Fatigue strength is the maximum stress a material can withstand for a specified number of cycles without failing. In the context of auto engines, components are subjected to repeated stress and strain. Understanding fatigue strength helps B2B buyers select durable components that will perform reliably over time, crucial for maintaining operational efficiency.

Which Trade Terms Should B2B Buyers Understand in Auto Engine Manufacturing?

Familiarity with industry terminology is essential for effective communication and negotiation in auto engine manufacturing. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the auto industry, purchasing from an OEM often ensures compatibility and quality, as these manufacturers adhere to stringent industry standards. B2B buyers should prioritize OEMs for critical engine components to guarantee reliability. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers, as it affects inventory management and cash flow. Buyers should negotiate MOQs with suppliers to align with their production needs while avoiding excess stock. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For auto engine manufacturers, issuing RFQs helps ensure competitive pricing and enables buyers to compare different suppliers’ offerings. Crafting clear and detailed RFQs can lead to better negotiations and sourcing outcomes. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms helps B2B buyers manage risk and costs associated with international shipping. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight), which dictate when the risk transfers from seller to buyer. -

Lead Time

Lead time is the period between placing an order and receiving the goods. In auto engine manufacturing, understanding lead times is crucial for planning production schedules and managing supply chain efficiency. Buyers should engage with suppliers to establish realistic lead times to avoid production delays.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions, streamline procurement processes, and enhance their operational effectiveness in the auto engine manufacturing sector.

Navigating Market Dynamics and Sourcing Trends in the auto engine manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Auto Engine Manufacturing Sector?

The auto engine manufacturing sector is experiencing significant shifts driven by several global factors. Firstly, the rise in electric vehicle (EV) adoption is reshaping traditional engine manufacturing paradigms, compelling manufacturers to diversify their offerings. This trend is particularly relevant for international B2B buyers in regions like Europe, where stringent emissions regulations push automakers toward sustainable solutions. In parallel, the demand for hybrid engines is also surging, especially in markets such as South America and the Middle East, where fuel efficiency remains a priority.

Furthermore, advancements in manufacturing technologies such as additive manufacturing (3D printing) and Industry 4.0 are revolutionizing sourcing strategies. These technologies enable faster prototyping and reduce lead times, allowing B2B buyers to respond swiftly to market demands. Data analytics and IoT applications are also enhancing supply chain visibility, providing buyers with real-time insights into inventory levels and production processes.

A stock image related to auto engine manufacturer.

Lastly, geopolitical factors, including trade policies and tariffs, are influencing sourcing decisions. Buyers from Africa and South America must navigate these complexities to secure competitive pricing and reliable supply chains. Understanding local market conditions and leveraging regional partnerships can be instrumental in overcoming these challenges.

How Important Is Sustainability and Ethical Sourcing in the Auto Engine Manufacturing Sector?

Sustainability and ethical sourcing have become critical focal points for B2B buyers in the auto engine manufacturing sector. The environmental impact of traditional engine production methods is prompting companies to rethink their sourcing strategies. Buyers are increasingly seeking manufacturers who prioritize sustainable practices, such as reducing carbon footprints and minimizing waste.

Ethical supply chains are essential not only for compliance with international regulations but also for enhancing brand reputation. Buyers should look for suppliers who can demonstrate transparency in their operations and adhere to recognized ethical standards. Certifications such as ISO 14001 for environmental management and the Global Reporting Initiative (GRI) can provide assurance that a supplier is committed to sustainable practices.

Moreover, the use of ‘green’ materials, such as recycled metals and bio-based composites, is gaining traction in the industry. These materials not only reduce environmental impact but can also appeal to consumers increasingly concerned about sustainability. Buyers should prioritize partnerships with manufacturers who invest in innovative materials that align with the growing demand for eco-friendly products.

What Is the Brief Evolution and History of the Auto Engine Manufacturing Sector?

The auto engine manufacturing sector has undergone significant evolution since the advent of the internal combustion engine in the late 19th century. Initially dominated by steam and gasoline engines, the industry expanded rapidly with technological advancements, leading to mass production techniques in the early 20th century. This period marked the rise of major automotive manufacturers, establishing foundational practices in engine design and manufacturing.

In recent decades, the sector has faced transformative changes due to globalization and technological innovation. The introduction of computer-aided design (CAD) revolutionized engine development, while recent trends toward electric and hybrid engines have prompted a shift in focus from traditional engine manufacturing to more sustainable alternatives. As the industry continues to adapt, understanding its historical context helps B2B buyers appreciate the ongoing changes and seize opportunities in a rapidly evolving market.

Frequently Asked Questions (FAQs) for B2B Buyers of auto engine manufacturer

-

How do I solve the challenge of sourcing high-quality auto engines from manufacturers?

To effectively source high-quality auto engines, begin by conducting thorough market research to identify reputable manufacturers. Use industry directories, trade shows, and online platforms like Alibaba or ThomasNet to find potential suppliers. Request samples and certifications to assess quality. Establish communication with the manufacturers to discuss their production processes and quality assurance measures. Additionally, consider visiting their facilities if feasible, as this can provide insights into their operational standards and build trust. -

What is the best way to evaluate auto engine manufacturers for my business needs?

Evaluating auto engine manufacturers involves several key steps. First, check their industry experience and specialization in the type of engine you require. Look for customer reviews and case studies to gauge reliability and performance. Verify certifications like ISO 9001 to ensure quality management. Assess their production capacity and lead times to meet your demand. Finally, engage in direct discussions regarding customization options and after-sales support to determine if they align with your business objectives. -

How can I customize auto engines to meet specific requirements?

Customization of auto engines is often possible, but it requires clear communication with the manufacturer. Begin by outlining your specific needs regarding engine specifications, performance metrics, and any regulatory compliance requirements. Discuss these needs with potential suppliers to understand their flexibility in design and manufacturing processes. It may also be beneficial to engage in collaborative development, where you can work closely with the engineering team to create prototypes before finalizing the order. -

What are the minimum order quantities (MOQs) for auto engines from manufacturers?

Minimum order quantities (MOQs) can vary significantly among auto engine manufacturers. Typically, larger manufacturers may have higher MOQs due to their production setup and costs. However, smaller or specialized manufacturers might offer lower MOQs to attract international buyers. When negotiating, consider your budget and inventory management capabilities. It’s advisable to discuss potential adjustments to MOQs if you’re testing a new product line or entering a new market. -

What payment terms should I expect when purchasing auto engines internationally?

Payment terms for international purchases can differ based on manufacturer policies and buyer negotiation. Common terms include Letters of Credit (LC), Advance Payments, or 30-60 day payment terms after delivery. It’s essential to clarify these terms early in negotiations to avoid misunderstandings. Additionally, consider the implications of currency fluctuations and international transaction fees. Establishing a reliable payment method can enhance trust and facilitate smoother transactions with suppliers. -

How do I ensure quality assurance when sourcing auto engines from manufacturers?

Ensuring quality assurance starts with selecting manufacturers that have robust quality control processes in place. Request detailed information about their QA procedures and certifications. Implement a system for regular inspections and audits of the manufacturing process, which may include third-party inspections. Establish clear quality expectations in your contract, including specifications and testing protocols. Ongoing communication with the supplier about any quality concerns is crucial for maintaining standards. -

What logistics considerations should I keep in mind when importing auto engines?

Logistics is a critical aspect of importing auto engines. Start by understanding the shipping methods available, such as air freight for speed or sea freight for cost-effectiveness. Factor in customs regulations and duties specific to your country, as these can impact overall costs and timelines. Collaborate with experienced logistics providers to handle documentation and ensure compliance with international trade regulations. Lastly, plan for storage and distribution once the engines arrive to minimize delays in your supply chain. -

How can I navigate international trade regulations when sourcing auto engines?

Navigating international trade regulations requires diligent research and preparation. Familiarize yourself with the import/export regulations of both your country and the manufacturer’s country. This includes understanding tariffs, trade agreements, and product compliance standards. Engage with customs brokers or trade consultants who can provide insights and assistance in navigating the complexities of international shipping. Keeping abreast of any changes in trade policies is essential to avoid potential disruptions in your supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for auto engine manufacturer

In the rapidly evolving landscape of the auto engine manufacturing industry, strategic sourcing emerges as a pivotal component for international B2B buyers. By focusing on supplier diversification, buyers can mitigate risks associated with supply chain disruptions, which have become increasingly prevalent in recent years. Leveraging local suppliers in regions such as Africa, South America, and the Middle East can enhance responsiveness and reduce logistics costs, while partnerships with established European manufacturers can provide access to advanced technology and quality standards.

What are the key benefits of implementing strategic sourcing in your procurement process? Firstly, it allows for better negotiation leverage and cost management, ensuring that your organization remains competitive. Secondly, it fosters innovation through collaboration with suppliers who can contribute unique insights and technologies to your projects.

Looking ahead, the global demand for sustainable and efficient auto engines will continue to grow. B2B buyers are encouraged to embrace strategic sourcing as a dynamic tool to not only streamline operations but also to position themselves at the forefront of industry advancements. By proactively engaging with suppliers across various regions, you can ensure a resilient and forward-thinking supply chain that meets the challenges of tomorrow.