Discover Top Benefits: Car Accessorie Manufacturer Guide (2025)

Introduction: Navigating the Global Market for car accessorie manufacturer

Navigating the global market for car accessories manufacturing can be a daunting task for international B2B buyers, especially when sourcing quality components that meet diverse regional demands. With an increasing number of vehicles on the roads in regions like Africa, South America, the Middle East, and Europe, the need for reliable and innovative car accessories has never been more critical. This guide serves as a comprehensive resource for understanding the vast landscape of car accessory manufacturers, covering essential topics such as types of accessories, applications, supplier vetting processes, and cost considerations.

In this guide, international B2B buyers will discover practical insights on how to effectively source car accessories that align with their specific market needs. Whether you’re looking for cutting-edge infotainment systems, durable protective gear, or aesthetic enhancements, we will equip you with the knowledge to make informed purchasing decisions.

Additionally, we will address common challenges faced by buyers in various markets, such as navigating import regulations, understanding local consumer preferences, and establishing trustworthy supplier relationships. By leveraging the insights provided in this guide, you will be empowered to streamline your procurement processes, ensuring you secure high-quality products that drive customer satisfaction and business growth.

Understanding car accessorie manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM (Original Equipment Manufacturer) | Produces parts that are identical to the original vehicle specifications. | Vehicle assembly, replacement parts, warranty services. | Pros: High compatibility, reliability. Cons: Higher cost, limited customization. |

| Aftermarket Manufacturers | Offers parts and accessories that are not made by the vehicle’s original manufacturer. | Customization, performance upgrades, repairs. | Pros: Cost-effective, diverse options. Cons: Variable quality, potential compatibility issues. |

| Specialty Accessory Suppliers | Focus on niche markets, providing unique accessories tailored to specific vehicle types. | Upgrades, personalization, lifestyle accessories. | Pros: Unique offerings, targeted solutions. Cons: Limited availability, potentially higher prices. |

| Private Label Manufacturers | Produce products that are branded under another company’s label. | Retail, e-commerce, brand differentiation. | Pros: Brand control, flexible pricing. Cons: Quality may vary based on supplier. |

| Custom Fabricators | Design and produce bespoke accessories based on specific client requirements. | High-end vehicles, bespoke modifications. | Pros: Tailored solutions, exclusivity. Cons: Longer lead times, higher costs. |

What are OEM Manufacturers and Why are They Important for B2B Buyers?

OEM manufacturers are crucial for businesses that prioritize high-quality replacements and components that match the original specifications of vehicles. These manufacturers produce parts that are identical to those used in the assembly of vehicles, ensuring seamless integration and reliability. B2B buyers, especially those involved in vehicle assembly or maintenance services, benefit from OEM parts due to their guaranteed compatibility and long-term performance. However, the trade-off often comes in the form of higher costs compared to alternative sources.

How Do Aftermarket Manufacturers Provide Value to B2B Buyers?

Aftermarket manufacturers present a compelling option for businesses looking to offer cost-effective solutions without sacrificing quality. They produce parts and accessories that can enhance vehicle performance or aesthetics, catering to a wide range of customer preferences. For B2B buyers, this means access to a diverse product range that can meet various needs, from standard replacements to performance upgrades. However, buyers should be cautious about the variable quality and potential compatibility issues that may arise with aftermarket parts.

What Makes Specialty Accessory Suppliers Unique in the B2B Market?

Specialty accessory suppliers serve niche markets by providing unique products tailored to specific types of vehicles or customer needs. These manufacturers focus on creating accessories that enhance the lifestyle or functionality of vehicles, making them attractive to businesses looking to differentiate their offerings. For B2B buyers, the main advantage lies in the exclusivity and targeted solutions these suppliers provide. However, the trade-offs include limited availability and potentially higher prices for specialized products.

Why Choose Private Label Manufacturers for Branding?

Private label manufacturers offer businesses the ability to create branded products without the overhead of production. This option allows companies to maintain brand identity while benefiting from the manufacturing capabilities of established suppliers. For B2B buyers, private labeling can lead to better pricing flexibility and control over product quality. However, it’s essential to ensure that the supplier maintains consistent quality, as this can vary significantly from one manufacturer to another.

When Should B2B Buyers Consider Custom Fabricators?

Custom fabricators are ideal for businesses seeking bespoke solutions that cater to specific client requirements or unique vehicle modifications. These manufacturers can design and produce accessories tailored to individual specifications, which is particularly valuable in high-end markets or specialized applications. While custom fabricators provide exclusivity and tailored solutions, B2B buyers should be prepared for longer lead times and higher costs associated with bespoke manufacturing processes.

Related Video: Small Block Ford Variations- Whats the difference?

Key Industrial Applications of car accessorie manufacturer

| Industry/Sector | Specific Application of Car Accessory Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Aftermarket | Custom Interior Accessories | Enhances vehicle aesthetics and comfort | Quality of materials, compatibility with various models, local regulations |

| Fleet Management | GPS and Tracking Devices | Improves vehicle security and operational efficiency | Durability, real-time data capabilities, integration with existing systems |

| E-commerce and Retail | Car Care Products | Boosts customer satisfaction and repeat sales | Brand reputation, product efficacy, shipping logistics |

| Car Rental Services | Vehicle Enhancement Kits | Attracts customers with upgraded features | Cost-effectiveness, ease of installation, availability of support |

| Electric Vehicles | Charging Accessories | Supports the growing EV market and sustainability | Compliance with safety standards, charging speed, compatibility with EV models |

What Are the Key Applications of Car Accessory Manufacturing in the Automotive Aftermarket?

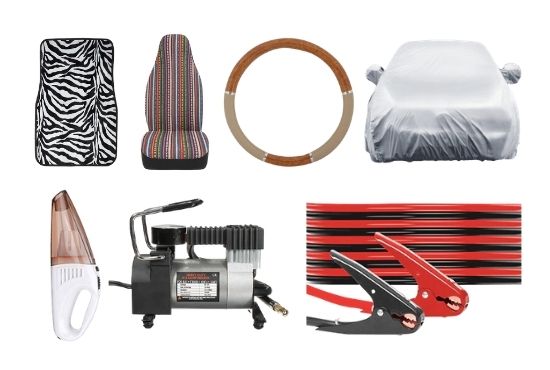

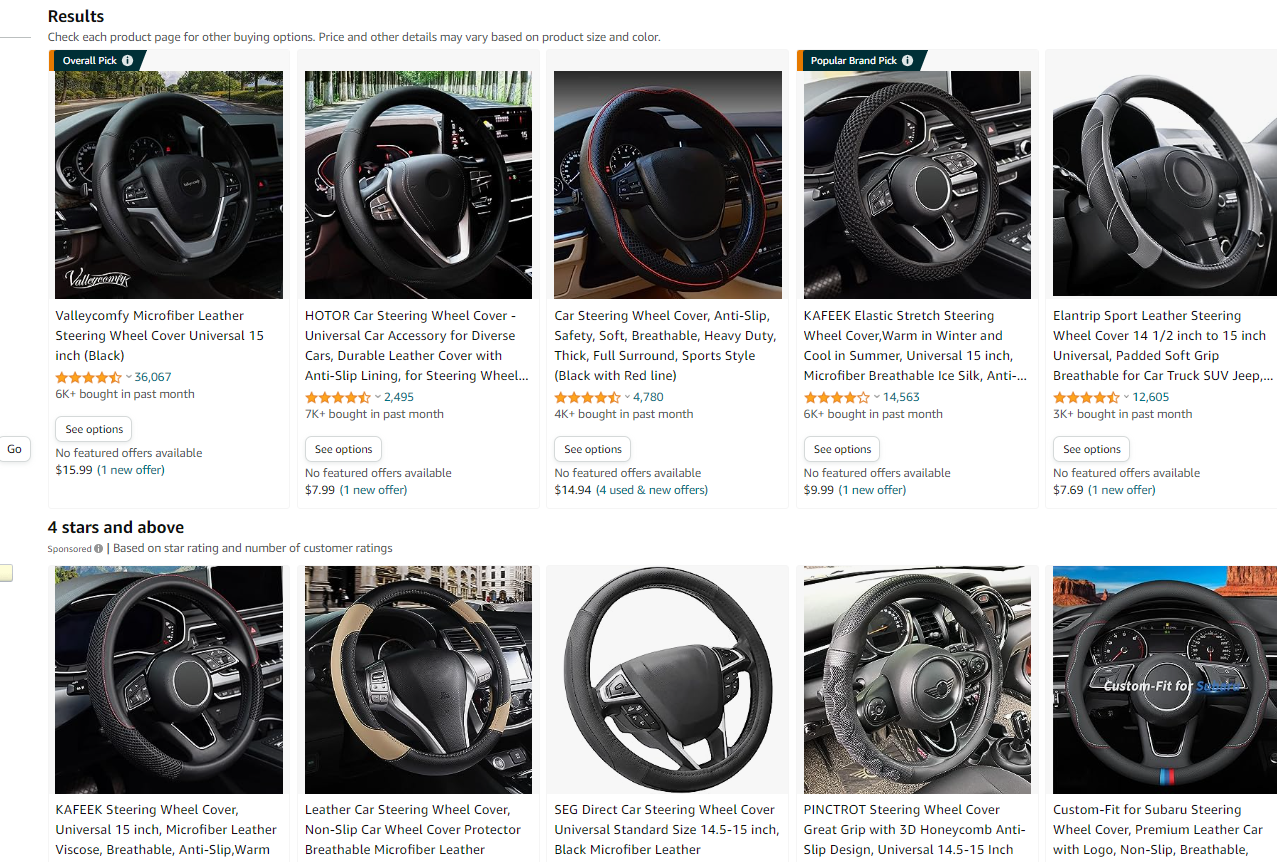

The automotive aftermarket is a significant sector where car accessory manufacturers thrive, particularly in producing custom interior accessories. These products, such as seat covers, floor mats, and steering wheel covers, enhance vehicle aesthetics and comfort. For international B2B buyers, especially in emerging markets like Africa and South America, sourcing high-quality materials that meet local regulations is crucial. Additionally, compatibility with various vehicle models is a key consideration, ensuring that the products can be easily integrated into a wide range of cars.

How Do GPS and Tracking Devices Benefit Fleet Management?

In fleet management, GPS and tracking devices are essential accessories that enhance vehicle security and operational efficiency. These devices provide real-time location data, which helps businesses monitor their fleet’s movements and optimize routes. International buyers should prioritize the durability of these devices, ensuring they can withstand various environmental conditions. Moreover, the ability to integrate these tracking systems with existing fleet management software is a critical factor that can improve overall operational effectiveness.

What Role Do Car Care Products Play in E-commerce and Retail?

Car care products represent a lucrative application for car accessory manufacturers in the e-commerce and retail sectors. These products, including waxes, polishes, and cleaning supplies, are essential for maintaining a vehicle’s appearance and longevity. For businesses, offering high-quality car care products can significantly boost customer satisfaction and encourage repeat sales. When sourcing these products, B2B buyers should focus on the brand reputation and product efficacy, as well as efficient shipping logistics to ensure timely delivery to their customers.

How Can Vehicle Enhancement Kits Attract Car Rental Services?

Car rental services often utilize vehicle enhancement kits to attract customers by offering upgraded features such as advanced infotainment systems or aesthetic modifications. These enhancements can differentiate rental offerings in a competitive market. For B2B buyers in this sector, cost-effectiveness and ease of installation are paramount, as they seek to minimize downtime and maximize vehicle availability. Additionally, ensuring that there is adequate support for installation and maintenance can enhance the overall rental experience for customers.

Why Are Charging Accessories Crucial for Electric Vehicles?

With the growing popularity of electric vehicles (EVs), charging accessories have become a vital application for car accessory manufacturers. These accessories, including home charging stations and portable chargers, support the transition to sustainable transportation. International buyers must consider compliance with safety standards and the charging speed of these accessories to meet customer expectations. Furthermore, ensuring compatibility with various EV models is essential to cater to a diverse customer base, particularly in regions with increasing EV adoption like Europe and parts of the Middle East.

Related Video: FANUC Industrial Robots | AUDI Case Study

3 Common User Pain Points for ‘car accessorie manufacturer’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Components for Car Accessories

The Problem: International B2B buyers often face challenges in sourcing high-quality components for car accessories due to a fragmented supplier landscape. In regions such as Africa and South America, manufacturers may struggle with inconsistent quality standards, leading to potential product failures that could damage their reputation. For instance, a buyer sourcing steering wheel covers may encounter suppliers that offer varying levels of material quality, affecting durability and customer satisfaction.

The Solution: To overcome this sourcing challenge, buyers should prioritize establishing relationships with reputable car accessory manufacturers known for their quality assurance processes. Conduct thorough due diligence by requesting samples and certifications that validate the materials used. Additionally, consider leveraging online platforms that connect B2B buyers with verified manufacturers, such as Alibaba or ThomasNet. Engaging in industry trade shows or exhibitions can also provide opportunities to meet potential suppliers face-to-face, fostering trust and allowing buyers to assess product quality directly.

Scenario 2: Navigating Regulatory Compliance in Different Markets

The Problem: B2B buyers in the car accessories sector often face the complex landscape of regulatory compliance, which varies significantly across regions like Europe, the Middle East, and Africa. For example, a buyer importing car seat covers may encounter different safety and environmental regulations that impact product specifications and marketability. Non-compliance can result in costly fines, product recalls, and damage to brand reputation.

The Solution: To navigate these regulatory challenges effectively, buyers should invest time in understanding the specific compliance requirements of each target market. This includes researching local laws regarding product safety, environmental impact, and labeling. Collaborating with local legal experts or compliance consultants can provide invaluable insights and help ensure that all products meet necessary regulations before entering the market. Furthermore, manufacturers should be encouraged to maintain compliance documentation that can be shared with buyers, simplifying the verification process.

Scenario 3: Managing Supply Chain Disruptions and Delays

The Problem: Supply chain disruptions are a persistent issue for B2B buyers in the car accessory market, often exacerbated by geopolitical tensions, natural disasters, or global pandemics. Buyers from regions like South Africa or Brazil may experience delays in receiving essential components, which can halt production lines and lead to missed sales opportunities. These disruptions can also create a ripple effect, impacting relationships with customers who depend on timely delivery.

The Solution: To mitigate the risks associated with supply chain disruptions, buyers should adopt a multi-sourcing strategy. This involves diversifying their supplier base to include multiple manufacturers from different regions, reducing dependency on a single source. Implementing just-in-time inventory systems can also help manage stock levels more effectively, allowing for quick adjustments in response to supply changes. Additionally, buyers should maintain open lines of communication with suppliers, establishing contingency plans and alternative sourcing options well in advance of potential disruptions. This proactive approach not only enhances resilience but also fosters stronger partnerships with suppliers.

Strategic Material Selection Guide for car accessorie manufacturer

What Are the Key Properties of Common Materials Used in Car Accessories?

When selecting materials for car accessories, manufacturers must consider properties such as temperature resistance, pressure ratings, and corrosion resistance. These properties directly affect the performance and longevity of the products.

1. Polypropylene (PP)

Polypropylene is a thermoplastic polymer widely used in automotive applications due to its excellent chemical resistance and lightweight nature. It can withstand temperatures up to 100°C (212°F) and exhibits good impact resistance.

Pros & Cons:

– Pros: Lightweight, cost-effective, and easy to mold into complex shapes. It also has good resistance to fatigue and is recyclable.

– Cons: Not suitable for high-temperature applications beyond its rating, and can become brittle over time when exposed to UV light.

Impact on Application:

Polypropylene is ideal for interior components like dashboards and storage bins, where durability and lightweight properties are crucial.

Considerations for International Buyers:

B2B buyers from regions like Africa and South America should ensure compliance with local automotive standards. The material’s recyclability aligns with increasing environmental regulations in Europe.

2. Aluminum

Aluminum is a lightweight metal known for its strength and corrosion resistance. It can handle high temperatures and is often used in structural components.

Pros & Cons:

– Pros: Excellent strength-to-weight ratio, corrosion-resistant, and easily recyclable. It can also be anodized for additional surface protection.

– Cons: Higher cost compared to plastics and can be more complex to manufacture due to the need for specialized tooling.

Impact on Application:

Aluminum is commonly used in exterior parts like trim and brackets, where strength and aesthetics are important.

Considerations for International Buyers:

Buyers in the Middle East should consider aluminum’s performance in high-temperature environments. Compliance with standards like ASTM for aluminum alloys is crucial.

3. Rubber

Rubber is used extensively in automotive applications for seals, gaskets, and tires due to its flexibility and excellent sealing properties. It can withstand a range of temperatures, typically from -40°C to 120°C (-40°F to 248°F).

Pros & Cons:

– Pros: Excellent flexibility, good vibration dampening, and effective sealing capabilities.

– Cons: Can degrade over time due to ozone exposure and UV light, leading to a shorter lifespan compared to other materials.

Impact on Application:

Rubber is critical in applications requiring sealing and cushioning, such as weather stripping and suspension components.

Considerations for International Buyers:

B2B buyers should check for compliance with automotive standards, especially in Europe, where regulations on material safety and environmental impact are stringent.

4. Glass Fiber Reinforced Plastic (GFRP)

GFRP is a composite material that combines glass fibers with a resin matrix. It offers high strength and rigidity while remaining lightweight.

Pros & Cons:

– Pros: Exceptional strength-to-weight ratio, corrosion resistance, and can be molded into complex shapes.

– Cons: Higher manufacturing costs and complexity in production processes compared to traditional plastics.

Impact on Application:

GFRP is suitable for high-performance applications like body panels and structural components where weight savings are essential.

Considerations for International Buyers:

Buyers from Europe and South America should be aware of the specific standards for composite materials in automotive applications, ensuring they meet local regulations.

Summary Table of Material Selection for Car Accessories

| Material | Typical Use Case for car accessorie manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | Interior components like dashboards | Lightweight and cost-effective | Limited high-temperature performance | Low |

| Aluminum | Exterior parts like trim and brackets | Excellent strength-to-weight ratio | Higher cost and complex manufacturing | Med |

| Rubber | Seals and gaskets | Excellent sealing and flexibility | Degrades under UV and ozone exposure | Low |

| Glass Fiber Reinforced Plastic (GFRP) | Body panels and structural components | High strength-to-weight ratio | Higher manufacturing complexity | High |

This strategic material selection guide provides essential insights for international B2B buyers in the automotive accessories industry, facilitating informed decisions that align with regional standards and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for car accessorie manufacturer

What Are the Key Manufacturing Processes for Car Accessories?

The manufacturing of car accessories involves a series of critical stages that ensure the final product meets industry standards and customer expectations. Understanding these processes can help international B2B buyers make informed decisions when sourcing from manufacturers.

What Are the Main Stages of Car Accessory Manufacturing?

-

Material Preparation: The first step in manufacturing car accessories is the selection and preparation of raw materials. Common materials include plastics, metals, and textiles. Suppliers often use advanced technologies such as CNC machining and injection molding to cut and shape materials to precise specifications. Buyers should inquire about the sourcing of materials, focusing on sustainability and compliance with international regulations.

-

Forming: After preparation, materials undergo forming processes. Techniques such as stamping, bending, and extrusion are frequently used for metal components, while plastics may be molded or thermoformed. Understanding the forming techniques employed can help buyers assess the durability and functionality of the products they intend to purchase.

-

Assembly: The assembly stage involves putting together various components to create the final accessory. This could include attaching electrical parts, fasteners, or other elements. Manufacturers may utilize automated assembly lines or manual labor, depending on the complexity of the product. Buyers should evaluate the assembly processes to ensure that they align with their quality expectations and delivery timelines.

-

Finishing: The final stage of manufacturing is finishing, which enhances the aesthetic and functional qualities of the product. This may involve painting, coating, or polishing the accessory. Buyers should inquire about the finishing techniques used and the environmental considerations associated with them, such as VOC emissions from paints or coatings.

How Is Quality Assurance Implemented in Car Accessory Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process, ensuring that products meet established standards and customer expectations. Here’s how it typically unfolds:

What Are the Relevant International Standards for Quality Assurance?

International standards such as ISO 9001 play a vital role in the quality assurance of car accessories. ISO 9001 focuses on quality management systems and is widely recognized across various industries. Compliance with this standard can assure buyers of consistent quality and reliability in the manufacturing processes.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are crucial for certain car accessories. CE marking indicates compliance with European health, safety, and environmental protection standards, while API certification is essential for lubricants and other engine-related products.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival at the manufacturing facility. Ensuring that materials meet specifications is critical to preventing defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves continuous monitoring of production activities. This includes checks at various stages of assembly and forming to ensure that processes remain within defined parameters.

-

Final Quality Control (FQC): Once the product is assembled, FQC is conducted to verify that the finished accessory meets all specifications and quality standards. This may involve functional testing, visual inspections, and measurements.

What Testing Methods Are Commonly Used in Quality Assurance?

B2B buyers should be familiar with the various testing methods that manufacturers employ to ensure product quality:

-

Mechanical Testing: This includes tensile strength tests, impact tests, and fatigue tests, ensuring that materials can withstand the stresses of real-world use.

-

Electrical Testing: For accessories with electronic components, manufacturers conduct electrical testing to verify functionality, safety, and compliance with relevant standards.

-

Environmental Testing: Assessing how products perform under various environmental conditions (e.g., temperature fluctuations, humidity) is crucial for ensuring longevity and reliability.

How Can B2B Buyers Verify Supplier Quality Control Processes?

When sourcing car accessories, international B2B buyers must implement strategies to verify the quality control processes of their suppliers:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should assess whether the supplier has valid certifications and adheres to international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the QC measures in place. These reports should include information on defect rates, testing results, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspections can be performed at various stages of production, ensuring transparency and reliability.

What Are the QC and Certification Nuances for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances when it comes to quality assurance and certifications:

-

Regional Compliance: Different regions may have varying compliance requirements. For instance, products sold in Europe must meet CE marking standards, while those in the Middle East might require local certifications. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Cultural Considerations: Understanding cultural differences in business practices can influence quality assurance. Buyers should establish clear communication channels with suppliers to address any potential misunderstandings related to quality expectations.

-

Cost vs. Quality Trade-offs: While price is a significant factor in sourcing, buyers must balance cost with quality. Cheaper products may not always meet the desired standards, leading to higher long-term costs due to returns and replacements.

In conclusion, understanding the manufacturing processes and quality assurance measures in car accessory manufacturing is essential for international B2B buyers. By focusing on these aspects, buyers can ensure they source high-quality products that meet their market demands while building strong, reliable supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car accessorie manufacturer’

In the dynamic landscape of automotive accessories, international B2B buyers must navigate a variety of factors to ensure they source high-quality products effectively. This practical sourcing guide outlines a step-by-step checklist designed to streamline the procurement process for car accessory manufacturers, especially for buyers in Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of successful sourcing. Detail the materials, dimensions, compliance standards, and performance requirements that the accessories must meet. This clarity helps suppliers understand your needs and ensures that the products you receive are fit for purpose.

- Material Requirements: Specify if you need lightweight, durable materials or eco-friendly options.

- Compliance Standards: Ensure products meet local regulations and international standards, such as ISO certifications.

Step 2: Conduct Market Research

Understanding the market landscape is essential before engaging suppliers. Research trends in car accessories, including popular products in your target regions. This knowledge will help you identify potential suppliers who specialize in these products.

- Competitive Analysis: Analyze competitors’ offerings and pricing strategies to gauge market expectations.

- Consumer Preferences: Stay informed about local consumer preferences which can influence product features and styles.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; conduct background checks and look for reviews.

- Quality Assurance Processes: Inquire about their quality control measures and certifications.

- Production Capacity: Ensure they can meet your order volumes within your required timelines.

Step 4: Request Samples and Prototypes

Before making a bulk purchase, requesting samples or prototypes is vital. This step allows you to assess the quality, functionality, and aesthetic appeal of the products firsthand.

- Testing: Evaluate the samples under real-world conditions to ensure they meet your specifications.

- Feedback Loop: Share feedback with the supplier to address any necessary modifications before finalizing the order.

Step 5: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiating terms is crucial to protect your interests. Discuss pricing, payment terms, delivery schedules, and warranty options. A well-defined contract can prevent misunderstandings later.

- Payment Options: Explore various payment methods and consider escrow services for larger transactions.

- Delivery Clauses: Clearly outline delivery timelines and penalties for delays to hold suppliers accountable.

Step 6: Verify Supplier Certifications

Ensure that the suppliers possess all necessary certifications that validate their compliance with industry standards. This verification is especially important for buyers in regulated markets.

- Quality Certifications: Look for ISO, CE, or other relevant quality certifications.

- Sustainability Certifications: If applicable, confirm that the supplier adheres to environmental standards, which can be a significant selling point in many markets.

Step 7: Establish a Long-Term Relationship

Once you’ve completed your initial procurement, focus on building a long-term relationship with your supplier. Regular communication and feedback can foster collaboration and continuous improvement.

- Performance Reviews: Schedule periodic assessments of product quality and service levels.

- Future Collaboration: Discuss opportunities for innovation and new product development based on market trends.

By following this checklist, international B2B buyers can effectively navigate the complexities of sourcing car accessories, ensuring they select the right suppliers and products to meet their business needs.

A stock image related to car accessorie manufacturer.

Comprehensive Cost and Pricing Analysis for car accessorie manufacturer Sourcing

What Are the Key Cost Components in Car Accessory Manufacturing?

Understanding the cost structure of car accessory manufacturing is essential for international B2B buyers. The primary components include:

-

Materials: The choice of materials significantly impacts costs. For instance, high-quality plastics or metals may increase the expense but ensure durability. Buyers should consider sourcing from regions with abundant raw materials to minimize costs.

-

Labor: Labor costs vary widely based on geographic location and skill levels. Countries in Africa and South America may offer lower labor costs, but it’s crucial to assess the skill level of the workforce to ensure quality production.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and administrative expenses. Efficient manufacturing processes can reduce overhead, leading to lower pricing for buyers.

-

Tooling: Initial tooling costs can be high, especially for custom designs. Buyers should inquire about tooling costs upfront, as they can be amortized over larger production runs.

-

Quality Control (QC): Investing in robust QC processes is vital for ensuring product consistency and meeting international standards. Buyers should verify the QC procedures in place to avoid costly recalls or compliance issues.

A stock image related to car accessorie manufacturer.

-

Logistics: Transportation costs can vary based on the shipping method, distance, and Incoterms. Analyzing these factors can help buyers make informed decisions about supplier locations.

-

Margin: Manufacturers typically add a profit margin to cover risks and ensure sustainability. Understanding the typical margins in your target market can help in negotiations.

How Do Price Influencers Affect Car Accessory Costs?

Several factors influence the pricing of car accessories, and understanding these can help buyers negotiate better deals:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically reduce per-unit costs. Buyers should assess their needs and negotiate MOQs that align with their purchasing capabilities.

-

Specifications and Customization: Custom designs or specifications can increase costs. Buyers should balance the need for customization with budget constraints.

-

Materials: The type and quality of materials used significantly affect pricing. For example, eco-friendly materials may come at a premium but can enhance brand reputation.

-

Quality and Certifications: Products with international certifications (e.g., ISO, CE) often command higher prices. Buyers should consider whether these certifications are necessary for their market.

-

Supplier Factors: Supplier reliability, reputation, and production capacity can impact pricing. It’s advisable to conduct thorough supplier evaluations before making commitments.

-

Incoterms: The chosen Incoterms can influence logistics costs and responsibilities. Understanding these terms is crucial for accurately calculating the total landed cost of products.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing Car Accessories?

To maximize cost-efficiency when sourcing car accessories, international B2B buyers can adopt the following strategies:

-

Negotiate Wisely: Always negotiate pricing based on the total cost of ownership rather than just the initial purchase price. This includes considering logistics, warranties, and after-sales support.

-

Focus on Total Cost of Ownership (TCO): Assess the long-term costs associated with the product, such as maintenance, durability, and resale value. Lower upfront costs may lead to higher long-term expenses.

-

Understand Pricing Nuances: Different regions may have varying pricing strategies based on local market conditions, currency fluctuations, and economic factors. Buyers from Africa, South America, the Middle East, and Europe should consider these factors when making purchasing decisions.

-

Leverage Local Knowledge: Collaborate with local agents or consultants who understand the regional market dynamics. This can provide insights into fair pricing and reliable suppliers.

-

Stay Informed on Market Trends: Keeping up-to-date with global and regional trends in the automotive industry can aid in anticipating price changes and making informed sourcing decisions.

Disclaimer on Indicative Prices

Prices in the car accessory manufacturing industry can fluctuate based on market conditions, currency exchange rates, and other external factors. Buyers should always seek updated quotations and conduct thorough market research before finalizing any purchasing agreements.

Alternatives Analysis: Comparing car accessorie manufacturer With Other Solutions

In the competitive landscape of the automotive accessories market, B2B buyers often face the challenge of selecting the most suitable solution for their needs. Understanding the various alternatives available can help inform purchasing decisions, particularly for international buyers from diverse regions such as Africa, South America, the Middle East, and Europe. Below is a comparative analysis of car accessory manufacturers against alternative solutions, providing actionable insights for decision-makers.

| Comparison Aspect | Car Accessorie Manufacturer | 3D Printing Technology | Custom Parts Fabrication |

|---|---|---|---|

| Performance | High-quality production, tailored designs. | Excellent for prototyping and unique designs but may lack mass production efficiency. | Custom designs can meet specific needs but may have longer lead times. |

| Cost | Moderate to high depending on the scale of production. | Initial setup costs can be high, but costs decrease with volume. | Higher cost per unit, especially for low-volume runs. |

| Ease of Implementation | Streamlined processes with established supply chains. | Requires knowledge of 3D modeling and design software. | Dependent on skilled labor and technology, which may vary by region. |

| Maintenance | Regular quality checks required; generally low maintenance. | Minimal maintenance once the system is set up; requires skilled operators. | Maintenance varies based on the fabrication method and equipment used. |

| Best Use Case | Ideal for large-scale orders and standard products. | Best for rapid prototyping and custom designs. | Suitable for specialized components where off-the-shelf solutions do not suffice. |

What Are the Benefits of Using 3D Printing Technology for Car Accessories?

3D printing technology offers significant advantages for businesses that prioritize customization and rapid prototyping. One of the primary benefits is the ability to create complex designs without the constraints of traditional manufacturing methods. This technology allows for quick iterations and modifications, making it ideal for companies looking to test new ideas or create unique, tailored accessories. However, the initial investment in 3D printing equipment and expertise can be substantial, and the production speed may not match that of traditional manufacturing for larger orders.

How Does Custom Parts Fabrication Compare to Traditional Car Accessory Manufacturing?

Custom parts fabrication presents a flexible alternative to standard car accessory manufacturing. It excels in producing specialized components that may not be available through mass production. This method allows for a high degree of personalization, catering to specific client needs. However, it often involves higher costs per unit and longer lead times, making it less suitable for high-volume orders. Additionally, the success of this approach heavily depends on the availability of skilled labor and advanced fabrication technologies in the region.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right solution for automotive accessories, B2B buyers should consider their specific requirements, including production volume, budget constraints, and the need for customization. If the primary goal is to obtain high-quality, standardized products in large quantities, partnering with a reputable car accessory manufacturer may be the best choice. Conversely, businesses focused on innovation and unique designs might find that 3D printing or custom parts fabrication aligns better with their objectives. By carefully evaluating these alternatives, buyers can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for car accessorie manufacturer

What Are the Essential Technical Properties for Car Accessory Manufacturers?

When sourcing car accessories, international B2B buyers must understand the critical technical properties that ensure product quality and compatibility. Here are some of the key specifications:

-

Material Grade

The material grade refers to the quality and type of materials used in manufacturing car accessories, such as plastics, metals, or composites. High-grade materials often indicate better durability, safety, and performance. For buyers, selecting the right material grade is crucial for ensuring that accessories meet regulatory standards and customer expectations in their respective markets. -

Tolerance Levels

Tolerance levels define the acceptable range of variation in the dimensions of manufactured parts. This specification is vital for ensuring that components fit together seamlessly and function properly. Buyers should prioritize manufacturers who can consistently meet tight tolerances, as this directly impacts the performance and reliability of the final product. -

Surface Finish

The surface finish of a car accessory can affect not only its aesthetic appeal but also its functionality, such as resistance to corrosion and wear. Common finishes include anodizing, powder coating, and polishing. Understanding the surface finish is essential for buyers looking to enhance the visual quality of their products while maintaining durability. -

Performance Standards

Performance standards specify the operational capabilities of car accessories under various conditions (e.g., temperature, load, and environmental exposure). These standards, often aligned with industry regulations, are critical for ensuring that products can withstand real-world usage. Buyers should verify that manufacturers adhere to recognized performance benchmarks to ensure safety and reliability. -

Certifications and Compliance

Certifications, such as ISO, CE, or specific automotive standards, signify that a manufacturer meets established quality and safety requirements. For international buyers, ensuring compliance with local regulations and standards is essential to avoid legal issues and ensure market acceptance.

What Are the Common Trade Terminology Used in the Car Accessories Industry?

Familiarity with industry-specific jargon can significantly enhance communication and negotiation with suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are sold under another company’s brand name. For buyers, understanding OEM relationships can provide insight into product quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to consider as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their purchasing capabilities while ensuring they can meet market demand. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price offers from suppliers for specific products or services. This term is vital for initiating the procurement process, allowing buyers to compare offers effectively and make informed decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and tariffs. Understanding these terms helps buyers clarify logistics and avoid misunderstandings regarding costs and responsibilities. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. For B2B buyers, understanding lead times is essential for effective inventory planning and ensuring timely product availability in the market. -

Aftermarket

The aftermarket refers to the secondary market for car accessories and parts that are not supplied by the original manufacturer. This term is important for buyers looking to expand their product offerings and tap into additional revenue streams.

By grasping these essential technical properties and industry terms, international B2B buyers can make informed decisions, streamline procurement processes, and enhance their competitive edge in the car accessories market.

Navigating Market Dynamics and Sourcing Trends in the car accessorie manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Car Accessory Manufacturing Sector?

The car accessory manufacturing sector is experiencing a significant transformation, driven by technological advancements, consumer preferences, and evolving market dynamics. One of the primary global drivers is the increasing demand for personalization in vehicles. B2B buyers are looking for innovative accessories that enhance vehicle aesthetics and functionality, such as advanced infotainment systems, custom-fit floor mats, and enhanced safety features.

Emerging technologies, including IoT (Internet of Things) and smart connectivity, are reshaping product offerings. For instance, accessories that integrate with mobile apps for remote vehicle monitoring are gaining traction. Additionally, the rise of electric vehicles (EVs) has spurred demand for specialized accessories tailored to this market, such as charging station kits and lightweight components that improve efficiency.

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must consider regional market dynamics. In Africa and South America, the market is characterized by a growing middle class with increasing disposable income, leading to higher demand for quality car accessories. Conversely, in the Middle East and Europe, sustainability and compliance with environmental regulations are becoming paramount. Buyers should keep abreast of local market trends and consumer preferences, as these can vary significantly across regions.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in Car Accessory Manufacturing?

Sustainability and ethical sourcing are no longer optional considerations but essential elements for B2B buyers in the car accessory manufacturing sector. The environmental impact of manufacturing processes, including carbon emissions and waste generation, has prompted many companies to rethink their supply chains. Buyers are increasingly prioritizing manufacturers who demonstrate a commitment to sustainability, such as using recycled materials and implementing energy-efficient production methods.

Ethical sourcing practices, including fair labor conditions and transparent supply chains, are crucial for maintaining brand integrity and consumer trust. B2B buyers should seek suppliers with certifications such as ISO 14001 for environmental management or Fair Trade for labor practices. These certifications not only validate a manufacturer’s commitment to sustainability but also enhance their appeal to environmentally conscious consumers.

Incorporating sustainable practices can also lead to cost savings in the long run. For instance, using eco-friendly materials may reduce waste disposal costs and improve operational efficiency. As the global push for greener practices continues, B2B buyers who prioritize sustainability in their sourcing decisions will likely gain a competitive edge in the marketplace.

What Is the Evolution of the Car Accessory Manufacturing Sector?

The car accessory manufacturing sector has evolved significantly over the last few decades. Initially dominated by basic functional accessories, the market has shifted towards high-tech and personalized products. The introduction of advanced manufacturing technologies, such as 3D printing, has enabled manufacturers to offer customized solutions that cater to individual consumer preferences.

In recent years, the rise of e-commerce has transformed the way accessories are marketed and sold. B2B buyers now have access to a global marketplace, allowing them to source products from a diverse range of suppliers. This evolution has not only increased competition but has also led to greater innovation in product design and functionality.

As the automotive industry continues to embrace technological advancements and sustainability, the car accessory manufacturing sector is poised for further growth and transformation. B2B buyers who stay informed about these trends and adapt their sourcing strategies accordingly will be well-positioned to capitalize on new opportunities in this dynamic market.

Frequently Asked Questions (FAQs) for B2B Buyers of car accessorie manufacturer

-

How do I select the right car accessory manufacturer for my business needs?

Selecting the right manufacturer requires thorough research. Start by assessing their production capabilities, certifications, and experience in your specific market. Look for manufacturers who specialize in the type of accessories you need, whether they are for electric vehicles, SUVs, or other categories. Request samples to evaluate quality and inquire about their compliance with international standards. Additionally, check customer reviews and testimonials to gauge reliability and performance. -

What is the minimum order quantity (MOQ) for car accessories?

MOQs can vary significantly among manufacturers. Some may have a low MOQ of 100 units, while others might require orders of 1,000 or more. It’s essential to communicate your needs upfront to understand the manufacturer’s capacity to meet your order size. Many manufacturers offer flexible MOQs for established clients or bulk orders, so negotiate based on your business volume and potential for long-term partnership. -

What payment terms should I expect when sourcing from a car accessory manufacturer?

Payment terms can differ based on the manufacturer’s policies and the buyer’s negotiation skills. Common terms include a 30% deposit before production and the remaining 70% upon shipment. Be cautious of manufacturers requiring full payment upfront, as this can be a red flag. Always clarify payment methods accepted, such as bank transfers or letters of credit, and consider using escrow services for added security in international transactions.

-

How can I ensure the quality of car accessories before shipment?

Quality assurance is crucial in international trade. Request a comprehensive quality control plan from your manufacturer, which includes inspections at various production stages. You may also consider hiring a third-party inspection service to conduct pre-shipment inspections. Ensure that the manufacturer provides certifications, such as ISO, which indicate adherence to quality management standards, and ask for sample products to evaluate before placing larger orders. -

What are the typical lead times for car accessory production?

Lead times can vary based on several factors, including the complexity of the accessories, the manufacturer’s production capacity, and your order size. Generally, expect a timeframe of 4 to 12 weeks from order confirmation to delivery. For customized products, the lead time may extend due to design and approval processes. Always confirm lead times upfront and factor in additional time for shipping, especially for international orders. -

How do I handle shipping and logistics when sourcing car accessories internationally?

Shipping and logistics are critical components of international sourcing. Collaborate with manufacturers who have experience in exporting to your region. Choose a reliable freight forwarder to manage shipping arrangements, customs clearance, and delivery timelines. Understand the Incoterms (International Commercial Terms) involved, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), to clarify responsibilities for shipping costs and risks.

-

What should I consider when customizing car accessories?

Customization can differentiate your product offerings but requires careful planning. Discuss design specifications, material options, and branding elements with your manufacturer early in the process. Consider the implications of customization on production lead times and costs. It’s also advisable to request prototypes to ensure the final product meets your expectations before committing to a larger order. -

What are the common challenges in sourcing car accessories from international manufacturers?

Challenges can include communication barriers, cultural differences, and variations in quality standards. Time zone differences may hinder timely responses, and differing regulations can complicate compliance. To mitigate these issues, establish clear communication channels, utilize project management tools, and conduct regular follow-ups. Building a strong relationship with your manufacturer can also help address challenges more effectively and ensure smoother transactions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for car accessorie manufacturer

In today’s competitive landscape, strategic sourcing stands as a cornerstone for B2B buyers in the car accessories manufacturing sector. By establishing robust supplier relationships, businesses can not only secure high-quality products but also leverage cost efficiencies that directly impact their bottom line. Emphasizing the importance of understanding local market dynamics—whether in Africa, South America, the Middle East, or Europe—can enhance negotiation power and lead to better sourcing decisions.

How can international B2B buyers optimize their sourcing strategies for car accessories? It starts with identifying suppliers who align with your operational needs and quality standards. Engaging in comprehensive market research to understand the specific demands of your target region will enable you to tailor your offerings effectively.

As we look ahead, the evolving automotive landscape, characterized by increasing consumer demand for innovative and sustainable accessories, presents a wealth of opportunities. Buyers are encouraged to stay agile and responsive to market trends, ensuring that their sourcing strategies are not only effective today but also adaptable for the future. Embrace strategic sourcing as a vital element of your business strategy, and position yourself to capitalize on the burgeoning global demand for car accessories.