Discover Top Benefits: Choosing a Peristaltic Pump Manufacturer (2025)

Introduction: Navigating the Global Market for peristaltic pump manufacturer

In the competitive landscape of industrial equipment, sourcing a reliable peristaltic pump manufacturer can pose significant challenges for international B2B buyers. The complexity of selecting the right pump—considering factors such as application needs, material compatibility, and performance specifications—can be daunting. This guide is designed to demystify the process, offering a comprehensive overview of peristaltic pumps, including their various types and applications across different industries.

Buyers from Africa, South America, the Middle East, and Europe will find actionable insights into the critical aspects of supplier vetting, cost considerations, and the latest innovations in pump technology. With the right knowledge, businesses can make informed purchasing decisions that not only meet their operational requirements but also align with their budget and quality expectations.

This guide empowers B2B buyers by providing a structured approach to navigating the global market for peristaltic pumps. It highlights key questions to consider when evaluating manufacturers, essential criteria for assessing product quality, and tips for negotiating favorable terms. By leveraging this information, buyers can streamline their procurement processes and establish fruitful partnerships with manufacturers that can support their growth and operational efficiency.

Understanding peristaltic pump manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hose Peristaltic Pumps | Flexible hoses that create a pumping action through compression | Food and beverage, pharmaceuticals, wastewater | Pros: Gentle handling of shear-sensitive fluids; easy to clean. Cons: Limited pressure capabilities. |

| Tube Peristaltic Pumps | Rigid tubes that provide a more robust pumping solution | Chemical processing, industrial applications | Pros: High-pressure capability; durable. Cons: More complex maintenance requirements. |

| Digital Peristaltic Pumps | Integrated digital controls for precise flow management | Laboratory applications, medical devices | Pros: Accurate flow rates; programmable settings. Cons: Higher initial investment. |

| Sanitary Peristaltic Pumps | Designed for hygienic applications with smooth surfaces | Dairy, biotech, and food industries | Pros: Meets strict sanitary standards; easy to sanitize. Cons: Higher cost due to specialized materials. |

| Heavy-Duty Peristaltic Pumps | Engineered for tough environments and high viscosity fluids | Mining, oil and gas, and heavy industrial sectors | Pros: Handles viscous and abrasive materials; robust construction. Cons: Bulkier and may require more energy. |

What Are the Characteristics of Hose Peristaltic Pumps?

Hose peristaltic pumps are characterized by their use of flexible hoses that are compressed to create flow. They are particularly suitable for applications requiring gentle handling of shear-sensitive fluids, such as food and beverage processing or pharmaceuticals. When considering a purchase, buyers should focus on the pump’s material compatibility and ease of maintenance, as these factors significantly influence operational efficiency and hygiene standards.

How Do Tube Peristaltic Pumps Differ?

Tube peristaltic pumps utilize rigid tubes to facilitate a more robust pumping action. They are ideal for chemical processing and industrial applications where higher pressures are necessary. B2B buyers should evaluate the pump’s pressure ratings and material compatibility, as these will determine its suitability for specific chemical handling and processing tasks. Maintenance complexity is also a critical consideration, as it can impact overall operational downtime.

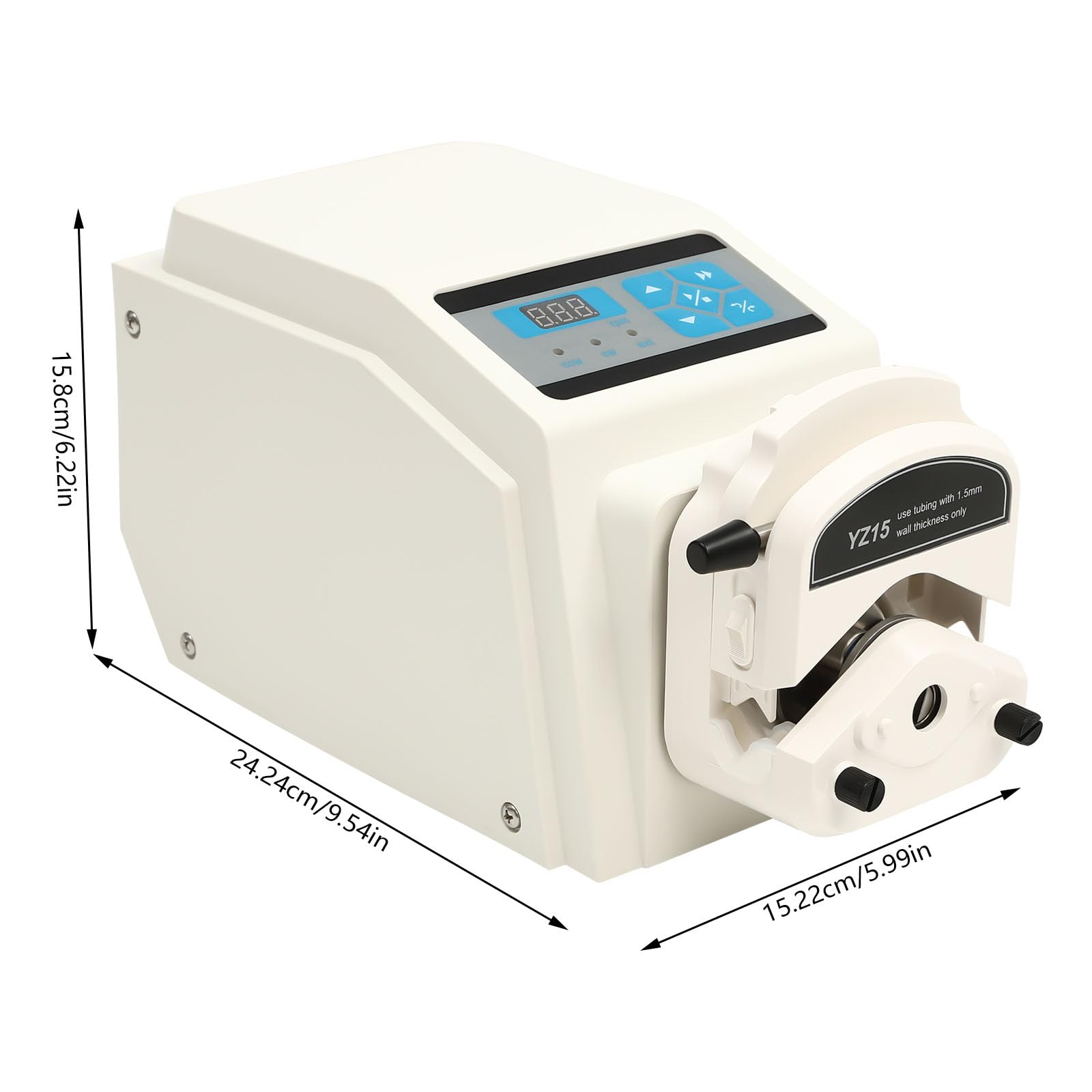

What Advantages Do Digital Peristaltic Pumps Offer?

Digital peristaltic pumps come equipped with integrated digital controls, allowing for precise flow management and monitoring. They are commonly used in laboratory and medical device applications where accuracy is paramount. Buyers should consider the initial investment versus the long-term savings from reduced operational errors and enhanced control capabilities. Additionally, the ability to program settings can lead to greater efficiency in high-throughput environments.

Why Choose Sanitary Peristaltic Pumps?

Sanitary peristaltic pumps are designed with smooth surfaces and materials that meet stringent hygiene standards, making them ideal for industries such as dairy, biotech, and food processing. When purchasing, B2B buyers should ensure that the pump complies with relevant regulations and standards, as this will impact both product safety and marketability. The ease of sanitation is another vital factor, as it influences operational efficiency and compliance.

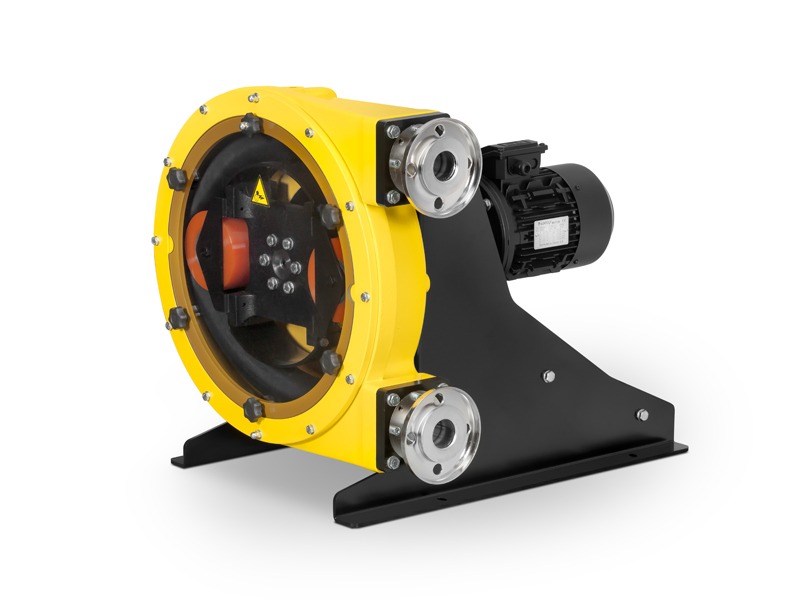

What Are the Features of Heavy-Duty Peristaltic Pumps?

Heavy-duty peristaltic pumps are built to withstand harsh environments and can handle high-viscosity fluids, making them suitable for sectors like mining, oil and gas, and heavy industry. Buyers should assess the pump’s construction materials and energy consumption, as these will determine both durability and operational costs. While these pumps are robust, their bulkiness may require additional space and energy considerations in the operational setup.

Related Video: Peristaltic Dosing Pump YZ1515X

Key Industrial Applications of peristaltic pump manufacturer

| Industry/Sector | Specific Application of peristaltic pump manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Transfer of viscous liquids like sauces and creams | Ensures hygienic transfer without contamination, preserving quality | Compliance with food safety regulations; materials suitable for food contact |

| Water and Wastewater Treatment | Chemical dosing for pH adjustment and disinfection | Enhances process efficiency and water quality | Reliability and accuracy in dosing; resistance to corrosive chemicals |

| Pharmaceutical Manufacturing | Accurate dosing of active ingredients in liquid formulations | Guarantees precise formulation, leading to consistent product quality | Compliance with GMP standards; easy cleaning and maintenance |

| Mining and Mineral Processing | Slurry transfer and chemical processing | Reduces wear and tear on equipment, increasing operational uptime | Durability in harsh environments; ability to handle abrasive materials |

| Agriculture and Horticulture | Fertilizer and pesticide application | Optimizes resource use, improving crop yield and sustainability | Compatibility with various liquid types; ease of integration with existing systems |

How Are Peristaltic Pumps Used in the Food and Beverage Industry?

In the food and beverage sector, peristaltic pumps are crucial for transferring viscous liquids such as sauces, creams, and other semi-solid products. These pumps operate by compressing and releasing a flexible tube, allowing for smooth and hygienic transfer. This method reduces the risk of contamination, ensuring that the quality of the product is maintained throughout the process. For international buyers, understanding the importance of compliance with food safety regulations and selecting materials that are suitable for food contact is essential for successful sourcing.

What Role Do Peristaltic Pumps Play in Water and Wastewater Treatment?

Peristaltic pumps are widely used in water and wastewater treatment plants for chemical dosing, particularly for pH adjustment and disinfection processes. Their design allows for precise dosing, which is critical for maintaining water quality and treatment efficiency. Buyers in this sector should focus on the reliability and accuracy of the pumps, as well as their resistance to corrosive chemicals. This ensures that the pumps can withstand the harsh conditions often found in wastewater applications.

How Are Peristaltic Pumps Essential in Pharmaceutical Manufacturing?

In pharmaceutical manufacturing, peristaltic pumps are utilized for the accurate dosing of active ingredients in liquid formulations. The precision offered by these pumps is vital for producing consistent and high-quality products, which is crucial in a highly regulated industry. Buyers must consider compliance with Good Manufacturing Practice (GMP) standards, as well as the ease of cleaning and maintenance of the pumps, to ensure operational efficiency and product safety.

What Benefits Do Peristaltic Pumps Provide in Mining and Mineral Processing?

Peristaltic pumps are employed in mining and mineral processing for slurry transfer and chemical processing applications. Their ability to handle abrasive materials while minimizing wear and tear on equipment leads to increased operational uptime and reduced maintenance costs. For international buyers, durability in harsh environments is a key consideration, along with the pump’s capability to manage varying slurry compositions effectively.

How Are Peristaltic Pumps Used in Agriculture and Horticulture?

In agriculture and horticulture, peristaltic pumps are ideal for the application of fertilizers and pesticides. These pumps enable optimized resource use, which contributes to improved crop yields and sustainability. Buyers should look for pumps that are compatible with various liquid types and can easily integrate into existing systems. This compatibility ensures efficient application processes, which are critical for maximizing agricultural productivity.

Related Video: How Peristaltic Metering Pumps Work – Helpful Animation by Albin Pump

3 Common User Pain Points for ‘peristaltic pump manufacturer’ & Their Solutions

Scenario 1: High Maintenance Costs of Peristaltic Pumps

The Problem:

B2B buyers often encounter significant challenges with the maintenance and operational costs associated with peristaltic pumps. In regions such as Africa and South America, where access to spare parts and skilled technicians may be limited, the cost of downtime can escalate quickly. Companies may find themselves spending more on repairs and replacements than anticipated, which can adversely impact their bottom line and operational efficiency. Additionally, inconsistent maintenance practices can lead to premature pump failures, further compounding the issue.

The Solution:

To mitigate high maintenance costs, B2B buyers should prioritize sourcing peristaltic pumps from manufacturers that offer comprehensive service agreements and support. When selecting a supplier, inquire about the availability of training programs for in-house technicians. This investment in training can empower your team to perform routine maintenance and troubleshooting, reducing reliance on external services. Furthermore, consider manufacturers that provide detailed maintenance manuals and easy access to spare parts. Establishing a partnership with a reputable supplier that ensures timely delivery of components can also help minimize downtime and maintenance expenses. Regularly scheduled maintenance checks can be instituted to catch potential issues before they escalate, leading to more efficient operations.

Scenario 2: Inconsistent Pump Performance in Diverse Applications

The Problem:

Many B2B buyers experience inconsistency in pump performance, particularly when peristaltic pumps are used across various applications, such as chemical processing, food and beverage, or wastewater treatment. This inconsistency can lead to product contamination, inefficiencies, and safety hazards, especially in regions with fluctuating environmental conditions. For example, temperature variations can affect the viscosity of the fluids being pumped, leading to erratic flow rates and operational challenges.

The Solution:

To ensure consistent performance across diverse applications, buyers should collaborate closely with manufacturers during the specification phase. Detailed discussions regarding the specific fluids, environmental conditions, and application requirements can lead to tailored solutions. Buyers should request pump models designed for their unique applications, including those with variable speed drives or adjustable flow rates to accommodate different viscosities. Additionally, seek manufacturers that offer testing services to validate pump performance under your specific conditions prior to purchase. Implementing a robust monitoring system can also help track pump performance in real time, allowing for quick adjustments and proactive maintenance.

Scenario 3: Difficulty in Integrating Peristaltic Pumps with Existing Systems

The Problem:

Another common pain point for international B2B buyers is the challenge of integrating new peristaltic pumps with existing production or processing systems. This is particularly prevalent in the Middle East and Europe, where industries often rely on complex, interlinked systems. Compatibility issues can lead to increased installation costs, project delays, and potential disruptions in production schedules, which can be detrimental in highly competitive markets.

The Solution:

To address integration challenges, buyers should conduct a thorough assessment of their current systems before selecting a peristaltic pump. Engage with manufacturers who offer customization options that align with your existing infrastructure, including specific fittings, control systems, and automation capabilities. It is also beneficial to request case studies or references from manufacturers that demonstrate successful integrations in similar environments. Moreover, consider enlisting the expertise of a systems integrator who can provide insights into compatibility and installation best practices. This proactive approach will not only streamline the installation process but also enhance operational efficiency by ensuring that the new pump seamlessly integrates with existing workflows.

Strategic Material Selection Guide for peristaltic pump manufacturer

When selecting materials for peristaltic pumps, international B2B buyers must consider various factors that influence performance, durability, and cost-effectiveness. Below is an analysis of four common materials used in the manufacture of peristaltic pumps, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Silicone in Peristaltic Pumps?

Silicone is a widely used material for the tubing in peristaltic pumps due to its excellent flexibility and resilience. It can withstand a temperature range of -60°C to 200°C and has good pressure ratings, typically around 3 bar. Silicone also exhibits excellent chemical resistance, making it suitable for a variety of media, including food and pharmaceuticals.

Pros and Cons: The primary advantage of silicone is its biocompatibility, which is crucial for applications in the food and medical sectors. However, it can be more expensive than other materials, and its susceptibility to abrasion can limit its lifespan in abrasive applications.

Impact on Application: Silicone is ideal for applications requiring high purity and flexibility. Buyers must ensure that the silicone meets relevant standards, such as FDA or EU regulations, especially in food and pharmaceutical applications.

How Does PVC Compare as a Material for Peristaltic Pumps?

Polyvinyl Chloride (PVC) is another common material, particularly known for its cost-effectiveness and versatility. PVC tubing can handle temperatures up to 60°C and pressures of around 5 bar. It is resistant to many chemicals, making it suitable for a wide range of applications.

Pros and Cons: PVC is relatively inexpensive and easy to manufacture, which can significantly lower the overall cost of the pump. However, it is less flexible than silicone and may not be suitable for high-temperature applications. Additionally, the environmental impact of PVC production and disposal can be a concern for some buyers.

Impact on Application: PVC is often used in industrial applications where cost is a significant factor. Buyers should consider compliance with local environmental regulations, especially in regions like Europe, where sustainability is increasingly prioritized.

What Are the Benefits of Using Polyurethane in Peristaltic Pumps?

Polyurethane is known for its excellent abrasion resistance and durability, making it suitable for harsh applications. It can handle temperatures from -30°C to 80°C and pressures up to 6 bar. Its chemical resistance is also commendable, although it may not be suitable for all solvents.

Pros and Cons: The primary advantage of polyurethane is its toughness and longevity, which can lead to lower maintenance costs over time. However, it can be more complex to manufacture and may carry a higher initial cost compared to PVC.

Impact on Application: Polyurethane is particularly effective in applications involving abrasive slurries or materials. Buyers should verify the material’s compatibility with the specific media they intend to pump, as certain chemicals can degrade polyurethane.

How Does Stainless Steel Enhance the Performance of Peristaltic Pumps?

Stainless steel is often used for the pump housing and components due to its strength and corrosion resistance. It can withstand high temperatures (up to 400°C) and pressures (up to 20 bar), making it suitable for demanding applications.

Pros and Cons: The durability and longevity of stainless steel are significant advantages, especially in corrosive environments. However, the material is heavier and more expensive than alternatives like PVC or polyurethane, which may impact shipping costs and installation.

Impact on Application: Stainless steel is ideal for applications in the food and beverage industry, pharmaceuticals, and chemical processing. Buyers should ensure compliance with relevant standards such as ASTM or DIN, particularly in regions with stringent regulations.

Summary Table of Material Selection for Peristaltic Pumps

| Material | Typical Use Case for peristaltic pump manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone | Food and pharmaceutical applications | High biocompatibility | Higher cost, abrasion sensitivity | High |

| PVC | General industrial applications | Cost-effective, easy to manufacture | Less flexible, environmental concerns | Low |

| Polyurethane | Abrasive material handling | Excellent abrasion resistance | Complex manufacturing, higher cost | Medium |

| Stainless Steel | Chemical processing, food and beverage | High durability and corrosion resistance | Heavier, more expensive | High |

This strategic material selection guide aims to empower international B2B buyers with the necessary insights to make informed decisions tailored to their specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for peristaltic pump manufacturer

What Are the Main Stages in the Manufacturing Process of Peristaltic Pumps?

The manufacturing process of peristaltic pumps involves several key stages that ensure high-quality output and adherence to industry standards. The primary stages include:

-

Material Preparation: This initial phase involves selecting and preparing the right materials, such as elastomers for the tubing, metals for the pump housing, and other components. Suppliers should source materials from reputable vendors to ensure consistency and durability.

-

Forming: In this stage, the prepared materials are shaped into the necessary components. Techniques such as injection molding for plastic parts and CNC machining for metal components are commonly used. The choice of technique depends on the material properties and the design specifications of the pump.

-

Assembly: Once the components are formed, they are assembled into the final product. This stage is crucial, as it involves precise alignment and integration of parts to ensure optimal performance. Automated assembly lines may be employed to enhance efficiency and reduce the likelihood of human error.

-

Finishing: The final touches are applied during this stage, which may include surface treatments, painting, and the application of protective coatings. Finishing not only enhances aesthetic appeal but also contributes to the pump’s resistance to environmental factors, which is particularly important for B2B buyers in diverse climates.

How Is Quality Assurance Integrated into Peristaltic Pump Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that the final product meets both international and industry-specific standards. Key elements of QA include:

-

Adherence to International Standards: Many manufacturers comply with ISO 9001, which sets the framework for quality management systems. This certification demonstrates a commitment to continuous improvement and customer satisfaction, essential for B2B buyers looking for reliable suppliers.

-

Industry-Specific Certifications: Depending on the application, pumps may also need to meet additional standards, such as CE marking for European markets or API standards for petroleum applications. Buyers should inquire about the specific certifications relevant to their industry to ensure compliance and safety.

-

Quality Control Checkpoints: Effective QA involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This phase assesses the quality of raw materials before production begins. Ensuring that materials meet specifications is vital for the overall quality of the final product.

– In-Process Quality Control (IPQC): During manufacturing, IPQC checks are performed to monitor the production process. This includes regular inspections and measurements to detect any deviations from standards early on.

– Final Quality Control (FQC): Before shipment, the finished pumps undergo rigorous testing to verify their performance and safety. This includes pressure testing, flow rate measurement, and functionality tests.

What Common Testing Methods Are Used in Peristaltic Pump Quality Assurance?

To ensure that peristaltic pumps operate efficiently and reliably, manufacturers employ various testing methods:

-

Hydraulic Testing: This method checks the pump’s ability to handle the intended fluid pressures without leaks or failures. It is crucial for applications involving high pressure or corrosive substances.

-

Performance Testing: This includes measuring flow rates and pressure drops to ensure the pump meets specified performance criteria. This testing is essential for B2B buyers to confirm that the pumps will function effectively in their intended applications.

-

Durability Testing: Manufacturers may conduct stress tests to evaluate how pumps perform under extreme conditions, such as high temperatures or prolonged operation. These tests help ascertain the long-term reliability of the product.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial to ensure reliability and performance. Here are several actionable steps:

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing processes and quality assurance practices firsthand. This step can reveal a lot about the supplier’s commitment to quality.

-

Requesting Quality Reports: Buyers should ask for documentation related to quality control, including test results, inspection reports, and certifications. A reputable supplier should readily provide this information, demonstrating transparency in their operations.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can occur at various stages of manufacturing, offering peace of mind regarding the quality of the products.

-

Understanding Certification Nuances: Buyers should familiarize themselves with the certifications that are relevant in their regions, such as CE for Europe or API for oil and gas applications. Knowing the nuances of these certifications can help buyers make informed decisions and avoid potential compliance issues.

Conclusion: Ensuring Quality in Peristaltic Pump Procurement

For international B2B buyers, particularly in emerging markets, understanding the manufacturing processes and quality assurance measures of peristaltic pump manufacturers is essential for successful procurement. By focusing on material preparation, effective manufacturing techniques, and rigorous quality control practices, buyers can ensure that they select suppliers capable of meeting their operational needs while adhering to international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘peristaltic pump manufacturer’

This guide serves as a practical checklist for B2B buyers looking to procure peristaltic pumps. By following these steps, you can ensure a thorough and efficient sourcing process, ultimately leading to better investment decisions and enhanced operational efficiency.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for selecting the right peristaltic pump. Consider factors such as flow rate, pressure requirements, and the type of fluids being handled. This step will guide you in identifying suppliers that can meet your specific needs and prevent costly mismatches later in the procurement process.

Step 2: Conduct Market Research on Suppliers

Conducting comprehensive market research will help you identify potential suppliers in different regions. Focus on suppliers with a strong reputation in the peristaltic pump industry, particularly those with experience in your geographical area. Use resources such as industry directories, trade shows, and online reviews to gather a list of viable candidates.

Step 3: Evaluate Supplier Capabilities and Experience

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Pay attention to their experience with specific applications and industries, which can indicate their ability to meet your unique requirements.

- Look for certifications: Ensure they hold relevant industry certifications, which can signify adherence to quality standards.

- Assess manufacturing capabilities: Inquire about their production capacity, technology, and quality control processes.

Step 4: Verify Supplier Certifications and Compliance

Certifications and compliance with international standards are vital indicators of a supplier’s reliability. Ensure that the manufacturers you consider comply with ISO standards or any other relevant certifications specific to your industry. This not only ensures quality but also protects you from potential legal issues related to product safety and efficacy.

Step 5: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that break down costs, delivery timelines, and payment terms. This transparency will allow you to compare offers effectively and make informed decisions. Look for any hidden costs associated with shipping, installation, or after-sales service.

Step 6: Assess After-Sales Support and Warranty Options

Evaluate the after-sales support offered by the suppliers. Strong after-sales service can significantly impact the performance and longevity of your equipment. Inquire about warranty options and support for maintenance, as well as training for your staff on how to operate the pumps effectively.

Step 7: Negotiate Terms and Finalize the Agreement

Once you have selected a supplier, enter into negotiations to finalize the terms of your agreement. Be clear about your expectations regarding delivery schedules, quality assurance, and penalties for non-compliance. A well-structured contract protects both parties and sets the foundation for a successful partnership.

By following this sourcing checklist, B2B buyers can streamline their procurement process for peristaltic pumps, ensuring they select suppliers that align with their operational needs and strategic goals.

Comprehensive Cost and Pricing Analysis for peristaltic pump manufacturer Sourcing

What Are the Key Cost Components in Sourcing Peristaltic Pumps?

When sourcing peristaltic pumps, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of materials used significantly affects the cost. For instance, high-grade rubber tubing and corrosion-resistant metals can elevate expenses but enhance pump longevity and reliability.

-

Labor: Labor costs vary significantly based on geographic location. Regions with lower labor costs, such as parts of South America or Southeast Asia, can offer more competitive pricing, but this may come with trade-offs in quality or expertise.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Manufacturers with optimized processes and efficient production lines can offer lower overhead, resulting in more competitive pricing.

-

Tooling: The cost of tooling is particularly relevant for customized pump designs. Complex tooling requirements can increase initial costs but may lead to lower unit costs in larger production runs.

-

Quality Control (QC): Implementing robust QC processes ensures product reliability and compliance with industry standards. While this may add to the upfront costs, it can significantly reduce long-term expenses related to defects and failures.

-

Logistics: Shipping costs, including freight and customs duties, must be factored into the overall budget. Proximity to suppliers can reduce logistics costs, making sourcing from nearby regions like Europe more appealing for buyers in the Middle East.

-

Margin: Manufacturer margins can vary widely based on brand reputation, market demand, and competition. Understanding these margins can help buyers negotiate better prices.

How Do Price Influencers Impact Peristaltic Pump Costs?

Several factors influence the pricing of peristaltic pumps, which can affect sourcing strategies:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes typically lead to lower per-unit costs due to economies of scale. Buyers should consider their operational needs and negotiate for favorable terms based on projected usage.

-

Specifications and Customization: Custom features can substantially increase costs. Buyers should balance their requirements with budget constraints, ensuring they don’t pay for unnecessary customization.

-

Materials and Quality Certifications: Pumps made with higher quality materials or those that meet specific certifications (e.g., ISO, FDA) often command higher prices. Buyers need to assess the necessity of these certifications based on their applications.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established manufacturers may charge a premium for their brand, while newer entrants may offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for accurate cost assessments.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

To maximize value while sourcing peristaltic pumps, international B2B buyers should consider the following strategies:

-

Negotiate Terms: Always engage in negotiations to explore better pricing, especially for large orders. Suppliers may be willing to offer discounts for long-term contracts or bulk purchases.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operational efficiency, and potential downtime costs. A higher upfront investment may yield savings over time through lower operational costs.

-

Understand Pricing Nuances for Different Regions: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing differences. Factors like currency fluctuations, local tariffs, and import duties can influence overall costs.

-

Conduct Market Research: Stay informed about market trends and competitor pricing. This knowledge can empower buyers during negotiations and help them secure better deals.

-

Build Strong Relationships with Suppliers: Establishing a good rapport with manufacturers can lead to better service and pricing. Long-term partnerships often result in preferential treatment and insights into upcoming products or innovations.

Disclaimer on Indicative Prices

Prices for peristaltic pumps can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing peristaltic pump manufacturer With Other Solutions

When considering the procurement of a peristaltic pump manufacturer, it is crucial to evaluate alternative solutions that could also fulfill the pumping requirements of your business. This analysis aids international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, in making informed decisions. Below, we compare peristaltic pumps against two viable alternatives: diaphragm pumps and screw pumps.

Comparison Table of Peristaltic Pumps and Alternatives

| Comparison Aspect | Peristaltic Pump Manufacturer | Diaphragm Pump | Screw Pump |

|---|---|---|---|

| Performance | Excellent for viscous fluids | Good for a range of fluids | High flow rates |

| Cost | Moderate initial investment | Generally lower cost | Higher initial investment |

| Ease of Implementation | Easy to install and operate | Requires skilled labor | Complex installation |

| Maintenance | Low maintenance requirements | Moderate maintenance needs | High maintenance needs |

| Best Use Case | Pharmaceutical, food & beverage | Water treatment, chemicals | Oil and gas, high viscosity |

What Are the Advantages and Disadvantages of Diaphragm Pumps?

Diaphragm pumps are known for their versatility and ability to handle various fluid types, including corrosive liquids. Their relatively lower initial cost makes them attractive for businesses with budget constraints. However, they may require skilled labor for installation and maintenance, which could lead to higher operational costs in the long run. Moreover, diaphragm pumps can be less efficient than peristaltic pumps when dealing with highly viscous fluids, making them less ideal for specialized applications.

How Do Screw Pumps Compare in Terms of Performance and Cost?

Screw pumps excel in handling high flow rates and are particularly effective for transporting highly viscous fluids, making them suitable for industries such as oil and gas. However, they come with a higher initial investment and complex installation requirements, which can be a barrier for some businesses. Maintenance needs for screw pumps are also more demanding, requiring specialized knowledge and tools. This makes them a less desirable option for companies seeking low-maintenance solutions.

How Can B2B Buyers Choose the Right Pump for Their Needs?

Selecting the right pumping solution depends on various factors, including the specific application, fluid characteristics, budget, and maintenance capabilities. For businesses in the pharmaceutical or food and beverage sectors, where fluid integrity is crucial, a peristaltic pump may be the best choice. Conversely, if cost is a primary concern and the application involves less viscous fluids, a diaphragm pump might suffice. For industries dealing with high viscosity and flow demands, screw pumps could be the optimal solution despite their higher costs and maintenance requirements.

In conclusion, international B2B buyers must assess their unique operational needs and constraints when comparing peristaltic pumps with alternatives like diaphragm and screw pumps. By considering the performance, cost, ease of implementation, maintenance, and best use cases of each option, businesses can make strategic decisions that align with their long-term goals.

Essential Technical Properties and Trade Terminology for peristaltic pump manufacturer

What Are the Critical Technical Properties of Peristaltic Pumps for B2B Buyers?

Understanding the essential technical properties of peristaltic pumps is crucial for making informed purchasing decisions. Here are some key specifications that every B2B buyer should consider:

1. Material Grade: Why Is It Important?

The material grade of a peristaltic pump affects its durability and compatibility with various fluids. Common materials include natural rubber, silicone, and thermoplastic elastomers. Selecting the appropriate material is vital for ensuring the pump can handle specific chemical compositions without degrading, which can lead to costly downtime or product contamination.

2. Flow Rate: How Does It Impact Your Operations?

Flow rate, typically measured in liters per minute (LPM) or gallons per minute (GPM), indicates how much fluid the pump can move within a given time. This specification is crucial for determining whether the pump meets the operational demands of your application. A mismatch in flow rate can lead to inefficiencies and delays in production.

3. Tolerance: What Role Does It Play in Precision?

Tolerance refers to the allowable deviation from a specified dimension, which is crucial for applications requiring precise dosing or fluid transfer. High-tolerance pumps ensure that the correct volume of fluid is delivered consistently, making them essential for industries like pharmaceuticals and food processing where accuracy is paramount.

4. Pressure Rating: Why Is It Essential for Performance?

The pressure rating of a peristaltic pump defines the maximum pressure it can handle without failure. This is especially important in processes requiring high viscosity fluids or in applications where back pressure is a concern. Understanding the pressure capabilities will help ensure that the pump operates efficiently within your system’s requirements.

5. Tubing Size: How Does It Affect Fluid Dynamics?

The inner diameter of the tubing used in peristaltic pumps directly influences the flow characteristics and the overall efficiency of fluid transfer. Selecting the correct tubing size is essential to minimize turbulence and ensure optimal performance, particularly in high-speed applications.

What Are the Common Trade Terms Used in the Peristaltic Pump Industry?

Familiarizing yourself with industry jargon can facilitate smoother negotiations and understanding between buyers and manufacturers. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer): What Does It Signify?

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help you identify reliable sources for peristaltic pumps and spare parts, ensuring you receive quality products tailored to your specifications.

2. MOQ (Minimum Order Quantity): Why Should You Be Aware of It?

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management. Suppliers in different regions, such as Africa or Europe, may have varying MOQs, impacting your purchasing strategy.

3. RFQ (Request for Quotation): How to Use It Effectively?

An RFQ is a document sent to suppliers asking for pricing and other details for specific products. Crafting a clear and detailed RFQ can help you receive accurate quotes and compare options more effectively, enabling you to make informed purchasing decisions.

4. Incoterms: What Are They and Why Do They Matter?

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help you navigate shipping logistics and clarify who bears the risk and cost at various stages of the delivery process.

5. Lead Time: How Does It Affect Your Supply Chain?

Lead time refers to the time taken from placing an order until the product is delivered. Understanding lead times is essential for effective supply chain management, allowing you to plan production schedules and inventory levels accordingly.

Conclusion

By grasping these essential technical properties and trade terminologies, B2B buyers can enhance their procurement strategies for peristaltic pumps. Whether you’re sourcing from Africa, South America, the Middle East, or Europe, this knowledge will empower you to make informed decisions that align with your operational needs and market conditions.

Navigating Market Dynamics and Sourcing Trends in the peristaltic pump manufacturer Sector

What Are the Key Market Trends Impacting Peristaltic Pump Manufacturers?

The peristaltic pump market is experiencing robust growth driven by several global dynamics. One of the primary factors is the increasing demand for precision fluid handling across various industries such as pharmaceuticals, food and beverage, and water treatment. This demand is further enhanced by technological advancements, such as the integration of IoT and automation, which enable more efficient and precise pump operations. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these trends is crucial for making informed sourcing decisions.

Emerging sourcing trends include a shift towards digital procurement platforms that streamline the purchasing process, allowing buyers to easily compare suppliers and prices. Additionally, there is a growing emphasis on local sourcing to mitigate supply chain disruptions, which have been highlighted by recent global events. Buyers are increasingly seeking suppliers who can provide not only competitive pricing but also reliability and flexibility in delivery schedules.

A stock image related to peristaltic pump manufacturer.

Furthermore, the focus on customization is gaining traction, as industries look for pumps that can be tailored to specific applications. This trend presents an opportunity for buyers to engage with manufacturers that offer modular designs and bespoke solutions, ensuring that they can meet unique operational needs.

How Can Sustainability and Ethical Sourcing Influence Your Supply Chain Decisions?

Sustainability is no longer just a buzzword; it has become a critical factor for B2B buyers in the peristaltic pump sector. The environmental impact of manufacturing processes and the lifecycle of products are under increasing scrutiny. Buyers are encouraged to seek out manufacturers that prioritize sustainability in their operations. This includes the use of eco-friendly materials, efficient energy consumption, and waste reduction initiatives.

Ethical sourcing is equally important. Establishing a supply chain that adheres to ethical labor practices and transparency can enhance a company’s reputation and ensure compliance with international regulations. Buyers should look for manufacturers with certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety), which demonstrate a commitment to sustainability and ethical practices.

Moreover, opting for “green” materials in the manufacturing of peristaltic pumps not only reduces environmental impact but can also lead to long-term cost savings through increased efficiency and reduced waste. By prioritizing suppliers that align with these sustainability goals, B2B buyers can contribute to a more responsible supply chain while meeting their operational needs.

What Has Driven the Evolution of Peristaltic Pumps in the B2B Sector?

The evolution of peristaltic pumps can be traced back to their initial use in various industrial applications. Originally developed for simple fluid transfer, advancements in technology have transformed these pumps into sophisticated devices capable of handling a wide range of fluids, including viscous, corrosive, and shear-sensitive materials.

A stock image related to peristaltic pump manufacturer.

Over the years, the introduction of new materials, such as advanced elastomers and plastics, has enhanced the durability and performance of peristaltic pumps. Additionally, the rise of automation and digital technologies has further propelled their development, enabling real-time monitoring and control of fluid dynamics.

For B2B buyers, understanding this historical context is vital, as it highlights the continuous innovation within the sector. Engaging with manufacturers that are at the forefront of these advancements can lead to better product selection and improved operational efficiency, ensuring that businesses remain competitive in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of peristaltic pump manufacturer

-

How do I choose the right peristaltic pump for my application?

Choosing the right peristaltic pump requires a clear understanding of your specific application needs. Consider factors such as the type of fluid being pumped, the required flow rate, and the pressure conditions. Additionally, assess the pump’s material compatibility with your fluid to prevent any chemical reactions. Consulting with manufacturers can provide insights into the best options available, ensuring optimal performance and longevity in your operations. -

What is the best peristaltic pump for high-viscosity fluids?

For high-viscosity fluids, look for peristaltic pumps designed with robust rollers and a larger diameter tubing to accommodate thicker substances. These pumps often feature adjustable speed settings to fine-tune the flow rate. Brands known for their high-performance models in this area include Watson-Marlow and Verder. Always verify the pump’s specifications to ensure it meets the viscosity requirements of your specific application. -

What are the key factors to consider when vetting a peristaltic pump manufacturer?

When vetting a peristaltic pump manufacturer, consider their industry experience, customer reviews, and certifications. Look for manufacturers with a proven track record of quality and reliability in your specific sector. It’s also essential to evaluate their production capabilities, customization options, and after-sales support. Engaging in direct conversations with their technical teams can provide valuable insights into their expertise and responsiveness. -

What customization options are typically available for peristaltic pumps?

Many manufacturers offer customization options for peristaltic pumps, including variations in pump size, material selection, and control systems. Custom tubing diameters, roller designs, and even unique software integration can also be tailored to meet specific operational needs. Discussing your requirements with the manufacturer upfront can help you identify the most suitable customization options that enhance performance for your application. -

What is the typical minimum order quantity (MOQ) for peristaltic pumps?

Minimum order quantities (MOQs) for peristaltic pumps can vary significantly among manufacturers. Generally, MOQs can range from a single unit for standard products to larger quantities for customized solutions. It’s advisable to inquire directly with manufacturers about their MOQ policies, as many are willing to negotiate based on your specific needs or to accommodate first-time buyers. -

What payment terms should I expect when sourcing from a peristaltic pump manufacturer?

Payment terms can vary widely depending on the manufacturer and your location. Common terms include partial upfront payments with the balance due upon delivery or net 30/60 days after invoice. For international transactions, consider additional payment methods such as letters of credit or escrow services to ensure security. Always clarify payment terms before finalizing any agreements to avoid misunderstandings. -

How can I ensure quality assurance (QA) when purchasing peristaltic pumps?

To ensure quality assurance when purchasing peristaltic pumps, request detailed documentation on the manufacturer’s QA processes. This should include certifications like ISO 9001, which indicates adherence to quality management standards. Additionally, inquire about testing protocols, warranty policies, and the availability of third-party testing for compliance with industry standards. Establishing these criteria helps mitigate risks associated with product quality. -

What logistics considerations should I keep in mind when importing peristaltic pumps?

When importing peristaltic pumps, consider logistics factors such as shipping methods, customs regulations, and lead times. Select a reliable freight forwarder familiar with your destination country’s import requirements to streamline the process. Additionally, factor in duties and taxes, which can significantly affect your total cost. Keeping open communication with the manufacturer regarding shipment tracking and delivery schedules can also help manage expectations effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for peristaltic pump manufacturer

In the ever-evolving landscape of industrial applications, the strategic sourcing of peristaltic pumps is crucial for optimizing operational efficiency and cost-effectiveness. International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, must prioritize suppliers that not only deliver high-quality products but also demonstrate reliability and compliance with regional standards. Investing in long-term partnerships with manufacturers who understand local market dynamics can yield significant advantages, including tailored solutions and enhanced support.

What should B2B buyers consider when sourcing peristaltic pumps? It is essential to evaluate the supplier’s technological capabilities, customer service, and adaptability to changing market needs. Engaging with manufacturers who are committed to innovation and sustainability can also provide a competitive edge, ensuring that your operations remain at the forefront of industry advancements.

As we look to the future, the demand for advanced peristaltic pumps will continue to grow, driven by expanding sectors such as pharmaceuticals, food and beverage, and water treatment. Now is the time for international buyers to leverage strategic sourcing practices that not only meet immediate needs but also align with long-term business goals. Embrace the opportunity to explore new partnerships and invest in solutions that will propel your business forward in a global marketplace.