Discover Top Benefits: Choosing a Window Regulator Supplier (2025)

Introduction: Navigating the Global Market for window regulator supplier

Navigating the complexities of sourcing a reliable window regulator supplier can be a daunting challenge for international B2B buyers, especially in emerging markets like Africa and South America. The automotive industry is rapidly evolving, and securing high-quality window regulators that meet both safety and performance standards is crucial for maintaining a competitive edge. This guide is designed to equip you with the insights needed to make informed purchasing decisions, covering essential aspects such as the various types of window regulators, their applications across different vehicle models, and effective supplier vetting processes.

Within this comprehensive resource, we delve into cost considerations, supplier reliability, and the importance of understanding regional market dynamics, particularly for buyers from diverse areas including Colombia, Kenya, the Middle East, and Europe. By highlighting best practices and actionable strategies, this guide empowers you to navigate the global market with confidence. It will help you identify reputable suppliers, negotiate favorable terms, and ensure the quality of the products you procure.

Whether you’re looking to enhance your supply chain efficiency or ensure compliance with international standards, our insights will serve as a roadmap to successful sourcing. With the right knowledge at your fingertips, you can streamline your purchasing process and foster lasting partnerships with window regulator suppliers worldwide.

Understanding window regulator supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cable Window Regulators | Use cables and pulleys for operation | Automotive manufacturing | Pros: Cost-effective; Cons: Less durable over time |

| Power Window Regulators | Electric operation with motors | Automotive, commercial vehicles | Pros: Efficient; Cons: Higher initial investment |

| Manual Window Regulators | Hand-crank operation | Budget vehicles, older models | Pros: Simple design; Cons: Labor-intensive to use |

| Scissor Window Regulators | Scissor mechanism for vertical movement | Heavy-duty trucks, SUVs | Pros: Robust design; Cons: Heavier, less compact |

| Liftgate Window Regulators | Designed specifically for hatchbacks and SUVs | Automotive, aftermarket parts | Pros: Specialized design; Cons: Limited applications |

What are Cable Window Regulators and Their B2B Suitability?

Cable window regulators utilize a system of cables and pulleys to facilitate window movement. They are primarily used in the automotive sector, particularly in cost-sensitive applications. B2B buyers should consider the cost-effectiveness of these regulators, especially for mass production. However, they may need to balance this with the understanding that while initial costs are lower, durability may be compromised, leading to potential long-term expenses due to repairs or replacements.

How Do Power Window Regulators Operate and What Are Their Advantages?

Power window regulators are powered by electric motors, providing efficient and effortless window operation. They are widely used in both passenger and commercial vehicles. For B2B buyers, the main consideration is the upfront investment versus the operational efficiency they offer. While they tend to be more expensive initially, the ease of use and reduced manual labor can justify the cost over time, especially in markets that prioritize modern features.

What Are Manual Window Regulators and When Are They Preferred?

Manual window regulators operate via a hand-crank mechanism, making them a straightforward solution for budget vehicles and older models. They are often preferred in regions with lower purchasing power or in markets where simplicity is valued. Buyers should evaluate the trade-off between lower costs and the labor-intensive nature of manual operation. These regulators can be suitable for niche markets where durability and low maintenance are prioritized.

What Makes Scissor Window Regulators Unique for Heavy-Duty Applications?

Scissor window regulators use a scissor-like mechanism to lift windows vertically, making them ideal for heavy-duty applications like trucks and SUVs. Their robust design can withstand harsher conditions, which is a critical factor for B2B buyers in industries requiring durability. However, buyers should consider the weight and size of these regulators, as they may not be suitable for all vehicle types, potentially limiting their applicability in lighter models.

Why Choose Liftgate Window Regulators for Specific Automotive Needs?

Liftgate window regulators are specifically designed for hatchbacks and SUVs, addressing the unique requirements of these vehicles. They provide a tailored solution for automotive manufacturers and aftermarket suppliers. B2B buyers should consider the specialized nature of these regulators, as they can enhance vehicle functionality but may also limit their use in other vehicle types. This specialization can lead to a competitive advantage in markets focused on specific vehicle models.

Related Video: Replace 2001-2005 Ford Explorer Front Power Window Regulator, How to Change Install 2002 2003 2004

Key Industrial Applications of window regulator supplier

| Industry/Sector | Specific Application of window regulator supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Supply of window regulators for vehicles | Enhances vehicle safety and comfort; improves customer satisfaction | Compliance with international automotive standards; reliability and durability of components |

| Construction and Real Estate | Installation of window regulators in commercial buildings | Increases energy efficiency and aesthetic appeal of buildings | Customization options for various building designs; local regulations adherence |

| Agricultural Machinery | Integration in farm equipment for operator visibility | Improves safety and operational efficiency; reduces maintenance costs | Adaptability to different machinery types; availability of spare parts |

| Transportation and Logistics | Use in commercial transport vehicles | Ensures driver comfort and safety; enhances vehicle performance | Supplier’s ability to meet bulk orders; lead times and delivery schedules |

| Renewable Energy Sector | Application in solar panel housing for adjustable windows | Maximizes energy capture and efficiency; prolongs equipment life | Compatibility with various solar technologies; environmental impact considerations |

How is Window Regulator Supplier Utilized in Automotive Manufacturing?

In the automotive industry, window regulators are critical components that enable the smooth operation of vehicle windows. Suppliers provide mechanisms that enhance safety features, such as automatic window reversal systems to prevent injuries. International buyers, particularly from Africa and South America, must consider compliance with regional automotive standards and the reliability of these components under diverse climatic conditions. Sourcing high-quality regulators can significantly improve customer satisfaction, as well as reduce warranty claims and maintenance costs.

What are the Applications in Construction and Real Estate?

In the construction sector, window regulators are essential for the installation of operable windows in commercial buildings. They contribute to energy efficiency by allowing natural ventilation, which can lead to reduced energy consumption. Buyers from Europe and the Middle East should focus on suppliers that offer customization to fit various architectural designs and comply with local building codes. The aesthetic appeal provided by high-quality window regulators can also enhance property value, making it a worthwhile investment.

How is Window Regulator Supplier Used in Agricultural Machinery?

Agricultural machinery often requires robust window regulators to ensure operator visibility and safety. Suppliers provide durable mechanisms that withstand harsh environments while reducing maintenance needs. For international buyers from regions like Kenya, where agricultural activities are vital, sourcing adaptable window regulators that can fit various types of machinery is essential. This not only enhances operational efficiency but also promotes safer working conditions for operators.

What Role do Window Regulators Play in Transportation and Logistics?

In the transportation and logistics industry, window regulators are crucial for ensuring driver comfort and safety in commercial vehicles. They facilitate easy window operation, which is vital for ventilation and communication during loading and unloading. Buyers in this sector must consider suppliers that can fulfill bulk orders efficiently and maintain consistent lead times. The ability to source high-quality regulators that enhance vehicle performance can lead to improved operational outcomes and reduced downtime.

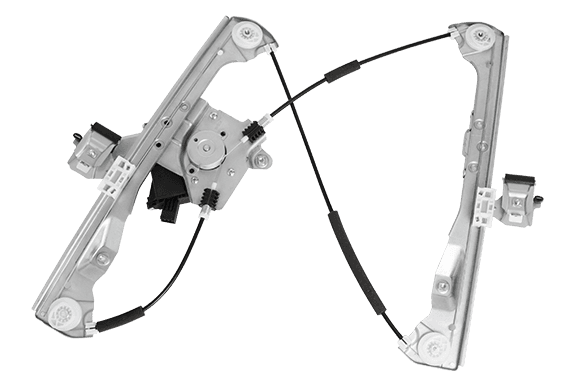

A stock image related to window regulator supplier.

How is Window Regulator Supplier Relevant to the Renewable Energy Sector?

In the renewable energy sector, particularly in solar panel housing, window regulators allow for the adjustment of panels to maximize sunlight capture. This functionality can significantly improve energy efficiency and prolong the lifespan of the equipment. Buyers from Europe and South America should look for suppliers that offer regulators compatible with various solar technologies while considering the environmental impact of their sourcing decisions. Investing in reliable window regulators can enhance the overall effectiveness of renewable energy installations.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘window regulator supplier’ & Their Solutions

Scenario 1: Delays in Supply Chain Affecting Production Schedules

The Problem: For B2B buyers sourcing window regulators, delays in supply chain logistics can lead to significant disruptions in production schedules. This is particularly relevant in regions like Africa and South America, where infrastructure challenges and political instability may impact timely deliveries. Buyers may find themselves facing shortages of essential components, causing production halts and resulting in lost revenue and dissatisfied customers.

The Solution: To mitigate supply chain delays, B2B buyers should establish strong relationships with multiple window regulator suppliers. Diversifying suppliers not only reduces dependency on a single source but also allows for flexibility in sourcing when disruptions occur. Additionally, buyers should implement just-in-time inventory practices that align with their production schedules, enabling them to manage stock levels effectively. Investing in supply chain management software can provide real-time visibility into order statuses and potential delays, empowering buyers to make informed decisions and adjust production timelines accordingly.

Scenario 2: Variability in Product Quality and Specifications

The Problem: Another pain point for international buyers is the inconsistency in product quality and specifications from different suppliers. This issue can be particularly pronounced when sourcing from emerging markets, where manufacturing standards may vary. Buyers may receive window regulators that do not meet their specifications or quality expectations, leading to increased returns, warranty claims, and damage to their brand reputation.

The Solution: To ensure consistent quality, B2B buyers should conduct thorough due diligence before partnering with a window regulator supplier. This includes requesting product samples, visiting manufacturing facilities, and reviewing quality certifications such as ISO standards. Establishing clear specifications and performance benchmarks in the procurement contract can also help hold suppliers accountable. Furthermore, implementing a rigorous quality assurance process, including regular audits and inspections of incoming products, can help maintain high standards and minimize the risks associated with variability in quality.

Scenario 3: Limited Technical Support and After-Sales Service

The Problem: B2B buyers often face challenges when suppliers provide inadequate technical support and after-sales service. This is especially critical in regions like the Middle East and Europe, where technical expertise may be required to install or troubleshoot window regulators. Insufficient support can lead to increased downtime and higher costs for businesses that rely on these components.

The Solution: To address this issue, buyers should prioritize suppliers that offer robust technical support and after-sales services as part of their value proposition. This includes not only responsive customer service but also access to comprehensive installation guides, training sessions, and troubleshooting resources. Buyers should inquire about the availability of local representatives who can provide on-site assistance when needed. Building a collaborative relationship with the supplier can also facilitate better communication and support, ensuring that buyers receive the necessary assistance to resolve any issues promptly.

Strategic Material Selection Guide for window regulator supplier

What Are the Key Materials Used in Window Regulators?

When selecting materials for window regulators, international B2B buyers should consider several common options: steel, aluminum, plastic, and composites. Each material has unique properties and implications for performance, manufacturing, and cost, making it essential to align material choice with specific application requirements.

How Does Steel Perform as a Material for Window Regulators?

Steel is a traditional choice for window regulators due to its high strength and durability. It typically has excellent temperature and pressure ratings, making it suitable for a wide range of environmental conditions. Steel’s corrosion resistance can be enhanced with coatings, which is crucial for regions with high humidity or saline environments, such as coastal areas in Africa and South America.

Pros: Steel is cost-effective and readily available, making it a popular choice for manufacturers. Its high tensile strength ensures that window regulators can withstand significant forces without deforming.

Cons: The main drawback of steel is its weight, which can impact the overall vehicle weight and fuel efficiency. Additionally, it may require more complex manufacturing processes, such as welding or machining, which can increase production time and costs.

Impact on Application: Steel is highly compatible with various media, including lubricants and hydraulic fluids, commonly used in window regulator systems.

Considerations for International Buyers: Compliance with standards such as ASTM A36 for structural steel is vital. Buyers from regions like Europe may also need to consider EU regulations regarding material sustainability and recyclability.

What Are the Advantages of Using Aluminum in Window Regulators?

Aluminum is increasingly favored for its lightweight properties and corrosion resistance. It typically performs well in temperature extremes and offers good strength-to-weight ratios, making it suitable for modern vehicle designs focused on efficiency.

Pros: The primary advantage of aluminum is its reduced weight, which can enhance vehicle performance and fuel economy. Additionally, aluminum can be extruded into complex shapes, allowing for innovative designs.

Cons: The main limitation is its higher cost compared to steel. Aluminum also has lower tensile strength, which may require thicker sections to achieve the same performance level as steel, potentially negating some weight benefits.

Impact on Application: Aluminum is compatible with various lubricants and does not corrode easily, making it suitable for long-term applications in diverse climates.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B221 for aluminum extrusions. In regions like the Middle East, where high temperatures are prevalent, understanding the thermal expansion properties of aluminum is crucial.

Why Choose Plastic for Window Regulators?

Plastic materials, particularly engineered plastics like nylon or polycarbonate, are popular for window regulators due to their lightweight and corrosion-resistant properties. They can be molded into complex shapes, allowing for design flexibility.

Pros: Plastics are typically less expensive than metals and can reduce overall vehicle weight, contributing to fuel efficiency. Their resistance to corrosion and chemicals makes them suitable for various environments.

Cons: The primary disadvantage is lower strength compared to metals, which may limit their use in high-stress applications. Plastics may also degrade over time when exposed to UV light, necessitating the use of additives or coatings.

Impact on Application: Plastics are compatible with various lubricants but may require specific formulations to ensure long-term performance.

Considerations for International Buyers: Compliance with standards such as ASTM D638 for tensile properties of plastics is essential. Buyers in regions like South America should consider the impact of local UV exposure on plastic durability.

How Do Composites Enhance Window Regulator Performance?

Composite materials, such as fiberglass-reinforced plastics, offer unique advantages in window regulator applications. They combine the lightweight properties of plastics with the strength of fibers, resulting in a highly durable material.

Pros: Composites provide excellent strength-to-weight ratios and can be tailored for specific performance characteristics. They also exhibit good resistance to corrosion and environmental degradation.

Cons: The main drawback is the higher manufacturing complexity and cost. Composites often require specialized processes for molding and curing, which can increase lead times.

Impact on Application: Composites can be designed to withstand specific environmental conditions, making them suitable for a variety of climates.

Considerations for International Buyers: Compliance with industry-specific standards, such as ASTM D3039 for composite materials, is crucial. Buyers from Europe and Africa should also consider the environmental impact and recyclability of composite materials.

Summary Table of Material Selection for Window Regulators

| Material | Typical Use Case for Window Regulator Supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-stress applications requiring durability | High tensile strength and cost-effectiveness | Heavy and complex manufacturing processes | Medium |

| Aluminum | Lightweight designs for fuel-efficient vehicles | Reduced weight and good corrosion resistance | Higher cost and lower tensile strength | High |

| Plastic | Lightweight and corrosion-resistant applications | Lower cost and design flexibility | Lower strength and UV degradation risk | Low |

| Composites | Advanced applications requiring tailored properties | Excellent strength-to-weight ratio | Higher manufacturing complexity and cost | High |

In-depth Look: Manufacturing Processes and Quality Assurance for window regulator supplier

What Are the Main Stages of Manufacturing Window Regulators?

A stock image related to window regulator supplier.

The manufacturing process of window regulators involves several critical stages that ensure the final product meets the required quality and performance standards. Understanding these stages can empower B2B buyers to make informed decisions when selecting suppliers.

1. Material Preparation

The first stage is material preparation, where raw materials such as steel, plastic, and rubber are sourced and inspected. Suppliers typically use high-grade materials to ensure durability and functionality. International B2B buyers should inquire about the material specifications and certifications, such as ASTM or ISO standards, to ensure compliance with their local requirements.

2. Forming Techniques

Once materials are prepared, the next step is forming. This involves processes like stamping, bending, and molding to create the various components of the window regulator. Advanced techniques, such as CNC machining and laser cutting, are often employed to achieve precise shapes and dimensions. Buyers should assess the technology used by suppliers to ensure they can meet specific design requirements and tolerances.

3. Assembly Process

The assembly stage involves bringing together all the formed components. This may include integrating gears, cables, and electrical components for powered window regulators. Automated assembly lines are increasingly common, which enhances efficiency and reduces human error. B2B buyers should ask about the assembly methods and whether they utilize automation, as this can impact production speed and consistency.

4. Finishing Touches

Finishing processes such as painting, coating, or surface treatment are crucial for enhancing durability and aesthetics. These processes also help in corrosion resistance, which is particularly important in regions with harsh weather conditions. Buyers should verify the finishing techniques employed and request samples to evaluate the quality.

How Is Quality Assurance Implemented in Window Regulator Manufacturing?

Quality assurance (QA) is an essential component of the manufacturing process, ensuring that window regulators meet industry standards and customer expectations. Below are key aspects of QA that international B2B buyers should consider.

What International Standards Should Buyers Be Aware Of?

International standards, such as ISO 9001, govern quality management systems and are vital for any window regulator supplier. Compliance with these standards indicates that the supplier has established processes for continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE (for European markets) and API (for automotive parts) should also be considered. Buyers should request documentation that verifies a supplier’s compliance with these standards.

Which Quality Control Checkpoints Are Commonly Used?

Quality control (QC) checkpoints during manufacturing can be categorized into three main stages:

-

Incoming Quality Control (IQC): This is performed on raw materials and components before they enter the manufacturing process. Suppliers should have robust inspection protocols to ensure that only materials meeting specifications are used.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC helps identify defects early. Techniques like statistical process control (SPC) can be utilized to monitor production consistency.

-

Final Quality Control (FQC): This final inspection ensures that the completed window regulators meet all specifications and performance criteria. Tests may include functional testing, dimensional inspections, and lifecycle testing.

What Common Testing Methods Are Utilized in Quality Assurance?

Testing methods play a critical role in the QA process. Common testing techniques include:

-

Functional Testing: Ensures that the window regulator operates as intended under various conditions.

-

Durability Testing: Simulates long-term use to identify potential failures.

-

Environmental Testing: Assesses performance under temperature variations, humidity, and exposure to chemicals.

International B2B buyers should inquire about the specific testing methods employed by suppliers and request access to test reports for transparency.

How Can Buyers Verify Supplier Quality Control?

Verifying the quality control measures of a potential supplier is crucial for B2B buyers. Here are several effective strategies:

Conducting Supplier Audits

Regular audits can provide insights into a supplier’s manufacturing processes and quality assurance practices. Buyers should consider scheduling on-site audits or utilizing third-party audit services to assess compliance with quality standards.

Reviewing Quality Reports

Requesting detailed quality reports from suppliers can help buyers understand their QC processes and any issues encountered during production. This transparency can build trust and assure buyers of the supplier’s commitment to quality.

Utilizing Third-Party Inspection Services

Engaging third-party inspection services is another way to ensure the quality of products before shipment. These services can perform pre-shipment inspections to verify that the window regulators meet agreed specifications.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing window regulators from suppliers in regions like Africa, South America, the Middle East, and Europe, buyers must be mindful of several nuances:

-

Regulatory Compliance: Different regions have varying regulatory requirements. Understanding these can help buyers avoid compliance issues that could affect product acceptance in their local markets.

-

Cultural Differences: Communication and negotiation styles may differ across regions. Building strong relationships with suppliers can enhance collaboration and improve quality outcomes.

-

Logistical Challenges: International shipping can introduce risks such as damage or delays. Buyers should work with suppliers that have robust logistics management practices to mitigate these risks.

By understanding the manufacturing processes and quality assurance measures in window regulator production, international B2B buyers can make more informed decisions, ultimately leading to better supplier relationships and product satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘window regulator supplier’

The following guide offers a practical checklist for international B2B buyers aiming to source window regulator suppliers effectively. By following these steps, you can ensure a streamlined procurement process, minimize risks, and establish beneficial relationships with reliable suppliers.

Step 1: Define Your Technical Specifications

Clearly articulating your technical requirements is crucial before engaging with suppliers. This includes understanding the specific types of window regulators you need, such as manual or power-operated, and their compatibility with various vehicle models. Providing detailed specifications will help potential suppliers assess their ability to meet your needs and reduce the chances of miscommunication later in the process.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential window regulator suppliers. Utilize industry directories, trade shows, and online platforms like Alibaba or ThomasNet to compile a list of candidates. Pay attention to suppliers with experience in your region, as they may better understand local market demands and regulations.

Step 3: Verify Supplier Certifications

Before proceeding, it’s essential to confirm that your shortlisted suppliers hold relevant certifications. Look for ISO certifications, which indicate adherence to international quality management standards. Additionally, check for compliance with local regulations and safety standards, as this can affect the reliability and legality of the products you source.

Step 4: Request Samples and Prototypes

Requesting samples or prototypes from potential suppliers is a critical step in evaluating their product quality. Analyze the materials, craftsmanship, and performance of the samples to ensure they meet your specifications. This hands-on assessment can save you from costly mistakes later by identifying any issues before bulk purchasing.

Step 5: Assess Pricing and Payment Terms

Pricing is a vital factor in supplier selection, but it should not be the only consideration. Compare quotes from multiple suppliers while considering the total cost of ownership, which includes shipping, taxes, and potential tariffs. Additionally, negotiate payment terms that align with your cash flow needs, and ensure they are clearly documented to avoid future disputes.

Step 6: Evaluate Customer Support and Communication

Assess the level of customer service and communication provided by potential suppliers. A responsive supplier can greatly enhance your procurement experience, especially when addressing issues like product recalls or delays. During initial communications, gauge their willingness to provide ongoing support and how quickly they respond to inquiries.

Step 7: Establish a Trial Order

Before committing to a large order, consider placing a trial order with your chosen supplier. This will allow you to assess their reliability, lead times, and overall service quality. Monitor the order process closely and gather feedback from your team to ensure the supplier meets your expectations before scaling up your procurement efforts.

By following these steps, B2B buyers can navigate the complexities of sourcing window regulators, ensuring they find reliable suppliers that meet their specific needs and contribute to their business success.

Comprehensive Cost and Pricing Analysis for window regulator supplier Sourcing

What Are the Key Cost Components of Window Regulator Supplier Sourcing?

When sourcing window regulators, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

- Materials: The quality of materials, such as plastic and metal components, directly affects the price. High-grade materials may cost more but can enhance durability and performance.

- Labor: Labor costs vary significantly across regions. Countries with lower wage rates may offer competitive pricing, but it’s essential to consider the skill level and efficiency of the workforce.

- Manufacturing Overhead: This encompasses indirect costs related to production, such as utilities, rent, and administrative expenses. Suppliers with optimized operations can provide better pricing.

- Tooling: Initial tooling costs can be substantial, especially for custom designs. These costs are often amortized over the production run, affecting pricing.

- Quality Control (QC): Investments in quality assurance processes are essential for maintaining standards. Suppliers with robust QC protocols may have higher upfront costs but can save buyers from future issues.

- Logistics: Shipping costs are influenced by the distance from the supplier to the buyer, chosen transport modes, and regional tariffs. Efficient logistics can reduce overall expenses.

- Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Understanding the margin expectations can help in negotiations.

How Do Price Influencers Impact Sourcing Decisions for Window Regulators?

Various factors influence pricing in the window regulator market, and recognizing these can empower buyers to make informed decisions:

- Volume/MOQ: Minimum Order Quantities (MOQs) can significantly impact pricing. Higher volumes often lead to bulk discounts, making it beneficial for buyers to negotiate favorable terms.

- Specifications and Customization: Custom designs or specific performance requirements can increase costs. Clearly defining specifications upfront can help prevent unexpected expenses.

- Materials Used: The choice of materials can lead to significant price variations. Buyers should balance cost against performance to ensure value.

- Quality Certifications: Suppliers with industry certifications (e.g., ISO, IATF) may charge more due to their commitment to quality. However, these certifications can mitigate risks and enhance product reliability.

- Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium but offer better service and product assurance.

- Incoterms: The choice of Incoterms (International Commercial Terms) affects the allocation of shipping costs and risks. Understanding these terms can lead to better cost management.

What Are Effective Buyer Tips for Cost-Efficiency in Window Regulator Sourcing?

To maximize value in sourcing window regulators, international buyers should consider these actionable tips:

- Negotiate Strategically: Leverage knowledge of cost components and price influencers during negotiations. A well-informed buyer can secure better terms and pricing.

- Evaluate Total Cost of Ownership (TCO): Focus on the TCO rather than just the purchase price. Consider long-term costs such as maintenance, warranties, and potential downtime.

- Be Aware of Regional Pricing Nuances: Pricing can differ based on the buyer’s location due to local market conditions, tariffs, and logistics costs. Buyers from regions like Africa, South America, the Middle East, and Europe should account for these variances.

- Conduct Market Research: Stay informed about market trends and competitor pricing. This knowledge can provide leverage during negotiations and sourcing decisions.

- Build Strong Relationships with Suppliers: Long-term partnerships can lead to more favorable pricing and terms. Suppliers are often willing to offer discounts to loyal customers.

Conclusion

Navigating the complexities of window regulator sourcing requires a comprehensive understanding of cost structures and pricing influences. By focusing on these elements and employing strategic negotiation tactics, international B2B buyers can optimize their sourcing decisions, ultimately leading to better product quality and cost-efficiency. Always remember that prices can vary significantly based on numerous factors, so conducting thorough research and maintaining flexibility in negotiations is crucial for success.

Alternatives Analysis: Comparing window regulator supplier With Other Solutions

Introduction: Why Explore Alternatives to Window Regulator Suppliers?

In the competitive landscape of automotive components, B2B buyers often seek to optimize their supply chains by evaluating various solutions for window regulators. While traditional window regulator suppliers provide reliable products, exploring alternatives can reveal innovative technologies and methods that may offer better performance, cost-effectiveness, and ease of integration. This section delves into a comparative analysis of window regulator suppliers against two viable alternatives: electric window actuator systems and manual window systems.

Comparison Table: Window Regulator Supplier vs. Alternatives

| Comparison Aspect | Window Regulator Supplier | Electric Window Actuator Systems | Manual Window Systems |

|---|---|---|---|

| Performance | High reliability and durability | Offers swift operation and responsiveness | Basic functionality, slower operation |

| Cost | Moderate to high | Higher initial investment but lower long-term costs | Low initial cost, potential for higher labor costs |

| Ease of Implementation | Straightforward installation | Requires additional electrical integration | Simple installation, no electrical work required |

| Maintenance | Moderate upkeep, parts readily available | Low maintenance, but components may require specialized service | Very low maintenance, easily accessible parts |

| Best Use Case | High-volume automotive production | Premium vehicles or specific applications needing advanced features | Budget vehicles or retrofitting older models |

What Are the Advantages and Disadvantages of Electric Window Actuator Systems?

Electric window actuator systems represent a modern alternative to traditional window regulators. These systems utilize electric motors to control window movement, offering several benefits such as faster operation and improved user experience. They are particularly advantageous in premium vehicles where speed and efficiency are paramount. However, the initial investment is higher, and the integration of electrical systems can complicate installation. Additionally, while maintenance requirements are low, repairs can be costly if specialized service is needed.

How Do Manual Window Systems Compare to Window Regulator Suppliers?

Manual window systems provide a simplistic approach to window regulation. They rely on a hand-crank mechanism, making them highly reliable and easy to install. The low initial cost appeals to budget-conscious buyers, particularly for older vehicles or those in developing markets. However, the performance is limited, as manual systems can be slower and require physical effort to operate. Maintenance is minimal, but these systems lack the advanced features and convenience found in electric solutions, which may deter buyers looking for modern functionalities.

Conclusion: How Should B2B Buyers Choose the Right Solution for Their Needs?

When evaluating window regulator solutions, B2B buyers should consider their specific application requirements, budget constraints, and the operational environment. If reliability and durability are paramount, traditional window regulator suppliers may still be the best choice. However, for those seeking innovation and efficiency, electric window actuator systems could provide enhanced performance and user satisfaction. Conversely, manual systems are ideal for cost-sensitive projects or retrofitting older models. By weighing the pros and cons of each option, buyers can make informed decisions that align with their strategic goals and customer expectations.

Essential Technical Properties and Trade Terminology for window regulator supplier

What Are the Key Technical Properties of Window Regulators?

Understanding the technical specifications of window regulators is vital for B2B buyers, particularly when sourcing high-quality components that meet industry standards. Here are some essential properties to consider:

1. Material Grade

The material grade of window regulators typically includes metals such as steel, aluminum, or composite materials. Each grade has different strength, corrosion resistance, and weight characteristics. Selecting the right material is crucial as it affects the durability and performance of the window regulator in various environmental conditions. For instance, aluminum is lightweight and resistant to corrosion, making it suitable for automotive applications in humid climates.

2. Load Capacity

Load capacity refers to the maximum weight that a window regulator can handle during operation. It is essential for ensuring that the regulator can support the weight of the vehicle’s window without failure. Buyers should request load capacity specifications to ensure compatibility with their vehicle models, particularly in regions with larger or heavier windows.

3. Tolerance Levels

Tolerance levels indicate the allowable variation in dimensions and specifications. High tolerance levels ensure that the window regulator fits precisely within the vehicle’s design, reducing the risk of malfunctions. For international buyers, understanding tolerance requirements can help in sourcing components that meet local manufacturing standards and regulations.

4. Actuation Type

Window regulators can be manual or power-operated. Understanding the actuation type is vital for buyers, as it influences installation complexity and user experience. Power-operated regulators are often preferred for their convenience, but they require additional electrical components, which may increase costs and complexity.

5. Operating Temperature Range

The operating temperature range specifies the temperatures within which the window regulator can function effectively. This property is particularly important for buyers in regions with extreme climates, as it ensures that the regulator will perform reliably under various conditions without degrading in performance.

What Are Common Trade Terminology and Their Importance in Sourcing Window Regulators?

Familiarity with industry terminology can streamline the sourcing process and enhance communication with suppliers. Here are some common terms relevant to window regulators:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture parts that are sold under another company’s brand. In the context of window regulators, purchasing OEM parts ensures that the components meet the original specifications of the vehicle manufacturer. This is crucial for maintaining quality and compatibility, especially for international buyers sourcing replacements.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory costs effectively. For businesses in Africa and South America, where import regulations can be stringent, negotiating favorable MOQs can significantly impact overall procurement costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and availability for specific products. This process is vital for comparing costs and terms from different suppliers, allowing buyers to make informed decisions. For B2B buyers, a well-structured RFQ can facilitate better negotiations and foster long-term supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping costs, insurance, and risk transfer. Familiarity with Incoterms is crucial for international buyers to understand their obligations and protect against potential losses during transit.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. It is an essential factor in supply chain management, particularly for buyers who operate on tight schedules. Understanding lead times can help businesses in Europe and the Middle East plan their operations and inventory more effectively.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing window regulators, ultimately leading to better product quality and improved supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the window regulator supplier Sector

What Are the Current Market Dynamics and Sourcing Trends in the Window Regulator Supplier Sector?

The global window regulator supplier market is shaped by several key drivers that influence sourcing strategies for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. The automotive industry is witnessing a notable shift towards electric vehicles (EVs), which has led to increased demand for innovative window regulator technologies that enhance efficiency and user experience. This shift is particularly evident in countries such as Kenya, where the adoption of EVs is gaining momentum, and Colombia, where government policies are encouraging sustainable automotive solutions.

Emerging technologies, such as automated manufacturing and Industry 4.0, are revolutionizing the production processes in the window regulator sector. Buyers are increasingly looking for suppliers that leverage these advancements, as they can significantly reduce lead times and costs while ensuring higher quality products. Furthermore, the integration of smart technologies in window regulators, including features like automatic anti-pinch systems, is becoming a standard expectation among buyers, reflecting a shift towards enhanced vehicle safety and convenience.

Additionally, geopolitical factors and trade dynamics are influencing sourcing decisions. Buyers in the Middle East and Africa are seeking suppliers that can offer competitive pricing without compromising on quality. This has led to an increased interest in local suppliers and those who can provide robust logistics solutions to mitigate risks associated with international shipping.

How Can Sustainability and Ethical Sourcing Impact Your Supply Chain Decisions?

Sustainability and ethical sourcing are increasingly critical in the window regulator supplier sector. The environmental impact of manufacturing processes, particularly in automotive components, has come under scrutiny. Buyers are now prioritizing suppliers who adopt sustainable practices, such as minimizing waste and utilizing renewable energy sources in their production processes. This shift is not only beneficial for the environment but also aligns with the growing consumer demand for greener products.

Moreover, ethical supply chains are essential for building brand reputation and consumer trust. B2B buyers are encouraged to partner with suppliers who are transparent about their sourcing practices and adhere to international labor standards. Certifications like ISO 14001 for environmental management and Fair Trade certifications can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Incorporating ‘green’ materials, such as recycled plastics and eco-friendly coatings, into window regulator production is another trend that B2B buyers should consider. This not only reduces the carbon footprint but can also enhance the marketability of products, particularly in regions like Europe, where regulatory frameworks are increasingly favoring sustainable products.

What Is the Evolution of the Window Regulator Supplier Sector?

The window regulator supplier sector has evolved significantly over the past few decades, transitioning from basic mechanical systems to sophisticated electronic solutions. Initially, manual window regulators dominated the market, but advancements in technology have led to the widespread adoption of power window systems, driven by consumer demand for convenience and enhanced vehicle features.

As automotive technology continues to advance, the sector is now witnessing a shift towards smart window regulators that integrate seamlessly with vehicle electronics, offering features such as remote operation and automatic adjustments based on weather conditions. This evolution reflects the broader trends within the automotive industry, where innovation and sustainability are becoming pivotal in shaping the future of vehicle components. For international B2B buyers, understanding this evolution is crucial for making informed sourcing decisions that align with market demands and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of window regulator supplier

-

How do I choose the right window regulator supplier for my business needs?

Selecting the right window regulator supplier involves several critical factors. Start by evaluating the supplier’s experience in the automotive parts industry, particularly their specialization in window regulators. Check for certifications and compliance with international quality standards, such as ISO 9001. Additionally, consider their product range, customization options, and capacity to meet your specific needs. Engaging in direct communication with potential suppliers can also help assess their responsiveness and willingness to accommodate your requests. -

What should I consider when assessing the quality of window regulators?

Quality assessment of window regulators includes evaluating the materials used, manufacturing processes, and performance under various conditions. Request samples to test durability and functionality, and inquire about the supplier’s quality assurance protocols. Certifications like TS16949 can indicate adherence to high-quality manufacturing standards. It’s also advisable to read reviews and testimonials from other businesses that have sourced from the supplier to gauge their reputation in the market. -

What are the typical minimum order quantities (MOQs) for window regulators?

Minimum order quantities (MOQs) can vary significantly among suppliers and depend on factors such as the type of window regulator and the supplier’s production capacity. Generally, MOQs can range from 100 to 1,000 units. For international buyers, especially from regions like Africa or South America, negotiating MOQs can be possible, particularly if you are willing to establish a long-term partnership. Discussing your needs directly with the supplier can lead to tailored solutions that suit your purchasing strategy. -

What payment terms should I expect from window regulator suppliers?

Payment terms for window regulator suppliers vary but often include options such as advance payment, letters of credit, or net payment terms (e.g., 30, 60, or 90 days after delivery). It’s essential to clarify these terms upfront to avoid misunderstandings. For international transactions, consider using secure payment methods to mitigate risks. Building a solid relationship with your supplier can also lead to more favorable payment terms over time. -

How can I ensure timely logistics and delivery of window regulators?

To ensure timely logistics and delivery, first, clarify the supplier’s shipping capabilities, including preferred carriers and estimated delivery times. It’s crucial to discuss and agree on shipping terms, such as Incoterms, to understand responsibilities for costs and risks. Additionally, consider using freight forwarders experienced in international shipping to streamline the process. Regular communication with your supplier during the shipping process can also help preempt potential delays. -

What customization options are available for window regulators?

Many window regulator suppliers offer customization options to meet specific client requirements. This can include variations in size, materials, and features such as motor types or cable lengths. When engaging with suppliers, be clear about your specifications and any unique needs your market may have. Requesting prototypes or design samples can further assist in ensuring the final product aligns with your expectations before placing a bulk order. -

What quality assurance practices should I expect from reputable suppliers?

Reputable window regulator suppliers typically implement strict quality assurance practices that may include routine inspections, testing of raw materials, and final product evaluations before shipment. Inquire about their quality management systems and whether they conduct third-party audits. A supplier committed to quality will often provide documentation detailing their QA processes, which can help you ensure that you are receiving reliable products. -

How can I effectively communicate my requirements to a window regulator supplier?

Effective communication is key when working with window regulator suppliers. Begin by preparing a detailed specification document outlining your requirements, including technical details, expected delivery timelines, and quality standards. Utilize visual aids, such as diagrams or samples, to enhance understanding. Regular follow-ups and open channels for feedback can foster collaboration, allowing both parties to address any issues promptly and ensuring that your needs are met throughout the procurement process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for window regulator supplier

Why is Strategic Sourcing Essential for Window Regulator Suppliers?

In conclusion, strategic sourcing plays a pivotal role in optimizing the supply chain for window regulators, particularly for B2B buyers in emerging markets such as Africa, South America, the Middle East, and Europe. By carefully selecting suppliers based on quality, reliability, and cost-effectiveness, businesses can enhance their competitive advantage while ensuring product availability and compliance with local regulations.

Buyers should prioritize establishing strong partnerships with suppliers who understand regional market dynamics and can offer innovative solutions tailored to specific needs. Emphasizing long-term relationships rather than transactional exchanges will foster collaboration, leading to improved product development and service delivery.

What Should International Buyers Consider Moving Forward?

As we look to the future, international B2B buyers are encouraged to stay proactive in their sourcing strategies. Embrace digital tools for supplier evaluation and market analysis, which can uncover opportunities for cost savings and efficiency gains. Additionally, consider diversifying your supplier base to mitigate risks associated with geopolitical uncertainties and supply chain disruptions.

In this evolving landscape, the ability to adapt and innovate will be key to success. Engage with suppliers who are committed to sustainability and technological advancements, as these factors will significantly influence market trends. By taking these actionable steps, businesses can not only secure their supply chains but also position themselves as leaders in the window regulator market.