Discover Top Benefits: Choosing an Optical Transceiver Supplier (2025)

Introduction: Navigating the Global Market for optical transceiver supplier

In today’s interconnected world, sourcing an optical transceiver supplier can present a formidable challenge for international B2B buyers. The rapid evolution of telecommunications and data transmission technology requires businesses to not only understand the technical specifications but also to navigate a complex global supply chain. This guide is designed to empower companies from diverse regions, including Africa, South America, the Middle East, and Europe, by providing them with actionable insights into the optical transceiver market.

Throughout this comprehensive guide, we will explore various types of optical transceivers, their applications across different industries, and the critical factors to consider when vetting potential suppliers. Understanding the nuances of optical transceivers, from form factors to data rates, is essential for making informed purchasing decisions. Additionally, we will delve into cost considerations, including how to negotiate pricing and assess value in the context of your specific business needs.

By equipping B2B buyers with the knowledge to evaluate suppliers effectively, this guide aims to streamline the procurement process and foster strategic partnerships. Whether you are a business in Argentina looking to enhance your network infrastructure or a company in Saudi Arabia aiming to improve data center operations, our insights will help you navigate the complexities of sourcing the right optical transceiver supplier. Prepare to enhance your purchasing strategy with confidence and clarity.

Understanding optical transceiver supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SFP (Small Form-factor Pluggable) | Compact size, hot-swappable, supports various protocols | Data centers, enterprise networks | Pros: Versatile, cost-effective. Cons: Limited range compared to others. |

| QSFP (Quad Small Form-factor Pluggable) | High-density, supports multiple channels in one transceiver | High-bandwidth applications, cloud computing | Pros: High throughput, space-saving. Cons: Typically more expensive. |

| XFP (10 Gigabit Small Form-factor Pluggable) | Designed for 10G networks, longer reach capabilities | Telecom, data centers | Pros: Robust performance, long-distance capability. Cons: Larger than SFP. |

| CFP (C Form-factor Pluggable) | Designed for high-speed applications, supports 100G | Large-scale data transport, metro networks | Pros: High capacity, supports various protocols. Cons: Higher power consumption. |

| DWDM (Dense Wavelength Division Multiplexing) | Enables multiple signals over a single fiber | Long-haul telecommunications, data center interconnects | Pros: Maximizes fiber capacity. Cons: Complexity in installation and management. |

What are the Characteristics and Suitability of SFP Transceivers?

SFP transceivers are compact and versatile, making them a popular choice for various applications in data centers and enterprise networks. They support multiple protocols, allowing for seamless integration into existing systems. Buyers should consider the specific networking needs, as SFPs are ideal for shorter distances, typically up to 80 km, depending on the specific type used. Their hot-swappable feature also means minimal downtime during upgrades, which is a significant advantage for B2B operations.

How Do QSFP Transceivers Cater to High Bandwidth Applications?

QSFP transceivers are designed to support high-density and high-bandwidth applications, making them essential for cloud computing and data centers that require robust data transfer capabilities. These transceivers can handle multiple channels, providing up to 400 Gbps of throughput in a single module. Buyers in this category should evaluate their bandwidth needs and available space, as QSFPs offer a space-saving solution without compromising performance. However, they tend to be more expensive than standard SFPs, so budget considerations are crucial.

What are the Key Features of XFP Transceivers for Telecom Applications?

XFP transceivers are specifically designed for 10G networks, making them suitable for telecom applications and data centers that require reliable long-distance connectivity. With their ability to cover distances up to 80 km, XFPs are a robust choice for businesses focusing on high-performance networking. Buyers should weigh the benefits of their longer reach against the larger physical size of XFP modules compared to SFPs. The performance trade-off often justifies the investment for businesses with extensive network demands.

What Advantages Do CFP Transceivers Offer for Large-Scale Data Transport?

CFP transceivers are engineered for high-speed applications, particularly in large-scale data transport and metro networks. They support data rates of 100 Gbps, making them ideal for businesses that need to transfer vast amounts of data quickly. While they provide significant capacity, buyers should consider the higher power consumption associated with CFPs, which may impact operational costs. Understanding the specific networking environment and the required data capacity is vital for making informed purchasing decisions.

How Does DWDM Technology Maximize Fiber Capacity for Telecommunications?

DWDM transceivers are designed to enable multiple signals to travel over a single fiber, making them invaluable for long-haul telecommunications and data center interconnects. This technology maximizes fiber utilization, allowing businesses to expand capacity without the need for additional fiber installations. However, the complexity of DWDM systems can be a barrier for some buyers, requiring careful planning and management. Organizations should assess their current and future bandwidth requirements to determine if the investment in DWDM technology aligns with their strategic goals.

Related Video: SFP Optical Transceiver Overall Introduction| FS

Key Industrial Applications of optical transceiver supplier

| Industry/Sector | Specific Application of Optical Transceiver Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | High-Speed Data Transmission | Enhanced bandwidth and reduced latency for better service | Compatibility with existing infrastructure, reliability, and scalability |

| Data Centers | Interconnecting Servers and Storage Systems | Improved data transfer rates and efficiency | Power consumption, form factor, and support for various protocols |

| Smart Cities | IoT Connectivity and Smart Grid Solutions | Real-time data processing and improved urban services | Range, durability, and compliance with local regulations |

| Healthcare | Telemedicine and Remote Patient Monitoring | Enhanced patient care and operational efficiency | Regulatory compliance, data security, and integration with existing systems |

| Industrial Automation | Real-Time Monitoring and Control Systems | Increased operational efficiency and reduced downtime | Environmental resilience, compatibility with automation protocols, and support services |

How Are Optical Transceiver Suppliers Used in Telecommunications?

In the telecommunications sector, optical transceivers are pivotal for high-speed data transmission over long distances. They facilitate the transfer of vast amounts of data, enabling service providers to offer enhanced bandwidth and reduced latency. For international B2B buyers, especially from regions like Africa and the Middle East, sourcing reliable optical transceivers means ensuring compatibility with existing infrastructure while also considering scalability options to accommodate future growth.

What Role Do Optical Transceivers Play in Data Centers?

In data centers, optical transceivers are essential for interconnecting servers and storage systems. They significantly improve data transfer rates, thereby enhancing overall efficiency. Buyers from Europe and South America should focus on power consumption and form factors that fit their specific layouts. Additionally, ensuring support for various data transfer protocols can help maintain seamless operations and future-proof investments.

How Are Optical Transceivers Beneficial for Smart Cities?

Smart cities leverage optical transceivers for IoT connectivity and smart grid solutions. These components allow for real-time data processing, which is crucial for improving urban services such as traffic management and energy distribution. Buyers in emerging markets like those in Africa must prioritize the range and durability of these transceivers, alongside compliance with local regulations to ensure successful implementation in varied environments.

In What Ways Do Optical Transceivers Enhance Healthcare?

In the healthcare sector, optical transceivers support telemedicine and remote patient monitoring by enabling fast and secure data transmission. This technology enhances patient care and operational efficiency by allowing healthcare providers to access critical information in real-time. Buyers, particularly from regions with strict regulations like Europe, should ensure that the transceivers meet all regulatory compliance standards, prioritize data security, and integrate well with existing healthcare systems.

How Do Optical Transceivers Improve Industrial Automation?

Optical transceivers are integral to real-time monitoring and control systems in industrial automation. They help increase operational efficiency and reduce downtime by facilitating swift data exchange between machinery and control systems. Buyers from South America and the Middle East should consider environmental resilience and compatibility with existing automation protocols when sourcing these components. Additionally, support services can be a crucial factor in ensuring ongoing operational success.

Related Video: Introduction of Optical Transceiver Module and Its Applications

3 Common User Pain Points for ‘optical transceiver supplier’ & Their Solutions

Scenario 1: Supply Chain Disruptions and Inconsistent Quality

The Problem:

B2B buyers, especially in regions like Africa and South America, often face significant supply chain disruptions when sourcing optical transceivers. These disruptions can lead to delays in project timelines and increased costs. Additionally, the inconsistency in product quality from different suppliers can result in compatibility issues, impacting the overall network performance. Buyers may receive subpar products that do not meet the specified standards, leading to operational inefficiencies and increased maintenance costs.

The Solution:

To overcome these challenges, buyers should conduct thorough due diligence on potential suppliers. Start by assessing the supplier’s reputation and reliability through industry reviews and testimonials. Consider sourcing from suppliers who offer warranties or guarantees on their products, as this indicates confidence in their quality. Establish strong communication with suppliers to ensure transparency about lead times and quality control processes. Additionally, consider diversifying your supplier base to mitigate risks associated with reliance on a single source. Implementing a robust vendor management system can also help track supplier performance and maintain quality standards.

Scenario 2: Lack of Technical Support and Expertise

The Problem:

Many B2B buyers encounter difficulties due to a lack of technical support when integrating optical transceivers into their existing systems. This is particularly true for companies in emerging markets, where in-house expertise may be limited. Buyers often find themselves struggling with installation, configuration, and troubleshooting, which can lead to extended downtimes and frustration.

The Solution:

To address this issue, buyers should prioritize suppliers who provide comprehensive technical support and resources. Look for suppliers that offer training sessions, detailed documentation, and responsive customer service. It may also be beneficial to engage with suppliers who have local representatives or partnerships in your region, as they can provide on-site assistance when needed. Additionally, consider joining industry forums or groups focused on optical networking, as these can be valuable resources for sharing knowledge and best practices. Investing in training for your team can also enhance their capability to manage and troubleshoot optical transceiver systems effectively.

Scenario 3: Cost Management and Budget Constraints

The Problem:

Cost management is a critical concern for B2B buyers, particularly in regions like the Middle East and Europe where budget constraints can significantly impact purchasing decisions. Buyers may struggle to balance the need for high-quality optical transceivers with the pressure to minimize costs. This can lead to compromises on product quality, which can have long-term implications for network performance and reliability.

The Solution:

To effectively manage costs while ensuring quality, buyers should adopt a strategic sourcing approach. Start by establishing a clear understanding of your specific requirements and create a detailed procurement plan that aligns with your budget. Explore bulk purchasing options or long-term contracts with suppliers to secure better pricing. Additionally, consider leveraging technology such as e-procurement platforms to streamline the buying process and gain access to competitive pricing. Regularly review and analyze your purchasing data to identify trends and areas for cost savings. Engaging in collaborative procurement with other businesses can also help in negotiating better rates and sharing resources, ultimately leading to more cost-effective solutions.

Strategic Material Selection Guide for optical transceiver supplier

When selecting materials for optical transceivers, understanding the properties, advantages, and limitations of common materials is crucial for international B2B buyers. This guide analyzes several materials that are frequently used in the manufacturing of optical transceivers, focusing on their performance characteristics and implications for applications in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Glass Fiber in Optical Transceivers?

Glass fiber is a primary material used in optical transceivers due to its excellent light transmission properties. Key properties include high temperature resistance (up to 1000°C), low attenuation, and minimal signal distortion. Additionally, glass fiber is resistant to electromagnetic interference, making it suitable for environments with high electrical noise.

Pros and Cons:

The durability of glass fiber is a significant advantage, as it can withstand harsh environmental conditions. However, its brittleness can pose challenges during manufacturing and installation, potentially leading to breakage. Furthermore, while glass fiber is generally cost-effective in bulk, the initial manufacturing complexity can drive up costs for smaller orders.

Impact on Application:

Glass fiber is ideal for long-distance data transmission, making it suitable for telecommunications and data centers. Buyers in regions with advanced infrastructure, like Europe, will find glass fiber particularly beneficial, while emerging markets may need to consider installation costs.

How Do Polymer Materials Affect Optical Transceiver Performance?

Polymers, such as polycarbonate and PMMA (polymethyl methacrylate), are increasingly used in optical transceivers for their lightweight and flexible properties. They typically have lower temperature resistance (up to 85°C) compared to glass but offer better impact resistance and ease of handling.

Pros and Cons:

The main advantage of polymer materials is their lower weight and cost, which can significantly reduce shipping expenses. However, their lower thermal stability and susceptibility to UV degradation can limit their application in harsh environments. As such, international buyers from regions with extreme weather conditions, like parts of Africa and the Middle East, should evaluate the suitability of polymers carefully.

Impact on Application:

Polymers are well-suited for short-distance applications and consumer electronics. In markets like South America, where cost efficiency is crucial, polymers may be preferred for local manufacturing.

What Are the Considerations for Metal Components in Optical Transceivers?

Metals such as aluminum and stainless steel are often used in the housing and connectors of optical transceivers. These materials provide excellent structural integrity and resistance to corrosion, especially in humid or saline environments.

Pros and Cons:

The primary advantage of metals is their strength and durability, which can enhance the longevity of the transceiver. However, the weight and higher cost of metals compared to polymers may be a disadvantage for certain applications. Additionally, the manufacturing complexity can increase production time and costs.

Impact on Application:

Metal components are crucial in environments where mechanical stress is a concern, such as industrial applications. Buyers from the Middle East, where humidity can be high, should prioritize corrosion-resistant metals like stainless steel.

How Do Ceramics Contribute to Optical Transceiver Design?

Ceramics are less common but increasingly used in specialized optical transceiver applications due to their high temperature and chemical resistance. They can withstand extreme conditions (up to 1500°C) and have excellent insulating properties.

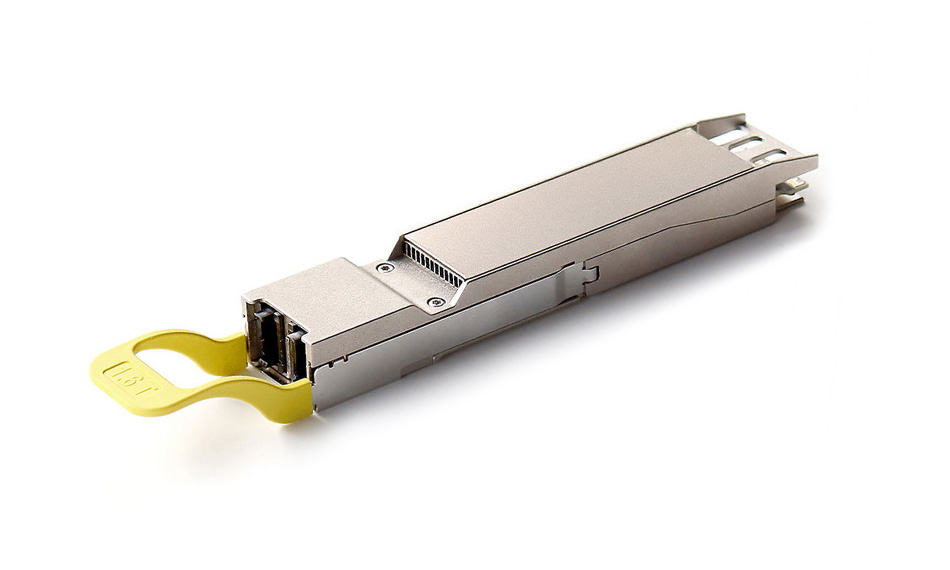

A stock image related to optical transceiver supplier.

Pros and Cons:

Ceramics provide exceptional durability and stability, making them suitable for high-performance applications. However, they are brittle and can be challenging to manufacture, leading to higher costs and complexity.

Impact on Application:

Ceramic materials are ideal for high-temperature environments, such as aerospace or military applications. For international buyers from Europe, where precision and reliability are paramount, ceramics may be a preferred choice despite the higher costs.

Summary Table of Material Selection for Optical Transceivers

| Material | Typical Use Case for optical transceiver supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass Fiber | Long-distance telecommunications | Excellent light transmission | Brittle, manufacturing complexity | Medium |

| Polymer | Short-distance applications, consumer electronics | Lightweight and cost-effective | Lower thermal stability, UV degradation | Low |

| Metal | Industrial applications, housing and connectors | High strength and durability | Heavier, higher cost | Medium to High |

| Ceramic | High-performance, aerospace applications | Exceptional durability and stability | Brittle, high manufacturing complexity | High |

This guide provides an overview of the materials used in optical transceivers, along with considerations for international B2B buyers. Understanding these factors can help in making informed decisions that align with specific operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for optical transceiver supplier

What Are the Main Stages in the Manufacturing Process of Optical Transceivers?

The manufacturing of optical transceivers involves several critical stages that ensure the final product meets the necessary performance and quality standards. Understanding these stages can help international B2B buyers assess potential suppliers effectively.

1. Material Preparation

The first stage involves sourcing high-quality materials essential for optical transceivers. This includes semiconductors, optical fibers, and various electronic components. Suppliers typically rely on certified vendors to ensure the materials meet international standards, which is crucial for maintaining product reliability. Buyers should inquire about the origin of materials and whether they comply with regional and international regulations.

2. Forming

In the forming stage, raw materials are processed into usable components. This may involve precision cutting, molding, or etching of semiconductor chips and other elements. Advanced techniques like photolithography are often employed to create intricate patterns necessary for optical functionality. Buyers should ask suppliers about the technologies they use and their capabilities for customization, which can affect the overall performance of the transceivers.

3. Assembly

The assembly stage is where various components are brought together to create the optical transceiver. This process often requires automated machinery and skilled labor to ensure precision. Techniques such as surface mount technology (SMT) are commonly used to place components on circuit boards. B2B buyers should assess the assembly capabilities of potential suppliers, including their flexibility in handling different designs and volumes.

4. Finishing

Finally, the finishing stage involves final inspections, packaging, and labeling of the optical transceivers. This is where aesthetic and functional quality checks occur. Buyers should pay attention to the supplier’s finishing processes, as these can impact the product’s market readiness and customer acceptance.

How Do Quality Assurance Practices Ensure Reliable Optical Transceivers?

Quality assurance (QA) is vital in the manufacturing of optical transceivers, ensuring that products meet industry standards and customer expectations. Here are the key aspects of QA that international B2B buyers should consider.

Relevant International Standards for Optical Transceivers

Optical transceiver suppliers often adhere to several international standards, including ISO 9001, which outlines quality management principles. Compliance with these standards ensures that suppliers maintain consistent quality in their processes. In addition to ISO, industry-specific certifications such as CE (Conformité Européenne) for the European market and API (American Petroleum Institute) for specialized applications may be relevant depending on the end-use of the transceivers.

What Are the Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint ensures that the raw materials meet specified standards before production begins.

- In-Process Quality Control (IPQC): During manufacturing, IPQC monitors critical processes to detect and rectify issues early.

- Final Quality Control (FQC): This final inspection verifies that finished products meet all specifications before they are shipped.

B2B buyers should inquire about the frequency and rigor of these checkpoints in their potential suppliers’ processes.

What Common Testing Methods Are Used for Optical Transceivers?

Testing methods are critical in verifying the performance and reliability of optical transceivers. Here are some common techniques:

- Optical Performance Testing: This involves measuring parameters such as insertion loss, return loss, and wavelength stability.

- Environmental Testing: Suppliers often conduct tests under varying temperature and humidity conditions to assess product durability.

- Electromagnetic Compatibility (EMC) Testing: This ensures that the transceivers do not interfere with other electronic devices and comply with international EMC standards.

Buyers should request detailed testing reports from suppliers to verify that these methods are employed consistently.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are several ways B2B buyers can perform due diligence:

Conducting Audits

Regular audits of suppliers can provide insights into their manufacturing and quality control practices. Buyers should consider conducting both on-site audits and remote assessments, especially for suppliers located in Africa, South America, the Middle East, and Europe.

Requesting Quality Reports

A stock image related to optical transceiver supplier.

Suppliers should provide quality reports that detail their QC processes, including statistics on defect rates and corrective actions taken. This information can help buyers gauge the reliability of the supplier.

Utilizing Third-Party Inspections

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s manufacturing processes and quality control measures. These inspections can provide additional assurance that products meet specified standards.

What Are the Quality Control and Certification Nuances for International Buyers?

International B2B buyers face unique challenges when sourcing optical transceivers from suppliers across different regions. Understanding these nuances can help mitigate risks:

Regional Compliance Requirements

Different regions may have specific compliance requirements that must be met. For instance, products sold in Europe must comply with CE marking, while those in the Middle East may need to adhere to specific local regulations. Buyers should ensure that their suppliers are aware of and comply with these regional standards.

Language and Documentation Barriers

Language differences can complicate the understanding of quality standards and certifications. Buyers should ensure that suppliers provide documentation in a language that is accessible to their teams, including detailed QC reports and certifications.

Cultural Differences in Quality Expectations

Cultural perceptions of quality may vary significantly between regions. Buyers should communicate their quality expectations clearly and ensure that suppliers understand these requirements to avoid discrepancies.

By gaining an in-depth understanding of the manufacturing processes and quality assurance practices of optical transceiver suppliers, international B2B buyers can make informed decisions that align with their operational needs and market demands. This knowledge not only enhances supplier selection but also fosters long-term partnerships built on trust and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘optical transceiver supplier’

This guide provides a structured approach for international B2B buyers seeking to procure optical transceivers. The procurement process can be complex, particularly for buyers from diverse regions such as Africa, South America, the Middle East, and Europe. By following this step-by-step checklist, you can ensure a more efficient sourcing process, minimizing risks and maximizing value.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it’s critical to have a clear understanding of your technical requirements. This includes the type of optical transceiver needed (e.g., SFP, SFP+, QSFP), the transmission distance, and data rate.

– Consider your network environment: Evaluate whether you need single-mode or multi-mode transceivers based on your infrastructure.

– Anticipate future needs: Think about scalability and compatibility with existing systems.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a proven track record in the optical transceiver market. Look for companies that specialize in your required type of transceiver and have experience in your geographic area.

– Use industry directories: Leverage platforms like Alibaba, Global Sources, or specialized telecommunications directories.

– Seek regional suppliers: Prioritize suppliers who understand local market dynamics and regulations.

Step 3: Evaluate Supplier Credentials and Certifications

Verifying supplier credentials is essential to ensure they meet industry standards and regulations. Check for certifications like ISO 9001 for quality management and any relevant telecom certifications.

– Ask for compliance documentation: Ensure the supplier adheres to international standards, particularly if you’re in regions with strict regulations.

– Assess past performance: Look for certifications that reflect reliability and quality control.

Step 4: Request Samples and Test Products

Before making a bulk purchase, request samples to evaluate product quality and compatibility with your existing systems. Testing ensures that the transceivers meet your performance expectations.

– Conduct real-world testing: Test samples in your operational environment to assess their reliability.

– Evaluate technical support: Gauge the supplier’s responsiveness and support during the testing phase.

Step 5: Negotiate Pricing and Terms

Once you have narrowed down your options, engage in discussions about pricing, payment terms, and delivery schedules.

– Consider total cost of ownership: Look beyond the initial price to factor in warranty, support, and potential future upgrades.

– Explore volume discounts: If you anticipate ongoing needs, negotiate bulk purchasing agreements.

Step 6: Assess Logistics and Delivery Capabilities

Ensure that the supplier can meet your logistical needs, especially if you are sourcing from different continents. Evaluate their ability to deliver on time and their shipping options.

– Review shipping methods: Understand the available shipping options, including air freight for urgent needs versus sea freight for cost savings.

– Check customs and import regulations: Familiarize yourself with any import duties or regulations that could affect delivery times.

Step 7: Establish a Long-term Relationship

After a successful procurement, consider developing a long-term partnership with the supplier. This can lead to better pricing, priority support, and access to new products.

– Communicate regularly: Maintain open lines of communication to address any issues promptly.

– Involve them in future planning: Share your growth plans to align their offerings with your evolving needs.

By following these steps, B2B buyers can streamline their sourcing process for optical transceivers, ensuring they make informed decisions that align with their technical and business requirements.

Comprehensive Cost and Pricing Analysis for optical transceiver supplier Sourcing

What Are the Key Components of Optical Transceiver Cost Structure?

When sourcing optical transceivers, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly influences the overall cost. High-quality components like lasers, photodiodes, and substrates can drive prices up but are crucial for performance and reliability.

-

Labor: Skilled labor is required for assembly and testing of optical transceivers. Labor costs can vary significantly based on the region and the complexity of the product.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and indirect labor. Efficient manufacturing processes can help reduce these expenses, thus lowering overall product costs.

-

Tooling: The initial investment in specialized tools and machinery can be substantial. However, once amortized over production runs, these costs can become negligible per unit.

-

Quality Control (QC): Rigorous testing and quality assurance processes add to costs but are vital for maintaining product reliability and securing certifications that enhance marketability.

-

Logistics: Transportation and warehousing costs can vary based on the supplier’s location and shipping terms. Considering logistics in the cost analysis is crucial for determining the Total Cost of Ownership (TCO).

-

Margin: Suppliers typically apply a margin based on their operational costs and market conditions. Understanding the margin can help buyers gauge pricing competitiveness.

How Do Price Influencers Affect Optical Transceiver Sourcing?

Several factors influence the pricing of optical transceivers, which buyers must consider when negotiating.

-

Volume/MOQ: Minimum order quantities (MOQ) and bulk purchase volumes can lead to significant discounts. Suppliers often offer tiered pricing, so negotiating for larger orders can yield cost savings.

-

Specifications and Customization: Customized optical transceivers tailored to specific applications may incur additional costs. Buyers should weigh the need for customization against budget constraints.

-

Materials: The choice of materials not only affects performance but also the price. High-grade materials may offer better performance but come with a higher price tag.

-

Quality and Certifications: Products that meet international quality standards or come with certifications (like ISO or Telcordia) may command higher prices. However, these certifications are often essential for market acceptance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium but offer better support and warranty options.

-

Incoterms: Understanding Incoterms is crucial for international purchases. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) affect the overall cost and responsibility for shipping.

What Are the Best Practices for Negotiating Optical Transceiver Prices?

When negotiating with suppliers, international B2B buyers should adopt strategic approaches to maximize value.

-

Research and Benchmarking: Understanding market prices and competitor offerings can provide leverage in negotiations. Collect data on similar products to establish a baseline.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, operation, and potential failures. Emphasizing TCO can justify higher initial costs if long-term savings are evident.

-

Build Relationships: Establishing a rapport with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable conditions than transactional relationships.

-

Negotiate Terms: Don’t just focus on price. Negotiate payment terms, delivery schedules, and warranties, which can all contribute to overall cost savings.

-

Evaluate Multiple Suppliers: Compare quotes from multiple suppliers to ensure competitive pricing. This can also provide insights into market standards and potential areas for negotiation.

Conclusion: Understanding Pricing Nuances for International B2B Buyers

For buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the comprehensive cost and pricing dynamics of optical transceivers is critical. By analyzing cost components, recognizing price influencers, and employing effective negotiation strategies, buyers can make informed decisions that align with their budgetary and operational needs. Keep in mind that prices can fluctuate based on market conditions, so always seek updated quotes and be prepared to adapt your sourcing strategy accordingly.

Alternatives Analysis: Comparing optical transceiver supplier With Other Solutions

Understanding Alternatives to Optical Transceiver Suppliers

In the rapidly evolving landscape of telecommunications and data networking, the choice of components can significantly impact performance and cost. While optical transceivers have become a standard solution for high-speed data transmission, it’s crucial for B2B buyers to consider alternative technologies that may better suit their specific needs. This section will analyze optical transceiver suppliers against other viable solutions, providing insights to help international buyers make informed decisions.

Comparison Table of Optical Transceiver Supplier and Alternatives

| Comparison Aspect | Optical Transceiver Supplier | Direct Attached Copper (DAC) | Passive Optical Networks (PON) |

|---|---|---|---|

| Performance | High-speed data transfer (up to 400 Gbps) | Moderate speed (up to 10 Gbps) | High-speed with shared bandwidth |

| Cost | Higher initial investment but lower operational costs | Lower upfront cost, higher power consumption | Moderate cost with good scalability |

| Ease of Implementation | Requires specialized knowledge for installation | Easy to deploy with standard connectors | More complex due to network design |

| Maintenance | Low maintenance with minimal intervention | Higher maintenance due to power needs | Low maintenance with centralized management |

| Best Use Case | Long-distance, high-bandwidth applications | Short-range, low-latency connections | Broadband service delivery in urban areas |

What Are the Advantages and Disadvantages of Direct Attached Copper (DAC)?

Direct Attached Copper (DAC) cables are an alternative to optical transceivers, primarily used for short distances. The key advantage of DAC is its lower upfront cost, making it an attractive option for budget-conscious buyers. Additionally, DAC is straightforward to implement, requiring standard connectors and minimal configuration. However, the performance is limited to moderate speeds (typically up to 10 Gbps), which may not suffice for high-demand applications. Moreover, DAC cables consume more power, leading to higher operational costs in the long run.

How Do Passive Optical Networks (PON) Compare to Optical Transceiver Suppliers?

Passive Optical Networks (PON) represent another alternative for data transmission, especially in urban broadband applications. PON systems can deliver high-speed connections while efficiently sharing bandwidth among multiple users. The advantages of PON include moderate initial costs and excellent scalability, making it suitable for expanding networks. However, the implementation process can be more complex than optical transceivers, requiring thorough network design and planning. Maintenance is generally low, but centralized management is necessary for optimal performance, which could be a drawback for organizations with limited technical expertise.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right solution between optical transceiver suppliers and their alternatives hinges on understanding specific business requirements. Buyers should assess factors such as performance needs, budget constraints, and ease of implementation. For businesses requiring high-speed and long-distance capabilities, optical transceivers may be the best choice despite the higher initial investment. Conversely, for those focused on short-range connections or cost-effectiveness, DAC or PON systems could offer significant advantages. Ultimately, a thorough evaluation of each option against your organization’s operational goals will enable you to make the most informed decision.

Essential Technical Properties and Trade Terminology for optical transceiver supplier

What Are the Key Technical Properties of Optical Transceivers?

When evaluating optical transceivers, it’s essential to understand the key technical properties that determine their performance and suitability for specific applications. Here are critical specifications to consider:

1. Wavelength

Wavelength, measured in nanometers (nm), indicates the light frequency used for data transmission. Common wavelengths for optical transceivers include 850 nm, 1310 nm, and 1550 nm. For B2B buyers, selecting the appropriate wavelength is crucial as it affects data rate, distance, and compatibility with existing systems. A mismatch can lead to signal loss and reduced performance.

2. Data Rate

The data rate, expressed in gigabits per second (Gbps), defines the speed at which data can be transmitted. Common rates include 1 Gbps, 10 Gbps, and 100 Gbps. For international buyers, understanding the required data rate is vital for ensuring that the transceiver meets the demands of their network infrastructure, particularly in sectors requiring high-speed data transfer, such as finance and telecommunications.

3. Distance

Distance specifications indicate the maximum length over which a transceiver can reliably transmit data. This is often categorized into short-range (SR), long-range (LR), and extended-range (ER). Buyers must consider their operational environment; for instance, longer distances may be necessary in rural areas of Africa or South America, while urban settings may require shorter-range solutions.

4. Connector Type

The connector type determines how the transceiver interfaces with fiber optic cables. Common types include LC, SC, and MPO connectors. Understanding the connector type is essential for ensuring compatibility with existing network setups. International buyers should verify connector standards in their region to avoid compatibility issues.

5. Power Consumption

Power consumption, measured in watts, indicates how much energy the transceiver uses during operation. This is increasingly important for companies focused on sustainability and operational costs. Lower power consumption can lead to reduced energy costs and a smaller carbon footprint, appealing to environmentally conscious businesses.

What Are Common Trade Terms Used in the Optical Transceiver Industry?

Familiarizing yourself with industry terminology is crucial for effective communication and negotiation with suppliers. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the optical transceiver market, buyers often engage with OEMs to ensure they receive high-quality products that meet specific standards. Understanding OEM relationships can help buyers assess product reliability and brand reputation.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is essential for buyers to understand MOQ as it affects inventory management and cash flow. In regions like South America and Africa, where smaller businesses may operate, negotiating MOQs can lead to more flexible purchasing options.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing for specific products. This is a critical step in the procurement process, allowing buyers to compare prices and terms across multiple suppliers. A well-structured RFQ can result in better pricing and conditions, benefiting the buyer’s bottom line.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with Incoterms can help buyers understand shipping costs, risks, and responsibilities, especially when sourcing from international suppliers in Europe or the Middle East.

5. Lead Time

Lead time refers to the time it takes for a supplier to fulfill an order from the moment it is placed until delivery. Understanding lead times is crucial for project planning and ensuring that products are available when needed, particularly in fast-paced markets.

By grasping these essential technical properties and trade terminologies, B2B buyers can navigate the optical transceiver market more effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the optical transceiver supplier Sector

What Are the Current Market Dynamics and Key Trends in the Optical Transceiver Sector?

The optical transceiver market is experiencing rapid growth, driven by the increasing demand for high-speed data transmission in various sectors, including telecommunications, data centers, and cloud computing. As global connectivity expands, particularly in regions like Africa, South America, the Middle East, and Europe, businesses must stay informed about the latest developments. Key trends include the rise of 5G technology, which necessitates more advanced optical solutions, and the growing adoption of Artificial Intelligence (AI) and Machine Learning (ML) in network management to optimize performance and reduce costs.

Moreover, there is a shift toward miniaturization and integration of optical components, which enhances efficiency and reduces the overall footprint of transceiver systems. For international buyers, understanding these trends is crucial for making informed sourcing decisions. Companies should prioritize suppliers that offer cutting-edge technology and scalability to meet future demands. Additionally, regional market dynamics, such as varying regulatory environments and local competition, can significantly impact sourcing strategies. Buyers from diverse regions should leverage these insights to identify suppliers that align with their specific needs and compliance requirements.

How Can Sustainability and Ethical Sourcing Impact Your Supply Chain in the Optical Transceiver Industry?

Sustainability is becoming a critical factor in the sourcing decisions of international B2B buyers, particularly in the optical transceiver sector. The environmental impact of production processes and materials used in transceivers can significantly affect a company’s brand reputation and regulatory compliance. Buyers should seek suppliers who prioritize sustainable practices, such as using eco-friendly materials and minimizing waste in their manufacturing processes.

Ethical sourcing is equally important, as it ensures that suppliers adhere to fair labor practices and environmental standards. Certifications like ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) can serve as indicators of a supplier’s commitment to sustainability. By partnering with suppliers who value ethical practices, companies not only enhance their corporate responsibility but also contribute to a more sustainable future. Buyers should actively inquire about sustainability initiatives and certifications when evaluating potential suppliers, as this can lead to long-term partnerships that align with their values and goals.

What Is the Brief Evolution of the Optical Transceiver Market?

The optical transceiver market has evolved significantly since its inception in the late 20th century. Initially, these devices were primarily used in telecommunication networks to facilitate long-distance data transmission. However, with the advent of the internet and the exponential growth of data traffic, the demand for faster and more efficient optical transceivers surged.

Over the years, advancements in technology have led to the development of more compact and powerful transceivers capable of supporting higher bandwidths and longer distances. The introduction of new standards, such as 100G and 400G, has also transformed the market, making it essential for buyers to stay updated on the latest specifications and capabilities. This evolution underscores the importance of strategic sourcing and the need for buyers to engage with suppliers that can provide innovative solutions tailored to their specific operational requirements.

Frequently Asked Questions (FAQs) for B2B Buyers of optical transceiver supplier

-

How do I evaluate the reliability of an optical transceiver supplier?

To evaluate the reliability of an optical transceiver supplier, consider their industry experience, customer reviews, and certifications. Check for compliance with international standards such as ISO or IEC, which indicates quality assurance. Request case studies or references from existing clients, especially those in your region, to gauge performance and service. Additionally, assess their response time and customer support capabilities, as these factors are crucial for ongoing business relationships. -

What are the key specifications to look for in optical transceivers?

When sourcing optical transceivers, focus on specifications such as data rate, wavelength, and compatibility with your existing infrastructure. Consider the form factor (e.g., SFP, SFP+, QSFP) and distance capabilities, as well as the type of fiber (single-mode or multi-mode). Additionally, look for features like digital diagnostics monitoring (DDM) and power consumption ratings, as these can impact both performance and operational costs in the long run. -

What payment terms should I expect when dealing with optical transceiver suppliers?

Payment terms can vary significantly among suppliers, but common options include upfront payment, partial payment upon order confirmation, and payment upon delivery. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risk. Be sure to clarify any additional costs related to shipping, customs duties, and taxes, which can affect your total expenditure. -

How can I customize optical transceivers to meet my specific needs?

Most reputable optical transceiver suppliers offer customization options to accommodate specific requirements, such as tailored wavelengths, casing colors, or branding. When discussing customization, provide detailed specifications and any relevant standards your application requires. Ensure that the supplier has the capability to deliver custom products within your desired timeframe and can maintain quality assurance throughout the manufacturing process. -

What is the minimum order quantity (MOQ) for optical transceivers?

Minimum order quantities can vary widely between suppliers, often depending on the type of transceiver and the level of customization required. While some suppliers may allow orders of a few units, others may have MOQs in the hundreds or thousands. It’s essential to discuss your needs upfront and negotiate terms that are feasible for your business, especially if you are entering a new market or testing a product line. -

How do I ensure quality assurance when sourcing optical transceivers?

To ensure quality assurance, request detailed information about the supplier’s manufacturing processes and quality control measures. Look for suppliers that provide testing reports and certifications for their products. Additionally, consider suppliers that offer warranties or guarantees on their transceivers, which can provide peace of mind regarding their reliability and performance. -

What logistics considerations should I be aware of when importing optical transceivers?

When importing optical transceivers, consider shipping methods, lead times, and potential customs regulations that may affect your delivery. Verify that the supplier can provide necessary documentation, such as certificates of origin and compliance. Be aware of any import duties and taxes that may apply in your region, as these can significantly impact overall costs. Partnering with a logistics provider experienced in international trade can help streamline this process. -

How can I find a reputable optical transceiver supplier in my region?

To find a reputable optical transceiver supplier, start by researching industry-specific trade shows and conferences where you can meet suppliers directly. Utilize online B2B marketplaces and directories that focus on electronics and telecommunications. Additionally, leverage professional networks and associations in your region, which can provide recommendations and reviews. Always conduct due diligence by checking references and assessing the supplier’s past performance before making a commitment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for optical transceiver supplier

In the competitive landscape of optical transceiver procurement, strategic sourcing emerges as a critical component for international B2B buyers. By understanding market dynamics, regional suppliers, and technological advancements, companies from Africa, South America, the Middle East, and Europe can make informed purchasing decisions. The importance of evaluating supplier capabilities, quality certifications, and support services cannot be overstated, as these factors directly influence operational efficiency and long-term partnerships.

Moreover, leveraging data analytics to assess pricing trends and supplier performance will empower buyers to negotiate more favorable terms and minimize risks associated with supply chain disruptions. As the demand for high-speed connectivity continues to grow, particularly in emerging markets, aligning with reliable optical transceiver suppliers is essential for maintaining a competitive edge.

Looking ahead, international B2B buyers are encouraged to actively engage with suppliers and invest in building strategic relationships. By fostering collaboration and innovation, organizations can not only enhance their procurement strategies but also contribute to a more resilient and sustainable supply chain. Embrace the opportunity to transform your sourcing approach and position your business for success in the evolving digital landscape.