Discover Top Benefits from X Ray Machine Manufacturers (2025)

Introduction: Navigating the Global Market for x ray machine manufacturer

As international B2B buyers embark on the journey of sourcing x-ray machines, they often face a myriad of challenges, including understanding the diverse range of products available and ensuring compliance with local regulations. The global market for x-ray machine manufacturers is vast and complex, particularly for buyers from regions such as Africa, South America, the Middle East, and Europe. This guide aims to demystify the process of selecting the right x-ray equipment by providing insights into various types, applications, and the latest technological advancements that influence purchasing decisions.

Navigating this landscape involves more than just identifying suppliers; it requires a deep understanding of the market dynamics, supplier vetting processes, cost structures, and the specific needs of healthcare facilities in different regions. Whether you are in South Africa looking for portable x-ray solutions, or in Europe assessing advanced imaging technologies, this guide will equip you with the knowledge necessary to make informed decisions.

From understanding the importance of regulatory compliance to evaluating supplier reliability and performance, this comprehensive resource empowers B2B buyers to optimize their purchasing strategies. By addressing common concerns and providing actionable insights, this guide seeks to enhance your ability to select the best x-ray machine manufacturer that aligns with your operational needs and budgetary constraints.

Understanding x ray machine manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional X-Ray Machines | Utilize film to capture images; cost-effective; low-tech. | General diagnostics, rural clinics | Pros: Affordable, easy to maintain. Cons: Lower image quality, slower process. |

| Digital X-Ray Systems | Use digital sensors for immediate image capture; high clarity. | Hospitals, specialized imaging centers | Pros: Faster results, superior image quality. Cons: Higher initial investment. |

| Portable X-Ray Machines | Compact and mobile; battery-operated options available. | Fieldwork, emergency services, rural areas | Pros: Versatile, easy to transport. Cons: Limited features compared to larger systems. |

| Fluoroscopy Machines | Real-time imaging; often used in surgical settings. | Interventional radiology, surgery | Pros: Dynamic imaging, useful for procedures. Cons: Higher operational costs. |

| Cone Beam CT Systems | 3D imaging; specialized for dental and maxillofacial uses. | Dental practices, orthodontics | Pros: Detailed imaging, lower radiation dose. Cons: Niche application, expensive. |

What Are the Characteristics of Conventional X-Ray Machines?

Conventional X-ray machines are the most traditional type, primarily utilizing film to capture images. They are cost-effective and straightforward, making them suitable for rural clinics and general diagnostics where budget constraints are a concern. Buyers should consider the lower image quality and slower processing times, which may not meet the demands of more advanced medical facilities. However, their ease of maintenance and affordability can be significant advantages for smaller healthcare providers.

How Do Digital X-Ray Systems Enhance Diagnostic Capabilities?

Digital X-ray systems represent a significant advancement in imaging technology, employing digital sensors that provide immediate image capture and superior clarity. These systems are widely used in hospitals and specialized imaging centers, where rapid diagnosis is critical. While the initial investment is higher than conventional machines, the long-term benefits, including faster workflow and improved patient care, make them an attractive option for B2B buyers looking to enhance their diagnostic capabilities.

What Advantages Do Portable X-Ray Machines Offer?

Portable X-ray machines are designed for mobility, making them ideal for fieldwork, emergency services, and rural areas where access to traditional imaging facilities may be limited. These machines can be battery-operated and easily transported, allowing for immediate imaging in various settings. However, potential buyers should be aware that while they offer versatility, they may come with limited features compared to stationary systems, which could impact the breadth of diagnostic capabilities.

Why Are Fluoroscopy Machines Essential in Surgical Settings?

Fluoroscopy machines provide real-time imaging, making them indispensable in surgical settings and interventional radiology. They allow medical professionals to visualize the movement of organs and devices within the body, facilitating complex procedures. While they offer dynamic imaging capabilities, buyers must consider the higher operational costs associated with these systems, including maintenance and the need for specialized training for staff.

What Niche Applications Do Cone Beam CT Systems Serve?

Cone Beam CT systems are tailored for 3D imaging, particularly in dental and maxillofacial applications. They offer detailed imaging with a lower radiation dose compared to traditional CT systems, making them a safer option for patients. However, their niche application means that buyers should assess whether their practice can justify the investment, as the cost can be significant. For dental practices focusing on orthodontics or implantology, the benefits often outweigh the cons.

Related Video: X Ray Machine | Part 1| Biomedical Engineers TV |

Key Industrial Applications of x ray machine manufacturer

| Industry/Sector | Specific Application of X-ray Machine Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Medical Imaging and Diagnostics | Enhanced patient care through accurate diagnostics | Compliance with health regulations and standards |

| Manufacturing | Quality Control in Production Lines | Increased product reliability and reduced waste | Integration with existing production systems |

| Aerospace | Non-Destructive Testing of Components | Assurance of safety and compliance with regulations | Certification and calibration of machines |

| Security | Cargo and Baggage Screening | Improved security and threat detection | Speed and efficiency of scanning capabilities |

| Mining and Minerals | Material Composition Analysis | Optimized resource extraction and reduced costs | Adaptability to harsh environments and portability |

How is X-ray Technology Used in Healthcare for International Buyers?

In the healthcare sector, X-ray machines are essential for medical imaging and diagnostics. They enable healthcare professionals to visualize internal structures, aiding in the early detection of diseases. For international B2B buyers, especially in regions like Africa and South America, sourcing advanced X-ray technology that complies with local health regulations is critical. Buyers must also consider the machine’s ease of use and maintenance, ensuring that healthcare staff are adequately trained to operate the equipment effectively.

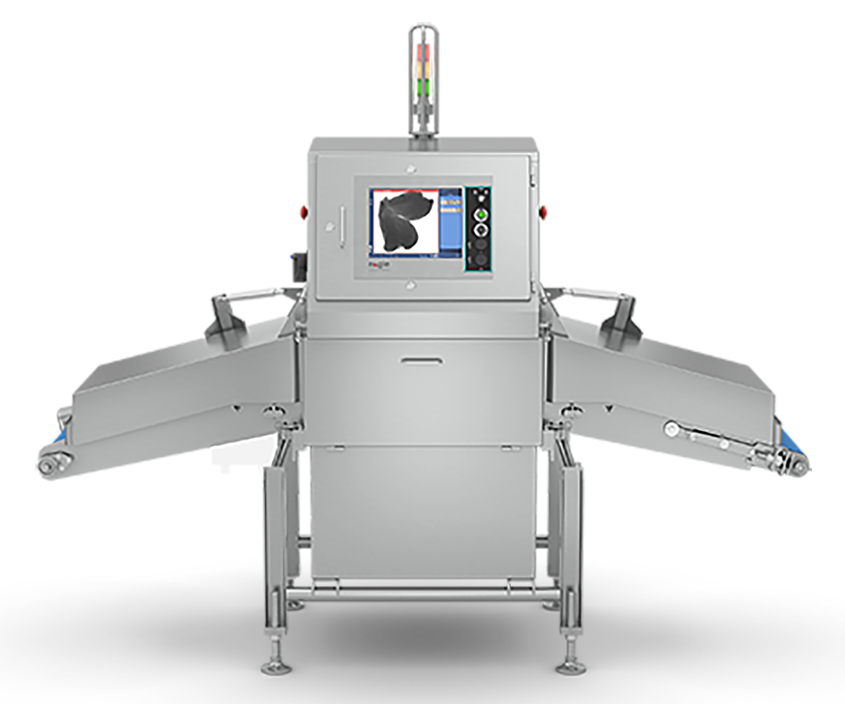

A stock image related to x ray machine manufacturer.

What Role Does X-ray Play in Manufacturing Quality Control?

In manufacturing, X-ray machines are employed for quality control in production lines. They allow manufacturers to inspect the integrity of products, identifying defects or inconsistencies before items reach the market. This application is particularly valuable for businesses in Europe and the Middle East, where stringent quality standards are enforced. Buyers should prioritize X-ray machines that can seamlessly integrate with existing production systems and provide real-time data analytics to enhance operational efficiency.

How is X-ray Technology Applied in Aerospace Non-Destructive Testing?

In the aerospace industry, X-ray technology is crucial for non-destructive testing (NDT) of components. It ensures that parts meet safety standards without damaging them. For international buyers, particularly those in regions with burgeoning aerospace industries, sourcing X-ray machines that are certified and calibrated for precise measurements is vital. Additionally, understanding the machine’s ability to handle various materials and thicknesses will aid in making informed purchasing decisions.

Why is X-ray Important for Security Screening?

X-ray machines are widely used in security applications, particularly for cargo and baggage screening. They enhance security measures by detecting concealed threats in luggage and freight. For B2B buyers in the Middle East and Africa, where security concerns are heightened, investing in high-speed and efficient X-ray machines is essential. Buyers should evaluate the machine’s throughput capabilities and image clarity to ensure effective screening processes that do not compromise efficiency.

What Benefits Does X-ray Technology Offer in Mining and Minerals?

In the mining and minerals sector, X-ray machines are utilized for material composition analysis. This application helps companies optimize resource extraction and reduce operational costs by providing precise data on material quality. International buyers, particularly from South America and Africa, should consider machines that are robust and portable, capable of functioning in harsh environments. Additionally, understanding the specific analytical capabilities of the X-ray machines can significantly impact the efficiency of mining operations.

Related Video: X ray Machine – Components & Working Mechanism | Topics In Description Below

3 Common User Pain Points for ‘x ray machine manufacturer’ & Their Solutions

Scenario 1: Limited Access to Technical Support for X-Ray Machines

The Problem: In regions such as Africa and South America, many healthcare facilities struggle with limited access to technical support for their X-ray machines. This can result in prolonged downtime when issues arise, leading to delayed patient diagnoses and treatments. The lack of readily available support can also discourage healthcare providers from investing in advanced X-ray technologies, fearing that they will not receive adequate assistance when problems occur.

The Solution: When sourcing X-ray machines, B2B buyers should prioritize manufacturers that offer robust technical support services, including remote troubleshooting and on-site maintenance. Buyers can inquire about the manufacturer’s service level agreements (SLAs) to ensure timely support. Additionally, establishing a local partnership with a service provider that specializes in medical equipment can enhance support availability. Investing in training for local technicians on the specific X-ray machines can also create a self-sufficient maintenance culture, ensuring that facilities can quickly resolve minor issues without waiting for external help.

Scenario 2: High Cost of Replacement Parts for X-Ray Machines

The Problem: B2B buyers often face financial challenges related to the high cost of replacement parts for X-ray machines. In many cases, especially in the Middle East and Europe, the cost of importing parts can be prohibitive, leading to extended downtimes and increased operational costs. Healthcare providers may struggle to budget for these expenses, which can deter them from upgrading their equipment or investing in necessary repairs.

The Solution: To mitigate the financial burden of replacement parts, buyers should seek manufacturers that provide competitive pricing on parts or offer comprehensive maintenance packages that include regular servicing and parts at a reduced cost. Engaging in long-term contracts with manufacturers can also facilitate bulk purchasing discounts. Furthermore, buyers can explore local suppliers or third-party providers who offer compatible parts at lower prices. Conducting thorough research and creating a network with other healthcare facilities can help in sharing best practices for cost-effective maintenance strategies.

Scenario 3: Difficulty in Understanding Regulatory Compliance for X-Ray Machines

The Problem: Navigating the complex landscape of regulatory compliance can be a significant pain point for B2B buyers of X-ray machines, particularly in Europe and the Middle East. Different countries have varying standards regarding radiation safety, equipment quality, and operational protocols, which can be overwhelming for buyers who are unfamiliar with these regulations. Non-compliance can result in heavy fines and operational shutdowns, making it essential for buyers to fully understand local laws.

The Solution: To address compliance issues, buyers should engage with manufacturers that have a deep understanding of local regulations and can provide guidance on meeting these requirements. It is beneficial to request documentation that demonstrates the machine’s compliance with regional standards, such as CE marking in Europe or local health authority approvals. Buyers should also consider hiring a compliance consultant or joining industry associations that focus on medical device regulation to stay informed about changes in the law. Regular training sessions for staff on compliance can further ensure that all operational practices meet the necessary guidelines, thereby reducing the risk of penalties.

By identifying these common pain points and implementing the suggested solutions, B2B buyers can make informed decisions that enhance their operational efficiency and compliance while maximizing the value of their X-ray machines.

Strategic Material Selection Guide for x ray machine manufacturer

When selecting materials for X-ray machines, manufacturers must consider a variety of factors that influence performance, durability, and compliance with international standards. Here, we analyze four common materials used in the construction of X-ray machines: stainless steel, aluminum, lead, and composite materials. Each material has its unique properties, advantages, and limitations, which can significantly affect the end product’s suitability for different applications.

What Are the Key Properties of Stainless Steel for X-ray Machines?

Stainless steel is renowned for its excellent corrosion resistance, high strength, and durability, making it a popular choice for structural components in X-ray machines. It can withstand high temperatures and pressures, which is essential for maintaining operational integrity during extended use. The material’s non-reactive nature ensures that it does not compromise the integrity of the components it houses.

Pros & Cons:

The primary advantage of stainless steel is its longevity and resistance to wear and tear, which reduces maintenance costs over time. However, it is relatively heavy, which can complicate the design and increase manufacturing costs. Furthermore, the complexity of machining stainless steel can lead to longer production times.

Impact on Application:

Stainless steel is particularly suitable for components that require high durability and resistance to environmental factors, such as the housing of X-ray tubes.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure that the stainless steel used complies with ASTM standards, particularly ASTM A240 for stainless steel sheets and plates. Understanding local regulations regarding material safety and environmental impact is also crucial.

How Does Aluminum Benefit X-ray Machine Manufacturing?

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, making it an attractive option for various components in X-ray machines. Its lower density compared to stainless steel allows for easier handling and installation.

Pros & Cons:

The primary advantage of aluminum is its lightweight nature, which can enhance the portability of mobile X-ray units. However, aluminum’s lower strength compared to stainless steel may limit its use in high-stress applications. Additionally, while it is generally more cost-effective, the manufacturing process can involve complex machining to achieve the desired specifications.

Impact on Application:

Aluminum is often used in the construction of frames and casings for X-ray machines, where weight savings are critical without compromising performance.

Considerations for International Buyers:

Buyers should verify that the aluminum used meets international standards such as JIS H 4000. Regions like Europe may have specific regulations regarding the recycling and disposal of aluminum products.

What Role Does Lead Play in X-ray Machine Design?

Lead is a crucial material in X-ray machines due to its exceptional ability to absorb radiation, providing essential shielding. Its high density makes it effective at protecting both operators and patients from unnecessary exposure.

Pros & Cons:

The key advantage of lead is its effectiveness in radiation shielding, which is vital for safety in medical and industrial applications. However, lead is heavy and can be challenging to work with, requiring careful handling and disposal due to its toxic properties. This can increase overall costs and complicate compliance with health and safety regulations.

Impact on Application:

Lead is primarily used in protective barriers and aprons, ensuring safety in environments where X-ray machines are operated.

Considerations for International Buyers:

Compliance with local regulations regarding lead usage is critical, especially in regions like the Middle East and Europe, where strict guidelines exist concerning hazardous materials.

How Do Composite Materials Enhance X-ray Machine Performance?

Composite materials, which often combine plastics with other materials, offer unique benefits in terms of weight reduction and flexibility in design. They can be engineered to provide specific properties, such as enhanced durability or improved thermal management.

Pros & Cons:

The main advantage of composites is their lightweight nature and the ability to tailor properties for specific applications. However, they can be more expensive than traditional materials and may require specialized manufacturing processes, which can complicate production.

Impact on Application:

Composites are increasingly used in non-structural components of X-ray machines, such as housings and covers, where weight and thermal properties are critical.

Considerations for International Buyers:

Buyers should ensure that composite materials comply with relevant standards, such as DIN EN ISO 1043 for plastics, and be aware of the material’s lifecycle and recyclability.

Summary Table of Material Selection for X-ray Machines

| Material | Typical Use Case for X-ray Machine Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components and housing | High durability and corrosion resistance | Heavy and complex to machine | High |

| Aluminum | Frames and casings | Lightweight and corrosion-resistant | Lower strength and complex machining | Medium |

| Lead | Radiation shielding barriers and aprons | Effective radiation absorption | Heavy and toxic, requiring careful handling | High |

| Composite | Non-structural components like housings | Lightweight and customizable properties | More expensive and complex to manufacture | Medium to High |

This guide provides essential insights into material selection for X-ray machine manufacturers, ensuring that international B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for x ray machine manufacturer

What Are the Key Stages in the Manufacturing Process of X-Ray Machines?

The manufacturing of X-ray machines involves several critical stages, each designed to ensure the reliability and performance of the final product. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

– Selection of High-Quality Materials: The manufacturing process begins with the selection of high-quality materials, such as specialized alloys for the housing and advanced polymers for insulation. It’s essential for manufacturers to source materials that meet stringent international standards to ensure durability and safety.

– Material Testing: Before proceeding, materials undergo rigorous testing for compliance with industry standards. This is vital to ensure that they can withstand the operational demands of X-ray machines. -

Forming Techniques

– Precision Machining: This stage involves machining components to precise specifications. Techniques such as CNC machining are commonly employed to achieve the necessary tolerances, which is crucial for the accurate functioning of the X-ray equipment.

– Metal Fabrication: Metal forming processes, including stamping and bending, are utilized to create the machine’s structural components. These processes are critical to achieving the required strength and rigidity. -

Assembly of Components

– Sub-Assembly and Integration: Once individual components are manufactured, they are assembled into sub-units. This may include the integration of electronic components, detectors, and imaging systems, which require careful alignment and calibration.

– Testing During Assembly: Throughout the assembly process, manufacturers perform in-process quality control (IPQC) checks to ensure that each component fits and functions correctly. This step is crucial to identify any issues early in the process. -

Finishing Touches

– Surface Treatment and Coating: After assembly, components undergo surface treatment processes to enhance durability and reduce corrosion. Coatings may also be applied to improve aesthetic appeal and ease of cleaning.

– Final Assembly and Calibration: The final assembly includes attaching the control panel, power systems, and any additional features. Calibration is performed to ensure that the X-ray machine operates within specified parameters, adhering to safety standards.

How Is Quality Assurance Implemented in X-Ray Machine Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that the final product meets both regulatory and customer expectations. Manufacturers typically adhere to various international and industry-specific standards.

-

Adherence to International Standards

– ISO 9001 Certification: Many X-ray machine manufacturers obtain ISO 9001 certification, which demonstrates a commitment to quality management systems. This certification requires ongoing evaluation and continuous improvement of processes.

– Compliance with CE Marking: For manufacturers targeting the European market, CE marking is essential. This indicates compliance with European health, safety, and environmental protection standards. -

Industry-Specific Certifications

– API and Other Relevant Standards: Depending on the application, manufacturers may also seek certifications from organizations such as the American Petroleum Institute (API) for specific medical applications. This is particularly relevant in regions with stringent medical device regulations. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival at the manufacturing facility. Only materials that pass this inspection proceed to production.

– In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to monitor the quality of work at various stages, ensuring that any defects are identified and corrected immediately.

– Final Quality Control (FQC): At the end of the manufacturing process, a comprehensive inspection is conducted to ensure that the finished product meets all specifications and quality standards before shipping.

What Common Testing Methods Are Used to Ensure Quality in X-Ray Machines?

Testing is crucial for validating the performance and safety of X-ray machines. Several common methods are employed:

-

Functional Testing: This involves verifying that all systems and components operate as intended. Functional tests may include checking the imaging capabilities, radiation output, and safety features.

-

Performance Testing: X-ray machines undergo performance testing to evaluate their imaging quality and diagnostic efficacy. This can include assessing resolution, contrast, and exposure times.

-

Safety Testing: Safety tests ensure that the machine operates within safe radiation levels and that protective features function correctly. This is particularly important for compliance with health regulations.

-

Environmental Testing: Manufacturers may also conduct environmental tests to determine how the machine performs under various conditions, including temperature fluctuations and humidity levels.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure they meet specific needs and standards.

-

Conducting Supplier Audits: Buyers should consider conducting on-site audits of potential suppliers. This allows for a firsthand assessment of the manufacturing processes, quality control measures, and adherence to international standards.

-

Requesting Quality Control Documentation: Suppliers should provide documentation that outlines their quality assurance processes, including IQC, IPQC, and FQC reports. These documents can provide insights into their commitment to quality.

-

Engaging Third-Party Inspection Services: Utilizing third-party inspection services can help buyers gain an unbiased evaluation of the supplier’s quality control practices. These services can conduct independent assessments and provide detailed reports.

-

Understanding Certification Nuances: Buyers should familiarize themselves with the certification nuances specific to their region. For instance, understanding the implications of ISO certifications, CE marking, and local regulatory requirements can significantly impact purchasing decisions.

Conclusion: Ensuring Quality in Your X-Ray Machine Procurement

For international B2B buyers, understanding the manufacturing processes and quality assurance measures of X-ray machine manufacturers is crucial. By focusing on the detailed stages of production and the rigorous quality control protocols in place, buyers can make informed decisions that align with their operational needs and regulatory requirements. Engaging in thorough verification processes further ensures that the purchased equipment will meet the highest standards of safety and performance, ultimately supporting effective healthcare delivery in their respective regions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘x ray machine manufacturer’

This guide aims to provide international B2B buyers with a structured approach to sourcing X-ray machine manufacturers. By following this checklist, you can ensure that your procurement process is thorough, minimizing risks while maximizing the quality and suitability of the equipment for your specific needs.

Step 1: Define Your Technical Specifications

Before you begin the sourcing process, it’s crucial to have a clear understanding of your technical requirements. Consider factors such as the type of X-ray machine needed (e.g., portable vs. fixed), image quality specifications, and additional features like digital capabilities or radiation safety standards. Clearly defined specifications will help you communicate effectively with potential suppliers and ensure that you receive quotes that meet your needs.

Step 2: Research Potential Suppliers

Conduct extensive research to identify potential manufacturers of X-ray machines. Utilize industry directories, trade shows, and online platforms to compile a list of suppliers. Focus on their market reputation, production capabilities, and geographical reach. Look for manufacturers with a solid track record of delivering high-quality products in your region, such as Africa or South America.

Step 3: Verify Supplier Certifications

It is essential to verify that your potential suppliers hold the necessary certifications and licenses. Check for compliance with international standards such as ISO 13485 for medical devices and specific regulations in your country. Certifications not only demonstrate a manufacturer’s commitment to quality but also ensure that the machines meet safety and performance standards.

Step 4: Request Product Samples and Demonstrations

Once you have narrowed down your list, request product samples or demonstrations of the X-ray machines. This step allows you to assess the quality and functionality of the machines firsthand. Pay attention to ease of use, image clarity, and any additional features that may be beneficial for your operations. A demonstration can also provide insights into the manufacturer’s customer support and service capabilities.

Step 5: Evaluate Pricing and Payment Terms

When evaluating suppliers, consider not only the price of the X-ray machines but also the overall value offered. Look for transparent pricing structures, including shipping and installation costs. Additionally, discuss payment terms; flexible financing options may be important, especially for buyers in regions with fluctuating currency values. Ensure that the total cost aligns with your budget without compromising on quality.

Step 6: Check After-Sales Support and Warranty

Assess the after-sales support offered by potential suppliers, as this can significantly impact your satisfaction and operational efficiency. Inquire about warranty terms, maintenance services, and availability of spare parts. A reliable supplier should provide comprehensive support that ensures your X-ray machines remain operational and effective over time.

Step 7: Make an Informed Decision

After completing the previous steps, compile all the information to make a well-informed decision. Consider factors such as supplier reliability, product quality, after-sales support, and total cost of ownership. Engaging in discussions with your team and possibly consulting with industry experts can also provide valuable insights that lead to a successful procurement process.

Following this checklist will help you navigate the complexities of sourcing X-ray machines, ensuring that you select a manufacturer that meets your operational needs and standards.

Comprehensive Cost and Pricing Analysis for x ray machine manufacturer Sourcing

What Are the Key Cost Components in X-Ray Machine Manufacturing?

When sourcing X-ray machines, understanding the cost structure is vital. The main cost components include:

-

Materials: The selection of high-quality materials significantly impacts the overall cost. Key materials in X-ray machines include metals, electronic components, and specialized imaging sensors. Prices can vary based on the supplier and region, with advanced materials often leading to higher costs.

-

Labor: Labor costs encompass wages for skilled technicians and engineers involved in the manufacturing process. Regions with lower labor costs, like parts of South America and Africa, may offer competitive pricing, but it’s essential to consider the skill level and expertise required for X-ray machine assembly.

-

Manufacturing Overhead: This includes the costs of utilities, rent, and administrative expenses necessary for production. Manufacturers in Europe might face higher overhead costs due to stricter regulations and higher living standards.

-

Tooling: The initial investment in tools and machinery can be substantial. Custom tooling for specific X-ray machine designs can increase upfront costs but may reduce per-unit costs in larger production runs.

-

Quality Control (QC): Ensuring that each machine meets regulatory standards requires a robust QC process. This can add to the cost but is essential for compliance and safety, particularly in regions with stringent medical device regulations.

-

Logistics: Shipping costs can vary widely based on the destination and shipping method. International buyers must consider tariffs, insurance, and potential delays in their logistics planning.

-

Margin: Manufacturers typically add a profit margin to cover their risk and investment. Understanding typical margins in the industry can help buyers gauge whether they are being offered a fair price.

How Do Price Influencers Affect X-Ray Machine Sourcing?

Several factors can influence the pricing of X-ray machines:

-

Volume/MOQ: Manufacturers often provide discounts for bulk orders. Understanding Minimum Order Quantities (MOQ) can help buyers negotiate better pricing. Ordering larger volumes can lead to substantial cost savings.

-

Specifications and Customization: Custom features tailored to specific medical applications can drive up costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials directly affects durability and performance. Higher-quality materials often come with certifications that may be necessary for regulatory compliance, impacting the overall price.

-

Supplier Factors: The reputation and location of the supplier can influence pricing. Established manufacturers in Europe may charge more due to their experience and certifications, while emerging suppliers in Africa or South America may offer lower prices but with varying quality assurances.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can impact the total cost. Buyers should clarify whether the quoted price includes shipping, insurance, and customs duties to avoid unexpected costs.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing X-Ray Machines?

International B2B buyers should consider the following strategies to enhance cost-efficiency:

-

Negotiation: Always be prepared to negotiate prices. Understanding the supplier’s cost structure can provide leverage in discussions. Highlighting potential long-term partnerships can also encourage suppliers to offer better terms.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, potential repairs, and operational costs over the machine’s lifespan. A lower upfront cost may lead to higher TCO if the machine is less reliable.

-

Pricing Nuances for Different Regions: Be aware of regional pricing trends. For instance, manufacturers in Africa may have lower costs due to local sourcing but could lack certain certifications required in Europe.

-

Conduct Thorough Research: Evaluate multiple suppliers and compare their offerings, prices, and terms. Utilize online platforms and trade shows to gather insights and establish connections.

Disclaimer on Indicative Prices

Prices for X-ray machines can vary widely based on specifications, supplier relationships, and market conditions. The information provided here serves as a guideline; buyers should conduct thorough due diligence and obtain quotes from multiple manufacturers to get the best deal tailored to their needs.

Alternatives Analysis: Comparing x ray machine manufacturer With Other Solutions

Understanding the Importance of Alternatives in X-Ray Technology

When considering the procurement of an X-ray machine, it’s crucial for international B2B buyers to explore various alternatives that can meet their specific operational requirements. Each solution comes with its own set of advantages and challenges, influencing factors such as performance, cost, and implementation. This analysis will compare traditional X-ray machine manufacturers with two viable alternatives: Computed Tomography (CT) scanners and Digital Radiography (DR) systems.

Comparison Table

| Comparison Aspect | X Ray Machine Manufacturer | Computed Tomography (CT) Scanner | Digital Radiography (DR) System |

|---|---|---|---|

| Performance | High resolution imaging, quick results | Superior 3D imaging, detailed cross-sectional views | Fast imaging, real-time processing |

| Cost | High initial investment, variable maintenance costs | Higher initial cost, but versatile for multiple applications | Lower initial investment, affordable maintenance |

| Ease of Implementation | Moderate, requires training and space | Requires specialized installation and training | Easy to integrate into existing systems |

| Maintenance | Regular maintenance needed, parts can be expensive | High maintenance costs due to complexity | Low maintenance, fewer parts to manage |

| Best Use Case | General diagnostics and routine checks | Complex diagnostics, oncology, trauma | Emergency rooms, outpatient clinics |

What Are the Pros and Cons of Computed Tomography (CT) Scanners?

Computed Tomography (CT) scanners provide advanced imaging capabilities, allowing for detailed cross-sectional views of the body. This technology is especially beneficial in complex diagnostics, such as oncology and trauma cases. However, the initial investment is significantly higher than traditional X-ray machines, and ongoing maintenance can be costly due to the sophisticated nature of the equipment. Additionally, the installation process can be complex, requiring specialized training for operators.

How Does Digital Radiography (DR) Compare to Traditional X-Ray Machines?

Digital Radiography (DR) systems represent a modern alternative that offers rapid imaging and real-time processing capabilities. They are generally easier to implement and integrate into existing healthcare facilities, making them an attractive option for emergency rooms and outpatient clinics. The initial investment is typically lower than that of traditional X-ray machines, and maintenance costs are minimal due to fewer moving parts. However, the image resolution may not match that of high-end X-ray machines or CT scanners, which could limit their utility in certain diagnostic scenarios.

How to Choose the Right Solution for Your Needs

When selecting the right imaging solution, B2B buyers must consider several factors, including the specific diagnostic needs of their facility, budget constraints, and the technical capabilities of their staff. An X-ray machine may be ideal for routine diagnostics, while a CT scanner may be necessary for more complex cases. Conversely, a Digital Radiography system could serve well in high-volume environments where speed and efficiency are critical. By carefully evaluating these alternatives, buyers can make informed decisions that align with their operational goals and enhance patient care.

Essential Technical Properties and Trade Terminology for x ray machine manufacturer

What Are the Essential Technical Properties of X-Ray Machines?

Understanding the critical specifications of x-ray machines is vital for international B2B buyers. These properties not only affect the performance and durability of the equipment but also influence procurement decisions and long-term operational costs.

1. Material Grade

Material grade refers to the quality and type of materials used in the construction of x-ray machines. High-grade materials such as stainless steel or specialized alloys ensure durability and resistance to corrosion, which is particularly important in harsh environments. For B2B buyers, selecting machines made from superior materials can lead to lower maintenance costs and extended equipment lifespan.

2. Tolerance

Tolerance indicates the permissible limit of variation in a machine’s dimensions. In x-ray machines, precise tolerances are crucial for ensuring accurate imaging and reliable operation. Buyers should prioritize manufacturers that adhere to strict tolerance standards, as this can significantly impact the quality of diagnostic results and patient safety.

3. Power Output

Power output is measured in kilovolts (kV) and determines the machine’s capability to penetrate different materials. Higher power output allows for clearer images of denser objects, which is essential in medical and industrial applications. B2B buyers must consider their specific use cases when assessing power output to ensure that the equipment meets their imaging needs.

4. Imaging Resolution

Imaging resolution defines the clarity and detail of the x-ray images produced. It is typically measured in line pairs per millimeter (lp/mm). For buyers, high-resolution imaging is critical for accurate diagnosis and assessment. Investing in machines with superior imaging resolution can enhance service quality and customer satisfaction.

5. Safety Features

Safety features in x-ray machines include shielding, automatic shut-off mechanisms, and user-friendly interfaces. These elements are crucial for protecting operators and patients from unnecessary radiation exposure. B2B buyers should prioritize machines with robust safety features, as they not only comply with regulatory standards but also enhance operational safety.

Which Trade Terminology Should International B2B Buyers Understand?

Familiarity with trade terminology can streamline the purchasing process and enhance negotiations for international buyers.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or products that are used in another company’s end product. In the context of x-ray machines, it refers to manufacturers that produce machines or parts for other brands. Understanding OEM relationships can help buyers identify quality products and establish reliable supply chains.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units that a supplier is willing to sell in a single order. This term is crucial for B2B buyers, as it can affect inventory management and cost efficiency. Buyers should negotiate MOQs that align with their operational needs and financial capabilities.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. For B2B buyers, issuing an RFQ can facilitate competitive pricing and ensure that they receive the best value for their investment. It’s essential to provide clear specifications to receive accurate quotes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They outline the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms helps buyers manage logistics effectively and avoid unexpected costs, making it a critical aspect of international procurement.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. In the context of x-ray machines, lead time can vary based on manufacturing processes and shipping logistics. Buyers should inquire about lead times during negotiations to plan their operations accordingly and avoid disruptions.

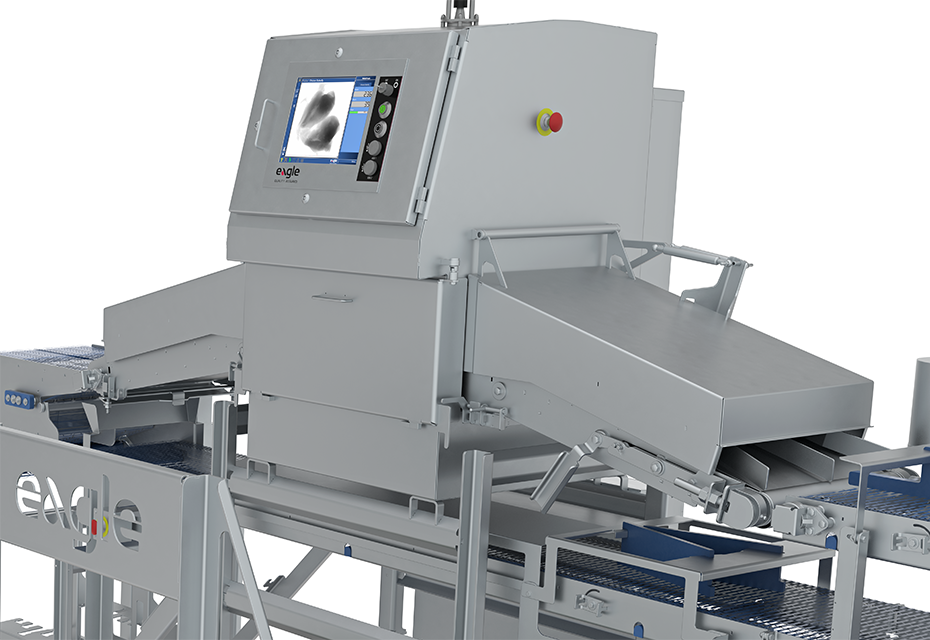

A stock image related to x ray machine manufacturer.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing x-ray machines, ensuring they select the right products that meet their operational requirements.

Navigating Market Dynamics and Sourcing Trends in the x ray machine manufacturer Sector

What Are the Key Market Dynamics and Trends in the X-Ray Machine Manufacturing Sector?

The x-ray machine manufacturing sector is experiencing significant growth driven by various global factors. Rising healthcare expenditures, particularly in developing regions such as Africa and South America, are prompting increased investments in medical infrastructure. Additionally, the ongoing advancements in imaging technology—such as digital radiography and portable x-ray systems—are reshaping buyer preferences and requirements. B2B buyers are increasingly seeking high-quality imaging solutions that enhance diagnostic capabilities while being cost-effective.

Emerging trends in the sector include the integration of artificial intelligence and machine learning in imaging processes. These technologies improve accuracy and efficiency, thereby attracting international buyers looking for cutting-edge solutions. Moreover, the COVID-19 pandemic has accelerated the demand for portable and mobile x-ray machines, allowing healthcare providers in remote areas to deliver timely diagnostic services. As a result, B2B buyers must remain agile and informed about these trends to make strategic sourcing decisions that align with evolving market dynamics.

How Is Sustainability and Ethical Sourcing Shaping the X-Ray Machine Manufacturing Sector?

Sustainability has become a critical consideration in the x-ray machine manufacturing sector. Environmental impacts associated with manufacturing processes, such as waste generation and resource depletion, are prompting buyers to prioritize suppliers with sustainable practices. Ethical sourcing is essential not only for compliance with regulations but also for enhancing brand reputation. International buyers from Africa, South America, the Middle East, and Europe are increasingly scrutinizing their supply chains to ensure they align with sustainability goals.

Buyers should look for manufacturers that utilize ‘green’ certifications, such as ISO 14001, which indicates a commitment to environmental management. Additionally, sourcing materials that are recyclable or produced through eco-friendly processes can help reduce the overall environmental footprint. By choosing suppliers that adhere to sustainable practices, B2B buyers can foster a positive impact on the planet while also meeting the expectations of socially conscious stakeholders.

How Has the X-Ray Machine Manufacturing Sector Evolved Over Time?

The x-ray machine manufacturing sector has undergone significant evolution since the discovery of x-rays in the late 19th century. Initially, machines were bulky and predominantly used in hospitals. However, advancements in technology have led to the development of compact and portable x-ray systems that cater to a broader range of healthcare settings, including rural clinics and emergency services.

In recent years, the focus has shifted towards digital imaging, which provides higher resolution and faster processing times compared to traditional film. This transition has been fueled by the increasing demand for efficient diagnostic solutions, particularly in regions with limited access to healthcare services. As a result, B2B buyers must consider the historical context of the industry to understand current innovations and anticipate future trends in x-ray machine manufacturing.

Frequently Asked Questions (FAQs) for B2B Buyers of x ray machine manufacturer

-

How do I ensure quality when sourcing X-ray machines from international manufacturers?

To ensure quality when sourcing X-ray machines, start by conducting thorough research on the manufacturer’s reputation. Look for certifications such as ISO 13485, which ensures adherence to quality management systems in medical devices. Request product samples and conduct performance evaluations. Additionally, consider third-party inspections or audits to validate manufacturing processes. Engaging with other businesses that have previously sourced from the manufacturer can provide valuable insights into quality and reliability. -

What are the key features to look for in a reliable X-ray machine manufacturer?

When evaluating an X-ray machine manufacturer, key features to consider include technological advancements, compliance with international standards, and customization capabilities. A reliable manufacturer should offer machines that are user-friendly, efficient, and equipped with the latest imaging technology. Assess their after-sales support, warranty terms, and availability of spare parts. Moreover, their experience in your specific market can be a significant advantage. -

What are the common payment terms for purchasing X-ray machines internationally?

Payment terms for purchasing X-ray machines can vary significantly by manufacturer and region. Common practices include a 30% upfront deposit with the balance due prior to shipment, or payment via Letter of Credit (LC) to secure transactions. It’s essential to clarify terms early in negotiations to avoid misunderstandings. Consider discussing flexible payment options, especially for larger orders, and always ensure that payment methods are secure to protect your investment. -

How can I verify the credibility of an X-ray machine supplier?

To verify the credibility of an X-ray machine supplier, start by checking their business credentials, including registration, certifications, and any industry awards. Seek references from previous clients to gauge their experiences. Online reviews and ratings can also offer insights into the supplier’s reliability. Additionally, visiting the manufacturer’s facility, if feasible, can provide first-hand assurance of their operations and quality control measures. -

What are the typical minimum order quantities (MOQs) for X-ray machines?

Minimum order quantities (MOQs) for X-ray machines can vary widely depending on the manufacturer and the specific model. Many manufacturers set MOQs to ensure production efficiency, often ranging from one to several units. It’s advisable to discuss your requirements directly with suppliers to negotiate MOQs that align with your needs. Some manufacturers may offer flexibility, especially for first-time buyers or in the case of custom orders. -

How do I handle logistics and shipping for X-ray machines purchased internationally?

Handling logistics for international purchases of X-ray machines involves coordinating with freight forwarders and understanding customs regulations in your country. Discuss shipping options with the manufacturer, including the Incoterms (e.g., CIF, FOB) that determine responsibilities for shipping costs and risks. Ensure that all necessary documentation, such as import permits and customs declarations, is prepared in advance to avoid delays. It’s prudent to also consider insurance for high-value equipment during transit. -

What customization options are available for X-ray machines?

Customization options for X-ray machines can include modifications in software, hardware configurations, and specific imaging capabilities tailored to your operational needs. Many manufacturers offer different models that can be adjusted based on features like image resolution, processing speed, and user interface. Discuss your specific requirements with potential suppliers to explore how they can accommodate your needs and ensure that the machine aligns with your operational workflow. -

What should I know about warranty and after-sales support for X-ray machines?

Warranty terms for X-ray machines typically cover defects in materials and workmanship for a specified period, usually ranging from one to three years. It’s crucial to understand what is included in the warranty, such as parts, labor, and service support. After-sales support is equally important; inquire about the availability of technical assistance, training for your staff, and response times for service requests. A manufacturer with robust after-sales support can significantly enhance your operational efficiency and machine longevity.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for x ray machine manufacturer

In today’s competitive landscape, strategic sourcing for X-ray machines is crucial for international buyers, especially in emerging markets such as Africa, South America, the Middle East, and Europe. Engaging with reliable manufacturers not only ensures access to cutting-edge technology but also fosters long-term partnerships that can enhance operational efficiency.

Why is Strategic Sourcing Essential for X-ray Machine Purchases?

By prioritizing strategic sourcing, buyers can leverage better pricing, superior quality, and innovation. Understanding local regulatory requirements and market dynamics can further streamline the procurement process, ensuring compliance and minimizing risks. Additionally, collaborating with manufacturers that offer robust after-sales support can significantly reduce downtime and enhance the longevity of the equipment.

What Should Buyers Consider in the Future?

As the healthcare landscape evolves, so too will the demands for advanced imaging solutions. International buyers should stay abreast of technological advancements and market trends to make informed decisions. Investing in partnerships with manufacturers who prioritize sustainability and innovation will not only fulfill current needs but also prepare for future challenges.

In conclusion, the path to successful procurement of X-ray machines lies in strategic sourcing. We encourage international B2B buyers to actively engage with manufacturers who align with their vision and values. This proactive approach will not only foster competitive advantages but also contribute to the overall improvement of healthcare delivery in their respective regions.