Discover Top Benefits of a Pharmaceutical Machinery Supplier (2025)

Introduction: Navigating the Global Market for pharmaceutical machinery supplier

Navigating the complexities of sourcing pharmaceutical machinery can pose significant challenges for international B2B buyers, especially when considering the unique regulatory environments and market dynamics across regions like Africa, South America, the Middle East, and Europe. In this guide, we delve into the essential aspects of selecting a reliable pharmaceutical machinery supplier, highlighting various types of equipment, their applications, and the critical factors to consider during the vetting process.

Understanding the nuances of supplier relationships is crucial; buyers must assess not only the machinery’s technical specifications but also the supplier’s compliance with international standards and their capacity for after-sales support. This comprehensive resource equips B2B buyers with actionable insights on cost analysis, negotiating best practices, and establishing long-term partnerships that foster operational success.

By addressing key questions such as “What are the essential criteria for evaluating pharmaceutical machinery suppliers?” and “How can I ensure compliance with local regulations?” this guide empowers businesses to make informed purchasing decisions. Whether you are in a burgeoning market in Africa or a well-established industry in Europe, our goal is to facilitate a smooth sourcing process that aligns with your operational needs and strategic objectives.

Understanding pharmaceutical machinery supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Contract Manufacturing Organizations (CMOs) | Provide outsourced manufacturing services, expertise in regulatory compliance | Drug formulation, packaging, and distribution | Pros: Cost-effective, access to expertise. Cons: Less control over processes. |

| Original Equipment Manufacturers (OEMs) | Design and produce machinery for pharmaceutical applications, often customized | Equipment for production lines, quality control | Pros: High customization, advanced technology. Cons: Higher initial investment. |

| Equipment Suppliers | Offer a range of machinery and equipment, may include new or refurbished options | General manufacturing needs, maintenance | Pros: Diverse options, competitive pricing. Cons: Varying quality standards. |

| Technology Providers | Focus on automation and software solutions for manufacturing processes | Process optimization, data management | Pros: Enhanced efficiency, real-time monitoring. Cons: Integration complexity, ongoing costs. |

| Service Providers | Provide maintenance, repair, and technical support for existing machinery | Equipment upkeep, compliance audits | Pros: Ensures operational continuity, expert support. Cons: Potentially high service costs. |

What Are Contract Manufacturing Organizations (CMOs) in the Pharmaceutical Industry?

Contract Manufacturing Organizations (CMOs) are essential partners for pharmaceutical companies looking to outsource their manufacturing processes. These organizations specialize in drug formulation, packaging, and distribution, providing expertise in navigating complex regulatory environments. B2B buyers should consider the cost-effectiveness and specialized knowledge CMOs bring to the table, but they must also weigh the potential downsides, such as reduced control over manufacturing processes.

How Do Original Equipment Manufacturers (OEMs) Differ from Other Suppliers?

Original Equipment Manufacturers (OEMs) are pivotal in the pharmaceutical machinery landscape, focusing on designing and producing specialized equipment tailored to client specifications. Their offerings often include advanced technologies that enhance production efficiency and quality control. While OEMs provide high customization options, buyers should be prepared for a higher initial investment compared to other suppliers.

Why Choose Equipment Suppliers for Pharmaceutical Machinery?

Equipment suppliers offer a diverse range of machinery, including both new and refurbished options, catering to various pharmaceutical manufacturing needs. They play a crucial role in providing cost-effective solutions for companies looking to scale their production without significant capital expenditure. However, buyers should remain vigilant about the varying quality standards across different suppliers, which can impact overall operational efficiency.

What Role Do Technology Providers Play in Pharmaceutical Machinery?

Technology providers are increasingly important in the pharmaceutical sector, focusing on automation and software solutions that optimize manufacturing processes. Their solutions often include real-time monitoring and data management systems that enhance operational efficiency. While these technologies can significantly improve productivity, B2B buyers must consider the complexity of integration and the ongoing costs associated with technology updates and maintenance.

How Can Service Providers Support Pharmaceutical Machinery Operations?

Service providers specialize in the maintenance, repair, and technical support of pharmaceutical machinery, ensuring operational continuity and compliance with industry regulations. They are vital for companies looking to maintain their equipment in peak condition, thus avoiding costly downtimes. However, buyers should be aware of the potentially high service costs and ensure they choose providers with a strong track record of reliability and expertise.

Related Video: 5 AWESOME MEDICINE MAKING MACHINERY IN PHARMACEUTICAL INDUSTRY

Key Industrial Applications of pharmaceutical machinery supplier

| Industry/Sector | Specific Application of Pharmaceutical Machinery Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Tablet Compression Machines | Increased production efficiency and consistent quality | Compliance with GMP standards, machine capacity |

| Biotechnology | Fermentation Equipment | Enhanced yield in drug production | Material compatibility, scalability, and automation |

| Nutraceuticals | Powder Mixing Equipment | Improved product formulation and consistency | Supplier reliability, customization options |

| Cosmetics | Filling and Sealing Machines | Streamlined packaging processes and reduced waste | Precision in dosing, adaptability to different products |

| Veterinary Medicine | Blister Packaging Machines | Extended shelf life and improved product safety | Regulatory compliance, material sourcing |

How is Pharmaceutical Machinery Used in the Pharmaceutical Industry?

In the pharmaceutical sector, tablet compression machines are essential for producing solid dosage forms. These machines enable manufacturers to produce high volumes of tablets with precise dosage and uniformity, addressing challenges related to variability in weight and content. International buyers should ensure that suppliers adhere to Good Manufacturing Practices (GMP) and can provide equipment that meets their specific production capacities and quality standards.

What Role Does Fermentation Equipment Play in Biotechnology?

Fermentation equipment is critical in biotechnology for the production of biopharmaceuticals, including vaccines and monoclonal antibodies. These systems enhance the yield by optimizing the growth conditions for microorganisms. Buyers from regions like Africa and South America should focus on suppliers that offer scalable solutions and can customize the equipment to fit specific microbial strains and production processes, ensuring a competitive edge in the market.

How is Powder Mixing Equipment Beneficial for Nutraceuticals?

In the nutraceutical industry, powder mixing equipment is used to blend various ingredients to create supplements with consistent quality. The machinery helps to solve issues related to ingredient segregation and uneven distribution. When sourcing this equipment, businesses should consider the reliability of the supplier and whether they can offer tailored solutions that meet specific formulation needs, especially for unique regional ingredients.

Why are Filling and Sealing Machines Important for Cosmetics?

Filling and sealing machines streamline the packaging process for cosmetic products, ensuring accuracy in dosing and reducing material waste. This is particularly important for brands aiming to maintain sustainability while meeting consumer demand. Buyers should look for machinery that is adaptable to different product types and can comply with the varying regulations across different markets, particularly in Europe and the Middle East.

How Do Blister Packaging Machines Enhance Veterinary Medicine?

In veterinary medicine, blister packaging machines are used to package medications securely, extending their shelf life and ensuring product safety. This is crucial for maintaining the efficacy of veterinary drugs in diverse climates, particularly in regions with high temperatures like parts of Africa and the Middle East. Buyers should prioritize suppliers who understand the regulatory requirements and can provide materials that are compatible with veterinary applications.

Related Video: Learn the names of chemistry laboratory equipments and their uses

3 Common User Pain Points for ‘pharmaceutical machinery supplier’ & Their Solutions

Scenario 1: Navigating Complex Compliance Regulations in Machinery Sourcing

The Problem:

B2B buyers in the pharmaceutical sector often face the daunting challenge of navigating complex compliance regulations when sourcing machinery. Each country has its own standards for safety, quality, and efficacy. For instance, a buyer in South America may struggle to align their procurement process with both local regulations and international standards like Good Manufacturing Practices (GMP). This confusion can lead to delays in procurement, risk of non-compliance, and potential financial penalties.

The Solution:

To effectively manage compliance requirements, buyers should start by conducting thorough research on the specific regulations applicable in their region and industry. Engaging with local regulatory bodies or industry associations can provide valuable insights. Additionally, when sourcing from suppliers, request documentation that outlines their compliance with relevant standards, such as ISO certifications or FDA approvals. Developing a checklist that includes necessary compliance documents will streamline the evaluation process. Furthermore, establishing a close relationship with the machinery supplier can facilitate ongoing support regarding compliance updates, ensuring that your operations remain aligned with regulatory changes.

Scenario 2: Overcoming Machinery Downtime Due to Technical Failures

The Problem:

Technical failures in pharmaceutical machinery can lead to significant downtime, which directly impacts production schedules and revenue. Buyers often find themselves in a predicament where the machinery they invested in does not perform as expected or requires frequent repairs, causing delays in product delivery and dissatisfaction among stakeholders.

The Solution:

To mitigate the risk of machinery downtime, it is crucial for buyers to conduct a comprehensive assessment of the supplier’s technical support and maintenance offerings before making a purchase. Look for suppliers who provide robust after-sales support, including regular maintenance schedules and access to spare parts. Establishing a service-level agreement (SLA) with the supplier that guarantees timely support and repair services can also be beneficial. Additionally, investing in training for staff on how to properly operate and maintain machinery can reduce the likelihood of operator-induced errors that lead to breakdowns. Regularly scheduled maintenance checks should be part of the operational plan to preemptively address any potential issues.

Scenario 3: Addressing the Challenge of Customization and Scalability

The Problem:

As pharmaceutical companies grow, their machinery needs often evolve. Buyers may face challenges when existing machinery is unable to scale up or adapt to new product lines or processes. This can be particularly frustrating for companies looking to innovate or expand into new markets, as they may find themselves constrained by outdated equipment.

The Solution:

When sourcing pharmaceutical machinery, buyers should prioritize suppliers that offer customizable solutions. Engage in detailed discussions about your current and future production needs during the procurement process. Request case studies or examples of how the supplier has successfully adapted their machinery for other clients. Ensure that the machinery can be easily upgraded or modified, rather than requiring a complete replacement. Also, consider suppliers who offer modular machinery designs, allowing for gradual scalability without large upfront investments. Finally, keep a clear line of communication open with the supplier to facilitate adjustments as your production requirements change over time, ensuring long-term compatibility and flexibility.

Strategic Material Selection Guide for pharmaceutical machinery supplier

What Are the Key Materials Used in Pharmaceutical Machinery?

When selecting materials for pharmaceutical machinery, it is essential to consider properties such as temperature and pressure ratings, corrosion resistance, and compatibility with various media. The following analysis highlights four common materials used in this sector, focusing on their properties, pros and cons, and specific considerations for international B2B buyers.

How Does Stainless Steel Perform in Pharmaceutical Machinery?

Key Properties:

Stainless steel is known for its excellent corrosion resistance and high-temperature tolerance, making it ideal for a variety of pharmaceutical applications. It typically withstands temperatures up to 800°F (427°C) and pressures that can reach 1500 psi, depending on the grade.

Pros & Cons:

The durability of stainless steel is a significant advantage, as it can withstand harsh cleaning processes and resist contamination. However, it can be costly, especially for high-grade alloys like 316L, which are often required for pharmaceutical applications.

Impact on Application:

Stainless steel is compatible with a wide range of media, including corrosive substances, making it suitable for various processes in pharmaceutical production. Its non-reactive nature ensures that it does not leach harmful substances into products.

Considerations for International Buyers:

Buyers from regions like Africa, South America, the Middle East, and Europe should ensure compliance with international standards such as ASTM A240 and DIN 17440. Additionally, understanding local regulations regarding material sourcing and environmental impact is crucial.

What Role Does Glass Play in Pharmaceutical Machinery?

Key Properties:

Glass is highly resistant to chemical corrosion and can withstand high temperatures, making it suitable for applications involving reactive substances. It can typically endure temperatures up to 500°F (260°C).

Pros & Cons:

The primary advantage of glass is its inertness; it does not react with most chemicals, ensuring product purity. However, glass is brittle and can break easily, posing risks in high-pressure environments.

Impact on Application:

Glass is often used in laboratory settings and for storage containers, where contamination must be minimized. Its transparency allows for easy monitoring of contents, which is beneficial for quality control.

Considerations for International Buyers:

International buyers should be aware of the standards for glass used in pharmaceutical applications, such as USP and ISO regulations. Ensuring that suppliers meet these standards is vital for compliance and safety.

How Does Plastic Compare in Pharmaceutical Machinery?

Key Properties:

Plastics, particularly high-performance polymers like PTFE and PEEK, offer excellent chemical resistance and can operate at temperatures up to 500°F (260°C). They are also lightweight and flexible.

Pros & Cons:

The main advantage of plastics is their versatility and lower cost compared to metals. However, they may not be suitable for high-pressure applications and can degrade over time when exposed to certain chemicals.

Impact on Application:

Plastics are commonly used for components that require flexibility or electrical insulation, such as seals and gaskets. Their compatibility with various media makes them popular in diverse pharmaceutical processes.

Considerations for International Buyers:

Buyers should verify that the plastics used comply with FDA regulations and relevant international standards. Understanding the specific chemical compatibility of plastics with the intended media is also critical.

What About Titanium in Pharmaceutical Machinery?

Key Properties:

Titanium is known for its exceptional strength-to-weight ratio and excellent corrosion resistance, particularly in aggressive environments. It can withstand temperatures up to 1,600°F (871°C) and high pressures.

Pros & Cons:

Titanium’s main advantage is its durability and ability to resist corrosion, making it ideal for long-term use in harsh conditions. However, it is one of the more expensive materials, which can impact overall project budgets.

Impact on Application:

Due to its strength and resistance to corrosion, titanium is often used in critical components of pharmaceutical machinery, such as valves and pumps. Its non-reactive nature ensures that it does not contaminate products.

Considerations for International Buyers:

International buyers should be aware of the specific grades of titanium required for pharmaceutical use, such as Grade 2 and Grade 5. Compliance with standards like ASTM B348 and ISO 5832 is essential for ensuring material quality.

Summary Table of Material Selection for Pharmaceutical Machinery

| Material | Typical Use Case for pharmaceutical machinery supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Tanks, pipes, and valves | Excellent corrosion resistance | High cost for premium grades | High |

| Glass | Storage containers, laboratory equipment | Inert and non-reactive | Brittle and prone to breakage | Medium |

| Plastic | Seals, gaskets, and flexible components | Versatile and cost-effective | Limited high-pressure applications | Low |

| Titanium | Critical components like valves and pumps | Exceptional strength and durability | High cost | High |

This strategic material selection guide provides international B2B buyers with essential insights into the materials used in pharmaceutical machinery, helping them make informed decisions that align with their operational needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for pharmaceutical machinery supplier

What Are the Key Manufacturing Processes for Pharmaceutical Machinery Suppliers?

When selecting a pharmaceutical machinery supplier, understanding the manufacturing processes involved is crucial. The production of pharmaceutical machinery typically involves several key stages, which ensure that the final products meet the stringent requirements of the pharmaceutical industry.

1. Material Preparation: How Are Raw Materials Processed?

The first stage in the manufacturing process is material preparation. This involves sourcing and preparing raw materials that meet the specifications required for pharmaceutical machinery. Suppliers often use materials such as stainless steel, plastics, and advanced alloys, which must comply with industry standards to avoid contamination and ensure durability.

- Key Techniques: Common techniques include cutting, machining, and surface treatment. These processes help in achieving the precise dimensions and finishes necessary for the components used in pharmaceutical equipment.

2. Forming: What Techniques Are Used to Shape Components?

The forming stage is where raw materials are transformed into usable parts. This can involve various methods such as casting, forging, and molding.

- Casting: This involves pouring molten material into molds to create complex shapes.

- Forging: Used for creating strong components, forging involves shaping metal through compressive forces.

- Molding: Particularly important for plastic parts, this process shapes materials under heat and pressure.

Each method must be chosen based on the requirements of the final product, as they significantly impact the machinery’s performance and reliability.

3. Assembly: How Are Components Brought Together?

Once individual parts are manufactured, they undergo assembly. This stage is critical as it integrates various components into a functioning machine.

- Assembly Techniques: Suppliers may utilize manual assembly, automated assembly lines, or a combination of both. Automated systems improve consistency and speed, while manual assembly allows for greater oversight and quality control.

During assembly, suppliers must ensure that all components fit precisely and function as intended, as any defects can lead to operational failures.

4. Finishing: What Processes Ensure Quality and Aesthetics?

The finishing stage enhances both the performance and appearance of the machinery. This can include processes such as polishing, coating, and painting.

- Quality Coatings: These are applied to prevent corrosion and improve hygiene, which is particularly important in pharmaceutical settings. Coatings must be compatible with the materials used and meet regulatory standards.

The finishing process not only improves the product’s aesthetics but also its functional longevity, making it a vital step in manufacturing.

How Is Quality Assurance Implemented in Pharmaceutical Machinery Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process for pharmaceutical machinery suppliers. It ensures that products meet both international standards and specific industry requirements.

1. What International Standards Should B2B Buyers Be Aware Of?

Pharmaceutical machinery suppliers typically adhere to several international standards, which provide a framework for quality management:

- ISO 9001: This standard focuses on quality management systems and is applicable across industries, including pharmaceuticals. It emphasizes a process-oriented approach to improve customer satisfaction and operational efficiency.

- CE Marking: For suppliers targeting the European market, CE marking is essential as it indicates conformity with health, safety, and environmental protection standards.

- API Standards: These standards are specifically relevant to active pharmaceutical ingredients and ensure that equipment used in their production is safe and reliable.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are crucial in identifying defects at various stages of manufacturing. Common QC checkpoints include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help catch any defects early, allowing for corrective measures to be taken immediately.

- Final Quality Control (FQC): Before shipment, the completed machinery undergoes rigorous testing to ensure it meets all specifications and performance standards.

3. What Testing Methods Are Commonly Used?

To verify quality, suppliers employ various testing methods, including:

- Functional Testing: Ensures that all machinery components operate correctly.

- Stress Testing: Assesses how machinery performs under extreme conditions.

- Visual Inspection: A thorough examination of the machinery’s appearance and construction to identify any visible defects.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

For B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance processes is essential before making procurement decisions.

1. What Should Buyers Look for in Supplier Audits?

Buyers should request detailed audits of the supplier’s manufacturing processes and quality control systems. Key areas to focus on include:

- Compliance with International Standards: Ensure that suppliers have certifications like ISO 9001 or CE marking.

- Documentation of Quality Control Processes: This includes records of inspections, testing results, and corrective actions taken.

2. How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can provide additional assurance of the supplier’s quality processes. These independent audits help verify compliance with industry standards and can highlight areas for improvement that the supplier may need to address.

3. What Nuances Should International Buyers Consider?

International buyers should be aware of regulatory nuances that may vary by region. For instance, certain countries may have specific requirements for the pharmaceutical industry that go beyond standard certifications. Understanding these regulations is crucial for ensuring that machinery is compliant and can be effectively integrated into local operations.

Conclusion

In-depth knowledge of manufacturing processes and quality assurance is essential for international B2B buyers in the pharmaceutical machinery sector. By understanding the stages of production and the importance of quality control, buyers can make informed decisions, ensuring that they partner with suppliers who prioritize excellence and compliance. This not only enhances operational efficiency but also mitigates risks associated with non-compliance and machinery failures.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pharmaceutical machinery supplier’

In the global pharmaceutical industry, sourcing machinery requires careful consideration and strategic planning. This checklist serves as a practical guide for B2B buyers from Africa, South America, the Middle East, and Europe who are looking to procure pharmaceutical machinery effectively and efficiently.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of successful procurement. Understand the type of machinery needed—whether it’s for tablet compression, liquid filling, or packaging—and outline the specific requirements such as capacity, dimensions, and compliance with local regulations. This will help you communicate effectively with suppliers and ensure you receive appropriate machinery that meets your operational needs.

Step 2: Conduct Market Research

Invest time in researching potential suppliers in the pharmaceutical machinery market. Look for companies with a proven track record in your specific machinery type and geographic region. Utilize online directories, trade shows, and industry forums to gather information and reviews. This step is crucial to identify reputable suppliers and understand market trends that could influence pricing and availability.

Step 3: Evaluate Supplier Certifications

Certifications are essential indicators of a supplier’s credibility and product quality. Verify that potential suppliers hold relevant certifications, such as ISO 9001 for quality management or specific certifications related to pharmaceutical manufacturing (e.g., cGMP). This not only ensures compliance with industry standards but also enhances your confidence in their machinery.

Step 4: Request Detailed Proposals

Once you have shortlisted potential suppliers, request detailed proposals that outline machinery specifications, pricing, delivery timelines, and after-sales support. A comprehensive proposal allows for easier comparison between suppliers and helps clarify any ambiguities regarding the machinery’s capabilities and support services. Ensure that the proposal includes terms of warranty and service agreements.

Step 5: Visit Supplier Facilities (if possible)

If feasible, plan a visit to the supplier’s manufacturing facilities. This firsthand experience allows you to assess the production processes, quality control measures, and the overall operational environment. Observing the machinery in action can provide insights into its performance and reliability, as well as the supplier’s commitment to quality.

Step 6: Check References and Customer Feedback

Before finalizing your choice, request references from other clients who have purchased similar machinery from the supplier. Reach out to these contacts to gain insights into their experiences regarding the machinery’s performance, supplier responsiveness, and after-sales support. Customer feedback is invaluable for making an informed decision and avoiding potential pitfalls.

Step 7: Negotiate Terms and Finalize the Contract

After selecting a supplier, enter negotiations to finalize pricing, delivery schedules, and payment terms. Ensure that all aspects of the agreement, including warranties and service provisions, are clearly documented in the contract. A well-negotiated contract protects your interests and sets clear expectations for both parties.

By following this checklist, B2B buyers can navigate the complex landscape of pharmaceutical machinery procurement with greater confidence and clarity, ensuring they make well-informed decisions that align with their operational goals.

Comprehensive Cost and Pricing Analysis for pharmaceutical machinery supplier Sourcing

What Are the Key Cost Components in Pharmaceutical Machinery Sourcing?

When sourcing pharmaceutical machinery, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The quality and type of materials used significantly influence the price. High-grade materials, essential for compliance with pharmaceutical standards, can increase costs. Always verify the specifications of materials against your requirements.

-

Labor: Labor costs can vary by region. Countries with higher wage standards may have higher production costs, affecting the overall pricing. It’s essential to assess whether the labor force has the necessary expertise in pharmaceutical manufacturing.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and administrative expenses. Understanding the overhead can help buyers gauge the reasonableness of a supplier’s pricing.

-

Tooling: Custom machinery often requires specialized tooling. The costs associated with creating these tools can be significant, especially for bespoke machinery tailored to specific manufacturing processes.

-

Quality Control (QC): Given the critical nature of pharmaceutical production, rigorous QC measures are mandatory. Suppliers will factor in the costs of testing and certification into their pricing.

-

Logistics: Transportation and warehousing costs can vary widely based on distance and the complexity of delivery. For international buyers, understanding shipping costs and potential tariffs is vital.

-

Margin: Suppliers will include their profit margin in the pricing. This can vary based on market conditions and the competitive landscape.

How Do Price Influencers Affect Pharmaceutical Machinery Costs?

Several factors can influence the pricing of pharmaceutical machinery:

-

Volume/MOQ: Larger orders often come with discounts, so consider negotiating minimum order quantities (MOQ) to lower per-unit costs.

-

Specifications and Customization: Customized machinery incurs additional costs due to the need for specialized engineering and production processes. Be clear about your requirements upfront to avoid unexpected charges.

-

Materials: The choice of materials will impact both the initial cost and long-term maintenance expenses. Discuss options with suppliers to find a balance between quality and cost.

-

Quality and Certifications: Compliance with international standards (like ISO or GMP) is critical in the pharmaceutical industry. Higher certification levels often lead to higher prices, but they also ensure safety and reliability.

-

Supplier Factors: Established suppliers may charge more due to their reputation and reliability. However, newer suppliers might offer competitive prices to build their portfolio. Assess the trade-offs between cost and reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for determining responsibility for shipping costs and risks. This can significantly affect the total cost of ownership.

What Are Some Effective Buyer Tips for Negotiating Pharmaceutical Machinery Prices?

Navigating the pricing landscape of pharmaceutical machinery requires strategic negotiation and a keen understanding of total costs. Here are some actionable tips:

-

Negotiate Terms: Always negotiate payment terms, delivery schedules, and warranty conditions. Suppliers may be flexible on price if they can secure a long-term contract.

-

Assess Total Cost of Ownership (TCO): Beyond the purchase price, consider maintenance, operation, and potential downtime costs. A lower initial price may lead to higher long-term expenses.

-

Leverage Market Research: Conduct thorough market research to understand pricing trends and competitor offers. This information can strengthen your negotiation position.

-

Be Clear About Specifications: Clearly define machinery specifications and requirements in your RFQ (Request for Quotation). This reduces the risk of misunderstandings and unexpected costs later.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing from local suppliers may reduce logistics costs and lead times. However, ensure they meet international standards.

-

Be Aware of Pricing Nuances: International buyers should be conscious of currency fluctuations, import duties, and taxes that can influence the final cost.

Disclaimer on Indicative Prices

Prices for pharmaceutical machinery can vary widely based on the specific requirements and market conditions. The information provided here is indicative and should be confirmed with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing pharmaceutical machinery supplier With Other Solutions

When considering the procurement of pharmaceutical machinery, it’s vital to explore alternative solutions that may provide similar functionalities or even enhance operational efficiency. This analysis will compare the traditional pharmaceutical machinery supplier against alternative solutions, helping international B2B buyers from regions such as Africa, South America, the Middle East, and Europe make informed decisions.

Comparison Table of Pharmaceutical Machinery Supplier and Alternatives

| Comparison Aspect | Pharmaceutical Machinery Supplier | Alternative 1: Contract Manufacturing Organizations (CMOs) | Alternative 2: Automated Robotic Systems |

|---|---|---|---|

| Performance | High precision and reliability | Varies; often high for established CMOs | High speed and accuracy |

| Cost | Higher initial investment | Generally lower upfront costs, but ongoing fees apply | Moderate initial investment, variable ROI |

| Ease of Implementation | Requires training and installation | Quick to engage but may involve complex contracts | Requires programming and setup |

| Maintenance | Regular maintenance required | Maintenance handled by CMO | Minimal, but requires technical expertise |

| Best Use Case | In-house production for quality | Outsourcing production to save costs and time | High-volume, repetitive tasks |

What Are the Pros and Cons of Contract Manufacturing Organizations (CMOs)?

Contract Manufacturing Organizations (CMOs) serve as an alternative for companies looking to outsource their pharmaceutical production. One of the main advantages is the cost-effectiveness; CMOs eliminate the need for significant capital investment in machinery. They also provide flexibility in scaling production up or down based on demand. However, relying on a CMO can lead to concerns about quality control and intellectual property security. Additionally, the time taken to establish contracts and partnerships can delay production timelines.

How Do Automated Robotic Systems Compare in the Pharmaceutical Industry?

Automated robotic systems are increasingly being utilized for pharmaceutical manufacturing due to their ability to perform repetitive tasks with high speed and precision. These systems can significantly increase throughput and reduce human error, making them an attractive choice for high-volume production. However, the initial investment can be substantial, and the setup process may require specialized knowledge. Moreover, while robots excel in repetitive tasks, they may lack the flexibility needed for diverse product lines, which can be a limitation in dynamic production environments.

Conclusion: How to Choose the Right Pharmaceutical Machinery Solution

Selecting the right solution for pharmaceutical manufacturing depends on various factors, including production volume, budget, and specific operational needs. For companies prioritizing quality and control, investing in a pharmaceutical machinery supplier may be the best route. Conversely, businesses looking for cost efficiency and flexibility may find that partnering with a CMO suits their needs better. Automated robotic systems can be ideal for those aiming for high efficiency in repetitive tasks. Ultimately, B2B buyers must weigh their unique requirements against the advantages and limitations of each option to make an informed choice that aligns with their strategic objectives.

Essential Technical Properties and Trade Terminology for pharmaceutical machinery supplier

What Are the Essential Technical Properties of Pharmaceutical Machinery?

Understanding the technical properties of pharmaceutical machinery is crucial for B2B buyers, especially when sourcing equipment that meets regulatory standards and operational needs. Here are some critical specifications to consider:

1. Material Grade: Why Is It Important?

The material grade of pharmaceutical machinery often dictates its durability, resistance to corrosion, and compliance with hygiene standards. Common materials include stainless steel, which offers excellent resistance to rust and is easy to clean. Buyers should assess the material grade to ensure it aligns with the specific requirements of their production processes, especially in sterile environments.

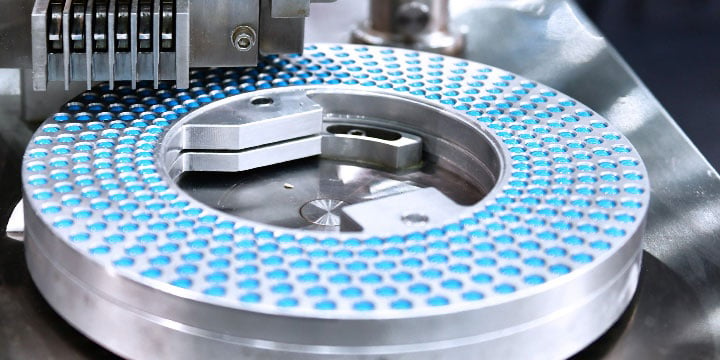

A stock image related to pharmaceutical machinery supplier.

2. Tolerance: How Does It Affect Performance?

A stock image related to pharmaceutical machinery supplier.

Tolerance refers to the permissible limit or limits of variation in a physical dimension. In pharmaceutical manufacturing, precise tolerances are essential to ensure that machines operate efficiently and produce consistent results. A small deviation can lead to significant quality issues in drug production, making it vital for suppliers to provide detailed tolerance specifications.

3. Throughput Capacity: What Should You Know?

Throughput capacity indicates the maximum amount of product that a machine can process in a given time frame. This is a critical factor for buyers who need to meet production targets. Understanding a machine’s throughput helps in evaluating whether it can accommodate current and future production demands, influencing purchasing decisions significantly.

4. Cleanability: Why Is It a Key Factor?

Cleanability refers to how easily a machine can be cleaned and sanitized. In the pharmaceutical industry, maintaining strict hygiene standards is non-negotiable. Equipment that is designed with smooth surfaces, minimal joints, and accessible components will help ensure compliance with Good Manufacturing Practices (GMP). Buyers should prioritize machines that facilitate easy cleaning to reduce downtime and avoid contamination risks.

5. Automation Level: How Does It Impact Efficiency?

The level of automation in pharmaceutical machinery can greatly affect operational efficiency and labor costs. Automated machines reduce the need for manual intervention, leading to increased production speeds and lower error rates. Buyers should evaluate their operational needs and consider how much automation is necessary to optimize their processes.

What Are Common Trade Terminology and Their Significance in Pharmaceutical Machinery Procurement?

Familiarity with industry jargon can significantly streamline the procurement process. Here are some essential terms:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the pharmaceutical machinery sector, working with OEMs ensures that buyers receive high-quality equipment tailored to their specifications. Understanding the role of OEMs helps buyers make informed decisions about sourcing and compatibility.

2. MOQ (Minimum Order Quantity): How Does It Affect Purchasing?

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for international buyers as it can impact inventory management and cash flow. Understanding MOQs helps businesses plan their purchases more effectively, ensuring they meet production needs without overcommitting resources.

3. RFQ (Request for Quotation): Why Is It Important?

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. It is vital for buyers to clearly outline their requirements in an RFQ to receive accurate and competitive pricing. This process aids in comparing different suppliers and making cost-effective decisions.

4. Incoterms: What Do They Cover?

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms is essential for international B2B transactions, as they clarify who pays for shipping, insurance, and customs duties. Understanding these terms helps buyers mitigate risks and avoid unexpected costs.

5. GMP (Good Manufacturing Practices): Why Should You Comply?

GMP refers to the practices that ensure products are consistently produced and controlled according to quality standards. Compliance with GMP is mandatory in the pharmaceutical industry, affecting the choice of machinery and suppliers. Buyers should ensure that their suppliers adhere to GMP to maintain product quality and regulatory compliance.

By understanding these technical properties and trade terminologies, international B2B buyers can navigate the complexities of sourcing pharmaceutical machinery more effectively, ensuring compliance and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the pharmaceutical machinery supplier Sector

What Are the Current Market Dynamics and Key Trends Affecting Pharmaceutical Machinery Suppliers?

The global pharmaceutical machinery market is evolving rapidly, driven by several key factors. One of the primary drivers is the increasing demand for high-quality pharmaceuticals, which necessitates advanced machinery capable of meeting stringent regulatory requirements. Innovations in technology, particularly automation and Industry 4.0, are shaping the landscape by enhancing production efficiency and reducing human error. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly seeking suppliers who can provide cutting-edge machinery that integrates these technologies.

Emerging trends include the rise of personalized medicine, which requires flexible manufacturing processes. This trend is prompting suppliers to develop modular and scalable machinery that can adapt to varying production needs. Additionally, the ongoing emphasis on cost-efficiency is pushing buyers to explore suppliers that offer value-added services, such as maintenance and training, alongside their equipment. Buyers should pay attention to regional market dynamics as well; for instance, the Middle East is seeing a surge in pharmaceutical investments, while Europe is focusing on sustainability and compliance with the EU’s Green Deal.

How Can Sustainability and Ethical Sourcing Influence B2B Decisions in the Pharmaceutical Machinery Sector?

Sustainability is becoming a pivotal factor for international B2B buyers in the pharmaceutical machinery sector. The environmental impact of production processes is under scrutiny, and companies are increasingly held accountable for their carbon footprints. Buyers are encouraged to prioritize suppliers who adopt sustainable practices, such as using energy-efficient machinery and minimizing waste during production.

Ethical sourcing is equally vital, as it ensures that materials used in manufacturing machinery are obtained responsibly. Suppliers who can provide transparency in their supply chains, coupled with certifications for environmentally friendly materials, are likely to gain a competitive edge. Certifications such as ISO 14001 (Environmental Management) and EMAS (Eco-Management and Audit Scheme) are indicators of a supplier’s commitment to sustainability. By choosing suppliers with such credentials, international buyers not only enhance their own brand reputation but also align with global sustainability goals.

What is the Evolution of the Pharmaceutical Machinery Supplier Sector?

The pharmaceutical machinery supplier sector has undergone significant transformation over the past few decades. Initially characterized by manual processes, the industry has shifted towards automation and digitalization, driven by the need for higher efficiency and precision. The introduction of Computerized Numerical Control (CNC) machines in the 1980s marked a turning point, enabling manufacturers to produce complex components with minimal human intervention.

As regulatory requirements became more stringent, suppliers adapted by incorporating advanced technologies such as real-time monitoring and data analytics into their machinery. This evolution has not only improved compliance but also facilitated the shift towards personalized medicine, allowing for greater flexibility in manufacturing processes. As the market continues to evolve, the focus on sustainability and ethical sourcing will shape the future of pharmaceutical machinery suppliers, creating new opportunities and challenges for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of pharmaceutical machinery supplier

-

How do I choose the right pharmaceutical machinery supplier for my business needs?

Selecting the right pharmaceutical machinery supplier involves evaluating their industry experience, product range, and customer service. Look for suppliers with a proven track record in your specific market, such as Africa, South America, or the Middle East. Request case studies or references from similar businesses to gauge reliability. Additionally, assess their capacity for customization to meet your specific production requirements. A supplier’s willingness to provide technical support and training is also crucial for ensuring seamless integration and operation of machinery. -

What are the key factors to consider when evaluating pharmaceutical machinery quality?

Quality evaluation of pharmaceutical machinery should focus on compliance with international standards such as ISO and cGMP. Inspect the materials used in manufacturing to ensure durability and resistance to corrosion, which is vital in pharmaceutical applications. Additionally, review the machine’s performance metrics, including efficiency, speed, and accuracy. Requesting documentation related to quality assurance processes, along with certifications, can provide further assurance of the machinery’s reliability and safety. -

What are the typical payment terms offered by pharmaceutical machinery suppliers?

Payment terms can vary significantly among suppliers. Common arrangements include upfront deposits, milestone payments, or full payment upon delivery. For international transactions, it’s prudent to negotiate terms that mitigate risk, such as using letters of credit or escrow services. Ensure that the payment structure aligns with your cash flow cycle. It’s also important to clarify the currency used and any potential fees associated with currency conversion or international transfers. -

What should I know about the minimum order quantities (MOQ) for pharmaceutical machinery?

Minimum order quantities (MOQ) can vary widely between suppliers and types of machinery. Some suppliers may require MOQs to ensure cost-effectiveness, while others may be more flexible, especially for first-time buyers. When negotiating, consider your production needs and storage capabilities. If you’re uncertain about committing to high MOQs, inquire about sample orders or pilot projects that can help you evaluate the machinery’s performance before making a larger investment. -

How can I ensure effective logistics and delivery for my pharmaceutical machinery?

Effective logistics planning is crucial for the timely delivery of pharmaceutical machinery. Discuss shipping methods with your supplier, considering air freight for expedited needs or sea freight for larger shipments. Understand the customs regulations in your country to avoid delays. It’s also wise to choose a supplier who offers logistics support, including tracking services. Establish clear timelines for delivery and inspect the machinery upon arrival to ensure it meets your specifications. -

What are the customization options available for pharmaceutical machinery?

Customization options can range from software adjustments to physical modifications of machinery. Discuss your specific production requirements with potential suppliers to understand their capabilities. Many suppliers offer tailored solutions that can enhance efficiency or adapt to unique product specifications. Ensure that any customization is compliant with industry regulations and standards. Request prototypes or CAD drawings to visualize how the modifications will impact your production line. -

How do I assess the technical support and after-sales service provided by suppliers?

Assessing technical support and after-sales service begins with direct communication with suppliers. Inquire about the availability of support teams, response times, and the types of assistance offered, such as installation, training, and maintenance. Evaluate their warranty policies and the ease of obtaining spare parts. A supplier that prioritizes customer service can significantly impact your operations, ensuring that any issues are resolved quickly to minimize downtime. -

What regulations should I be aware of when importing pharmaceutical machinery?

When importing pharmaceutical machinery, it’s essential to familiarize yourself with both local and international regulations. Check for compliance with health and safety standards, as well as certifications required by your government. Each country may have specific import regulations, including tariffs, taxes, and documentation requirements. Engage with customs brokers or legal experts who specialize in international trade to navigate these complexities effectively and ensure a smooth import process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pharmaceutical machinery supplier

In the evolving landscape of pharmaceutical manufacturing, strategic sourcing is not merely a procurement function but a vital component of operational excellence. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, must recognize the importance of partnering with reliable pharmaceutical machinery suppliers who understand local market dynamics and regulatory requirements.

What Are the Key Takeaways for B2B Buyers in Pharmaceutical Machinery?

By focusing on strategic sourcing, buyers can mitigate risks associated with supply chain disruptions, ensure compliance with international standards, and enhance product quality through advanced machinery. Engaging with suppliers that offer innovative solutions tailored to specific needs can lead to cost efficiencies and improved time-to-market for pharmaceutical products.

How Can Buyers Prepare for Future Trends in Pharmaceutical Machinery?

As the industry moves towards automation and digitalization, B2B buyers should prioritize suppliers who are not only technologically adept but also committed to sustainable practices. A proactive approach in evaluating supplier capabilities and aligning them with future trends will be crucial for maintaining a competitive edge.

In conclusion, the future of pharmaceutical machinery sourcing is promising, with significant opportunities for those who strategically engage in the market. Now is the time for international buyers to leverage these insights and build partnerships that drive innovation and growth in their operations.