Discover Top Benefits of a Plastic Bag Manufacturer (2025)

Introduction: Navigating the Global Market for plastic bag manufacturer

Navigating the global market for plastic bag manufacturing presents a unique set of challenges for B2B buyers, especially when sourcing sustainable and cost-effective solutions. The increasing demand for eco-friendly alternatives and compliance with various regulations can make it difficult to identify the right supplier. This comprehensive guide serves as your roadmap, detailing the diverse types of plastic bags available, their applications across different industries, and essential criteria for vetting suppliers.

As an international B2B buyer from regions such as Africa, South America, the Middle East, or Europe, you will gain insights into pricing structures, quality assessments, and the latest innovations in plastic bag manufacturing. Whether you are looking for biodegradable options, custom designs, or bulk purchasing strategies, this guide empowers you to make informed decisions that align with both your operational needs and environmental goals.

By understanding the landscape of the plastic bag industry, you can confidently navigate supplier negotiations, optimize your purchasing strategy, and enhance your supply chain efficiency. Equip yourself with the knowledge to choose suppliers who not only meet your specifications but also contribute to a sustainable future.

Understanding plastic bag manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| HDPE Bags | Made from high-density polyethylene; strong and durable. | Retail, grocery, packaging. | Pros: Cost-effective, recyclable. Cons: Limited barrier properties. |

| LDPE Bags | Flexible and lightweight; low-density polyethylene. | Food packaging, industrial uses. | Pros: Excellent clarity, moisture-resistant. Cons: Less strength than HDPE. |

| Biodegradable Bags | Made from materials that break down naturally. | Eco-friendly retail, grocery. | Pros: Environmentally friendly, compliance with regulations. Cons: Generally higher cost. |

| Woven Polypropylene Bags | Durable, reusable, and breathable fabric-like structure. | Agriculture, bulk packaging. | Pros: Strong, suitable for heavy loads. Cons: Higher initial investment. |

| Custom Printed Bags | Tailored designs and branding options. | Marketing, promotional events. | Pros: Enhances brand visibility. Cons: Longer lead times and potentially higher costs. |

What Are HDPE Bags and Their B2B Relevance?

High-Density Polyethylene (HDPE) bags are known for their strength and durability, making them ideal for various applications in retail, grocery, and packaging. They provide excellent protection against moisture and are often used for carrying groceries and other heavy items. When purchasing HDPE bags, B2B buyers should consider the bag’s thickness (measured in mils), as this affects its strength and durability. Additionally, as HDPE bags are recyclable, businesses can align their procurement with sustainability goals.

How Do LDPE Bags Differ from HDPE Bags?

Low-Density Polyethylene (LDPE) bags are lightweight and flexible, making them suitable for food packaging and industrial applications. Their excellent clarity allows consumers to see the contents, which is particularly beneficial in retail settings. When selecting LDPE bags, B2B buyers should focus on their intended use; for instance, bags designed for food should comply with safety regulations. While LDPE bags offer moisture resistance, they do have lower tensile strength compared to HDPE, which is an important consideration for businesses needing robust packaging.

Why Choose Biodegradable Bags for Your Business?

Biodegradable bags are an eco-friendly alternative made from materials that decompose naturally, making them a popular choice for businesses aiming to reduce their environmental footprint. These bags are increasingly used in retail and grocery sectors, especially in regions where regulations mandate sustainable practices. B2B buyers should evaluate the compostability certifications of these bags and consider their cost-effectiveness in relation to branding and compliance with environmental regulations. Although they may be pricier, the positive brand image can be worth the investment.

What Are the Benefits of Woven Polypropylene Bags?

Woven polypropylene bags are known for their strength and durability, making them suitable for heavy loads, particularly in agriculture and bulk packaging. These reusable bags are breathable, which helps to maintain the quality of perishable goods. Buyers should consider the bag’s weight capacity and weave density when purchasing. While the initial investment may be higher, their long lifespan and reusability can lead to cost savings over time, making them a smart choice for businesses focused on sustainability.

How Can Custom Printed Bags Enhance Brand Visibility?

Custom printed bags provide businesses with the opportunity to showcase their branding and marketing messages effectively. These bags are widely used in promotional events and retail, allowing companies to enhance their visibility and attract new customers. When considering custom printed bags, B2B buyers should factor in design complexity, lead times, and order quantities, as these can affect overall costs. While they may require a larger upfront investment, the long-term marketing benefits can significantly outweigh the initial costs.

Related Video: How Plastic Bag Manufactured || Plastic Bag Making & Manufacturing Process

Key Industrial Applications of plastic bag manufacturer

| Industry/Sector | Specific Application of plastic bag manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Custom food packaging bags | Extended shelf life and compliance with food safety regulations | Material safety certifications, custom sizing, and sealing options |

| Retail and E-commerce | Branded shopping bags | Enhanced brand visibility and customer loyalty | Customization options, durability, and eco-friendliness |

| Agriculture and Horticulture | Seed and fertilizer bags | Protection from environmental factors and easy handling | UV resistance, moisture barrier properties, and sizes |

| Healthcare | Medical waste disposal bags | Compliance with health regulations and safe disposal | Strength, leak resistance, and certification standards |

| Industrial and Manufacturing | Bulk packaging for components | Cost-effective transport and protection of goods | Load capacity, material strength, and custom dimensions |

What Are the Key Applications of Plastic Bags in the Food and Beverage Industry?

In the food and beverage sector, plastic bag manufacturers provide custom food packaging solutions that help extend the shelf life of products while ensuring compliance with stringent food safety regulations. These bags can be tailored for various food items, including perishables, snacks, and beverages. For international buyers, particularly from regions like Africa and South America, sourcing needs to prioritize material safety certifications to comply with local regulations, as well as custom sizing to fit diverse product ranges.

How Do Retail and E-commerce Businesses Benefit from Plastic Bags?

Retailers and e-commerce businesses utilize branded shopping bags to enhance brand visibility and foster customer loyalty. These bags serve not only as packaging but also as a marketing tool that customers carry around, effectively advertising the brand. For B2B buyers in Europe, the focus should be on customization options that reflect brand identity, along with durability to withstand multiple uses, and eco-friendliness to meet the increasing demand for sustainable practices.

Why Are Plastic Bags Important in Agriculture and Horticulture?

In agriculture, plastic bags are crucial for packaging seeds and fertilizers, offering protection from environmental factors like moisture and pests. They facilitate easy handling and application of products, making them indispensable for farmers and distributors alike. Buyers, especially from the Middle East, should consider sourcing bags with UV resistance and moisture barrier properties to ensure product integrity during transport and storage.

What Role Do Plastic Bags Play in Healthcare?

Healthcare facilities rely on medical waste disposal bags manufactured from high-strength plastic to ensure safe and compliant disposal of hazardous materials. These bags must meet strict health regulations and provide leak resistance to prevent contamination. For international B2B buyers, particularly in regions like Africa, it is essential to prioritize sourcing bags that adhere to certification standards to ensure safety and compliance.

How Do Industrial and Manufacturing Sectors Utilize Plastic Bags?

In the industrial sector, bulk packaging solutions from plastic bag manufacturers are used to transport components and materials efficiently. These bags offer cost-effective transportation while providing protection against damage during transit. Buyers from South America and Europe should focus on sourcing bags that meet specific load capacities and material strength requirements to ensure safe handling and storage of goods.

3 Common User Pain Points for ‘plastic bag manufacturer’ & Their Solutions

Scenario 1: Sourcing High-Quality Plastic Bags at Competitive Prices

The Problem: B2B buyers often struggle to find plastic bag manufacturers that provide high-quality products at competitive prices. In many regions, especially in Africa and South America, there is a wide variance in quality, which can lead to issues such as bag tears or leaks, resulting in product loss and customer dissatisfaction. Additionally, buyers may face challenges in obtaining samples or accurate product specifications, which complicates the decision-making process.

The Solution: To effectively source high-quality plastic bags, buyers should implement a multi-step approach. First, conduct thorough market research to identify reputable manufacturers with positive reviews and a proven track record. Platforms such as Alibaba or local trade shows can be invaluable for discovering potential suppliers. Once potential manufacturers are identified, request samples to evaluate quality firsthand. During this stage, buyers should specify their requirements clearly, including material type, thickness, and any additional features like biodegradability or custom printing. Engaging in direct communication with manufacturers to discuss quality assurance processes can also mitigate risks. Finally, consider negotiating bulk pricing or long-term contracts to secure better rates while ensuring consistent quality.

Scenario 2: Managing Compliance with Environmental Regulations

The Problem: Navigating environmental regulations surrounding plastic usage can be particularly daunting for B2B buyers in Europe and the Middle East, where legislation is becoming increasingly stringent. Buyers may find themselves unsure about which materials meet compliance standards or how to adapt their sourcing practices accordingly. This uncertainty can lead to potential fines, increased scrutiny, and damage to a company’s reputation.

The Solution: To manage compliance effectively, buyers should stay informed about local and international regulations regarding plastic usage. Engaging with industry associations or regulatory bodies can provide insights into upcoming changes. When selecting a manufacturer, prioritize those that have certifications for sustainable practices, such as ISO 14001 for environmental management. Buyers should also inquire about the manufacturer’s ability to produce biodegradable or recyclable bags that meet compliance standards. Furthermore, consider establishing a compliance checklist that includes documentation from the manufacturer to verify that materials used are environmentally friendly. This proactive approach not only ensures compliance but can also enhance the brand’s reputation as a responsible business.

Scenario 3: Ensuring Timely Delivery and Supply Chain Reliability

The Problem: Timely delivery is a critical factor for B2B buyers relying on plastic bags for their operations. Delays in receiving materials can disrupt production schedules and lead to missed deadlines, particularly for companies operating in fast-paced sectors like retail or food service. Buyers may also encounter unexpected issues in the supply chain, such as transportation strikes or natural disasters, exacerbating delivery challenges.

The Solution: To ensure timely delivery and enhance supply chain reliability, buyers should establish clear communication channels with their manufacturers. Implementing a just-in-time inventory system can help minimize excess stock while ensuring that materials are available when needed. Additionally, consider diversifying your supplier base to mitigate risks associated with relying on a single manufacturer. Create contingency plans that outline alternative suppliers and emergency protocols in case of delays. Regularly reviewing performance metrics with suppliers can also foster accountability and prompt timely deliveries. Lastly, building strong relationships with manufacturers can lead to better prioritization of orders and more flexibility in meeting urgent requests, thus ensuring smoother operations.

Strategic Material Selection Guide for plastic bag manufacturer

What Are the Key Properties of Common Materials Used in Plastic Bag Manufacturing?

When selecting materials for plastic bag manufacturing, it is essential to consider their properties. The most common materials include Polyethylene (PE), Polypropylene (PP), Low-Density Polyethylene (LDPE), and Biodegradable Plastics. Each material has unique characteristics that influence its performance, cost, and suitability for specific applications.

Polyethylene (PE): A Versatile Choice

Polyethylene is one of the most widely used materials in plastic bag manufacturing. It is known for its excellent chemical resistance, flexibility, and durability. PE bags can withstand a range of temperatures, making them suitable for various applications, from grocery bags to industrial packaging.

Pros:

– High durability and tear resistance.

– Cost-effective and widely available.

– Excellent moisture barrier properties.

Cons:

– Limited temperature resistance compared to other plastics.

– Environmental concerns regarding disposal.

For international B2B buyers, compliance with regional standards such as ASTM D1709 for impact resistance is crucial. Buyers in Europe may also need to consider the European Union’s directives on single-use plastics.

Polypropylene (PP): Strong and Stiff

Polypropylene is another popular material, particularly for applications requiring more rigidity and strength. It offers higher temperature resistance than polyethylene, making it suitable for hot-fill applications.

Pros:

– Higher tensile strength and stiffness.

– Good resistance to chemicals and fatigue.

– Can be produced in a variety of colors.

Cons:

– More expensive than polyethylene.

– Less flexible, which may limit some applications.

B2B buyers should note that polypropylene bags often meet the requirements of various standards, including ISO 9001 for quality management. Buyers in Africa and South America may find PP bags particularly advantageous for packaging food products due to their durability.

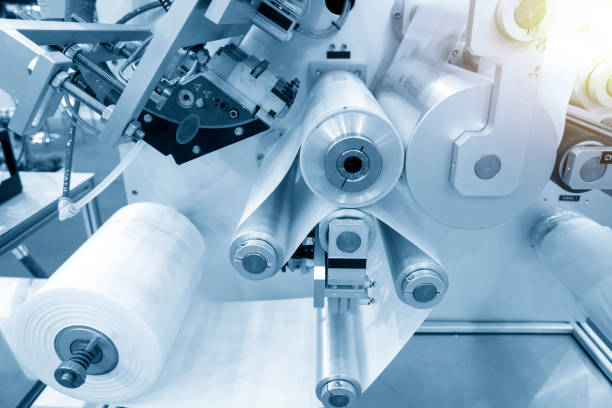

A stock image related to plastic bag manufacturer.

Low-Density Polyethylene (LDPE): The Flexible Option

Low-Density Polyethylene is known for its flexibility and softness, making it an excellent choice for applications requiring stretchability, such as grocery bags and liners.

Pros:

– Highly flexible and lightweight.

– Good moisture barrier properties.

– Cost-effective for high-volume production.

Cons:

– Lower strength compared to other plastics.

– Limited resistance to UV light.

For international buyers, LDPE’s compliance with standards such as ASTM D882 for tensile strength is critical. In regions like the Middle East, where UV exposure is high, buyers should consider additional treatments to enhance durability.

Biodegradable Plastics: The Eco-Friendly Alternative

Biodegradable plastics are increasingly popular due to growing environmental concerns. These materials can break down more quickly than traditional plastics, making them a suitable choice for eco-conscious companies.

Pros:

– Environmentally friendly and compostable.

– Can reduce landfill waste.

– Growing consumer preference for sustainable products.

Cons:

– Generally more expensive than conventional plastics.

– Performance can vary significantly based on environmental conditions.

International buyers, particularly in Europe, must ensure that biodegradable plastics meet EN 13432 standards for compostability. This compliance is vital for companies aiming to enhance their sustainability credentials.

Summary Table of Material Selection for Plastic Bag Manufacturing

| Material | Typical Use Case for plastic bag manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Grocery bags, industrial packaging | High durability and tear resistance | Limited temperature resistance | Low |

| Polypropylene (PP) | Food packaging, retail bags | Higher tensile strength and stiffness | More expensive than polyethylene | Medium |

| Low-Density Polyethylene (LDPE) | Grocery bags, liners | Highly flexible and lightweight | Lower strength compared to other plastics | Low |

| Biodegradable Plastics | Eco-friendly bags, compostable packaging | Environmentally friendly and compostable | Generally more expensive | High |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their operational needs and sustainability goals.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic bag manufacturer

What Are the Key Stages in the Manufacturing Process of Plastic Bags?

The manufacturing process of plastic bags involves several critical stages that ensure the final product meets industry standards and customer expectations. Understanding these stages can help international B2B buyers make informed decisions when selecting a supplier.

-

Material Preparation

The process begins with the selection of raw materials, predominantly polyethylene (PE) or polypropylene (PP). These materials are sourced based on the required properties of the final product, such as strength, flexibility, and environmental considerations. The materials are then processed into granules and may undergo blending with additives for enhanced performance attributes like UV resistance or biodegradability. -

Forming

The forming stage typically employs techniques such as extrusion or blow molding. In extrusion, the plastic granules are melted and forced through a die to create a continuous film, which is then cooled and rolled into large sheets. In blow molding, air is injected into a molten tube of plastic, which expands to form the bag shape. Each method has its advantages depending on the desired bag specifications. -

Assembly

Once formed, the bags may require assembly processes, especially if they are multi-layered or designed with features such as handles or zippers. This stage may involve cutting the film to size, welding seams, or attaching additional components. Automated machinery often handles this process to ensure precision and efficiency. -

Finishing

The final stage includes printing, labeling, and quality checks. Printing can be done using flexographic or gravure techniques, allowing for high-quality graphics and branding. After printing, bags are typically folded, stacked, and packaged for shipment. This stage is crucial for branding and compliance with any regulatory requirements.

How Is Quality Assurance Implemented in Plastic Bag Manufacturing?

Quality assurance (QA) is essential in ensuring that plastic bags meet both international standards and specific customer requirements. The following components outline a robust QA framework in the manufacturing process.

-

International Standards and Certifications

International standards like ISO 9001 establish quality management systems that manufacturers must adhere to. Additionally, certifications such as CE mark for compliance with European safety standards or API specifications for certain industrial applications can enhance credibility. B2B buyers should inquire about these certifications when evaluating potential suppliers. -

Quality Control Checkpoints

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during the production process helps identify any deviations from quality standards.

– Final Quality Control (FQC): The finished products are thoroughly tested to ensure they meet both internal and external quality benchmarks before shipment. -

Common Testing Methods

Various testing methods are employed to assess the quality of plastic bags. These may include tensile strength tests, impact resistance tests, and environmental testing to ensure compliance with relevant standards. B2B buyers should request detailed test reports to verify that products meet their specific requirements.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying a supplier’s quality control processes is critical for B2B buyers, especially when dealing with international suppliers. Here are several strategies to ensure robust QC:

-

Conduct Supplier Audits

Periodic audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. This can include reviewing their production facilities, quality management systems, and compliance with international standards. -

Request Quality Assurance Reports

Suppliers should be able to provide detailed reports on their quality assurance practices, including data from IQC, IPQC, and FQC. This transparency is crucial for building trust and ensuring product quality. -

Engage Third-Party Inspectors

Utilizing third-party inspection services can further validate a supplier’s claims regarding quality control. These independent inspectors can conduct thorough assessments of the manufacturing process, raw materials, and final products, providing unbiased reports.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate specific challenges related to quality control:

-

Regulatory Compliance

Different regions have varying regulations governing the production and use of plastic products. B2B buyers should ensure that suppliers comply with local laws, such as restrictions on certain materials or requirements for recycling and waste management. -

Cultural and Language Barriers

Communication can be a challenge when dealing with international suppliers. It is advisable to establish clear documentation and guidelines to minimize misunderstandings related to quality expectations and compliance. -

Logistics and Supply Chain Considerations

The logistics of transporting goods across borders can impact quality. B2B buyers should work closely with suppliers to ensure that proper handling and storage conditions are maintained throughout the supply chain to prevent damage or degradation of the product.

Conclusion

Understanding the manufacturing processes and quality assurance measures in plastic bag production is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, along with robust quality control practices, buyers can make informed decisions that align with their business needs. Regular audits, detailed reports, and third-party inspections further enhance confidence in supplier quality, ensuring that the products meet the necessary standards for various markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic bag manufacturer’

A stock image related to plastic bag manufacturer.

The purpose of this guide is to equip international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, with a structured approach to sourcing plastic bag manufacturers. By following these steps, you can ensure that you choose a supplier who meets your quality, compliance, and logistical needs.

1. Define Your Technical Specifications

Clearly outline the types of plastic bags you require, including dimensions, materials, and any specific functionalities (e.g., biodegradable options). This step is essential as it sets the foundation for your sourcing process. Consider sub-bullets such as:

– Material Types: Are you looking for HDPE, LDPE, or biodegradable materials?

– Bag Types: Will you need shopping bags, trash bags, or custom printed options?

2. Research Potential Manufacturers

Conduct thorough research to identify manufacturers that specialize in the production of the types of plastic bags you need. Look for suppliers with a strong reputation in the industry and positive reviews. Utilize platforms like Alibaba, Global Sources, or local trade directories. Key points to check include:

– Company Background: Years in business, market presence, and certifications.

– Product Range: Do they offer a variety of products that suit your needs?

3. Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO 9001 for quality management and environmental certifications if applicable. Certifications are crucial indicators of a manufacturer’s commitment to quality and compliance with international standards. Look for:

– Quality Assurance Protocols: How does the manufacturer ensure product quality?

– Sustainability Practices: Are they compliant with environmental regulations, especially in regions with stringent laws?

4. Request Samples for Quality Assurance

Before making a large order, always request product samples. This allows you to assess the quality of the bags firsthand. Pay attention to:

– Material Quality: Is it durable and meets your specifications?

– Print Quality: If applicable, are the colors and designs accurate?

5. Discuss Minimum Order Quantities (MOQs)

Understand the manufacturer’s minimum order quantities, as this can significantly impact your budget and inventory management. Some manufacturers may have high MOQs that could lead to excess stock. Important considerations include:

– Negotiation Flexibility: Are they willing to accommodate smaller orders?

– Bulk Pricing: What are the cost implications of ordering larger quantities?

6. Evaluate Logistics and Shipping Terms

Assess the logistics involved in shipping your orders from the manufacturer to your location. Discuss shipping options, lead times, and costs upfront to avoid surprises later. Key factors to evaluate are:

– Shipping Methods: Are they using sea freight, air freight, or a combination?

– Delivery Times: How long will it take for your order to arrive?

7. Establish Clear Payment Terms

Discuss and agree on payment terms before finalizing the deal. Clear payment terms protect both parties and establish trust. Consider:

– Payment Methods: Are they flexible with payment options (e.g., PayPal, bank transfers)?

– Deposit Requirements: What percentage is required upfront, and what are the conditions for the remaining balance?

By following this checklist, you can systematically approach the sourcing process for plastic bag manufacturers, ensuring that you make informed decisions that align with your business goals.

Comprehensive Cost and Pricing Analysis for plastic bag manufacturer Sourcing

What Are the Key Cost Components in Plastic Bag Manufacturing?

Understanding the cost structure is vital for international B2B buyers sourcing plastic bags. The primary cost components include:

-

Materials: The type of resin (e.g., LDPE, HDPE) significantly impacts costs. Prices can fluctuate based on global oil prices and availability. Buyers should consider sourcing from regions with abundant raw materials to minimize expenses.

-

Labor: Labor costs vary by region. In countries with lower labor costs, manufacturers might offer more competitive pricing. However, it’s essential to assess the skill level of labor, as this can affect product quality.

-

Manufacturing Overhead: This includes utilities, maintenance, and factory costs. Efficient manufacturers often minimize overhead through automation and streamlined processes, leading to lower prices for buyers.

-

Tooling: Custom molds and machinery setup can be significant upfront costs. Buyers should inquire about tooling fees, especially for custom bag designs, as these can add to the initial order cost.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability. While this adds to costs, it can prevent expensive returns and damage to brand reputation.

-

Logistics: Shipping costs depend on distance, transport mode, and Incoterms. Buyers must evaluate these factors when calculating total sourcing costs.

-

Margin: Manufacturers typically mark up prices to ensure profitability. Understanding the typical margins in the industry can help buyers gauge fair pricing.

How Do Price Influencers Impact B2B Sourcing of Plastic Bags?

Several factors can influence the pricing of plastic bags for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to better pricing. Manufacturers may offer discounts for bulk purchases, making it essential for buyers to assess their needs carefully.

-

Specifications and Customization: Custom designs or unique specifications can increase costs. Buyers should weigh the benefits of customization against the added expenses.

-

Materials and Quality Certifications: The choice of materials impacts not only cost but also compliance with regulations, especially in regions like Europe where environmental standards are stringent. Certifications can add credibility but may also elevate prices.

-

Supplier Factors: A supplier’s reputation, reliability, and location can influence pricing. Established suppliers may charge more for their experience and quality assurance.

-

Incoterms: Understanding Incoterms is crucial for managing logistics and related costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks.

What Tips Can Help Buyers Optimize Costs in Plastic Bag Sourcing?

To maximize cost-effectiveness when sourcing plastic bags, consider the following strategies:

-

Negotiate Pricing: Engage suppliers in discussions about pricing. Use volume commitments or long-term contracts as leverage for better rates.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider logistics, storage, and potential waste when calculating TCO. A cheaper product may lead to higher overall costs if it requires more frequent replacement.

-

Research Market Trends: Stay informed about fluctuations in raw material prices and global market conditions. This knowledge can aid in timing purchases effectively.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better terms, exclusive deals, and improved service.

-

Consider Regional Suppliers: For buyers from Africa, South America, the Middle East, and Europe, sourcing from local or regional manufacturers can reduce shipping costs and lead times, enhancing overall efficiency.

Disclaimer on Pricing

Prices for plastic bags can vary significantly based on factors such as supplier location, material costs, and order volume. Always request quotes from multiple suppliers and confirm details before making purchasing decisions to ensure you receive the best value for your investment.

Alternatives Analysis: Comparing plastic bag manufacturer With Other Solutions

In today’s eco-conscious market, international B2B buyers are increasingly exploring alternatives to traditional plastic bags. Understanding the various options available can empower businesses to make informed decisions that align with their sustainability goals and operational needs. This section presents a comparative analysis of plastic bag manufacturing against two viable alternatives: biodegradable bags and reusable cloth bags.

| Comparison Aspect | Plastic Bag Manufacturer | Biodegradable Bags | Reusable Cloth Bags |

|---|---|---|---|

| Performance | High durability; suitable for various products. | Decomposes under specific conditions; performance may vary. | High durability; reusable multiple times. |

| Cost | Generally lower cost per unit. | Higher initial cost; may require bulk purchases. | Moderate to high initial cost; cost-effective over time. |

| Ease of Implementation | Widely available; easy to source. | Availability may vary; supplier education needed. | Requires supplier partnerships and education for users. |

| Maintenance | Minimal; single-use. | Requires proper disposal methods. | Requires regular washing; more care needed. |

| Best Use Case | Retail and packaging of various goods. | Eco-conscious businesses looking to minimize waste. | Companies aiming to promote sustainability and reduce single-use plastics. |

What are Biodegradable Bags and Their Pros and Cons?

Biodegradable bags are designed to break down more quickly than traditional plastic bags, often using materials derived from renewable resources. Their primary advantage lies in their reduced environmental impact, making them appealing to businesses focused on sustainability. However, the effectiveness of biodegradable bags can be contingent upon specific composting conditions; if not disposed of correctly, they may still contribute to pollution. Additionally, they tend to have a higher initial cost compared to conventional plastic bags.

How Do Reusable Cloth Bags Compare?

Reusable cloth bags are a durable alternative, allowing for multiple uses and reducing overall waste. They are often made from cotton, jute, or other sustainable materials, which can enhance a brand’s eco-friendly image. The initial investment is higher, but over time, the cost per use decreases significantly. However, these bags require regular cleaning and maintenance, which may not be feasible for all businesses. Furthermore, without proper education on their use, customers may not utilize them effectively.

Conclusion: How to Choose the Right Solution for Your Business Needs?

When selecting the appropriate packaging solution, B2B buyers must consider their unique operational requirements, budget constraints, and sustainability goals. Each option presents its own set of advantages and challenges. Plastic bag manufacturers offer a cost-effective and versatile solution, while biodegradable and reusable cloth bags promote environmental responsibility. Ultimately, the decision should align with the company’s values, customer expectations, and regulatory considerations within their respective markets in Africa, South America, the Middle East, or Europe. By evaluating these factors carefully, businesses can make informed choices that not only meet their needs but also contribute positively to the environment.

Essential Technical Properties and Trade Terminology for plastic bag manufacturer

What Are the Key Technical Properties of Plastic Bags for B2B Buyers?

When selecting plastic bags for commercial use, understanding critical technical specifications is vital for ensuring quality, compliance, and suitability for specific applications. Here are some essential properties that B2B buyers should consider:

-

Material Grade

– The most common materials used in plastic bags are polyethylene (PE) and polypropylene (PP). Material grade refers to the specific type of resin used in manufacturing, which affects the bag’s strength, flexibility, and clarity. Higher-grade materials typically offer better performance characteristics, making them suitable for heavier loads or more demanding applications. -

Thickness (Mil or Micron)

– Thickness is often measured in mils (thousandths of an inch) or microns (one-thousandth of a millimeter). A thicker bag generally has a higher load-bearing capacity and enhanced durability, which is crucial for industries that require robust packaging solutions. Understanding the required thickness helps businesses avoid under-specifying, which can lead to product damage and increased costs. -

Tolerance

– Tolerance refers to the permissible variation in bag dimensions and properties during manufacturing. This is essential for ensuring that the bags fit their intended purpose, particularly in automated packaging environments. Tight tolerances can enhance efficiency and reduce waste, making it a critical factor for B2B buyers focused on operational performance. -

Seal Strength

– This property indicates how well the bag can maintain its integrity when sealed. Strong seals are essential for preventing leaks and ensuring the contents remain secure during transport. Buyers should evaluate seal strength specifications to ensure compatibility with their products, especially for items that may be sensitive to exposure or contamination. -

Tensile Strength

– Tensile strength measures the force required to break the bag. A higher tensile strength indicates a more durable product that can withstand stress without tearing. This is particularly important for bags used in heavy-duty applications, such as agricultural or industrial settings. -

Transparency and Clarity

– The clarity of plastic bags can impact branding and product visibility. High clarity is often desired for retail applications, as it allows customers to see the product inside. However, for industrial uses, opacity may be preferred to protect contents from light degradation.

What Are Common Trade Terms in the Plastic Bag Manufacturing Industry?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B marketplace. Here are some common terms that buyers should familiarize themselves with:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce products that are then rebranded and sold by another company. In the context of plastic bags, buyers may work with OEMs to create custom bags tailored to their specifications while leveraging the manufacturer’s expertise and production capabilities. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory levels and production schedules effectively. It can also impact pricing; larger orders may yield better unit costs. -

RFQ (Request for Quotation)

– An RFQ is a formal document sent by buyers to suppliers to request pricing and terms for specific products. This is a critical step in the procurement process, allowing buyers to compare options and negotiate better deals. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms used in international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and costs associated with transporting plastic bags across borders. -

Lead Time

– Lead time refers to the duration from placing an order until its delivery. Understanding lead times is crucial for B2B buyers to plan inventory and production schedules effectively, ensuring they have the necessary materials when needed. -

Sustainability Compliance

– This term encompasses the environmental standards that plastic products must meet, especially in regions with strict regulations. Buyers should ensure that their suppliers adhere to sustainability practices to align with corporate responsibility goals and comply with local laws.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing plastic bags, ultimately enhancing operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the plastic bag manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Plastic Bag Manufacturing Sector?

The plastic bag manufacturing sector is experiencing transformative changes driven by several global factors. The demand for plastic bags is largely influenced by rising e-commerce, retail expansion, and the ongoing need for cost-effective packaging solutions. Particularly in regions like Africa and South America, increased consumer spending and urbanization are propelling the market. Additionally, advancements in manufacturing technologies, such as automation and digitalization, are streamlining production processes, making sourcing more efficient for international buyers.

Emerging B2B tech trends include the adoption of Industry 4.0 practices, which involve the integration of IoT (Internet of Things) devices in the manufacturing process. This enhances operational efficiency and provides real-time data analytics for better decision-making. Moreover, the rise of online marketplaces and e-commerce platforms allows buyers from the Middle East and Europe to easily source products from manufacturers across the globe, thus widening their options and reducing lead times.

International buyers should also keep an eye on regional regulations and trade agreements that may influence market dynamics. For instance, the European Union is tightening regulations on single-use plastics, affecting sourcing strategies for European buyers. Understanding these dynamics is crucial for buyers looking to navigate the complex landscape of the plastic bag manufacturing industry effectively.

How Important Is Sustainability and Ethical Sourcing in the Plastic Bag Manufacturing Sector?

As environmental concerns gain traction globally, sustainability has become a focal point for B2B buyers in the plastic bag sector. The environmental impact of plastic production and disposal is significant, leading to increased scrutiny from consumers and regulatory bodies. Ethical sourcing has emerged as a critical factor for international buyers, particularly in Europe, where consumers are increasingly favoring brands that demonstrate a commitment to sustainability.

To address these concerns, many manufacturers are investing in ‘green’ certifications and sustainable materials. Options such as biodegradable plastics, recycled materials, and compostable bags are gaining popularity. Buyers should prioritize suppliers who are transparent about their sourcing practices and can provide certifications that validate their sustainability claims. This not only aligns with ethical consumerism but also prepares businesses for future regulations aimed at reducing plastic waste.

Furthermore, ethical supply chains are not just about compliance; they can enhance brand reputation and customer loyalty. International buyers from Africa, South America, the Middle East, and Europe should seek partnerships with manufacturers who demonstrate a commitment to ethical practices, as this can be a differentiating factor in competitive markets.

What Has Been the Evolution of the Plastic Bag Manufacturing Sector?

The evolution of the plastic bag manufacturing sector dates back to the mid-20th century when polyethylene bags began to replace paper and cloth alternatives due to their lightweight and cost-effective nature. Initially celebrated for their convenience, plastic bags soon faced criticism for their environmental impact, leading to widespread calls for regulation and reduction.

In recent years, the industry has shifted towards more sustainable practices, spurred by consumer demand and regulatory pressures. Innovations in materials science have led to the development of biodegradable and compostable plastic bags, catering to a more environmentally conscious market. As international buyers navigate these changes, understanding the historical context of the industry can provide valuable insights into current trends and future directions. This awareness is essential for making informed sourcing decisions in an increasingly complex global market.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic bag manufacturer

-

How do I choose the right plastic bag manufacturer for my business needs?

Choosing the right plastic bag manufacturer involves several steps. Start by assessing your specific requirements, such as bag type, size, and material. Research potential manufacturers in regions like Africa, South America, the Middle East, and Europe, focusing on their production capabilities, certifications, and customer reviews. It’s crucial to request samples to evaluate the quality and durability of their products. Additionally, consider their ability to meet your delivery timelines and their experience in your industry to ensure they can cater to your unique needs. -

What factors should I consider when vetting a plastic bag supplier?

When vetting a plastic bag supplier, consider their production capacity, quality control processes, and compliance with international regulations. Request information about their certifications, such as ISO or environmental standards, to ensure they adhere to best practices. It’s also beneficial to check their financial stability and reputation in the market. Engage with previous clients to understand their experiences and the supplier’s responsiveness to issues. Lastly, ensure the supplier can provide customization options to meet your branding or functional requirements. -

What is the minimum order quantity (MOQ) for plastic bags?

The minimum order quantity (MOQ) for plastic bags can vary significantly depending on the manufacturer and the type of bags you require. Typically, MOQs can range from 1,000 to 10,000 units for standard products, while customized bags may have higher MOQs. It’s important to discuss your needs with potential suppliers to find a balance between cost efficiency and your order size. Be aware that ordering below the MOQ may result in higher per-unit costs, so consider your long-term demand when negotiating. -

What are the payment terms I should expect from plastic bag manufacturers?

Payment terms from plastic bag manufacturers can vary widely, but common practices include a 30% upfront deposit with the balance due before shipment. Some manufacturers may offer credit terms for established businesses. It’s essential to clarify these terms during negotiations to avoid misunderstandings. Additionally, consider using secure payment methods like letters of credit or escrow services, especially when dealing with international suppliers, to mitigate risks and ensure compliance with contractual obligations. -

How can I ensure quality assurance for my plastic bags?

To ensure quality assurance for your plastic bags, establish clear specifications and standards before production begins. Request samples and conduct thorough inspections upon receipt. Many manufacturers offer quality control checks at various stages of production, so inquire about their processes. It may also be beneficial to engage a third-party quality assurance service to conduct inspections on-site or pre-shipment. Regular communication with your supplier can help address any issues promptly and ensure the final products meet your expectations. -

What logistics considerations should I be aware of when importing plastic bags?

When importing plastic bags, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder with experience in handling plastic products to navigate the complexities of international shipping. Ensure you understand the documentation required for customs clearance, including invoices and packing lists. Additionally, factor in lead times for production and shipping to align with your inventory needs, and be prepared for potential delays due to customs inspections or geopolitical issues. -

What customization options are typically available for plastic bags?

Most plastic bag manufacturers offer a variety of customization options, including size, thickness, color, and printing. You can choose from different types of bags, such as biodegradable, reusable, or printed with your logo and branding. Discuss your specific requirements with potential suppliers to explore their capabilities. Some manufacturers also provide design assistance to help you create an appealing product that meets your marketing needs. Keep in mind that customization may impact MOQs and lead times, so plan accordingly. -

How do I handle issues with defective plastic bags from my supplier?

If you encounter defective plastic bags, promptly communicate the issue with your supplier, providing detailed documentation such as photos and descriptions. Most reputable manufacturers will have a return policy or warranty that covers defective products. Discuss potential solutions, which may include replacements, refunds, or discounts on future orders. Establishing a clear line of communication and maintaining a professional relationship can help resolve issues effectively. Additionally, consider developing a quality inspection plan for future orders to minimize defects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for plastic bag manufacturer

What Are the Key Takeaways for International B2B Buyers in Plastic Bag Manufacturing?

In today’s dynamic market, strategic sourcing emerges as a vital component for B2B buyers in the plastic bag manufacturing sector. By understanding the diverse sourcing strategies available, buyers can significantly enhance their supply chain efficiency while ensuring compliance with regional regulations. The emphasis on sustainability is more than a trend; it’s a necessity that can drive customer loyalty and brand reputation. Buyers should prioritize partnerships with manufacturers that not only offer high-quality products but also demonstrate a commitment to environmentally-friendly practices.

How Can Buyers Prepare for Future Trends in Plastic Bag Manufacturing?

Looking ahead, the landscape of plastic bag manufacturing is likely to evolve with technological advancements and shifting consumer preferences. Buyers from Africa, South America, the Middle East, and Europe must stay informed about emerging materials and production techniques that meet both market demand and environmental standards. Investing in strategic partnerships and leveraging data analytics can provide insights that drive smarter purchasing decisions.

What Should Be the Next Steps for B2B Buyers in This Sector?

As you navigate this complex market, take action by establishing clear criteria for evaluating suppliers, including their sustainability practices and capacity for innovation. Engage in continuous dialogue with manufacturers to foster relationships that can adapt to changing market dynamics. By making informed sourcing decisions today, you position your business for long-term success in a competitive global marketplace.