Discover Top Benefits of a Reliable Power Bank Supplier (2025)

Introduction: Navigating the Global Market for power bank supplier

In an increasingly digital world, the demand for reliable power solutions has surged, making the role of a power bank supplier critical for international B2B buyers. Companies across various industries are grappling with the challenge of sourcing high-quality power banks that meet their specific needs—whether for retail distribution, corporate gifting, or as part of a larger product offering. This guide is designed to help buyers navigate the complexities of the global market, providing insights into different types of power banks, their applications, and essential supplier vetting criteria.

As the market evolves, understanding the nuances of power bank technology and trends can significantly impact purchasing decisions. This comprehensive guide covers vital aspects such as pricing structures, quality assurance, and the importance of supplier certifications. It empowers B2B buyers from Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil, to make informed choices that align with their business objectives.

By equipping buyers with actionable insights and practical strategies, this guide serves as a roadmap for successfully sourcing power banks in a competitive landscape. Whether you are a procurement manager looking to optimize your supply chain or a business owner aiming to enhance your product line, the information contained herein will enhance your purchasing strategy and drive business growth.

Understanding power bank supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM/ODM Power Bank Suppliers | Customizable designs, branding options | Retail, promotional products | Pros: Tailored solutions; Cons: Higher MOQ and longer lead times. |

| Bulk Power Bank Suppliers | Large volume production with standard designs | Corporate gifts, events | Pros: Cost-effective; Cons: Limited customization. |

| Specialty Power Bank Suppliers | Unique features like solar charging, rugged designs | Outdoor events, emergency supplies | Pros: Niche market appeal; Cons: Higher price points. |

| High-Capacity Power Bank Suppliers | Larger battery capacities, fast charging technologies | Electronics retailers, tech companies | Pros: Long-lasting performance; Cons: Bulkier designs. |

| Eco-Friendly Power Bank Suppliers | Sustainable materials, energy-efficient production | Green businesses, eco-conscious brands | Pros: Positive brand image; Cons: Potentially higher costs. |

What are OEM/ODM Power Bank Suppliers and Their B2B Relevance?

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) power bank suppliers offer customizable solutions that allow businesses to create unique products tailored to their branding and specific market needs. These suppliers are essential for companies looking to differentiate themselves in a crowded market, such as retailers and promotional product companies. However, buyers should consider the minimum order quantities (MOQ) and longer lead times associated with these custom solutions, which may affect inventory management and cash flow.

How Do Bulk Power Bank Suppliers Operate?

Bulk power bank suppliers focus on producing large quantities of standardized products, making them ideal for businesses looking to procure power banks at a lower cost. These suppliers are often utilized by corporations for giveaways, trade shows, or promotional events. While bulk purchasing can significantly reduce costs, buyers may encounter limitations in terms of product customization and branding, which can affect the overall impact of promotional efforts.

What Makes Specialty Power Bank Suppliers Unique?

Specialty power bank suppliers differentiate themselves by offering unique features, such as solar charging capabilities or rugged designs suitable for outdoor use. These products are particularly valuable for businesses in industries like outdoor recreation, emergency preparedness, and adventure tourism. While these specialty products can command a premium price, they also provide a competitive edge in niche markets, allowing businesses to cater to specific consumer needs.

Why Choose High-Capacity Power Bank Suppliers?

High-capacity power bank suppliers provide products with larger battery capacities and advanced charging technologies, making them suitable for tech companies and electronics retailers. These suppliers are ideal for businesses targeting consumers who require reliable and long-lasting power solutions for their devices. However, the bulkier designs associated with high-capacity power banks may not appeal to all consumers, which is a consideration for businesses aiming for portability.

What are the Advantages of Eco-Friendly Power Bank Suppliers?

Eco-friendly power bank suppliers focus on sustainable production practices and materials, appealing to businesses that prioritize environmental responsibility. These suppliers are well-suited for green businesses and brands looking to enhance their corporate social responsibility (CSR) initiatives. While the use of sustainable materials can lead to higher costs, the positive brand image and consumer loyalty generated by eco-friendly practices can offset these expenses, making them a worthwhile investment for many B2B buyers.

Related Video: Understanding Switching Mode Power Supplies

Key Industrial Applications of power bank supplier

| Industry/Sector | Specific Application of power bank supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Mobile network stations | Ensures uninterrupted service and minimizes downtime | Reliability, capacity, and compatibility with existing systems |

| Healthcare | Medical devices and equipment | Enhances operational efficiency and patient care availability | Compliance with health regulations, portability, and safety |

| Retail | Point of Sale (POS) systems | Improves customer experience and sales efficiency | Battery life, charging speed, and design aesthetics |

| Construction | Power tools and machinery | Increases productivity and reduces project delays | Durability, power output, and weather resistance |

| Event Management | Charging stations for attendees | Enhances attendee satisfaction and engagement | Portability, capacity, and ease of setup |

How Are Power Banks Used in Telecommunications?

In the telecommunications sector, power bank suppliers provide mobile network stations with reliable backup power solutions. These power banks ensure uninterrupted service during outages or peak usage times, minimizing downtime and maintaining customer satisfaction. International buyers, especially from regions with unstable power grids, should prioritize sourcing power banks with high reliability and compatibility with existing network infrastructure to avoid service interruptions.

What Role Do Power Banks Play in Healthcare?

In healthcare, power banks are essential for powering medical devices and equipment, ensuring they remain operational during emergencies. This application enhances operational efficiency and ensures that critical care is available when needed. Buyers in this sector must consider compliance with health regulations, portability for easy transport, and safety features to protect sensitive medical equipment.

How Do Power Banks Benefit Retail Environments?

Retail businesses utilize power banks to support Point of Sale (POS) systems, allowing for seamless transactions even during power outages. This capability improves customer experience by reducing wait times and enhancing sales efficiency. When sourcing power banks for retail applications, businesses should focus on battery life, charging speed, and design aesthetics to ensure they fit well within the retail environment while meeting operational needs.

What Are the Applications of Power Banks in Construction?

In the construction industry, power banks are used to power tools and machinery on job sites, increasing productivity and reducing project delays due to power issues. These portable power solutions are crucial for remote locations where access to electrical outlets may be limited. Buyers should prioritize durability, power output, and weather resistance when sourcing power banks for construction applications to withstand harsh working conditions.

How Are Power Banks Used in Event Management?

Event management companies use power banks to set up charging stations for attendees, enhancing their experience and engagement during events. Providing accessible charging solutions can significantly improve attendee satisfaction and encourage longer participation. Key considerations for sourcing power banks in this context include portability, capacity, and ease of setup to facilitate quick deployment at various venues.

Related Video: Industrial Control Panel Basics

3 Common User Pain Points for ‘power bank supplier’ & Their Solutions

Scenario 1: Inconsistent Quality of Power Banks

The Problem:

B2B buyers often face the challenge of inconsistent quality when sourcing power banks from suppliers. This inconsistency can lead to significant issues, including customer dissatisfaction, increased return rates, and damage to the buyer’s brand reputation. For example, a company may receive a shipment where some power banks fail to hold a charge or have a lower capacity than advertised. This not only affects customer trust but can also result in financial losses due to warranty claims or replacements.

The Solution:

To mitigate the risk of inconsistent quality, buyers should implement a rigorous supplier evaluation process. Begin by requesting samples from multiple suppliers to assess the quality firsthand. Conduct tests that measure charging efficiency, capacity, and durability. Additionally, inquire about the supplier’s quality assurance processes, such as certifications (e.g., ISO 9001) and testing protocols. Establishing clear specifications and performance standards in the contract can also hold suppliers accountable. Regular quality audits and feedback loops can further ensure that the products meet your expectations consistently.

Scenario 2: Complicated Import Regulations and Shipping Delays

The Problem:

International buyers, particularly in regions like Africa and South America, frequently encounter complicated import regulations and shipping delays when sourcing power banks. These logistical challenges can lead to unexpected costs, inventory shortages, and missed sales opportunities. For instance, if a shipment is held up in customs due to improper documentation, the buyer may have to wait weeks or even months to receive their products.

The Solution:

To navigate these logistical hurdles, buyers should familiarize themselves with the import regulations specific to their country, including tariffs, taxes, and documentation requirements. Working with a reliable freight forwarder can help streamline the shipping process and ensure compliance with all regulations. Additionally, maintaining open lines of communication with suppliers about shipping methods and timelines is essential. Consider utilizing suppliers who have experience with international shipping and can provide guidance on the necessary documentation. Building a buffer into your inventory strategy can also help mitigate the impact of delays on your business operations.

Scenario 3: Limited Customization Options for Branding

The Problem:

Many B2B buyers seek power banks that can be customized to reflect their brand identity, but suppliers often offer limited options. This lack of flexibility can hinder a buyer’s marketing efforts and dilute brand recognition. For example, a company may want to have its logo printed on the power banks, but the supplier may only provide a standard design, making it difficult to stand out in a competitive market.

The Solution:

To find suppliers that offer customizable options, buyers should conduct thorough market research and reach out to multiple manufacturers. Look for suppliers who specialize in promotional products or have a strong portfolio showcasing customizable designs. Clearly communicate your branding needs and ask for examples of previous work to ensure the supplier can meet your requirements. Establishing a partnership with a supplier that values customization can also lead to unique product offerings that enhance your brand’s visibility. Additionally, consider ordering a small batch of customized power banks to test the market response before committing to larger orders.

Strategic Material Selection Guide for power bank supplier

When selecting materials for power banks, international B2B buyers must consider various factors that influence product performance, durability, and cost-effectiveness. Below, we analyze four common materials used in power bank manufacturing, focusing on their properties, advantages, disadvantages, and implications for buyers in regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Aluminum in Power Banks?

Aluminum is a widely used material in power bank casings due to its excellent strength-to-weight ratio and corrosion resistance. It can withstand moderate temperatures and pressures, making it suitable for portable electronics. The lightweight nature of aluminum also contributes to the overall portability of power banks.

Pros and Cons:

– Pros: Durable, lightweight, and aesthetically pleasing with options for anodization.

– Cons: Higher manufacturing costs compared to plastics and can be prone to dents and scratches.

Impact on Application: Aluminum’s corrosion resistance makes it ideal for outdoor or humid environments, ensuring longevity in diverse climates.

Considerations for International Buyers: Buyers should ensure compliance with regional standards such as ASTM for materials and consider the aesthetic preferences in their target markets, particularly in Europe, where design plays a significant role.

How Does Plastic Compare as a Material for Power Banks?

Plastics, particularly ABS (Acrylonitrile Butadiene Styrene) and polycarbonate, are common choices for power bank housings. They offer good impact resistance and can be molded into complex shapes, which is beneficial for design flexibility.

Pros and Cons:

– Pros: Cost-effective, lightweight, and available in various colors and finishes.

– Cons: Lower temperature resistance and potential for warping under high heat.

Impact on Application: Plastic materials are suitable for consumer electronics but may not perform well in extreme conditions, such as high temperatures or exposure to direct sunlight.

Considerations for International Buyers: Buyers should verify that the plastics used meet local safety standards, such as those set by the European Union regarding chemical safety (REACH compliance).

What Are the Benefits of Using Lithium-Ion Cells in Power Banks?

Lithium-ion (Li-ion) cells are the most common battery type used in power banks due to their high energy density and rechargeability. They operate efficiently over a wide temperature range and have a relatively low self-discharge rate.

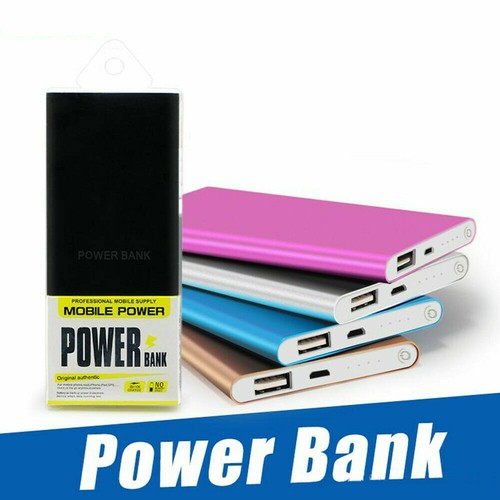

A stock image related to power bank supplier.

Pros and Cons:

– Pros: High capacity, lightweight, and long cycle life.

– Cons: Higher cost and the need for protective circuitry to prevent overheating or overcharging.

Impact on Application: Li-ion batteries are ideal for high-capacity power banks, especially those designed for charging smartphones and tablets.

Considerations for International Buyers: Compliance with international safety standards, such as UN 38.3 for lithium batteries, is crucial to avoid shipping and handling issues, especially in regions with stringent regulations like Europe.

Why is Steel Sometimes Chosen for Power Bank Components?

Steel, particularly stainless steel, is sometimes used for internal components or structural elements of power banks. It offers excellent strength and durability, making it suitable for products requiring a robust design.

Pros and Cons:

– Pros: Highly durable, resistant to corrosion, and provides structural integrity.

– Cons: Heavier than other materials and can increase overall product weight.

Impact on Application: Steel is beneficial in power banks designed for rugged use, such as in industrial or outdoor applications.

Considerations for International Buyers: Buyers should consider the weight implications for portability and ensure that the steel used meets relevant material standards, such as DIN or JIS, particularly for markets in Europe and Asia.

Summary Table of Material Selection for Power Banks

| Material | Typical Use Case for power bank supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Power bank casing | Lightweight and corrosion-resistant | Higher manufacturing costs | Medium |

| Plastic | Power bank casing | Cost-effective and flexible design | Lower temperature resistance | Low |

| Lithium-Ion | Battery cells | High energy density and rechargeability | Higher cost and requires safety circuitry | High |

| Steel | Structural components | Excellent durability and strength | Increases overall product weight | Medium |

In conclusion, selecting the right material for power banks involves balancing performance, cost, and compliance with regional standards. Understanding the properties and implications of each material can help international B2B buyers make informed decisions that align with their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for power bank supplier

What Are the Main Stages in the Manufacturing Process of Power Banks?

The manufacturing process of power banks is a complex, multi-stage operation that ensures high-quality and reliable products. The key stages typically include:

-

Material Preparation: The first step involves sourcing and preparing raw materials such as lithium-ion cells, circuit boards, casings, and connectors. Suppliers must ensure that these materials comply with international safety and environmental standards. For example, lithium-ion cells should meet the UN38.3 standard for transportation safety.

-

Forming: In this stage, the prepared materials are shaped into their respective components. This may include processes like injection molding for casings or PCB etching for circuit boards. Precision in this phase is critical, as any defects can affect the overall performance of the power bank.

-

Assembly: During assembly, the various components are combined. This typically involves soldering the circuit boards to the battery cells, fitting them into their casings, and integrating charging ports. Automated assembly lines are often used to enhance efficiency and consistency.

-

Finishing: The final stage includes quality checks, packaging, and labeling. This is crucial for ensuring that the product meets aesthetic and functional standards before it reaches the market. Proper packaging is also important for protecting the power banks during shipping.

What Key Techniques Are Used in Power Bank Manufacturing?

Power bank manufacturers utilize various advanced techniques to improve efficiency and product quality:

-

Automation: Automated assembly lines are common in power bank production, reducing labor costs and increasing production speed. Automation also minimizes human error, ensuring a more consistent quality.

-

Surface Mount Technology (SMT): This technique is widely used for mounting electronic components directly onto the surface of printed circuit boards (PCBs). SMT allows for a more compact design and better performance of the power bank.

-

Battery Management Systems (BMS): Integrating BMS into the power banks ensures optimal charging and discharging cycles, enhancing battery life and safety. It helps in monitoring battery health and preventing overcharging, which is crucial for customer safety.

How Is Quality Assurance Implemented in Power Bank Manufacturing?

Quality assurance (QA) in power bank manufacturing is critical to ensure safety and performance. Here are the key components of an effective QA process:

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should ensure that their suppliers adhere to relevant international quality standards, including:

-

ISO 9001: This standard focuses on quality management systems and is crucial for ensuring that suppliers have a robust QA framework in place.

-

CE Marking: In Europe, CE marking indicates that the product complies with safety, health, and environmental protection standards. It’s essential for market access within the EU.

-

RoHS Compliance: The Restriction of Hazardous Substances (RoHS) directive limits the use of specific hazardous materials in electronic products, ensuring environmental safety.

What Are the Key Quality Control Checkpoints in Power Bank Manufacturing?

Quality control (QC) checkpoints are integral to the manufacturing process, ensuring that each stage meets quality standards. The main checkpoints include:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for defects before they enter the production process. This includes testing battery cells for capacity and safety.

-

In-Process Quality Control (IPQC): During the assembly phase, ongoing inspections are conducted to ensure that the manufacturing process adheres to established standards. This may involve checking solder joints and component placements.

-

Final Quality Control (FQC): After assembly, power banks undergo rigorous testing to ensure they function as intended. Tests may include charging and discharging cycles, stress tests, and safety checks for overheating or short circuits.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should adopt several strategies to verify the quality control practices of their suppliers:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control measures, and compliance with international standards. This can provide insights into the supplier’s operational integrity.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s QA processes and performance metrics. These reports should include data on defect rates, testing outcomes, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These services can conduct random checks at various stages of the manufacturing process.

What Common Testing Methods Are Used in Power Bank Quality Control?

Power banks undergo various testing methods to ensure their safety and performance. Some common testing methods include:

-

Electrical Testing: This includes tests for voltage, capacity, and current output. It verifies that the power bank delivers the promised specifications.

-

Environmental Testing: Power banks are subjected to temperature and humidity tests to ensure they can operate reliably in different environmental conditions.

-

Safety Testing: This involves assessing the product against safety standards to prevent risks like overheating, short-circuiting, or battery leakage.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers need to be aware of specific nuances regarding quality control:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. For example, while CE marking is essential in Europe, UL certification may be required in North America. Understanding these differences is crucial for market entry.

-

Cultural Considerations: Communication styles and business practices may differ across regions, affecting how quality control is perceived and implemented. Building strong relationships with suppliers can enhance mutual understanding and compliance.

-

Logistical Challenges: The geographical distance can lead to challenges in monitoring quality control processes. Establishing clear communication channels and regular reporting can mitigate these issues.

By understanding the manufacturing processes and quality assurance practices of power bank suppliers, international B2B buyers can make informed decisions and ensure they partner with reliable manufacturers. This knowledge is essential for navigating the complexities of global sourcing, particularly for buyers in Africa, South America, the Middle East, and Europe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘power bank supplier’

A stock image related to power bank supplier.

To effectively source a power bank supplier, it’s essential to follow a structured approach that ensures you find a reliable partner who meets your business needs. This checklist provides actionable steps tailored for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before initiating contact with suppliers, clearly outline the technical specifications for the power banks you require. This includes battery capacity (mAh), charging speed (W), and safety certifications (e.g., CE, FCC). Having these details defined helps streamline discussions and ensures that suppliers understand your exact needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Utilize online directories, trade shows, and industry-specific platforms to compile a list of manufacturers. Focus on suppliers with a strong market presence and positive reviews. This groundwork is critical for narrowing down your options to those who are reputable and capable of fulfilling your requirements.

Step 3: Evaluate Supplier Certifications

✅ Verify Supplier Certifications

Certifications like ISO 9001 and RoHS compliance are indicators of quality and safety standards. Request copies of relevant certifications to ensure that the suppliers adhere to international quality standards. This step is crucial in mitigating risks associated with product quality and compliance, particularly in diverse regulatory environments.

Step 4: Request Samples for Quality Testing

Before finalizing a supplier, it’s advisable to request samples of their power banks. This allows you to assess the product quality firsthand. Evaluate factors such as build quality, charging efficiency, and overall performance. Testing samples helps prevent potential issues after placing a bulk order and ensures the product meets your brand standards.

Step 5: Assess Production Capacity and Lead Times

Understand the supplier’s production capacity and lead times. Inquire about their ability to scale production based on your demand, especially during peak seasons. Reliable suppliers should provide clear timelines for order fulfillment. Knowing this information is vital to align your inventory and marketing strategies accordingly.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery conditions. Ensure that all agreements are documented to avoid misunderstandings later. A well-structured contract protects both parties and sets clear expectations.

Step 7: Establish Clear Communication Channels

Effective communication is essential for a successful partnership. Establish preferred communication channels and set regular check-ins to discuss order updates and any issues that may arise. Clear communication helps build a strong relationship with your supplier and ensures that both parties are aligned throughout the procurement process.

By following this step-by-step checklist, B2B buyers can confidently navigate the sourcing process for power bank suppliers, ensuring a partnership that meets their technical, quality, and logistical needs.

Comprehensive Cost and Pricing Analysis for power bank supplier Sourcing

What Are the Key Cost Components in Power Bank Supplier Sourcing?

When sourcing power banks, international B2B buyers must understand the various cost components that contribute to the final price. The primary components include:

-

Materials: The cost of raw materials, such as lithium-ion batteries, casings, and circuitry, constitutes a significant portion of the total cost. Prices can fluctuate based on global demand and availability, particularly for lithium and cobalt, which are critical for battery production.

-

Labor: Labor costs vary significantly based on the supplier’s location. In regions like South America or Africa, labor may be cheaper, but this can come with trade-offs in terms of expertise and production quality.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Suppliers in Europe, particularly Germany, may have higher overhead due to stringent labor laws and regulations, impacting overall pricing.

-

Tooling: Initial tooling costs for custom designs can be substantial. Buyers should be prepared for these upfront costs if they seek unique specifications or branding on their power banks.

-

Quality Control (QC): Ensuring the quality of power banks through rigorous testing and quality assurance processes is essential. This can add to the overall cost but is crucial for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping costs depend on the Incoterms agreed upon, which dictate who is responsible for shipping, insurance, and tariffs. International buyers must factor in logistics costs, which can vary greatly based on distance and shipping method.

-

Margin: Finally, the supplier’s profit margin will vary based on their business model and market positioning. It’s essential to understand that higher quality often comes with a higher margin.

How Do Price Influencers Affect Power Bank Costs?

Several factors influence the pricing of power banks, including:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide better pricing for larger orders. Understanding the MOQ can help buyers negotiate better rates, particularly for bulk purchases.

-

Specifications and Customization: Custom designs or specific features, such as fast charging or solar capabilities, can significantly increase costs. Buyers should clearly define their requirements to avoid unexpected pricing.

-

Materials and Quality Certifications: The choice of materials and certifications (e.g., CE, RoHS) can impact pricing. High-quality materials and compliance with international standards typically lead to higher costs but can enhance product reliability and marketability.

-

Supplier Factors: The supplier’s reputation, experience, and location can all affect pricing. Established suppliers with a track record of quality may charge more but can also offer peace of mind regarding product performance.

-

Incoterms: Understanding the agreed Incoterms can help buyers calculate the total landed cost of the power banks. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift responsibilities and costs between buyer and supplier.

What Are the Best Negotiation Tips for International B2B Buyers?

B2B buyers should consider the following strategies to optimize their sourcing process:

-

Conduct Thorough Market Research: Understanding market trends and pricing benchmarks can provide leverage during negotiations. This is especially relevant for buyers from Africa and South America, where local suppliers may have different pricing structures.

-

Negotiate Terms Beyond Price: Focus on securing favorable terms regarding payment schedules, lead times, and post-purchase support. This can enhance the overall value of the deal.

-

Evaluate Total Cost of Ownership (TCO): Consider all costs associated with the product over its lifecycle, including maintenance, potential failures, and replacement. A lower upfront cost may not always equate to a better deal if long-term costs are high.

-

Establish Relationships: Building long-term relationships with suppliers can result in better pricing and service. Suppliers may be more willing to negotiate if they see a potential for ongoing business.

Conclusion: Understanding Pricing Nuances for Effective Sourcing

International B2B buyers must navigate a complex landscape when sourcing power banks. By understanding the cost components, price influencers, and effective negotiation strategies, buyers from regions like Europe, Africa, and South America can make informed decisions that optimize their sourcing efforts. It is advisable to approach negotiations with a clear understanding of both the market and supplier dynamics to achieve the best possible outcomes.

- Disclaimer: Prices mentioned are indicative and can vary based on market conditions and supplier negotiations.*

Alternatives Analysis: Comparing power bank supplier With Other Solutions

Understanding Alternatives to Power Bank Suppliers

In the global market, B2B buyers are often faced with multiple solutions to meet their energy needs. While power banks are popular for portable energy storage, there are alternative technologies and methods that can provide similar benefits. Understanding these options can help buyers make informed decisions based on performance, cost, and specific use cases.

Comparison Table of Power Bank Supplier and Alternatives

| Comparison Aspect | Power Bank Supplier | Solar Chargers | Portable Generators |

|---|---|---|---|

| Performance | Moderate capacity, portable | Variable capacity, depends on sunlight | High capacity, reliable power output |

| Cost | Moderate upfront cost | Higher initial investment; long-term savings | Higher upfront and maintenance costs |

| Ease of Implementation | User-friendly, plug-and-play | Requires setup and sunlight exposure | Requires fuel and setup, more complex |

| Maintenance | Low maintenance | Minimal, but needs clean solar panels | Regular maintenance required (oil, fuel) |

| Best Use Case | Mobile devices, short trips | Outdoor activities, remote locations | Construction sites, heavy equipment |

Analyzing Alternatives in Detail

What Are the Advantages and Disadvantages of Solar Chargers?

Solar chargers harness energy from the sun, making them a sustainable alternative to traditional power banks. Their performance can vary significantly based on sunlight availability, which can be a drawback in overcast regions. However, they provide a long-term cost-saving benefit since they require no fuel and have minimal operational costs after the initial investment. Solar chargers are best suited for outdoor enthusiasts and remote locations where access to electricity is limited.

How Do Portable Generators Compare to Power Banks?

Portable generators offer a robust alternative, particularly for high-energy demands. They can power multiple devices simultaneously and are ideal for construction sites or events needing consistent energy. However, they come with higher upfront costs and require regular maintenance, such as fuel checks and oil changes. While they are less portable than power banks, their reliability makes them suitable for heavy-duty applications where power supply is crucial.

Conclusion: Choosing the Right Energy Solution for Your Needs

For B2B buyers in Africa, South America, the Middle East, and Europe, selecting the right energy solution involves evaluating specific operational needs, budget constraints, and the intended use case. Power banks excel in portability and ease of use for short-term applications, while solar chargers and portable generators may provide better long-term value and reliability for more extensive energy requirements. By carefully assessing the performance, cost, and maintenance of each option, buyers can make strategic decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for power bank supplier

What Are the Key Technical Properties of Power Banks for B2B Buyers?

When sourcing power banks, understanding the technical specifications is essential for making informed purchasing decisions. Here are several critical specifications that B2B buyers should consider:

-

Battery Capacity (mAh)

– Measured in milliampere-hours (mAh), this indicates how much charge the power bank can store. A higher capacity means more power can be stored, allowing for multiple charges of devices. For international buyers, especially in regions with limited access to electricity, selecting power banks with higher capacities is crucial for reliability. -

Output Power (W)

– This refers to the amount of power the device can deliver to connected devices, often measured in watts (W). Understanding the output power is important to ensure compatibility with various devices, as different gadgets may require different power levels for optimal charging. -

Input Power (W)

– Similar to output power, input power measures how quickly the power bank can recharge itself. A higher input wattage means shorter charging times. For businesses that rely on quick turnaround times, selecting power banks with high input power can significantly improve efficiency. -

Material Grade

– The material used in the construction of the power bank affects its durability and safety. Common materials include ABS plastic and aluminum. Buyers should consider the environmental impact and quality of materials, especially if the power bank will be used in rugged conditions. -

Charging Technology (e.g., Quick Charge, Power Delivery)

– Advanced charging technologies like Quick Charge or Power Delivery allow for faster charging times and enhanced efficiency. These technologies are increasingly important for business users who need to charge devices quickly to minimize downtime. -

Safety Features

– Look for power banks that include safety features such as overcharge protection, short circuit protection, and temperature control. These features help prevent damage to both the power bank and connected devices, which is critical for maintaining operational integrity in a business context.

What Are Common Trade Terms Used in Power Bank Supply?

Navigating the power bank supply chain involves understanding key trade terminology. Here are several important terms that every B2B buyer should be familiar with:

-

OEM (Original Equipment Manufacturer)

– This refers to companies that produce products that are marketed under another company’s brand. For B2B buyers, partnering with OEMs can allow for customized power bank solutions tailored to specific branding and functional requirements. -

MOQ (Minimum Order Quantity)

– MOQ indicates the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is crucial for budget planning and inventory management, especially for businesses that may not require large quantities. -

RFQ (Request for Quotation)

– An RFQ is a document used by buyers to request price quotes from suppliers for specific products. This process is essential for comparing costs and ensuring that you receive competitive pricing from different suppliers. -

Incoterms (International Commercial Terms)

– These are a series of international sales terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps businesses understand shipping costs, risk management, and delivery responsibilities. -

Lead Time

– This term refers to the amount of time it takes from placing an order to the delivery of the product. For B2B buyers, knowing the lead time is vital for supply chain management and ensuring timely product availability. -

Warranty Period

– The warranty period indicates how long the manufacturer guarantees the product against defects. Understanding warranty terms is important for risk management and maintaining product reliability, especially in bulk purchases.

By grasping these technical properties and trade terms, international B2B buyers can make better-informed decisions when sourcing power banks, ensuring they select products that meet their operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the power bank supplier Sector

What Are the Current Market Dynamics and Key Trends in the Power Bank Supplier Sector?

The power bank supplier sector is experiencing significant transformation driven by several global factors. The increasing reliance on portable devices, coupled with the rise of remote work and digital nomadism, has escalated demand for reliable and efficient power solutions. In regions like Africa and South America, where electricity supply can be inconsistent, power banks serve as essential tools for both consumers and businesses. Meanwhile, in Europe and the Middle East, the focus is shifting towards high-capacity and fast-charging options, reflecting a tech-savvy consumer base that prioritizes efficiency.

Emerging trends in sourcing include a growing preference for suppliers who can offer customization options. International B2B buyers are seeking products that can be tailored to specific market needs, whether that’s branding for corporate gifts or unique functionalities like solar charging. Additionally, the rise of e-commerce platforms has made it easier for businesses to source power banks directly from manufacturers, bypassing traditional distribution channels. This shift requires buyers to be savvy about online sourcing, evaluating supplier credibility and product quality effectively.

How Is Sustainability Impacting the Sourcing of Power Banks in B2B Transactions?

Sustainability is becoming a pivotal factor in the power bank supplier landscape. B2B buyers are increasingly aware of the environmental impact of their purchases, pushing suppliers to adopt greener practices. This includes using recyclable materials, reducing packaging waste, and minimizing carbon footprints during production. Buyers from Europe, in particular, are driving demand for power banks that meet stringent environmental regulations, such as the EU’s Eco-Design Directive.

The importance of ethical sourcing cannot be overstated. Buyers are seeking suppliers that prioritize fair labor practices and ethical supply chains. Certifications such as ISO 14001 for environmental management and Fair Trade certifications are becoming essential criteria in supplier selection. By aligning their sourcing strategies with these values, international buyers can enhance their brand reputation and appeal to environmentally conscious consumers.

What Is the Brief Evolution of the Power Bank Supplier Sector?

The power bank industry has evolved significantly since its inception in the early 2000s. Initially, power banks were bulky and offered limited capacity, primarily designed for emergency charging. However, as smartphone technology advanced and the demand for mobile power surged, manufacturers began innovating. The introduction of lithium polymer batteries provided a lighter, more efficient alternative, enabling the creation of compact designs with higher capacities.

In recent years, the advent of fast charging technology has further transformed the market, allowing users to charge devices in record time. As a result, power banks are no longer seen merely as backup solutions but as essential accessories for modern living. This evolution presents B2B buyers with a diverse range of options, from ultra-portable models to high-capacity power banks equipped with multiple output ports, catering to a variety of business needs.

Frequently Asked Questions (FAQs) for B2B Buyers of power bank supplier

-

How do I evaluate the credibility of a power bank supplier?

To assess the credibility of a power bank supplier, start by checking their business licenses and certifications, such as ISO or CE marks, which indicate compliance with international safety standards. Request references from previous clients, and look for online reviews or testimonials. Additionally, consider visiting their manufacturing facility if possible, or utilize third-party verification services to confirm their operational capabilities and quality control processes. -

What is the best way to negotiate payment terms with a power bank supplier?

Negotiating payment terms typically involves establishing a balance between risk management and cash flow needs. Common terms include a deposit of 30% upfront with the remaining 70% due upon delivery. For larger orders, consider requesting extended payment terms or a letter of credit to secure the transaction. Always ensure that the payment method is reliable and offers buyer protection, such as PayPal or escrow services for added security. -

What are the typical minimum order quantities (MOQ) for power banks?

Minimum order quantities (MOQ) for power banks can vary significantly based on the supplier and customization options. Generally, MOQs range from 100 to 1,000 units. If you are looking for customized designs or features, expect higher MOQs due to the additional manufacturing costs. It’s advisable to discuss flexibility with the supplier, especially if you are testing a new market or product line. -

How can I ensure quality assurance when sourcing power banks?

To ensure quality assurance, implement a multi-step process that includes pre-production inspections, in-process quality checks, and final product evaluations. Request samples before placing a bulk order to assess quality firsthand. Additionally, consider hiring third-party inspection services to conduct thorough evaluations during production and prior to shipment, ensuring that the products meet your specifications and standards. -

What customization options are available for power banks?

Many power bank suppliers offer a range of customization options, including branding, capacity, color, and size. You can request features such as LED indicators, fast charging capabilities, or multiple output ports. Discuss your specific requirements with the supplier to understand the extent of customization available, as some may have limitations based on their manufacturing processes. -

How do I handle logistics and shipping for power bank orders?

When managing logistics and shipping for power bank orders, consider factors such as shipping methods, costs, and delivery timelines. Work closely with your supplier to determine the best shipping options—air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Ensure that customs documentation is correctly handled to prevent delays, and consider using freight forwarders who specialize in international shipping to streamline the process. -

What should I know about warranty and after-sales service for power banks?

Understanding warranty terms and after-sales service is crucial for maintaining customer satisfaction. Most reputable power bank suppliers offer warranties ranging from 12 to 24 months, covering defects in materials and workmanship. Clarify the warranty process and after-sales support, including how repairs or replacements will be handled. Ensure that the supplier provides clear guidelines for returns and exchanges to facilitate smooth transactions. -

How do I stay compliant with international regulations when importing power banks?

To remain compliant with international regulations when importing power banks, familiarize yourself with the specific import laws of your country and the countries you are exporting to. Key regulations often include safety standards, electrical certifications, and environmental considerations like RoHS compliance. Work with your supplier to ensure that all products meet these requirements and keep updated with any changes in regulations to avoid potential penalties or shipment delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for power bank supplier

Why Is Strategic Sourcing Essential for Power Bank Suppliers?

In conclusion, effective strategic sourcing is pivotal for international B2B buyers seeking reliable power bank suppliers. By focusing on quality, cost efficiency, and supplier reliability, businesses can significantly enhance their procurement processes. Engaging with suppliers from diverse regions, such as Africa, South America, the Middle East, and Europe, allows companies to leverage competitive advantages, including local market insights and innovative product offerings.

What Are the Key Takeaways for International B2B Buyers?

- Prioritize Quality and Compliance: Ensure that suppliers meet international quality standards and regulatory requirements to avoid future liabilities.

- Evaluate Supplier Relationships: Building long-term partnerships can lead to better pricing, priority service, and innovative product developments.

- Leverage Technology: Utilize digital tools for better supplier management, inventory tracking, and data analysis to drive efficiency.

How Can Buyers Prepare for Future Trends?

As the demand for portable charging solutions continues to rise, international B2B buyers must stay informed about emerging technologies and market trends. This proactive approach will enable businesses to adapt swiftly to changing consumer needs and preferences. By investing in strategic sourcing today, companies can secure a competitive edge in the evolving power bank market.

Take action now by assessing your current sourcing strategies and exploring potential new suppliers to ensure your business remains at the forefront of the industry.