Discover Top Benefits of a Reliable Sweater Supplier (2025)

Introduction: Navigating the Global Market for sweater supplier

In today’s interconnected world, sourcing the right sweater supplier can pose significant challenges for international B2B buyers. From identifying reputable manufacturers to ensuring compliance with quality standards, the process can be daunting, especially for businesses in regions such as Africa, South America, the Middle East, and Europe. This comprehensive guide serves as an essential resource for navigating the complexities of the global market for sweater suppliers, equipping you with the knowledge to make informed purchasing decisions.

Throughout this guide, we will explore various types of sweaters available, ranging from casual wear to high-performance options, and their diverse applications in different markets. Understanding the nuances of supplier vetting is crucial; we will provide actionable insights into evaluating potential partners based on quality, reliability, and ethical practices. Additionally, we will delve into cost considerations, helping you balance budget constraints with the need for quality and sustainability.

By empowering B2B buyers with a thorough understanding of the global sweater supply landscape, this guide aims to simplify the sourcing process. Whether you are a business owner in Kenya seeking to expand your product line or a distributor in Europe looking for competitive suppliers, our insights will help you navigate the challenges of sourcing effectively and efficiently. Prepare to enhance your procurement strategy and establish fruitful partnerships with trusted sweater suppliers worldwide.

Understanding sweater supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wholesale Sweater Suppliers | Large volume production, varied styles | Retail, e-commerce, promotional events | Pros: Cost-effective, diverse options. Cons: Minimum order quantities may apply. |

| Custom Sweater Manufacturers | Tailored designs, small batch production | Corporate branding, promotional giveaways | Pros: Unique designs, brand alignment. Cons: Higher costs, longer lead times. |

| Sustainable Sweater Suppliers | Eco-friendly materials, ethical labor practices | Niche markets, environmentally conscious brands | Pros: Market differentiation, positive brand image. Cons: Potentially higher prices. |

| Knitting Factories | In-house production, specialized knitting techniques | Bulk orders, specialized designs | Pros: Control over quality, quick turnaround. Cons: Limited styles compared to wholesalers. |

| Importers/Distributors | Wide range of sourced products, established networks | Retail chains, export markets | Pros: Access to global trends, diverse offerings. Cons: Markup costs, potential delays in shipping. |

What Are the Characteristics of Wholesale Sweater Suppliers?

Wholesale sweater suppliers typically focus on large-scale production, offering a wide array of styles and sizes. They are ideal for businesses looking to stock retail stores or e-commerce platforms with diverse options at competitive prices. When considering wholesale suppliers, B2B buyers should evaluate minimum order quantities and shipping costs, as these can significantly impact overall expenses. Additionally, it’s essential to assess the supplier’s ability to maintain consistent quality across large orders.

How Do Custom Sweater Manufacturers Cater to Unique Needs?

Custom sweater manufacturers specialize in creating tailored designs that meet specific branding or promotional needs. These suppliers often work in smaller batches, allowing for greater flexibility in design and material selection. B2B buyers seeking to differentiate their brand through unique apparel should consider factors such as design capabilities, lead times, and pricing structures. While custom sweaters can enhance brand visibility, buyers should also be aware of the potential for higher costs and longer production timelines.

Why Choose Sustainable Sweater Suppliers for Ethical Sourcing?

Sustainable sweater suppliers focus on eco-friendly materials and ethical labor practices, making them a great choice for businesses targeting environmentally conscious consumers. These suppliers often provide transparency in their sourcing and manufacturing processes, which can enhance brand reputation. B2B buyers should consider the trade-offs involved, such as potentially higher prices and limited availability of certain styles. However, the long-term benefits of aligning with sustainable practices can lead to increased customer loyalty and market differentiation.

What Advantages Do Knitting Factories Offer for Specialized Needs?

Knitting factories are characterized by their in-house production capabilities and specialized knitting techniques. This type of supplier is suitable for businesses requiring bulk orders or specific design features that may not be available through wholesalers. Buyers should evaluate the factory’s experience, quality control measures, and flexibility in adapting to custom requests. While knitting factories often provide quicker turnaround times, their style offerings may be more limited compared to wholesale suppliers.

How Do Importers and Distributors Expand Product Access?

Importers and distributors serve as intermediaries, providing access to a wide range of sweater products sourced from various manufacturers. This can be particularly beneficial for retail chains and businesses looking to tap into global fashion trends. B2B buyers should assess the distributor’s network, product diversity, and shipping reliability. While this option can enhance product variety, buyers should be mindful of markup costs and potential delays in delivery that can affect inventory management.

Key Industrial Applications of sweater supplier

| Industry/Sector | Specific Application of Sweater Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Seasonal Fashion Collections | Enhances brand image and customer loyalty | Quality, design trends, and production lead times |

| Corporate Apparel | Employee Uniforms and Corporate Gifts | Promotes brand identity and employee satisfaction | Customization options, fabric durability, and sizes |

| Sports and Outdoor Gear | Performance Sweaters for Outdoor Activities | Meets specific performance needs and safety standards | Breathability, moisture-wicking properties, and fit |

| Education | School Uniforms and Sweaters for Institutions | Fosters community spirit and school identity | Compliance with dress codes, size ranges, and pricing |

| Hospitality | Sweaters for Staff Uniforms in Hotels and Restaurants | Enhances customer experience and professional appearance | Fabric comfort, style coordination, and maintenance |

How Are Sweater Suppliers Beneficial to the Retail Sector?

In the retail industry, sweater suppliers play a crucial role in seasonal fashion collections. They provide a variety of styles and materials that can be tailored to current fashion trends, helping retailers attract customers and boost sales. By partnering with reliable suppliers, retailers can ensure high-quality products that enhance their brand image and foster customer loyalty. International buyers, especially from Africa and South America, should consider the supplier’s ability to respond to rapid fashion cycles and maintain consistent quality.

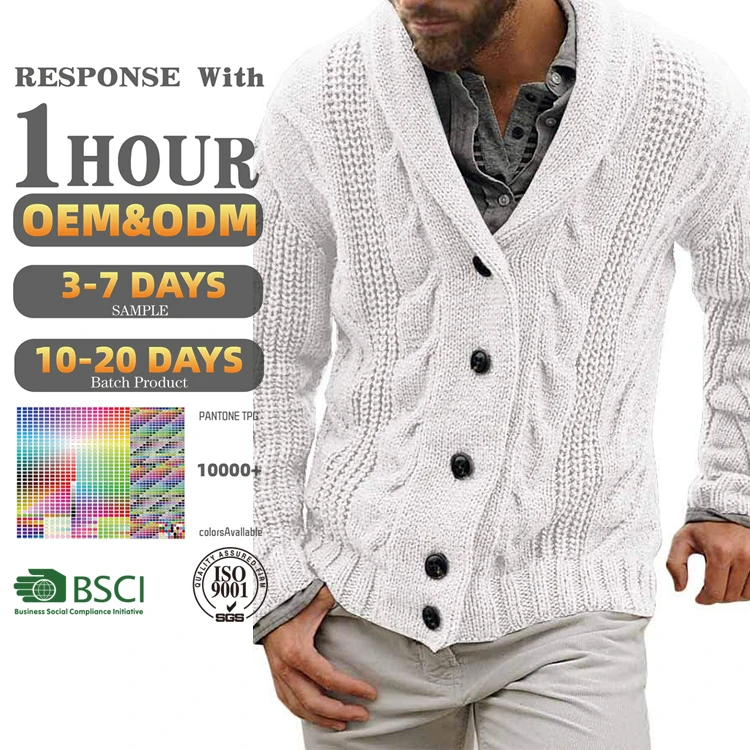

A stock image related to sweater supplier.

What Role Do Sweater Suppliers Play in Corporate Apparel?

Corporate apparel often includes sweaters that serve as employee uniforms or promotional gifts. These garments help promote brand identity while ensuring employees look professional and cohesive. When sourcing sweaters for corporate use, businesses should prioritize customization options, fabric durability, and size availability to meet diverse employee needs. Buyers from the Middle East and Europe should also evaluate suppliers’ capabilities in providing sustainable and ethically produced options, reflecting growing corporate responsibility trends.

How Are Sweater Suppliers Meeting the Needs of the Sports and Outdoor Gear Industry?

In the sports and outdoor gear sector, sweater suppliers provide performance-focused garments designed for outdoor activities. These sweaters often feature moisture-wicking properties, breathability, and lightweight materials that enhance user comfort and safety. Buyers in regions like Australia and Africa, where outdoor activities are prevalent, should seek suppliers with expertise in technical fabrics and innovative designs. Ensuring that the products meet specific performance standards is essential for maintaining customer satisfaction and safety.

What Are the Key Considerations for Sweater Suppliers in the Education Sector?

Educational institutions frequently utilize sweater suppliers for school uniforms and branded sweaters. These garments foster a sense of community and school spirit among students. When sourcing, institutions should consider compliance with dress codes, a wide range of sizes, and competitive pricing. International buyers, particularly from Europe, should also assess the supplier’s ability to deliver large orders on time, ensuring that all students are outfitted appropriately at the start of the academic year.

How Do Sweater Suppliers Enhance the Hospitality Industry?

In the hospitality sector, sweaters are often used as staff uniforms in hotels and restaurants. These garments contribute to a professional appearance and enhance the overall customer experience. Buyers in this industry should focus on fabric comfort, style coordination with existing uniforms, and ease of maintenance when selecting a supplier. Given the high turnover and demand in hospitality, suppliers should also demonstrate reliability in meeting quick turnaround times for replenishing stock.

Related Video: Sweater Manufacturing | A to Z Auto Production system | Knit to Pack| sweater factory in Bangladesh

3 Common User Pain Points for ‘sweater supplier’ & Their Solutions

Scenario 1: Navigating Supply Chain Disruptions in Sweater Sourcing

The Problem:

B2B buyers often face significant challenges with supply chain disruptions, especially when sourcing sweaters from international suppliers. Issues such as political instability, logistical hurdles, and global economic fluctuations can lead to delays in production and shipping. This uncertainty not only impacts stock levels but also affects customer satisfaction, ultimately harming the buyer’s reputation in the market. Buyers in regions like Africa and South America, who may already contend with less robust logistics infrastructure, are particularly vulnerable to these disruptions.

The Solution:

To mitigate the risks associated with supply chain disruptions, buyers should adopt a multi-supplier strategy. By diversifying their supplier base across different regions, businesses can reduce their dependency on a single source and enhance their resilience against localized disruptions. Furthermore, it’s essential to establish clear communication channels with suppliers to receive timely updates on production and shipping statuses. Utilizing supply chain management software can also help track shipments and predict potential delays, allowing buyers to make informed decisions. Building relationships with suppliers who have strong logistical capabilities, especially those familiar with the specific challenges of the buyer’s region, can further streamline the process.

Scenario 2: Ensuring Quality Control in Sweater Manufacturing

The Problem:

Quality control is a critical concern for B2B buyers, particularly in the fashion and apparel industry. When sourcing sweaters from suppliers, there can be discrepancies in material quality, sizing, and overall craftsmanship. These inconsistencies can lead to high return rates and lost sales, particularly for businesses looking to establish a strong brand reputation. Buyers from Europe, for example, may have specific standards that need to be met, making it crucial to ensure that suppliers adhere to these guidelines.

The Solution:

To ensure consistent quality, buyers should implement a stringent quality assurance process. This can include setting clear specifications for materials and workmanship in the initial contract with the supplier. Buyers might also consider conducting factory audits or quality inspections at various stages of the production process. Engaging third-party quality control services can provide an objective assessment and help catch issues before the products reach the market. Additionally, establishing a feedback loop with suppliers allows for continuous improvement based on past issues, fostering a collaborative approach to quality enhancement.

Scenario 3: Adapting to Rapid Market Trends in Sweater Fashion

The Problem:

In the fast-paced world of fashion, trends can shift rapidly, often leaving B2B buyers struggling to keep their inventory relevant. Buyers from regions like the Middle East and South America may find it challenging to predict which sweater styles, colors, and materials will resonate with their customers, particularly when seasonal changes and cultural influences come into play. Failure to adapt can result in unsold inventory and significant financial losses.

The Solution:

To stay ahead of market trends, buyers should invest in market research and trend forecasting services. Partnering with local fashion consultants who understand regional preferences can provide invaluable insights into what styles are gaining traction. Additionally, maintaining flexible inventory management practices allows buyers to pivot quickly in response to changing demands. Implementing a pre-order model can also help gauge customer interest before committing to large production runs. By leveraging data analytics to track sales patterns and consumer behavior, buyers can make informed decisions that align their product offerings with market demand, ultimately leading to increased sales and customer loyalty.

Strategic Material Selection Guide for sweater supplier

When selecting materials for sweater production, international B2B buyers must consider various factors that impact product quality, performance, and market acceptance. Below, we analyze four common materials used in sweater manufacturing, focusing on their properties, pros and cons, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Cotton in Sweater Manufacturing?

Cotton is a natural fiber known for its softness, breathability, and comfort. It typically performs well in moderate temperatures, making it suitable for various climates. Cotton sweaters can withstand washing and maintain their shape, but they may not provide the same thermal insulation as synthetic fibers.

Pros & Cons of Cotton

- Pros: Excellent moisture absorption, hypoallergenic, and biodegradable. Cotton is also relatively inexpensive and widely available.

- Cons: Lower durability compared to synthetic materials, prone to shrinking, and less effective in extreme weather conditions.

Impact on Application

Cotton is compatible with casual wear and everyday use. However, it may not be ideal for high-performance applications, such as outdoor activities in colder climates.

Considerations for International Buyers

Buyers in regions like Africa and South America should consider local cotton availability and pricing fluctuations. Compliance with organic standards, such as GOTS (Global Organic Textile Standard), may also influence purchasing decisions.

How Does Wool Compare as a Material for Sweaters?

Wool is renowned for its excellent thermal properties, making it a popular choice for colder climates. It can wick moisture away from the skin while providing insulation, even when wet. Wool fibers are naturally elastic, helping garments retain their shape.

Pros & Cons of Wool

- Pros: Superior warmth, moisture-wicking properties, and natural odor resistance. Wool is also biodegradable and renewable.

- Cons: Higher cost than cotton, can be itchy for some users, and requires special care to avoid shrinkage.

Impact on Application

Wool is ideal for winter apparel and outdoor gear, particularly in regions with cold winters, such as parts of Europe and the Middle East.

Considerations for International Buyers

Buyers should be aware of the wool market’s seasonal fluctuations and animal welfare standards. Compliance with regulations regarding mulesing practices may be particularly relevant in European markets.

What Are the Benefits of Synthetic Fibers in Sweater Production?

Synthetic fibers, such as polyester and acrylic, are commonly used in sweater manufacturing due to their durability and cost-effectiveness. These materials often provide excellent moisture-wicking capabilities and can be engineered for specific performance characteristics.

Pros & Cons of Synthetic Fibers

- Pros: High durability, lightweight, and quick-drying. They are also resistant to shrinking and wrinkling.

- Cons: Less breathable than natural fibers, can retain odors, and are less environmentally friendly due to petroleum-based origins.

Impact on Application

Synthetic sweaters are suitable for activewear and casual clothing, particularly in warmer climates where breathability is less critical.

Considerations for International Buyers

Buyers should consider sustainability certifications, such as Oeko-Tex, especially in European markets where eco-consciousness is high. Cost-effectiveness is a significant advantage for buyers in emerging markets in Africa and South America.

Why Choose Blends for Sweater Manufacturing?

Blended materials, such as cotton-polyester or wool-acrylic, combine the benefits of natural and synthetic fibers. These blends can enhance performance characteristics while reducing costs.

Pros & Cons of Blends

- Pros: Improved durability, comfort, and versatility. Blends can be tailored to meet specific market demands.

- Cons: Potentially less eco-friendly than 100% natural fibers, and quality can vary widely based on the blend ratio.

Impact on Application

Blended sweaters can cater to a diverse range of applications, from casual to semi-formal wear, making them a versatile choice for various markets.

Considerations for International Buyers

Buyers should evaluate the blend ratios based on target markets and consumer preferences. Compliance with textile regulations in their respective regions is also crucial.

Summary Table of Strategic Material Selection for Sweater Suppliers

| Material | Typical Use Case for sweater supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton | Casual wear, everyday use | Softness and breathability | Lower durability, prone to shrinking | Low |

| Wool | Winter apparel, outdoor gear | Superior warmth and moisture-wicking | Higher cost, requires special care | High |

| Synthetic | Activewear, casual clothing | High durability and quick-drying | Less breathable, can retain odors | Medium |

| Blends | Versatile applications | Combines benefits of natural and synthetic | Quality can vary based on blend ratio | Medium |

This guide aims to equip international B2B buyers with the knowledge to make informed decisions when selecting materials for sweater production, ensuring they meet market demands while adhering to compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for sweater supplier

What Are the Main Stages of Sweater Manufacturing?

The manufacturing process for sweaters involves several critical stages that ensure the final product meets quality and design specifications. Here’s an overview of the main stages:

1. Material Preparation

The first step in sweater manufacturing is the selection and preparation of raw materials. Common materials include wool, cotton, acrylic, and blends. Each material has specific properties that influence the sweater’s warmth, breathability, and durability.

-

Sourcing Quality Yarn: International B2B buyers should ensure that suppliers source high-quality yarn from reputable manufacturers. This often involves checking the fiber’s origin and the supplier’s certifications.

-

Color and Dyeing Process: Color consistency is crucial. Suppliers may utilize various dyeing techniques, including yarn dyeing or piece dyeing, to achieve the desired shades. Buyers should inquire about the dyeing methods used, as they can impact both colorfastness and eco-friendliness.

2. Forming

In this stage, the prepared yarn is transformed into fabric. This involves techniques such as knitting or weaving.

-

Knitting Techniques: Most sweaters are produced through knitting, which allows for elasticity and comfort. Different knitting techniques, such as flat knitting or circular knitting, can yield different textures and patterns. B2B buyers should ask suppliers about their knitting capabilities to ensure they can meet specific design requirements.

-

Weaving for Specialty Fabrics: While less common for sweaters, some suppliers may offer woven options for unique textures. Understanding the supplier’s capabilities in both knitting and weaving can help buyers make informed decisions.

3. Assembly

Once the fabric is produced, the assembly process begins. This includes cutting the fabric into specific patterns and sewing the pieces together.

-

Pattern Cutting: Precise cutting of the fabric is essential for ensuring that each sweater fits correctly. Suppliers should use advanced cutting technology to minimize waste and ensure accuracy.

-

Sewing Techniques: The assembly process can involve various stitching methods, such as overlock stitching or flatlock stitching. Buyers should evaluate the supplier’s sewing capabilities and inquire about the machinery used to ensure high-quality seams.

4. Finishing

The final stage involves finishing processes that enhance the sweater’s appearance and functionality.

-

Washing and Blocking: Sweaters are often washed to remove any residual chemicals and then blocked to shape the fabric. This step can significantly affect the final look and feel of the product.

-

Final Inspection and Packaging: Before packaging, a final inspection ensures that each sweater meets quality standards. Buyers should ask about the supplier’s packaging methods, as proper packaging can prevent damage during transit.

How is Quality Control Implemented in Sweater Manufacturing?

Quality control (QC) is a crucial component of the manufacturing process, ensuring that the final product meets both international standards and buyer expectations. Here’s how QC is typically implemented:

Relevant International Standards and Certifications

B2B buyers should be aware of various international standards that govern quality in manufacturing:

-

ISO 9001: This standard focuses on quality management systems and is crucial for suppliers aiming to demonstrate their commitment to quality.

-

CE Marking: For buyers in Europe, CE marking indicates that the product meets EU safety, health, and environmental requirements.

-

API Standards: In some cases, especially for technical textiles, API standards may apply. Understanding these standards can help buyers assess a supplier’s quality assurance capabilities.

Key QC Checkpoints in the Manufacturing Process

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications before production begins.

-

In-Process Quality Control (IPQC): During production, continuous monitoring helps catch issues early. This stage often includes random sampling and testing of fabric and seams.

-

Final Quality Control (FQC): After assembly, the final inspection checks for defects, ensuring that each sweater meets the required quality standards before packaging.

What Testing Methods Are Commonly Used in Sweater Manufacturing?

To ensure that sweaters meet quality and safety standards, various testing methods are employed:

-

Physical Testing: This includes checks for fabric strength, seam durability, and stretchability. Buyers can request reports on these tests to assess quality.

-

Colorfastness Tests: These tests determine how well the fabric holds its color when exposed to washing and light. Suppliers should provide certification to demonstrate compliance with colorfastness standards.

-

Safety Tests: For markets with strict regulations, such as Europe, safety tests ensure that the materials used do not contain harmful substances. Buyers should verify that suppliers conduct these tests regularly.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure they receive high-quality products. Here are some actionable steps:

Conducting Supplier Audits

Regular audits can help buyers assess the supplier’s compliance with quality standards. This may include:

-

On-Site Inspections: Visiting the manufacturing facility allows buyers to observe the production process and QC measures firsthand.

-

Reviewing Documentation: Buyers should request and review quality control documentation, including inspection reports and certifications.

Requesting Quality Assurance Reports

Buyers can ask suppliers to provide detailed quality assurance reports that outline the testing methods used and the results obtained. This transparency helps build trust and ensures that quality standards are being met.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These services can conduct inspections at various stages of production, providing buyers with additional assurance regarding product quality.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing sweaters from suppliers in different regions, B2B buyers should consider several nuances:

-

Cultural Differences in Quality Standards: Quality expectations can vary significantly across regions. Buyers from Africa and South America may have different standards compared to those in Europe or the Middle East. Understanding these differences can help in setting clear expectations with suppliers.

-

Compliance with Local Regulations: Buyers should ensure that suppliers comply with local regulations in their own markets, particularly regarding safety and environmental standards. This is especially important for buyers in Europe, where compliance is strictly enforced.

-

Language Barriers and Communication: Effective communication is key to ensuring quality. Buyers should consider language barriers and work with suppliers that offer clear communication channels, including documentation in the buyer’s preferred language.

A stock image related to sweater supplier.

By understanding the manufacturing processes and quality assurance practices involved in sweater production, international B2B buyers can make informed decisions when sourcing from suppliers across Africa, South America, the Middle East, and Europe. Ensuring that suppliers adhere to international standards and maintain rigorous quality control processes will ultimately lead to better product quality and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sweater supplier’

The following guide serves as a practical checklist for international B2B buyers looking to procure sweaters from reliable suppliers. By following these steps, you can ensure a streamlined sourcing process that meets your business needs and quality standards.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is essential for effective sourcing. This includes material types (e.g., wool, cotton, synthetic blends), design styles (e.g., crew neck, V-neck, cardigan), and size ranges. Providing detailed specifications helps suppliers understand your exact requirements, reducing the chances of miscommunication later in the process.

Step 2: Conduct Market Research for Potential Suppliers

Before reaching out to suppliers, conduct thorough market research to identify potential candidates. Look for suppliers that specialize in sweater production and have a strong reputation in your target regions (Africa, South America, the Middle East, and Europe). Utilize platforms like Alibaba, Global Sources, and industry trade shows to gather a list of potential suppliers.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that potential suppliers hold relevant certifications and comply with international quality standards. Certifications such as ISO 9001 (Quality Management) and OEKO-TEX (Sustainability) indicate a commitment to quality and ethical practices. This step is crucial to ensure that the products you source meet your quality benchmarks and regulatory requirements in your market.

Step 4: Request Samples for Quality Assessment

Once you’ve shortlisted potential suppliers, request samples to assess the quality of their products. Examine the material, stitching, and overall craftsmanship to ensure they align with your specifications. This step is vital in verifying that the supplier can deliver the quality you need before placing a bulk order.

Step 5: Negotiate Pricing and Payment Terms

Engage in negotiations regarding pricing and payment terms with your selected suppliers. Understand the factors that influence pricing, such as order volume, customization, and shipping costs. Establish clear payment terms that protect your interests, such as partial upfront payments or payment upon delivery.

Step 6: Establish Clear Communication Channels

Effective communication is key to a successful partnership with your supplier. Set up regular check-ins and updates to discuss production timelines, quality control, and any potential issues that may arise. This proactive approach will help build trust and ensure that both parties are aligned throughout the sourcing process.

Step 7: Plan for Logistics and Shipping

Lastly, consider the logistics involved in shipping your sweaters from the supplier to your location. Evaluate shipping methods, costs, and delivery timelines to ensure that your products arrive on time and in good condition. Understanding the logistics process will help you manage your inventory effectively and meet your customers’ demands.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing sweaters and build reliable partnerships with suppliers across different regions.

Comprehensive Cost and Pricing Analysis for sweater supplier Sourcing

What Are the Key Cost Components in Sweater Supplier Sourcing?

Understanding the cost structure of sourcing from sweater suppliers is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of yarn (wool, cotton, synthetic blends) significantly influences cost. Natural fibers often command higher prices, while synthetic materials may offer cost savings but can impact quality perceptions.

-

Labor: Labor costs can vary dramatically based on the country of origin. For instance, countries in Southeast Asia typically have lower labor costs compared to those in Europe or North America. This factor can affect the overall pricing strategy of the supplier.

-

Manufacturing Overhead: This includes utilities, equipment depreciation, and facility costs. Suppliers with efficient operations may pass savings onto buyers, making it essential to assess their production capabilities.

-

Tooling: Initial setup costs for machinery and molds can be significant, especially for custom designs. Buyers should inquire about these costs, as they can affect pricing, particularly for small orders.

-

Quality Control (QC): Implementing stringent QC measures ensures the final product meets specifications but adds to costs. It’s advisable to confirm the QC processes in place to prevent future issues.

-

Logistics: Transportation costs, including shipping, duties, and tariffs, can add up, especially for international shipments. Understanding Incoterms is critical for determining who bears these costs.

-

Margin: Supplier profit margins can vary based on market competition and perceived value. Buyers should be aware that higher-quality suppliers may charge more due to their reputation and reliability.

How Do Pricing Influencers Affect Sweater Supplier Costs?

Several factors can influence the pricing dynamics in sweater sourcing:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their inventory needs.

-

Specifications and Customization: Custom designs or specific fabric qualities can increase costs. Buyers must weigh the benefits of customization against the additional expenses incurred.

-

Material Quality and Certifications: Sourcing high-quality or certified materials (like organic or recycled fibers) can significantly impact pricing. It’s crucial to balance quality requirements with budget constraints.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can also influence pricing. Established suppliers with a track record may charge a premium but offer reliability and quality assurance.

-

Incoterms: Understanding the shipping terms can affect overall costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping costs and risks, impacting final pricing.

What Are Essential Buyer Tips for Negotiating Sweater Supplier Prices?

To navigate the complexities of sweater supplier pricing effectively, buyers should consider the following strategies:

-

Negotiate with Clarity: Be clear about your requirements and expectations. Provide detailed specifications to minimize misunderstandings that can lead to added costs.

-

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes purchase price, shipping, duties, and potential returns. A lower upfront cost may not always lead to savings if quality issues arise later.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions. Currency fluctuations, political stability, and economic factors can influence supplier pricing and reliability.

-

Build Relationships: Developing strong relationships with suppliers can lead to better pricing and terms. Regular communication fosters trust and can result in preferential treatment during negotiations.

Disclaimer on Indicative Prices

While this analysis provides a comprehensive overview, it’s important to note that prices can fluctuate based on market conditions, material availability, and supplier negotiations. Buyers should conduct thorough research and request detailed quotes from multiple suppliers to ensure they receive competitive pricing.

Alternatives Analysis: Comparing sweater supplier With Other Solutions

Understanding the Importance of Alternative Solutions for Sweater Supply

In the competitive landscape of international B2B trade, particularly for buyers in regions like Africa, South America, the Middle East, and Europe, evaluating alternatives to traditional sweater suppliers is crucial. Whether you’re a retailer seeking to diversify your product offerings or a manufacturer looking for cost-effective production methods, understanding the various options available can lead to better decision-making and optimized supply chain management.

Comparison of Sweater Supplier with Alternative Solutions

| Comparison Aspect | Sweater Supplier | Alternative 1: Direct Knitting Machines | Alternative 2: Local Artisans |

|---|---|---|---|

| Performance | High-quality, consistent supply | Variable quality, dependent on machine settings | Highly variable, quality depends on artisan skill |

| Cost | Medium to high, depending on order volume | High initial investment, lower long-term costs | Generally lower costs, but inconsistent pricing |

| Ease of Implementation | Moderate; requires supplier vetting and contracts | High; requires installation and training | Low; informal agreements and local relationships |

| Maintenance | Supplier manages logistics | Requires regular maintenance and skilled technicians | Minimal; dependent on artisan’s capacity |

| Best Use Case | Large scale, consistent demand | Custom, high-volume production | Unique, artisanal, low-volume projects |

What Are the Pros and Cons of Direct Knitting Machines?

Direct knitting machines represent a significant technological advancement in the sweater manufacturing process. Pros include the ability to produce sweaters in large quantities, maintaining consistent quality across batches. They also allow for customization in design and size without the need for extensive manual labor, making them suitable for businesses with high production needs. However, the cons involve a substantial initial investment for the machinery and the necessity for skilled technicians to operate and maintain the machines. Additionally, the reliance on technology can lead to downtime if maintenance is neglected, impacting production schedules.

How Do Local Artisans Compare to Traditional Suppliers?

Engaging local artisans can provide an appealing alternative to conventional sweater suppliers, especially for brands focusing on sustainability and unique designs. The pros of this approach include lower production costs and the potential to create one-of-a-kind products that resonate with consumers looking for authenticity. Moreover, working with artisans can foster community relationships and support local economies. On the downside, the cons include variability in quality and delivery times, as production is often dependent on the artisan’s capacity and skill level. This method is best suited for businesses aiming for niche markets rather than large-scale distribution.

Making the Right Choice for Your Sweater Supply Needs

When evaluating the best solution for your sweater supply needs, consider your business model, target market, and production requirements. If you are a large retailer focused on high-volume sales, a traditional sweater supplier or direct knitting machines may provide the consistency and scale you require. Conversely, if your brand emphasizes unique, handcrafted items, engaging local artisans could enhance your product offerings and appeal to niche consumer segments. Ultimately, the right choice will depend on balancing quality, cost, and operational feasibility to align with your strategic goals.

Essential Technical Properties and Trade Terminology for sweater supplier

What Are the Key Technical Properties to Consider When Sourcing Sweaters?

When sourcing sweaters, understanding the technical properties is crucial for making informed decisions that impact quality, cost, and customer satisfaction. Here are several critical specifications to consider:

1. Material Grade

The material grade of a sweater indicates the quality and durability of the fabric used. Common materials include cotton, wool, acrylic, and blends. Higher-grade materials typically offer better breathability, warmth, and comfort, which can enhance the perceived value of your product. For B2B buyers, selecting the right material grade can help differentiate offerings in a competitive market.

2. Stitch Density

Stitch density refers to the number of stitches per inch in the fabric. A higher stitch density usually results in a more durable and refined product, while lower density can lead to a more casual appearance. Buyers should evaluate stitch density based on their target market; for instance, luxury brands may prefer higher densities for premium offerings, while casual lines may opt for lower densities to reduce costs.

3. Tolerance Levels

Tolerance levels define the acceptable variations in size and dimensions of the finished product. For sweaters, this includes measurements such as sleeve length, body length, and width. Understanding these tolerances is vital for maintaining consistency across production runs. Buyers should ensure that suppliers can meet their specified tolerance levels to prevent issues related to sizing discrepancies, which can lead to customer dissatisfaction.

4. Weight Per Square Meter (GSM)

Weight per square meter (GSM) is a critical specification that indicates the thickness and heaviness of the fabric. Heavier fabrics, typically above 300 GSM, are suitable for colder climates, while lighter fabrics work well in warmer conditions. For international buyers, selecting the appropriate GSM can help align products with regional climate conditions and customer preferences.

5. Color Fastness

Color fastness refers to the ability of the fabric to retain its color when exposed to washing, light, and rubbing. High color fastness is essential for maintaining the appearance of sweaters over time. B2B buyers should prioritize suppliers that adhere to international standards for color fastness to ensure long-lasting products that meet customer expectations.

What Are Common Trade Terminologies Relevant to Sweater Sourcing?

Familiarity with industry jargon can enhance communication with suppliers and streamline the procurement process. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are sold under another company’s brand name. In the context of sweaters, buyers may work with OEM suppliers to create custom designs or private-label products. Understanding OEM relationships can help buyers leverage supplier capabilities for unique offerings.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to produce or sell. This figure can significantly affect purchasing decisions, particularly for smaller businesses or startups. Buyers should negotiate MOQs that align with their sales forecasts to avoid excess inventory and cash flow issues.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers use to solicit price quotes from suppliers for specific products or services. In sweater procurement, an RFQ can help buyers compare pricing, quality, and delivery terms from multiple suppliers. Crafting a detailed RFQ can lead to better supplier responses and more favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms, such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight), is crucial for managing shipping costs and responsibilities effectively.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Understanding lead times is vital for B2B buyers to ensure timely product availability and to plan marketing strategies accordingly. Buyers should negotiate lead times with suppliers to align with their inventory management needs.

By grasping these technical properties and trade terminologies, international B2B buyers can navigate the complexities of sourcing sweaters more effectively, ultimately leading to better purchasing decisions and enhanced business outcomes.

Navigating Market Dynamics and Sourcing Trends in the sweater supplier Sector

What Are the Current Market Dynamics and Sourcing Trends in the Sweater Supplier Sector?

The global sweater supplier market is witnessing significant transformations driven by several key factors. Firstly, consumer preferences are shifting towards sustainable and ethically sourced apparel, prompting suppliers to adapt their strategies. Buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking suppliers who align with these values. The rise of e-commerce and digital platforms has further facilitated global sourcing, enabling B2B buyers to connect with suppliers more efficiently than ever before.

Emerging technologies like Artificial Intelligence (AI) and blockchain are reshaping the sourcing landscape. AI is being utilized for demand forecasting and inventory management, ensuring that suppliers can meet the fluctuating demands of international markets. Blockchain technology enhances supply chain transparency, allowing buyers to trace the origins of materials used in their products, which is particularly important for ethical sourcing.

Additionally, there is a growing emphasis on regional sourcing. For instance, buyers in Europe are increasingly looking to local suppliers to reduce lead times and logistics costs, while those in Africa are leveraging regional production capabilities to fulfill domestic and international demand. Understanding these dynamics is crucial for B2B buyers who wish to navigate the complexities of the global sweater supply market effectively.

How Is Sustainability Influencing the Sweater Supplier Industry?

Sustainability has become a cornerstone of modern sourcing practices within the sweater supplier sector. The environmental impact of textile production, particularly in terms of water consumption and chemical usage, has come under scrutiny. International B2B buyers are now prioritizing suppliers who implement sustainable practices in their production processes. This includes using organic cotton, recycled materials, and eco-friendly dyes, all of which contribute to reducing the overall carbon footprint.

Ethical supply chains are equally important. B2B buyers must ensure that their suppliers adhere to fair labor practices and provide safe working conditions. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are becoming essential for buyers looking to validate the sustainability claims of their suppliers. These certifications not only enhance brand reputation but also meet the growing consumer demand for transparency and accountability in the fashion industry.

Furthermore, adopting sustainable practices can lead to long-term cost savings. For example, investing in energy-efficient machinery can reduce operational costs over time. B2B buyers should actively seek suppliers who are committed to sustainability, as this alignment can create a competitive edge in a market increasingly focused on ethical consumption.

What Is the Evolution of the Sweater Supplier Market?

The sweater supplier market has undergone significant evolution over the decades, transitioning from local artisanal production to a globalized industry. Initially, sweaters were handcrafted in small workshops, emphasizing quality and uniqueness. However, as demand surged, mass production techniques emerged, leading to increased availability and lower prices.

In recent years, the market has shifted again, influenced by globalization and technological advancements. The rise of fast fashion has transformed how sweaters are produced and consumed, with suppliers needing to respond rapidly to changing trends. Today, the focus is shifting back towards sustainability and ethical practices, as consumers become more conscious of their purchasing decisions.

This evolution highlights the importance for B2B buyers to stay informed about market trends and supplier capabilities. Understanding the historical context of the sweater supplier market can provide valuable insights into current dynamics and future opportunities, enabling more strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of sweater supplier

-

How do I ensure I choose a reliable sweater supplier?

To select a reliable sweater supplier, conduct thorough research on potential partners. Look for suppliers with a solid reputation, verified customer reviews, and a history of successful international transactions. Engage in direct communication to assess their responsiveness and willingness to accommodate your needs. It’s also beneficial to ask for references and explore their production facilities if possible. Consider using platforms that specialize in B2B supplier vetting to further verify the supplier’s credibility. -

What is the best way to customize sweaters for my brand?

When seeking customization for your sweaters, start by discussing your design requirements, including materials, colors, and logos, with potential suppliers. Request samples to evaluate the quality and ensure it aligns with your brand’s standards. Establish clear communication regarding minimum order quantities (MOQs) for customized products, as these can vary significantly among suppliers. Collaborate closely with the supplier throughout the design process to ensure your vision is accurately translated into the final product. -

What should I consider regarding minimum order quantities (MOQ) when sourcing sweaters?

Minimum order quantities (MOQs) can vary widely depending on the supplier and the complexity of the order. When sourcing sweaters, ensure you clarify the MOQ upfront to avoid unexpected costs or inventory issues. If your business is small or just starting, consider suppliers who offer lower MOQs or flexible ordering options. Additionally, assess whether the MOQ aligns with your inventory capacity and sales forecasts to maintain a healthy stock without overcommitting resources. -

What payment terms are standard when dealing with international sweater suppliers?

Standard payment terms can vary based on the supplier and the relationship established. Common terms include 30% upfront payment and the remaining 70% upon delivery, or net 30 days after receiving the goods. Always negotiate payment terms that protect your cash flow while ensuring the supplier is incentivized to meet quality and delivery timelines. Consider using secure payment methods, such as letters of credit or escrow services, especially for larger transactions, to mitigate risks. -

How can I ensure quality assurance when ordering sweaters from suppliers?

To ensure quality assurance, request detailed product specifications and quality control procedures from your supplier. It’s advisable to establish a quality assurance agreement that outlines acceptable quality standards and inspection processes. Consider hiring third-party inspection services to verify the quality before shipment. Furthermore, maintaining open communication with the supplier throughout the production process can help address any potential issues early on. -

What are the best logistics practices for importing sweaters from suppliers?

Effective logistics practices include selecting reliable freight forwarders who understand customs regulations and can navigate international shipping complexities. Determine the most cost-effective shipping method based on your timeline and budget, considering air freight for urgent orders and sea freight for larger shipments. Ensure all documentation, such as commercial invoices and packing lists, is accurate and complete to avoid delays at customs. Tracking shipments closely will help you manage inventory levels and customer expectations. -

How do I handle returns and exchanges with international sweater suppliers?

Handling returns and exchanges requires clear communication and predefined policies. Before placing an order, confirm the supplier’s return policy, including timelines and conditions for returns. Establish a process for handling defective items and ensure that both parties understand the logistics and costs involved in returning goods. Document all agreements in writing to avoid misunderstandings, and maintain a good relationship with your supplier to facilitate smoother resolutions. -

What factors should I consider when sourcing sweaters for different climates?

When sourcing sweaters for varying climates, consider the materials used, as different fabrics provide varying levels of warmth and breathability. For colder regions, opt for heavier materials like wool or fleece, while lighter, breathable fabrics like cotton or blends may be suitable for warmer climates. Analyze your target market’s preferences and seasonal trends to make informed decisions. Collaborating with suppliers who have experience in producing climate-appropriate apparel can enhance your product offering and customer satisfaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for sweater supplier

What Are the Key Takeaways for International B2B Buyers in Sweater Sourcing?

In conclusion, strategic sourcing remains a pivotal approach for international B2B buyers seeking reliable sweater suppliers. By prioritizing sustainable practices, understanding regional market dynamics, and leveraging technology for supply chain management, businesses can enhance their procurement processes. Buyers from Africa, South America, the Middle East, and Europe should focus on establishing long-term relationships with suppliers who align with their values and operational needs. This not only fosters loyalty but also ensures quality and consistency in supply.

How Can Strategic Sourcing Drive Competitive Advantage?

The value of strategic sourcing transcends mere cost savings; it drives innovation, enhances product quality, and promotes agility in responding to market changes. By adopting a data-driven approach, buyers can make informed decisions that align with their strategic objectives. Engaging in thorough market research and supplier audits can mitigate risks and uncover opportunities for value creation.

What Should B2B Buyers Do Next?

As we look to the future, B2B buyers are encouraged to embrace a proactive sourcing strategy that emphasizes collaboration and adaptability. Engage with suppliers who are not only responsive but also committed to ethical practices and sustainability. This approach will not only safeguard your supply chain but also position your business as a leader in responsible sourcing. Take the next step today—evaluate your current sourcing strategies and explore new partnerships that can elevate your sweater offerings in a competitive global market.