Discover Top Benefits of a Reliable TFT LCD Supplier (2025)

Introduction: Navigating the Global Market for tft lcd supplier

In an increasingly interconnected world, sourcing a reliable TFT LCD supplier presents a significant challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe demand high-quality display solutions, understanding the nuances of the global market becomes essential for making informed purchasing decisions. This guide aims to demystify the complexities associated with sourcing TFT LCDs, exploring various types, applications, and critical factors that influence supplier selection.

Navigating the TFT LCD landscape involves more than just identifying suppliers; it requires a comprehensive understanding of product specifications, pricing structures, and supplier vetting processes. This guide will delve into essential considerations such as the different types of TFT LCD panels available, their applications across diverse industries, and the latest advancements in technology that impact performance and cost. Additionally, we will provide actionable insights on how to effectively evaluate potential suppliers to ensure they meet quality standards and compliance requirements.

By equipping B2B buyers with this knowledge, we empower them to make strategic purchasing decisions that align with their business goals. Whether you’re based in bustling cities like Jakarta, vibrant hubs in South Africa, or emerging markets in South America, this guide serves as a valuable resource to navigate the intricacies of sourcing TFT LCDs globally. Engage with the content to transform your procurement process into a competitive advantage.

Understanding tft lcd supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard TFT LCD Suppliers | Mass production, cost-effective, basic functionality | Consumer electronics, displays | Pros: Affordable, widely available. Cons: Limited customization options. |

| Industrial TFT LCD Suppliers | Rugged designs, enhanced durability, specialized features | Manufacturing, medical devices | Pros: High durability, tailored solutions. Cons: Higher cost, longer lead times. |

| Custom TFT LCD Suppliers | Tailored specifications, unique design capabilities | Specialized equipment, niche markets | Pros: Exact match to requirements. Cons: Longer development time, potentially higher costs. |

| High-Resolution TFT LCD Suppliers | Advanced technology, superior image quality, high pixel density | High-end displays, gaming, medical imaging | Pros: Exceptional visual performance. Cons: Premium pricing, may require specific integration expertise. |

| Eco-Friendly TFT LCD Suppliers | Sustainable materials, energy-efficient production | Green technology, eco-conscious brands | Pros: Aligns with sustainability goals. Cons: Limited availability, potentially higher costs. |

What Are the Characteristics of Standard TFT LCD Suppliers?

Standard TFT LCD suppliers focus on mass production and affordability, making them a go-to choice for businesses needing basic display solutions. These suppliers typically provide products that meet general market demands, making them widely accessible. They are ideal for consumer electronics and basic display applications where cost efficiency is paramount. However, buyers should consider the trade-off in customization options, which may not meet specific project requirements.

How Do Industrial TFT LCD Suppliers Stand Out?

Industrial TFT LCD suppliers offer enhanced durability and specialized features tailored for rigorous environments. Their products are designed to withstand harsh conditions, making them suitable for applications in manufacturing and medical devices. When purchasing from these suppliers, B2B buyers should evaluate the durability and reliability of the displays, as well as any certifications required for specific industries. While the initial cost may be higher, the longevity and performance can justify the investment.

What Are the Benefits of Custom TFT LCD Suppliers?

Custom TFT LCD suppliers provide tailored solutions that cater to unique project specifications and design requirements. This is particularly beneficial for businesses operating in niche markets or specialized equipment sectors. Buyers should consider the flexibility offered by these suppliers, as they can create displays that perfectly align with their needs. However, it’s essential to be aware of the longer development times and potentially higher costs associated with custom solutions.

Why Choose High-Resolution TFT LCD Suppliers?

High-resolution TFT LCD suppliers focus on advanced technology and superior image quality, making their products ideal for high-end displays, gaming, and medical imaging applications. These suppliers leverage cutting-edge technology to deliver displays with high pixel density and exceptional visual performance. B2B buyers should assess their integration capabilities and the specific requirements of their projects, as the premium pricing associated with these displays may be justified by their performance benefits.

What Are the Advantages of Eco-Friendly TFT LCD Suppliers?

Eco-friendly TFT LCD suppliers prioritize sustainable materials and energy-efficient production processes, appealing to businesses that align with green technology and corporate social responsibility initiatives. These suppliers cater to eco-conscious brands looking to minimize their environmental impact. While the products may be limited in availability and potentially more expensive, the alignment with sustainability goals can enhance a brand’s reputation and appeal to environmentally aware consumers. Buyers should evaluate the sustainability certifications and practices of these suppliers to ensure compliance with their values.

Related Video: How TFT LCD ( thin film transistor liquid-crystal display ) display monitor work? (Animation)

Key Industrial Applications of tft lcd supplier

| Industry/Sector | Specific Application of TFT LCD Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | In-car infotainment systems | Enhanced user experience and safety features | Durability, temperature resistance, and customization options |

| Healthcare | Medical imaging devices | High-resolution displays for accurate diagnostics | Compliance with medical regulations, reliability, and service support |

| Industrial Automation | Control panels and HMI (Human-Machine Interface) | Improved operational efficiency and user interaction | Integration capabilities, response time, and environmental resilience |

| Consumer Electronics | Smart home devices | Seamless user interaction and aesthetic appeal | Size, power consumption, and compatibility with IoT standards |

| Retail | Digital signage and advertising displays | Increased engagement and sales conversion | Brightness, viewing angles, and durability for outdoor use |

How is TFT LCD Used in the Automotive Sector?

In the automotive industry, TFT LCDs are integral to in-car infotainment systems, providing drivers and passengers with interactive interfaces for navigation, media, and vehicle diagnostics. These displays solve the problem of user engagement by offering high-resolution graphics and responsive touch capabilities. Buyers in this sector must consider durability against vibrations, temperature fluctuations, and customization options to meet branding needs. Sourcing from reputable TFT LCD suppliers ensures compliance with automotive standards, particularly for safety and performance.

What Role Does TFT LCD Play in Healthcare Applications?

In healthcare, TFT LCDs are used in medical imaging devices such as ultrasound machines, MRI scanners, and patient monitoring systems. The high-resolution displays enable healthcare professionals to visualize critical data accurately, leading to better diagnostics and patient outcomes. For international buyers, it is essential to consider suppliers that adhere to medical device regulations and provide robust after-sales support. Reliability and long-term service agreements are crucial, as any downtime in medical equipment can have serious repercussions.

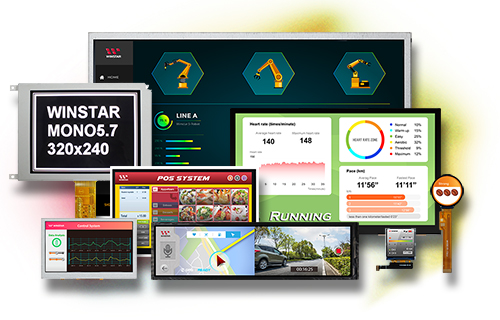

A stock image related to tft lcd supplier.

Why is TFT LCD Important for Industrial Automation?

TFT LCDs are pivotal in industrial automation, particularly in control panels and Human-Machine Interfaces (HMIs). They enhance operational efficiency by allowing real-time data visualization and user interaction. This technology solves issues related to manual data entry and monitoring, reducing human error. Buyers must prioritize suppliers that offer integration capabilities with existing systems and ensure fast response times. Additionally, environmental resilience, such as resistance to dust and moisture, is a key factor for sourcing TFT LCDs in this sector.

How are TFT LCDs Transforming Consumer Electronics?

In the consumer electronics sector, TFT LCDs are widely used in smart home devices, such as thermostats and security systems. These displays facilitate seamless user interaction and contribute to the aesthetic appeal of the products. For B2B buyers, sourcing TFT LCDs involves considering factors like size, power consumption, and compatibility with Internet of Things (IoT) standards. As consumers increasingly demand smart features, partnering with TFT LCD suppliers that can provide innovative solutions is essential for staying competitive.

What Benefits Do TFT LCDs Offer in Retail?

Retail environments leverage TFT LCDs for digital signage and advertising displays, which are crucial for engaging customers and driving sales. These displays can dynamically showcase promotions and enhance the shopping experience. Buyers should focus on sourcing TFT LCDs with high brightness and wide viewing angles to ensure visibility in various lighting conditions. Additionally, durability is vital for outdoor applications, making it important to choose suppliers that offer robust products capable of withstanding environmental challenges.

Related Video: Using DWIN 7-inch TFT LCD Display with Arduino to Control Relay, Servo & RGB LED

3 Common User Pain Points for ‘tft lcd supplier’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem:

B2B buyers often face significant challenges when sourcing TFT LCDs due to inconsistent quality among different suppliers. This issue can stem from varying manufacturing processes and quality control standards, which may lead to discrepancies in display performance, color accuracy, and durability. For buyers in regions like Africa and South America, where the market may not be saturated with reliable suppliers, the risk of receiving subpar products can result in costly project delays and damage to business reputation.

The Solution:

To mitigate quality inconsistencies, buyers should prioritize sourcing suppliers with established quality assurance protocols. Start by requesting certifications such as ISO 9001, which indicates a commitment to quality management systems. Conduct thorough due diligence by reviewing supplier audits and customer testimonials. It’s also beneficial to request samples before placing large orders, allowing for hands-on evaluation of the product quality. Establishing a clear communication channel with suppliers to set specific quality expectations and regular performance reviews can further ensure that the products meet the required standards.

Scenario 2: Long Lead Times Impacting Production Schedules

The Problem:

International buyers frequently encounter long lead times when ordering TFT LCDs, which can severely disrupt production schedules. This challenge is particularly pronounced for companies in the Middle East and Europe, where tight project timelines are the norm. Delays in receiving components can lead to missed deadlines and financial losses, forcing companies to either expedite shipping at a premium cost or postpone launches.

The Solution:

To address lead time issues, it is essential for buyers to engage in proactive planning and transparent communication with suppliers. Request detailed production timelines and build a buffer into project schedules to account for unforeseen delays. Consider diversifying your supplier base by identifying multiple TFT LCD suppliers across different regions, thus reducing reliance on a single source. Additionally, exploring suppliers that offer expedited shipping options or local distribution centers can significantly cut down on lead times. Establishing a strategic partnership with suppliers can also facilitate priority handling for future orders.

Scenario 3: Difficulty in Customization for Unique Applications

The Problem:

Many B2B buyers struggle with the challenge of customizing TFT LCDs for specific applications, particularly in niche markets such as medical devices or industrial automation. Buyers often find that many suppliers only offer standard models, making it difficult to source displays that meet their unique specifications. This limitation can hinder innovation and create a competitive disadvantage in the marketplace.

The Solution:

To overcome customization challenges, buyers should actively seek suppliers that specialize in bespoke TFT LCD solutions. Initiate discussions about your specific requirements early in the sourcing process. Providing detailed specifications, including size, resolution, interface requirements, and environmental considerations, can help suppliers understand your needs better. Additionally, leverage suppliers with R&D capabilities that can assist in product development. Consider collaborative projects where you can co-design solutions, ensuring that the final product aligns perfectly with your application requirements. Engaging in these partnerships not only enhances product quality but can also lead to unique offerings that differentiate your brand in the market.

Strategic Material Selection Guide for tft lcd supplier

What Are the Key Materials for TFT LCD Suppliers?

When selecting materials for TFT LCDs, several factors influence the performance, durability, and cost-effectiveness of the final product. Below, we analyze four common materials used in the manufacturing of TFT LCDs, considering their properties, advantages, disadvantages, and implications for international B2B buyers.

Which Glass Types Are Most Effective for TFT LCDs?

Key Properties: Glass is a primary material in TFT LCDs, known for its excellent optical clarity and rigidity. It typically withstands temperatures ranging from -40°C to 85°C and can endure high pressure without deforming.

Pros & Cons: The main advantage of glass is its durability and resistance to environmental factors. However, it can be heavy and fragile, which may lead to breakage during shipping or installation. The manufacturing complexity is moderate, requiring precise cutting and coating processes.

Impact on Application: Glass is compatible with various media, including touch sensors and anti-reflective coatings, enhancing user experience.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Africa and South America should ensure that the glass meets local safety regulations, as well as any specific requirements for electronics.

How Do Plastics Compare in TFT LCD Manufacturing?

Key Properties: Plastics, such as polycarbonate and acrylic, are lightweight and can be molded into complex shapes. They typically have a temperature rating of around -20°C to 80°C and are less prone to shattering compared to glass.

Pros & Cons: The primary advantage of plastics is their lightweight nature and lower cost, making them suitable for portable devices. However, they may not offer the same level of optical clarity and can be more susceptible to scratching and UV degradation.

Impact on Application: Plastics are often used in applications requiring flexibility and impact resistance, such as portable displays.

Considerations for International Buyers: Buyers should verify the UV resistance and compliance with standards like JIS for plastics used in electronics. In regions like the Middle East, where UV exposure is high, ensuring durability against sun damage is essential.

What Role Does Indium Tin Oxide (ITO) Play in TFT LCDs?

Key Properties: ITO is a conductive material used for touch screens and displays, providing high transparency and excellent conductivity. It can operate effectively within a temperature range of -40°C to 80°C.

Pros & Cons: The main advantage of ITO is its ability to maintain high optical clarity while providing touch sensitivity. However, it is relatively expensive and can be brittle, which complicates manufacturing.

Impact on Application: ITO is critical in applications requiring touch functionality, particularly in consumer electronics and industrial displays.

Considerations for International Buyers: Buyers should be aware of the sourcing of ITO, as it is often derived from indium, a rare metal. Compliance with environmental regulations regarding rare materials is vital, especially in Europe where sustainability is a priority.

How Important Are Backlight Materials in TFT LCDs?

Key Properties: Backlight materials, such as LED and CCFL, are essential for display brightness. LEDs have a longer lifespan and lower energy consumption, while CCFLs provide even illumination.

Pros & Cons: The advantage of LEDs is their energy efficiency and compact size, making them suitable for modern devices. However, they can be more expensive than CCFLs. CCFLs, while cheaper, are bulkier and less energy-efficient.

Impact on Application: The choice of backlight directly influences the display’s brightness and energy consumption, impacting battery life in portable devices.

Considerations for International Buyers: Buyers should consider energy efficiency standards, especially in regions with strict regulations on electronic waste and energy consumption. Compliance with local energy standards is crucial for market acceptance.

Summary Table of Material Selection for TFT LCD Suppliers

| Material | Typical Use Case for TFT LCD Supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Main display surface | High durability and optical clarity | Heavy and fragile | High |

| Plastics | Portable devices | Lightweight and cost-effective | Less optical clarity, UV degradation | Medium |

| Indium Tin Oxide (ITO) | Touch-sensitive displays | High transparency and conductivity | Expensive and brittle | High |

| Backlight Materials | Display illumination | Energy-efficient (LEDs) | Higher cost (LEDs), bulkiness (CCFLs) | Medium |

This strategic material selection guide provides essential insights for international B2B buyers in Africa, South America, the Middle East, and Europe, enabling informed decisions when sourcing TFT LCD components.

In-depth Look: Manufacturing Processes and Quality Assurance for tft lcd supplier

What Are the Main Stages in the Manufacturing Process of TFT LCD Panels?

The manufacturing of Thin Film Transistor Liquid Crystal Display (TFT LCD) panels involves several crucial stages, each requiring precision and quality control to ensure the final product meets industry standards. Understanding these stages is vital for B2B buyers seeking reliable suppliers.

1. Material Preparation

The first step in the TFT LCD manufacturing process involves sourcing and preparing raw materials. Key components include glass substrates, liquid crystal materials, and various electronic components such as transistors and capacitors. Suppliers should demonstrate the ability to source high-quality materials, often requiring certifications to ensure compliance with international standards.

2. Forming

Once materials are prepared, the next stage is forming the glass substrates. This typically involves cutting and polishing glass to the required specifications. Buyers should inquire about the technology used in this process, as advanced techniques like chemical strengthening can enhance durability and performance.

3. Assembly

The assembly process is where the various components are integrated. This includes the application of transparent electrodes and the precise alignment of liquid crystal layers. Automated assembly lines are common, as they ensure high precision and efficiency. Buyers should assess the supplier’s capability to handle large-scale production while maintaining quality.

4. Finishing

Finishing involves several processes, including lamination, bonding, and surface treatment to enhance display quality and protect against environmental factors. This stage is critical for ensuring that the final product not only meets visual standards but also adheres to durability requirements. Buyers should look for suppliers who utilize advanced finishing techniques that comply with international quality standards.

How Is Quality Assurance Implemented in TFT LCD Manufacturing?

Quality assurance (QA) is paramount in the TFT LCD manufacturing process. Suppliers must adhere to both international standards and industry-specific regulations to ensure product reliability and safety.

What International Standards Should B2B Buyers Look For?

International standards such as ISO 9001 are critical for ensuring consistent quality management systems. Suppliers should be certified to these standards, demonstrating their commitment to quality. Other relevant certifications include CE marking for compliance with European health and safety standards, and RoHS compliance to ensure that hazardous substances are minimized.

What Are the Key Quality Control Checkpoints?

Quality control (QC) in TFT LCD manufacturing typically involves several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials and components upon arrival. Suppliers should have stringent protocols for inspecting materials against quality specifications.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC is essential to monitor processes at various stages. This includes checks for proper assembly and alignment, ensuring that any defects are caught early.

-

Final Quality Control (FQC): After assembly, FQC involves comprehensive testing of the finished products. This includes functionality tests and visual inspections to guarantee that products meet specifications before shipment.

Which Testing Methods Are Commonly Used in TFT LCD Quality Assurance?

Various testing methods are employed to ensure that TFT LCD panels meet the required standards. These include:

-

Visual Inspection: Essential for identifying surface defects and ensuring uniformity.

-

Electrical Testing: Verifies that the electrical components function correctly, ensuring that the display operates as intended.

-

Performance Testing: Assesses brightness, contrast, and response times to confirm that the panel meets performance specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are some actionable steps:

Conduct Supplier Audits

Auditing potential suppliers can provide insights into their manufacturing processes and quality control systems. Buyers should develop a checklist based on industry standards and conduct on-site visits when feasible.

Request Quality Reports

Suppliers should be willing to provide documentation of their quality control processes, including reports from IQC, IPQC, and FQC stages. These reports can help buyers gauge the supplier’s commitment to quality.

Engage Third-Party Inspection Services

Utilizing third-party inspection services can offer an unbiased evaluation of a supplier’s manufacturing and quality control practices. These services can conduct thorough inspections and provide certification that adds credibility to the supplier.

What Are the QC and Certification Nuances for International Buyers?

When sourcing TFT LCD panels internationally, buyers must navigate various certification and quality assurance nuances. Understanding regional compliance requirements is crucial. For example, European buyers should be particularly mindful of CE certification and RoHS compliance, while buyers in regions like Africa and South America may need to consider local regulations that differ from international standards.

Additionally, buyers should be aware of the potential for differing quality expectations based on regional norms. Engaging in discussions with suppliers about their understanding of these nuances can foster better partnerships and ensure that the products meet specific market needs.

Conclusion

By grasping the intricacies of the manufacturing processes and quality assurance practices involved in TFT LCD production, B2B buyers can make informed decisions when selecting suppliers. Emphasizing the importance of material quality, process control, and rigorous testing will not only enhance product reliability but also ensure compliance with international standards, ultimately leading to successful partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tft lcd supplier’

This practical sourcing guide serves as a comprehensive checklist for international B2B buyers looking to procure TFT LCDs. By following these steps, you will ensure that your sourcing process is efficient, cost-effective, and aligned with your business needs.

Step 1: Define Your Technical Specifications

Before engaging with potential suppliers, it’s crucial to outline your specific requirements for TFT LCDs. Consider factors such as screen size, resolution, brightness, and viewing angles. Clear technical specifications will help you communicate effectively with suppliers and ensure they understand your needs.

- Resolution and Size: Determine the pixel density and physical dimensions that best fit your application.

- Usage Environment: Consider whether the displays will be used indoors or outdoors, which affects brightness and durability.

Step 2: Conduct Market Research on Suppliers

Understanding the market landscape is essential for identifying potential suppliers. Research various TFT LCD manufacturers and distributors, focusing on their reputation, product offerings, and geographical reach.

- Industry Reviews: Look for reviews and testimonials from other businesses that have sourced from these suppliers.

- Trade Shows and Expos: Attend industry events to meet suppliers and evaluate their products firsthand.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Financial Stability: Assess their financial health to ensure they can meet your order demands.

- Quality Assurance: Inquire about their quality control processes and certifications (e.g., ISO 9001).

Step 4: Verify Supplier Certifications and Compliance

Ensure that potential suppliers adhere to international standards and regulations. This step is vital to guarantee product quality and safety, especially when sourcing from regions with varying compliance standards.

- Environmental Standards: Check for certifications like RoHS or WEEE to ensure the supplier meets environmental regulations.

- Product Safety: Confirm that the products comply with relevant safety standards in your target market.

Step 5: Request Samples for Evaluation

Before placing a bulk order, always request samples to assess quality and compatibility with your project requirements. This step allows you to conduct hands-on testing to ensure the product meets your expectations.

- Performance Testing: Evaluate the sample’s performance under real-world conditions.

- Compatibility Checks: Ensure that the TFT LCD integrates seamlessly with your existing systems.

Step 6: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier, engage in discussions regarding pricing, payment terms, and delivery schedules. Effective negotiation can lead to cost savings and better service agreements.

- Volume Discounts: Inquire about pricing tiers for bulk orders.

- Payment Flexibility: Discuss options that can ease cash flow, such as extended payment terms.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful partnership. Establish clear lines of communication to discuss any issues that may arise during the sourcing process.

- Regular Updates: Set a schedule for updates on production timelines and any potential delays.

- Feedback Mechanism: Create a process for providing feedback to the supplier to improve future transactions.

By following this step-by-step checklist, international B2B buyers can enhance their sourcing process for TFT LCDs, ensuring they find reliable suppliers that meet their specific needs.

Comprehensive Cost and Pricing Analysis for tft lcd supplier Sourcing

What Are the Key Cost Components for TFT LCD Supplier Sourcing?

Understanding the cost structure of TFT LCD suppliers is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials such as glass substrates, liquid crystals, and backlight units can vary significantly based on global market prices and availability. Buyers should be aware of fluctuations that can impact overall costs.

-

Labor: Labor costs differ by region, with countries in Asia often having lower wages compared to those in Europe or North America. However, the skill level and expertise required for manufacturing high-quality TFT LCDs can also affect labor costs.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, utilities, and maintenance. Efficient manufacturing processes can reduce overhead, impacting the final pricing.

-

Tooling: Initial tooling costs for custom designs or specialized products can be substantial. Buyers should consider these costs when evaluating the total investment required.

-

Quality Control (QC): Ensuring product quality is paramount, and QC processes can add to the overall cost. Buyers should assess the supplier’s QC standards to avoid potential issues that could lead to expensive returns or replacements.

-

Logistics: Shipping costs, including freight, insurance, and tariffs, can significantly influence the total cost. It’s essential to factor in the logistics when sourcing from suppliers in different geographical locations.

-

Margin: Suppliers will add a profit margin to cover their operational costs and risks. Understanding typical margin ranges within the TFT LCD market can help buyers gauge whether they are receiving competitive pricing.

How Do Price Influencers Impact TFT LCD Supplier Costs?

Several factors can influence pricing in the TFT LCD market, which international B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide better pricing at higher volumes. Understanding the MOQ can help buyers negotiate better deals, especially when planning for future demand.

-

Specifications and Customization: Customized TFT LCDs with specific features or sizes typically cost more due to additional design and manufacturing requirements. Buyers should clarify their needs upfront to avoid unexpected costs.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (such as ISO) can impact pricing. Higher quality materials or certifications may lead to increased costs but can also enhance product reliability.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can affect pricing. It is advisable to research potential suppliers thoroughly to understand their market positioning.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) define the responsibilities of buyers and suppliers regarding shipping, insurance, and tariffs. Choosing the right Incoterms can significantly affect the total landed cost.

What Tips Can Help International B2B Buyers Optimize TFT LCD Supplier Pricing?

B2B buyers can adopt several strategies to ensure cost efficiency when sourcing TFT LCDs:

-

Negotiation: Engage in open discussions with suppliers about pricing, especially regarding volume discounts or long-term contracts. Building a good relationship can lead to better terms and conditions.

-

Total Cost of Ownership (TCO): Evaluate the total cost of ownership, which includes purchase price, maintenance, and potential warranty costs. A lower purchase price may not always result in lower TCO if quality issues arise.

-

Pricing Nuances for International Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing trends and currency fluctuations. Understanding these nuances can aid in making informed purchasing decisions.

-

Research and Benchmarking: Conduct thorough market research to benchmark prices from multiple suppliers. This practice can reveal competitive pricing and help avoid overpaying.

In conclusion, a comprehensive understanding of the cost structure and pricing influencers in the TFT LCD market is vital for international B2B buyers. By leveraging negotiation tactics and considering the total cost of ownership, buyers can secure favorable deals while ensuring quality and reliability in their purchases. Always remember that indicative prices can vary based on market conditions and should be verified through direct supplier communication.

Alternatives Analysis: Comparing tft lcd supplier With Other Solutions

When considering the procurement of TFT LCD displays, it is essential to explore alternative solutions that can provide similar functionalities or benefits. This analysis will compare TFT LCD suppliers with two viable alternatives: OLED displays and E-Ink technology. Each of these alternatives presents unique characteristics that may align better with specific business needs and applications.

Comparison Table: How Do TFT LCD Suppliers Stack Up Against Alternatives?

| Comparison Aspect | TFT LCD Supplier | OLED Displays | E-Ink Technology |

|---|---|---|---|

| Performance | High brightness, good color accuracy | Superior contrast, faster response time | Low refresh rate, limited color range |

| Cost | Moderate cost | Higher initial investment | Generally lower cost |

| Ease of Implementation | Standard integration processes | May require specialized knowledge | Simple integration, but limited to specific applications |

| Maintenance | Low maintenance, durable | Sensitive to burn-in, moderate maintenance | Minimal maintenance required |

| Best Use Case | General-purpose displays, industrial use | High-end consumer electronics, displays requiring deep blacks | E-readers, low-power applications |

What Are the Advantages and Disadvantages of OLED Displays as an Alternative?

OLED (Organic Light Emitting Diode) displays are known for their vibrant colors and deeper blacks due to their ability to turn off individual pixels. This technology excels in performance, offering faster response times and higher contrast ratios compared to TFT LCDs. However, they come with a higher price tag and potential burn-in issues, which could be a concern for businesses utilizing static images for prolonged periods. OLEDs are best suited for applications where image quality is paramount, such as high-end smartphones and televisions.

How Does E-Ink Technology Compare to TFT LCD Suppliers?

A stock image related to tft lcd supplier.

E-Ink technology, primarily used in e-readers, offers a unique advantage of low power consumption and excellent readability in direct sunlight. The technology mimics the appearance of ink on paper, making it ideal for applications where reading is the primary function. However, E-Ink displays have a limited refresh rate and a narrower color palette, which makes them unsuitable for dynamic visuals or applications requiring vibrant color displays. They are a cost-effective solution for businesses focusing on text-heavy content or outdoor signage where power efficiency is crucial.

How Should B2B Buyers Choose the Right Display Solution?

Choosing the right display solution involves evaluating specific business needs, including performance requirements, budget constraints, and the intended application of the displays. B2B buyers should consider the environment in which the displays will be used—whether they require high contrast for vibrant media or low power consumption for extended use. Additionally, assessing long-term maintenance costs and potential integration challenges can further inform the decision-making process. By aligning the technology with business objectives, buyers can ensure they select the most effective solution for their unique needs.

Essential Technical Properties and Trade Terminology for tft lcd supplier

What Are the Key Technical Properties of TFT LCD Panels?

Understanding the technical properties of TFT LCD panels is crucial for international B2B buyers seeking reliable suppliers. Here are some of the essential specifications to consider:

1. Resolution

Resolution refers to the number of pixels displayed on the screen, typically expressed in width x height (e.g., 1920×1080). Higher resolutions yield sharper images, making this property vital for applications requiring detailed visuals, such as medical imaging or high-end gaming. Buyers should assess their end-use requirements to determine the appropriate resolution.

2. Brightness (Nits)

Measured in nits, brightness indicates how well a display can be viewed under various lighting conditions. A brighter display improves visibility in outdoor settings or well-lit environments, which is particularly important for signage and industrial applications. Buyers should evaluate the ambient light conditions where the panels will be used to ensure optimal performance.

3. Viewing Angle

The viewing angle describes the maximum angle at which a display can be viewed without significant degradation in image quality. A wider viewing angle is essential for applications involving multiple viewers, such as in conference rooms or public displays. Buyers should seek panels with a viewing angle of at least 160 degrees for better versatility.

4. Color Gamut

Color gamut refers to the range of colors that a display can reproduce. A broader color gamut allows for more vibrant and accurate color representation, essential for graphics-intensive applications like design and video editing. Buyers should consider panels that meet specific color standards (e.g., sRGB, Adobe RGB) relevant to their industry needs.

5. Response Time

Response time measures how quickly a pixel can change from one color to another, typically expressed in milliseconds (ms). A lower response time is critical for applications involving fast-moving images, such as gaming or video playback. Buyers should look for panels with a response time under 5ms for optimal performance in dynamic content.

6. Material Grade

The material grade affects durability, weight, and overall performance of the TFT LCD panels. Common materials include glass and plastic substrates, with specific coatings for protection against scratches and glare. Buyers must consider the environment in which the panels will be used to choose the appropriate material grade, ensuring longevity and reliability.

What Are Common Trade Terminologies in the TFT LCD Industry?

Familiarity with industry jargon is key for effective communication with TFT LCD suppliers. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for customized solutions or specific branding on TFT LCD panels.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest number of units that a supplier is willing to sell. This term is vital for budgeting and inventory management, especially for smaller businesses or startups that may not require large quantities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. It allows buyers to compare offers from multiple suppliers, ensuring they get the best deal possible. Crafting a detailed RFQ can help clarify requirements and expedite the procurement process.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risk, and delivery responsibilities, which are crucial for effective negotiation and contract management.

5. Lead Time

Lead time refers to the period from placing an order to its delivery. Understanding lead times is essential for planning and inventory management, especially when dealing with global suppliers where delays can occur due to customs or shipping logistics.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing TFT LCD panels, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the tft lcd supplier Sector

What Are the Current Market Dynamics and Key Trends in the TFT LCD Supplier Sector?

The global TFT LCD (Thin-Film Transistor Liquid Crystal Display) market is experiencing significant evolution driven by technological advancements, increasing demand for high-definition displays, and the rapid growth of the electronics sector. Key drivers include the proliferation of consumer electronics, such as smartphones, tablets, and televisions, alongside the rise of industries like automotive and healthcare that increasingly rely on advanced display technology.

Emerging B2B sourcing trends are leaning towards partnerships with suppliers who can offer integrated solutions that combine TFT LCD technology with other components, thereby streamlining the supply chain. International buyers from Africa, South America, the Middle East, and Europe are increasingly looking for suppliers that provide not just the displays but also display modules and touch panels, which enhance product offerings and reduce lead times. Additionally, the shift towards online procurement platforms is making it easier for buyers to compare suppliers, access product specifications, and negotiate prices, thus fostering a more competitive landscape.

Buyers should also be aware of the geopolitical factors affecting the TFT LCD market, such as trade tariffs and restrictions, especially in the context of sourcing from Asia. Understanding regional trade agreements and local manufacturing capabilities can provide a strategic advantage in negotiating contracts and ensuring supply continuity.

How Important Is Sustainability and Ethical Sourcing in the TFT LCD Supply Chain?

In today’s global market, sustainability and ethical sourcing are not just trends but essential components of a responsible supply chain. The environmental impact of TFT LCD manufacturing is considerable, as it involves significant energy consumption and the use of hazardous materials. B2B buyers must prioritize suppliers that adhere to environmentally friendly practices, such as reducing waste, recycling materials, and utilizing energy-efficient manufacturing processes.

Ethical sourcing is equally crucial, as buyers are increasingly held accountable for the practices of their suppliers. Ensuring that suppliers comply with labor standards and human rights regulations can mitigate risks associated with supply chain disruptions and enhance corporate reputation. Certifications like ISO 14001 for environmental management and R2 for responsible recycling can serve as indicators of a supplier’s commitment to sustainability.

Moreover, materials such as recycled glass and eco-friendly backlighting technologies are becoming more prevalent in the TFT LCD sector. By opting for suppliers who invest in sustainable materials and practices, international buyers can not only reduce their carbon footprint but also align their procurement strategies with consumer expectations and regulatory requirements.

What Is the Brief Evolution and History of TFT LCD Technology?

The TFT LCD technology has evolved significantly since its inception in the 1970s. Initially developed for niche applications, it gained momentum in the 1990s with the advent of portable devices and laptops, where its lightweight and slim profile proved advantageous. The introduction of active matrix technology enabled higher resolution displays, making TFT LCDs the preferred choice for consumer electronics.

As the market matured, advancements in backlighting technologies and color reproduction further enhanced display quality, making TFT LCDs a staple in televisions and monitors. Today, the sector is witnessing a shift towards more innovative applications, including flexible displays and integration with smart technologies, reflecting the ongoing demand for improved user experience and functionality.

International B2B buyers must recognize the historical context of TFT LCD technology as they navigate the current market landscape. Understanding its evolution not only helps in making informed sourcing decisions but also provides insights into future trends and potential opportunities in the display technology market.

Frequently Asked Questions (FAQs) for B2B Buyers of tft lcd supplier

-

How can I identify a reliable TFT LCD supplier for my business needs?

Identifying a reliable TFT LCD supplier begins with thorough research. Look for suppliers with a strong online presence, positive customer reviews, and industry certifications. Utilize platforms like Alibaba or Global Sources to compare suppliers based on ratings and feedback. Additionally, engage in direct communication to assess their responsiveness and willingness to provide detailed product information. Request samples to evaluate product quality before making a larger commitment. -

What factors should I consider when negotiating payment terms with a TFT LCD supplier?

When negotiating payment terms, consider factors such as order size, supplier reputation, and your cash flow situation. Common terms include a deposit upfront with the balance due upon delivery or after inspection. Ensure that the terms are mutually beneficial and allow for sufficient time to inspect goods upon arrival. It’s also prudent to discuss payment methods that offer protection, such as letters of credit or escrow services, especially for international transactions. -

What are the minimum order quantities (MOQ) typically required by TFT LCD suppliers?

Minimum order quantities (MOQ) can vary significantly among TFT LCD suppliers, often ranging from 100 to 1,000 units. Factors influencing MOQ include production costs, customizations, and the supplier’s capacity. For new buyers, it’s advisable to inquire about lower MOQs for initial orders or sample batches to test products before committing to larger quantities. Some suppliers may offer flexible MOQs based on long-term partnership intentions. -

How can I ensure quality assurance when sourcing TFT LCD products?

To ensure quality assurance, establish clear specifications and standards upfront, including resolution, brightness, and durability. Request certifications that demonstrate compliance with international quality standards, such as ISO 9001. It’s beneficial to conduct factory audits or third-party inspections before shipment. Implement a clear return and warranty policy to address any quality issues that may arise post-delivery, ensuring your investment is protected. -

What customization options are available when sourcing TFT LCD screens?

Many TFT LCD suppliers offer customization options, including screen sizes, resolutions, interfaces, and backlight types. When discussing customization, clearly communicate your requirements and specifications. Some suppliers may require higher MOQs for customized products, so it’s essential to balance your needs with production capabilities. Request detailed prototypes to evaluate customizations before placing larger orders. -

How do I manage logistics and shipping for TFT LCD products?

Managing logistics involves coordinating with your supplier regarding shipping methods and timelines. Depending on your location, options may include air freight for faster delivery or sea freight for cost efficiency. Ensure that your supplier provides clear shipping terms, including Incoterms, to avoid any misunderstandings. Additionally, consider working with a freight forwarder experienced in handling electronics to streamline the process and manage customs clearance effectively. -

What should I know about international trade regulations when importing TFT LCDs?

When importing TFT LCDs, familiarize yourself with the trade regulations specific to your country and the supplier’s country. This includes understanding tariffs, import duties, and any required certifications or documentation. Research any restrictions on electronics imports, particularly in regions with stringent regulations. Engaging a customs broker can simplify the process, ensuring compliance and minimizing delays at customs. -

What are the common challenges faced when sourcing TFT LCD suppliers internationally?

Common challenges include language barriers, cultural differences, and varying quality standards. Time zone differences can complicate communication, leading to misunderstandings. Additionally, international shipping can introduce delays and increased costs. To mitigate these challenges, establish clear communication channels, use professional translation services if necessary, and consider working with suppliers who have experience in your market. Building strong relationships can also help navigate these hurdles effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for tft lcd supplier

As the global demand for TFT LCD technology continues to rise, the importance of strategic sourcing cannot be overstated. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of the TFT LCD supply chain is crucial. Key takeaways from this guide emphasize the need for thorough supplier evaluations, the advantages of building long-term partnerships, and the significance of regional market insights to mitigate risks and enhance procurement efficiency.

Investing time in strategic sourcing not only leads to cost savings but also fosters innovation and adaptability in an ever-evolving marketplace. Buyers are encouraged to leverage technological advancements and data analytics to make informed decisions and optimize their supply chains.

Looking ahead, the TFT LCD market is poised for significant growth, driven by advancements in display technology and increasing applications across various sectors. By proactively engaging with suppliers and staying informed about market trends, international buyers can position themselves advantageously. As you navigate your sourcing strategies, consider taking bold steps towards collaboration and innovation—this will ensure that your business remains competitive in a dynamic landscape.