Discover Top Benefits of Choosing a Forging Supplier (2025)

Introduction: Navigating the Global Market for forging supplier

In today’s competitive landscape, sourcing a reliable forging supplier is a critical challenge faced by international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With the global forging industry continuously evolving, businesses are required to navigate a complex web of suppliers, technologies, and market dynamics to secure high-quality products that meet their specifications and timelines. This guide aims to equip buyers with the essential knowledge and tools needed to effectively identify and evaluate forging suppliers that align with their operational needs.

Throughout this comprehensive guide, we will explore various types of forging processes, applications across different industries, and the key factors to consider when vetting potential suppliers. Buyers will gain insights into cost structures, quality assurance practices, and logistical considerations that can significantly impact procurement decisions. Moreover, we will delve into best practices for establishing long-term partnerships with suppliers, ensuring that businesses not only find suitable providers but also foster relationships that drive growth and innovation.

By empowering B2B buyers with actionable insights and strategic approaches, this guide serves as a vital resource for making informed purchasing decisions in the forging sector. Whether you are in France seeking precision components or in Argentina exploring bulk production options, the knowledge contained herein will help you navigate the global market with confidence and clarity.

Understanding forging supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Open Die Forging | Uses flat dies; allows for large workpieces and flexibility | Aerospace, automotive, construction | Pros: Versatile; Cons: Lower precision than closed die. |

| Closed Die Forging | Utilizes shaped dies; offers high precision and repeatability | Medical devices, precision machinery | Pros: High accuracy; Cons: Higher initial costs. |

| Rolled Forging | Involves continuous rolling of metal; efficient for high volumes | Rail, automotive, heavy machinery | Pros: Cost-effective for large quantities; Cons: Limited to certain shapes. |

| Hammer Forging | Uses mechanical hammers to shape metal; suitable for various materials | Heavy equipment, tools, fasteners | Pros: Strong parts; Cons: May require extensive finishing. |

| Upset Forging | Involves thickening a workpiece by applying pressure; ideal for specific applications | Fasteners, bolts, industrial components | Pros: Efficient for small parts; Cons: Limited to specific shapes and sizes. |

What Are the Characteristics of Open Die Forging?

Open die forging is characterized by the use of flat dies that allow the metal to flow freely, making it suitable for large and complex shapes. This method is particularly popular in industries like aerospace and automotive, where size and flexibility are crucial. When considering open die forging, B2B buyers should evaluate the supplier’s ability to handle large workpieces and the potential for custom designs. While it offers versatility, the trade-off is a lack of precision compared to other methods.

How Does Closed Die Forging Provide Precision for B2B Buyers?

Closed die forging employs shaped dies to create high-precision components, making it ideal for applications in medical devices and precision machinery. This method ensures consistency and repeatability, which is essential for industries where tolerances are tight. B2B buyers should consider the initial setup costs, as closed die forging can be more expensive upfront, but the long-term benefits of high-quality parts often justify the investment.

Why Choose Rolled Forging for High Volume Production?

Rolled forging is a continuous process that efficiently produces large quantities of metal parts. This method is particularly advantageous for sectors like rail and automotive, where mass production is essential. Buyers should assess their volume needs and the specific shapes required, as rolled forging is limited to certain configurations. While it is cost-effective for high volumes, it may not be suitable for bespoke or low-quantity orders.

What Are the Benefits of Hammer Forging in Heavy Equipment Manufacturing?

Hammer forging utilizes mechanical hammers to shape metal, resulting in strong and durable components. This method is widely used in the manufacturing of heavy equipment, tools, and fasteners. B2B buyers should weigh the strength and reliability of hammer-forged parts against the potential need for additional finishing work. While the process can produce robust products, the finishing requirements may add to the overall production time and cost.

In What Scenarios Is Upset Forging Most Effective?

Upset forging focuses on thickening a workpiece by applying localized pressure, making it ideal for producing small parts like fasteners and bolts. This method is efficient and helps in achieving high strength in the finished products. B2B buyers should consider the specific applications and size constraints when choosing upset forging, as it is limited to certain shapes. While it is effective for small components, its applicability may not extend to larger or more complex items.

Related Video: Heat Treatment -The Science of Forging (feat. Alec Steele)

Key Industrial Applications of forging supplier

| Industry/Sector | Specific Application of forging supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of crankshafts and connecting rods | Improved strength-to-weight ratio enhances vehicle performance | Certification and compliance with industry standards are crucial. |

| Aerospace | Manufacturing of turbine blades | High durability and resistance to extreme conditions | Ensure suppliers have experience with high-temperature alloys. |

| Oil & Gas | Creation of valve components | Enhanced reliability under high-pressure conditions | Focus on suppliers with a strong quality assurance process. |

| Construction & Heavy Equipment | Fabrication of structural components | Increased load-bearing capacity for safety and longevity | Verify the supplier’s capacity for large-scale production. |

| Agriculture & Farming | Production of agricultural machinery parts | Improved efficiency and reduced downtime | Look for suppliers with a history of innovation in agricultural applications. |

How is Forging Used in the Automotive Industry?

In the automotive sector, forging suppliers play a vital role in the production of crankshafts and connecting rods. These components require exceptional strength and fatigue resistance, which forged materials can provide. International buyers, particularly from regions like Africa and South America, should prioritize suppliers that adhere to strict automotive industry standards, ensuring both quality and reliability. Additionally, understanding the supplier’s ability to meet specific volume requirements can significantly impact production timelines and costs.

What is the Role of Forging in Aerospace Manufacturing?

Forging suppliers in the aerospace industry are crucial for manufacturing turbine blades, which must withstand extreme temperatures and pressures. The forging process enhances the material’s grain structure, resulting in increased durability and performance. Buyers from Europe and the Middle East should seek suppliers with expertise in high-temperature alloys and a proven track record in aerospace applications. Certifications such as AS9100 can also provide assurance of quality and compliance with industry regulations.

How Do Forging Suppliers Benefit the Oil & Gas Sector?

In the oil and gas industry, forging suppliers are essential for creating valve components that must operate reliably under high-pressure conditions. The forged components offer enhanced strength and durability, reducing the risk of failures that could lead to costly downtime. B2B buyers should focus on suppliers who have robust quality assurance processes and experience in handling the specific demands of the oil and gas sector, particularly in regions with challenging operational environments.

Why is Forging Important for Construction & Heavy Equipment?

Forging suppliers contribute significantly to the construction and heavy equipment sectors by fabricating structural components that are integral to machinery and buildings. These forged parts provide increased load-bearing capacity, which is crucial for safety and longevity. Buyers should ensure that their suppliers can handle large-scale production requirements and have the necessary certifications to meet construction industry standards. Understanding the supplier’s capabilities for custom solutions can also be beneficial.

How Does Forging Enhance Agricultural Machinery?

In agriculture, forging suppliers are responsible for producing parts for machinery that enhance operational efficiency. Forged components, such as gears and shafts, offer superior strength and durability, which can lead to reduced downtime and maintenance costs. Buyers should look for suppliers with a history of innovation in agricultural applications, as this can indicate a willingness to adapt to new technologies and requirements. Additionally, assessing the supplier’s ability to provide timely delivery can significantly impact operational efficiency in the field.

Related Video: The World Biggest Heavy Duty Hammer Forging Factory

3 Common User Pain Points for ‘forging supplier’ & Their Solutions

Scenario 1: Inconsistent Quality of Forged Components

The Problem:

B2B buyers often face the challenge of inconsistent quality when sourcing forged components from suppliers. This inconsistency can stem from various factors, including differences in manufacturing processes, materials used, and quality control measures. For companies in sectors like automotive or aerospace, where precision is critical, receiving components that do not meet specifications can lead to production delays, increased costs, and potential safety risks. Buyers may feel frustrated and overwhelmed by the need to vet multiple suppliers to find one that can reliably deliver high-quality products.

The Solution:

To mitigate quality inconsistency, international buyers should prioritize establishing clear specifications and standards before engaging with suppliers. This involves conducting thorough market research to identify reputable forging suppliers with proven track records. Buyers should request samples and certifications that demonstrate compliance with relevant industry standards, such as ISO 9001 or AS9100 for aerospace components. Additionally, consider implementing a robust supplier evaluation process that includes audits and performance reviews to ensure ongoing quality. Collaborating closely with suppliers during the design phase can also help clarify requirements, reducing the likelihood of quality issues down the line.

Scenario 2: Communication Barriers Across Different Time Zones

The Problem:

International B2B buyers often encounter significant communication barriers when dealing with forging suppliers from different regions, particularly when time zones vary widely. Delays in communication can lead to misunderstandings about project requirements, timelines, and adjustments needed during the forging process. This is especially problematic for buyers in Africa and South America who may be sourcing from suppliers in Europe or the Middle East, creating frustration and potential project delays.

The Solution:

To enhance communication, buyers should establish a clear communication strategy that includes scheduled meetings at mutually convenient times. Utilizing collaboration tools like Slack or Microsoft Teams can facilitate real-time updates and feedback, enabling quicker problem resolution. Additionally, consider appointing a dedicated project manager or liaison who understands both the buyer’s and supplier’s cultural contexts and can effectively bridge communication gaps. Providing suppliers with detailed briefs and visual aids can also help clarify expectations and minimize miscommunication.

Scenario 3: Difficulty in Finding Reliable Suppliers

The Problem:

Many B2B buyers struggle to identify reliable forging suppliers, especially in regions where the forging industry may not be as developed. This challenge can lead to wasted time and resources in vetting potential suppliers who ultimately do not meet the necessary standards or cannot fulfill orders on time. Buyers may feel overwhelmed by the sheer number of options and uncertain about how to assess a supplier’s reliability and capabilities effectively.

The Solution:

To streamline the supplier selection process, buyers should leverage industry networks and trade associations that can provide recommendations and insights on reputable forging suppliers. Participating in industry-specific trade shows and conferences can also facilitate direct interactions with potential suppliers, allowing buyers to assess their capabilities firsthand. Utilizing online platforms and directories that specialize in industrial suppliers can help narrow down options based on specific criteria like location, certifications, and customer reviews. Additionally, consider using a phased approach to supplier engagement, starting with smaller orders to evaluate performance before committing to larger contracts.

Strategic Material Selection Guide for forging supplier

When selecting materials for forging, international B2B buyers must consider various factors that influence product performance, cost, and compliance with industry standards. The following analysis focuses on four common materials used in forging: carbon steel, alloy steel, stainless steel, and titanium. Each material has unique properties and implications for different applications, making it essential to choose wisely based on specific project requirements.

What are the Key Properties of Carbon Steel for Forging?

Carbon steel is one of the most widely used materials in forging due to its excellent mechanical properties and versatility. It typically exhibits high strength and toughness, making it suitable for high-stress applications. Carbon steel can withstand significant temperature and pressure variations, and its corrosion resistance can be enhanced with surface treatments.

Pros: Carbon steel is relatively low-cost, widely available, and easy to machine. It also offers good wear resistance, making it ideal for components subjected to friction.

Cons: However, carbon steel can be prone to rusting if not properly treated or coated, and its performance may degrade in highly corrosive environments. Additionally, it may require heat treatment to achieve desired hardness levels.

Impact on Application: Carbon steel is commonly used in automotive and machinery components, where strength and durability are crucial. Buyers should ensure compliance with standards such as ASTM A36 or DIN 17100.

How Does Alloy Steel Compare in Terms of Performance?

Alloy steel is a blend of carbon steel with other elements like manganese, nickel, or chromium, which enhances its properties. This material is known for its high strength, toughness, and resistance to wear and fatigue.

Pros: The primary advantage of alloy steel is its ability to maintain performance under extreme conditions, making it suitable for heavy-duty applications. It is also more resistant to deformation than carbon steel.

Cons: The complexity of manufacturing alloy steel can lead to higher costs, and specific grades may require precise heat treatment to achieve optimal performance.

Impact on Application: Alloy steel is often used in the production of gears, shafts, and other critical components in industries such as aerospace and automotive. Buyers should be aware of compliance with standards like ASTM A514 or JIS G4053.

Why Choose Stainless Steel for Corrosion Resistance?

Stainless steel is renowned for its corrosion resistance, making it an ideal choice for applications exposed to moisture or chemicals. It contains a minimum of 10.5% chromium, which forms a passive layer that protects the material from rust.

Pros: The key advantage of stainless steel is its longevity and low maintenance requirements. It also has good mechanical properties, making it suitable for a wide range of applications.

Cons: The primary drawback is its higher cost compared to carbon and alloy steels. Additionally, stainless steel can be more challenging to forge due to its work-hardening properties.

Impact on Application: Stainless steel is widely used in food processing, medical devices, and marine applications. Buyers should ensure compliance with standards such as ASTM A276 or DIN 17440.

What Makes Titanium a Unique Choice for Forging?

Titanium is a lightweight, high-strength material that offers excellent corrosion resistance and biocompatibility. Its unique properties make it suitable for specialized applications in aerospace, medical, and chemical industries.

Pros: Titanium’s high strength-to-weight ratio is a significant advantage, allowing for lighter components without sacrificing durability. It also performs well in extreme temperatures and corrosive environments.

Cons: However, titanium is one of the more expensive materials, and its forging process can be complex, requiring specialized equipment and techniques.

Impact on Application: Titanium is commonly used in aerospace components, medical implants, and chemical processing equipment. Buyers should consider compliance with standards such as ASTM B348 or JIS H4650.

Summary Table of Material Selection for Forging Suppliers

| Material | Typical Use Case for forging supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Automotive and machinery components | Low cost and good wear resistance | Prone to rust without treatment | Low |

| Alloy Steel | Gears and critical aerospace components | High strength and fatigue resistance | Higher manufacturing complexity | Medium |

| Stainless Steel | Food processing and medical devices | Excellent corrosion resistance | Higher cost and difficult to forge | High |

| Titanium | Aerospace and medical implants | High strength-to-weight ratio | Expensive and complex to forge | High |

This strategic material selection guide provides international B2B buyers with essential insights into the properties, advantages, and limitations of common forging materials. Understanding these factors can aid in making informed decisions that align with specific project requirements and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for forging supplier

What Are the Key Stages in the Manufacturing Process for Forging Suppliers?

The manufacturing process for forging involves several critical stages, each designed to transform raw materials into high-quality forged products. Understanding these stages is essential for B2B buyers looking to engage with reliable forging suppliers.

-

Material Preparation

The first step in the forging process is material preparation, where raw materials—typically metals such as steel or aluminum—are sourced and prepared for forging. This may involve cutting large metal bars into smaller, manageable pieces, which can be heated for easier deformation. Proper material selection is crucial, as it directly impacts the mechanical properties of the final product. -

Forming Techniques

Once the materials are prepared, they undergo various forming techniques. The two primary methods are:

-

Open Die Forging: In this method, the metal is deformed between two flat dies. It allows for the production of large and heavy components but requires skilled operators to achieve the desired shapes.

-

Closed Die Forging: This method involves shaping the metal within a die that has a specific cavity. It is more precise and suitable for producing smaller, intricate parts with tighter tolerances.

Other techniques include hot forging, where materials are heated above their recrystallization temperature, and cold forging, which occurs at room temperature for increased strength.

-

Assembly and Machining

After the forging process, components may require assembly or further machining to achieve specific dimensions and surface finishes. This stage may involve processes such as drilling, milling, or grinding, ensuring the final product meets the required specifications. -

Finishing Processes

The finishing stage enhances the aesthetic and functional qualities of the forged parts. Techniques such as heat treatment, surface hardening, and coating can be applied to improve durability, corrosion resistance, and overall performance.

How Is Quality Assurance Implemented in Forging?

Quality assurance (QA) is a critical aspect of the forging industry, ensuring that products meet international standards and customer expectations. For B2B buyers, understanding QA processes is essential when evaluating potential suppliers.

-

International Standards to Look For

Many forging suppliers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE marking (for European markets) and API (American Petroleum Institute) standards are important indicators of a supplier’s commitment to quality. -

Quality Control Checkpoints

Effective quality control involves multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials upon arrival. Suppliers should verify that materials meet predefined specifications, ensuring the quality of the starting components.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are crucial. This may include monitoring temperature, pressure, and dimensional accuracy at various stages of forging and machining.

-

Final Quality Control (FQC): Once the products are finished, a thorough inspection is conducted to ensure they meet all specifications and standards before shipping to the customer.

- Common Testing Methods in Forging

Several testing methods are commonly employed to assess the quality of forged components. These include:

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, magnetic particle testing, and dye penetrant testing are used to identify internal and surface defects without damaging the product.

- Destructive Testing: Mechanical tests such as tensile, impact, and fatigue tests provide valuable data on material properties, but they do require sample destruction.

- Dimensional Inspection: Precision measuring tools are used to ensure that the forged parts meet specific tolerances and dimensions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of forging suppliers is paramount. Here are some actionable strategies:

-

Conduct Supplier Audits

Regular audits can provide insights into a supplier’s quality management system and manufacturing processes. B2B buyers should establish a framework for conducting these audits, focusing on quality control documentation, adherence to international standards, and overall operational efficiency. -

Request Quality Reports and Certifications

Buyers should request detailed quality assurance reports, including results from IQC, IPQC, and FQC checks. Additionally, verifying certifications can help confirm that the supplier meets required industry standards. -

Engage Third-Party Inspection Services

Utilizing third-party inspection agencies can provide an unbiased assessment of a supplier’s quality assurance practices. These services can perform audits, product inspections, and certification verifications, ensuring that buyers receive products that meet their quality standards. -

Understand QC Nuances for Different Markets

Quality control expectations can vary significantly between regions. For instance, European buyers may place greater emphasis on CE marking, while buyers in the Middle East might focus on specific industry standards. Understanding these nuances can help buyers tailor their evaluation processes to the specific market they are operating in.

Conclusion: Ensuring Quality in Forging Supply Chains

For international B2B buyers, understanding the manufacturing processes and quality assurance measures in the forging industry is crucial for selecting reliable suppliers. By focusing on detailed material preparation, forming techniques, and stringent quality control checkpoints, buyers can make informed decisions that enhance their supply chain’s efficiency and product quality. Engaging in thorough supplier verification practices will ensure that the products meet the required standards and specifications, ultimately leading to successful business outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘forging supplier’

In the competitive landscape of international B2B procurement, particularly for forging suppliers, having a structured approach is essential for successful sourcing. This guide provides a comprehensive checklist to help international buyers—especially from Africa, South America, the Middle East, and Europe—navigate the complexities of finding and partnering with reliable forging suppliers.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, it’s vital to clearly articulate your technical requirements. This includes material types, dimensions, tolerances, and any specific forging processes needed. A well-defined specification not only streamlines the sourcing process but also ensures that suppliers can meet your exact needs, reducing the risk of costly errors later on.

Step 2: Conduct Market Research for Forging Suppliers

Research is critical to identify potential suppliers in the forging industry. Utilize online databases, industry reports, and trade associations to compile a list of reputable suppliers. Pay attention to regional expertise, as suppliers from specific areas may offer specialized capabilities that align with your needs.

- Tip: Consider attending industry trade shows or exhibitions for networking opportunities and firsthand insights into supplier capabilities.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is paramount. Request detailed company profiles, case studies, and references from existing clients. This not only helps verify their experience but also provides insight into their reliability and quality of work.

- Checklist for evaluation:

- Assess their production capacity and lead times.

- Inquire about their quality control processes and certifications.

Step 4: Verify Supplier Certifications and Compliance

Ensure that the suppliers you are considering comply with relevant industry standards and regulations. Certifications such as ISO 9001 for quality management or specific industry certifications can be indicators of a supplier’s commitment to quality.

- Why it matters: Compliance with international standards not only ensures product quality but also mitigates risks associated with regulatory non-compliance.

Step 5: Request Samples and Conduct Quality Tests

Before finalizing your supplier, request samples of their products. This is an essential step to assess the quality and craftsmanship of the forging. Conduct independent quality tests to verify that the samples meet your specifications.

- Key considerations:

- Analyze the durability, finish, and precision of the samples.

- Ensure that the supplier is open to modifications based on feedback.

Step 6: Negotiate Terms and Conditions Clearly

Once you have selected a supplier, it’s crucial to negotiate terms and conditions clearly. Discuss pricing, payment terms, delivery schedules, and after-sales support. A well-defined agreement helps prevent misunderstandings and sets clear expectations for both parties.

- Important: Document all terms in a formal contract to safeguard your interests.

Step 7: Establish Communication and Relationship Management

Building a strong relationship with your chosen supplier can lead to improved collaboration and better service. Set up regular communication channels to discuss ongoing projects, quality feedback, and any potential issues.

- Why this is vital: Strong relationships can enhance responsiveness and flexibility, which are critical in a dynamic market environment.

By following this structured checklist, international B2B buyers can effectively navigate the sourcing process for forging suppliers, ensuring that they select partners who can meet their technical requirements and business objectives.

Comprehensive Cost and Pricing Analysis for forging supplier Sourcing

What Are the Key Cost Components in Sourcing Forging Suppliers?

Understanding the cost structure of forging suppliers is essential for B2B buyers to make informed purchasing decisions. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts overall costs. Common materials used in forging include steel, aluminum, and titanium. Prices fluctuate based on market demand and availability, so it’s crucial to stay updated on material costs.

-

Labor: Labor costs vary by region and the complexity of the forging process. Skilled labor is often more expensive but can yield higher-quality products. In regions such as Europe, labor costs may be higher than in Africa or South America, influencing the final price.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, which can be a point of negotiation with suppliers.

-

Tooling: Tooling costs can be significant, especially for custom forging projects. Buyers should consider whether the supplier has existing tooling that can reduce initial costs or if new tooling will be required, which can add to the overall expense.

-

Quality Control (QC): Implementing rigorous QC measures ensures product reliability but comes at a cost. Buyers should assess how the supplier manages QC and whether these costs are reflected in the pricing.

-

Logistics: Transportation and shipping costs can vary greatly depending on the supplier’s location and the delivery terms. International buyers need to factor in these costs when evaluating suppliers.

-

Margin: Suppliers will include a profit margin in their pricing. This can vary based on the supplier’s market position and competition. Understanding the typical margins in your industry can help in negotiations.

How Do Price Influencers Affect Forging Supplier Costs?

Several factors can influence the pricing offered by forging suppliers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs to optimize pricing.

-

Specifications and Customization: Custom specifications can drive up costs. Clear communication of requirements can help avoid unexpected expenses later in the process.

-

Material Selection: The choice of material not only affects the cost but also the performance characteristics of the forged product. Buyers should weigh the cost against the desired specifications.

-

Quality Certifications: Suppliers that meet international quality standards may charge more. However, investing in certified suppliers can lead to long-term savings by reducing failures and rework.

-

Supplier Factors: The supplier’s reputation, production capabilities, and location can all impact pricing. A well-established supplier may offer higher reliability but could also command a premium.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is crucial for international buyers. Terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) can influence the overall cost structure and should be clearly defined in contracts.

What Tips Can Help International B2B Buyers Optimize Costs?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, can leverage several strategies to optimize costs:

-

Negotiation Strategies: Building a strong relationship with suppliers can create opportunities for better pricing. Be prepared to negotiate terms and conditions to achieve cost-effective solutions.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price, but the total cost over the product’s lifecycle, including maintenance, logistics, and potential downtime.

-

Understanding Pricing Nuances: Be aware of regional pricing trends and economic factors that could affect costs. For instance, currency fluctuations and local economic conditions can impact supplier pricing.

-

Conducting Market Research: Stay informed about market trends and competitor pricing. This knowledge can empower buyers during negotiations and help them secure better deals.

-

Requesting Quotations from Multiple Suppliers: Gathering quotes from various suppliers allows for comparison and can lead to more competitive pricing.

Disclaimer on Indicative Prices

It is important to note that the prices associated with forging suppliers can vary widely based on specific project requirements, supplier capabilities, and market conditions. Always seek updated quotes and detailed breakdowns to ensure accurate budgeting and forecasting.

Alternatives Analysis: Comparing forging supplier With Other Solutions

Understanding the Importance of Alternative Solutions in Forging

When considering a forging supplier, it is essential to evaluate various alternatives that may align better with your business needs. Different methods and technologies can provide similar outputs, and understanding these alternatives will enable international B2B buyers to make informed decisions. In this analysis, we will compare forging suppliers with two viable alternatives: casting and additive manufacturing.

Comparative Analysis of Forging Supplier and Alternatives

| Comparison Aspect | Forging Supplier | Casting | Additive Manufacturing |

|---|---|---|---|

| Performance | High strength and durability | Variable strength; generally lower than forging | Good for complex geometries but lower strength |

| Cost | Moderate to high initial cost | Generally lower initial cost | High initial investment but can save costs on low-volume production |

| Ease of Implementation | Requires specialized equipment | Easier setup; fewer specialized tools needed | Requires advanced technology and skills |

| Maintenance | Requires regular maintenance | Minimal maintenance needed | Ongoing software and equipment updates required |

| Best Use Case | High-stress applications, automotive, aerospace | Large, simpler parts, decorative items | Custom, low-volume production, prototypes |

What Are the Advantages and Disadvantages of Casting?

Casting is a process that involves pouring liquid material into a mold to achieve the desired shape. One of the significant advantages of casting is its lower initial cost compared to forging. This makes it an attractive option for businesses that need to produce large, simpler parts or decorative items. However, the performance of cast products can vary significantly, often resulting in lower strength and durability than forged items. Additionally, casting may not be suitable for high-stress applications, which limits its use in industries like aerospace and automotive.

How Does Additive Manufacturing Compare to Forging?

Additive manufacturing, often known as 3D printing, has gained traction for its ability to create complex geometries that traditional methods cannot easily achieve. It allows for rapid prototyping and customization, making it ideal for low-volume production runs. However, the initial investment in additive manufacturing technology can be high, and the material strength is typically lower than that of forged parts. This limits its applicability in high-stress environments. Moreover, the process requires ongoing maintenance and updates to software and equipment, which can be a barrier for some businesses.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right solution involves assessing your specific requirements, including the performance needed, budget constraints, and production volume. For high-stress applications, a forging supplier may be the best choice due to the superior strength and durability of forged products. If cost is a significant factor and the parts are less critical, casting might be more suitable. For projects requiring rapid prototyping and customization, additive manufacturing could be the way to go despite its higher costs and complexity. Ultimately, understanding the strengths and weaknesses of each alternative will empower B2B buyers to make the most informed choice that aligns with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for forging supplier

What Are the Key Technical Properties That B2B Buyers Should Consider When Working with Forging Suppliers?

When engaging with forging suppliers, understanding the technical properties of the products is critical to ensuring that the components meet your specific needs. Here are some essential specifications to consider:

1. Material Grade

Material grade refers to the classification of the metal used in the forging process. Common grades include carbon steel, alloy steel, and stainless steel. Each grade has unique properties such as strength, ductility, and corrosion resistance. For B2B buyers, selecting the appropriate material grade is vital to ensure the final product performs well in its intended application and meets industry standards.

2. Tolerance

Tolerance specifies the allowable deviation from a specified dimension or property. It is crucial in forging because it impacts the fit and function of the final product. Tight tolerances may be required for high-precision applications, while looser tolerances can suffice for less critical uses. Understanding tolerance levels is essential for B2B buyers to ensure compatibility with existing systems and components.

3. Mechanical Properties

Mechanical properties such as tensile strength, yield strength, and hardness provide insights into how a forged component will behave under stress. These properties are influenced by the material used and the forging process itself. B2B buyers must assess these properties to ensure that the components will withstand operational demands and environmental conditions.

4. Surface Finish

Surface finish refers to the texture and smoothness of a forged part’s surface. It can affect not only the aesthetic appeal but also the performance characteristics, such as friction and wear resistance. Buyers should consider the required surface finish for their applications, as it can influence the longevity and functionality of the components.

5. Heat Treatment

Heat treatment is a process applied to alter the physical and sometimes chemical properties of a material. It can enhance strength, toughness, and ductility. For B2B buyers, understanding whether a supplier offers heat-treated forgings can be a significant factor in ensuring that the components will perform under demanding conditions.

Which Trade Terms Should International Buyers Understand When Dealing with Forging Suppliers?

Navigating the terminology used in the forging industry can be daunting for B2B buyers. Familiarity with common trade terms is essential for effective communication and negotiation. Here are key terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, working with OEMs can ensure that the components meet specific industry standards and are compatible with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers, particularly those in Africa and South America, as it affects inventory management and overall costs. Buyers should clarify MOQ with suppliers to ensure alignment with their purchasing capabilities.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. For international B2B buyers, submitting a well-structured RFQ can facilitate better pricing negotiations and help suppliers understand their needs more clearly.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that define responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to mitigate risks related to shipping, insurance, and delivery obligations.

5. Lead Time

Lead time refers to the period between the initiation of an order and its completion. Understanding lead times is essential for B2B buyers to plan their production schedules effectively and avoid delays in their supply chain.

By grasping these essential technical properties and trade terminology, B2B buyers can make informed decisions when sourcing from forging suppliers, ensuring that they procure the right products to meet their operational requirements.

Navigating Market Dynamics and Sourcing Trends in the forging supplier Sector

What are the Current Market Dynamics and Key Trends in the Forging Supplier Sector?

The forging supplier sector is witnessing dynamic changes driven by several global factors. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly focusing on suppliers that offer not only competitive pricing but also advanced technological capabilities. Key trends include the integration of Industry 4.0 technologies such as automation, AI, and IoT, which enhance operational efficiency and product quality. Buyers are now looking for suppliers who can leverage these technologies to provide real-time data and insights, improving decision-making and supply chain visibility.

Moreover, the shift towards regional sourcing is becoming prominent. With disruptions caused by global events, international buyers are prioritizing suppliers closer to their production facilities to mitigate risks and reduce lead times. This trend is especially relevant for buyers in South America and Africa, where local partnerships can enhance supply chain resilience. Additionally, sustainability is no longer a mere buzzword; it is a critical factor influencing purchasing decisions. Buyers are increasingly seeking suppliers that demonstrate a commitment to sustainable practices, including reducing carbon footprints and minimizing waste.

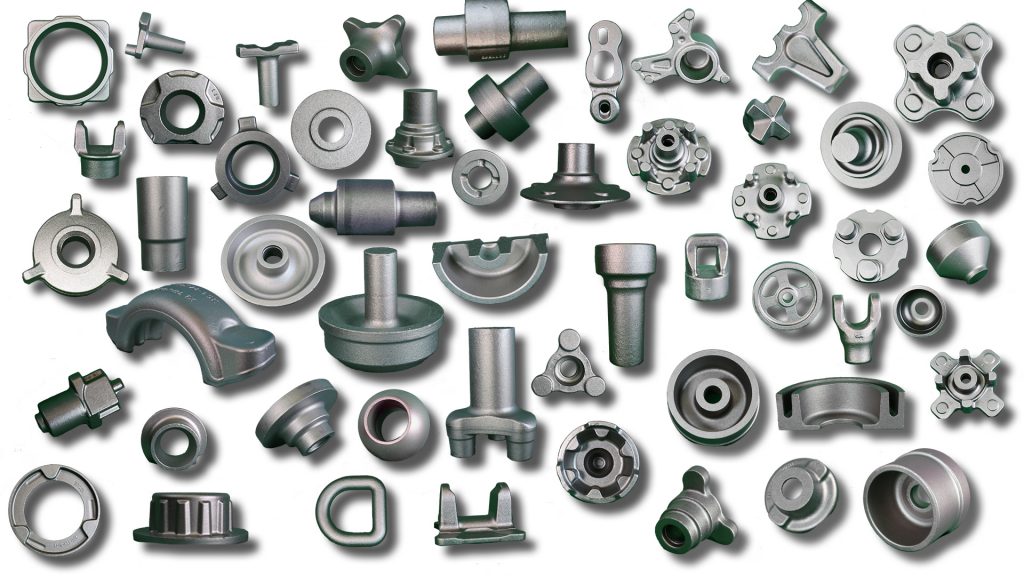

A stock image related to forging supplier.

How Does Sustainability and Ethical Sourcing Impact B2B Buyers in the Forging Sector?

Sustainability and ethical sourcing are paramount for international B2B buyers in the forging supplier sector. The environmental impact of forging processes, such as energy consumption and material waste, is under scrutiny. Buyers are now prioritizing suppliers that implement sustainable practices, such as using renewable energy sources and recycling materials. This shift not only meets regulatory requirements but also aligns with the growing consumer demand for environmentally responsible products.

Furthermore, the importance of ethical supply chains cannot be overstated. Buyers are increasingly concerned about labor practices and the sourcing of raw materials. They are seeking suppliers with certifications like ISO 14001 for environmental management and social compliance certifications that ensure fair labor practices. By partnering with ethically responsible suppliers, buyers can enhance their brand reputation and appeal to a broader customer base that values sustainability.

To stay competitive, suppliers in the forging sector are adopting green certifications and materials, showcasing their commitment to sustainability. This trend not only attracts environmentally conscious buyers but also positions suppliers favorably in a market where sustainability is becoming a key differentiator.

How Has the Forging Supplier Sector Evolved Over Time?

The forging supplier sector has evolved significantly over the decades, influenced by technological advancements and changing market demands. Initially, the industry was characterized by traditional, labor-intensive processes. However, the introduction of advanced forging techniques, such as precision forging and closed-die forging, has allowed for greater accuracy and efficiency in production.

In the early 2000s, globalization began reshaping the landscape, enabling suppliers to tap into international markets. This evolution has led to increased competition, compelling suppliers to innovate and invest in technology to meet the diverse needs of international buyers. Today, the sector is focused on not only enhancing product quality but also fostering sustainable practices and ethical sourcing, aligning with global trends that prioritize environmental and social responsibility.

A stock image related to forging supplier.

As international B2B buyers navigate this complex landscape, understanding these historical shifts can inform their sourcing strategies, ensuring they partner with suppliers capable of meeting modern demands.

Frequently Asked Questions (FAQs) for B2B Buyers of forging supplier

-

How do I choose the right forging supplier for my business needs?

Selecting the right forging supplier involves several key steps. First, assess the supplier’s expertise in your specific industry and the types of forgings you require. Check for certifications like ISO 9001, which indicate quality management standards. Request samples to evaluate the quality of their work and inquire about their production capabilities, lead times, and flexibility for customization. Finally, consider their geographic location and logistics capabilities, especially if you are sourcing from regions like Africa or South America, where shipping times may vary. -

What factors should I consider when evaluating a forging supplier’s capabilities?

When evaluating a forging supplier, consider their production capacity, technology, and experience in your industry. Look for suppliers who employ advanced forging techniques and have a solid track record of meeting client specifications. Assess their quality assurance processes, including any testing methods they use to ensure the durability and reliability of their products. Furthermore, understanding their ability to handle large orders or quick turnaround times is crucial, particularly for international buyers who may face longer lead times. -

What minimum order quantity (MOQ) should I expect from a forging supplier?

Minimum order quantities (MOQs) can vary widely among forging suppliers based on their production processes and the complexity of the parts. Many suppliers set MOQs to ensure cost-effectiveness in manufacturing. It’s essential to discuss your specific requirements upfront. If your needs are smaller, look for suppliers who offer flexibility or specialize in smaller production runs. Some suppliers may also provide tiered pricing based on order size, which could be beneficial for budgeting purposes. -

What payment terms are common when working with international forging suppliers?

Common payment terms can vary based on the supplier’s policies and the relationship you have established. Many suppliers may request a deposit (often 30-50%) upfront, with the balance due upon delivery or before shipment. Letters of credit are also a secure option for international transactions, ensuring payment upon fulfillment of agreed terms. Always clarify payment methods, currency, and any additional fees, such as bank charges or currency conversion fees, to avoid misunderstandings. -

How can I ensure quality assurance when sourcing from forging suppliers?

To ensure quality assurance, request detailed documentation of the supplier’s quality control processes. This may include certifications, inspection reports, and details about their testing methodologies. Conducting an on-site audit can provide deeper insights into their operations. Additionally, consider implementing a third-party inspection service before shipment to verify that the products meet your quality standards. Regular communication and establishing clear specifications will further enhance quality assurance throughout the production process. -

What are the logistics considerations when sourcing from forging suppliers in different regions?

Logistics can significantly impact the efficiency and cost of your procurement process. When sourcing from regions like Africa or South America, consider factors such as shipping times, customs regulations, and local transportation infrastructure. Ensure that the supplier has a reliable shipping partner and understand the incoterms that apply to your shipment. Evaluating potential delays at customs can also help you plan better and mitigate risks associated with international shipping. -

How do I handle customs and import regulations when sourcing from international forging suppliers?

Navigating customs and import regulations can be complex when sourcing internationally. Familiarize yourself with the import duties and tariffs applicable to your products in your home country. Collaborate with a customs broker who can assist you in ensuring compliance with local regulations, including necessary documentation and permits. It’s also beneficial to have open communication with your supplier regarding the required documentation they must provide for a smooth customs clearance process. -

Can forging suppliers accommodate customization requests for specific projects?

Many forging suppliers offer customization options to meet the unique requirements of specific projects. When inquiring about custom forgings, provide detailed specifications, including dimensions, materials, and any particular performance criteria. Discuss the feasibility of your request with the supplier, as well as any implications for pricing and lead times. Suppliers with advanced manufacturing capabilities are often more flexible and can work closely with you to develop tailored solutions that meet your project’s demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for forging supplier

What Are the Key Takeaways for International B2B Buyers in Forging Supplier Sourcing?

In the realm of forging supplier sourcing, strategic partnerships emerge as a cornerstone for success. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize aligning with suppliers who not only meet quality standards but also demonstrate flexibility and innovation. The ability to adapt to fluctuating market demands and technological advancements can significantly enhance supply chain resilience.

How Can Strategic Sourcing Drive Value?

Strategic sourcing is not merely a procurement process; it is a comprehensive approach that fosters long-term relationships, cost efficiency, and operational excellence. By leveraging data analytics and market insights, buyers can make informed decisions that lead to sustainable growth. Engaging in thorough supplier evaluations and fostering open communication channels ensures that both parties can navigate challenges collaboratively.

What Does the Future Hold for Forging Suppliers?

Looking ahead, the forging industry is poised for growth driven by technological advancements and increasing global demand. International buyers are encouraged to stay ahead of trends such as automation and sustainability practices. By actively participating in this evolving landscape, businesses can not only secure their supply chains but also position themselves as leaders in their respective markets.

Take the next step towards optimizing your sourcing strategy—forge strong partnerships today to unlock future potential and drive your business forward.