Discover Top Benefits of Choosing a Label Printer Manufacturer (2025)

Introduction: Navigating the Global Market for label printer manufacturer

In today’s fast-paced global market, sourcing the right label printer manufacturer can be a daunting challenge for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With numerous options available, selecting a supplier that meets specific operational needs—be it for inventory management, product labeling, or shipping—requires careful consideration. This guide serves as a comprehensive resource for international buyers, providing valuable insights into the various types of label printers, their applications across industries, and the factors influencing supplier selection.

Navigating the complexities of the label printer market involves more than just understanding the technology; it includes assessing the credibility of suppliers, evaluating cost structures, and recognizing the nuances of regional compliance and support services. This guide empowers decision-makers with actionable strategies to vet suppliers effectively, negotiate favorable terms, and ultimately make informed purchasing decisions that align with their business objectives.

Whether you’re a procurement officer in Turkey looking for reliable thermal printers or a logistics manager in Spain seeking durable label solutions, this resource is designed to enhance your understanding of the label printer landscape. With an emphasis on practical tips and regional considerations, you can confidently navigate the global market and find the ideal label printer manufacturer that meets your specific needs.

Understanding label printer manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Thermal Transfer Printers | Use heat to transfer ink from a ribbon to the label. | Shipping, manufacturing, retail | Pros: High-quality prints, durable labels. Cons: Requires ribbon replacement. |

| Direct Thermal Printers | Print directly on heat-sensitive media without ribbons. | Food packaging, logistics, healthcare | Pros: Lower operational costs, simpler maintenance. Cons: Labels may fade over time. |

| Inkjet Printers | Utilize liquid ink to produce high-resolution images. | Branding, custom labels, product packaging | Pros: Versatile, capable of vibrant colors. Cons: Slower printing speeds, higher ink costs. |

| Laser Printers | Use laser technology for fast, high-quality printing. | Office use, barcode printing | Pros: Fast production, sharp text quality. Cons: Higher initial investment, bulkier. |

| Portable Label Printers | Compact, battery-operated devices for on-the-go printing. | Fieldwork, inventory management | Pros: Convenience, easy to use. Cons: Limited print volume, smaller label sizes. |

What Are the Characteristics of Thermal Transfer Printers?

Thermal transfer printers are renowned for their ability to produce high-quality, durable labels by applying heat to transfer ink from a ribbon onto the label material. These printers are particularly well-suited for environments requiring long-lasting labels, such as shipping and manufacturing. When considering a thermal transfer printer, B2B buyers should evaluate ribbon compatibility, print speed, and the types of label materials supported to ensure they meet operational demands.

How Do Direct Thermal Printers Function?

Direct thermal printers operate by applying heat directly to heat-sensitive label stock, eliminating the need for ink ribbons. This makes them an economical choice for businesses in sectors like food packaging and logistics, where labels must be produced quickly and at lower costs. Buyers should consider the longevity of the labels, as they may fade over time, particularly if exposed to sunlight or heat, which could affect branding and compliance in certain industries.

Why Choose Inkjet Printers for Custom Labels?

Inkjet printers are ideal for businesses seeking to create vibrant, high-resolution labels with intricate designs. They are versatile and can handle various media types, making them suitable for branding and product packaging across different industries. However, B2B buyers must weigh the slower printing speeds and higher ink costs against their need for quality and customization. Assessing the volume of labels required can guide investment decisions in inkjet technology.

What Advantages Do Laser Printers Offer?

Laser printers utilize advanced laser technology to deliver fast, high-quality prints, making them a popular choice for office environments and barcode printing. Their ability to produce sharp text and graphics quickly allows businesses to maintain efficiency. However, B2B buyers should be prepared for a higher initial investment and consider the printer’s footprint, as laser printers can be bulkier than other types. Evaluating the total cost of ownership, including toner and maintenance, is crucial for long-term budgeting.

How Do Portable Label Printers Enhance Field Operations?

Portable label printers are compact, battery-operated devices designed for on-the-go printing, ideal for fieldwork and inventory management. Their convenience and ease of use allow staff to create labels wherever needed, improving operational efficiency. However, buyers should be aware of the limitations in print volume and label size, which may restrict their application in larger-scale operations. Understanding the specific needs of field teams can help in selecting the right model to enhance productivity.

Related Video: Phomemo Shipping Label Printer PM246s Review!

Key Industrial Applications of label printer manufacturer

| Industry/Sector | Specific Application of label printer manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Product labeling for packaging and compliance | Ensures regulatory compliance and enhances brand visibility | Quality of labels under varying temperatures and humidity |

| Pharmaceuticals | Patient and medication labeling | Improves patient safety and regulatory adherence | Accuracy in label printing and compliance standards |

| Logistics and Shipping | Shipping labels and tracking barcodes | Streamlines supply chain processes and reduces errors | Compatibility with existing logistics software |

| Retail | Price tags and promotional labels | Enhances customer experience and supports marketing efforts | Customization options and durability of labels |

| Manufacturing | Asset management and inventory labels | Improves inventory accuracy and operational efficiency | Scalability and integration with inventory systems |

How is Label Printer Technology Used in the Food and Beverage Sector?

In the food and beverage industry, label printers are essential for creating product labels that comply with local and international regulations. These labels often include nutritional information, ingredient lists, and allergen warnings. For international B2B buyers, especially in Africa and South America, sourcing printers that can handle diverse languages and comply with varying regulatory standards is crucial. Furthermore, labels must withstand various storage conditions, making durability a key requirement.

What Role Does Label Printing Play in Pharmaceuticals?

Pharmaceutical companies utilize label printers for accurate patient medication labeling, which is critical for ensuring patient safety and adhering to strict regulatory standards. These labels often include dosage instructions, expiration dates, and barcodes for tracking. Buyers from the Middle East and Europe should prioritize manufacturers that offer high-resolution printing capabilities and compliance with health regulations. Ensuring that the labels are resistant to moisture and tampering is also vital in this sector.

How Do Logistics and Shipping Benefit from Label Printers?

In logistics and shipping, label printers are used to create shipping labels and tracking barcodes that facilitate efficient movement of goods. This application is particularly important for B2B operations in Europe and Africa, where logistics can be complex and prone to errors. Companies should focus on printers that integrate seamlessly with their existing logistics software to streamline operations. Additionally, the ability to print on-demand can significantly reduce delays in shipping processes.

Why Are Retail Applications of Label Printers Important?

Retail businesses use label printers to produce price tags and promotional labels that enhance the shopping experience. These labels can attract customers and provide essential product information. For international buyers, particularly in South America and Turkey, it’s important to consider the customization options available, as well as the durability of labels in high-traffic environments. Investing in high-quality label printers can lead to improved customer engagement and sales.

How Does Label Printing Enhance Inventory Management in Manufacturing?

In manufacturing, label printers are crucial for asset management and inventory labeling, helping businesses maintain accurate stock levels and streamline operations. This application is especially relevant for B2B buyers in Europe and the Middle East, where regulatory compliance and operational efficiency are paramount. Buyers should look for printers that offer scalability and can integrate with existing inventory management systems to optimize their processes and reduce waste.

Related Video: DuraLabel Toro Max Industrial Label Printer

3 Common User Pain Points for ‘label printer manufacturer’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Label Printer for Specific Needs

The Problem:

B2B buyers often face challenges in identifying the most suitable label printer that aligns with their unique operational requirements. For instance, a logistics company in Turkey may require a printer that can handle high volumes of labels, while a small-scale manufacturer in South America might prioritize compact designs due to limited workspace. This mismatch can lead to costly investments in equipment that fails to meet performance expectations, resulting in wasted resources and decreased productivity.

The Solution:

To overcome this challenge, buyers should conduct a thorough needs assessment prior to sourcing a label printer. This involves evaluating factors such as print volume, label size, and material compatibility. Engaging directly with label printer manufacturers to request product demos or samples can provide invaluable insights into performance and usability. Additionally, leveraging online forums and industry-specific social media groups can help gather feedback from peers who have faced similar challenges. By taking a consultative approach and clearly communicating their needs, buyers can ensure they select a printer that not only meets their current demands but is also scalable for future growth.

Scenario 2: High Operational Costs Due to Inefficient Printing Processes

The Problem:

Many businesses encounter inflated operational costs stemming from inefficient label printing processes. A common scenario involves a manufacturing plant in Europe where outdated printers lead to frequent breakdowns, requiring costly repairs and downtime. Additionally, inefficient ink usage can result in higher expenses per label printed, which can significantly affect the bottom line over time.

The Solution:

Investing in modern label printers equipped with advanced technology can dramatically reduce operational costs. Buyers should look for printers that feature high-capacity ink cartridges and energy-efficient designs, which can lead to lower per-label costs. Furthermore, considering printers with automation capabilities can streamline the printing process, reducing labor costs and minimizing the risk of human error. When sourcing new printers, it’s beneficial to request total cost of ownership (TCO) analyses from manufacturers, which provide a comprehensive breakdown of costs over the printer’s lifespan. This strategic approach allows businesses to make informed decisions that align with their budgetary constraints.

Scenario 3: Challenges in Label Compliance and Regulatory Standards

The Problem:

International B2B buyers often struggle with ensuring that their label printing solutions comply with various regional regulatory standards. For instance, a company exporting goods from Africa to the EU must adhere to stringent labeling requirements, including language specifications and safety information. Failing to comply can result in delayed shipments, fines, and damaged reputations.

The Solution:

To mitigate compliance risks, businesses should prioritize label printers that offer customizable solutions to accommodate diverse regulatory requirements. Engaging with manufacturers who have a proven track record in global markets can provide essential insights into local standards. Additionally, incorporating software that automates compliance checks during the design process can save time and reduce errors. Buyers should also consider collaborating with legal experts in labeling regulations specific to their target markets. This proactive approach not only ensures compliance but also enhances the brand’s credibility in international trade. By investing in the right technology and expertise, companies can navigate the complexities of global labeling requirements effectively.

Strategic Material Selection Guide for label printer manufacturer

When selecting materials for label printing, manufacturers must consider various factors that influence the performance and suitability of the labels for different applications. Below, we analyze four common materials used in label printing, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Polyester Labels?

Polyester (PET) is a popular choice for label printing due to its excellent durability and resistance to various environmental factors. It can withstand high temperatures and is resistant to moisture, chemicals, and UV light. These properties make polyester labels ideal for outdoor applications and harsh industrial environments.

Pros: Polyester labels are highly durable, making them suitable for long-term use. They are also resistant to tearing and fading, ensuring that the printed information remains legible over time. The manufacturing process is relatively straightforward, allowing for quick production.

Cons: The primary drawback of polyester is its higher cost compared to other materials like paper. Additionally, while it is recyclable, not all facilities accept polyester, which could be a concern for environmentally conscious buyers.

Impact on Application: Polyester labels are compatible with a wide range of printing technologies, including thermal transfer and direct thermal printing. They are particularly effective for labels requiring high durability, such as those used in automotive, electronics, and chemical industries.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of local recycling capabilities for polyester. Compliance with international standards such as ASTM D1000 for adhesive tapes may also be relevant.

How Do Paper Labels Compare in Performance?

Paper labels are one of the most commonly used materials due to their versatility and cost-effectiveness. They are available in various finishes, including matte and glossy, and can be easily printed on using thermal transfer or inkjet technologies.

Pros: The primary advantage of paper labels is their low cost, making them an economical choice for high-volume applications. They are also easy to customize and can be produced quickly.

Cons: Paper labels generally lack the durability of synthetic materials. They are susceptible to moisture, fading, and tearing, which can limit their use in demanding environments.

Impact on Application: Paper labels are suitable for indoor applications, such as product labeling in retail, where exposure to moisture and harsh conditions is minimal. However, they may not be ideal for applications requiring long-term durability.

Considerations for International Buyers: Buyers in Europe, particularly in Spain, should consider compliance with the EU’s REACH regulation regarding chemical safety in labeling materials. Additionally, understanding local preferences for label aesthetics can guide material selection.

What Advantages Do Vinyl Labels Offer for Specific Applications?

Vinyl labels are known for their flexibility and resistance to water, chemicals, and UV light. This makes them suitable for various applications, including outdoor signage and labeling on products exposed to harsh conditions.

Pros: Vinyl labels are highly durable and can withstand extreme temperatures and environmental conditions. They are also available in a wide range of colors and finishes, allowing for creative branding opportunities.

Cons: The cost of vinyl labels is generally higher than paper, and the manufacturing process can be more complex, potentially leading to longer lead times.

Impact on Application: Vinyl labels are particularly effective for applications requiring high visibility and durability, such as outdoor products and equipment labeling.

Considerations for International Buyers: Buyers from the Middle East should ensure that vinyl labels comply with local environmental regulations, as PVC materials can have specific disposal requirements.

Why Are Polypropylene Labels Gaining Popularity?

Polypropylene (PP) labels are increasingly popular due to their balance of durability and cost. They offer good resistance to moisture and chemicals, making them suitable for various applications.

Pros: Polypropylene labels are lightweight and flexible, which allows for easy application on curved surfaces. They are also less expensive than polyester while still offering decent durability.

Cons: While polypropylene is more durable than paper, it does not match the performance of polyester or vinyl in extreme conditions. Additionally, the printing quality may vary depending on the technology used.

Impact on Application: Polypropylene labels are versatile and can be used in both indoor and outdoor applications, such as food packaging and consumer goods.

Considerations for International Buyers: Buyers in Turkey should consider local standards for food safety and labeling compliance when selecting polypropylene for food-related applications.

Summary Table of Material Selection for Label Printer Manufacturers

| Material | Typical Use Case for label printer manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Outdoor labels, industrial applications | High durability and chemical resistance | Higher cost than paper | High |

| Paper | Retail product labeling, indoor applications | Cost-effective and easy to print | Susceptible to moisture and fading | Low |

| Vinyl | Outdoor signage, harsh environment labeling | Excellent durability and flexibility | Higher cost and complex manufacturing | High |

| Polypropylene | Food packaging, consumer goods labeling | Good balance of durability and cost | Lower durability than polyester | Medium |

This guide aims to provide B2B buyers with actionable insights into material selection for label printing, helping them make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for label printer manufacturer

What Are the Main Stages of Manufacturing Processes for Label Printers?

When considering the purchase of label printers, understanding the manufacturing processes is crucial for B2B buyers. The typical production of label printers involves several key stages:

-

Material Preparation: The initial stage involves selecting high-quality raw materials, including plastics, metals, and electronic components. Manufacturers often prioritize materials that ensure durability and functionality under various operating conditions. Buyers should inquire about the sourcing of these materials and their compliance with international standards.

-

Forming: This stage encompasses techniques such as injection molding for plastic parts and die-casting for metal components. Advanced methods like 3D printing are also gaining traction for prototyping and producing complex parts. B2B buyers should assess whether manufacturers use state-of-the-art technology that enhances precision and reduces waste.

-

Assembly: In the assembly phase, components are meticulously put together, often through automated processes to ensure consistency. This can involve both manual and robotic assembly lines. Buyers should look for manufacturers who employ lean manufacturing principles to optimize efficiency and reduce lead times.

-

Finishing: The final stage includes surface treatment, painting, and printing of labels. This process not only enhances aesthetic appeal but also ensures that the printers can withstand environmental factors. Buyers should verify the finishing techniques used and whether they meet their specific branding requirements.

Which Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is paramount in the manufacturing of label printers. Several international and industry-specific standards are critical for ensuring product reliability and safety:

-

ISO 9001: This globally recognized standard focuses on quality management systems and is essential for ensuring that manufacturers consistently meet customer and regulatory requirements. B2B buyers should confirm that potential suppliers hold ISO 9001 certification.

-

CE Marking: For buyers in Europe, CE marking signifies that a product meets EU safety, health, and environmental protection standards. This certification is particularly important for electronic label printers.

-

API Standards: If the label printers are intended for use in specific industries such as pharmaceuticals, adherence to API standards is crucial. Buyers should inquire about compliance with these standards to ensure safety and efficacy.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early and maintain high standards:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components before they enter the production line. Manufacturers should have stringent criteria in place for supplier selection and material acceptance.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor processes and identify any deviations from quality standards. This proactive approach helps mitigate issues before they escalate.

-

Final Quality Control (FQC): Once the assembly is complete, a comprehensive review is conducted to ensure that each label printer meets all specifications and standards. Buyers should request documentation on FQC processes to understand how thorough these checks are.

What Common Testing Methods Are Used in Quality Control?

Testing methods are essential for verifying the functionality and reliability of label printers. Common methods include:

-

Functional Testing: Ensures that all features of the label printer work as intended. This may include print quality, speed, and connectivity checks.

-

Environmental Testing: Assesses how the printer performs under various environmental conditions such as temperature and humidity. This is particularly important for printers used in diverse climates.

-

Durability Testing: Evaluates the longevity of the printer components under regular use. This can involve simulating extended operation to identify potential failures.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that a supplier adheres to rigorous quality control practices, B2B buyers should consider several verification methods:

-

Supplier Audits: Conducting on-site audits can provide valuable insights into the manufacturer’s processes, facilities, and compliance with quality standards. This is particularly important for buyers from regions like Africa and South America, where local standards may vary.

-

Quality Reports: Requesting detailed quality reports, including statistics on defect rates and corrective actions taken, can help buyers gauge a manufacturer’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a manufacturer’s quality control measures. This is especially beneficial for buyers looking to mitigate risks associated with international procurement.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential:

-

Cultural Differences: Different regions may have varying perceptions of quality. Buyers should communicate clearly about their expectations and ensure that suppliers understand the specific standards required in their markets.

-

Logistics and Supply Chain Considerations: International shipping can introduce additional risks. Buyers should inquire about how manufacturers ensure quality throughout the supply chain, from production to delivery.

-

Regulatory Compliance: Buyers must be aware of the regulatory landscape in their respective countries. Ensuring that products meet local regulations can prevent costly delays and compliance issues.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when selecting label printer manufacturers, ensuring that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘label printer manufacturer’

Introduction

In the competitive landscape of international B2B procurement, sourcing a reliable label printer manufacturer requires a methodical approach. This checklist is designed to guide buyers from Africa, South America, the Middle East, and Europe in effectively navigating the complexities of this process. By following these steps, you can ensure that your selection not only meets your technical requirements but also aligns with your business objectives.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline your technical requirements. Consider factors such as the type of labels you will print, volume, speed, and connectivity options. This clarity will streamline your search and help avoid misalignment with suppliers.

- Label Types: Identify if you need thermal, inkjet, or laser printers based on your label material.

- Print Volume: Estimate your monthly usage to determine the necessary printer capacity.

Step 2: Conduct Market Research

Understanding the market landscape is vital for identifying potential manufacturers. Research various companies, focusing on their product offerings, market reputation, and geographic presence. This step helps you create a shortlist of potential suppliers.

- Competitor Analysis: Look into what similar businesses are using for their labeling needs.

- Industry Trends: Stay updated on emerging technologies and innovations in label printing.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request detailed company profiles, product catalogs, and customer testimonials. It’s crucial to assess their experience and expertise in your specific industry.

- References: Ask for references from other businesses in your sector to gauge satisfaction levels.

- Certifications: Verify if they hold relevant industry certifications that indicate quality standards.

Step 4: Request Samples and Test Products

Once you have shortlisted potential manufacturers, request samples of their label printers. Testing the equipment in your operational environment allows you to assess performance, quality, and usability firsthand.

- Print Quality: Evaluate the clarity and durability of the labels produced.

- User Experience: Consider ease of use and maintenance requirements.

Step 5: Negotiate Terms and Pricing

Engaging in negotiations is crucial to securing favorable terms. Discuss pricing, payment options, warranty coverage, and service agreements. Transparency in this phase can prevent misunderstandings later.

- Volume Discounts: Inquire about bulk purchase discounts or long-term contract benefits.

- Service Level Agreements (SLAs): Ensure clear terms regarding support and maintenance services.

Step 6: Verify Compliance and Regulations

Before finalizing your choice, confirm that the manufacturer complies with international standards and local regulations. This step is especially important for buyers in diverse regions, as compliance can significantly affect product usability.

- Safety Standards: Check adherence to safety and environmental regulations pertinent to your region.

- Import Regulations: Ensure that the products can be legally imported into your country.

Step 7: Finalize the Agreement and Place Your Order

After thorough evaluation and negotiation, finalize the terms of your agreement. Ensure that all aspects discussed are documented in a formal contract. Once satisfied, place your order with confidence.

- Clear Documentation: Keep records of all communications and agreements for future reference.

- Follow-Up Plan: Establish a timeline for delivery and setup to ensure timely implementation.

By adhering to this structured checklist, you can make informed decisions when sourcing a label printer manufacturer, ultimately leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for label printer manufacturer Sourcing

What Are the Key Cost Components in Label Printer Manufacturing?

Understanding the cost structure of label printer manufacturing is crucial for B2B buyers looking to source effectively. The primary cost components include:

-

Materials: The type and quality of materials used in manufacturing label printers significantly impact costs. High-quality plastics and metals can increase expenses but enhance durability and performance.

-

Labor: Labor costs vary by region and are influenced by the skill level required for assembly and quality assurance. For instance, manufacturers in Europe may incur higher labor costs compared to those in Africa or South America.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and administrative expenses. It’s essential to evaluate how these overheads are distributed across different manufacturers.

-

Tooling: Initial tooling costs can be substantial, particularly for customized printers. Buyers should inquire about these expenses, as they can affect the overall pricing, especially for low-volume orders.

-

Quality Control (QC): Implementing stringent QC processes can add to the cost but ensures product reliability. This is especially important for businesses in sectors that require compliance with specific standards.

-

Logistics: Shipping costs can vary significantly based on distance, mode of transport, and the chosen Incoterms. Understanding these logistics can help buyers mitigate unexpected expenses.

-

Margin: The manufacturer’s profit margin is a critical component of the final price. Different manufacturers may have varying pricing strategies based on their market position and brand reputation.

How Do Price Influencers Affect Label Printer Sourcing?

Several factors can influence the pricing of label printers, making it imperative for international buyers to consider:

-

Volume and Minimum Order Quantity (MOQ): Generally, larger orders can secure better pricing due to economies of scale. Buyers should negotiate MOQs that align with their purchasing capabilities.

-

Specifications and Customization: Tailored features or unique specifications can lead to increased costs. Buyers should clearly outline their requirements to avoid unexpected surcharges.

-

Materials and Quality Certifications: The choice of materials not only affects the durability of the printers but also the overall cost. Additionally, certifications such as ISO can add to the price, reflecting the manufacturer’s commitment to quality.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established manufacturers with a track record may charge a premium for their products.

-

Incoterms: Understanding Incoterms is essential for international buyers. They determine who is responsible for shipping, insurance, and tariffs, which can significantly impact the total cost.

What Are Some Effective Buyer Tips for Cost-Efficiency?

International B2B buyers can implement several strategies to enhance cost-efficiency when sourcing label printers:

-

Negotiation Skills: Effective negotiation can lead to better pricing. Buyers should be prepared to discuss terms and build long-term relationships with suppliers to secure favorable conditions.

-

Total Cost of Ownership (TCO): Beyond initial purchase price, buyers should consider the TCO, which includes maintenance, operation, and potential downtime costs. A cheaper printer may end up being more expensive in the long run if it requires frequent repairs or replacements.

-

Pricing Nuances for Different Regions: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing differences. For example, logistics costs may be higher when sourcing from Europe to Africa due to distance and regulatory barriers.

-

Research and Benchmarking: Conducting thorough market research and benchmarking against competitors can provide insights into fair pricing and help buyers make informed decisions.

Disclaimer on Indicative Prices

Prices for label printers can fluctuate based on various factors, including market conditions, material costs, and exchange rates. Buyers should always request detailed quotations and remain flexible to negotiate terms that best suit their operational needs.

Alternatives Analysis: Comparing label printer manufacturer With Other Solutions

Understanding the Need for Alternative Solutions in Label Printing

In the ever-evolving landscape of B2B operations, businesses must evaluate various solutions to meet their labeling needs efficiently. While label printer manufacturers offer specialized equipment for high-quality printing, several alternative solutions can also serve similar purposes. This analysis will compare label printer manufacturers with two viable alternatives: digital printing services and thermal transfer printers. By understanding the strengths and weaknesses of each option, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe can make informed decisions tailored to their specific requirements.

Comparison Table of Label Printing Solutions

| Comparison Aspect | Label Printer Manufacturer | Digital Printing Services | Thermal Transfer Printers |

|---|---|---|---|

| Performance | High-quality, consistent output | Variable quality depending on service provider | Excellent for durability and clarity |

| Cost | Higher initial investment, lower long-term cost | Variable pricing, generally lower initial cost | Moderate initial cost, low consumables cost |

| Ease of Implementation | Requires training and setup | Simple ordering process | Requires setup and calibration |

| Maintenance | Regular maintenance needed | No maintenance required by the buyer | Moderate maintenance, dependent on usage |

| Best Use Case | High-volume production, custom labels | Short runs, variable designs | Durable labels for harsh environments |

What Are the Pros and Cons of Digital Printing Services?

Digital printing services provide an attractive alternative for businesses that require flexibility in their labeling solutions. The primary advantage is the ability to produce short runs of labels with complex designs without the need for significant upfront investment in equipment. This can be particularly beneficial for smaller businesses or those looking to test new products. However, the variability in quality and reliability based on the service provider can be a drawback. Furthermore, while costs may be lower initially, expenses can accumulate with frequent orders.

How Do Thermal Transfer Printers Compare to Label Printer Manufacturers?

Thermal transfer printers utilize heat to transfer ink from a ribbon onto labels, making them an excellent choice for applications that demand durability. They excel in producing high-quality, long-lasting labels suitable for harsh environments, such as in manufacturing or logistics. The initial setup cost is moderate, but ongoing consumables (like ribbons) can add to the overall expense. Maintenance is generally manageable, but it does require some attention to ensure consistent performance. Businesses that prioritize label longevity and clarity may find thermal transfer printers to be a more suitable solution.

Conclusion: How to Choose the Right Label Printing Solution for Your Business

Selecting the right label printing solution depends on your specific business needs, volume requirements, and budget constraints. Label printer manufacturers are ideal for high-volume production with consistent quality, while digital printing services offer flexibility for shorter runs and varied designs. Thermal transfer printers stand out for their durability in demanding environments. B2B buyers should carefully assess their operational requirements, including cost, performance, and ease of implementation, to determine which solution aligns best with their labeling objectives. By doing so, they can optimize their labeling processes and enhance overall operational efficiency.

Essential Technical Properties and Trade Terminology for label printer manufacturer

What Are the Key Technical Properties of Label Printers?

Understanding the essential technical properties of label printers is crucial for B2B buyers, especially when selecting equipment that meets specific operational needs. Here are some critical specifications to consider:

1. Material Grade

The material grade of label printers affects their durability and performance. High-grade materials can withstand harsher environments, which is particularly important for industries in Africa and the Middle East where conditions may be extreme. Choosing printers with robust materials ensures longevity and reduces the frequency of replacements, saving costs in the long run.

2. Print Resolution

Print resolution, measured in dots per inch (DPI), determines the clarity of the printed labels. For applications requiring high-quality barcodes or intricate designs, a printer with a resolution of at least 300 DPI is recommended. This is particularly relevant for sectors like retail and logistics in Europe and South America, where label legibility can impact customer satisfaction and compliance.

3. Print Speed

Print speed, typically expressed in inches per second (IPS), is vital for businesses with high-volume label production. A faster printer can significantly improve operational efficiency, especially in manufacturing and distribution sectors. Buyers should assess their label printing demands and choose a printer that aligns with their production timelines to avoid bottlenecks.

4. Tolerance

Tolerance refers to the acceptable variance in dimensions during the printing process. A lower tolerance indicates higher precision, which is crucial for labels that need to fit specific packaging or tracking systems. This is particularly important for industries such as pharmaceuticals and food and beverage, where compliance with regulations and standards is mandatory.

5. Connectivity Options

Connectivity options, such as USB, Ethernet, and wireless capabilities, are essential for integration into existing systems. For B2B buyers, especially those in regions with varying technological infrastructure, selecting a printer with versatile connectivity ensures seamless operation and adaptability to different software environments.

Which Trade Terminology Should B2B Buyers Know When Purchasing Label Printers?

Familiarity with trade terminology can streamline the purchasing process and improve negotiation outcomes. Here are some commonly used terms in the label printer industry:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that may be marketed by another company. When purchasing label printers, understanding whether you are dealing with an OEM can affect warranty, support, and parts availability. This is particularly relevant for buyers in Africa and South America, where after-sales support can vary significantly.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management. B2B buyers should negotiate MOQs based on their projected needs to avoid overstocking or stockouts, which can hinder operations.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing and terms for specific products. For international buyers, particularly in Europe and the Middle East, issuing an RFQ can help in comparing options from multiple manufacturers and ensuring competitive pricing.

4. Incoterms

Incoterms, or International Commercial Terms, define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers engaged in cross-border purchases, as they clarify shipping responsibilities, risk management, and cost allocation.

5. Warranty and Support

Warranty terms and support services vary widely among manufacturers. Buyers should thoroughly review these terms to ensure they have adequate coverage for repairs and replacements. This is especially important for businesses in regions where service availability may be limited.

By understanding these technical properties and trade terminologies, international B2B buyers can make informed decisions when selecting label printers, ensuring that they meet their operational requirements while optimizing costs and efficiency.

Navigating Market Dynamics and Sourcing Trends in the label printer manufacturer Sector

What Are the Current Market Dynamics Influencing the Label Printer Manufacturer Sector?

The label printer manufacturer sector is experiencing significant transformation driven by technological advancements and evolving market demands. Key global drivers include the rise of e-commerce, which has increased the need for efficient labeling solutions in logistics and inventory management. In regions like Africa and South America, the expansion of local manufacturing capabilities is creating opportunities for international buyers to source competitively priced label printers. Additionally, the Middle East and European markets are witnessing a surge in demand for customized labeling solutions, particularly in sectors such as pharmaceuticals, food and beverage, and retail.

Emerging B2B tech trends are reshaping the landscape, with innovations like IoT-enabled printers and cloud-based printing solutions gaining traction. These technologies enhance operational efficiency and provide real-time data analytics, essential for international buyers seeking to optimize their supply chains. Furthermore, sustainability is becoming a crucial consideration, with many manufacturers adopting eco-friendly practices and materials. For B2B buyers, understanding these dynamics is vital for making informed sourcing decisions that align with their operational goals and market expectations.

How Important Is Sustainability and Ethical Sourcing in the Label Printer Manufacturing Sector?

Sustainability and ethical sourcing have become imperative for businesses in the label printer manufacturing sector. Environmental impact considerations are increasingly influencing purchasing decisions, as consumers and businesses alike demand greener solutions. For international B2B buyers, especially those in Europe, Turkey, and the Middle East, aligning with manufacturers who prioritize sustainability can enhance their brand reputation and customer loyalty.

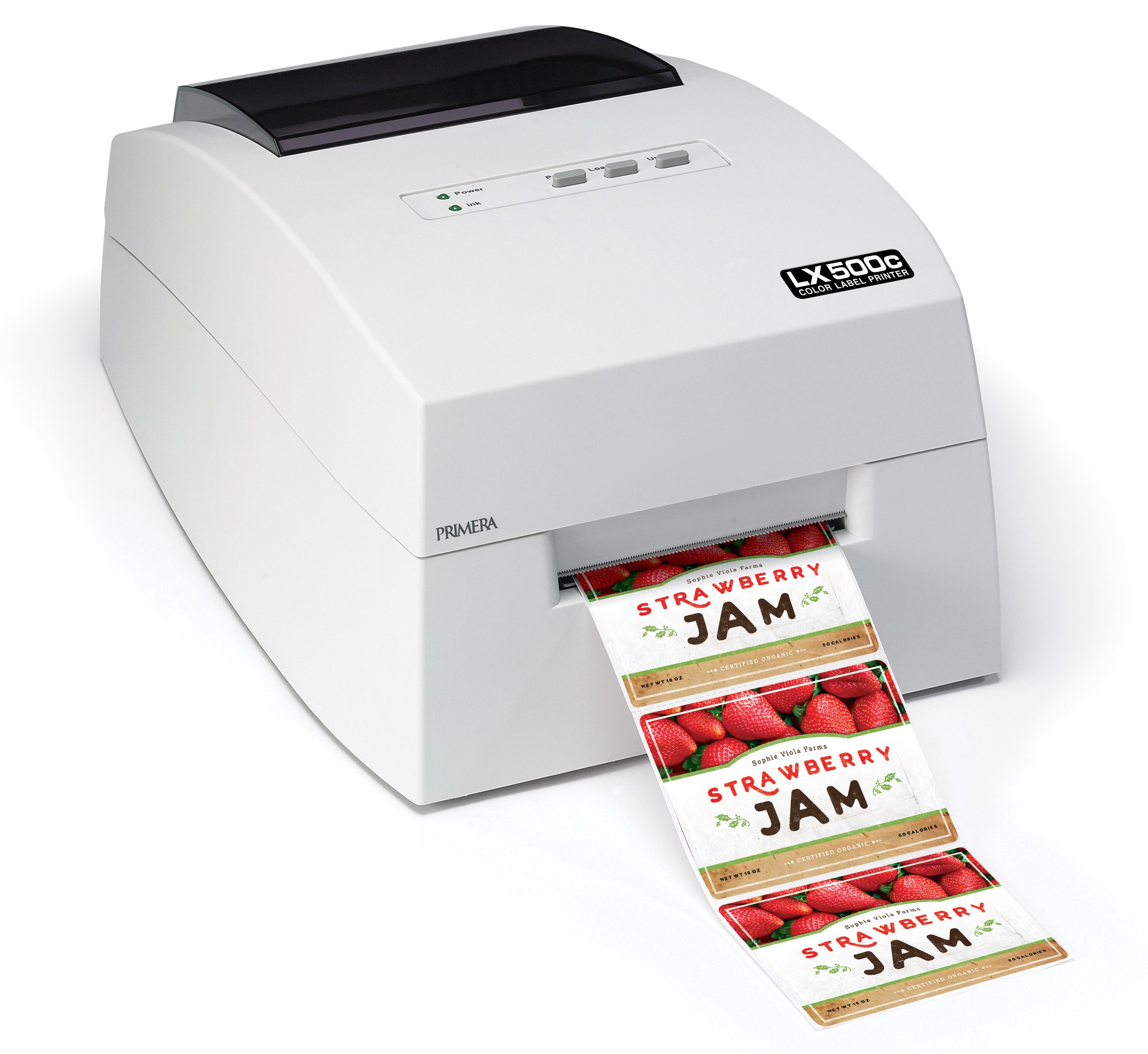

A stock image related to label printer manufacturer.

The importance of ethical supply chains cannot be overstated. Buyers are encouraged to seek out manufacturers that are transparent about their sourcing practices and that utilize certified sustainable materials. Green certifications, such as FSC (Forest Stewardship Council) and ISO 14001, indicate a commitment to environmental responsibility and can significantly influence buyer decisions. Moreover, many manufacturers are now investing in biodegradable labels and recyclable packaging, which not only reduce waste but also cater to the growing consumer demand for eco-friendly products. By prioritizing sustainability, B2B buyers can ensure compliance with regulatory standards and appeal to environmentally conscious consumers.

How Has the Label Printer Manufacturing Sector Evolved Over Time?

The label printer manufacturing sector has undergone remarkable evolution over the past few decades. Initially dominated by traditional printing methods, the industry has shifted towards digital technologies, allowing for greater customization and efficiency. Early label printers were primarily used for basic labeling tasks, but advancements in technology have enabled the production of high-quality, variable-data labels that cater to diverse industries.

In recent years, the introduction of smart label printers equipped with connectivity features has further revolutionized the sector. These printers not only streamline the printing process but also integrate seamlessly with existing supply chain technologies. This evolution reflects a broader trend towards automation and digitalization in the manufacturing sector, providing B2B buyers with innovative solutions that enhance productivity and reduce operational costs. Understanding this historical context is essential for international buyers looking to identify reliable suppliers and stay ahead of industry trends.

Frequently Asked Questions (FAQs) for B2B Buyers of label printer manufacturer

-

How do I choose the right label printer manufacturer for my business needs?

Choosing the right label printer manufacturer involves assessing your specific printing requirements, such as volume, label size, and material compatibility. Research manufacturers with a proven track record in your industry, and request samples to evaluate print quality. Also, consider their customer service, warranty terms, and technical support. Engaging with other businesses in your region can provide insights into reliable manufacturers that suit your needs. -

What are the key factors to consider when sourcing a label printer supplier internationally?

When sourcing a label printer supplier internationally, consider factors like compliance with local regulations, shipping costs, and delivery timelines. Evaluate the supplier’s production capacity and quality assurance processes. It’s also crucial to assess their experience in your market, especially if you’re in regions like Africa or South America, where logistics can vary significantly. Establish communication regarding any potential language barriers to ensure clarity in your orders. -

What customization options should I expect from a label printer manufacturer?

Most label printer manufacturers offer customization options tailored to your specific needs. This may include custom label sizes, materials, and print designs. Additionally, inquire about software compatibility for label design and integration with your existing systems. Understanding the extent of customization available is essential, especially for businesses in diverse markets like the Middle East or Europe, where branding may vary significantly. -

What is the typical minimum order quantity (MOQ) for label printers?

Minimum order quantities (MOQs) for label printers can vary widely depending on the manufacturer and the type of printer. Generally, you can expect MOQs to range from a few units to several hundred. It is advisable to negotiate MOQs, especially for small to medium-sized enterprises, to ensure that your initial investment aligns with your budget and operational needs. Always confirm whether the MOQ affects pricing and lead times. -

What payment terms are common when purchasing from international label printer manufacturers?

Payment terms can differ significantly among international suppliers. Common practices include upfront payments, partial payments, or letters of credit, especially for larger orders. It’s essential to discuss payment terms upfront and ensure they align with your cash flow strategy. Buyers from Africa and South America should be aware of potential currency exchange issues and transaction fees that could impact overall costs. -

How do I ensure quality assurance when sourcing label printers from manufacturers?

To ensure quality assurance, request certifications such as ISO 9001 from potential manufacturers. Additionally, consider implementing a quality control process that includes regular inspections and testing of the printers. Building a relationship with your supplier can facilitate better communication regarding quality expectations. Engaging third-party inspection services may also be beneficial, particularly for large orders or unfamiliar suppliers. -

What logistics considerations should I keep in mind when importing label printers?

Logistics plays a crucial role in the importation of label printers. Consider shipping methods (air vs. sea), customs duties, and local regulations in your region. Work with a logistics partner who understands international trade and can navigate customs efficiently. Ensure that you factor in potential delays due to shipping or customs clearance, especially when sourcing from regions like Europe or the Middle East.

A stock image related to label printer manufacturer.

- How can I effectively communicate my needs to a label printer manufacturer?

Effective communication begins with detailed documentation of your requirements. Provide clear specifications regarding label sizes, materials, and printing technology. Establish regular communication channels, such as email or video calls, to discuss progress and address any concerns. If language barriers exist, consider hiring a translator or using professional translation services to ensure mutual understanding, particularly when dealing with manufacturers from diverse regions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for label printer manufacturer

In the rapidly evolving landscape of label printing, strategic sourcing emerges as a critical component for international B2B buyers. By understanding market dynamics and supplier capabilities, companies in Africa, South America, the Middle East, and Europe can optimize their procurement processes, ensuring they secure high-quality products at competitive prices. The emphasis on building strong supplier relationships not only enhances supply chain resilience but also fosters innovation, enabling businesses to stay ahead in a competitive marketplace.

What are the benefits of adopting a strategic sourcing approach? Buyers can leverage data-driven insights to identify the most suitable suppliers, negotiate favorable terms, and manage risks effectively. Additionally, as sustainability becomes a priority, sourcing from manufacturers committed to environmentally friendly practices can enhance brand reputation and meet regulatory requirements.

Looking ahead, the label printer market is set to experience significant growth, driven by technological advancements and increasing demand across various sectors. International B2B buyers should actively engage with manufacturers to explore customized solutions that meet their unique needs. Embrace this opportunity to refine your sourcing strategy and position your business for future success in the label printing industry.