Discover Top Benefits of Choosing a Seed Manufacturer (2025)

Introduction: Navigating the Global Market for seed manufacturer

Navigating the global market for seed manufacturers poses significant challenges for international B2B buyers, particularly those based in Africa, South America, the Middle East, and Europe. With an increasing demand for high-quality seeds that cater to diverse agricultural needs, sourcing the right seed manufacturers is crucial. This guide aims to equip buyers with comprehensive insights into the seed manufacturing industry, covering essential aspects such as types of seeds available, their applications, supplier vetting processes, and cost considerations.

Understanding the nuances of seed sourcing can empower businesses to make informed purchasing decisions that align with their agricultural goals. This guide not only delineates the various seed types, such as hybrid, organic, and heirloom seeds, but also provides a thorough analysis of their specific applications in different climates and soil conditions. Additionally, we will delve into the critical process of vetting suppliers, highlighting key factors to consider, including certifications, sustainability practices, and past performance.

By the end of this guide, international B2B buyers will be better positioned to navigate the complexities of the seed market, ensuring they select reliable partners who can deliver quality products tailored to their needs. Whether you are a buyer in Argentina seeking drought-resistant varieties or a distributor in Europe interested in organic options, this guide serves as your roadmap to success in the seed manufacturing landscape.

Understanding seed manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Seed Producers | Focus on traditional breeding methods, non-GMO seeds. | Crop production in traditional agriculture | Pros: Established practices, often lower cost. Cons: Limited genetic diversity, may not meet specific climate needs. |

| Hybrid Seed Manufacturers | Produce seeds from cross-breeding, offering higher yields. | Large-scale farming, commercial crops | Pros: Improved disease resistance, higher yields. Cons: Higher costs, dependency on manufacturers for seed supply. |

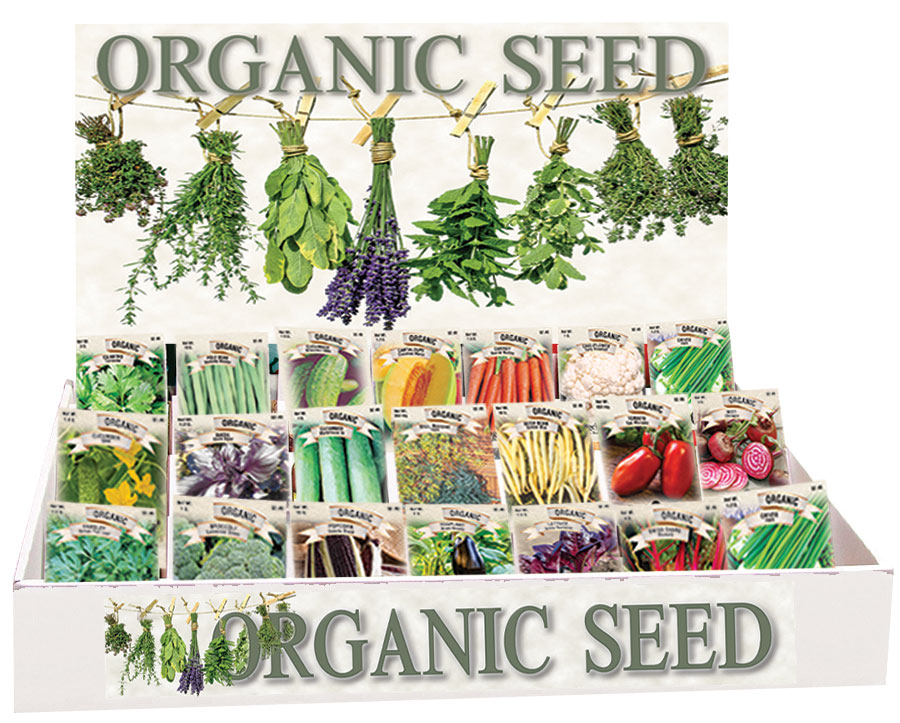

| Organic Seed Suppliers | Specialize in seeds grown without synthetic fertilizers or pesticides. | Organic farming, sustainable agriculture | Pros: Appeals to eco-conscious buyers, supports organic certification. Cons: Higher prices, limited availability. |

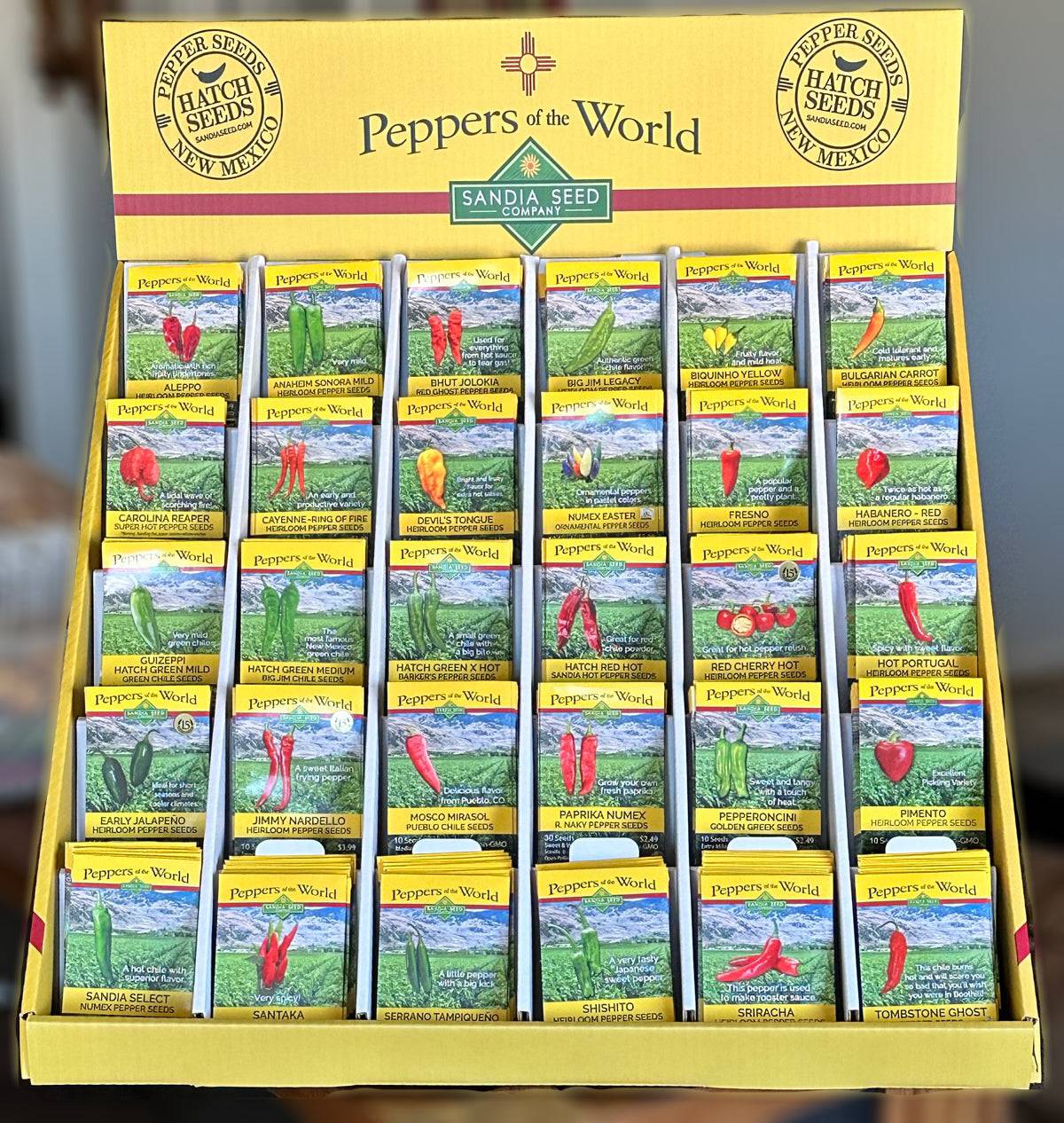

| Specialty Seed Producers | Focus on niche markets, including heirloom and rare seed varieties. | Small-scale farms, specialty crops | Pros: Unique varieties, potential for high market value. Cons: Limited supply, often higher costs. |

| Biotech Seed Companies | Use genetic engineering to enhance traits like drought resistance. | High-tech agriculture, climate-resilient crops | Pros: Tailored traits for specific conditions, potential for higher yields. Cons: Regulatory scrutiny, public resistance to GMOs. |

What are Conventional Seed Producers and Their B2B Relevance?

Conventional seed producers primarily rely on traditional breeding methods to create seeds that are often non-GMO. They cater to the agricultural sector, providing seeds for staple crops such as maize, wheat, and rice. For B2B buyers, these seeds present a cost-effective option, especially for large-scale farming operations. However, buyers should consider the potential limitations in genetic diversity, which may affect crop resilience in changing climates.

How Do Hybrid Seed Manufacturers Benefit B2B Buyers?

Hybrid seed manufacturers focus on producing seeds through controlled cross-breeding techniques, resulting in plants with improved traits such as higher yields and enhanced disease resistance. This type of seed is particularly suitable for commercial farming operations that prioritize productivity. While the benefits include superior performance and reliability, buyers must be aware of the higher costs and the potential for dependency on the manufacturer for seed supply, which can impact long-term planning.

What are Organic Seed Suppliers and Their Market Position?

Organic seed suppliers provide seeds that are cultivated without synthetic fertilizers or pesticides, catering to the growing demand for organic produce. These suppliers appeal to B2B buyers in the organic farming sector, allowing them to maintain organic certification and meet consumer demand for sustainable products. The primary consideration for buyers is the higher price point, which can affect profitability, alongside the challenge of limited availability in some regions.

What Niche Markets Do Specialty Seed Producers Serve?

Specialty seed producers focus on niche markets by offering unique varieties such as heirloom seeds or crops with specific traits. These producers are essential for small-scale farms and businesses that aim to differentiate their products in the marketplace. While the potential for high market value exists, buyers must consider the often higher costs and limited supply, which can affect their ability to scale production.

How Do Biotech Seed Companies Innovate in Agriculture?

Biotech seed companies utilize genetic engineering to develop seeds with enhanced traits, such as drought resistance and pest tolerance. These seeds are increasingly relevant for high-tech agriculture, especially in regions facing climate challenges. For B2B buyers, the tailored traits can lead to improved yields and reduced losses. However, the regulatory scrutiny surrounding GMOs and public resistance may pose challenges in certain markets, making careful consideration essential for buyers.

Related Video: The Genius Behind Bach’s Goldberg Variations: CANONS

Key Industrial Applications of seed manufacturer

| Industry/Sector | Specific Application of Seed Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Production of high-yield crops | Increases productivity and profitability for farmers | Quality of seeds, resistance to pests/diseases |

| Horticulture | Development of specialized ornamental plants | Enhances aesthetic appeal and market value | Seed variety, growth conditions, and climate adaptability |

| Biofuel Production | Cultivation of energy crops like soybeans | Reduces dependency on fossil fuels, promotes sustainability | Seed quality, oil content, and growth cycle |

| Food Processing | Supply of seeds for staple crops like maize | Ensures food security and supply chain reliability | Consistency in seed quality, compliance with local regulations |

| Research and Development | Genetic research for crop improvement | Drives innovation and adaptation in agriculture | Access to diverse seed varieties, research partnerships |

How is Seed Manufacturer Used in Agriculture?

In the agriculture sector, seed manufacturers play a pivotal role by providing high-yield seeds that significantly enhance crop production. For international buyers, particularly in Africa and South America, sourcing high-quality seeds can lead to increased productivity and profitability. Buyers must consider the specific resistance traits of seeds against local pests and diseases to ensure optimal growth and yield.

What Role Does Seed Manufacturer Play in Horticulture?

Seed manufacturers are essential in horticulture for developing specialized ornamental plants. These plants not only enhance the aesthetic appeal of landscapes but also increase market value for nurseries and garden centers. International buyers should focus on seed varieties that are adaptable to local climates and growth conditions, ensuring successful cultivation and sales.

How is Seed Manufacturer Integral to Biofuel Production?

The biofuel production industry relies heavily on seed manufacturers for cultivating energy crops like soybeans and canola. These crops are crucial for reducing dependency on fossil fuels and promoting sustainable energy sources. Buyers in this sector should prioritize seeds with high oil content and suitable growth cycles to maximize energy yield and production efficiency.

How Does Seed Manufacturer Support Food Processing?

In food processing, seed manufacturers supply seeds for staple crops such as maize and wheat, which are vital for ensuring food security. By sourcing consistent and high-quality seeds, businesses can ensure reliable supply chains and maintain product quality. Buyers must be aware of local regulations regarding seed quality and food safety standards when sourcing seeds for processing.

What is the Importance of Seed Manufacturer in Research and Development?

Seed manufacturers are also integral to research and development, especially in genetic research aimed at crop improvement. This innovation drives adaptation to changing climate conditions and pest pressures, which is essential for sustainable agriculture. International buyers should seek partnerships with seed manufacturers that offer access to diverse seed varieties and collaborative research opportunities to enhance agricultural resilience.

A stock image related to seed manufacturer.

Related Video: Uses Technology in the Conduct of Survey || Joel Vacalares

3 Common User Pain Points for ‘seed manufacturer’ & Their Solutions

Scenario 1: Difficulty in Ensuring Seed Quality and Consistency

The Problem:

For B2B buyers in agriculture, particularly those sourcing seeds from international manufacturers, the challenge of ensuring seed quality and consistency can be significant. Variability in germination rates, seed purity, and health can lead to poor crop yields, which directly impacts profitability. Buyers may face difficulties when suppliers do not adhere to quality standards or when they are unable to provide certification for seed quality, leading to uncertainty and potential financial losses.

The Solution:

To mitigate these risks, buyers should prioritize sourcing seeds from manufacturers that offer comprehensive quality assurance protocols. Request detailed certifications, such as those from the International Seed Testing Association (ISTA) or other recognized bodies. Additionally, consider establishing long-term partnerships with manufacturers who can provide consistent quality through robust testing and quality control measures. Implementing a trial phase with smaller orders can also help assess the performance of seeds before making larger purchases. Utilizing seed traceability systems allows buyers to track seed quality back to its source, ensuring adherence to standards.

Scenario 2: Navigating Regulatory Compliance Across Regions

The Problem:

International buyers often struggle with navigating the complex regulatory landscape surrounding seed importation. Different countries have varying regulations regarding seed treatment, genetic modification, and phytosanitary measures. This inconsistency can lead to delays, additional costs, and even the rejection of shipments if the seeds do not meet local compliance standards.

The Solution:

To overcome regulatory hurdles, B2B buyers should invest time in understanding the specific regulations of their target markets. Engaging with local agricultural authorities or hiring consultants who specialize in agricultural compliance can provide invaluable insights. Additionally, working with seed manufacturers who are experienced in international trade can streamline the process, as they will often have established compliance protocols in place. Regular training sessions for procurement teams on the latest regulations can also prevent costly mistakes and ensure smooth operations.

Scenario 3: Limited Access to Innovative Seed Varieties

The Problem:

B2B buyers in regions like Africa or South America may find it challenging to access innovative seed varieties that are crucial for adapting to climate change or improving crop resilience. Limited access to modern breeding techniques or the latest genetic research can result in stagnation and reduced competitiveness in global markets. Buyers may also be concerned about the sustainability and environmental impact of traditional seed varieties.

The Solution:

To address this issue, buyers should actively seek partnerships with seed manufacturers who invest in research and development (R&D). Participating in agricultural exhibitions and conferences can help buyers discover cutting-edge innovations and forge relationships with suppliers dedicated to sustainable practices. Additionally, collaborating with local agricultural universities or research institutions can provide access to new seed technologies and breeding programs tailored to specific environmental conditions. Forming cooperatives among local farmers to collectively purchase innovative seeds can also enhance bargaining power and access to premium varieties.

Strategic Material Selection Guide for seed manufacturer

When selecting materials for seed manufacturing, international B2B buyers must consider various factors that influence product performance, cost, and compliance with regional standards. Below is an analysis of four common materials used in seed manufacturing, detailing their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polyethylene in Seed Manufacturing?

Polyethylene (PE) is a widely used plastic material known for its excellent chemical resistance and durability. It can withstand temperatures ranging from -50°C to 80°C, making it suitable for various environmental conditions. Its corrosion resistance ensures that it does not react with most agricultural chemicals, which is critical for seed storage and transportation.

Pros and Cons:

– Pros: Lightweight, cost-effective, and easy to manufacture. Its flexibility allows for various applications, including seed bags and containers.

– Cons: Limited resistance to UV radiation can lead to degradation over time, especially in sunny regions. It may not be suitable for high-temperature applications beyond its rating.

Impact on Application:

Polyethylene is compatible with most seed types and agricultural chemicals, making it a versatile choice for seed packaging. However, buyers should consider the local climate and storage conditions to ensure longevity.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local regulations regarding plastic use and recycling. Standards such as ASTM D3350 for polyethylene should be verified.

How Does Polypropylene Compare for Seed Packaging?

Polypropylene (PP) is another plastic material favored for its high melting point (up to 100°C) and excellent chemical resistance. It is often used for seed bags and containers due to its rigidity and ability to withstand stress.

Pros and Cons:

– Pros: Offers a good balance between strength and weight. Resistant to moisture and chemicals, making it ideal for agricultural applications.

– Cons: More expensive than polyethylene and can be less flexible, which may limit its use in certain packaging designs.

Impact on Application:

Polypropylene is particularly effective for seeds that require moisture control, as it prevents water ingress. Its strength makes it suitable for bulk storage and transportation.

Considerations for International Buyers:

Compliance with standards such as ISO 1873-1 for polypropylene is essential. Buyers in Europe may also need to consider EU regulations on plastic materials.

What Are the Benefits of Using Glass in Seed Storage?

Glass is an excellent material for seed storage due to its impermeability and inert nature. It does not react with seeds or their protective coatings, ensuring that the seeds remain viable over time.

Pros and Cons:

– Pros: Provides a hermetic seal, protecting seeds from moisture, pests, and contaminants. It is also recyclable and environmentally friendly.

– Cons: Heavy and fragile, making it less suitable for transportation. Higher manufacturing costs compared to plastics.

Impact on Application:

Glass containers are ideal for long-term seed storage, particularly for high-value or rare seeds. They maintain seed viability by providing a stable environment.

Considerations for International Buyers:

Buyers should consider the logistics of transporting glass containers, especially in regions with less developed infrastructure. Compliance with safety standards for packaging is also critical.

Why Is Metal an Option for Seed Packaging?

Metal, particularly aluminum and tin, is used in seed packaging for its durability and barrier properties. It is resistant to moisture, light, and oxygen, which helps preserve seed quality.

Pros and Cons:

– Pros: Excellent barrier properties, making it suitable for sensitive seeds. Durable and can withstand harsh environmental conditions.

– Cons: Higher cost and weight compared to plastics. Potential for corrosion if not properly treated.

Impact on Application:

Metal packaging is particularly effective for seeds that are sensitive to light and moisture. It is often used for premium seed varieties that require extended shelf life.

Considerations for International Buyers:

Compliance with local regulations on metal packaging is necessary, especially regarding food safety standards. Buyers should also consider the recyclability of metal in their regions.

Summary Table of Material Selection for Seed Manufacturing

| Material | Typical Use Case for seed manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Seed bags and containers | Lightweight and cost-effective | Limited UV resistance | Low |

| Polypropylene | Bulk seed storage | Moisture and chemical resistance | Higher cost than polyethylene | Medium |

| Glass | Long-term seed storage | Hermetic seal and inert nature | Heavy and fragile | High |

| Metal | Premium seed packaging | Excellent barrier properties | Higher cost and potential corrosion | High |

This strategic material selection guide provides B2B buyers with the insights needed to make informed decisions tailored to their specific market conditions and regulatory environments.

In-depth Look: Manufacturing Processes and Quality Assurance for seed manufacturer

What Are the Key Stages in the Manufacturing Process for Seed Production?

Seed manufacturing is a complex process that involves several crucial stages to ensure the production of high-quality seeds. Understanding these stages is essential for B2B buyers looking to source seeds internationally.

-

Material Preparation: This initial stage involves selecting and preparing the raw materials needed for seed production. Seed manufacturers often begin with the selection of parent plants that exhibit desirable traits. This may include evaluating the genetic makeup and health of the plants. Once selected, seeds are harvested, cleaned, and sometimes treated with fungicides or insecticides to ensure they are free from pests and diseases.

-

Forming: In this stage, the seeds undergo various processes to promote germination and growth. This may involve coating the seeds with fertilizers or growth stimulants. Coating is a critical step as it can enhance seed performance and protect against environmental stresses. Additionally, techniques such as pelleting (where seeds are coated with a material that improves handling and planting) may be employed.

-

Assembly: Assembly in seed manufacturing refers to the organization of seeds into batches for packaging and distribution. This stage often involves sorting seeds based on size, weight, and quality. Automated systems are frequently used to enhance efficiency and reduce human error.

-

Finishing: The final stage involves packaging the seeds for delivery. This includes labeling, which provides essential information such as seed type, lot number, and expiration date. Proper packaging is crucial to protect seeds from moisture and damage during transport.

How Is Quality Assurance Implemented in Seed Manufacturing?

Quality assurance (QA) in seed manufacturing is vital for maintaining standards that meet international regulations. B2B buyers need to understand the quality control (QC) processes that ensure the reliability and performance of seeds.

What Are the Relevant International Standards for Seed Quality?

Seed manufacturers often adhere to various international standards to ensure product quality. The most notable include:

-

ISO 9001: This is a widely recognized quality management standard that outlines criteria for a quality management system. Compliance with ISO 9001 ensures that manufacturers can consistently provide products that meet customer and regulatory requirements.

-

Seed Certification Standards: Different regions have specific seed certification standards, such as the OECD Seed Scheme. This ensures that seeds meet specific genetic, physical, and health standards.

-

CE Marking: For products sold within the European Union, CE marking indicates conformity with health, safety, and environmental protection standards.

What Are the Key QC Checkpoints in Seed Manufacturing?

Quality control checkpoints throughout the manufacturing process are essential to ensure seed quality. These typically include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival. Seeds must be evaluated for purity, germination rates, and moisture content.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are made to ensure that production techniques are being followed correctly. This may involve monitoring temperatures during seed treatment or checking the consistency of coatings.

-

Final Quality Control (FQC): Once the seeds are packaged, they undergo final inspection. This includes testing for germination rates, disease resistance, and overall quality to ensure they meet customer specifications.

What Testing Methods Are Commonly Used in Seed Quality Assurance?

Several testing methods are crucial for assessing seed quality:

-

Germination Tests: These tests determine the percentage of seeds that sprout under controlled conditions. This provides insights into the seed’s viability.

-

Purity Tests: These tests assess the genetic purity of seeds by identifying the presence of other seed types or contaminants.

-

Moisture Content Tests: Ensuring seeds are at the right moisture level is critical for storage and germination. High moisture content can lead to mold and reduced shelf life.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control measures of seed suppliers. Here are some actionable strategies:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. This allows buyers to assess compliance with international standards and identify any potential risks.

-

Requesting Quality Reports: Buyers should request detailed quality assurance reports, including results from germination and purity tests. These reports can help assess the reliability of the supplier’s products.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control measures. This is particularly important for international transactions, where standards may vary.

What Are the Nuances of QC and Certification for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is essential. Buyers from regions like Africa, South America, the Middle East, and Europe should consider the following:

-

Regulatory Compliance: Different countries have specific regulations regarding seed importation. Buyers must ensure that their suppliers comply with these regulations to avoid penalties.

-

Cultural Considerations: Cultural differences may influence manufacturing practices and quality perceptions. Buyers should communicate clearly with suppliers to align expectations.

-

Local Standards vs. International Standards: Suppliers may adhere to local standards that differ from international standards. Buyers should verify that the seeds meet their specific market requirements.

Conclusion

Understanding the manufacturing processes and quality assurance measures in seed production is crucial for B2B buyers looking to source seeds effectively. By focusing on key stages, international standards, and verification strategies, buyers can make informed decisions that ensure the quality and reliability of their seed supplies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘seed manufacturer’

To effectively source seeds from manufacturers, international B2B buyers need a structured approach. This checklist provides actionable steps to help you identify, evaluate, and select the right seed manufacturer tailored to your specific requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to clearly outline your technical specifications. This includes the types of seeds you need, the desired quality standards, and any specific traits (e.g., drought resistance, disease tolerance) that are critical for your agricultural practices. Having a well-defined specification helps streamline the selection process and ensures that potential suppliers can meet your expectations.

Step 2: Conduct Market Research on Seed Manufacturers

Understanding the landscape of seed manufacturers is crucial. Investigate the market presence of different manufacturers, focusing on their reputation, experience, and product offerings. Utilize online directories, trade shows, and industry publications to gather insights. This research will help you identify key players in the regions of interest, particularly in Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Potential Suppliers

Thoroughly vet each potential supplier to ensure they align with your requirements. Request detailed company profiles, product catalogs, and customer references. It’s also beneficial to seek case studies or testimonials from buyers within similar industries or geographical areas. This evaluation process minimizes the risk of partnering with unreliable suppliers.

Step 4: Verify Supplier Certifications and Compliance

Make sure that the manufacturers you are considering possess the necessary certifications and comply with international agricultural standards. Look for certifications such as ISO, organic, or local agricultural authority approvals. Compliance not only guarantees product quality but also ensures that the seeds are safe for use in your region.

Step 5: Request Samples for Quality Assessment

Before making a substantial commitment, request seed samples from shortlisted suppliers. Assess the quality of these samples based on germination rates, purity, and physical characteristics. Conduct trials in your local environment to evaluate how well the seeds perform under your specific conditions. This step is vital to ensure that the seeds meet your operational needs.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable manufacturer, engage in negotiations regarding pricing, payment terms, delivery schedules, and after-sales support. Ensure that both parties understand the terms clearly to avoid misunderstandings later on. Establishing a transparent negotiation process fosters a strong business relationship.

Step 7: Establish a Long-Term Relationship

After successfully sourcing your seeds, focus on building a long-term relationship with your supplier. Regular communication, feedback on seed performance, and discussions about future needs can help strengthen this partnership. A reliable supplier can become a crucial ally in your agricultural endeavors, offering insights and support as your business grows.

By following this step-by-step checklist, you can effectively navigate the sourcing process for seed manufacturers and make informed decisions that align with your agricultural goals.

Comprehensive Cost and Pricing Analysis for seed manufacturer Sourcing

What Are the Key Cost Components in Seed Manufacturing?

Understanding the cost structure of seed manufacturing is crucial for international B2B buyers. The main cost components include:

-

Materials: The primary cost driver in seed manufacturing. This includes the cost of seeds, fertilizers, and other raw materials. The type of seeds, such as hybrid or organic, significantly impacts material costs.

-

Labor: Labor costs involve wages for skilled and unskilled workers involved in planting, harvesting, and processing seeds. The labor cost can vary based on the region and local wage standards.

-

Manufacturing Overhead: This encompasses indirect costs related to production, such as utilities, facility maintenance, and equipment depreciation. Efficient production processes can help reduce these overheads.

-

Tooling: Investment in specialized equipment and tools for seed processing and packaging can add to initial costs but may lead to long-term savings through increased efficiency.

-

Quality Control (QC): Ensuring seed quality through testing and certification adds to costs. However, high-quality seeds can command better prices in the market.

-

Logistics: Transportation and storage costs are crucial, especially for international shipping. These costs can fluctuate based on fuel prices and shipping routes.

-

Margin: Profit margins for seed manufacturers can vary widely, influenced by market demand, competition, and production efficiency.

How Do Pricing Influencers Impact Seed Manufacturing Costs?

Several factors influence the pricing of seeds, which international B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to find a balance between inventory costs and price savings.

-

Specifications and Customization: Custom seed varieties that meet specific agricultural needs can attract premium pricing. Buyers should assess whether customization is necessary for their markets.

-

Materials and Quality Certifications: Higher quality seeds often come with certifications that validate their quality, which can increase costs. Buyers should weigh the benefits of certified seeds against their price.

-

Supplier Factors: Supplier reputation, reliability, and geographic location can affect pricing. Establishing strong relationships with suppliers can lead to better pricing and terms.

-

Incoterms: Understanding shipping terms (Incoterms) is vital for calculating total landed costs. Different terms can shift responsibility for costs and risks from the seller to the buyer.

What Tips Can Help International Buyers Negotiate Better Prices?

B2B buyers from regions like Africa, South America, the Middle East, and Europe can adopt several strategies to enhance cost-efficiency:

-

Negotiate Effectively: Leverage your purchasing power by negotiating terms and prices with suppliers. Be prepared to discuss bulk purchases or long-term contracts to secure favorable rates.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider long-term costs associated with transportation, storage, and potential crop yields when assessing seed value.

-

Understand Pricing Nuances: Be aware that seed prices can be influenced by seasonal demand, crop cycles, and local market conditions. Keeping abreast of these factors can empower buyers to make informed purchasing decisions.

-

Consider Local Suppliers: Sourcing from local manufacturers can reduce logistics costs and lead to quicker turnaround times. Additionally, local suppliers may have a better understanding of regional agricultural needs.

-

Seek Multiple Quotes: To ensure competitive pricing, request quotes from multiple suppliers. This can provide insights into market pricing and help identify the best value.

Disclaimer on Indicative Prices

It’s essential to note that seed prices can fluctuate based on a variety of market conditions. Buyers should conduct thorough research and engage in direct discussions with suppliers to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing seed manufacturer With Other Solutions

Understanding Alternatives to Seed Manufacturers

When considering the best solutions for agricultural needs, international B2B buyers must evaluate various options beyond traditional seed manufacturers. Alternatives may include biotechnological innovations, hybrid seed varieties, and sustainable farming practices that offer distinct advantages or address specific challenges in different regions, such as Africa, South America, the Middle East, and Europe. This section explores these alternatives, providing insights into their performance, cost-effectiveness, ease of implementation, maintenance requirements, and best use cases.

Comparison Table of Seed Manufacturer and Alternatives

| Comparison Aspect | Seed Manufacturer | Biotechnological Seeds | Organic Seed Solutions |

|---|---|---|---|

| Performance | High yield potential | Very high yield; pest-resistant | Moderate yield; organic growth |

| Cost | Moderate initial cost | Higher upfront investment | Often higher due to organic certification |

| Ease of Implementation | Established practices | Requires technical knowledge | Simple but requires adherence to organic standards |

| Maintenance | Standard agricultural practices | Low maintenance; genetically engineered | Higher maintenance; organic pest control |

| Best Use Case | Conventional farming | Large-scale commercial agriculture | Sustainable and health-conscious markets |

Detailed Breakdown of Alternatives

Biotechnological Seeds: What Are Their Advantages and Disadvantages?

Biotechnological seeds, often genetically modified, are engineered to enhance certain traits such as pest resistance and drought tolerance. This can lead to significantly higher yields, making them ideal for large-scale commercial agriculture. However, they require a higher initial investment due to research and development costs. Additionally, implementing biotechnological seeds often necessitates specific technical knowledge, which can pose a challenge for smaller operations or those in developing regions. While maintenance is generally low, the regulatory landscape surrounding genetically modified organisms (GMOs) can be complex, particularly in certain markets.

Organic Seed Solutions: Are They Worth the Investment?

Organic seed solutions focus on sustainable agricultural practices and cater to a growing market of health-conscious consumers. These seeds yield moderate outputs but are cultivated without synthetic pesticides or fertilizers, promoting environmental health. While the initial cost can be higher due to organic certification processes, they often command a premium price in the market. The ease of implementation is relatively straightforward; however, maintaining organic standards can be labor-intensive, requiring ongoing pest management and soil health practices. These solutions are best suited for niche markets that prioritize sustainability and health.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the appropriate solution for agricultural needs hinges on various factors, including regional agricultural practices, market demand, and the buyer’s operational capacity. B2B buyers should conduct a thorough analysis of their specific requirements, including budget constraints, desired yield, and maintenance capabilities. By weighing the advantages and disadvantages of seed manufacturers, biotechnological seeds, and organic seed solutions, buyers can make informed decisions that align with their business goals and contribute to sustainable agricultural practices. Ultimately, understanding the unique benefits of each alternative will empower buyers to choose the solution that best meets their needs in an increasingly competitive market.

Essential Technical Properties and Trade Terminology for seed manufacturer

What Are the Essential Technical Properties for Seed Manufacturers?

When engaging with seed manufacturers, understanding the critical technical properties of seeds is essential for making informed purchasing decisions. Here are some key specifications to consider:

1. Germination Rate

The germination rate indicates the percentage of seeds that are expected to sprout under optimal conditions. This metric is crucial for buyers as it directly affects crop yield and overall profitability. High germination rates ensure that fewer seeds are needed for planting, optimizing costs and resources.

2. Purity Level

Purity level refers to the percentage of seeds that are of the specified variety and free from contaminants such as weeds or other crop seeds. It is vital for maintaining the integrity of crops and preventing cross-contamination, which can lead to significant losses. Buyers should seek seeds with high purity levels to ensure the quality of their harvest.

3. Seed Size and Weight

The size and weight of seeds can influence planting methods, spacing, and ultimately, crop performance. Different crops may require specific seed sizes for optimal growth. Understanding these dimensions helps buyers select the right seeds for their agricultural practices and ensures compatibility with planting equipment.

4. Moisture Content

Moisture content is the percentage of water in seeds at the time of sale. Proper moisture levels are essential for seed longevity and viability. Seeds with high moisture content can lead to mold and decay, while excessively dry seeds may have reduced germination rates. Buyers should ensure that moisture content aligns with storage and planting requirements.

5. Vigor

Seed vigor refers to the ability of seeds to germinate and grow quickly under suboptimal conditions. High vigor levels can mitigate risks related to poor soil quality or adverse weather. For international buyers, especially in regions with variable climates, assessing seed vigor is key to ensuring robust crop establishment.

What Are the Common Trade Terms Used in the Seed Manufacturing Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the seed manufacturing sector. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

In the context of seeds, an OEM refers to companies that produce seeds for other brands to sell under their name. Understanding OEM relationships can help buyers identify the source of their seeds and establish trust in the product’s quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of seeds that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchasing strategies and manage inventory effectively. It is particularly important for businesses looking to optimize costs while meeting their agricultural needs.

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers for specific seed products. This process allows buyers to compare different offerings and negotiate better deals. An effective RFQ can lead to cost savings and improved supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms is crucial for buyers in Africa, South America, the Middle East, and Europe to understand their obligations and minimize risks during importation.

5. Certification

Certification refers to the official validation of seed quality and authenticity by recognized authorities. Certifications such as organic or non-GMO can significantly influence buyer decisions. Understanding the different certifications helps buyers ensure compliance with local regulations and consumer preferences.

Conclusion

For international B2B buyers in the seed manufacturing industry, grasping these essential technical properties and trade terms is vital for making informed decisions. Whether assessing seed quality or navigating trade negotiations, this knowledge empowers buyers to optimize their agricultural operations and enhance profitability.

Navigating Market Dynamics and Sourcing Trends in the seed manufacturer Sector

What are the Current Market Dynamics and Key Trends in the Seed Manufacturer Sector?

The global seed manufacturing sector is increasingly influenced by several key drivers, including technological advancements, climate change, and shifting consumer preferences. The integration of precision agriculture technologies—such as drones, data analytics, and IoT—has revolutionized the way seeds are produced and distributed. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these technological trends is crucial for optimizing sourcing strategies and enhancing yield outcomes.

Emerging sourcing trends emphasize the importance of local partnerships and regional seed varieties that cater to specific climatic conditions and agricultural practices. In Africa, for instance, there is a growing demand for drought-resistant seeds due to changing weather patterns. Similarly, South American buyers are increasingly looking for genetically modified (GM) seeds that promise higher yields and pest resistance. Buyers should also be aware of the regulatory landscape surrounding GM seeds, as regulations can vary significantly between regions.

Moreover, the trend towards digital platforms for seed sourcing is gaining traction. B2B platforms are enabling buyers to connect directly with manufacturers, fostering transparency in the supply chain and facilitating better price negotiations. As buyers from Europe focus on sustainability, they are more likely to favor suppliers who demonstrate compliance with environmental regulations and sustainable farming practices.

How is Sustainability and Ethical Sourcing Impacting the Seed Manufacturing Sector?

Sustainability is becoming a cornerstone of the seed manufacturing industry. The environmental impact of conventional farming practices has led to a heightened awareness of the need for sustainable solutions. B2B buyers are increasingly prioritizing ethical sourcing, focusing on suppliers that utilize sustainable practices, such as organic seed production and eco-friendly packaging.

The importance of ethical supply chains cannot be overstated. Buyers are encouraged to assess their suppliers’ commitment to sustainability by looking for certifications such as Organic, Non-GMO Project Verified, and GlobalG.A.P. These certifications not only ensure that the products are produced in an environmentally responsible manner but also enhance the marketability of the seeds in increasingly eco-conscious markets.

Furthermore, the demand for ‘green’ materials is influencing the types of seeds being produced. For example, seeds that require less water or are resilient to pests can significantly reduce the need for chemical fertilizers and pesticides. This aligns with the growing consumer preference for organic products and can provide a competitive edge for suppliers who embrace these practices.

What is the Brief Evolution and History of the Seed Manufacturing Sector?

The seed manufacturing sector has evolved dramatically over the centuries, transitioning from traditional farming practices to a highly sophisticated industry driven by scientific research and technological advancements. Historically, seeds were saved and exchanged among farmers, relying heavily on local biodiversity. However, the Green Revolution in the mid-20th century marked a pivotal moment, introducing high-yielding varieties and chemical inputs that dramatically increased agricultural productivity.

A stock image related to seed manufacturer.

In recent decades, the industry has witnessed a shift towards biotechnology and genetic engineering, leading to the development of GM seeds that offer enhanced traits such as pest resistance and improved nutritional profiles. This evolution has not only transformed agricultural practices but has also raised ethical and regulatory discussions around the use of GMOs. As international B2B buyers navigate this landscape, understanding the historical context of seed production can provide valuable insights into current sourcing decisions and market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of seed manufacturer

-

How do I choose the right seed manufacturer for my business needs?

Choosing the right seed manufacturer involves assessing several critical factors. Start by evaluating the manufacturer’s reputation and history in the industry. Look for certifications that demonstrate quality assurance, such as ISO certifications. Additionally, consider their range of seed varieties to ensure they meet your specific agricultural requirements. Engaging with previous clients for testimonials can also provide insights into their reliability and service quality. -

What are the key factors to consider when sourcing seeds internationally?

When sourcing seeds internationally, consider import regulations in your country, as they can affect the types of seeds you can import. Evaluate the manufacturer’s ability to comply with these regulations and their experience in international shipping. Additionally, assess the quality of the seeds and any certifications that guarantee their viability. Lastly, consider the logistics involved, including shipping times and costs, to ensure timely delivery for your planting schedule. -

What minimum order quantities (MOQ) should I expect when purchasing seeds?

Minimum order quantities (MOQ) can vary significantly among seed manufacturers. Typically, MOQs can range from a few hundred to several thousand units, depending on the type of seeds and the manufacturer’s policies. It’s essential to communicate your needs upfront to negotiate terms that suit your purchasing capabilities. Smaller suppliers may offer more flexible MOQs, while larger manufacturers might have stricter requirements due to production costs. -

How can I ensure the quality of seeds before making a purchase?

To ensure seed quality, request samples before finalizing your order. Conduct germination tests on these samples to verify their viability. Additionally, ask for documentation such as seed health certificates, which indicate that the seeds are disease-free and meet quality standards. Establishing a quality assurance process with the manufacturer can also help maintain high standards for future orders. -

What payment terms should I negotiate with a seed manufacturer?

When negotiating payment terms, consider factors like your cash flow and the manufacturer’s policies. Common terms include a deposit upfront (often 30-50%) with the balance due upon delivery. For larger orders, you might negotiate installment payments based on delivery milestones. Ensure to clarify any penalties for late payments or discounts for early settlements, as these can affect your overall cost. -

How can I effectively vet a seed supplier before committing to a contract?

To vet a seed supplier, start by researching their business background, including years of operation and market reputation. Request references from past clients to assess their reliability and service quality. Additionally, check for industry certifications and compliance with international standards. A site visit can also be beneficial to observe their production processes and facilities firsthand. -

What logistics considerations should I keep in mind when sourcing seeds?

Logistics are crucial when sourcing seeds, particularly regarding shipping methods and timelines. Ensure that the supplier can provide reliable shipping options that align with your planting schedule. Additionally, consider customs clearance processes and potential delays at borders. It’s also wise to discuss responsibilities for damages or losses during transit to clarify liability. -

How can I customize seed orders to fit my specific agricultural needs?

Customizing seed orders often involves discussing specific varieties, treatment options, and packaging sizes with the manufacturer. Many seed suppliers offer hybrid or genetically modified options tailored to regional climates and soil types. Clearly communicate your requirements, including any certifications you may need (e.g., organic). Collaborating closely with the manufacturer can result in a tailored solution that meets your agricultural goals effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for seed manufacturer

In the rapidly evolving landscape of seed manufacturing, strategic sourcing emerges as a critical approach for international B2B buyers seeking competitive advantage. By prioritizing relationships with reliable suppliers, buyers can ensure access to high-quality seeds that meet regional agricultural demands while also enhancing sustainability practices.

How Can Strategic Sourcing Enhance Your Seed Supply Chain?

Leveraging strategic sourcing not only mitigates risks associated with supply chain disruptions but also fosters innovation through collaborative partnerships. Buyers from Africa, South America, the Middle East, and Europe should focus on aligning their sourcing strategies with the unique agricultural challenges and market dynamics of their regions. This alignment will enable them to capitalize on local insights and trends, ensuring they remain agile and responsive to market needs.

What Should You Do Next in Your Sourcing Strategy?

As you look to the future, consider investing in technology and data analytics to refine your sourcing processes further. Embrace sustainable practices by sourcing from suppliers committed to eco-friendly production methods, which can enhance your brand’s reputation and appeal to environmentally conscious consumers.

In conclusion, the path forward for international B2B buyers in the seed manufacturing sector is ripe with opportunity. By adopting a proactive and strategic sourcing approach, you can secure a robust supply chain that not only drives profitability but also supports the long-term sustainability of agricultural practices. Engage with your suppliers today and start shaping a future that benefits your business and the environment alike.