Discover Top Benefits of Choosing a Spy Camera Manufacturer (2025)

Introduction: Navigating the Global Market for spy camera manufacturer

In today’s rapidly evolving digital landscape, sourcing reliable spy camera manufacturers presents a unique challenge for international B2B buyers. As security concerns heighten across various sectors—from corporate espionage to personal safety—businesses in regions such as Africa, South America, the Middle East, and Europe, including countries like Egypt and Italy, are increasingly seeking advanced surveillance solutions. This comprehensive guide aims to equip buyers with the knowledge necessary to navigate the complexities of the global market for spy cameras, ensuring informed purchasing decisions.

This guide covers a wide array of critical aspects, including the different types of spy cameras available, their diverse applications across various industries, and the essential criteria for vetting suppliers effectively. Additionally, we delve into cost considerations, helping you understand pricing structures and value propositions to ensure you receive the best return on investment.

By addressing these key elements, this guide empowers B2B buyers to make strategic choices tailored to their specific needs. Whether you are looking to enhance security measures in your business or seeking innovative surveillance solutions for clients, understanding the nuances of sourcing from international suppliers is crucial. With actionable insights and expert recommendations, you’ll be well-equipped to navigate the global market and forge successful partnerships with reputable spy camera manufacturers.

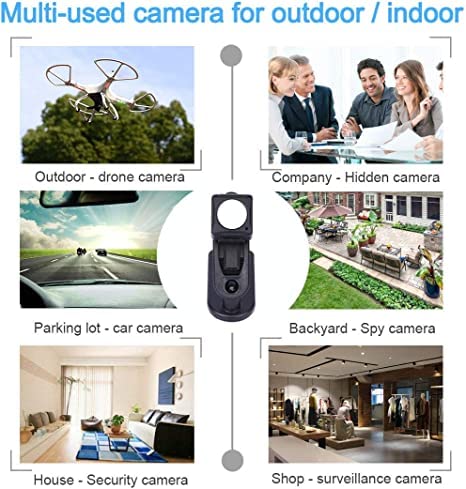

Understanding spy camera manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wireless Spy Cameras | Remote access, Wi-Fi enabled, compact design | Security monitoring, surveillance | Pros: Easy installation, flexible placement. Cons: Vulnerable to hacking, requires stable internet. |

| Hidden Cameras | Disguised as everyday objects (e.g., smoke detectors) | Retail theft prevention, employee monitoring | Pros: Discreet, effective for covert surveillance. Cons: Limited recording time, potential legal issues. |

| Body-Worn Cameras | Portable, often used by security personnel | Law enforcement, private security | Pros: Provides real-time footage, enhances accountability. Cons: Battery life can be short, may require training. |

| Miniature Cameras | Small size, high-resolution video | Personal security, investigative work | Pros: Versatile use, unobtrusive. Cons: Limited features, may lack advanced functionalities. |

| IP Surveillance Cameras | Networked, allows remote viewing and control | Large-scale security systems, monitoring critical areas | Pros: Scalable, high-quality video. Cons: More complex setup, higher initial investment. |

What Are Wireless Spy Cameras and Their B2B Relevance?

Wireless spy cameras are designed for easy installation and remote access through Wi-Fi. Their compact design allows for flexible placement in various environments, making them ideal for businesses needing security monitoring or surveillance. When purchasing, B2B buyers should consider the camera’s compatibility with existing security systems, its resolution, and the potential vulnerabilities associated with wireless technology, such as hacking risks.

How Do Hidden Cameras Function in a Business Environment?

Hidden cameras are cleverly disguised as common objects like smoke detectors or picture frames, making them effective for covert surveillance. They are commonly used in retail settings for theft prevention or in offices for employee monitoring. B2B buyers should evaluate the camera’s recording capabilities, storage options, and legal considerations regarding privacy and surveillance laws in their respective regions.

What Are the Benefits of Body-Worn Cameras for Security Personnel?

Body-worn cameras are portable devices often used by security personnel and law enforcement to capture real-time footage. These cameras enhance accountability and provide valuable evidence in case of disputes. When considering a purchase, B2B buyers should assess the camera’s battery life, durability, and ease of use, as well as any necessary training for personnel on how to operate these devices effectively.

Why Choose Miniature Cameras for Discreet Surveillance?

Miniature cameras are small, high-resolution devices that offer versatile use for personal security or investigative work. Their unobtrusive nature makes them suitable for businesses requiring discreet surveillance without drawing attention. Buyers should focus on the camera’s resolution, recording duration, and any additional features that may enhance its functionality, such as motion detection or night vision.

How Do IP Surveillance Cameras Enhance Large-Scale Security Systems?

IP surveillance cameras are networked devices that allow for remote viewing and control, making them a critical component of large-scale security systems. They are particularly useful for monitoring critical areas in businesses, such as warehouses or data centers. B2B buyers must consider the setup complexity, required infrastructure, and overall cost, including installation and maintenance, when investing in IP surveillance technology.

Related Video: How to operate V380 PRO WiFi hidden spy camera

Key Industrial Applications of spy camera manufacturer

| Industry/Sector | Specific Application of spy camera manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Security Services | Surveillance of high-risk areas | Enhanced security and risk mitigation | Compliance with local regulations, image quality, and reliability |

| Retail | Loss prevention and customer behavior analysis | Reduced shrinkage and improved customer insights | Discreet design, integration with existing systems, and data analytics capabilities |

| Transportation & Logistics | Fleet monitoring and driver behavior assessment | Increased safety and efficiency in operations | Real-time monitoring features, durability, and data storage solutions |

| Education | Classroom monitoring for safety and compliance | Improved safety for students and staff | Privacy considerations, ease of installation, and remote access capabilities |

| Manufacturing | Quality control and process monitoring | Enhanced product quality and operational efficiency | Robustness, compatibility with existing machinery, and data reporting features |

What are the Key Applications of Spy Cameras in Security Services?

In the security sector, spy cameras are integral for monitoring high-risk areas such as banks, airports, and public spaces. They provide real-time surveillance, enabling rapid response to incidents and reducing theft or vandalism. For international buyers, particularly from regions like Africa and the Middle East, sourcing cameras that comply with local regulations and offer high image quality is crucial. Additionally, reliability and the ability to integrate with existing security systems are vital for maximizing investment.

How Do Spy Cameras Enhance Retail Loss Prevention?

In retail environments, spy cameras are used to deter theft and analyze customer behavior. By strategically placing cameras, businesses can monitor potential shoplifting activities and gain insights into shopping patterns, leading to improved store layouts and product placements. For B2B buyers in Europe and South America, considerations such as discreet design and the ability to integrate with data analytics systems are essential for effective loss prevention strategies.

What Role Do Spy Cameras Play in Transportation and Logistics?

In the transportation and logistics sector, spy cameras serve to monitor fleet operations and assess driver behavior. This application enhances safety, reduces accidents, and increases overall operational efficiency. Buyers from regions like Africa and South America should prioritize features such as real-time monitoring capabilities, durability for harsh environments, and comprehensive data storage solutions to ensure that the investment is both effective and sustainable.

How are Spy Cameras Used in Educational Institutions?

Spy cameras in educational settings are primarily used for classroom monitoring to ensure safety and compliance with regulations. They help protect students and staff by providing a secure environment and can be instrumental in addressing bullying or misconduct. International buyers, especially from Europe, need to consider privacy issues and the ease of installation when sourcing these cameras, ensuring that they comply with local laws regarding surveillance in educational institutions.

What Benefits Do Spy Cameras Offer in Manufacturing Quality Control?

In manufacturing, spy cameras are essential for quality control and monitoring production processes. They enable real-time observation of operations, helping to identify defects and inefficiencies. This leads to enhanced product quality and operational efficiency, which are critical for maintaining competitive advantage. B2B buyers, particularly from Africa and the Middle East, should look for robust cameras that can withstand industrial environments and seamlessly integrate with existing machinery for optimal results.

Related Video: A9 Mini Camera | v720 APP Setup and Tutorial Guide | Review, Test, and Unboxing | 2023

3 Common User Pain Points for ‘spy camera manufacturer’ & Their Solutions

Scenario 1: Difficulty in Understanding Legal Compliance for Spy Cameras

The Problem:

International B2B buyers often face significant challenges regarding the legal compliance of spy cameras, particularly in regions with stringent privacy laws. For instance, a security firm in Italy may struggle to navigate the complexities of the General Data Protection Regulation (GDPR) while sourcing spy cameras. This uncertainty can lead to costly legal repercussions if the equipment is misused or if the privacy of individuals is inadvertently compromised. Additionally, buyers from countries in Africa and the Middle East may encounter differing regulations that complicate their purchasing decisions.

The Solution:

To overcome these compliance challenges, B2B buyers should prioritize sourcing from manufacturers that provide comprehensive legal documentation and compliance guidelines specific to the regions they operate in. It is advisable to request detailed information about how the manufacturer ensures that their products meet local regulations, including certifications and testing reports. Buyers can also benefit from consulting legal experts or local authorities to gain a clear understanding of applicable laws. Establishing a proactive relationship with the manufacturer can further ensure that any new legal developments are communicated effectively.

Scenario 2: Concerns About Product Quality and Reliability

The Problem:

A significant concern for B2B buyers is the quality and reliability of spy cameras. For example, a surveillance company in South America may have previously experienced issues with low-quality cameras that failed to perform under challenging environmental conditions, such as high humidity or extreme temperatures. These unreliable products can lead to operational inefficiencies and damage to the company’s reputation, making it crucial for buyers to ensure they are investing in high-quality equipment.

The Solution:

To mitigate concerns about product quality, buyers should conduct thorough due diligence on potential manufacturers. This includes reviewing product specifications, testing results, and user testimonials. Engaging in direct conversations with the manufacturer can also provide insights into their quality assurance processes and the materials used in their products. Buyers should consider requesting samples for testing in their specific operational environments. Additionally, establishing a long-term partnership with a reputable manufacturer can lead to better quality control and ongoing support for product maintenance.

Scenario 3: Challenges in Technical Support and Integration

The Problem:

B2B buyers often encounter difficulties with the technical support and integration of spy camera systems into their existing security frameworks. For instance, a company in Egypt may purchase a state-of-the-art spy camera system but find that the installation process is complicated and that the manufacturer’s support is inadequate. This can lead to extended downtimes and frustration for the end-users, ultimately affecting the company’s operational efficiency.

The Solution:

To address these integration challenges, buyers should seek manufacturers that offer comprehensive installation support and training. Before making a purchase, it is essential to inquire about the technical support services provided, including installation assistance, user manuals, and ongoing maintenance. Buyers should also consider manufacturers that offer customizable solutions that can easily integrate with their current systems. Establishing a clear communication channel with the manufacturer post-purchase can facilitate troubleshooting and ensure a smoother integration process, enhancing overall user satisfaction.

Strategic Material Selection Guide for spy camera manufacturer

When selecting materials for manufacturing spy cameras, understanding the properties, advantages, and limitations of each option is crucial. This guide will analyze four common materials used in the production of spy cameras, focusing on their performance characteristics, suitability for specific applications, and considerations for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

What Are the Key Properties of ABS Plastic for Spy Cameras?

Acrylonitrile Butadiene Styrene (ABS) plastic is a widely used material in the production of consumer electronics, including spy cameras. It offers excellent impact resistance and toughness, making it suitable for devices that may be subjected to rough handling. ABS has a temperature tolerance ranging from -20°C to 80°C, which is adequate for most indoor applications.

Pros & Cons:

The primary advantage of ABS is its low cost and ease of manufacturing, which translates to lower production costs for manufacturers. However, its susceptibility to UV degradation and chemical corrosion can limit its use in outdoor environments.

Impact on Application:

ABS is compatible with various electronic components and is often used in the housing of spy cameras. However, it may not withstand extreme environmental conditions, which is a consideration for buyers in regions with harsh climates.

Considerations for Buyers:

International buyers should ensure that ABS complies with local regulations and standards, such as ASTM D638 for tensile strength. In regions like Egypt or Italy, where environmental regulations may be stricter, understanding the material’s limitations is essential.

How Does Aluminum Benefit Spy Camera Manufacturing?

Aluminum is another popular choice for spy camera manufacturers due to its lightweight and corrosion-resistant properties. It can withstand temperatures from -40°C to 150°C, making it suitable for both indoor and outdoor applications.

Pros & Cons:

The key advantage of aluminum is its durability and resistance to environmental factors, which enhances the longevity of the camera. However, it is more expensive than plastics and can complicate manufacturing processes due to the need for specialized equipment.

Impact on Application:

Aluminum is often used in the casing of spy cameras, particularly those intended for outdoor use. Its thermal conductivity also helps in dissipating heat generated by electronic components.

Considerations for Buyers:

B2B buyers should consider the weight-to-strength ratio when selecting aluminum for spy cameras. Compliance with standards such as DIN 17615 for aluminum alloys is important, especially in European markets.

What Role Does Polycarbonate Play in Spy Camera Design?

Polycarbonate is known for its high impact resistance and optical clarity, making it an excellent choice for lens covers in spy cameras. It can operate effectively in temperatures ranging from -40°C to 120°C.

Pros & Cons:

The primary advantage of polycarbonate is its ability to withstand significant impact without shattering, which is crucial for security applications. However, it is more expensive than ABS and can be prone to scratching without proper coatings.

Impact on Application:

Polycarbonate is often used for lens covers due to its clarity and durability, ensuring that the camera captures high-quality images.

Considerations for Buyers:

Buyers should be aware of the need for anti-scratch coatings to enhance the longevity of polycarbonate components. Compliance with international standards such as ISO 7391 for optical materials is also essential.

Why Choose Stainless Steel for Spy Camera Manufacturing?

Stainless steel is a premium material choice for high-end spy cameras, particularly those designed for rugged environments. It offers excellent corrosion resistance and can handle temperatures from -200°C to 800°C.

Pros & Cons:

The main advantage of stainless steel is its durability and resistance to corrosion, making it suitable for outdoor applications. However, it is the most expensive material on this list and can complicate manufacturing due to its hardness.

Impact on Application:

Stainless steel is often used in the construction of high-end spy cameras that require robust housing to protect sensitive components from environmental damage.

Considerations for Buyers:

International buyers must consider the cost implications of using stainless steel, especially in regions where budget constraints are a concern. Compliance with standards like ASTM A240 for stainless steel is critical for maintaining quality.

Summary Table of Material Selection for Spy Cameras

| Material | Typical Use Case for spy camera manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| ABS Plastic | Housing for indoor spy cameras | Low cost and easy to manufacture | Susceptible to UV degradation | Low |

| Aluminum | Outdoor camera casings | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | Medium |

| Polycarbonate | Lens covers for spy cameras | High impact resistance and clarity | Prone to scratching | Medium |

| Stainless Steel | High-end outdoor spy cameras | Excellent durability and corrosion resistance | High cost and manufacturing complexity | High |

By carefully considering these materials and their properties, international B2B buyers can make informed decisions that align with their specific needs and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for spy camera manufacturer

What Are the Key Stages in the Manufacturing Process of Spy Cameras?

The manufacturing process of spy cameras involves multiple stages that ensure high-quality output and adherence to industry standards. Understanding these stages is crucial for international B2B buyers who need reliable products. Here are the main stages involved:

Material Preparation

The first stage in manufacturing spy cameras is material preparation. This includes sourcing high-quality components such as lenses, sensors, and circuit boards. Suppliers often use materials that have undergone rigorous testing to ensure durability and performance. For B2B buyers, it’s essential to inquire about the source of materials and whether they meet specific international standards, such as RoHS (Restriction of Hazardous Substances) for electronic components.

Forming: What Techniques Are Used?

Forming is the next step, where raw materials are shaped into the necessary components. Techniques such as injection molding and CNC machining are commonly employed. Injection molding is particularly useful for creating complex plastic housings, while CNC machining is ideal for precise metal parts. Buyers should seek manufacturers who use advanced techniques, as this often results in better quality and fewer defects.

A stock image related to spy camera manufacturer.

Assembly: How Are Components Joined Together?

The assembly stage involves putting together all the components to create a fully functional spy camera. This can be done manually or via automated processes. Manual assembly allows for more intricate work, while automation speeds up production. Quality control at this stage is vital; buyers should ask potential suppliers about their assembly processes and whether they employ skilled technicians or robotics to ensure high precision.

Finishing: What Quality Enhancements Are Applied?

Finishing processes, such as painting, coating, and testing, are the final steps before the product is packaged. These enhancements improve aesthetics and durability. For instance, applying a protective coating can make the camera resistant to environmental factors. B2B buyers should inquire about the types of finishes offered and their impact on the product’s longevity and performance.

What Quality Assurance Measures Should B2B Buyers Expect?

A stock image related to spy camera manufacturer.

Quality assurance (QA) is a critical aspect of the manufacturing process for spy cameras. It ensures that the final products meet the required specifications and standards. Understanding the QA measures in place can help international B2B buyers make informed decisions.

What International Standards Apply to Spy Camera Manufacturing?

Many manufacturers adhere to international quality standards, such as ISO 9001, which focuses on quality management systems. Compliance with these standards indicates a commitment to quality and continuous improvement. Additionally, certifications like CE (Conformité Européenne) ensure that products meet European safety and health requirements. B2B buyers from Europe, Africa, and South America should prioritize suppliers with these certifications to mitigate risks.

What Are the Key Quality Control Checkpoints?

Quality control in spy camera manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This is the first line of defense, where incoming materials and components are inspected for quality before they enter production.

-

In-Process Quality Control (IPQC): During assembly, various checks are performed to ensure that the assembly process adheres to quality standards. This may include visual inspections and functional tests.

-

Final Quality Control (FQC): After assembly, the final product undergoes comprehensive testing to ensure it meets all specifications and quality standards before being shipped.

B2B buyers should inquire about the specific QC procedures employed by potential suppliers, including the frequency and methods of inspections.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are actionable insights on how to conduct this verification:

What Auditing Processes Should Be Conducted?

Conducting audits is a practical way to assess a supplier’s quality control practices. Buyers can either perform these audits themselves or hire third-party auditing firms specializing in manufacturing processes. During the audit, key areas to evaluate include the effectiveness of the IQC, IPQC, and FQC processes, as well as employee training and adherence to international standards.

How Can Quality Reports and Documentation Help?

Requesting quality reports and documentation from suppliers can provide insights into their quality management practices. Look for reports that outline test results, defect rates, and corrective actions taken for any issues identified. This documentation serves as a transparent record of the supplier’s commitment to maintaining high-quality standards.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can further ensure that the products meet specified quality criteria. These services can conduct random inspections during various manufacturing stages, providing an unbiased assessment of the supplier’s quality control processes. For B2B buyers from regions like Africa and South America, this step is especially crucial, as it helps mitigate risks associated with sourcing products from different geographic locations.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing spy cameras internationally, buyers must navigate various quality control nuances that may vary by region. Here are some considerations:

Understanding Regional Standards

Different regions may have specific standards and regulations that affect product quality. For example, European buyers must adhere to CE marking requirements, while Middle Eastern countries may have their own regulatory frameworks. B2B buyers should familiarize themselves with these standards and ensure that suppliers comply.

Language and Communication Barriers

Communication is vital in ensuring quality. Buyers should consider language barriers that may exist when dealing with suppliers from different regions. Clear communication about quality expectations, standards, and requirements can help prevent misunderstandings that could impact product quality.

Cultural Differences in Quality Perception

Cultural perceptions of quality can also influence manufacturing processes. Buyers should be aware that what constitutes “quality” may differ across cultures. Establishing strong relationships and clear expectations can help bridge these differences, ensuring that both parties are aligned on quality standards.

Conclusion

Understanding the manufacturing processes and quality assurance measures for spy cameras is essential for international B2B buyers. By focusing on key manufacturing stages, relevant quality standards, and effective verification methods, buyers can make informed decisions and ensure they source reliable products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘spy camera manufacturer’

Introduction

In the dynamic landscape of security technology, sourcing a reliable spy camera manufacturer is critical for businesses aiming to enhance their surveillance capabilities. This guide provides an actionable checklist for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, to navigate the complexities of procurement effectively. By following these steps, you can ensure that you partner with a manufacturer that meets your specific needs and standards.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. Consider factors such as resolution, connectivity options (Wi-Fi, Bluetooth), and battery life. A well-defined specification helps streamline your search and ensures that potential manufacturers can meet your operational needs.

- Key Considerations:

- Determine the type of spy cameras required (e.g., hidden, portable, or stationary).

- Assess compatibility with existing systems or software.

Step 2: Research Market Trends and Innovations

Understanding current market trends and technological advancements in the spy camera sector is essential. This knowledge will inform your sourcing decisions and help you identify manufacturers that are at the forefront of innovation.

- Action Items:

- Follow industry news, reports, and technological advancements.

- Attend trade shows or webinars focused on surveillance technology.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation of their capabilities. Request detailed company profiles, product catalogs, and case studies to assess their experience and reputation in the market.

- Important Checks:

- Look for references from other businesses in similar industries.

- Verify their production capacity and lead times to ensure they can meet your demands.

Step 4: ✅ Verify Supplier Certifications

Ensure that potential manufacturers hold relevant certifications that guarantee quality and compliance with international standards. This is crucial for maintaining the integrity of your security solutions.

- Certifications to Look For:

- ISO 9001 for quality management.

- CE marking for compliance with European safety standards.

Step 5: Request Product Samples

Before making a bulk purchase, request samples of the spy cameras you are considering. Testing the products firsthand allows you to evaluate their performance and suitability for your specific applications.

- Evaluation Criteria:

- Assess image quality, ease of use, and durability.

- Ensure that the cameras meet your predefined technical specifications.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable manufacturer, it’s time to negotiate terms and pricing. Establish clear expectations regarding payment terms, delivery schedules, and warranty conditions to avoid misunderstandings later.

- Key Negotiation Points:

- Discuss bulk order discounts and payment methods.

- Clarify warranty coverage and after-sales support options.

Step 7: Establish a Clear Communication Channel

Effective communication is vital for a successful partnership with your chosen manufacturer. Establish a clear line of communication to address any concerns or questions throughout the procurement process.

- Communication Strategies:

- Utilize project management tools for ongoing updates.

- Schedule regular check-ins to monitor progress and resolve issues promptly.

By following this comprehensive checklist, B2B buyers can approach the sourcing of spy camera manufacturers with confidence, ensuring they select a partner that aligns with their technical requirements and business objectives.

Comprehensive Cost and Pricing Analysis for spy camera manufacturer Sourcing

What Are the Key Cost Components in Spy Camera Manufacturing?

Understanding the cost structure of a spy camera manufacturer is essential for B2B buyers looking to source effectively. The main cost components include:

-

Materials: The choice of materials significantly influences the overall cost. High-quality lenses, sensors, and housing materials can drive up expenses. Buyers should consider sourcing from suppliers who offer a balance between quality and price.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Countries with lower labor costs may offer more competitive pricing, but this can sometimes impact quality. It’s crucial to assess the skill level and experience of the workforce.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead, which in turn can lower the price for buyers.

-

Tooling: The initial investment in tools and machinery can be significant, especially for custom designs. Buyers should inquire about tooling costs upfront to understand how these will be amortized in the pricing.

-

Quality Control (QC): A robust QC process ensures product reliability and compliance with international standards. While it may add to the cost, it is essential for long-term satisfaction and reducing returns.

-

Logistics: Shipping costs can fluctuate based on distance, mode of transport, and customs duties. Understanding these logistics costs is crucial for calculating the total landed cost of the products.

-

Margin: Manufacturers typically build in a profit margin that reflects their business model and market conditions. Buyers should be aware of this margin when negotiating prices.

How Do Price Influencers Affect Spy Camera Sourcing?

Several factors can influence the pricing of spy cameras, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts, as manufacturers can spread costs over a greater number of units. Buyers should negotiate MOQs to optimize their purchasing strategy.

-

Specifications and Customization: Custom features or specifications can substantially increase costs. Buyers should clearly define their needs to avoid unexpected price hikes.

-

Material Quality and Certifications: Higher quality materials and certifications (like CE or RoHS compliance) can increase costs but are crucial for meeting regulatory standards in different regions. Buyers should weigh the importance of these factors against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their track record, but the cost is often justified by the quality and service provided.

-

Incoterms: Understanding Incoterms is vital for international transactions. These terms determine who is responsible for shipping, insurance, and tariffs, impacting the overall cost. Buyers should clarify these terms to avoid hidden charges.

What Buyer Tips Can Enhance Cost-Efficiency in Spy Camera Sourcing?

To maximize value when sourcing spy cameras, buyers should consider the following strategies:

-

Negotiation Skills: Developing strong negotiation skills can lead to better pricing. Always be prepared to discuss volume discounts, payment terms, and shipping arrangements.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors like maintenance, warranty, and the expected lifespan of the cameras. A higher upfront cost may result in lower TCO if the product is more durable and reliable.

-

Understanding Pricing Nuances: Different regions may have varying pricing structures. For instance, manufacturers in Europe may have higher labor costs but offer better quality assurance compared to those in Africa or South America. Buyers should research these nuances to inform their sourcing decisions.

-

Market Research: Conduct thorough market research to understand prevailing prices and trends. Engaging with industry analysts or reports can provide insights that help in negotiations.

-

Supplier Relationships: Building strong relationships with suppliers can yield long-term benefits, including better pricing, priority service, and access to new products.

Disclaimer on Indicative Prices

Pricing for spy cameras can vary significantly based on the factors discussed above. It is advisable for buyers to seek quotes from multiple suppliers to obtain a comprehensive understanding of current market prices and to negotiate based on specific needs and conditions.

Alternatives Analysis: Comparing spy camera manufacturer With Other Solutions

Understanding Alternative Solutions to Spy Camera Manufacturers

When considering surveillance solutions, international B2B buyers must evaluate various options to ensure they select the most effective and cost-efficient technology. Spy cameras are popular for covert monitoring, but other alternatives may provide similar capabilities with distinct advantages. This analysis compares spy camera manufacturers with smart home security systems and drone surveillance, offering insights to help businesses make informed decisions.

Comparison Table of Surveillance Solutions

| Comparison Aspect | Spy Camera Manufacturer | Smart Home Security Systems | Drone Surveillance |

|---|---|---|---|

| Performance | High-resolution video, discreet | Integrated systems with alerts | Aerial surveillance, wide area coverage |

| Cost | Moderate to high | Variable, often subscription-based | High initial investment, ongoing costs |

| Ease of Implementation | Requires installation and setup | User-friendly, often plug-and-play | Complex setup, regulatory considerations |

| Maintenance | Periodic updates and checks | Minimal, mainly software updates | Regular maintenance and calibration |

| Best Use Case | Covert operations, private surveillance | Residential and small business security | Large area surveillance, crowd monitoring |

What Are the Pros and Cons of Smart Home Security Systems?

Smart home security systems offer an integrated approach to safety and surveillance, combining alarms, cameras, and motion sensors. They typically come with user-friendly interfaces and mobile applications for real-time monitoring and alerts. The cost can vary significantly based on the features chosen, and while some systems require a subscription, many are affordable upfront. However, they may not provide the same level of discreetness as spy cameras, making them less suitable for covert operations.

How Does Drone Surveillance Compare to Spy Cameras?

Drone surveillance presents a unique alternative with its ability to cover large areas from an aerial perspective. This technology is particularly effective for monitoring outdoor events or expansive properties. Drones can capture high-definition video and images, but they come with higher initial costs and may require extensive training for operators. Additionally, regulatory issues regarding airspace can complicate their implementation. While drones are excellent for specific scenarios, they may not be practical for everyday surveillance needs.

Conclusion: How Should B2B Buyers Choose the Right Surveillance Solution?

Choosing the right surveillance solution depends on various factors, including the specific needs of the business, budget constraints, and the intended application. B2B buyers from regions like Africa, South America, the Middle East, and Europe should assess whether they need covert monitoring or comprehensive security systems. Considerations such as ease of implementation and maintenance are crucial, especially for businesses lacking technical expertise. By carefully evaluating these alternatives, buyers can make informed decisions that align with their operational requirements and financial capabilities.

Essential Technical Properties and Trade Terminology for spy camera manufacturer

What Are the Essential Technical Properties for Spy Cameras?

When evaluating spy camera manufacturers, understanding key technical properties is crucial for making informed purchasing decisions. Here are some of the most critical specifications that B2B buyers should consider:

1. Resolution

Resolution refers to the detail an image holds, typically measured in megapixels (MP). For spy cameras, higher resolution translates to clearer images and videos, which is vital for surveillance purposes. A resolution of at least 1080p (Full HD) is recommended for most applications, while 4K cameras offer superior clarity for detailed monitoring. Buyers should prioritize manufacturers that provide high-resolution options to ensure optimal performance.

2. Field of View (FOV)

The field of view determines how much area a camera can capture. It is measured in degrees and varies significantly between models. A wider FOV allows for broader surveillance coverage, reducing the number of cameras needed for a particular area. Buyers should assess their specific surveillance needs to determine the appropriate FOV, balancing coverage with image distortion that can occur at extreme angles.

3. Low-Light Performance

Low-light performance indicates how well a camera can capture images in dim conditions. This is particularly important for spy cameras, which may need to operate in poorly lit environments. Specifications such as the camera’s minimum illumination level (measured in lux) and the presence of infrared (IR) capabilities are critical. Buyers should look for models with enhanced low-light functionality to ensure reliable performance at all times.

4. Audio Capabilities

Many spy cameras come equipped with built-in audio recording features. The quality of audio capture can vary, impacting the effectiveness of surveillance. Specifications to consider include microphone sensitivity and noise reduction capabilities. Buyers should evaluate whether audio is necessary for their specific use case and choose manufacturers that deliver high-quality sound alongside video.

5. Durability and Material Grade

The durability of a spy camera is often determined by the materials used in its construction. Common materials include plastic, metal, and weather-resistant coatings. For outdoor use, buyers should look for cameras with IP ratings (Ingress Protection) that indicate resistance to dust and moisture. Understanding material grades and their implications for durability can help buyers select products that withstand their intended environments.

What Trade Terminology Should International B2B Buyers Know?

Familiarity with industry-specific terminology can streamline the procurement process and enhance negotiations. Here are some essential trade terms relevant to spy camera manufacturing:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of spy cameras, buyers may work with OEMs to create customized products or private-label solutions. Understanding OEM relationships can facilitate better sourcing decisions and product customization.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers to grasp, as it affects inventory management and cost efficiency. Buyers should negotiate MOQs based on their purchasing power and forecasted demand to avoid overstocking or understocking.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to solicit pricing and terms for specific products or services. When considering spy cameras, submitting an RFQ allows buyers to compare offers from multiple manufacturers and negotiate better deals. Crafting a clear and detailed RFQ can lead to more accurate and competitive responses.

4. Incoterms

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping and delivery. Key terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Understanding Incoterms is essential for international buyers to clarify shipping costs, risks, and obligations, thus preventing potential disputes.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. This metric is crucial for buyers who need to align inventory levels with market demands. Understanding lead times can help buyers plan their purchasing cycles effectively and maintain adequate stock levels.

By grasping these technical properties and trade terminologies, international B2B buyers can enhance their decision-making processes and establish successful partnerships with spy camera manufacturers.

Navigating Market Dynamics and Sourcing Trends in the spy camera manufacturer Sector

What Are the Key Market Dynamics and Trends in the Spy Camera Manufacturing Sector?

The spy camera manufacturing sector is experiencing significant growth, driven by advancements in technology and increasing demand for surveillance solutions across various industries. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of several key trends shaping the market.

-

Technological Advancements: Innovations in miniaturization and wireless technology have led to the development of smaller, more efficient spy cameras. These devices can now integrate with IoT ecosystems, allowing for real-time monitoring and data analysis. Buyers should look for manufacturers that offer cutting-edge technology to stay competitive.

-

Increased Demand for Security Solutions: With rising concerns over security and privacy, businesses are investing more in surveillance solutions. This trend is particularly pronounced in urban areas of Africa and South America, where crime rates may necessitate heightened security measures. B2B buyers should assess their specific security needs and look for manufacturers that can provide tailored solutions.

-

Regulatory Considerations: Different regions have varying regulations regarding surveillance equipment. For instance, European countries have stringent data protection laws that influence how spy cameras can be used. Buyers must ensure that they understand local regulations and select manufacturers that comply with these standards to avoid legal complications.

-

Emerging Markets: Countries in Africa and the Middle East are witnessing a surge in demand for surveillance technologies, driven by urbanization and the need for enhanced security measures. B2B buyers from these regions should focus on sourcing from manufacturers that understand the local market dynamics and can offer customized products.

How Can Sustainability and Ethical Sourcing Impact the Spy Camera Manufacturing Sector?

Sustainability and ethical sourcing are increasingly becoming pivotal considerations for B2B buyers in the spy camera manufacturing sector. The environmental impact of electronic waste and the sourcing of materials are critical factors that influence purchasing decisions.

-

Environmental Concerns: The production of electronic devices, including spy cameras, contributes to environmental degradation. Buyers should seek manufacturers that prioritize eco-friendly practices, such as reducing carbon footprints and utilizing sustainable materials. These practices not only benefit the environment but can also enhance a company’s reputation in the market.

-

Importance of Ethical Supply Chains: Transparency in the supply chain is crucial for ethical sourcing. Buyers should inquire about the sourcing of raw materials and labor practices used by manufacturers. Engaging with suppliers who adhere to ethical standards can mitigate risks associated with labor exploitation and contribute to sustainable development.

-

Green Certifications and Materials: Buyers should look for manufacturers that offer ‘green’ certifications, such as ISO 14001, which indicates a commitment to environmental management. Additionally, sourcing products made from recycled materials or those that are energy-efficient can help in achieving sustainability goals while meeting consumer demand for responsible products.

What Is the Brief Evolution of the Spy Camera Manufacturing Sector?

The spy camera manufacturing sector has evolved significantly over the past few decades. Originally, surveillance equipment was bulky, expensive, and primarily used by government agencies. However, technological advancements in the 21st century have democratized access to surveillance solutions. The introduction of digital technology, miniaturization, and wireless connectivity has enabled the production of compact, affordable cameras that cater to both commercial and personal use.

As security concerns have escalated globally, so has the demand for spy cameras. Today, a diverse range of industries, from retail to private security, relies on these devices for enhanced safety and operational efficiency. This evolution highlights the importance for B2B buyers to stay informed about technological advancements and emerging trends to make strategic sourcing decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of spy camera manufacturer

-

How do I choose the right spy camera manufacturer for my business needs?

Choosing the right spy camera manufacturer involves assessing several factors. Start by evaluating their product range and specifications to ensure they align with your needs. Check for certifications and compliance with international standards, which are crucial for quality assurance. Additionally, consider their experience in the industry, customer reviews, and after-sales support. Engaging in direct communication can also provide insights into their responsiveness and willingness to customize products according to your specifications. -

What are the most important features to look for in spy cameras?

When sourcing spy cameras, prioritize features such as resolution, battery life, storage capacity, and connectivity options (e.g., Wi-Fi or Bluetooth). Consider the intended use—whether for surveillance, security, or personal safety—as this will dictate specific requirements like motion detection, night vision, and durability. Additionally, assess the ease of installation and user interface, as these can significantly impact the usability of the camera in various environments. -

What minimum order quantities (MOQ) should I expect from spy camera manufacturers?

Minimum order quantities can vary widely among manufacturers. Some may allow orders as low as 50 units, while others might require a minimum of 500 or more. It’s essential to discuss your needs upfront and negotiate the MOQ based on your business size and market demand. Smaller manufacturers may be more flexible, while larger firms often maintain strict MOQs due to production costs. Understanding these terms will help you manage inventory and cash flow effectively. -

What payment terms are commonly offered by spy camera manufacturers?

Payment terms can differ significantly based on the manufacturer and your negotiation power. Common options include upfront payments, partial payments before shipment, or net payment terms (e.g., 30, 60, or 90 days after delivery). It’s vital to clarify these terms early in the negotiation process to avoid misunderstandings. Additionally, consider using secure payment methods such as letters of credit or escrow services to protect your investment, especially when dealing with international suppliers. -

How can I verify the credibility of a spy camera manufacturer?

Verifying the credibility of a spy camera manufacturer involves several steps. Start by checking their business registration and certifications, which can indicate compliance with local and international standards. Request references or case studies from previous clients, particularly those in your region. Utilizing third-party platforms like Alibaba or Global Sources can also provide insights through buyer feedback. Finally, consider visiting their facility if feasible, as this can offer a firsthand look at their manufacturing capabilities and quality control processes. -

What quality assurance processes should I expect from a spy camera manufacturer?

A reputable spy camera manufacturer should have robust quality assurance (QA) processes in place. Look for manufacturers that conduct regular inspections during production, as well as final product testing for functionality and reliability. Certifications such as ISO 9001 indicate adherence to international QA standards. Additionally, inquire about their return and warranty policies, as these can provide assurance of product quality and the manufacturer’s confidence in their offerings. -

What logistics considerations should I keep in mind when sourcing spy cameras internationally?

When sourcing spy cameras internationally, logistics considerations are crucial for ensuring timely delivery and cost-effectiveness. Evaluate shipping options, including air freight for speed and sea freight for cost savings. Be aware of customs regulations and import duties that may apply in your country. Establishing a reliable logistics partner can help streamline the process. Additionally, consider the manufacturer’s ability to provide tracking information and their policies on handling delays or damages during transit. -

Can spy camera manufacturers customize products to meet specific requirements?

Many spy camera manufacturers offer customization options to cater to the unique needs of their clients. This can include modifications in design, features, and packaging. When approaching manufacturers, clearly outline your requirements and inquire about their capabilities for customization. Be prepared to discuss minimum order quantities, as custom orders may have higher MOQs. Understanding the lead times for custom products is also essential to align with your business timelines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for spy camera manufacturer

What Are the Key Takeaways for B2B Buyers in the Spy Camera Market?

As we conclude this guide on strategic sourcing for spy camera manufacturers, it’s essential to highlight the pivotal role of strategic sourcing in optimizing procurement processes. B2B buyers from Africa, South America, the Middle East, and Europe must focus on building relationships with reliable manufacturers who offer quality assurance, technological innovation, and competitive pricing. Understanding local regulations and market demands can further enhance sourcing strategies, ensuring compliance and alignment with consumer needs.

How Can Strategic Sourcing Drive Competitive Advantage?

Investing in strategic sourcing not only reduces costs but also fosters a supply chain that is resilient and responsive to market fluctuations. By leveraging data analytics and supplier performance metrics, international buyers can make informed decisions that enhance their competitive edge. Furthermore, engaging with manufacturers that prioritize sustainability and ethical practices can significantly boost brand reputation in today’s conscientious market.

What Should B2B Buyers Consider Moving Forward?

Looking ahead, it is crucial for B2B buyers to remain proactive in their sourcing strategies. As technology evolves, so too should your approach to procurement. Foster partnerships with forward-thinking manufacturers, explore emerging markets, and stay abreast of industry trends to capitalize on new opportunities. By doing so, you position your business not just to survive but to thrive in the dynamic landscape of the spy camera industry.