Discover Top Benefits of Choosing an Artificial Turf Supplier (2025)

Introduction: Navigating the Global Market for artificial turf supplier

In an increasingly competitive landscape, sourcing an artificial turf supplier can pose significant challenges for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. As the demand for high-quality synthetic grass continues to rise due to its versatility in applications ranging from sports fields to landscaping, navigating the multitude of options and ensuring the best value becomes paramount. This comprehensive guide is designed to empower you with the knowledge necessary to make informed purchasing decisions.

Throughout this guide, we will explore various types of artificial turf, their specific applications, and the critical factors to consider when vetting suppliers. Understanding the differences between products, such as infill types and durability ratings, will enable you to match the right turf to your project needs. Additionally, we will delve into cost considerations, helping you to budget effectively while avoiding common pitfalls associated with low-quality materials.

This guide is tailored specifically for international buyers, with insights relevant to diverse markets including Italy, Poland, and beyond. By equipping yourself with the right information, you can confidently navigate the global market for artificial turf suppliers, ensuring that your investment leads to enhanced performance and satisfaction in your projects.

Understanding artificial turf supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Synthetic Grass Suppliers | High durability, realistic appearance, UV resistance | Sports fields, landscaping, playgrounds | Pros: Low maintenance, weather-resistant. Cons: Initial cost can be high. |

| Infill Suppliers | Variety of infill materials (rubber, sand, etc.) | Athletic fields, golf courses, dog parks | Pros: Enhances performance, customizable. Cons: Infill can degrade over time. |

| Installation Services | Professional installation and maintenance services | Commercial properties, schools, municipalities | Pros: Ensures quality installation, reduces long-term costs. Cons: Additional service fees. |

| Custom Turf Manufacturers | Tailored designs and colors, specific performance features | Branding, unique landscaping solutions | Pros: Unique aesthetics, meets specific needs. Cons: Longer lead times, potentially higher costs. |

| Eco-Friendly Turf Suppliers | Made from recycled materials, sustainable practices | Green spaces, schools, parks | Pros: Environmentally friendly, grants eligibility. Cons: May have limited availability. |

What Are the Characteristics of Synthetic Grass Suppliers?

Synthetic grass suppliers focus on providing high-quality artificial turf that mimics the look and feel of natural grass. These suppliers often emphasize durability and UV resistance, making their products ideal for various applications, including sports fields, landscaping, and playgrounds. B2B buyers should consider the long-term maintenance costs versus the initial investment, as synthetic grass can be more expensive upfront but offers lower maintenance costs over time.

How Do Infill Suppliers Enhance Artificial Turf?

Infill suppliers offer a range of materials, such as rubber and sand, that enhance the performance of artificial turf systems. Infill provides cushioning, stability, and can improve drainage, making it crucial for athletic fields, golf courses, and dog parks. When purchasing infill, B2B buyers should assess the longevity and quality of the infill material, as some may degrade faster than others, impacting the overall performance of the turf.

Why Are Installation Services Important for Artificial Turf?

Installation services are essential for ensuring that artificial turf is laid correctly to maximize its lifespan and performance. Professional installers have the expertise to address site-specific challenges and can often provide maintenance services post-installation. For B2B buyers, investing in professional installation can reduce long-term costs associated with repairs or replacements due to improper installation, although it may involve additional service fees.

What Are the Benefits of Custom Turf Manufacturers?

Custom turf manufacturers provide tailored solutions that meet the specific needs of businesses, including unique colors, designs, and performance features. This customization is particularly beneficial for branding efforts or unique landscaping projects. However, B2B buyers should be aware that custom orders may come with longer lead times and potentially higher costs, so careful planning is essential.

How Do Eco-Friendly Turf Suppliers Stand Out?

Eco-friendly turf suppliers focus on sustainable practices, often using recycled materials to create their products. This type of artificial turf is ideal for green spaces, schools, and parks, appealing to businesses looking to enhance their sustainability efforts. While these products may qualify for environmental grants, buyers should consider the availability and potential performance trade-offs compared to traditional options.

Related Video: How to properly install artificial grass – Bella Turf

Key Industrial Applications of artificial turf supplier

| Industry/Sector | Specific Application of Artificial Turf Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports Facilities | Football and Soccer Fields | Enhanced performance and safety for athletes | Durability, weather resistance, and compliance with sports regulations |

| Landscaping and Urban Development | Parks and Recreational Areas | Low maintenance and aesthetic appeal | Environmental impact, drainage solutions, and local climate adaptability |

| Commercial Real Estate | Rooftop Gardens and Patios | Increased property value and tenant attraction | Customization options, installation expertise, and warranty terms |

| Education Institutions | School Playgrounds and Athletic Fields | Safe play environments and reduced injury risks | Compliance with safety standards, ease of installation, and longevity |

| Event Venues | Temporary Sports and Event Setups | Quick installation and cost-effectiveness | Portability, ease of maintenance, and aesthetic versatility |

How is Artificial Turf Used in Sports Facilities?

In sports facilities, artificial turf serves as a reliable surface for football and soccer fields, enhancing performance while ensuring safety for athletes. This application addresses common issues such as wear and tear from heavy use, which can lead to unsafe playing conditions on natural grass. For international buyers, particularly in regions with varying climates, sourcing turf that offers durability and weather resistance is crucial. Compliance with sports regulations is another key consideration, ensuring that the turf meets the standards set by governing bodies.

What are the Benefits of Artificial Turf in Landscaping and Urban Development?

In landscaping and urban development, artificial turf is increasingly used in parks and recreational areas. Its low maintenance requirements and aesthetic appeal make it a preferred choice for urban planners looking to create green spaces without the hassle of upkeep. For buyers in Africa and South America, where water scarcity can be an issue, selecting turf that incorporates effective drainage solutions and is adaptable to local climates is essential. Additionally, understanding the environmental impact of artificial turf can inform sourcing decisions.

How Does Artificial Turf Enhance Commercial Real Estate?

For commercial real estate, artificial turf is a valuable addition to rooftop gardens and patios, significantly increasing property value and attracting tenants. This application not only enhances the visual appeal of a property but also provides functional outdoor spaces for relaxation or events. When sourcing artificial turf for these applications, buyers should consider customization options to align with their branding and aesthetic preferences. Installation expertise and warranty terms are also vital to ensure a long-lasting investment.

Why is Artificial Turf Important for Education Institutions?

In education institutions, artificial turf is widely used for school playgrounds and athletic fields, creating safe play environments that reduce injury risks. The durability of artificial turf ensures that these facilities can withstand heavy usage while maintaining safety standards. For international buyers, particularly in Europe, it is crucial to ensure compliance with local safety regulations when sourcing turf. Additionally, ease of installation and longevity are important factors that can influence purchasing decisions.

How is Artificial Turf Beneficial for Event Venues?

Event venues benefit from the use of artificial turf for temporary sports and event setups due to its quick installation and cost-effectiveness. This application allows venues to transform spaces for various events, from sports to outdoor gatherings, without the long-term commitment associated with natural grass. Buyers should prioritize portability and ease of maintenance when sourcing turf for these applications, ensuring that it meets the aesthetic needs of different events while remaining practical for set-up and take-down.

Related Video: How To Install Synthetic Turf

3 Common User Pain Points for ‘artificial turf supplier’ & Their Solutions

Scenario 1: Inconsistent Quality of Artificial Turf Products

The Problem: B2B buyers often face the challenge of inconsistent quality when sourcing artificial turf. This inconsistency can lead to significant issues, such as premature wear, color fading, or even safety hazards in sports applications. For international buyers, especially those in emerging markets in Africa and South America, the lack of established quality control standards can exacerbate this problem, leading to costly replacements and a tarnished reputation.

The Solution: To mitigate this issue, buyers should conduct thorough due diligence when selecting suppliers. This involves requesting product samples and certifications that demonstrate compliance with international quality standards such as FIFA for sports turf or ISO certifications for manufacturing processes. Additionally, establishing a long-term partnership with suppliers who have a proven track record of quality assurance can help. Implementing a regular quality review process upon delivery can also help maintain consistency, ensuring that the turf meets the specified requirements.

Scenario 2: Limited Customization Options for Specific Projects

The Problem: Many B2B buyers discover that their suppliers offer limited customization options when it comes to artificial turf. This can be particularly problematic for projects that require specific colors, textures, or performance characteristics tailored to unique applications, such as landscaping, playgrounds, or sports fields. Buyers from regions like the Middle East, where aesthetic and functional demands are high due to climatic conditions, often find it difficult to source products that meet these nuanced requirements.

The Solution: To overcome this limitation, buyers should prioritize suppliers who offer customizable solutions. Engaging in open discussions about specific project needs can lead to collaborative product development. It’s advisable to request detailed portfolios from suppliers showcasing previous custom projects and to inquire about their capacity for bespoke orders. Establishing a clear communication channel with the supplier’s design team can ensure that all specifications are accurately captured and implemented.

Scenario 3: High Costs and Budget Constraints

The Problem: Cost is a critical concern for B2B buyers, especially in competitive markets. Many buyers encounter inflated pricing from artificial turf suppliers, which can strain budgets and limit project feasibility. This issue is particularly pronounced in regions like Europe and South America, where economic fluctuations can impact purchasing power and project funding.

The Solution: Buyers can address high costs by exploring multiple sourcing strategies. This includes comparing quotes from various suppliers, considering bulk purchasing options, and negotiating long-term contracts that may offer discounts. Additionally, buyers should evaluate the total cost of ownership, which encompasses installation, maintenance, and lifespan, rather than focusing solely on initial purchase price. Investing in higher-quality turf may yield better long-term savings despite a higher upfront cost. Engaging with local distributors or suppliers who understand regional pricing can also provide access to more competitive rates, ensuring the project stays within budget.

Strategic Material Selection Guide for artificial turf supplier

When selecting materials for artificial turf, various factors influence the performance, durability, and overall suitability of the product for different applications. Below, we analyze four common materials used in artificial turf, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polyethylene in Artificial Turf?

Polyethylene (PE) is one of the most widely used materials in artificial turf production. Its key properties include excellent UV resistance, flexibility, and a temperature rating that can withstand varying climates. PE fibers are designed to mimic natural grass, providing a soft feel underfoot while maintaining durability.

Pros & Cons: The primary advantage of polyethylene is its durability and resistance to wear, making it suitable for high-traffic areas such as sports fields. However, it can be more expensive than other materials, which may deter budget-conscious buyers. Additionally, while PE is generally resistant to corrosion, it can be susceptible to heat degradation in extremely high temperatures.

Impact on Application: Polyethylene is compatible with a wide range of infill materials, enhancing drainage and performance. It is particularly favored in regions with moderate climates but may require additional considerations in hotter areas.

Considerations for International Buyers: Buyers in Europe, such as Italy and Poland, should ensure compliance with EU standards for environmental safety. In Africa and the Middle East, understanding local climate conditions is crucial for selecting the right type of polyethylene.

How Does Nylon Perform as a Material for Artificial Turf?

Nylon is known for its strength and resilience, making it another popular choice for artificial turf. Its key properties include high tensile strength and excellent abrasion resistance, which contribute to its longevity in high-use areas.

Pros & Cons: The main advantage of nylon is its ability to retain its shape and withstand heavy foot traffic, making it ideal for sports fields and playgrounds. However, nylon tends to be more expensive than polyethylene and requires complex manufacturing processes, which can increase overall costs.

Impact on Application: Nylon is particularly effective in applications requiring high durability, such as multi-sport facilities. Its compatibility with various infill materials allows for customization based on specific performance needs.

Considerations for International Buyers: Buyers should be aware of compliance with ASTM standards, especially in regions like Europe and North America. In South America, cost factors may significantly influence the choice of nylon due to its higher price point.

What Are the Benefits of Polypropylene in Artificial Turf?

Polypropylene (PP) is a cost-effective alternative used in artificial turf applications. Its key properties include lightweight design and good chemical resistance, making it suitable for various environments.

Pros & Cons: The primary advantage of polypropylene is its lower cost compared to PE and nylon, making it an attractive option for budget-sensitive projects. However, it is less durable and can wear down more quickly under heavy use, which may limit its application in high-traffic areas.

Impact on Application: Polypropylene is often used in residential applications or lower-traffic commercial settings. Its compatibility with various infill options allows for customization, but it may not perform well in extreme weather conditions.

Considerations for International Buyers: Buyers in Africa and South America may find polypropylene appealing due to its affordability, but they should consider the trade-off in durability. Compliance with local regulations regarding material safety is also essential.

How Does the Use of Natural Fiber Blends Affect Artificial Turf?

Natural fiber blends, often incorporating materials like coconut coir or bamboo, are gaining popularity for their eco-friendly properties. These materials offer unique benefits, including biodegradability and a natural appearance.

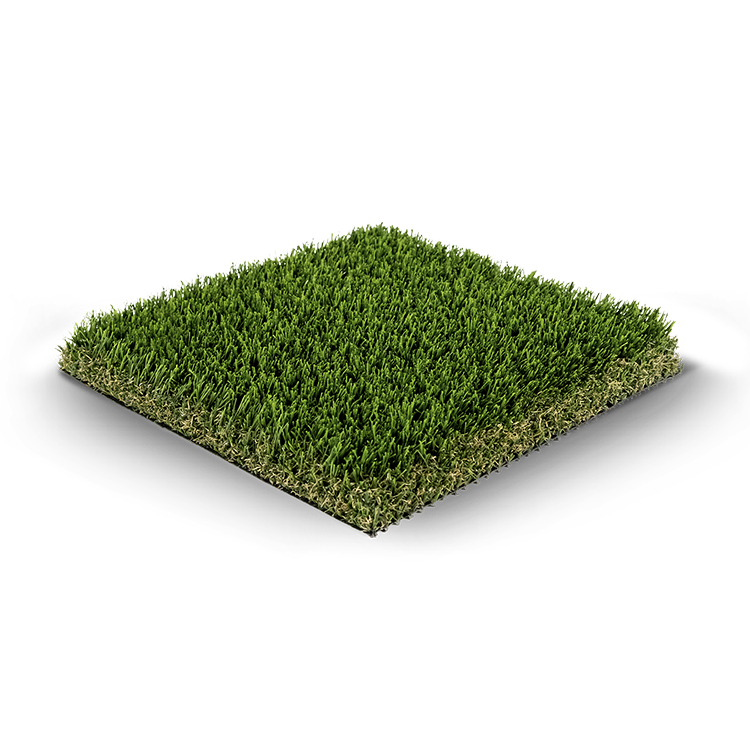

A stock image related to artificial turf supplier.

Pros & Cons: The main advantage of natural fiber blends is their sustainability and aesthetic appeal. However, they can be less durable than synthetic options, leading to higher maintenance costs over time.

Impact on Application: Natural fiber blends are suitable for residential lawns and recreational areas where aesthetics are prioritized over heavy use. They may require specific maintenance practices to ensure longevity.

Considerations for International Buyers: Buyers in Europe may be particularly interested in sustainable options due to increasing environmental regulations. Understanding local preferences for eco-friendly materials can influence purchasing decisions.

Summary Table of Material Selection for Artificial Turf

| Material | Typical Use Case for artificial turf supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Sports fields, high-traffic areas | Durable and UV resistant | Higher cost, heat degradation risk | Medium |

| Nylon | Multi-sport facilities, playgrounds | High strength and shape retention | Expensive, complex manufacturing | High |

| Polypropylene | Residential lawns, low-traffic areas | Cost-effective | Less durable, wears down quickly | Low |

| Natural Fiber Blends | Residential lawns, eco-friendly projects | Sustainable and aesthetically pleasing | Less durable, higher maintenance costs | Medium |

This strategic material selection guide aims to equip international B2B buyers with the insights needed to make informed decisions when sourcing artificial turf materials, considering both performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for artificial turf supplier

What Are the Key Stages in the Manufacturing Process of Artificial Turf?

The manufacturing of artificial turf involves several critical stages, each designed to ensure the final product meets stringent quality and performance standards. Understanding these processes is essential for B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, where the demand for high-quality turf is on the rise.

1. Material Preparation

The first stage of manufacturing artificial turf is material preparation. This involves sourcing high-quality raw materials, primarily polyethylene, polypropylene, and nylon fibers. The suppliers should focus on obtaining UV-resistant materials to ensure longevity, especially in regions with high sunlight exposure.

Additionally, the backing material, usually made from a combination of polyurethane or latex, is prepared at this stage. Buyers should inquire about the sourcing of these materials, as the quality and sustainability of raw materials can significantly influence the overall durability and environmental footprint of the turf.

2. Forming the Turf

Once materials are prepared, the next step is forming the turf. This process involves tufting, where yarn is inserted into the backing material using specialized tufting machines. The density of the tufting and the height of the fibers are crucial factors that impact the appearance and performance of the turf.

For buyers, understanding the tufting density is vital, as a higher density typically indicates a more durable product. It’s also important to ask suppliers about the machinery used in this process, as advanced technology can enhance consistency and quality.

3. Assembly and Coating

After tufting, the artificial turf undergoes an assembly process, where additional layers may be added for stability and durability. This often includes applying a secondary backing to enhance the turf’s overall strength. The coating stage is where a layer of adhesive is applied to secure the fibers and backing.

Buyers should assess the types of adhesives used, ensuring they are environmentally friendly and meet safety standards. Suppliers should provide detailed information about the assembly techniques and the materials involved to ensure compliance with international regulations.

4. Finishing Touches

The final stage in the manufacturing process is finishing. This involves cutting the turf to size, adding infill materials (like silica sand or rubber granules), and conducting a quality check to ensure all specifications are met. The finishing touches greatly affect the turf’s performance characteristics, such as drainage, cushioning, and overall aesthetics.

B2B buyers should request samples of the finished product to evaluate texture, color, and performance before making a purchase.

How Is Quality Assurance Implemented in Artificial Turf Manufacturing?

Quality assurance (QA) is a critical component of the artificial turf manufacturing process. It ensures that the products meet both international and industry-specific standards, providing buyers with confidence in their purchases.

What Are the Relevant International Standards for Artificial Turf?

International standards such as ISO 9001 play a significant role in quality assurance for artificial turf suppliers. ISO 9001 focuses on quality management systems and helps organizations ensure they meet customer and regulatory requirements.

In addition to ISO, various industry-specific certifications, such as CE marking (for compliance with European health, safety, and environmental protection standards) and API (American Petroleum Institute) certification, may also be relevant, depending on the turf’s intended use.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to maintain high standards. Common QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During production, continuous monitoring is conducted to identify and rectify defects in real-time.

- Final Quality Control (FQC): Before shipping, a thorough examination of the finished product is conducted to ensure it meets all quality specifications.

B2B buyers should inquire about the frequency and procedures for these QC checkpoints to assess the supplier’s commitment to quality.

What Common Testing Methods Are Used?

Testing methods for artificial turf can include:

- Durability Testing: Measures the turf’s resistance to wear and tear.

- UV Resistance Testing: Evaluates how well the turf withstands sun exposure.

- Fire Resistance Testing: Ensures the turf meets fire safety standards.

Suppliers should be able to provide test reports and certifications that demonstrate compliance with these testing protocols.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for international B2B buyers. Here are several strategies to ensure that the supplier adheres to high standards:

-

Conducting Supplier Audits: Regular audits can help assess the supplier’s manufacturing processes and quality assurance measures. Buyers can request to participate in or review audit reports.

-

Requesting Quality Assurance Reports: Suppliers should provide documentation that outlines their QA processes, including any certifications or test results.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures and product compliance.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must be aware of specific quality control nuances that may affect their purchasing decisions:

-

Cultural and Regulatory Differences: Different regions may have varying standards and expectations regarding quality. Buyers should familiarize themselves with local regulations that may impact turf installation and use.

-

Supply Chain Considerations: Understanding the supplier’s supply chain can help identify potential risks related to material sourcing and logistics, which can affect quality and delivery timelines.

-

Communication Barriers: Language differences can lead to misunderstandings regarding specifications and quality requirements. Establishing clear communication channels is essential for successful transactions.

Conclusion

Understanding the manufacturing processes and quality assurance measures of artificial turf suppliers is crucial for B2B buyers, especially from diverse regions like Africa, South America, the Middle East, and Europe. By focusing on material preparation, forming, assembly, finishing, and stringent quality control measures, buyers can make informed decisions that align with their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘artificial turf supplier’

Introduction

In the competitive landscape of artificial turf procurement, having a structured approach is essential for international B2B buyers. This checklist will guide you through the critical steps to ensure you partner with a reliable and quality artificial turf supplier. By following these steps, you can mitigate risks, enhance product quality, and ensure a successful procurement process tailored to your specific needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clarify your technical requirements for artificial turf. This includes understanding the intended use, whether for sports, landscaping, or playgrounds, and determining factors such as pile height, fiber type, and infill materials. Clearly defined specifications will help you communicate effectively with suppliers and ensure the product meets your expectations.

Step 2: Conduct Market Research on Suppliers

Research potential suppliers in your target regions, such as Africa, South America, the Middle East, and Europe. Look for companies with a strong reputation and positive reviews from previous clients. Utilize industry forums, trade shows, and online platforms to gather insights on supplier performance and market trends. This foundational knowledge will assist you in making informed decisions.

Step 3: Evaluate Supplier Certifications and Compliance

Ensure that potential suppliers possess relevant certifications, such as ISO quality standards and environmental compliance (e.g., REACH, RoHS). These certifications indicate a commitment to quality and sustainability, which are crucial for long-term partnerships. Inquire about their manufacturing processes and quality control measures to verify compliance with your region’s regulations.

Step 4: Request Samples and Product Specifications

Once you have shortlisted suppliers, request product samples to evaluate quality firsthand. Examine the durability, appearance, and feel of the turf. Additionally, ask for detailed product specifications, including warranty information and maintenance requirements. This step will allow you to compare offerings and make a more informed choice.

Step 5: Assess Pricing and Payment Terms

Obtain detailed quotes from multiple suppliers to assess pricing structures. Be aware that the cheapest option may not always provide the best value; consider factors such as quality, delivery times, and after-sales support. Clarify payment terms and conditions to avoid misunderstandings later in the procurement process.

Step 6: Check References and Past Projects

Request references from previous clients and case studies of similar projects completed by the supplier. This will give you insights into their reliability and customer service. Pay attention to feedback regarding the supplier’s ability to meet deadlines, product quality, and responsiveness to issues that may arise.

Step 7: Negotiate Contract Terms

Once you have selected a supplier, negotiate the contract terms carefully. Ensure that all aspects of the agreement are clearly defined, including delivery schedules, payment milestones, and warranty conditions. A well-structured contract protects both parties and establishes a framework for a successful business relationship.

By following this practical sourcing guide, B2B buyers can navigate the complexities of procuring artificial turf effectively, ensuring they select a supplier that meets their specific needs and expectations.

Comprehensive Cost and Pricing Analysis for artificial turf supplier Sourcing

What Are the Key Cost Components in Artificial Turf Supplier Sourcing?

When sourcing artificial turf, understanding the cost structure is crucial for international B2B buyers. The primary cost components can be categorized as follows:

-

Materials: The quality of raw materials, such as polyethylene or polypropylene fibers, significantly impacts pricing. High-quality, UV-resistant materials typically carry a higher price but offer longer durability.

-

Labor: Labor costs vary by region. Countries with lower labor costs may present more competitive pricing, but it is essential to consider the skill level and expertise of the workforce involved in the manufacturing process.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient production processes can reduce overheads, which can be reflected in the final price.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. Buyers should assess the necessity of these costs based on their specific requirements.

-

Quality Control (QC): Rigorous QC processes ensure that the artificial turf meets industry standards and regulations. Suppliers with robust QC measures may charge higher prices, but this can lead to fewer defects and lower warranty claims.

-

Logistics: Transportation costs can vary widely based on the distance from the supplier and the mode of transport. Buyers should factor in these logistics costs when evaluating supplier pricing.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Understanding how margins fluctuate with volume can aid in negotiations.

How Do Price Influencers Impact Artificial Turf Costs?

Several factors can influence the pricing of artificial turf, which international buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for bulk orders. Understanding the MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Custom turf solutions tailored to specific projects may incur additional costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO) can increase costs but also enhance product reliability and safety. Buyers should weigh the benefits against the costs.

-

Supplier Factors: The supplier’s reputation, experience, and production capacity can affect pricing. Established suppliers may charge more due to their reliability and service levels.

-

Incoterms: The agreed-upon Incoterms dictate who is responsible for shipping and insurance costs. Buyers should understand these terms to avoid hidden fees.

What Are the Best Buyer Tips for Cost Efficiency in Artificial Turf Sourcing?

To maximize cost efficiency when sourcing artificial turf, consider the following strategies:

-

Negotiate Wisely: Always engage in price negotiations. Be prepared to discuss volume, payment terms, and delivery schedules, which can all influence the final price.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase prices, consider the TCO, which includes installation, maintenance, and potential replacement costs. A slightly higher upfront cost may result in long-term savings.

-

Understand Pricing Nuances for International Markets: Different regions may have varying pricing structures due to local demand, import tariffs, and currency fluctuations. Buyers from Africa, South America, the Middle East, and Europe (e.g., Italy, Poland) should conduct thorough market research.

-

Request Detailed Quotes: Ensure that suppliers provide detailed quotes that break down all costs. This transparency can help in comparing offers from different suppliers and understanding pricing variances.

-

Stay Updated on Market Trends: Monitor industry trends and pricing fluctuations. Being informed about market conditions can provide leverage during negotiations.

Conclusion

Understanding the comprehensive cost structure and pricing dynamics of artificial turf sourcing is essential for international B2B buyers. By focusing on key cost components, price influencers, and strategic negotiation tips, buyers can make informed decisions that align with their project needs and budget constraints. Always consider the indicative nature of prices and conduct thorough due diligence before finalizing supplier agreements.

Alternatives Analysis: Comparing artificial turf supplier With Other Solutions

Understanding Alternatives to Artificial Turf Suppliers

When considering the procurement of artificial turf, international B2B buyers must evaluate not only the product itself but also alternative solutions that may better meet their specific needs. This section explores two prominent alternatives to artificial turf: natural grass and hybrid grass systems. Each option presents distinct advantages and challenges, making it essential for buyers to understand how they compare in various aspects such as performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table of Artificial Turf and Alternatives

| Comparison Aspect | Artificial Turf Supplier | Natural Grass | Hybrid Grass System |

|---|---|---|---|

| Performance | High durability; consistent playability | Variable; affected by weather and usage | Good durability; combines strengths of both |

| Cost | Higher initial investment, lower long-term maintenance | Lower initial cost, higher long-term maintenance | Moderate cost; balance of initial and ongoing expenses |

| Ease of Implementation | Quick installation; minimal site preparation required | Longer installation time; requires soil preparation | Moderate installation time; requires specialized knowledge |

| Maintenance | Low maintenance; occasional cleaning required | High maintenance; regular mowing, watering, and fertilizing | Moderate maintenance; requires some upkeep but less than natural grass |

| Best Use Case | Sports fields, commercial areas, residential landscaping | Residential lawns, parks, and gardens | High-traffic sports fields, areas needing resilience |

What Are the Advantages and Disadvantages of Natural Grass?

Natural grass is often favored for its aesthetic appeal and environmental benefits. It offers a softer playing surface, which can be advantageous in recreational settings. However, it requires significant maintenance, including regular watering, mowing, and fertilization, which can lead to higher long-term costs. Additionally, natural grass performance can suffer due to adverse weather conditions, making it less reliable for consistent use in various climates found in Africa, South America, the Middle East, and Europe.

How Does a Hybrid Grass System Compare?

Hybrid grass systems combine natural grass with synthetic fibers, providing a balance between durability and natural aesthetics. This system is particularly beneficial in regions with high foot traffic, as it offers improved resilience and playability compared to traditional natural grass. While the initial installation costs are moderate, buyers must still consider the ongoing maintenance requirements, which are typically lower than natural grass but higher than fully synthetic options. This makes hybrid grass an appealing choice for sports facilities looking to maximize usage without compromising quality.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right turf solution depends on various factors, including budget constraints, intended use, and regional climate conditions. B2B buyers should conduct a thorough needs assessment, considering both short-term and long-term implications of their choice. Engaging with suppliers for detailed proposals and conducting site visits can provide invaluable insights into which option—artificial turf, natural grass, or hybrid systems—will best serve their specific requirements. By weighing the pros and cons of each alternative, buyers can make informed decisions that enhance their investment in landscaping or sports infrastructure.

Essential Technical Properties and Trade Terminology for artificial turf supplier

What Are the Key Technical Properties of Artificial Turf?

When sourcing artificial turf, understanding its technical properties is crucial for ensuring product quality and performance. Here are several critical specifications that B2B buyers should consider:

1. Material Grade

Material grade refers to the quality and type of fibers used in the artificial turf. Common materials include polyethylene, polypropylene, and nylon. Each material offers different durability, appearance, and feel. For instance, polyethylene is often chosen for its softness and resilience, making it suitable for residential lawns and sports fields. Knowing the material grade helps buyers select turf that meets their specific application needs, whether it’s for landscaping or athletic use.

2. Pile Height

Pile height is the length of the grass blades and significantly impacts the aesthetic and functional properties of the turf. Typical pile heights range from 20mm to 60mm, with shorter blades providing a denser look suitable for high-traffic areas and longer blades offering a more realistic appearance. Buyers should assess the intended use and traffic levels to choose an appropriate pile height that balances realism and durability.

3. Infill Type and Depth

Infill is the material placed between the turf fibers to provide stability, cushioning, and support. Common infill materials include sand, rubber, and organic options. The depth of infill also varies and can affect drainage and performance. For example, rubber infill offers shock absorption, making it ideal for sports applications. Understanding infill types and their depths is essential for ensuring the longevity and functionality of the turf.

4. UV Stabilization

UV stabilization refers to the treatment applied to turf fibers to resist fading and degradation caused by sun exposure. This property is particularly important for regions with high sunlight exposure, such as Africa and the Middle East. Turf with adequate UV stabilization will maintain its color and integrity over time, reducing the need for replacements and ensuring a longer lifespan.

5. Drainage Capability

The drainage capability of artificial turf is critical, especially in areas prone to heavy rainfall. Proper drainage systems, such as perforated backing and drainage holes, prevent water pooling and ensure quick drying. Buyers should inquire about the drainage specifications to ensure optimal performance in various weather conditions.

What Are Common Trade Terms Used in the Artificial Turf Industry?

Understanding industry terminology can greatly enhance communication and negotiation with suppliers. Here are several common trade terms relevant to artificial turf procurement:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces products that are sold under another company’s brand. In the artificial turf industry, OEMs can provide customized products tailored to specific needs. Understanding OEM relationships can help buyers negotiate better terms and ensure product quality.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of product that a supplier is willing to sell. This is a critical consideration for buyers, particularly for smaller projects or companies. Knowing the MOQ can help businesses manage inventory and budget effectively, avoiding excess costs.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. It is essential for comparing offers and ensuring transparency in procurement. Buyers should prepare detailed RFQs to receive accurate and competitive quotes from potential suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Familiarity with Incoterms helps buyers understand shipping costs and liabilities, facilitating smoother international trade.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the products. Understanding lead times is crucial for project planning and ensuring timely delivery. Buyers should communicate their timelines clearly to suppliers to avoid delays in project execution.

By comprehensively understanding these technical properties and trade terminologies, international B2B buyers can make informed decisions and foster successful partnerships in the artificial turf industry.

Navigating Market Dynamics and Sourcing Trends in the artificial turf supplier Sector

What Are the Current Market Dynamics and Key Trends in the Artificial Turf Supplier Sector?

The artificial turf market is witnessing significant transformation, driven by several global factors. Increasing urbanization and the rising demand for low-maintenance landscaping solutions have propelled the need for artificial turf in various applications, including sports fields, residential areas, and commercial spaces. Emerging B2B technologies, such as advanced manufacturing processes and digital procurement platforms, are streamlining sourcing strategies. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe (notably Italy and Poland), should stay informed about these technological advancements to enhance their procurement efficiency.

Sourcing trends are also shifting towards customization and innovation. Suppliers are increasingly offering tailored solutions that cater to the unique needs of different markets. For instance, African buyers may seek products that withstand higher temperatures and arid conditions, while European buyers might focus on aesthetics and eco-friendliness. Additionally, the integration of smart technology in artificial turf, such as embedded sensors for monitoring wear and tear, is becoming a crucial consideration for buyers looking to optimize long-term investments.

How Does Sustainability and Ethical Sourcing Impact the Artificial Turf Supplier Industry?

Sustainability is a growing concern within the artificial turf sector, influencing both sourcing strategies and consumer preferences. International B2B buyers are increasingly prioritizing suppliers who adhere to environmentally sustainable practices. This includes the use of recycled materials in turf production and the implementation of energy-efficient manufacturing processes. Buyers from regions such as Europe, known for stringent environmental regulations, are particularly focused on sourcing products that align with these standards.

The importance of ethical supply chains cannot be overstated. Buyers should seek suppliers that are transparent about their sourcing practices, ensuring that materials are obtained responsibly and labor standards are upheld. Certifications such as the Global Recycled Standard (GRS) and the Cradle to Cradle Certified™ mark are essential indicators of a supplier’s commitment to sustainability. By prioritizing these certifications, B2B buyers can not only enhance their brand reputation but also contribute to a more sustainable future.

What Is the Evolution of the Artificial Turf Supplier Sector?

The artificial turf industry has evolved significantly over the past few decades. Initially, artificial turf was primarily used for sports fields, but its applications have expanded dramatically. The development of more advanced materials has led to the creation of softer, more durable, and realistic-looking turf, allowing it to be utilized in various sectors, including residential landscaping and playgrounds.

As market demands shifted, suppliers began to innovate, focusing on eco-friendly materials and sustainable production methods. This evolution reflects a broader trend in the B2B landscape, where buyers are increasingly looking for products that not only meet performance standards but also align with their values regarding environmental sustainability and ethical sourcing. Understanding this historical context can aid international buyers in making informed decisions that support both their operational needs and corporate social responsibility goals.

Frequently Asked Questions (FAQs) for B2B Buyers of artificial turf supplier

-

How do I choose the right artificial turf supplier for my project?

Choosing the right artificial turf supplier involves several key factors. First, assess their experience in the industry and their reputation among previous clients. Look for suppliers with a proven track record in delivering quality products that meet international standards. It’s also important to evaluate their product range to ensure they offer the specific type of turf suitable for your needs, whether for sports, landscaping, or recreational use. Finally, consider logistical capabilities, including delivery times and customer service support, especially if you are sourcing from regions like Africa, South America, or the Middle East. -

What are the key features to look for in artificial turf products?

When evaluating artificial turf products, key features to consider include durability, UV resistance, and infill material. Ensure the turf is designed to withstand varying weather conditions, especially in regions with extreme climates. Look for products that are non-toxic and environmentally friendly, which is increasingly important in markets such as Europe. Additionally, consider the pile height and density, as these factors influence the turf’s appearance and feel. A reputable supplier should provide detailed specifications and certifications to support their claims. -

What are the typical minimum order quantities (MOQ) for artificial turf?

Minimum order quantities (MOQ) for artificial turf can vary widely among suppliers, typically ranging from 100 to 500 square meters. Factors influencing MOQ include the supplier’s production capabilities, the type of turf, and the customization options you may require. For international buyers, it’s crucial to discuss MOQs upfront, as larger orders may lead to better pricing and favorable payment terms. Additionally, consider your project’s scale to determine whether the MOQ aligns with your requirements. -

How can I ensure quality assurance (QA) when sourcing artificial turf?

To ensure quality assurance when sourcing artificial turf, request samples before committing to a large order. Evaluate the materials used, construction methods, and overall finish. It’s also advisable to check for third-party certifications that verify the turf meets industry standards for durability and safety. Establish clear quality control processes with your supplier, including regular inspections during production and pre-shipment checks. This proactive approach can mitigate risks associated with quality discrepancies. -

What payment terms should I expect from artificial turf suppliers?

Payment terms can vary significantly based on the supplier’s policies and your negotiating power. Common arrangements include a deposit upon order confirmation, followed by the balance before shipment. For larger orders, suppliers may offer more flexible terms, such as extended payment periods or installment options. It’s essential to clarify payment terms upfront to avoid misunderstandings. International buyers should also consider currency fluctuations and transaction fees, especially when dealing with suppliers from different regions. -

How does logistics impact the sourcing of artificial turf internationally?

Logistics plays a critical role in the international sourcing of artificial turf. Factors such as shipping methods, delivery times, and customs clearance can significantly affect your project timeline. When selecting a supplier, inquire about their logistics capabilities and partnerships with shipping companies. It’s also wise to understand the import regulations and duties in your country to avoid unexpected costs. A reliable supplier should provide transparent information regarding shipping options and tracking capabilities. -

Can I customize the artificial turf according to my specifications?

Yes, many artificial turf suppliers offer customization options to meet specific project requirements. This may include variations in color, texture, pile height, and even branding elements for commercial applications. When discussing customization, provide detailed specifications and examples of what you envision. Keep in mind that custom orders may have higher MOQs and longer lead times. Ensure that the supplier can accommodate your needs without compromising quality.

A stock image related to artificial turf supplier.

- What are the best practices for maintaining artificial turf after installation?

Maintaining artificial turf is essential for longevity and aesthetics. Regular maintenance practices include brushing the turf to prevent matting, rinsing to remove debris, and checking for any signs of damage. It’s advisable to schedule periodic deep cleanings, especially in high-traffic areas. Additionally, be mindful of the infill material and replenish it as needed to maintain the turf’s performance. Establishing a maintenance plan with your supplier can help ensure the turf remains in optimal condition throughout its lifespan.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for artificial turf supplier

What Are the Key Takeaways for B2B Buyers in Artificial Turf Sourcing?

In conclusion, strategic sourcing of artificial turf is essential for international B2B buyers aiming to enhance their competitive edge. By leveraging data-driven insights, buyers can identify reliable suppliers, negotiate favorable terms, and ensure compliance with local regulations. The importance of quality assurance cannot be overstated; investing in high-grade materials not only reduces long-term costs but also enhances customer satisfaction and brand reputation.

How Can Buyers Prepare for Future Trends in Artificial Turf?

As the market evolves, staying ahead of trends such as sustainability and technological advancements will be crucial. Buyers from Africa, South America, the Middle East, and Europe, including regions like Italy and Poland, should actively seek suppliers who prioritize eco-friendly practices and innovative solutions. This proactive approach will not only meet growing consumer demands but also align with global sustainability goals.

What Steps Should International B2B Buyers Take Now?

To capitalize on these opportunities, it’s imperative for buyers to engage with multiple suppliers, conduct thorough market research, and build strategic partnerships. By doing so, they can foster a resilient supply chain capable of adapting to market fluctuations.

In this dynamic landscape, now is the time to take action. Equip your organization with the knowledge and resources necessary to make informed sourcing decisions that will drive growth and success in the artificial turf industry.