Discover Top Benefits of Electric Generator Manufacturers (2025)

Introduction: Navigating the Global Market for electric generator manufacturer

Navigating the complexities of sourcing electric generators can be a daunting task for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. With a wide array of manufacturers, varying technologies, and a multitude of applications—from industrial use to emergency backup power—the challenge lies not just in finding a reliable supplier, but also in understanding the specific needs of your operations. This comprehensive guide is designed to empower decision-makers by providing actionable insights into the global market for electric generator manufacturers.

Within this guide, you will discover the diverse types of electric generators available, including diesel, gas, and renewable energy options, along with their specific applications across different industries. We will delve into essential factors for supplier vetting, helping you assess the credibility and reliability of potential partners. Additionally, we’ll cover cost considerations, ensuring you can balance quality and budget effectively.

By equipping international B2B buyers with the knowledge to make informed purchasing decisions, this guide aims to simplify the process of sourcing electric generators. Whether you are a procurement manager in Brazil looking for a robust solution to power your operations or a business owner in France seeking sustainable energy options, you will find valuable insights tailored to your needs. Embrace the opportunity to enhance your purchasing strategy and ensure the success of your projects in a competitive global market.

Understanding electric generator manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Diesel Generators | Robust, fuel-efficient, and reliable | Construction sites, mining, and remote areas | Pros: High durability; Cons: Noise pollution and emissions. |

| Natural Gas Generators | Cleaner energy source, lower emissions | Industrial plants, commercial buildings | Pros: Environmentally friendly; Cons: Higher initial costs. |

| Portable Generators | Lightweight, easy to transport | Events, small businesses, emergency backup | Pros: Versatile and mobile; Cons: Limited power output. |

| Hybrid Generators | Combines diesel or gas with renewable sources | Off-grid locations, military applications | Pros: Fuel efficiency; Cons: Complexity in maintenance. |

| Solar Generators | Utilizes solar panels for power generation | Remote areas, eco-friendly projects | Pros: Renewable and sustainable; Cons: Dependent on sunlight. |

What are the Key Characteristics of Diesel Generators?

Diesel generators are known for their robustness and reliability, making them a preferred choice for demanding environments such as construction sites and mining operations. They are fuel-efficient, often providing a lower cost-per-kilowatt compared to other types. When considering diesel generators, B2B buyers should evaluate factors such as fuel availability, maintenance requirements, and noise regulations in their operating regions. Their durability is a significant advantage, but buyers should also be aware of the environmental implications, including emissions and noise pollution.

How Do Natural Gas Generators Stand Out?

Natural gas generators are increasingly favored for their cleaner emissions and efficiency. They are particularly suitable for industrial plants and commercial buildings that require a steady and reliable power supply. B2B buyers considering natural gas generators should assess the infrastructure for natural gas supply, as well as potential savings on fuel costs over time. Although they often come with higher upfront costs, their environmental benefits and operational efficiency can lead to long-term savings and compliance with stricter environmental regulations.

What Makes Portable Generators a Practical Choice?

Portable generators offer versatility and mobility, making them ideal for events, small businesses, and emergency backup. Their lightweight design allows for easy transport, which is a crucial factor for B2B buyers who need temporary power solutions. However, it’s important to note that portable generators typically have limited power output, which can restrict their applications. Buyers should consider their specific power needs and the generator’s runtime, as well as the type of fuel it uses, to ensure that it meets their operational requirements.

Why Consider Hybrid Generators for Your Business?

Hybrid generators combine traditional fuel sources with renewable energy, providing a more sustainable power solution. They are particularly advantageous for off-grid locations and military applications where fuel efficiency is paramount. B2B buyers interested in hybrid generators should evaluate the complexity of their maintenance and the initial investment required. While they offer improved fuel efficiency and reduced emissions, understanding the technology behind hybrid systems is crucial for ensuring reliable performance in various conditions.

How Do Solar Generators Fit into the B2B Landscape?

Solar generators harness solar energy to provide power, making them an eco-friendly option for businesses operating in remote areas or those committed to sustainability. They are particularly suitable for projects that prioritize renewable energy sources. However, B2B buyers must consider the dependence on sunlight and potential limitations during cloudy weather. Evaluating the initial setup costs versus long-term savings on fuel and maintenance is essential for making an informed purchasing decision. As technology advances, solar generators are becoming more efficient, making them a viable option for a growing number of businesses.

Related Video: How To Produce Huge Motor And Generator | Production Of Electric Machines

Key Industrial Applications of electric generator manufacturer

| Industry/Sector | Specific Application of electric generator manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Site Power Generation | Ensures continuous power supply for tools and equipment | Durability, fuel efficiency, and noise levels |

| Healthcare | Backup Power Systems | Maintains critical operations during outages | Compliance with health regulations and reliability |

| Agriculture | Irrigation and Livestock Management | Powers irrigation systems and farm machinery | Fuel type, output capacity, and maintenance support |

| Telecommunications | Network Operations | Supports data centers and telecom infrastructure | Scalability, energy efficiency, and remote monitoring |

| Manufacturing | Production Line Power Supply | Minimizes downtime and enhances productivity | Customization options and service agreements |

How is Electric Generator Manufacturing Used in Construction?

In the construction industry, electric generators are crucial for providing power to tools and machinery on-site. These generators ensure that operations run smoothly, even in remote locations where grid power is unavailable. For international buyers, especially in regions like Africa and South America, sourcing generators with high durability and fuel efficiency is vital, as these factors significantly impact operational costs. Additionally, noise levels should be considered to comply with local regulations and minimize disturbances in residential areas.

What Role Do Electric Generators Play in Healthcare Facilities?

Electric generators serve as backup power systems in healthcare facilities, ensuring that critical operations remain uninterrupted during power outages. This is particularly important in hospitals, where life-saving equipment must remain operational at all times. International B2B buyers in the healthcare sector must prioritize generators that meet stringent health regulations and offer high reliability. Additionally, understanding the specific power requirements of medical devices is essential for effective sourcing.

How are Electric Generators Beneficial in Agriculture?

In agriculture, electric generators are employed to power irrigation systems and various farm machinery, ensuring efficient water management and crop production. They are particularly valuable in regions with inconsistent power supply, such as parts of Africa and South America. Buyers in this sector should consider fuel types, output capacity, and the availability of maintenance support when selecting generators. These factors directly affect the generator’s performance and the agricultural operation’s overall efficiency.

Why are Electric Generators Essential for Telecommunications?

Telecommunication companies rely on electric generators to support network operations, including data centers and cell towers. Generators provide backup power to ensure uninterrupted service, which is crucial for maintaining customer satisfaction and operational integrity. For international buyers in the Middle East and Europe, sourcing generators that offer scalability and energy efficiency is essential, especially as demand for data services continues to grow. Remote monitoring capabilities can also enhance operational oversight.

How Do Electric Generators Enhance Manufacturing Processes?

In the manufacturing sector, electric generators are used to supply power to production lines, minimizing downtime and enhancing overall productivity. A consistent power supply is essential for maintaining manufacturing schedules and meeting delivery deadlines. Buyers from Europe and South America should look for generators with customization options to fit specific operational needs, as well as service agreements that ensure ongoing support and maintenance. This approach helps mitigate risks associated with power interruptions and equipment failures.

Related Video: How it Works – Thermoelectric Generator

3 Common User Pain Points for ‘electric generator manufacturer’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance for Generators

The Problem: For B2B buyers in regions such as Africa and the Middle East, compliance with local regulations can be a significant hurdle when purchasing electric generators. Different countries have unique standards concerning emissions, noise levels, and safety requirements. Failure to adhere to these regulations can lead to costly fines or delays in project timelines, complicating procurement processes and potentially damaging business reputations.

The Solution: To effectively navigate regulatory compliance, international buyers should begin by conducting thorough research on the specific regulations applicable in their target markets. Collaborating with local consultants or legal experts can provide insights into compliance requirements. Additionally, when sourcing from manufacturers, look for companies that have a proven track record of adhering to local standards and certifications. Request detailed documentation of compliance certifications from potential suppliers and consider manufacturers that offer generators designed to meet or exceed these local regulations. This proactive approach not only ensures compliance but also builds trust with local stakeholders.

Scenario 2: Managing Power Capacity and Reliability Issues

The Problem: Many businesses, particularly in South America and Africa, face challenges with unreliable power supply and the need for generators that can handle variable loads. This is crucial for industries such as construction, mining, and agriculture, where power interruptions can lead to substantial financial losses and operational inefficiencies. Buyers often struggle to determine the appropriate generator size and capacity to meet their specific energy demands.

The Solution: To address capacity and reliability issues, buyers should conduct a comprehensive energy audit to assess their power needs accurately. This involves evaluating peak load demands, daily usage patterns, and potential future expansions. Armed with this information, engage with electric generator manufacturers that offer customizable solutions tailored to specific requirements. Opt for manufacturers that provide load management systems and advanced technology, such as automatic voltage regulation (AVR) and real-time monitoring, to enhance reliability. Ensuring the generator has the ability to handle peak loads will mitigate disruptions and improve overall operational efficiency.

Scenario 3: Cost Management and Total Cost of Ownership (TCO)

The Problem: International B2B buyers frequently grapple with understanding the total cost of ownership (TCO) of electric generators, which extends beyond the initial purchase price. Factors such as fuel consumption, maintenance costs, and the lifespan of the generator can significantly impact the long-term financial viability of the investment. In regions with fluctuating fuel prices, like Europe and parts of Africa, these costs can vary widely, leading to budget overruns.

The Solution: To manage costs effectively, buyers should engage in a comprehensive TCO analysis before making a purchase. This includes calculating not only the upfront costs but also estimating operational expenses over the generator’s lifecycle. Seek out manufacturers that offer energy-efficient models and provide data on fuel consumption rates and maintenance schedules. Moreover, consider generators that come with extended warranties or service packages that can help mitigate long-term costs. Establishing a relationship with suppliers for ongoing maintenance support and spare parts availability will also ensure that the generator operates efficiently, further minimizing TCO and enhancing the return on investment.

Strategic Material Selection Guide for electric generator manufacturer

When selecting materials for electric generator manufacturing, it is crucial to consider not only the performance characteristics of the materials but also their suitability for specific applications and compliance with international standards. Below, we analyze four common materials used in the industry, highlighting their properties, advantages, disadvantages, and considerations for international buyers, particularly from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Steel in Electric Generators?

Steel is one of the most widely used materials in electric generator manufacturing due to its excellent mechanical properties. It offers high strength, good ductility, and can withstand elevated temperatures and pressures. Additionally, steel can be treated for enhanced corrosion resistance, which is vital in harsh environments.

Pros & Cons:

The durability of steel makes it suitable for heavy-duty applications, but its weight can be a disadvantage in portable generators. Manufacturing complexity varies depending on the type of steel and treatment processes, which can influence costs.

Impact on Application:

Steel’s compatibility with various media makes it versatile, but it may require protective coatings in corrosive environments.

Considerations for International Buyers:

Buyers must ensure compliance with standards such as ASTM A36 or DIN 17100. In regions like Africa and South America, sourcing local steel can mitigate logistics costs, while European buyers may prioritize high-grade steel for efficiency.

How Do Aluminum Alloys Benefit Electric Generator Design?

Aluminum alloys are increasingly popular in electric generator manufacturing due to their lightweight and corrosion-resistant properties. They are particularly beneficial in applications where weight reduction is essential, such as portable generators.

Pros & Cons:

Aluminum alloys offer excellent thermal and electrical conductivity, enhancing generator efficiency. However, they can be less durable than steel, making them unsuitable for high-stress applications. The manufacturing process can be more complex, potentially increasing costs.

Impact on Application:

Aluminum is compatible with various fuels and lubricants, making it a versatile choice. However, its lower strength limits its use in high-load scenarios.

Considerations for International Buyers:

Buyers should look for compliance with standards like ASTM B221 or JIS H4000. In regions such as the Middle East, where high temperatures are common, selecting the right aluminum alloy is crucial for performance.

Why is Copper Essential for Electric Generator Components?

Copper is a key material in electric generators, primarily used for windings and electrical connections due to its superior electrical conductivity. It also has excellent thermal properties, making it ideal for heat dissipation.

Pros & Cons:

The main advantage of copper is its conductivity, which enhances generator efficiency. However, copper is relatively expensive and can be prone to corrosion if not properly protected.

Impact on Application:

Copper is compatible with various electrical media, making it essential for reliable performance in electric generators.

Considerations for International Buyers:

Compliance with standards such as ASTM B170 is essential. Buyers in Europe may face stricter regulations regarding copper sourcing and recycling, which should be factored into procurement strategies.

What Role Does Composite Materials Play in Electric Generators?

Composite materials are increasingly utilized in electric generator manufacturing, especially in components requiring lightweight and high-strength characteristics. These materials can be engineered for specific applications, offering tailored properties.

Pros & Cons:

The primary advantage of composites is their excellent strength-to-weight ratio and corrosion resistance. However, they can be more expensive and complex to manufacture, potentially leading to higher production costs.

Impact on Application:

Composites can be engineered for specific media compatibility, making them suitable for a variety of applications, including those exposed to harsh environments.

Considerations for International Buyers:

Buyers should ensure compliance with relevant standards such as ASTM D3039. In regions like South America and Africa, the availability of composite materials may vary, impacting supply chain decisions.

Summary Table of Material Selection for Electric Generator Manufacturing

| Material | Typical Use Case for Electric Generator Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components and frames | High strength and durability | Heavy weight | Medium |

| Aluminum Alloys | Portable generators and casings | Lightweight and corrosion-resistant | Lower durability than steel | Medium |

| Copper | Electrical windings and connections | Superior electrical conductivity | High cost and corrosion susceptibility | High |

| Composite Materials | Specialized components requiring lightweight design | Excellent strength-to-weight ratio | Higher manufacturing complexity | High |

This strategic material selection guide provides actionable insights for international B2B buyers, enabling informed decisions that align with performance requirements, cost considerations, and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for electric generator manufacturer

What Are the Key Manufacturing Processes for Electric Generators?

Electric generators are complex machines that require meticulous manufacturing processes to ensure reliability and efficiency. The typical manufacturing stages include:

1. Material Preparation: What Materials Are Essential for Electric Generators?

The foundation of a high-quality electric generator lies in the materials used. Common materials include high-grade steel for the frame, copper for windings, and aluminum for housing. Suppliers should ensure that all materials meet international standards for durability and conductivity. B2B buyers should inquire about the sourcing of these materials, as local availability can significantly affect the overall cost and lead time.

2. Forming: Which Techniques Are Used in Shaping Components?

The forming stage involves shaping the raw materials into the desired components. Techniques such as stamping, forging, and casting are commonly employed. For example, stator and rotor components often undergo precision casting to achieve the required specifications. Buyers should look for manufacturers that utilize advanced forming technologies, as this can enhance the performance and lifespan of the generator.

3. Assembly: How Is the Generator Assembled for Optimal Performance?

Once the components are formed, they are assembled into the final product. This stage includes the installation of the rotor, stator, bearings, and other crucial components. Automated assembly lines are increasingly utilized to improve efficiency and consistency. B2B buyers should consider the assembly techniques used, as well as the manufacturer’s ability to customize solutions based on their specific requirements.

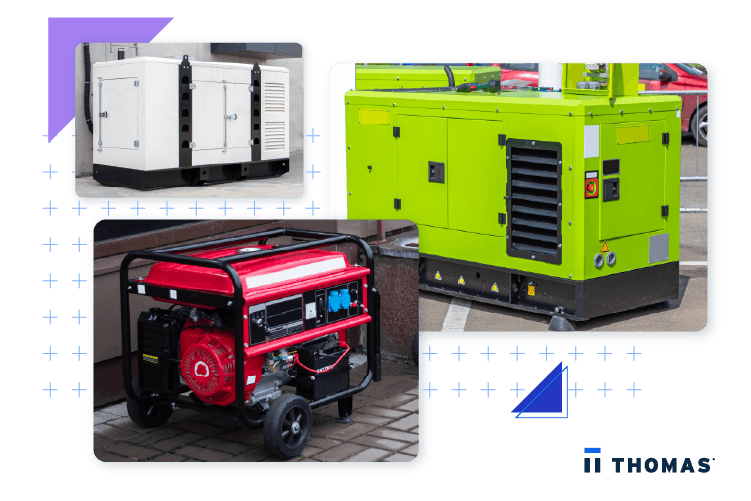

A stock image related to electric generator manufacturer.

4. Finishing: What Finishing Processes Ensure Quality and Durability?

The finishing stage includes surface treatments, painting, and protective coatings that enhance durability and aesthetics. Corrosion resistance is particularly important for generators used in harsh environments. Buyers should verify that manufacturers adhere to finishing standards that meet or exceed industry benchmarks, ensuring longevity and minimal maintenance.

What Quality Assurance Measures Should B2B Buyers Expect?

Quality assurance (QA) is critical in the manufacturing of electric generators to ensure that each unit meets the required standards for performance and safety. Key components of QA include:

International Standards: Which Certifications Should Manufacturers Hold?

Manufacturers of electric generators should comply with international standards such as ISO 9001, which focuses on quality management systems. Other certifications like CE marking (for compliance with European safety standards) and API (American Petroleum Institute) standards for oil and gas applications are also essential. Buyers should request documentation proving these certifications, as they indicate a commitment to quality.

Quality Control Checkpoints: What Are the Key QC Stages?

Quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early, reducing waste and rework.

- Final Quality Control (FQC): A comprehensive evaluation of the finished product before it leaves the factory. This includes performance testing and safety checks.

B2B buyers should inquire about the specific QC procedures employed and the frequency of inspections.

Common Testing Methods: How Are Generators Tested for Quality?

Electric generators undergo various testing methods, including:

- Load Testing: Assessing the generator’s performance under different load conditions to ensure it meets operational specifications.

- Insulation Resistance Testing: Checking the integrity of electrical insulation to prevent failures.

- Vibration Analysis: Monitoring for excessive vibrations, which can indicate mechanical issues.

Buyers should ask for detailed reports on testing methods and results to ensure transparency and confidence in the product.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that a manufacturer adheres to quality standards, B2B buyers can implement several verification strategies:

Conducting Supplier Audits: What Should Buyers Look For?

Regular supplier audits are essential for assessing compliance with quality standards. During an audit, buyers should evaluate:

- Manufacturing Processes: Observing the production line to understand the workflow and identify potential areas for improvement.

- Documentation: Reviewing quality management documents, inspection reports, and certification records.

- Employee Training: Ensuring that staff are adequately trained in quality assurance practices.

Requesting Quality Reports: What Information Should Be Included?

Buyers should request comprehensive quality reports that include data on:

- Defect Rates: Understanding the frequency of defects can provide insights into the manufacturer’s reliability.

- Corrective Actions: Information on how the manufacturer addresses quality issues can indicate their commitment to continuous improvement.

- Customer Feedback: Testimonials and case studies from other B2B clients can provide valuable perspectives on the manufacturer’s quality assurance capabilities.

Utilizing Third-Party Inspections: How Can Independent Checks Enhance Confidence?

Employing third-party inspection services can provide an unbiased assessment of a manufacturer’s quality control practices. These services can conduct pre-shipment inspections, ensuring that the products meet specified standards before they are shipped. Buyers should consider establishing relationships with reputable inspection companies to further ensure quality assurance.

What QC and Certification Nuances Should International B2B Buyers Consider?

When dealing with international suppliers, B2B buyers should be aware of specific nuances in quality control and certifications:

- Regional Compliance: Different regions may have varying compliance requirements. For instance, CE certification is crucial for products entering the European market, while UL certification is essential for the North American market.

- Language Barriers: Documentation may not always be available in English or the buyer’s preferred language. Buyers should ensure that they have access to all necessary documentation in a language they understand.

- Cultural Differences: Understanding cultural approaches to quality management and business practices can facilitate smoother negotiations and enhance supplier relationships.

Conclusion: Why Quality Assurance Is Key for Your Electric Generator Procurement

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance measures of electric generator manufacturers is essential. By focusing on material preparation, forming, assembly, and finishing processes, as well as robust QA practices, buyers can make informed decisions that ensure they procure reliable and high-quality products. Prioritizing supplier audits, quality reports, and third-party inspections will further enhance confidence in the procurement process, ultimately leading to successful partnerships in the competitive electric generator market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric generator manufacturer’

In the rapidly evolving market for electric generators, sourcing the right manufacturer is critical for international B2B buyers. This guide provides a step-by-step checklist designed to help you navigate the complexities of procurement, ensuring you select a supplier that meets your technical, financial, and logistical needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. Consider the type of generator (e.g., diesel, gas, or hybrid), power output, fuel efficiency, and intended applications. This clarity will help you filter potential suppliers who specialize in products that meet your specific needs.

- Power Output: Determine the kilowatt (kW) requirements based on your operational demands.

- Regulatory Compliance: Identify any local regulations regarding emissions or safety standards that the generator must comply with.

Step 2: Research Potential Manufacturers

Conduct thorough research to identify manufacturers that specialize in electric generators. Use industry databases, trade shows, and online marketplaces to compile a list of potential suppliers. This step is crucial as it lays the foundation for your supplier selection process.

- Online Reviews: Look for customer reviews and testimonials to gauge reliability and product performance.

- Industry Reputation: Investigate the manufacturer’s standing in the industry, including their experience and market share.

Step 3: Evaluate Supplier Capabilities

Once you have a shortlist, assess each supplier’s capabilities in terms of production capacity, technological expertise, and service offerings. Understanding their capabilities will ensure they can meet your volume and customization needs.

- Production Capacity: Confirm their ability to meet your timelines and order quantities.

- R&D Support: Check if they offer research and development for bespoke solutions, which can be critical for unique applications.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers possess the necessary certifications and quality standards relevant to electric generators. Certifications such as ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) can indicate a commitment to quality and sustainability.

- Compliance with Standards: Verify compliance with international standards like CE, UL, or local equivalents.

- Quality Control Processes: Ask about their quality assurance processes to ensure consistency in production.

Step 5: Request Detailed Quotations

When you narrow down your choices, request detailed quotations from each supplier. This should include pricing, payment terms, delivery schedules, and warranty information. Comparing these factors will help you make an informed decision.

- Cost Breakdown: Look for a transparent cost structure that outlines all potential expenses.

- Payment Terms: Understand the payment options available and any financing arrangements they offer.

Step 6: Check References and Case Studies

Before finalizing your decision, ask for references and case studies from the suppliers you are considering. Speaking with past clients can provide valuable insights into their reliability, product quality, and customer service.

- Similar Industry Experience: Focus on suppliers with experience in your specific industry to ensure they understand your needs.

- Feedback on After-Sales Service: Inquire about the level of support provided post-purchase, which is essential for long-term satisfaction.

Step 7: Negotiate Terms and Finalize the Agreement

After selecting your preferred supplier, enter into negotiations to finalize terms. Ensure that all agreements, including delivery timelines, service levels, and warranties, are clearly documented to avoid misunderstandings.

- Flexibility in Terms: Look for suppliers willing to accommodate specific terms that suit your business needs.

- Legal Review: Consider having a legal expert review the contract to ensure all aspects are covered.

Following this checklist will help international B2B buyers make informed decisions when sourcing electric generators, ultimately leading to successful partnerships and operational success.

Comprehensive Cost and Pricing Analysis for electric generator manufacturer Sourcing

What Are the Key Cost Components in Electric Generator Manufacturing?

Understanding the cost structure of electric generator manufacturing is crucial for international B2B buyers. The primary cost components include:

-

Materials: Raw materials such as steel, copper, and specialized electronic components constitute a significant portion of the total cost. Fluctuations in global commodity prices can dramatically impact the final pricing of generators.

-

Labor: Labor costs vary significantly across regions. For instance, manufacturers in Europe may have higher wage standards compared to those in parts of Africa or South America. This can influence the overall production costs and, ultimately, the pricing.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and equipment maintenance. Efficient management of these expenses can lead to cost savings, which can be passed on to buyers.

-

Tooling: The initial investment in tooling and machinery can be substantial. Custom tooling for specific generator designs can increase costs but may also enhance product quality and efficiency.

-

Quality Control (QC): Ensuring compliance with international quality standards often requires rigorous testing and certification processes, which can add to the overall manufacturing costs.

-

Logistics: Shipping and handling costs are particularly relevant for international buyers. The choice of Incoterms can affect logistics expenses, impacting the total cost of ownership.

-

Margin: Manufacturers typically add a profit margin to cover risks and ensure sustainability. This margin can vary based on market competition and perceived product value.

How Do Price Influencers Affect Electric Generator Sourcing?

Several factors influence the pricing of electric generators, particularly for international buyers:

-

Volume/MOQ: Ordering in bulk often leads to lower per-unit costs. Understanding the minimum order quantities (MOQ) can help buyers negotiate better pricing.

-

Specifications and Customization: Customized generators designed for specific applications may incur higher costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Materials and Quality Certifications: Generators made from higher-quality materials or those that meet stringent certifications (like ISO or CE) will generally cost more. Buyers should assess the importance of these factors based on their operational needs.

-

Supplier Factors: The reputation, reliability, and financial stability of suppliers can impact pricing. Established suppliers may charge more but often provide better quality assurance and post-sale support.

-

Incoterms: The choice of Incoterms can influence total costs significantly. For example, FOB (Free on Board) pricing may expose buyers to additional shipping risks, while DDP (Delivered Duty Paid) pricing includes all costs and risks until the goods reach the buyer’s location.

What Are the Best Practices for Negotiating Costs in Electric Generator Purchases?

When sourcing electric generators, international buyers should consider the following tips to enhance cost efficiency:

-

Conduct a Total Cost of Ownership (TCO) Analysis: Look beyond the initial purchase price. Include maintenance, fuel consumption, and potential downtime in your calculations. A generator with a higher upfront cost may offer lower operational expenses.

-

Leverage Volume Discounts: If your organization has consistent demand, negotiate for volume discounts. Suppliers often have pricing tiers that can be beneficial for bulk purchases.

-

Be Prepared to Walk Away: Establish a clear budget and stick to it. If a supplier cannot meet your price point, be ready to explore alternatives. This strategy can often lead to better offers.

-

Research Supplier Backgrounds: Investigate potential suppliers for their production capabilities, financial health, and reviews from previous clients. A reliable supplier can save you costs in the long run through quality products and reliable service.

-

Understand Regional Pricing Nuances: Be aware of the economic conditions and currency fluctuations in your target supplier’s region, as these can impact pricing. This knowledge can help you negotiate more effectively.

Conclusion: What Should International Buyers Keep in Mind?

When sourcing electric generators, international buyers must navigate a complex landscape of costs and pricing factors. Being informed about the components of cost and the various influencers on pricing can lead to better purchasing decisions. Always consider the total cost of ownership and seek to establish strong relationships with suppliers to ensure long-term value and reliability. Keep in mind that prices can vary widely based on numerous factors, so always verify costs with multiple suppliers to achieve the best deal.

Alternatives Analysis: Comparing electric generator manufacturer With Other Solutions

Introduction: What Are the Alternatives to Electric Generators?

In the quest for reliable power solutions, B2B buyers often explore various alternatives to traditional electric generators. These alternatives may provide similar functionalities, but their performance, cost, and implementation vary significantly. As international buyers from Africa, South America, the Middle East, and Europe assess their options, understanding these alternatives can lead to more informed purchasing decisions.

Comparison Table of Electric Generator Manufacturer and Alternatives

| Comparison Aspect | Electric Generator Manufacturer | Solar Power Systems | Battery Energy Storage Systems |

|---|---|---|---|

| Performance | High power output, suitable for heavy loads | Moderate power output, varies with sunlight | High efficiency in energy discharge, suitable for short-term use |

| Cost | High initial investment, ongoing fuel costs | Moderate initial investment, low operating costs | High initial investment, low maintenance costs |

| Ease of Implementation | Requires professional installation | Can be installed with basic skills | Generally easy to install, especially modular systems |

| Maintenance | Regular maintenance required, fuel management | Minimal maintenance, occasional cleaning | Minimal maintenance, battery replacement needed every few years |

| Best Use Case | Industrial applications, remote locations | Off-grid residential, commercial applications | Backup power, peak shaving, renewable integration |

What Are the Pros and Cons of Solar Power Systems?

Solar power systems harness energy from the sun to generate electricity. They are increasingly popular for businesses looking to reduce their carbon footprint and energy costs.

Pros:

– Sustainability: Solar energy is renewable and significantly reduces greenhouse gas emissions.

– Low Operating Costs: Once installed, solar systems have minimal operating costs compared to generators reliant on fuel.

– Government Incentives: Many countries offer financial incentives for solar installations, making them more affordable.

Cons:

– Intermittent Power Supply: Solar energy generation is dependent on sunlight, which can be inconsistent, especially in regions with frequent cloud cover or rainy seasons.

– Space Requirements: Solar panels require significant space for installation, which may not be feasible for all businesses.

– Initial Investment: While costs have decreased, the upfront investment can still be substantial.

How Do Battery Energy Storage Systems Compare?

Battery energy storage systems (BESS) store electricity generated from various sources for later use. They are particularly advantageous in managing energy supply and demand.

Pros:

– Flexibility: BESS can store energy from various sources, including solar and wind, allowing for use during peak demand times.

– Quick Deployment: Many battery systems are modular and can be deployed rapidly to meet urgent energy needs.

– Grid Support: These systems can help stabilize the grid by providing backup power during outages.

Cons:

– High Initial Costs: The upfront investment for battery systems can be significant, especially for large-scale applications.

– Limited Duration: Battery systems typically provide power for shorter durations compared to generators, making them less ideal for extended outages.

– Environmental Concerns: The production and disposal of batteries can raise environmental issues that some businesses may want to avoid.

Conclusion: How to Choose the Right Power Solution for Your Business

When selecting a power solution, international B2B buyers must consider their specific operational needs, budget constraints, and sustainability goals. Electric generators are ideal for heavy-duty applications and remote locations but come with high costs and maintenance requirements. In contrast, solar power systems offer a renewable option with lower operating costs but may face limitations in energy consistency and space. Battery energy storage systems provide flexibility and quick deployment but require careful consideration of initial investments and duration of power supply. By evaluating these factors, buyers can make informed decisions that align with their business objectives and regional energy policies.

Essential Technical Properties and Trade Terminology for electric generator manufacturer

What Are the Essential Technical Properties of Electric Generators?

Understanding the technical properties of electric generators is crucial for B2B buyers looking to make informed purchasing decisions. Here are some key specifications to consider:

1. Power Rating (kW or MW)

The power rating indicates the maximum output an electric generator can deliver. Measured in kilowatts (kW) or megawatts (MW), this specification directly impacts operational efficiency and suitability for specific applications. Buyers should match the power rating with their energy needs to avoid underperformance or excess capacity.

2. Fuel Type

Electric generators can operate on various fuel types, including diesel, natural gas, and renewable sources like solar or wind. The choice of fuel affects not only the operational cost but also the environmental impact and compliance with local regulations. B2B buyers should assess the availability and cost of these fuels in their region to ensure sustainable operations.

3. Efficiency Rating

Efficiency ratings, often expressed as a percentage, indicate how effectively a generator converts fuel into electrical power. Higher efficiency ratings lead to reduced fuel consumption and lower operational costs, making this a critical factor for B2B buyers focused on long-term savings.

4. Noise Level (dB)

The noise level of a generator is a significant consideration, especially in urban environments or areas with strict regulations. Measured in decibels (dB), lower noise levels enhance compliance with local noise ordinances and improve user satisfaction. Buyers should consider noise levels in relation to the intended installation site.

5. Tolerance and Material Grade

Tolerance refers to the acceptable range of variation in a generator’s dimensions and performance specifications, while material grade pertains to the quality of materials used in construction. High-quality materials and precise tolerances are essential for durability and reliability, particularly in challenging environments. For B2B buyers, understanding these specifications can lead to better maintenance and longer equipment lifespan.

What Are Common Trade Terms Used in the Electric Generator Industry?

Familiarity with industry terminology can significantly enhance negotiation and procurement processes. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, working directly with OEMs can lead to cost savings and ensure quality control, as they often provide comprehensive warranties and support.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum quantity of units that a supplier is willing to sell. Understanding MOQs is crucial for B2B buyers to manage inventory and cash flow effectively. Buyers should negotiate MOQs based on their operational needs and market demand.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. B2B buyers should prepare detailed RFQs to ensure they receive accurate and comparable quotes, facilitating better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, insurance, and risk management, ensuring smoother transactions across borders.

5. KVA (Kilovolt-Ampere)

KVA is a unit of measurement for apparent power in an electrical circuit. It is particularly relevant for electric generators as it helps in determining the required generator size based on the load demands. B2B buyers should consider KVA ratings when assessing generator capabilities for their specific applications.

Conclusion

Equipped with knowledge of essential technical properties and trade terminology, international B2B buyers can make more informed decisions when selecting electric generators. Understanding these specifications and terms not only enhances procurement efficiency but also contributes to long-term operational success.

Navigating Market Dynamics and Sourcing Trends in the electric generator manufacturer Sector

What Are the Current Market Dynamics in the Electric Generator Manufacturing Sector?

The electric generator manufacturing sector is undergoing significant transformation driven by various global factors. The increasing demand for reliable power sources, particularly in developing regions such as Africa and South America, is a key driver. These regions often experience inconsistent electricity supply, leading businesses to invest in generators for operational continuity. Additionally, the surge in renewable energy sources has created a shift towards hybrid generators that can integrate with solar and wind energy systems.

Emerging technologies, such as IoT (Internet of Things) integration, are also influencing sourcing trends. Smart generators equipped with real-time monitoring capabilities are becoming increasingly sought after, allowing businesses to optimize their energy consumption and reduce operational costs. B2B buyers are increasingly prioritizing suppliers who offer advanced technology solutions, ensuring they remain competitive in their respective markets.

International buyers should also be aware of market dynamics such as fluctuating raw material prices and geopolitical factors that can affect supply chains. In Europe, for instance, stringent regulations regarding emissions are pushing manufacturers to innovate towards cleaner technologies. Buyers from the Middle East and Africa should consider these dynamics when sourcing generators, focusing on manufacturers who not only meet regulatory standards but also provide value-added services such as maintenance and training.

How Can Sustainability and Ethical Sourcing Impact B2B Relationships in the Electric Generator Sector?

Sustainability is no longer just a buzzword; it has become a core consideration for B2B buyers in the electric generator manufacturing sector. The environmental impact of generators—particularly those reliant on fossil fuels—has prompted buyers to seek alternatives that minimize carbon footprints. This shift is especially relevant in regions like Europe, where regulatory frameworks are increasingly favoring sustainable practices.

Ethical sourcing is equally important, as buyers are becoming more conscious of their suppliers’ practices. Ensuring that manufacturers adhere to ethical labor practices and sustainable sourcing of materials not only enhances a company’s brand reputation but also builds trust with customers. For instance, buyers should inquire about the certifications held by manufacturers, such as ISO 14001 for environmental management or certifications for using recycled materials in production.

Moreover, green certifications like Energy Star or EcoLabel can guide buyers in selecting generators that meet high environmental standards. By prioritizing suppliers who invest in sustainable technologies and ethical practices, B2B buyers can contribute to a more responsible supply chain while also meeting the growing demand for eco-friendly solutions from their end customers.

What Historical Trends Have Shaped the Electric Generator Manufacturing Sector?

The evolution of the electric generator manufacturing sector has been marked by significant technological advancements and changing market demands. Initially, generators were predominantly fossil fuel-powered, with limited focus on efficiency or environmental impact. However, the oil crises of the 1970s catalyzed a shift towards more efficient and reliable power solutions, paving the way for the development of advanced generator technologies.

In the 1990s and early 2000s, the advent of digital controls and power electronics transformed generator operations, enhancing performance and reliability. As concerns about climate change gained prominence, manufacturers began exploring renewable energy integration, leading to the rise of hybrid and fully electric generators.

Today, the focus is on sustainable practices and innovation, with manufacturers increasingly leveraging IoT and AI technologies to enhance generator functionality. This historical context is vital for B2B buyers, as it highlights the importance of selecting suppliers who are not only aware of these trends but are also proactive in adopting new technologies and sustainable practices. Understanding these dynamics can empower international buyers to make informed sourcing decisions that align with their operational goals and environmental responsibilities.

Frequently Asked Questions (FAQs) for B2B Buyers of electric generator manufacturer

-

How do I ensure the quality of electric generators from manufacturers?

To ensure quality, start by requesting certifications such as ISO 9001, which signifies adherence to quality management standards. Conduct thorough supplier vetting through factory visits or third-party audits. Additionally, consider asking for product samples to evaluate performance and durability. Engaging in peer reviews or seeking testimonials from other B2B buyers can also provide insights into the manufacturer’s reliability and product quality. -

What are the key factors to consider when choosing an electric generator manufacturer?

Key factors include the manufacturer’s experience and reputation in the industry, their production capacity, and the range of products offered. Also, assess their ability to provide customization options that meet your specific needs, such as power output and fuel type. It’s essential to evaluate their customer service responsiveness and after-sales support to ensure smooth ongoing operations and maintenance. -

What is the typical minimum order quantity (MOQ) for electric generators?

Minimum order quantities can vary significantly among manufacturers. Generally, MOQs for electric generators range from 5 to 50 units, depending on the type and specifications. For bespoke models, manufacturers might require higher MOQs. It’s advisable to discuss your specific needs and negotiate terms that align with your purchasing strategy, especially if you are a smaller business or a first-time buyer. -

How can I negotiate favorable payment terms with electric generator manufacturers?

Negotiating payment terms involves clear communication of your cash flow requirements and understanding the manufacturer’s policies. Aim for terms such as 30% upfront and 70% upon delivery, which can help manage costs effectively. Some manufacturers may offer discounts for early payments or larger orders. Building a strong relationship with the supplier can also lead to more flexible terms over time. -

What are the most common logistics challenges when importing electric generators?

Common logistics challenges include customs clearance delays, shipping costs, and ensuring compliance with import regulations. It is crucial to understand the specific import duties applicable in your country and prepare all necessary documentation in advance. Collaborating with a freight forwarder experienced in handling heavy machinery can streamline the process and mitigate risks associated with transportation. -

How do I assess the reliability of an electric generator supplier?

To assess reliability, research the supplier’s history, including years in business and their client portfolio. Request references from previous clients, particularly those in your region, to gauge satisfaction levels. Additionally, consider their financial stability through credit checks and reviews. A supplier with a robust warranty policy and support structure is often more reliable, indicating confidence in their product quality. -

What customization options should I consider when sourcing electric generators?

Customization options can include power output specifications, fuel types (diesel, gas, etc.), and features such as noise reduction or portability. It is essential to communicate your requirements early in the procurement process to avoid costly modifications later. Understanding the specific application for your generator—be it for backup power or continuous use—will guide your customization needs. -

How can I stay updated on the latest electric generator technologies?

Staying informed on the latest technologies involves subscribing to industry publications, attending trade shows, and joining relevant online forums or professional networks. Manufacturers often share advancements through newsletters or webinars. Engaging with industry experts or consultants can also provide insights into emerging trends and innovations, helping you make informed decisions about your procurement strategy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electric generator manufacturer

A stock image related to electric generator manufacturer.

In the evolving landscape of electric generator manufacturing, strategic sourcing has emerged as a critical driver of competitive advantage. By prioritizing supplier relationships, understanding regional market dynamics, and leveraging technology, international B2B buyers can secure high-quality generators that meet their specific needs. This approach not only enhances operational efficiency but also mitigates risks associated with supply chain disruptions, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

How can buyers enhance their strategic sourcing for electric generators? Buyers should consider integrating local suppliers to strengthen their supply chains while fostering relationships that encourage innovation and sustainability. Additionally, aligning procurement strategies with long-term energy goals can lead to significant cost savings and improved reliability.

Looking ahead, the demand for efficient and eco-friendly electric generators is poised to grow, driven by increasing energy needs and regulatory pressures. By adopting a proactive sourcing strategy, B2B buyers can position themselves to capitalize on emerging opportunities in this vibrant sector. Now is the time to engage with manufacturers who prioritize quality and sustainability, ensuring that your sourcing decisions today will yield benefits for years to come.