Discover Top Benefits of Sourcing a Copper Wire Manufacturer (2025)

Introduction: Navigating the Global Market for copper wire manufacturer

Navigating the global market for copper wire manufacturers presents a unique set of challenges for international B2B buyers. With the increasing demand for high-quality copper wire in various sectors—including construction, electronics, and renewable energy—sourcing the right supplier can feel overwhelming. This guide is designed to equip buyers from Africa, South America, the Middle East, and Europe, including key markets like Brazil and the UK, with the essential knowledge and tools needed for informed purchasing decisions.

Throughout this comprehensive guide, we will explore the different types of copper wire, their various applications, and the critical factors to consider when vetting suppliers. Understanding these elements is vital for ensuring that your business receives products that meet industry standards and specifications. We will also discuss pricing strategies, helping you to navigate the often-complex cost structures associated with copper wire procurement.

By the end of this guide, you will be empowered to make strategic decisions that enhance your supply chain, mitigate risks, and ultimately drive your business’s success. Whether you are looking to establish long-term partnerships or simply need to fulfill immediate project requirements, our insights will help you navigate the complexities of the copper wire market with confidence.

Understanding copper wire manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Magnet Wire | Insulated copper wire designed for electromagnetic coils. | Electric motors, transformers, inductors. | Pros: High conductivity, flexible. Cons: Higher cost due to insulation. |

| Bare Copper Wire | Uninsulated copper wire, often used in electrical grounding. | Electrical wiring, grounding applications. | Pros: Cost-effective, excellent conductivity. Cons: Prone to corrosion without coating. |

| Stranded Copper Wire | Composed of multiple thin strands, offering flexibility. | Telecommunications, automotive wiring. | Pros: Greater flexibility, easier to route. Cons: Slightly lower conductivity than solid wire. |

| Tinned Copper Wire | Copper wire coated with tin to prevent oxidation. | Marine applications, outdoor wiring. | Pros: Corrosion-resistant, durable. Cons: Slightly higher price compared to bare copper. |

| Copper Clad Aluminum | Combines copper and aluminum, reducing weight and cost. | Power distribution, telecommunications. | Pros: Lightweight, cost-effective. Cons: Lower conductivity compared to pure copper. |

What Are the Characteristics of Magnet Wire?

Magnet wire is specifically designed for use in electromagnetic applications. Its insulation is critical for preventing electrical shorts, making it ideal for products like electric motors and transformers. When purchasing magnet wire, buyers should consider the wire gauge, insulation type, and temperature rating to ensure compatibility with their applications. This type of wire is particularly suitable for industries focused on energy and electronics, where performance and reliability are paramount.

How Does Bare Copper Wire Differ from Other Types?

Bare copper wire is the most basic form of copper wire, lacking insulation. Its primary advantage lies in its excellent conductivity and cost-effectiveness, making it a popular choice for electrical grounding and wiring applications. However, buyers must be cautious about its susceptibility to oxidation, which can impact performance over time. It is most suitable for industrial applications where reliability and conductivity are essential, and where protection from environmental factors can be managed.

What Benefits Does Stranded Copper Wire Offer?

Stranded copper wire consists of multiple thin strands twisted together, offering enhanced flexibility compared to solid wire. This feature makes it easier to handle and install, especially in applications requiring intricate routing, such as telecommunications and automotive wiring. Buyers should evaluate the wire’s gauge and strand count to ensure it meets their specific needs. While it may have slightly lower conductivity than solid wire, its flexibility can significantly improve usability in complex installations.

Why Choose Tinned Copper Wire for Your Applications?

Tinned copper wire is coated with a layer of tin, enhancing its resistance to corrosion, making it particularly suitable for marine and outdoor applications. Buyers must weigh the benefits of corrosion resistance against the slightly higher cost compared to bare copper. For businesses operating in harsh environments, this type of wire can be invaluable in maintaining long-term reliability and performance, especially in electrical connections exposed to moisture.

What Are the Advantages of Copper Clad Aluminum Wire?

Copper clad aluminum wire combines the benefits of both copper and aluminum, offering a lightweight and cost-effective solution for power distribution and telecommunications. While it has a lower conductivity compared to pure copper, its reduced weight can lead to easier installation and lower shipping costs. Buyers should consider the specific conductivity requirements of their projects, as well as the potential trade-offs in performance versus cost when choosing this type of wire.

Related Video: Copper Rod Plant 8 mm | RBD Machine | Copper Wire Manufacturing Process | Wire Drawing Process

Key Industrial Applications of copper wire manufacturer

| Industry/Sector | Specific Application of copper wire manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical & Electronics | Manufacturing of electrical cables and connectors | Enhanced conductivity and reliability in electrical systems | Quality standards, compliance with international certifications, and sourcing from reputable manufacturers |

| Telecommunications | DSL and fiber optic cable manufacturing | Improved data transmission speeds and network reliability | Technical specifications, compatibility with existing infrastructure, and after-sales support availability |

| Automotive | Wiring harness production for vehicles | Increased safety and performance in automotive systems | Resistance to heat and corrosion, customization options, and scalability of production |

| Construction | Electrical wiring for residential and commercial buildings | Compliance with safety regulations and energy efficiency | Local regulations, certifications, and availability of bulk supply |

| Renewable Energy | Solar panel and wind turbine wiring | Enhanced energy efficiency and sustainability | Resistance to environmental factors, compliance with green standards, and long-term reliability |

How is Copper Wire Used in the Electrical & Electronics Industry?

Copper wire is fundamental in the electrical and electronics sector, particularly in the manufacturing of electrical cables and connectors. These components are essential for ensuring high conductivity and reliability in electrical systems, which are crucial for both consumer and industrial applications. Buyers in this sector must prioritize manufacturers that adhere to stringent quality standards and international certifications to ensure the safety and efficiency of their products.

What Role Does Copper Wire Play in Telecommunications?

In telecommunications, copper wire is pivotal in the production of DSL and fiber optic cables. These cables are designed to facilitate high-speed data transmission, which is increasingly vital in today’s digital economy. International B2B buyers should focus on sourcing wires that meet specific technical specifications and ensure compatibility with existing infrastructure, as well as consider the availability of robust after-sales support to address any potential issues.

How is Copper Wire Utilized in the Automotive Sector?

The automotive industry relies heavily on copper wire for the production of wiring harnesses, which are essential for connecting various electrical components in vehicles. The use of copper enhances safety and performance by providing reliable electrical connections. Buyers should look for manufacturers that offer wires resistant to heat and corrosion, as well as customization options to meet specific vehicle requirements, ensuring scalability in production to meet market demands.

In What Ways is Copper Wire Used in Construction?

In the construction sector, copper wire is primarily used for electrical wiring in both residential and commercial buildings. This application is critical for ensuring compliance with safety regulations and enhancing energy efficiency. Buyers must consider local regulations and certifications when sourcing copper wire, as well as the availability of bulk supply to meet project timelines and requirements.

How Does Copper Wire Support Renewable Energy Initiatives?

Copper wire is increasingly important in the renewable energy sector, particularly in the wiring of solar panels and wind turbines. The use of copper enhances energy efficiency and contributes to sustainability efforts. Buyers should prioritize sourcing wires that are resistant to environmental factors and comply with green standards, ensuring long-term reliability and performance in renewable energy applications.

Related Video: Copper Mining Process You’ve Never Seen.Copper Tube &Copper Anodes Manufacturing From Recycled Scrap

3 Common User Pain Points for ‘copper wire manufacturer’ & Their Solutions

Scenario 1: Sourcing High-Quality Copper Wire Amid Supply Chain Disruptions

The Problem:

B2B buyers, especially in regions like Africa and South America, often face challenges in sourcing high-quality copper wire due to supply chain disruptions. Factors such as fluctuating prices, political instability, and logistics hurdles can lead to delays and inconsistencies in product quality. For instance, a manufacturer in Brazil might struggle to obtain reliable shipments of copper wire, resulting in production halts and financial losses. This situation is exacerbated by the lack of transparency in the supply chain, making it difficult for buyers to trace the origin and quality of the materials they are purchasing.

The Solution:

To navigate these challenges, B2B buyers should establish strong relationships with reputable copper wire manufacturers who prioritize supply chain transparency. It’s essential to conduct thorough due diligence before entering into agreements. This includes assessing the manufacturer’s certifications, quality control processes, and past performance. Additionally, leveraging technology such as blockchain can enhance traceability throughout the supply chain, providing buyers with real-time data on product origins and shipment statuses. Buyers should also consider diversifying their supplier base to mitigate risks associated with over-reliance on a single source. Engaging in regular communication with suppliers can foster collaboration and allow for proactive problem-solving in times of disruption.

Scenario 2: Meeting Technical Specifications and Compliance Standards

The Problem:

Many B2B buyers encounter difficulties ensuring that the copper wire they purchase meets specific technical specifications and regulatory compliance standards. In industries like construction and telecommunications, adhering to these standards is not just a legal requirement but also crucial for safety and performance. A buyer in the Middle East, for example, may find that the copper wire supplied does not conform to the local electrical codes, leading to potential project delays and increased costs for rework.

The Solution:

To address this pain point, buyers should clearly communicate their technical requirements and compliance standards to potential suppliers before placing orders. Creating a detailed specification sheet that outlines the necessary attributes, such as wire gauge, insulation type, and compliance certifications, can facilitate better alignment with manufacturers. It is also beneficial to request samples for testing prior to a large purchase, ensuring that the product meets all specifications. Building partnerships with manufacturers who have proven track records in quality assurance and compliance can further enhance reliability. Additionally, staying informed about changes in local regulations and industry standards will empower buyers to make informed decisions and avoid non-compliance issues.

Scenario 3: Managing Cost Fluctuations in Copper Wire Procurement

The Problem:

Cost fluctuations in copper wire can significantly impact budgeting and profitability for B2B buyers. Buyers in Europe, for instance, may experience sudden price hikes due to global market dynamics or changes in import tariffs. This volatility can make it challenging to forecast expenses accurately, leading to budgeting constraints and potential cash flow issues. Buyers may also find themselves in a bidding war, where they must compete with others for limited supplies at inflated prices.

The Solution:

To effectively manage procurement costs, buyers should adopt a strategic approach to sourcing copper wire. This includes negotiating long-term contracts with manufacturers that lock in prices for a set period, thereby mitigating the risk of sudden price increases. Buyers can also explore options for bulk purchasing or group buying with other businesses to leverage better pricing. Additionally, implementing a hedging strategy to purchase copper futures can provide further protection against price volatility. Regularly monitoring the copper market and staying informed about global economic factors can also enable buyers to make more strategic purchasing decisions. Engaging financial advisors with expertise in commodities can provide insights into market trends and assist in developing effective procurement strategies.

Strategic Material Selection Guide for copper wire manufacturer

What Are the Key Properties of Common Materials for Copper Wire Manufacturing?

When selecting materials for copper wire manufacturing, it’s essential to consider various factors that influence performance, durability, and cost. Below, we analyze four common materials used in this industry: copper, aluminum, steel, and polyvinyl chloride (PVC). Each material has unique properties and implications for international B2B buyers.

1. Copper

Key Properties:

Copper is a highly conductive metal with excellent thermal and electrical properties. It has a high melting point (1,984°F or 1,085°C), making it suitable for high-temperature applications. Additionally, copper exhibits good corrosion resistance, especially when treated with protective coatings.

Pros & Cons:

The primary advantage of copper is its superior conductivity, which makes it ideal for electrical wiring. However, its high cost compared to other materials can be a disadvantage, especially in large-scale applications. Manufacturing complexity is moderate, as copper can be easily drawn into wires.

Impact on Application:

Copper is compatible with various media, including water and air, making it versatile for different electrical applications. It is often used in power generation, telecommunications, and electronics.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM B3 and EN 1977. The demand for copper is high, so sourcing from reliable suppliers is critical to avoid price volatility.

2. Aluminum

Key Properties:

Aluminum is lightweight and has good conductivity, though it is less conductive than copper. It has a melting point of 1,221°F (660°C) and is resistant to corrosion due to a natural oxide layer.

Pros & Cons:

The main advantage of aluminum is its lower cost and weight, making it suitable for applications where weight savings are crucial. However, its lower conductivity can lead to higher energy losses in electrical applications. Manufacturing processes are generally simpler compared to copper.

Impact on Application:

Aluminum is often used in overhead power lines and applications where weight is a concern, such as in aerospace and automotive industries.

Considerations for International Buyers:

Buyers should be aware of standards like ASTM B800 and IEC 60228. In regions like Africa and South America, aluminum may be preferred for cost-sensitive projects, but performance limitations should be considered.

3. Steel

Key Properties:

Steel is known for its high tensile strength and durability. It has a melting point of approximately 2,500°F (1,370°C) and is highly resistant to deformation under stress.

Pros & Cons:

Steel’s primary advantage lies in its strength, making it suitable for applications requiring structural integrity. However, it is heavier and less conductive than both copper and aluminum, which can limit its use in electrical applications. The manufacturing process is more complex due to the need for additional treatments to enhance conductivity.

Impact on Application:

Steel is often used in the construction of power transmission towers and as a core material in some wire types to enhance strength.

Considerations for International Buyers:

Compliance with standards such as ASTM A36 and EN 10025 is crucial. Buyers in Europe and the Middle East may prefer steel for its strength, while those in Africa and South America might consider it for infrastructure projects.

4. Polyvinyl Chloride (PVC)

Key Properties:

PVC is a synthetic plastic polymer known for its durability and resistance to environmental factors. It has a high melting point of around 752°F (400°C) and is non-conductive.

Pros & Cons:

The key advantage of PVC is its excellent insulation properties, making it ideal for wire insulation. However, it is not suitable for high-temperature applications and can degrade under UV exposure. The manufacturing process is straightforward, but it requires careful handling to avoid environmental concerns.

Impact on Application:

PVC is primarily used as insulation for electrical wires, providing safety and protection against environmental factors.

Considerations for International Buyers:

Buyers should ensure compliance with standards like ASTM D3032 and EN 60454. In regions like Europe, there is a growing preference for environmentally friendly materials, which may influence the choice of insulation materials.

Summary Table of Material Selection for Copper Wire Manufacturing

| Material | Typical Use Case for Copper Wire Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical wiring, telecommunications | Superior conductivity | High cost | High |

| Aluminum | Overhead power lines, automotive applications | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Steel | Power transmission towers, structural cables | High tensile strength | Heavier and less conductive | Medium |

| Polyvinyl Chloride (PVC) | Wire insulation | Excellent insulation properties | Not suitable for high temperatures | Low |

This guide aims to assist international B2B buyers in making informed decisions regarding material selection for copper wire manufacturing, considering the unique needs and standards of their respective regions.

In-depth Look: Manufacturing Processes and Quality Assurance for copper wire manufacturer

What Are the Main Stages of the Manufacturing Process for Copper Wire?

Manufacturing copper wire involves several critical stages, each designed to ensure the highest quality and efficiency. The primary steps include:

-

Material Preparation: This initial stage involves sourcing high-purity copper, often in the form of cathodes, which are then melted in a furnace. The process may include refining the copper to remove impurities, which is essential for achieving desired electrical conductivity and mechanical properties.

-

Forming: Once the copper is prepared, it is extruded or drawn through dies to produce wire of various gauges. This is typically done using a wire drawing machine that reduces the diameter of the copper rod through successive passes. The forming process may also include processes like annealing, which improves ductility, making the wire easier to work with.

-

Assembly: In this stage, additional components may be attached to the wire, depending on the final product specifications. This could involve twisting strands together to create multi-strand cables or adding insulation layers if the wire is intended for electrical applications.

-

Finishing: The final stage includes surface treatments to enhance the wire’s properties. This might involve coating with materials to improve corrosion resistance or applying lubrication to facilitate further processing. Quality checks are performed throughout these stages to ensure compliance with specifications.

How Is Quality Assurance Implemented in Copper Wire Manufacturing?

Quality assurance (QA) is crucial in the copper wire manufacturing process, ensuring that the final products meet international and industry-specific standards.

What International Standards Should B2B Buyers Consider?

For international B2B buyers, familiarity with various quality standards is essential. Key standards include:

- ISO 9001: This is a globally recognized standard for quality management systems. It ensures that manufacturers have a consistent approach to quality across all processes.

- CE Marking: Particularly relevant in Europe, CE marking indicates compliance with EU safety, health, and environmental protection legislation.

- API Spec 5A: For copper wire used in oil and gas applications, compliance with API specifications ensures that the products are suitable for extreme environments.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves systematic checks at various stages of production, including:

-

Incoming Quality Control (IQC): Before production begins, raw materials are inspected for quality and conformity to specifications. This is the first line of defense against defects.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to ensure processes are operating within defined parameters. This includes checking dimensions, electrical conductivity, and mechanical properties.

-

Final Quality Control (FQC): After the manufacturing process, finished products undergo rigorous testing to confirm they meet all specifications. This may include tensile strength tests, electrical resistance tests, and surface quality inspections.

What Common Testing Methods Are Used in Quality Assurance?

To maintain high standards, various testing methods are employed in the QC process:

- Tensile Testing: Measures the strength and ductility of the copper wire.

- Electrical Conductivity Testing: Ensures that the wire meets conductivity standards, critical for electrical applications.

- Visual Inspection: Conducted to identify surface defects, such as oxidation or inconsistencies.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing may be used to detect internal flaws without damaging the wire.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s QC practices is essential. Here are actionable steps to ensure compliance:

-

Conduct Audits: Regular audits of the manufacturing facility can provide insights into the QC processes and adherence to standards. This can be done by the buyer or through third-party inspection services.

-

Request Quality Reports: Suppliers should provide comprehensive QC documentation, including test results and compliance certifications. This transparency helps build trust and ensures accountability.

-

Engage Third-Party Inspectors: Utilizing independent inspection agencies can provide an unbiased evaluation of the supplier’s processes and products. This is especially valuable in regions where local regulations may vary.

What Nuances Should International Buyers Be Aware of Regarding Quality Certification?

When sourcing copper wire internationally, understanding the nuances of QC and certification is critical:

-

Regional Standards Variability: Different regions may have varying standards and compliance requirements. For instance, while ISO standards are widely recognized, local certifications may also be necessary in certain markets.

-

Documentation Requirements: Buyers should ensure that all necessary documentation, including customs clearance and compliance certificates, is in order to avoid delays.

-

Cultural Considerations: Building relationships with suppliers can significantly impact the quality and reliability of the products. Understanding cultural nuances can enhance communication and foster long-term partnerships.

Conclusion

Understanding the manufacturing processes and quality assurance practices in copper wire manufacturing is vital for B2B buyers. By focusing on the stages of production, relevant standards, quality checkpoints, testing methods, and verification processes, buyers can make informed decisions. This knowledge not only aids in selecting reliable suppliers but also ensures that the products meet the rigorous demands of their respective industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘copper wire manufacturer’

In the competitive world of copper wire manufacturing, international B2B buyers must navigate a series of steps to ensure they select the right supplier. This practical sourcing guide provides a structured checklist to aid in the procurement process, tailored specifically for buyers from Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before reaching out to manufacturers, clearly outline your technical requirements for copper wire. This includes specifications such as wire gauge, conductivity, insulation type, and intended application. Having these details defined helps streamline communication and ensures potential suppliers can meet your needs.

- Wire Gauge: Determine the thickness of the wire required for your applications.

- Conductivity: Specify the level of conductivity needed, as this can affect performance.

- Insulation Type: Consider whether you need insulated wire for safety or specific environmental conditions.

Step 2: Conduct Market Research

Understanding the market landscape is essential for identifying potential suppliers. Research manufacturers that specialize in copper wire production, focusing on their reputation, product range, and geographic locations.

- Industry Reviews: Look for feedback from other buyers to gauge reliability.

- Product Range: Ensure the manufacturer offers a variety of products to meet diverse needs.

- Geographic Considerations: Evaluate suppliers based on their proximity to your operations for logistics efficiency.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, certifications, and references from existing clients in similar industries or regions. This step is crucial to ensure quality and reliability.

- Company Profiles: Review their history, capacity, and expertise in copper wire manufacturing.

- Certifications: Look for ISO or other relevant certifications that indicate adherence to quality standards.

- Client References: Ask for contacts who can provide insights into their experiences with the supplier.

Step 4: Verify Supplier Certifications

Check that the suppliers have the necessary certifications to comply with international standards. This not only ensures quality but also reduces the risk of future compliance issues.

- Quality Management Systems: Confirm they operate under recognized quality management systems.

- Environmental Standards: Verify adherence to environmental regulations, especially if sustainability is a concern for your business.

- Safety Certifications: Ensure that the products meet safety standards relevant to your industry.

Step 5: Request Samples and Test Quality

Before making a large order, request samples of the copper wire to evaluate quality. Testing these samples can help confirm that the specifications match your requirements and that the wire performs as expected.

- Performance Testing: Conduct tests to measure conductivity and durability.

- Material Inspection: Check for any defects or inconsistencies in the wire.

- Compliance Testing: Ensure the samples meet any applicable industry standards.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, it’s time to discuss pricing and terms. Be prepared to negotiate to ensure you receive the best value while maintaining quality.

- Volume Discounts: Inquire about pricing structures for bulk orders.

- Payment Terms: Discuss payment schedules that work for both parties.

- Delivery Timelines: Confirm lead times for production and delivery to avoid disruptions.

Step 7: Establish a Communication Protocol

Effective communication is vital for a successful partnership. Establish clear lines of communication with your supplier to facilitate prompt responses to inquiries and issues that may arise.

- Regular Updates: Set a schedule for regular updates on production status and logistics.

- Point of Contact: Designate a primary contact person on both sides to streamline communication.

- Feedback Mechanisms: Implement a system for providing feedback on quality and service to foster continuous improvement.

By following this checklist, B2B buyers can confidently navigate the procurement process for copper wire manufacturing, ensuring they select a reliable supplier that meets their technical and business needs.

Comprehensive Cost and Pricing Analysis for copper wire manufacturer Sourcing

What Are the Key Cost Components in Copper Wire Manufacturing?

When sourcing copper wire from manufacturers, understanding the cost structure is essential for making informed purchasing decisions. The main cost components include:

-

Materials: Copper is the primary raw material, and its price fluctuates based on market demand and supply dynamics. Buyers should track copper prices regularly and factor in potential price volatility when budgeting.

-

Labor: Labor costs vary significantly depending on the region and the skill level required. Manufacturers in countries with higher labor costs may charge more, while those in regions with lower labor costs might offer competitive pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers in the form of lower prices.

-

Tooling: Custom tooling for specific wire specifications can be a substantial initial investment. Buyers should consider whether they need standard products or custom solutions, as the latter typically incurs higher tooling costs.

-

Quality Control (QC): Ensuring product quality is paramount, especially for industries requiring high standards. Investing in robust QC processes may increase costs but can result in fewer defects and lower returns.

-

Logistics: Shipping costs can significantly affect the total price, particularly for international buyers. Factors such as distance, shipping method, and customs duties should be accounted for.

-

Margin: Manufacturers will include a profit margin in their pricing, which can vary based on competition and market demand.

How Do Price Influencers Affect Copper Wire Sourcing?

Several key factors influence the pricing of copper wire, which buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to bulk pricing discounts. Buyers in Africa, South America, the Middle East, and Europe should assess their needs and negotiate for better rates on higher volumes.

-

Specifications and Customization: Custom specifications can lead to increased costs. It’s advisable to determine necessary specifications upfront to avoid unexpected expenses later in the sourcing process.

-

Material Quality and Certifications: Higher quality materials and relevant certifications (e.g., ISO standards) can affect pricing. Buyers should evaluate whether premium materials are necessary for their applications.

-

Supplier Factors: The supplier’s reputation, experience, and production capacity can influence pricing. Engaging with established manufacturers may yield better quality and reliability, albeit at a potentially higher price.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) used in contracts is crucial. They define responsibilities regarding shipping, insurance, and tariffs, which can impact overall costs.

What Are the Best Buyer Tips for Sourcing Copper Wire?

International B2B buyers should adopt several strategies to optimize their sourcing process:

-

Effective Negotiation: Establish clear communication with suppliers and be prepared to negotiate on price, delivery times, and payment terms. Leverage competitive quotes from multiple manufacturers to strengthen your position.

-

Focus on Cost-Efficiency: Look beyond the initial price. Consider total cost of ownership (TCO), which includes long-term costs such as maintenance, energy efficiency, and potential wastage.

-

Understand Pricing Nuances for International Buyers: Be aware of currency fluctuations, import tariffs, and local regulations that can affect overall pricing. Establish relationships with local agents or consultants to navigate these complexities.

-

Conduct Regular Market Research: Keep abreast of market trends, material prices, and supplier performance. This knowledge can empower buyers to make timely decisions and capitalize on favorable market conditions.

Disclaimer on Pricing

Prices for copper wire manufacturing can vary widely based on the factors discussed above. The information provided is for indicative purposes only and should not be considered a binding quote. Buyers are encouraged to obtain formal quotes from manufacturers to ensure accurate pricing tailored to their specific requirements.

Alternatives Analysis: Comparing copper wire manufacturer With Other Solutions

When considering the procurement of copper wire, international B2B buyers should explore various alternatives that might suit their specific requirements better. The choice of materials and technologies can significantly impact the performance, cost, and overall efficiency of electrical systems. Below, we compare copper wire manufacturing with two viable alternatives: aluminum wire and fiber optic cables.

| Comparison Aspect | Copper Wire Manufacturer | Aluminum Wire | Fiber Optic Cables |

|---|---|---|---|

| Performance | High conductivity; reliable for power transmission | Lower conductivity; more resistance than copper | Extremely high bandwidth; ideal for data transmission |

| Cost | Generally higher initial cost | Lower initial cost; more cost-effective for large installations | Higher installation costs; fiber optic components can be expensive |

| Ease of Implementation | Established installation processes | Relatively easy; requires different fittings | Requires specialized skills for installation and maintenance |

| Maintenance | Low; resistant to corrosion | Moderate; prone to oxidation if not treated | Low; durable but sensitive to physical damage |

| Best Use Case | Power distribution, electrical wiring | Large-scale power distribution, overhead lines | Telecommunications, high-speed internet, and data centers |

What Are the Pros and Cons of Using Aluminum Wire as an Alternative?

Aluminum wire presents a cost-effective alternative to copper, particularly in large-scale installations. Its lower weight makes it easier to handle and install, especially for overhead power lines. However, aluminum has a higher resistance than copper, which can lead to energy losses in long-distance applications. Additionally, aluminum wiring requires specialized connectors to prevent oxidation, which can complicate maintenance.

How Does Fiber Optic Cable Compare to Copper Wire?

Fiber optic cables offer unparalleled performance in data transmission, making them ideal for telecommunications and high-speed networks. They can transmit signals over long distances with minimal loss, providing faster speeds than copper. However, the installation of fiber optics is more complex and often requires specialized technicians. The initial investment for fiber optic infrastructure can also be significant, which may deter some businesses from making the switch.

Conclusion: How Can B2B Buyers Make the Right Choice?

When selecting between copper wire and its alternatives, B2B buyers must assess their specific needs, including performance requirements, budget constraints, and the technical expertise available for installation and maintenance. Copper wire remains a reliable choice for traditional electrical applications, while aluminum may offer cost savings for larger projects. Fiber optics, though more expensive, is unmatched in speed and efficiency for data transmission. Ultimately, understanding the strengths and weaknesses of each option will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for copper wire manufacturer

What Are the Essential Technical Properties of Copper Wire?

Understanding the critical specifications of copper wire is essential for B2B buyers, especially when sourcing from international manufacturers. Here are some key technical properties to consider:

1. Material Grade

Copper wire is classified into various grades, typically denoted by the American Wire Gauge (AWG) system. The lower the AWG number, the thicker the wire, which directly influences its conductivity and resistance to heat. Higher grades are often required for high-performance applications, making this a vital consideration for industries like telecommunications and electronics.

2. Tolerance

Tolerance refers to the acceptable deviation in the wire’s diameter from its specified size. For instance, a tolerance of ±0.1 mm means the wire can be 0.1 mm thicker or thinner than specified. Tight tolerances are critical in applications where electrical performance is paramount, ensuring uniformity and reliability in electrical connections.

3. Electrical Conductivity

This property measures how well the copper wire conducts electricity, usually expressed in percentage IACS (International Annealed Copper Standard). High conductivity is essential for efficient power transmission, making it a critical factor for industries like renewable energy and electrical engineering.

4. Mechanical Strength

Mechanical strength indicates the wire’s ability to withstand physical stress without breaking. This property is vital for applications exposed to harsh environments, such as construction and automotive industries, where durability is non-negotiable.

5. Thermal Properties

Copper has excellent thermal conductivity, making it suitable for applications requiring heat dissipation. This property is particularly important in electrical components where overheating can lead to failures.

6. Corrosion Resistance

Copper wire is often treated with coatings to enhance its resistance to corrosion. This is especially important in humid or chemically aggressive environments, ensuring longevity and reducing maintenance costs.

What Are Common Trade Terms Used in the Copper Wire Industry?

Familiarity with industry jargon can streamline communications and negotiations for B2B buyers. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components that are used in another company’s end products. Understanding OEM relationships can help buyers assess the reliability and quality of copper wire sourced from manufacturers who supply to reputable brands.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. This term is crucial for B2B buyers to understand, as it can affect inventory levels and cash flow management. Knowing MOQs helps buyers plan their purchases effectively.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers. It’s an essential step in the procurement process, allowing buyers to compare offers and make informed decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in the transportation of goods. Understanding these terms is vital for international transactions, as they clarify shipping costs, risks, and delivery timelines.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the goods. This term is particularly important for international buyers who must consider shipping and customs clearance times, impacting project timelines.

6. Certification

Certification indicates that a product meets specific industry standards. Common certifications for copper wire include ISO, RoHS, and UL listings. Buyers should prioritize certified products to ensure compliance with safety and quality regulations.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing copper wire, enhancing their procurement strategies across diverse international markets.

Navigating Market Dynamics and Sourcing Trends in the copper wire manufacturer Sector

What are the Current Market Dynamics in the Copper Wire Manufacturing Sector?

The copper wire manufacturing sector is witnessing significant growth driven by multiple global factors. Increased demand for electric vehicles (EVs) and renewable energy solutions, particularly in Africa, South America, the Middle East, and Europe, is creating a surge in copper wire requirements. The transition towards green technologies and electrification of transportation systems is propelling this demand forward, making it crucial for B2B buyers to stay informed about the evolving landscape.

Emerging B2B technology trends, such as automation and digital supply chain management, are also reshaping how copper wire manufacturers operate. These advancements enable manufacturers to optimize production processes, reduce costs, and improve product quality. Furthermore, international B2B buyers should be aware of shifting sourcing dynamics; many manufacturers are diversifying their supplier networks to mitigate risks associated with geopolitical tensions and supply chain disruptions. This diversification allows companies to ensure a steady supply of copper while also exploring cost-effective sourcing options.

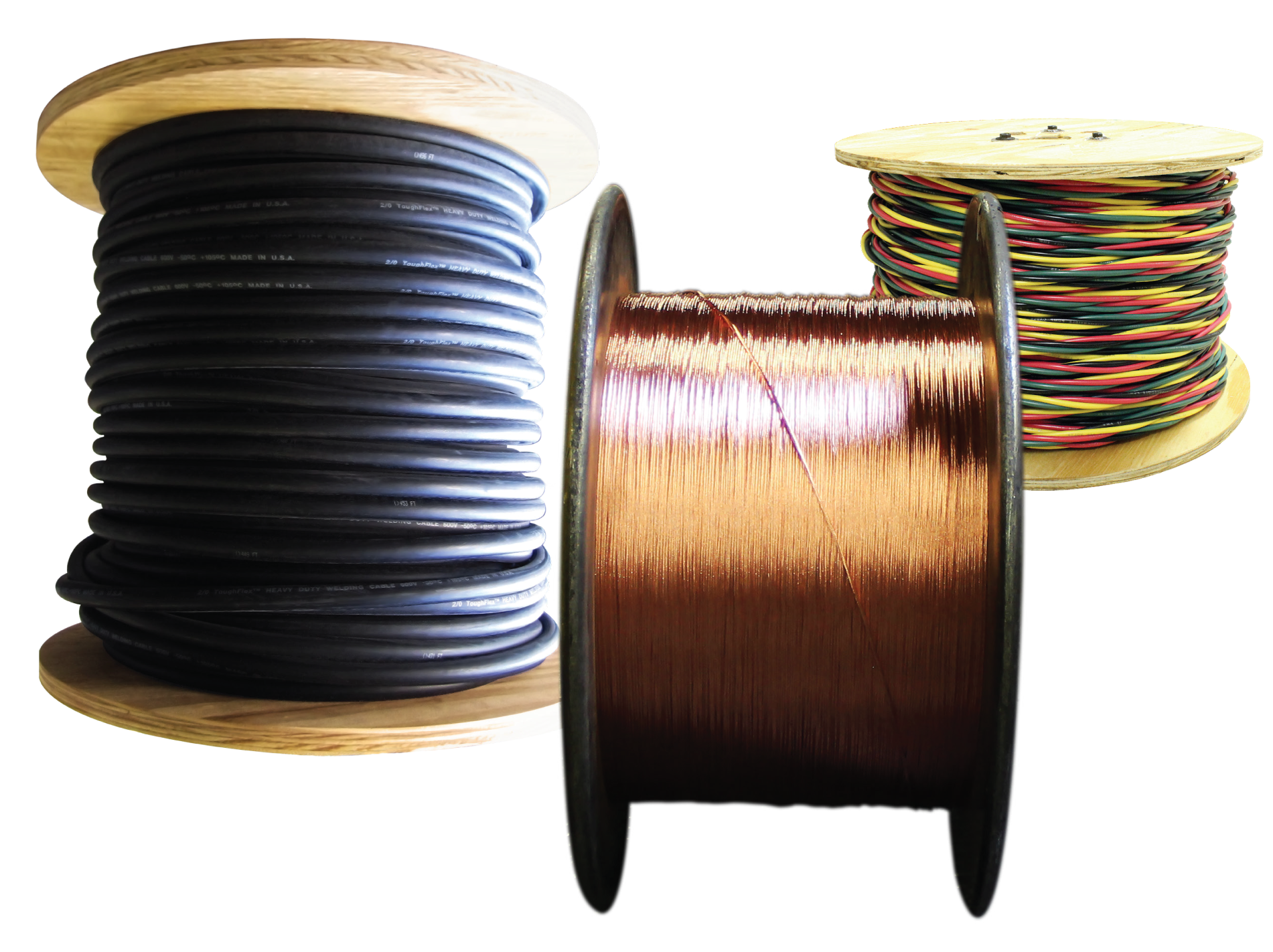

A stock image related to copper wire manufacturer.

How is Sustainability Impacting the Copper Wire Manufacturing Sector?

Sustainability is becoming a non-negotiable aspect of sourcing in the copper wire manufacturing industry. The environmental impact of copper mining and processing necessitates a shift towards more sustainable practices. B2B buyers must prioritize suppliers that adhere to ethical sourcing standards and demonstrate a commitment to minimizing their environmental footprint. This includes evaluating suppliers based on their energy consumption, waste management practices, and overall carbon emissions.

The importance of ethical supply chains cannot be overstated. As consumers and governments increasingly demand transparency, manufacturers are under pressure to adopt “green” certifications, such as ISO 14001 or the Responsible Minerals Initiative. These certifications not only enhance brand reputation but also ensure compliance with international environmental regulations. Buyers should seek out manufacturers that utilize recycled copper or eco-friendly materials in their products, as this aligns with the global push towards sustainable practices.

How Has the Copper Wire Manufacturing Sector Evolved Over Time?

The copper wire manufacturing sector has undergone substantial transformations over the years, influenced by technological advancements and changing market demands. Initially dominated by traditional manufacturing processes, the industry has embraced automation and smart manufacturing techniques. This evolution has resulted in improved efficiency, reduced waste, and enhanced product quality, which are critical for meeting the needs of contemporary B2B buyers.

Moreover, the rise of digital platforms has facilitated better communication and collaboration between manufacturers and buyers, streamlining the sourcing process. As the industry continues to evolve, staying abreast of these changes will be essential for international B2B buyers looking to make informed purchasing decisions in the copper wire sector.

Frequently Asked Questions (FAQs) for B2B Buyers of copper wire manufacturer

-

How do I choose the right copper wire manufacturer for my business needs?

When selecting a copper wire manufacturer, consider factors such as production capacity, quality certifications, and delivery timelines. Research the manufacturer’s reputation by reading reviews and seeking references from other B2B clients in your industry. Evaluate their ability to meet your specifications, including wire gauge, insulation types, and customizations. It’s also beneficial to assess their compliance with international quality standards, especially if you are sourcing from different continents like Africa or South America. -

What are the typical minimum order quantities (MOQs) for copper wire?

Minimum order quantities for copper wire can vary significantly between manufacturers. Generally, MOQs can range from 100 kg to several tons, depending on the type of wire and the manufacturer’s production capabilities. When negotiating, consider your current and future needs to ensure that the MOQ aligns with your inventory management strategy. If you require smaller quantities, look for manufacturers that offer flexibility or are willing to accommodate trial orders. -

How can I ensure the quality of copper wire products from a manufacturer?

To ensure quality, request samples of the copper wire before placing a large order. Verify that the manufacturer holds relevant certifications such as ISO 9001, which indicates a commitment to quality management. Additionally, inquire about their quality assurance processes, including testing methods for conductivity and insulation integrity. Establishing a clear quality control agreement can also protect your interests and ensure the products meet your specifications. -

What are common payment terms when dealing with copper wire manufacturers?

Payment terms can differ widely among manufacturers, typically ranging from 30% upfront with the remainder due upon delivery, to net 30 or net 60 days after receipt of goods. It’s crucial to discuss payment options early in the negotiation process. Consider using letters of credit for international transactions to mitigate risk. Always ensure that the payment terms are documented in the contract to avoid misunderstandings later. -

What logistics considerations should I keep in mind when sourcing copper wire internationally?

When sourcing copper wire internationally, consider the shipping methods, lead times, and customs regulations of both the exporting and importing countries. Evaluate the total landed cost, which includes shipping, duties, and any additional fees. Working with logistics experts or freight forwarders can streamline the process and ensure compliance with international trade laws. Additionally, be aware of potential delays due to customs inspections, especially in regions with stringent regulations. -

How can I customize my copper wire order to meet specific requirements?

Most manufacturers offer customization options for copper wire, including variations in gauge, insulation materials, and packaging. To initiate customization, clearly communicate your specifications and any industry standards you need to meet. Collaborate with the manufacturer’s engineering or design team to ensure that your requirements are feasible and can be produced within your desired timelines. Be prepared for potential additional costs associated with custom orders.

A stock image related to copper wire manufacturer.

-

What certifications should I look for in a copper wire manufacturer?

When sourcing copper wire, look for manufacturers that hold certifications such as ISO 9001 for quality management and RoHS compliance to ensure the products are free from hazardous substances. Depending on your market, additional certifications like UL (Underwriters Laboratories) for safety standards may also be necessary. These certifications not only assure product quality but also indicate that the manufacturer adheres to international safety and environmental standards. -

What are the benefits of sourcing copper wire from manufacturers in different regions?

Sourcing copper wire from various regions can offer benefits such as cost savings, access to specialized products, and diversification of supply chains. For example, manufacturers in South America may provide competitive pricing due to local raw material availability, while European manufacturers might excel in high-quality standards and advanced technology. Diversifying your suppliers can also mitigate risks associated with geopolitical issues, trade tariffs, or supply chain disruptions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for copper wire manufacturer

In the dynamic landscape of copper wire manufacturing, strategic sourcing emerges as a critical component for international B2B buyers aiming to optimize their supply chains. By understanding market trends and leveraging supplier relationships, businesses can enhance their procurement processes while ensuring product quality and cost efficiency. This approach not only mitigates risks associated with price volatility but also fosters innovation and sustainability in sourcing practices.

What are the key advantages of strategic sourcing for copper wire procurement? International buyers, particularly in regions like Africa, South America, the Middle East, and Europe, stand to gain significantly from implementing comprehensive sourcing strategies that include supplier diversification, rigorous quality assessments, and adherence to regulatory standards. These practices empower businesses to respond adeptly to market fluctuations and customer demands.

Looking ahead, as the demand for copper wire continues to rise driven by technological advancements and renewable energy initiatives, now is the time to refine your sourcing strategies. Engage with reputable suppliers, explore new markets, and remain adaptable to changing conditions. By prioritizing strategic sourcing, you can position your business for sustained growth and success in the competitive copper wire industry.