Discover Top Benefits of Working with a Blazer Manufacturer (2025)

Introduction: Navigating the Global Market for blazer manufacturer

Navigating the complexities of sourcing a reliable blazer manufacturer can be a daunting challenge for international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe. With varying standards of quality, production timelines, and cultural expectations, making informed purchasing decisions becomes critical. This comprehensive guide addresses key aspects of the blazer manufacturing market, including types of blazers, applications in various industries, supplier vetting processes, and cost considerations.

By offering actionable insights and a clear framework for evaluating potential suppliers, this guide empowers buyers to streamline their sourcing strategies and enhance their procurement processes. Whether you are seeking to outfit a corporate team in Poland or supply a fashion line in Mexico, understanding the intricacies of the global blazer market will equip you with the knowledge to make confident choices.

From identifying reputable manufacturers to negotiating favorable terms, this resource provides the tools necessary for successful partnerships. Explore the myriad of options available and take the first step towards optimizing your blazer procurement strategy in an increasingly competitive landscape.

Understanding blazer manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mass Production | High volume, standardized designs, cost-effective | Retail chains, department stores | Pros: Lower cost, consistent quality. Cons: Limited customization options. |

| Custom Manufacturing | Tailored designs, flexible production runs | Luxury brands, niche markets | Pros: Unique products, high quality. Cons: Higher costs, longer lead times. |

| Eco-Friendly | Sustainable materials, ethical production practices | Eco-conscious brands, startups | Pros: Appeals to environmentally aware consumers. Cons: Potentially higher costs, limited material availability. |

| Fast Fashion | Trend-driven, rapid production cycles | Fast fashion retailers | Pros: Quick turnaround, trendy designs. Cons: Quality may vary, ethical concerns. |

| Luxury Manufacturing | High-end materials, artisanal craftsmanship | High-end boutiques, luxury brands | Pros: Superior quality, exclusivity. Cons: Very high costs, longer production times. |

What Are the Characteristics of Mass Production Blazer Manufacturers?

Mass production blazer manufacturers focus on creating large quantities of standardized products. Their operations are streamlined for efficiency, allowing them to offer competitive pricing. This model is particularly suitable for retail chains and department stores that require consistent inventory levels. When considering mass production, B2B buyers should evaluate the trade-off between lower costs and the limited customization options, which may not cater to specific market niches.

How Do Custom Manufacturing Blazer Manufacturers Operate?

Custom manufacturing involves producing blazers tailored to specific client requirements, with a focus on unique designs and quality craftsmanship. This approach is ideal for luxury brands and niche markets that prioritize individuality over volume. Buyers looking for custom manufacturers should consider factors such as lead times and production costs, as these can significantly impact the overall investment.

What Makes Eco-Friendly Blazer Manufacturers Stand Out?

Eco-friendly blazer manufacturers utilize sustainable materials and ethical production practices to cater to the growing demand for environmentally responsible fashion. This type of manufacturing is particularly appealing to eco-conscious brands and startups aiming to establish a positive brand image. While these products may come at a higher price point, they often attract a dedicated customer base willing to invest in sustainable options.

Why Choose Fast Fashion Blazer Manufacturers?

Fast fashion manufacturers excel in producing trendy blazers at rapid speeds, allowing retailers to quickly respond to changing fashion trends. This model is highly effective for fast fashion retailers who prioritize quick inventory turnover. However, buyers should be aware of the potential downsides, such as variable quality and ethical concerns surrounding labor practices in fast fashion production.

What Are the Benefits of Luxury Manufacturing for Blazers?

Luxury manufacturing focuses on high-end materials and artisanal craftsmanship, catering to high-end boutiques and luxury brands. This type of manufacturer offers superior quality and exclusivity, making it appealing for buyers targeting affluent consumers. However, the significant costs and longer production times associated with luxury manufacturing may require buyers to have a well-defined target market to justify the investment.

Key Industrial Applications of blazer manufacturer

| Industry/Sector | Specific Application of blazer manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Supply of blazers for vehicle interiors and exteriors | Enhances aesthetic appeal and comfort for consumers | Material quality, compliance with safety standards, customization options |

| Fashion Retail | Production of blazers for retail clothing lines | Meets diverse consumer demands and trends | Fabric sourcing, ethical manufacturing practices, volume pricing |

| Corporate Wear | Custom blazers for corporate branding and employee uniforms | Strengthens brand identity and professionalism | Customization options, bulk order discounts, delivery timelines |

| Event Management | Blazers for event staff and promotional activities | Creates a cohesive brand image at events | Design flexibility, quick turnaround time, fabric durability |

| Hospitality | Blazers for hotel staff and restaurant uniforms | Enhances guest experience through professional appearance | Comfort and fit, laundering requirements, style consistency |

How is ‘blazer manufacturer’ utilized in the automotive industry?

In the automotive sector, blazer manufacturers supply high-quality blazers for vehicle interiors and exteriors. These blazers can be used in various applications, from upholstery to protective coverings. The use of blazers enhances the aesthetic appeal and comfort of vehicles, which is crucial for customer satisfaction. For international B2B buyers, sourcing considerations include ensuring compliance with safety standards and selecting materials that can withstand diverse climates, particularly in regions like Africa and the Middle East.

What role do blazers play in the fashion retail industry?

Blazer manufacturers are integral to the fashion retail industry by producing stylish blazers for various clothing lines. Retailers can meet diverse consumer demands by offering blazers that align with current fashion trends. The value here lies in the ability to provide unique designs that resonate with target demographics. For buyers in South America and Europe, key sourcing considerations include fabric quality, ethical manufacturing practices, and competitive pricing for bulk orders to maximize profitability.

How are blazers important for corporate wear?

In the corporate sector, custom blazers are essential for branding and employee uniforms. They help reinforce brand identity and project professionalism in client-facing roles. The use of blazers in corporate settings can improve employee morale and enhance customer perception. Buyers must consider customization options, bulk order discounts, and timely delivery to ensure that their branding initiatives are executed effectively, especially in fast-paced markets in Europe and the Middle East.

Why are blazers crucial for event management?

Blazers serve a significant role in event management by providing staff with a polished and cohesive appearance. This uniformity contributes to a professional brand image during events, which can positively influence attendee perceptions. Buyers in this sector should prioritize design flexibility, quick turnaround times, and the durability of materials, particularly for outdoor events in diverse climates like those found in Africa and South America.

How do blazers enhance the hospitality industry?

In the hospitality sector, blazers are used for hotel staff and restaurant uniforms, creating an impression of professionalism and attention to detail. A well-designed blazer can significantly enhance the guest experience, making staff appear approachable and competent. Buyers must focus on comfort, fit, and laundering requirements when selecting blazers, as these factors directly impact staff performance and guest satisfaction, especially in high-traffic environments in Europe and the Middle East.

Related Video: Types Of Flowmeters And Their Industrial Applications.

3 Common User Pain Points for ‘blazer manufacturer’ & Their Solutions

Scenario 1: Inconsistent Quality Across Orders

The Problem:

For B2B buyers, one of the most frustrating challenges when sourcing blazers from manufacturers is encountering inconsistent quality across different orders. This inconsistency can stem from variations in fabric quality, stitching, or finishing processes, leading to products that do not meet the expected standards. Buyers from regions such as Africa and South America may find it particularly challenging to establish trust with manufacturers, especially when faced with fluctuating quality that can damage their brand reputation and customer loyalty.

The Solution:

To mitigate this issue, B2B buyers should implement a robust supplier evaluation and quality assurance process. Begin by conducting thorough research to identify reputable manufacturers with a proven track record of consistent quality. Request samples of previous work to assess the craftsmanship and materials used. Establish clear quality standards and specifications in your contracts, detailing acceptable tolerances and quality metrics. Additionally, consider implementing regular quality audits and inspections during the production process. This proactive approach not only ensures that the products meet the required standards but also fosters a strong partnership with the manufacturer, reinforcing their commitment to quality.

Scenario 2: Long Lead Times Affecting Business Operations

The Problem:

B2B buyers often struggle with long lead times from blazer manufacturers, which can disrupt their supply chain and affect their ability to meet customer demands. This challenge is particularly prevalent in regions like the Middle East and Europe, where timely delivery is crucial for seasonal collections or promotional events. Delays can lead to lost sales opportunities and increased operational costs, creating a ripple effect throughout the business.

The Solution:

To address long lead times, buyers should prioritize manufacturers that offer transparency and flexibility in their production schedules. When negotiating contracts, inquire about their production capabilities, average lead times, and any potential bottlenecks. Establishing a buffer stock strategy can also be beneficial; by ordering a small quantity of blazers ahead of peak seasons, you can ensure availability while minimizing risk. Furthermore, consider diversifying your supplier base to include manufacturers from different regions, which can help mitigate risks associated with delays in one location. By fostering open communication with your suppliers about your needs and timelines, you can collaboratively develop solutions that enhance delivery performance.

Scenario 3: Difficulty in Customization and Personalization

The Problem:

B2B buyers often face challenges when seeking customization options for blazers, whether it be for branding, size variations, or unique designs. Manufacturers may have rigid production lines or limited flexibility, making it difficult to accommodate specific requests. This limitation can hinder buyers, especially in competitive markets in South America and Europe, where differentiation is key to attracting customers.

The Solution:

To overcome this challenge, buyers should clearly communicate their customization needs during the initial discussions with potential manufacturers. Look for manufacturers that specialize in bespoke production and have experience with similar customization requests. Request a portfolio showcasing their previous custom projects to gauge their capability. Additionally, consider collaborating with manufacturers that utilize advanced technologies, such as digital printing and automated cutting, which can facilitate more flexible production processes. Establish a close working relationship with your manufacturer to ensure they understand your vision and can adapt their processes accordingly. This collaborative approach not only enhances the likelihood of achieving your customization goals but also strengthens the partnership for future projects.

Strategic Material Selection Guide for blazer manufacturer

When selecting materials for blazer manufacturing, it is crucial to consider various factors, including performance properties, cost, and regional compliance standards. Below are analyses of four common materials used in blazer manufacturing, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Wool in Blazer Manufacturing?

Wool is a traditional fabric widely used in blazer manufacturing due to its natural properties. It offers excellent insulation, moisture-wicking capabilities, and breathability, making it suitable for various climates. Wool can withstand high temperatures without losing its shape, and it is naturally flame-resistant.

Pros: Wool is durable and maintains its appearance over time. Its natural elasticity allows it to resist wrinkles, making it ideal for high-end blazers.

Cons: The primary drawback is its cost, as high-quality wool can be expensive. Additionally, wool may require special care to avoid shrinkage and damage.

Impact on Application: Wool blazers are often preferred for formal and business settings, providing a sophisticated look. However, buyers must consider the climate of their region, as wool may be too warm in hot, humid areas.

Considerations for International Buyers: Buyers from Europe and the Middle East may prefer wool due to its traditional use in formal attire, while buyers from Africa and South America may seek alternatives that are more climate-appropriate. Compliance with textile standards, such as Oeko-Tex, is essential for ensuring product safety.

How Does Polyester Compare as a Material for Blazers?

Polyester is a synthetic fabric that has gained popularity in blazer manufacturing due to its affordability and versatility. It offers good durability, wrinkle resistance, and ease of care, making it suitable for everyday wear.

Pros: Polyester is cost-effective and can be produced in various colors and textures. It is also lightweight and dries quickly, making it ideal for travel.

Cons: The main limitation of polyester is its lower breathability compared to natural fibers, which may lead to discomfort in warmer climates. Additionally, it may not provide the same luxurious feel as wool.

Impact on Application: Polyester blazers are often used in casual and business-casual settings, appealing to a broader audience. However, they may not be suitable for formal occasions.

Considerations for International Buyers: Buyers from Africa and South America may favor polyester for its affordability and ease of maintenance, while European buyers may be more discerning about fabric quality. Compliance with international standards for synthetic textiles is crucial.

What Are the Benefits of Blends in Blazer Manufacturing?

Blended fabrics, such as wool-polyester or cotton-polyester blends, combine the advantages of both materials. These blends can enhance durability, comfort, and aesthetic appeal.

Pros: Blends can offer a balance of breathability and wrinkle resistance, making them versatile for various applications. They often come at a lower price point than pure wool.

Cons: The quality of blended fabrics can vary significantly, and lower-quality blends may not perform as well as their pure counterparts.

Impact on Application: Blended blazers can be suitable for both formal and casual settings, depending on the blend ratio. They can cater to a diverse market, appealing to buyers looking for quality at a reasonable price.

Considerations for International Buyers: Buyers should be aware of the blend composition and ensure compliance with regional textile regulations. Preferences may vary, with European buyers often prioritizing quality over cost.

Why Is Cotton a Popular Choice for Casual Blazers?

Cotton is another common material used in blazer manufacturing, especially for casual styles. It is breathable, soft, and comfortable, making it ideal for warmer climates.

Pros: Cotton is easy to care for and can be machine-washed, making it a practical choice for everyday wear. It is also relatively inexpensive compared to wool and blends.

Cons: Cotton blazers may lack the structure and durability of wool or blended fabrics. They can wrinkle easily and may not hold their shape as well over time.

Impact on Application: Cotton blazers are perfect for casual settings, outdoor events, and summer wear. They provide a relaxed look that appeals to a younger demographic.

Considerations for International Buyers: Buyers from warmer regions, such as Africa and South America, may prefer cotton for its comfort in hot weather. Compliance with organic cotton standards may also be a consideration for environmentally conscious buyers.

Summary Table of Material Selection for Blazer Manufacturing

| Material | Typical Use Case for blazer manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wool | Formal and business blazers | Excellent insulation and durability | High cost and care requirements | High |

| Polyester | Casual and business-casual blazers | Cost-effective and easy to care for | Lower breathability and feel | Low |

| Blends | Versatile blazers for various occasions | Balanced properties for comfort | Quality can vary significantly | Medium |

| Cotton | Casual blazers for warm climates | Soft, breathable, and practical | Less structure and durability | Low |

By carefully evaluating these materials, international B2B buyers can make informed decisions that align with their market needs and consumer preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for blazer manufacturer

What Are the Main Stages in the Manufacturing Process for Blazer Production?

The manufacturing process for blazers involves several critical stages that ensure the final product meets quality and design specifications. Understanding these stages can help international B2B buyers identify capable suppliers and assess their production capabilities effectively.

-

Material Preparation

The first stage involves selecting high-quality fabrics, linings, and interlinings. Common materials for blazers include wool, cotton, polyester blends, and specialty fabrics such as cashmere or linen. This stage also includes cutting the fabric into various pieces based on the design specifications. Advanced cutting techniques, such as laser cutting, may be employed to ensure precision and reduce material waste. -

Forming

In this stage, the cut fabric pieces undergo various processes, including stitching, pressing, and shaping. Manufacturers may use automated sewing machines for efficiency and consistency. Techniques such as flat-lock stitching or overlocking are often used to enhance durability and aesthetic appeal. The forming stage is crucial as it establishes the structure and fit of the blazer. -

Assembly

After forming, the individual components—such as sleeves, collars, and body pieces—are assembled. This stage requires meticulous attention to detail to ensure that seams align perfectly and that the blazer maintains its intended shape. Skilled workers often perform this stage, as it requires expertise in garment construction to handle complex designs or features like pockets and lining. -

Finishing

The final stage involves adding finishing touches such as buttons, zippers, and labels. The blazer is then pressed, cleaned, and inspected for defects. This stage may also include quality checks on the overall appearance, fit, and functionality of the blazer. Proper finishing is essential for delivering a product that meets or exceeds customer expectations.

What Quality Assurance Standards Should B2B Buyers Look For in Blazer Manufacturers?

Quality assurance (QA) is a vital aspect of the manufacturing process, particularly for international B2B transactions. Buyers should ensure that their suppliers adhere to relevant international standards and industry-specific certifications.

-

International Standards (ISO 9001)

ISO 9001 is a widely recognized quality management standard that ensures consistent quality in products and services. B2B buyers should look for manufacturers certified with ISO 9001, as it indicates a commitment to continuous improvement and customer satisfaction. -

Industry-Specific Certifications (CE, API)

Depending on the market and intended use, additional certifications may be relevant. For instance, the CE marking is important for products sold within the European Economic Area, indicating conformity with health, safety, and environmental protection standards. Buyers should verify that manufacturers possess any necessary industry-specific certifications to ensure compliance.

What Are the Key Quality Control Checkpoints in Blazer Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints designed to catch defects and ensure product quality.

-

Incoming Quality Control (IQC)

IQC is the first line of defense against defects. This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. B2B buyers should inquire about the IQC processes in place to ensure that only high-quality materials are used in production. -

In-Process Quality Control (IPQC)

IPQC is conducted during the manufacturing process. Regular inspections are performed to monitor the production line, ensuring that all processes adhere to established standards. This stage is crucial for catching defects early, minimizing waste, and preventing costly rework. -

Final Quality Control (FQC)

After assembly and finishing, FQC is the last opportunity to catch any defects before the product is shipped. This stage includes a thorough inspection of the finished blazers for visual appearance, fit, and functionality. B2B buyers should request details on the FQC procedures to confirm that all products meet their quality expectations.

How Can B2B Buyers Verify the Quality Control Processes of Blazer Manufacturers?

For international buyers, verifying the quality control processes of potential suppliers is essential to ensure reliable product delivery.

-

Conducting Audits

Regular audits of suppliers can provide insight into their quality control practices. Buyers can either perform these audits themselves or hire third-party firms specializing in supplier audits. An audit should assess compliance with quality standards, the effectiveness of processes, and the overall production environment. -

Reviewing Quality Reports

Manufacturers should provide detailed quality reports, including data on defect rates, inspection results, and corrective actions taken. Reviewing these reports allows buyers to gauge the effectiveness of the manufacturer’s quality control system. -

Third-Party Inspections

Engaging third-party inspection services before shipment can provide an additional layer of assurance. These inspections can verify product quality and compliance with buyer specifications, reducing the risk of receiving substandard products.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances that can affect their purchasing decisions.

-

Cultural and Regional Differences

Quality standards and expectations can vary significantly across regions. Buyers should familiarize themselves with local practices and regulations to avoid misunderstandings. For example, European buyers may have stricter standards compared to those in other regions. -

Communication Barriers

Effective communication is crucial for ensuring quality. Buyers should establish clear lines of communication with suppliers and ensure that language barriers do not impede quality discussions. Utilizing interpreters or bilingual staff can help bridge these gaps. -

Logistical Considerations

Shipping and logistics can impact product quality. Factors such as climate, transportation methods, and handling can affect the condition of blazers upon arrival. Buyers should discuss logistics with suppliers to ensure that products are adequately protected during transit.

By understanding the manufacturing processes and quality assurance protocols of blazer manufacturers, B2B buyers can make informed decisions that lead to successful partnerships and high-quality products.

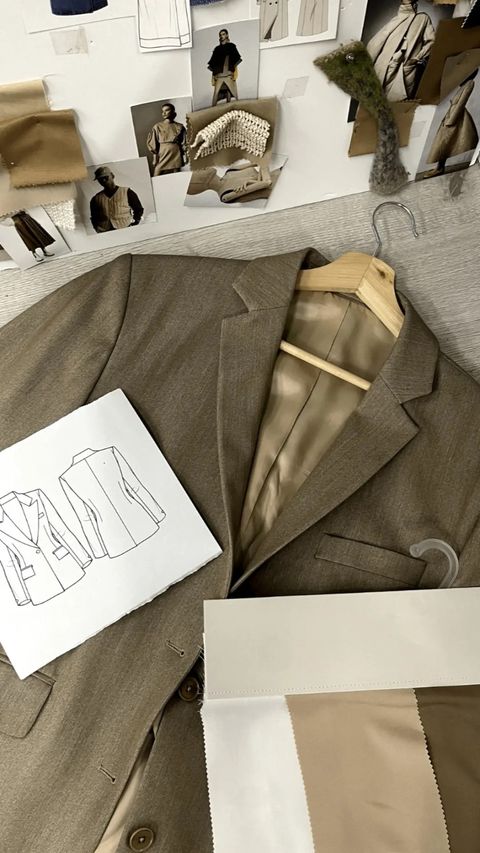

A stock image related to blazer manufacturer.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘blazer manufacturer’

When sourcing a blazer manufacturer, having a structured approach is essential to ensure that you find a reliable partner who meets your quality and business needs. This checklist provides actionable steps that will guide you through the sourcing process, helping you make informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the manufacturer can meet your product requirements. Consider factors such as fabric type, stitching quality, size range, and design features. Document these specifications in detail, as they will serve as a foundation for discussions with potential suppliers.

- Key Considerations:

- Identify the materials you prefer (e.g., wool, cotton, blends).

- Determine the desired fit and styles (e.g., tailored, casual).

- Specify any additional features (e.g., lining, pockets).

Step 2: Conduct Market Research

Before reaching out to manufacturers, conduct thorough market research to understand industry trends and pricing benchmarks. This knowledge will help you assess suppliers more effectively and negotiate better terms.

- Research Tools:

- Use industry reports to identify leading manufacturers.

- Explore online forums and social media groups for insights on current trends and challenges.

- Review competitor offerings to understand market positioning.

Step 3: Evaluate Potential Suppliers

Carefully vet each potential supplier to ensure they align with your business goals. Request company profiles, case studies, and references from buyers in similar industries or regions. This assessment will provide insight into their reliability and capacity.

- What to Look For:

- Certifications such as ISO or SA8000, which indicate adherence to quality standards.

- A portfolio showcasing previous work, particularly in your desired style.

- Client testimonials that highlight their experience and reliability.

Step 4: Verify Quality Control Processes

Understanding a manufacturer’s quality control processes is essential to ensure the final product meets your specifications. Ask about their inspection protocols and any third-party quality assurance measures they employ.

- Key Questions:

- What quality assurance processes do you have in place?

- How do you handle defective products or customer complaints?

- Can you provide samples for evaluation before full production?

Step 5: Negotiate Terms and Pricing

Once you have shortlisted potential suppliers, it’s time to negotiate terms and pricing. Be transparent about your budget and expectations, and explore options for bulk orders or long-term partnerships.

- Negotiation Tips:

- Discuss payment terms, lead times, and minimum order quantities.

- Consider establishing a trial order to assess quality before committing to larger purchases.

- Ensure clarity on shipping and handling costs to avoid unexpected expenses.

Step 6: Assess Communication and Responsiveness

Evaluate how well potential suppliers communicate and respond to inquiries. Effective communication is critical for a successful partnership, especially when dealing with potential issues during production.

- Communication Indicators:

- Promptness in responses to your queries.

- Clarity and professionalism in their communication style.

- Willingness to provide updates throughout the production process.

Step 7: Finalize the Agreement

After thorough evaluation and negotiation, finalize the agreement with the chosen manufacturer. Ensure that all terms, including specifications, pricing, and delivery timelines, are clearly documented in a contract.

- Contract Essentials:

- Include a detailed description of the products and specifications.

- Outline payment schedules and penalties for late deliveries.

- Specify terms for returns and refunds in case of quality issues.

By following this checklist, you can navigate the sourcing process for a blazer manufacturer effectively, ensuring a partnership that meets your business needs and quality expectations.

Comprehensive Cost and Pricing Analysis for blazer manufacturer Sourcing

What Are the Key Cost Components in Blazer Manufacturing?

When considering the sourcing of blazers, international B2B buyers must understand the various cost components involved in manufacturing. The primary factors include:

-

Materials: The choice of fabric, lining, and additional components significantly influences the overall cost. High-quality materials like wool, silk, or specialized blends will elevate prices, while cheaper synthetic options may reduce costs but could impact the product’s perceived value.

-

Labor: Labor costs can vary widely based on the manufacturing location. Countries with lower labor costs, such as those in parts of Africa and South America, may offer competitive pricing. However, it’s crucial to evaluate the skill level of the workforce, as this affects the quality of craftsmanship.

-

Manufacturing Overhead: This encompasses utilities, rent, and administrative costs associated with running a manufacturing facility. Buyers should inquire about these overheads to understand how they contribute to the final price.

-

Tooling: Custom tooling for specific designs can be a significant upfront investment. Buyers should consider whether the manufacturer has the capacity for custom designs and the associated costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures that products meet the required standards. Buyers should assess the QC measures of potential suppliers, as this can affect both pricing and product quality.

-

Logistics: Shipping and handling costs must also be factored into the total cost. The choice of logistics partner, shipping methods, and distance from the manufacturing site to the destination all influence this component.

-

Margin: Manufacturers typically include a profit margin in their pricing. Understanding the market dynamics and the competitive landscape can help buyers negotiate better terms.

How Do Price Influencers Affect Blazer Manufacturing Costs?

Several factors can influence the pricing of blazers, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs. Buyers should consider their needs carefully to optimize their order sizes and negotiate better rates.

-

Specifications and Customization: Custom designs or specific fabric requirements can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials Quality and Certifications: High-quality materials and certifications (e.g., sustainable sourcing, organic materials) can add to the price but may also enhance the product’s marketability.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can impact pricing. Buyers should conduct thorough due diligence to assess potential suppliers.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is crucial, as they determine who is responsible for shipping costs and risks. This can significantly affect the total landed cost of the blazers.

What Are Effective Buyer Tips for Negotiating Prices?

International B2B buyers should adopt strategic approaches to ensure cost-efficiency in sourcing blazers:

-

Negotiate Wisely: Engage suppliers in open discussions about pricing. Leverage your understanding of the cost components to negotiate better terms, particularly for larger orders.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors such as durability, maintenance, and potential resale value. A higher upfront cost may lead to lower long-term expenses.

-

Understand Pricing Nuances: Be aware that pricing can vary based on market conditions, currency fluctuations, and seasonal demand. Timing your purchases can lead to significant savings.

-

Build Relationships with Suppliers: Establishing a strong relationship with your suppliers can lead to better pricing, priority service, and access to exclusive products or customizations.

-

Consider Local Regulations and Tariffs: For buyers in regions like Europe, Africa, and the Middle East, understanding local import regulations, tariffs, and taxes is vital. This knowledge can help avoid unexpected costs and ensure compliance.

Disclaimer on Indicative Prices

Prices for blazer manufacturing can vary significantly based on the factors discussed. It is advisable for buyers to seek multiple quotes and perform a detailed cost analysis tailored to their specific needs and market conditions.

Alternatives Analysis: Comparing blazer manufacturer With Other Solutions

Understanding Alternatives to Blazer Manufacturing

In the competitive landscape of B2B apparel sourcing, understanding the alternatives to traditional blazer manufacturing is crucial for international buyers. Factors such as performance, cost, ease of implementation, and maintenance can significantly influence the decision-making process. This section provides a detailed comparison of blazer manufacturing against two viable alternatives: custom tailoring services and automated apparel production technologies.

Comparison Table of Blazer Manufacturing Alternatives

| Comparison Aspect | Blazer Manufacturer | Custom Tailoring Services | Automated Apparel Production Technologies |

|---|---|---|---|

| Performance | High-quality, consistent output | Personalized fit and style | High volume, consistent quality |

| Cost | Moderate to high | High (due to labor costs) | Lower per unit for large orders |

| Ease of Implementation | Relatively straightforward | Time-consuming | Requires initial investment in technology |

| Maintenance | Low maintenance | Requires ongoing adjustments | Minimal, depending on machine upkeep |

| Best Use Case | Bulk orders for businesses | Unique, one-off designs | Mass production and quick turnarounds |

What Are the Pros and Cons of Custom Tailoring Services?

A stock image related to blazer manufacturer.

Custom tailoring services provide a unique alternative for businesses looking for bespoke blazer solutions. The primary advantage is the personalized fit and style, allowing companies to create a distinctive brand identity. However, the costs associated with custom tailoring can be significantly higher due to labor-intensive processes, making it less viable for bulk orders. Additionally, the turnaround time can be lengthy, which may not align with urgent business needs.

How Do Automated Apparel Production Technologies Compare?

Automated apparel production technologies represent a modern solution for businesses aiming for efficiency. These systems can produce high volumes of blazers with consistent quality at a lower cost per unit, particularly beneficial for large orders. However, the initial investment in technology can be substantial, and the implementation process may require technical expertise. While maintenance needs are generally low, businesses must consider the long-term commitment to automation.

Conclusion: How Can B2B Buyers Choose the Right Blazer Solution?

For international B2B buyers, the choice between blazer manufacturing, custom tailoring, and automated production technologies hinges on specific business needs. Companies with a demand for bulk orders and consistent quality may find blazer manufacturing to be the most cost-effective solution. In contrast, those seeking unique designs or custom fits might lean towards tailoring services, despite the higher costs. Lastly, businesses looking to scale production efficiently could benefit from investing in automated technologies. Evaluating these options against factors like budget, urgency, and desired quality will enable buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for blazer manufacturer

What Are the Essential Technical Properties for Blazer Manufacturing?

Understanding the key technical properties of blazers is crucial for international B2B buyers. Here are some essential specifications that can impact the quality and functionality of the product:

-

Material Grade

The material grade refers to the specific type of fabric used in blazer manufacturing, such as wool, polyester, or cotton blends. Higher-grade materials typically offer better durability, comfort, and breathability, which are essential for end-users. B2B buyers should evaluate the material grade to ensure it aligns with their target market’s needs and preferences. -

Tolerance Levels

Tolerance levels in manufacturing indicate the acceptable range of variation for dimensions and specifications. For blazers, this could involve measurements for sleeve length, shoulder width, and overall fit. Proper tolerance ensures a consistent fit and quality, which is vital for maintaining brand reputation. Buyers should specify their tolerance requirements to avoid discrepancies in production. -

Stitch Density

Stitch density refers to the number of stitches per inch in the seams of the blazer. A higher stitch density usually translates to stronger seams and better durability. This is particularly important for blazers designed for frequent wear. Buyers should inquire about stitch density when evaluating suppliers to ensure product longevity. -

Weight of Fabric

The weight of the fabric, measured in grams per square meter (GSM), affects the blazer’s drape and overall feel. Lighter fabrics are suitable for warmer climates, while heavier fabrics provide insulation for colder environments. Buyers should consider the intended use and climate of their target market when selecting fabric weight. -

Color Fastness

Color fastness indicates the resistance of the fabric’s dye to fading or running when exposed to various conditions, such as washing or sunlight. High color fastness is essential for maintaining the visual appeal of blazers over time. B2B buyers should request testing results to ensure they meet their quality standards.

What Are Common Trade Terms in Blazer Manufacturing?

Navigating the world of blazer manufacturing involves understanding specific trade terminology. Here are some key terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then sold under another company’s brand name. In the context of blazers, OEMs may produce garments for various fashion labels. Understanding OEM relationships can help buyers find reliable manufacturers that meet their quality standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to produce or sell. This term is critical for B2B buyers as it impacts inventory management and cost-efficiency. Buyers should negotiate MOQs that align with their sales forecasts to avoid overstocking or understocking situations. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products. In blazer manufacturing, an RFQ typically outlines the desired specifications, quantities, and delivery timelines. Issuing an RFQ helps buyers compare prices and select suppliers that offer the best value. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects like shipping, insurance, and customs duties. Familiarity with Incoterms is essential for B2B buyers to understand their liabilities and ensure smooth logistics. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the finished product. This includes production and shipping time. Understanding lead times is crucial for inventory planning and meeting market demands. Buyers should always confirm lead times with suppliers to ensure timely delivery.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions that enhance their sourcing strategies and ultimately improve their bottom line.

Navigating Market Dynamics and Sourcing Trends in the blazer manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Blazer Manufacturing Sector?

The global blazer manufacturing sector is undergoing significant transformation driven by various factors. Key trends include the increasing demand for customization and personalization, particularly among millennials and Gen Z consumers. This demographic shift emphasizes the need for manufacturers to adopt flexible production techniques that allow for quick adjustments to designs and materials, catering to unique customer preferences. Additionally, advancements in technology, such as 3D printing and AI-driven design software, are reshaping the manufacturing landscape, enabling faster prototyping and production cycles.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The growth of e-commerce platforms has made sourcing more accessible, allowing buyers to connect directly with manufacturers, thus reducing costs and lead times. Furthermore, geopolitical shifts and trade agreements are influencing supply chain strategies, necessitating a keen awareness of regional market conditions and potential disruptions.

Emerging markets are also becoming focal points for sourcing blazers, as manufacturers seek to capitalize on lower labor costs and growing local demand. Buyers should be aware of these trends to identify potential suppliers that align with their business goals and ensure they remain competitive in an ever-evolving marketplace.

How Is Sustainability Influencing Sourcing Trends in Blazer Manufacturing?

Sustainability has become a central concern in the blazer manufacturing sector, with increasing pressure from consumers and regulatory bodies for environmentally responsible practices. The environmental impact of textile production is significant, contributing to pollution and waste. Consequently, B2B buyers are now prioritizing suppliers that demonstrate a commitment to ethical sourcing and sustainability.

Incorporating sustainable materials, such as organic cotton, recycled polyester, and eco-friendly dyes, not only helps reduce environmental footprints but also enhances brand reputation. Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are becoming essential for buyers seeking to ensure compliance with ethical sourcing standards.

Furthermore, ethical supply chains are gaining traction as consumers demand transparency regarding the origins of their clothing. This shift is particularly important for buyers in regions like Europe, where sustainability is a core consumer value. By partnering with manufacturers committed to sustainable practices, B2B buyers can enhance their corporate social responsibility (CSR) initiatives and appeal to eco-conscious consumers.

What Is the Historical Context of Blazer Manufacturing That B2B Buyers Should Know?

The blazer manufacturing sector has evolved significantly over the past few decades, transitioning from traditional craftsmanship to modern industrial production. Initially, blazers were primarily tailored for formal occasions, but the rise of casual and business-casual attire has broadened their appeal.

The introduction of synthetic materials in the mid-20th century revolutionized the industry, providing manufacturers with cost-effective options that appealed to a mass market. Today, the fusion of fashion and functionality continues to drive innovation, with manufacturers experimenting with various fabrics and technologies to meet changing consumer demands.

For B2B buyers, understanding this evolution is essential for recognizing the potential of both established and emerging manufacturers. The historical context provides insights into market maturity, innovation capabilities, and the adaptability of suppliers, which can inform sourcing decisions and partnerships in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of blazer manufacturer

-

How can I determine the quality of a blazer manufacturer?

To assess the quality of a blazer manufacturer, start by reviewing their certifications and industry standards compliance, such as ISO or other relevant quality management systems. Request samples of their products to evaluate fabric quality, stitching, and overall craftsmanship. Additionally, check customer reviews and case studies from previous clients, particularly those in your industry or region, to gauge their reputation and reliability. -

What are the key factors to consider when selecting a blazer manufacturer?

Key factors include the manufacturer’s experience in the industry, production capacity, and ability to meet your specific needs. Evaluate their design capabilities for customization, turnaround times, and communication efficiency. It’s also crucial to consider their compliance with international trade regulations and ethical manufacturing practices, especially when sourcing from regions like Africa or South America. -

What minimum order quantities (MOQ) should I expect from blazer manufacturers?

Minimum order quantities can vary significantly among manufacturers. Generally, you can expect MOQs ranging from 100 to 1,000 units, depending on the complexity of the design and the materials used. Some manufacturers may offer lower MOQs for initial orders or samples, but be prepared for higher costs per unit at smaller quantities. Always clarify MOQ terms during initial negotiations. -

What customization options are available when sourcing blazers?

Customization options typically include fabric selection, color choices, design modifications, and sizing adjustments. Some manufacturers may also provide branding options, such as embroidered logos or personalized labels. Discuss your specific requirements upfront to ensure the manufacturer can accommodate your requests and understand any additional costs or lead times associated with custom orders. -

What payment terms are common when working with blazer manufacturers?

Payment terms can vary widely, but common practices include a 30-50% deposit upon order confirmation, with the balance due before shipment. Some manufacturers may offer credit terms or flexible payment options based on your relationship and order history. Always negotiate clear payment terms and ensure they are documented in the contract to avoid misunderstandings. -

How can I ensure quality assurance during the manufacturing process?

Implementing quality assurance (QA) practices involves several steps. First, establish clear product specifications and quality standards in your contract. Consider scheduling regular inspections during the production process, either through third-party inspection services or by visiting the factory yourself. Additionally, request quality control reports and ensure the manufacturer has a robust QA system in place to monitor production consistency. -

What are the logistics considerations when sourcing blazers internationally?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose between air freight for speed and sea freight for cost-effectiveness, depending on your urgency. Familiarize yourself with the import/export regulations of both the manufacturer’s country and your own to avoid delays. Collaborate with a reliable freight forwarder who can assist with documentation and ensure smooth delivery. -

How can I build a long-term relationship with a blazer manufacturer?

Building a long-term relationship involves regular communication, transparency, and mutual respect. Provide feedback on products and services to help the manufacturer improve. Consider placing consistent orders to demonstrate commitment and reliability. Additionally, collaborating on new designs or product lines can strengthen your partnership, fostering loyalty and better pricing as your relationship develops.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for blazer manufacturer

As the global market for blazer manufacturing continues to evolve, strategic sourcing emerges as a critical component for international B2B buyers. By identifying reliable suppliers and fostering strong partnerships, companies can enhance their supply chain resilience and ensure consistent quality in their products. The importance of understanding regional market dynamics—especially in Africa, South America, the Middle East, and Europe—cannot be overstated. Buyers must consider local economic conditions, cultural preferences, and logistical challenges when selecting partners.

How can B2B buyers leverage strategic sourcing for competitive advantage? By embracing data-driven decision-making and conducting thorough market research, businesses can uncover opportunities for cost savings and innovation. Engaging in sustainable practices not only improves brand reputation but also meets the growing demand for ethically produced garments.

Looking ahead, the future of blazer manufacturing is promising. As trends shift towards customization and eco-friendly materials, international buyers are encouraged to adapt and innovate. Now is the time to strengthen your sourcing strategies and explore new partnerships that align with your business goals. Take the next step towards securing your supply chain and enhancing your product offerings by reaching out to potential suppliers today.