Discover Top Benefits of Working with a Wand Manufacturer (2025)

Introduction: Navigating the Global Market for wand manufacturer

In today’s competitive landscape, sourcing high-quality wand manufacturers can pose significant challenges for international B2B buyers. As the demand for unique and customizable wands grows across various sectors—including entertainment, education, and retail—navigating the complexities of global sourcing becomes essential. This guide provides a comprehensive overview of the wand manufacturing industry, delving into the different types of wands available, their diverse applications, and the critical factors to consider when vetting suppliers.

International buyers from Africa, South America, the Middle East, and Europe, particularly in regions like Italy and Australia, will find actionable insights tailored to their unique market dynamics. We will explore essential aspects such as cost considerations, production timelines, and quality assurance processes, empowering you to make informed purchasing decisions. By understanding the nuances of the wand manufacturing market, buyers can not only streamline their sourcing strategies but also enhance their product offerings, ensuring they meet customer demands effectively.

This guide serves as a valuable resource for businesses looking to thrive in the global market, enabling you to navigate challenges and capitalize on opportunities within the wand manufacturing sector. Whether you are a small retailer or a large distributor, the insights provided here will help you build a robust supply chain and foster lasting relationships with reputable manufacturers.

Understanding wand manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Craft Manufacturers | Handcrafted, unique designs, local materials | Boutique shops, artisanal markets | Pros: Unique offerings, high quality. Cons: Higher costs, longer lead times. |

| Industrial Scale Manufacturers | Mass-produced, standardized designs, cost-effective | Large retailers, e-commerce platforms | Pros: Competitive pricing, quick turnaround. Cons: Less customization, quality variability. |

| Custom Wand Manufacturers | Tailored designs based on client specifications | Specialty retailers, promotional events | Pros: Personalized products, branding opportunities. Cons: Longer production times, potentially higher costs. |

| Eco-Friendly Manufacturers | Sustainable materials, environmentally conscious | Green retailers, eco-conscious brands | Pros: Positive brand image, growing market demand. Cons: Limited material options, higher production costs. |

| Technology-Integrated Manufacturers | Incorporation of tech features (e.g., smart wands) | Tech retailers, educational institutions | Pros: Innovative products, niche market appeal. Cons: Higher complexity, requires tech support. |

What Are the Characteristics of Traditional Craft Manufacturers?

Traditional craft manufacturers specialize in creating wands that are often handcrafted using local materials. These artisans prioritize unique designs and techniques, making each wand a one-of-a-kind product. B2B buyers interested in this type often cater to boutique shops or artisanal markets looking for distinctive offerings. When purchasing, consider the longer lead times and higher costs associated with these handcrafted items, but also the potential for higher margins due to their uniqueness.

How Do Industrial Scale Manufacturers Operate?

Industrial scale manufacturers focus on mass production of wands, which allows them to offer standardized designs at competitive prices. This type is ideal for B2B buyers in large retail or e-commerce settings that require a steady supply of products. While the quick turnaround times and cost-effectiveness are appealing, buyers should be aware of the potential for quality variability and limited customization options, which could impact brand differentiation.

What Should B2B Buyers Know About Custom Wand Manufacturers?

Custom wand manufacturers provide the opportunity for tailored designs based on specific client needs. This type is particularly beneficial for specialty retailers or businesses hosting promotional events, as it allows for personalized branding opportunities. However, B2B buyers should anticipate longer production times and potentially higher costs. The ability to create a unique product can lead to enhanced customer engagement and loyalty, making it a worthwhile investment.

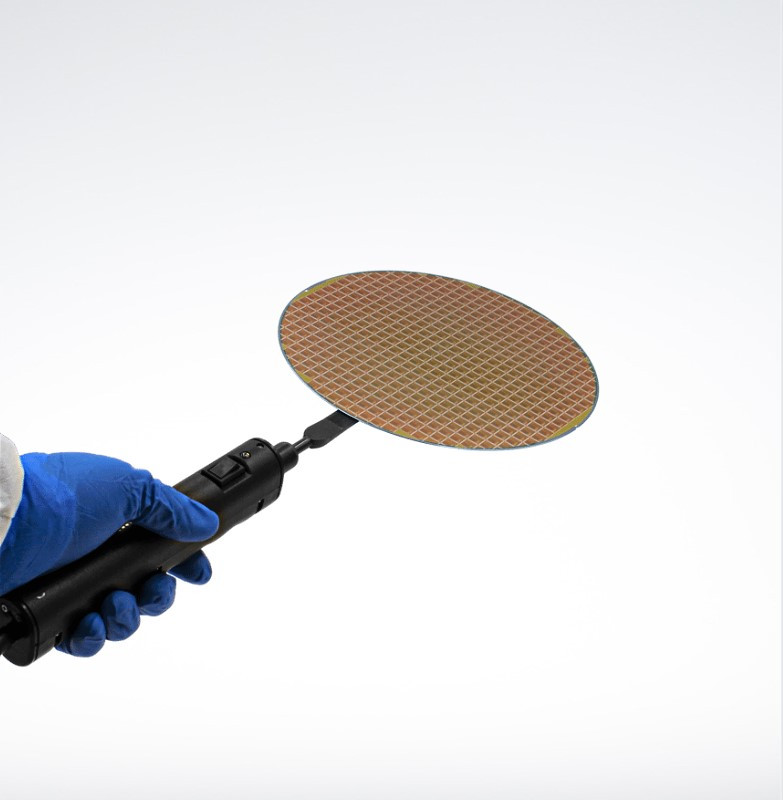

A stock image related to wand manufacturer.

Why Choose Eco-Friendly Manufacturers?

Eco-friendly manufacturers focus on sustainability, utilizing materials that are environmentally conscious. This type is increasingly relevant for green retailers and brands that prioritize corporate social responsibility. B2B buyers can benefit from a positive brand image and align with the growing consumer demand for eco-friendly products. However, it’s essential to consider the limited material options and higher production costs that may come with this choice.

How Are Technology-Integrated Manufacturers Innovating the Market?

Technology-integrated manufacturers are at the forefront of innovation, creating wands that incorporate tech features such as smart functionalities. This type appeals to tech retailers and educational institutions seeking to integrate modern technology into their offerings. While these products can capture niche market interest and provide unique selling propositions, buyers must be prepared for higher complexity and the need for technical support to ensure customer satisfaction.

Related Video: Variations In Construction Projects Explained

Key Industrial Applications of wand manufacturer

| Industry/Sector | Specific Application of Wand Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Medical Device Manufacturing | Enhances precision in diagnostics and treatment | Compliance with health regulations, quality assurance protocols |

| Entertainment | Stage and Event Production | Facilitates dynamic lighting and visual effects | Customization options, durability under high-intensity use |

| Education | Interactive Learning Tools | Engages students through interactive technology | Compatibility with existing systems, ease of use and training |

| Manufacturing | Automation and Robotics | Increases efficiency and reduces labor costs | Integration capabilities, technical support, and maintenance |

| Cosmetics | Application in Beauty Treatments | Improves application precision and customer satisfaction | Material safety, hypoallergenic options, and aesthetic appeal |

How is Wand Manufacturing Used in Healthcare Applications?

In the healthcare sector, wand manufacturers produce devices that enhance diagnostic and treatment capabilities. For instance, wand-like instruments are often used in minimally invasive surgeries and precise imaging techniques. These tools solve problems related to patient safety and procedural efficiency. International buyers from Africa and the Middle East should prioritize suppliers who adhere to stringent health regulations, ensuring product reliability and quality assurance, which are critical in this sensitive industry.

What Role Do Wands Play in Entertainment Production?

In the entertainment industry, wands are integral to stage and event production, enabling advanced lighting and visual effects. They are utilized in concerts, theater productions, and corporate events to create immersive experiences. The value lies in their ability to transform environments dynamically, enhancing audience engagement. Buyers from South America and Europe should seek manufacturers that offer customization options and durable products designed to withstand rigorous use.

How Do Wands Enhance Educational Tools?

Wand manufacturers supply interactive learning tools that have revolutionized classroom environments. These devices facilitate hands-on learning experiences, making education more engaging for students. They solve the challenge of passive learning by promoting interaction and participation. For B2B buyers in Europe, especially in Italy, it’s crucial to consider compatibility with existing educational technologies and the ease of training for educators to maximize the benefits of these tools.

What Are the Automation Applications of Wand Manufacturing in Manufacturing?

In the manufacturing sector, wands are often part of automation and robotics systems, used for tasks such as assembly, quality control, and packaging. These applications significantly enhance operational efficiency and reduce labor costs, addressing common challenges in production lines. International buyers, particularly from Africa and the Middle East, should focus on suppliers that provide robust integration capabilities and reliable technical support, ensuring seamless incorporation into existing manufacturing processes.

How Are Wands Used in the Cosmetics Industry?

Wand manufacturers cater to the cosmetics industry by producing tools that improve the application of beauty treatments. These products enhance precision in applying makeup and skincare, leading to increased customer satisfaction. Buyers should consider sourcing options that prioritize material safety and hypoallergenic properties, as well as the aesthetic appeal of the products, which can significantly impact brand perception in competitive markets in South America and Europe.

Related Video: Types Of Flowmeters And Their Industrial Applications.

3 Common User Pain Points for ‘wand manufacturer’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Wand Manufacturing

The Problem:

International B2B buyers often face significant challenges when it comes to ensuring the quality of wands sourced from manufacturers, especially when dealing with suppliers in regions with varying quality standards. For instance, a company in South America might find that the wands they receive from a Middle Eastern manufacturer do not meet their specifications or durability requirements. This inconsistency can lead to product failures, customer dissatisfaction, and ultimately, financial losses. Furthermore, language barriers and cultural differences can complicate the quality assurance process, making it difficult to communicate precise requirements.

The Solution:

To effectively navigate quality assurance issues, buyers should implement a robust supplier evaluation process before committing to a manufacturer. This includes conducting thorough background checks, reviewing product samples, and requesting certifications that demonstrate compliance with international quality standards, such as ISO 9001. Additionally, establishing a clear and detailed specification document that outlines the desired materials, dimensions, and performance criteria can help align expectations. Regular communication during the production process, including scheduled quality checks, can also mitigate risks. Consider utilizing third-party inspection services to verify product quality before shipment, ensuring that the delivered wands meet the agreed-upon standards.

Scenario 2: Dealing with Supply Chain Disruptions

The Problem:

Supply chain disruptions are a common pain point for B2B buyers in the wand manufacturing industry, particularly for those sourcing from international suppliers. For example, a manufacturer in Europe may experience delays due to geopolitical tensions or logistical challenges, impacting their ability to meet production schedules. This unpredictability can lead to stock shortages, missed deadlines, and a loss of competitive edge in the market, causing significant stress for procurement managers.

The Solution:

To counteract supply chain disruptions, buyers should diversify their supplier base by sourcing from multiple manufacturers across different regions. This strategy minimizes the risk of over-reliance on a single supplier and enhances flexibility in response to unforeseen challenges. Additionally, implementing a just-in-time inventory system can help manage stock levels more efficiently, allowing companies to respond quickly to changes in demand. Establishing strong relationships with logistics partners and utilizing real-time tracking technologies can also provide greater visibility into shipping statuses, enabling proactive decision-making to mitigate delays.

Scenario 3: Understanding Cost Structures and Pricing Transparency

The Problem:

Another prevalent challenge for B2B buyers is navigating the complex cost structures associated with wand manufacturing. Buyers often struggle to understand the various factors that contribute to pricing, leading to potential overpayments or misaligned budget expectations. For instance, a buyer from Africa might find that the quoted price for a batch of wands includes hidden fees, such as shipping costs or tariffs, which were not initially disclosed. This lack of transparency can create budgeting issues and strain supplier relationships.

The Solution:

To gain clarity on pricing structures, buyers should engage in open discussions with manufacturers about the components that make up the quoted price. Requesting a detailed breakdown of costs, including materials, labor, shipping, and any applicable taxes, can help illuminate potential hidden fees. Additionally, buyers can consider leveraging purchasing power by negotiating bulk discounts or exploring long-term contracts that lock in pricing. Utilizing cost analysis tools can also provide insight into market trends and help buyers make informed decisions. Finally, fostering transparent communication with suppliers can build trust and lead to better pricing agreements in the future, enhancing overall procurement efficiency.

Strategic Material Selection Guide for wand manufacturer

When selecting materials for wand manufacturing, it is essential to consider the unique properties, advantages, and limitations of various materials. This guide will analyze four common materials used in wand production, providing insights tailored for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Wood in Wand Manufacturing?

Wood is one of the most traditional materials used in wand manufacturing. Its natural aesthetics and varied grain patterns make it a popular choice.

- Key Properties: Wood is lightweight, has good tensile strength, and is generally easy to work with. However, it is susceptible to warping and moisture absorption, which can affect its performance over time.

- Pros & Cons: The primary advantage of wood is its natural beauty and the ability to customize each wand. However, wood can be less durable than synthetic materials and may require regular maintenance. It is also more sensitive to environmental conditions, which can lead to inconsistencies in quality.

- Impact on Application: Wood wands are often used in theatrical productions and magical performances where aesthetics are paramount, but they may not withstand harsh conditions or heavy usage.

- Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding the sourcing of wood, particularly in Europe where sustainability certifications are crucial. Familiarity with standards like FSC (Forest Stewardship Council) can enhance credibility.

How Does Plastic Compare as a Material for Wand Manufacturing?

Plastic has gained popularity in recent years due to its versatility and cost-effectiveness.

- Key Properties: Plastics can be engineered to have specific properties, such as high impact resistance and moisture resistance. They can also be molded into complex shapes, which is beneficial for intricate designs.

- Pros & Cons: The main advantage of plastic is its affordability and durability. However, lower-quality plastics may not provide the same aesthetic appeal as wood or metal, and they can be less environmentally friendly.

- Impact on Application: Plastic wands are often used in educational settings or as promotional items where cost and durability are more critical than aesthetics.

- Considerations for International Buyers: Compliance with environmental regulations is vital, especially in regions like Europe, where there is a strong push for sustainable materials. Buyers should also consider the recyclability of the plastics used.

What Are the Advantages of Metal in Wand Manufacturing?

Metal, particularly aluminum and stainless steel, is another option for wand manufacturing, known for its strength and durability.

- Key Properties: Metals offer excellent strength-to-weight ratios and resistance to corrosion, making them suitable for various applications. They can withstand high temperatures and pressures, which is beneficial in specific contexts.

- Pros & Cons: The durability of metal wands is a significant advantage, as they can endure heavy use without damage. However, they are typically more expensive and may require specialized manufacturing processes, such as machining or welding.

- Impact on Application: Metal wands are ideal for performance arts where durability is essential, such as in stage combat or special effects. Their weight can also add to the dramatic effect.

- Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM (American Society for Testing and Materials) or DIN (Deutsches Institut für Normung) for metal quality. Additionally, understanding the import regulations for metals in different regions is crucial.

Why Is Composite Material a Good Choice for Wand Manufacturing?

Composite materials, combining various substances, offer unique benefits for wand manufacturing.

- Key Properties: Composites can be engineered to provide high strength, low weight, and resistance to environmental factors. They often outperform traditional materials in terms of durability and performance.

- Pros & Cons: The primary advantage of composites is their versatility and ability to be tailored to specific performance requirements. However, they can be more expensive to produce and may require specialized knowledge for manufacturing.

- Impact on Application: Composite wands are excellent for high-performance applications, such as in competitive sports or specialized theatrical performances where both strength and aesthetics are critical.

- Considerations for International Buyers: Buyers should ensure that composite materials meet relevant international standards and certifications, particularly in markets with stringent regulations like the EU.

Summary Table of Material Selection for Wand Manufacturing

| Material | Typical Use Case for wand manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Theatrical performances, decorative items | Natural beauty and customization | Susceptible to warping and moisture | Medium |

| Plastic | Educational tools, promotional items | Cost-effective and durable | Less aesthetic appeal than wood | Low |

| Metal | Stage combat, special effects | High durability and strength | Higher manufacturing costs | High |

| Composite | High-performance applications, competitive sports | Tailored performance and durability | More expensive and complex to produce | High |

This strategic material selection guide provides a foundation for international B2B buyers to make informed decisions when sourcing materials for wand manufacturing, ensuring that they align with both performance needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for wand manufacturer

What Are the Key Stages in the Manufacturing Process for Wands?

Manufacturing wands involves several critical stages that ensure the final product meets both aesthetic and functional standards. Understanding these processes can help B2B buyers make informed decisions when sourcing products.

Material Preparation: What Materials Are Typically Used?

The first step in wand manufacturing is material preparation, which often involves selecting high-quality raw materials. Common materials include:

- Wood: Often used for traditional wands, sourced from sustainable forests.

- Metals: For more modern or ceremonial wands, metals like aluminum or brass may be employed.

- Resins and Composites: These materials are frequently used for their versatility and durability.

Buyers should inquire about the sourcing of materials and whether suppliers follow sustainable practices, especially important in regions like Africa and South America where environmental concerns are paramount.

How Are Wands Formed?

Once materials are prepared, the forming process begins. This can vary significantly based on the wand’s intended use. Key techniques include:

- Carving: Traditional wooden wands are often hand-carved, ensuring unique designs.

- Molding: For plastic or resin wands, injection molding is commonly used, allowing for mass production with consistent quality.

- Machining: Metal wands may be produced through CNC machining, which provides high precision.

Buyers should consider the implications of these techniques on both cost and delivery times. Handcrafted items may have longer lead times but offer unique value.

What Does the Assembly Process Entail?

After forming, the assembly process integrates different components of the wand. This may involve:

- Joining Techniques: Depending on the materials, techniques such as gluing, welding, or screwing may be used.

- Finishing Touches: This includes painting, varnishing, or adding decorative elements, ensuring the wand is visually appealing and functional.

Understanding the assembly process helps buyers evaluate potential lead times and the complexity involved in custom orders.

How Is Quality Assurance Implemented in Wand Manufacturing?

Quality assurance (QA) is critical in the wand manufacturing process to ensure products meet international standards. Key aspects include:

- International Standards Compliance: Many manufacturers adhere to ISO 9001, which outlines criteria for a quality management system. This standard is crucial for B2B buyers in Europe and other regions that prioritize quality assurance.

- Industry-Specific Standards: Depending on the wand’s use, certifications such as CE marking for European markets or API standards may be relevant.

Buyers should verify a manufacturer’s commitment to these standards, which can often be indicated on product specifications or marketing materials.

What Are the Key Quality Control Checkpoints?

To maintain high-quality standards, manufacturers implement several quality control (QC) checkpoints throughout the production process:

- Incoming Quality Control (IQC): This initial step assesses raw materials for defects before production begins. Buyers should inquire about the criteria used for material acceptance.

- In-Process Quality Control (IPQC): During manufacturing, random checks are performed to ensure that the process remains within specified limits.

- Final Quality Control (FQC): Once production is complete, a thorough inspection is conducted to ensure that the finished product meets all specifications.

Understanding these checkpoints can help B2B buyers assess how a manufacturer maintains quality throughout the production cycle.

What Testing Methods Are Commonly Used in Wand Manufacturing?

Various testing methods are employed to ensure that wands meet quality and safety standards. Some common techniques include:

- Dimensional Testing: Ensures that the wand meets specified measurements.

- Material Testing: Assess the durability and safety of materials used, particularly for those that might be exposed to wear and tear.

- Performance Testing: For functional wands, ensuring they meet operational standards is crucial.

B2B buyers should ask manufacturers about their testing protocols and any certifications that validate their testing methods.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for international B2B buyers. Here are some actionable steps:

- Request Documentation: Ask for quality control reports, certifications, and compliance documentation to review the supplier’s adherence to international standards.

- Conduct Audits: If possible, perform on-site audits to observe the manufacturing and QC processes firsthand.

- Utilize Third-Party Inspections: Engage third-party inspection services to conduct independent evaluations of the supplier’s processes and products.

These actions can significantly mitigate risks associated with sourcing from international suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from Africa, South America, the Middle East, and Europe should be aware of certain nuances in quality control:

- Cultural Differences: Quality expectations may vary across regions. Buyers should communicate their standards clearly and ensure that suppliers understand these expectations.

- Regulatory Compliance: Different regions may have specific regulations regarding product safety and quality, which suppliers must comply with.

- Supply Chain Transparency: Establishing transparency in the supply chain can help buyers monitor quality more effectively, especially when sourcing from diverse markets.

By understanding these nuances, buyers can make more informed decisions and build stronger relationships with suppliers.

Conclusion

In-depth knowledge of manufacturing processes and quality assurance practices is crucial for B2B buyers in the wand industry. By focusing on material selection, production techniques, and rigorous quality control measures, buyers can ensure they partner with manufacturers who deliver high-quality products. This understanding not only enhances the buyer’s ability to negotiate but also fosters confidence in the long-term success of their sourcing strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wand manufacturer’

In the competitive landscape of sourcing wands for various applications, having a structured approach can significantly enhance your procurement process. This checklist serves as a practical guide for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, to ensure that they make informed and strategic sourcing decisions.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, clearly outline your technical specifications. This includes the materials, dimensions, design requirements, and any specific features that the wands must have. A well-defined specification not only helps in receiving accurate quotes but also ensures that the product meets your functional and aesthetic needs.

- Material Requirements: Specify if you need wood, plastic, or metal.

- Dimensions: Provide exact measurements to avoid discrepancies.

Step 2: Conduct Market Research on Suppliers

To find the right manufacturers, perform thorough market research. Identify potential suppliers that specialize in wand manufacturing and have a proven track record. This step is essential for understanding the competitive landscape and the capabilities of various suppliers.

- Industry Reputation: Look for online reviews and testimonials.

- Market Presence: Evaluate their experience in international markets, particularly in your region.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, conduct a comprehensive evaluation. Request detailed company profiles, case studies, and references from previous buyers in a similar industry or region. This vetting process is vital to ensure reliability and quality.

- Certification Verification: Check for ISO certifications or other relevant industry standards.

- Quality Assurance Processes: Inquire about their quality control measures.

Step 4: Request Samples for Quality Assessment

Always request samples before finalizing your order. This allows you to assess the quality and craftsmanship of the wands firsthand. It is crucial to ensure that the samples align with your specifications and quality expectations.

- Testing Samples: Consider stress tests or usability assessments.

- Comparative Analysis: Evaluate samples from multiple suppliers to make informed decisions.

Step 5: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, payment terms, delivery schedules, and return policies. Clear terms are essential to avoid misunderstandings later in the partnership.

- Payment Options: Explore flexible payment terms that suit your cash flow.

- Delivery Timelines: Ensure that timelines align with your project schedules.

Step 6: Establish Communication Protocols

Effective communication is critical for a successful sourcing partnership. Establish clear lines of communication to ensure that both parties are on the same page regarding expectations, updates, and any potential issues.

- Regular Updates: Set a schedule for progress updates.

- Contact Points: Identify key contacts for both sides to streamline communication.

Step 7: Plan for Logistics and Import Regulations

Finally, understand the logistics involved in importing wands from your chosen supplier. Familiarize yourself with the import regulations and potential tariffs that may apply. Proper planning can help avoid delays and additional costs.

- Customs Documentation: Ensure that all necessary paperwork is prepared in advance.

- Shipping Options: Evaluate different shipping methods for cost-effectiveness and reliability.

By following this structured checklist, B2B buyers can confidently navigate the sourcing process for wand manufacturers, ensuring that they select the right partner to meet their needs while minimizing risks associated with international procurement.

Comprehensive Cost and Pricing Analysis for wand manufacturer Sourcing

What Are the Key Cost Components in Wand Manufacturing?

Understanding the cost structure of wand manufacturing is crucial for international B2B buyers to make informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include wood, resin, and metals, each with varying prices based on quality and availability. Sustainable materials may come at a premium but can enhance brand value.

-

Labor: Labor costs vary by region, influenced by local wage rates and the skill level required. For example, regions with a skilled artisan workforce may have higher labor costs but can offer superior craftsmanship.

-

Manufacturing Overhead: This includes utilities, rent, and operational costs. Manufacturers in regions with lower overhead costs can offer more competitive pricing.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. Buyers should consider whether the manufacturer has the capability to absorb these costs or if they will be passed on.

-

Quality Control (QC): Investment in QC ensures that the products meet specified standards, which can reduce returns and enhance customer satisfaction. However, stringent QC processes may lead to higher upfront costs.

-

Logistics: Shipping and handling costs can vary widely based on distance, transport methods, and import duties. Understanding the logistics involved can help buyers anticipate additional expenses.

-

Margin: Manufacturers typically add a margin to their costs to ensure profitability. This margin can vary based on market conditions and competition.

How Do Pricing Influencers Affect Wand Manufacturing Costs?

Several factors influence the pricing of wands, and understanding these can aid buyers in negotiating better deals:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Buyers should consider consolidating orders to take advantage of economies of scale.

-

Specifications and Customization: Custom designs or unique specifications may incur additional costs. It is essential for buyers to clarify their requirements upfront to avoid unexpected charges.

-

Material Quality and Certifications: Premium materials and certifications (like eco-friendly or safety standards) can increase costs but may also provide a competitive edge in the market.

-

Supplier Factors: The supplier’s reputation, location, and operational efficiencies can impact pricing. Established suppliers may charge more, but they often provide reliability and quality assurance.

-

Incoterms: Understanding Incoterms is vital for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of products, influencing overall pricing.

What Buyer Tips Can Optimize Wand Manufacturing Costs?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, the following strategies can enhance cost efficiency:

-

Negotiate Effectively: Open dialogue with suppliers can lead to better pricing. Discussing volume discounts, long-term contracts, or bundled services can yield significant savings.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes shipping, handling, storage, and potential wastage. This comprehensive view helps in making more informed purchasing decisions.

-

Understand Pricing Nuances: Be aware of how local economic conditions, currency fluctuations, and geopolitical factors can affect pricing. For instance, tariffs on imports may impact costs significantly, particularly for buyers in regions with stringent trade regulations.

-

Leverage Technology: Utilize digital platforms for sourcing to compare suppliers, read reviews, and gather insights on market pricing trends. This can help in making data-driven decisions.

Conclusion

Navigating the complexities of cost and pricing in wand manufacturing requires a thorough understanding of various components and influencers. By implementing strategic buying practices, international B2B buyers can optimize their sourcing decisions, ensuring they achieve the best value for their investments. Always remember that prices can fluctuate based on numerous factors; thus, maintaining flexibility in negotiations and sourcing strategies is essential for long-term success.

Alternatives Analysis: Comparing wand manufacturer With Other Solutions

Understanding Alternative Solutions to Wand Manufacturing

In the dynamic landscape of B2B manufacturing, international buyers must navigate various solutions to meet their specific needs. When considering a wand manufacturer, it is essential to explore viable alternatives that can provide similar functionalities and benefits. This analysis will focus on comparing traditional wand manufacturing with two notable alternatives: 3D Printing and Injection Molding. Each solution has unique strengths and weaknesses that can significantly impact business decisions.

| Comparison Aspect | Wand Manufacturer | 3D Printing | Injection Molding |

|---|---|---|---|

| Performance | High-quality, customizable | Good for prototypes, limited in mass production | Excellent for high-volume production |

| Cost | Moderate initial costs | High per-unit cost, but low initial investment | High setup costs, but low per-unit cost |

| Ease of Implementation | Requires skilled labor and time | Quick setup, no need for extensive tooling | Complex setup, requires molds |

| Maintenance | Varies by production scale | Low maintenance, but technology dependent | High maintenance for molds, but durable |

| Best Use Case | Custom, low-volume orders | Prototyping and small batches | High-volume, uniform products |

What Are the Pros and Cons of 3D Printing as an Alternative?

3D printing stands out as a flexible manufacturing method, particularly for businesses needing rapid prototyping or small batch production. One of its main advantages is the ability to create complex designs without the need for extensive tooling. This technology allows for quick iterations, which can significantly speed up product development cycles. However, the cost per unit remains high compared to traditional methods, making it less economical for large-scale production. Additionally, while 3D printing offers customization, the material options may be limited compared to traditional manufacturing techniques.

How Does Injection Molding Compare as an Alternative to Wand Manufacturing?

Injection molding is a well-established manufacturing process ideal for producing large quantities of identical items. Its main advantage lies in its cost-effectiveness at scale; once the initial mold is created, the cost per unit drops significantly. This method also supports a wide range of materials, allowing for robust and durable products. However, the high upfront costs associated with mold creation and the complexity of the setup process can be prohibitive for smaller businesses or those with fluctuating demand. Moreover, injection molding typically lacks the flexibility for customization that wand manufacturing or 3D printing can provide.

What Should B2B Buyers Consider When Choosing Between These Solutions?

Selecting the right manufacturing solution ultimately depends on a company’s specific needs, including production volume, budget constraints, and desired product characteristics. For businesses focused on high-volume orders with uniform specifications, injection molding may be the most suitable choice despite its initial investment. Conversely, companies looking for flexibility and rapid prototyping might find 3D printing more aligned with their goals, especially if they are testing new designs or require customization. Wand manufacturing remains a solid option for those needing high-quality, bespoke products in smaller quantities.

In conclusion, B2B buyers should conduct a thorough analysis of their requirements against the strengths and weaknesses of each manufacturing method. By doing so, they can make informed decisions that align with their operational goals and market demands, ensuring that they invest in the solution that best meets their needs.

Essential Technical Properties and Trade Terminology for wand manufacturer

What Are the Key Technical Properties Relevant to Wand Manufacturing?

Understanding the essential technical properties of wands is critical for B2B buyers to ensure product quality and performance. Here are several key specifications to consider:

1. Material Grade

The grade of the material used in wand manufacturing significantly affects durability and performance. Common materials include wood, plastic, or metal alloys, each offering unique benefits. For instance, hardwood wands provide an elegant appearance and durability, while plastic wands are lightweight and cost-effective. Selecting the appropriate material grade based on your target market and intended use is essential for meeting customer expectations.

2. Tolerance

Tolerance refers to the permissible limits of variation in a wand’s dimensions. This specification is crucial for ensuring that parts fit together correctly and function as intended. Inconsistent tolerances can lead to product failures or customer dissatisfaction. It’s vital to establish clear tolerance requirements in your specifications to maintain quality control and minimize returns.

3. Finish Quality

The finish quality of a wand impacts both aesthetics and functionality. This includes factors such as surface smoothness, coating, and color consistency. A high-quality finish not only enhances the visual appeal but also contributes to durability and resistance to wear. B2B buyers should prioritize suppliers who can consistently deliver superior finish quality to satisfy end-user expectations.

4. Weight Distribution

Weight distribution is an often-overlooked property that influences how a wand feels during use. A well-balanced wand enhances user experience, particularly in applications requiring prolonged handling. Buyers should inquire about the design process to ensure that the wand’s weight is evenly distributed, optimizing performance and comfort.

5. Customization Options

Customization capabilities allow buyers to tailor wands to specific market needs, such as branding or unique design features. Understanding the extent to which a manufacturer can accommodate custom requests—whether for color, engraving, or shape—can give your business a competitive edge. This flexibility can be particularly beneficial in niche markets.

What Trade Terms Should International Buyers Understand When Sourcing Wands?

Familiarizing yourself with industry jargon can streamline communication and negotiations with suppliers. Here are some common trade terms relevant to wand manufacturing:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are then sold by another company under their brand name. Understanding whether your supplier operates as an OEM can help clarify the manufacturing capabilities and the potential for customization. This term is especially relevant for buyers looking for branded products.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for budgeting and inventory management. Suppliers often set MOQs to ensure production efficiency, but understanding this can lead to better negotiation terms, especially for smaller businesses.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers asking for pricing and terms for specific products. Crafting a clear RFQ can help you receive accurate and comparable quotes, ensuring you make informed purchasing decisions. It is an essential step in the sourcing process.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help you understand shipping obligations and costs, ultimately influencing your total landed cost.

5. Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. Understanding lead times is crucial for inventory planning and customer satisfaction. It can vary significantly based on the supplier’s production capacity and logistics, so always clarify this aspect before finalizing agreements.

A stock image related to wand manufacturer.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions, ensuring they select the right wand manufacturer to meet their specific needs.

Navigating Market Dynamics and Sourcing Trends in the wand manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Wand Manufacturer Sector?

The wand manufacturing sector is witnessing significant transformation driven by global market dynamics and technological advancements. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, it’s crucial to understand these shifts. One of the primary drivers is the increasing demand for customized products. Businesses are leaning towards personalization, prompting manufacturers to invest in advanced manufacturing technologies such as 3D printing and CNC machining. These technologies enable the production of unique designs that cater to diverse consumer preferences across different regions.

Moreover, the rise of e-commerce platforms has streamlined the procurement process for B2B buyers, allowing easier access to a wider range of products. This trend is particularly impactful in regions like South America and Africa, where traditional supply chains are often less developed. Additionally, there is a growing emphasis on integrating digital tools, such as AI-driven inventory management systems, which optimize sourcing and reduce lead times.

Sustainability is another critical trend reshaping the industry. International buyers are increasingly prioritizing suppliers who adhere to environmentally friendly practices. This shift is not just a response to regulatory pressures; it also reflects changing consumer preferences, particularly in European markets, where eco-consciousness is prominent. Understanding these trends will empower B2B buyers to make informed sourcing decisions that align with both market demands and corporate social responsibility goals.

How Is Sustainability Impacting Sourcing Trends in the Wand Manufacturing Sector?

Sustainability and ethical sourcing have become paramount in the wand manufacturing sector. The environmental impact of production processes, such as resource depletion and waste generation, has prompted buyers to seek suppliers who prioritize sustainable practices. This shift is particularly relevant for B2B buyers in Europe, where stringent regulations regarding environmental standards are in place.

Ethical supply chains are gaining importance as consumers increasingly demand transparency. B2B buyers can enhance their brand reputation by partnering with manufacturers who source materials responsibly and maintain ethical labor practices. Certifications such as FSC (Forest Stewardship Council) for wood products and GOTS (Global Organic Textile Standard) for textiles are becoming essential for establishing credibility in the marketplace.

Additionally, the use of ‘green’ materials, such as recycled plastics and sustainably sourced woods, is on the rise. By incorporating these materials into their products, manufacturers not only reduce their environmental footprint but also appeal to a growing segment of eco-conscious consumers. For international buyers, understanding these sustainable sourcing trends is vital for aligning with market expectations and enhancing competitive advantage.

What Is the Historical Context of Wand Manufacturing in the B2B Space?

The wand manufacturing sector has evolved significantly over the decades, transitioning from artisanal craftsmanship to a more industrialized approach. Initially, wands were handcrafted by skilled artisans, with each piece reflecting unique cultural and personal significance. However, as demand increased, particularly in the entertainment and cosplay industries, manufacturers began adopting mass production techniques.

This evolution has been fueled by technological advancements, enabling manufacturers to produce wands that meet diverse consumer needs while maintaining quality. The rise of global trade has also expanded market access, allowing B2B buyers from various regions to source wands from manufacturers worldwide. Understanding this historical context provides valuable insights into current market dynamics and helps buyers navigate the complexities of sourcing in this ever-evolving sector.

Frequently Asked Questions (FAQs) for B2B Buyers of wand manufacturer

-

How do I choose the right wand manufacturer for my business needs?

When selecting a wand manufacturer, consider factors such as their production capacity, quality certifications, and experience in the industry. Request samples to assess the quality of their products and inquire about their customization options to ensure they can meet your specific requirements. Additionally, verify their reputation through customer testimonials and industry reviews. Establishing clear communication regarding your expectations and timelines is also crucial to ensure a successful partnership. -

What customization options are available when sourcing wands from manufacturers?

Many wand manufacturers offer a range of customization options, including material selection, size, color, and design features. Some may provide branding services, such as logo embossing or custom packaging. It’s essential to discuss your specific needs upfront and confirm the manufacturer’s capabilities. Ensure you understand any additional costs associated with customization and the lead times required for personalized orders. -

What is the minimum order quantity (MOQ) typically required by wand manufacturers?

The MOQ can vary significantly among wand manufacturers, often depending on the type of wand and the complexity of the design. While some manufacturers may accept orders as low as 100 units, others might require a minimum of 1,000 or more. Be sure to discuss your expected order volume during initial conversations to find a manufacturer that aligns with your purchasing capacity and business model. -

What payment terms should I expect when working with wand manufacturers?

Payment terms can differ widely based on the manufacturer and your location. Common terms include a 30% deposit upfront, with the remaining balance due upon delivery or prior to shipping. It’s essential to clarify payment methods accepted (e.g., wire transfer, credit card) and any potential currency exchange fees if dealing with international suppliers. Establishing favorable terms can help manage cash flow effectively. -

How can I ensure quality assurance when sourcing wands internationally?

To ensure quality assurance, request detailed product specifications and certifications from the manufacturer, such as ISO standards. Conducting factory audits or quality inspections during production can help mitigate risks. Additionally, consider utilizing third-party inspection services to verify product quality before shipment. Establishing a clear quality control process in your contract can also protect your interests. -

What logistics considerations should I keep in mind when importing wands?

Logistics play a critical role in international sourcing. Understand the shipping methods available, such as air freight for quicker delivery or sea freight for cost-effectiveness. Familiarize yourself with customs regulations and duties applicable in your country to avoid unexpected fees. Working with a reliable freight forwarder can help streamline the process and ensure timely delivery of your products. -

How do I vet a wand manufacturer for reliability and trustworthiness?

Conduct thorough research to vet potential manufacturers. Look for verified certifications, such as ISO or industry-specific accreditations. Request references from previous clients and check online reviews. It’s also advisable to start with a smaller order to assess their service quality and product consistency before committing to larger volumes. Establishing a direct line of communication can also help gauge their responsiveness and professionalism. -

What are the common challenges faced when sourcing wands internationally?

Common challenges include language barriers, differing quality standards, and varying legal regulations. Time zone differences can complicate communication, while cultural nuances may affect business negotiations. Additionally, fluctuating currency exchange rates can impact pricing. To mitigate these challenges, consider working with local agents or consultants who understand the market and can facilitate smoother transactions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for wand manufacturer

As international B2B buyers navigate the complexities of sourcing wands, it’s crucial to recognize the transformative power of strategic sourcing. This approach not only enhances supply chain efficiency but also fosters sustainable relationships with manufacturers across diverse regions, including Africa, South America, the Middle East, and Europe. By prioritizing factors such as quality assurance, ethical sourcing, and innovation, buyers can significantly elevate their procurement processes and ensure they select manufacturers that align with their business goals.

Furthermore, understanding regional market dynamics and cultural nuances can empower buyers to make informed decisions that lead to long-term partnerships. Investing time in supplier evaluations and leveraging technology for supply chain transparency can yield substantial returns, both financially and operationally.

Looking ahead, the wand manufacturing landscape is poised for growth, driven by increased demand for customization and sustainable practices. Buyers are encouraged to proactively engage with suppliers, explore collaborative opportunities, and stay informed about emerging trends. By doing so, they will not only secure competitive advantages but also contribute to a more resilient and innovative market. Embrace strategic sourcing today to unlock the full potential of your wand procurement strategy.