Discover Top Benefits of Working with a Wet Wipe Manufacturer (2025)

Introduction: Navigating the Global Market for wet wipe manufacturer

Navigating the global market for wet wipe manufacturers presents a unique set of challenges for international B2B buyers. As demand for hygiene products surges—especially in regions like Africa, South America, the Middle East, and Europe—the quest for reliable suppliers becomes increasingly critical. This guide aims to assist buyers in sourcing high-quality wet wipes that meet diverse needs, from personal care to industrial applications.

In the following sections, we will explore various types of wet wipes, their applications across different industries, and essential criteria for vetting suppliers. Buyers will gain insights into pricing structures, the significance of certifications, and trends shaping the market. This comprehensive overview empowers B2B buyers to make informed purchasing decisions, ensuring they select products that not only meet quality standards but also align with their business goals.

By addressing key challenges such as supplier reliability, product differentiation, and cost management, this guide positions buyers to successfully navigate the complexities of the wet wipe market. Whether you are looking to procure bulk supplies or seeking customized solutions, understanding the landscape of wet wipe manufacturing will enhance your procurement strategy and drive business growth.

Understanding wet wipe manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Personal Care Wipes | Soft, hypoallergenic materials, often infused with lotions or fragrances | Retail, hospitality, healthcare | Pros: High consumer demand; versatile use. Cons: Higher production costs may affect pricing. |

| Household Cleaning Wipes | Strong cleaning agents, durable fabric, often antibacterial | Cleaning services, facility management | Pros: Effective for quick cleaning; promotes hygiene. Cons: Potential chemical sensitivity for some users. |

| Industrial Wipes | Heavy-duty, solvent-resistant materials, designed for tough jobs | Manufacturing, automotive, construction | Pros: Extremely durable; designed for industrial-grade cleaning. Cons: Higher upfront investment. |

| Baby Wipes | Gentle, safe for skin, often biodegradable options available | Retail, childcare, healthcare | Pros: High safety standards; eco-friendly options. Cons: Limited shelf life; must ensure proper storage conditions. |

| Disinfectant Wipes | Pre-moistened with disinfecting solutions, effective against viruses and bacteria | Healthcare, food service, schools | Pros: Essential for maintaining hygiene; easy to use. Cons: May require specific storage conditions to maintain efficacy. |

What Are Personal Care Wipes and Their B2B Suitability?

Personal care wipes are designed for individual hygiene and grooming, often featuring hypoallergenic materials and skin-friendly ingredients. These wipes are suitable for various sectors, including retail, hospitality, and healthcare. B2B buyers should consider consumer preferences for ingredients and fragrance, as well as the potential for higher production costs that might impact retail pricing.

How Do Household Cleaning Wipes Serve B2B Markets?

Household cleaning wipes are formulated with robust cleaning agents and are often antibacterial, making them ideal for quick cleaning tasks. They are widely used in cleaning services and facility management. Buyers should evaluate the effectiveness of the cleaning agents and consider potential chemical sensitivities among users, which could influence product selection.

What Characteristics Define Industrial Wipes?

Industrial wipes are engineered for heavy-duty applications, featuring materials that resist solvents and abrasives. These wipes are essential in industries such as manufacturing, automotive, and construction. B2B purchasers need to assess the durability and cleaning efficiency of these wipes, keeping in mind that they typically require a higher upfront investment compared to other types.

What Are the Key Features of Baby Wipes for B2B Buyers?

Baby wipes are crafted to be gentle on sensitive skin, often incorporating biodegradable materials. They find applications in retail, childcare, and healthcare settings. When purchasing, B2B buyers should prioritize safety standards and consider the availability of eco-friendly options, while also being aware of the limited shelf life and storage requirements.

How Do Disinfectant Wipes Fit into B2B Hygiene Standards?

Disinfectant wipes are pre-moistened with solutions that effectively eliminate viruses and bacteria, making them indispensable in healthcare, food service, and educational institutions. Buyers should focus on the efficacy of the disinfectant solutions and ensure proper storage conditions to maintain their effectiveness. The ease of use and necessity for hygiene make these wipes a critical component of many B2B operations.

Related Video: Kansan Machinery – Wet Wipe Converting Machines

Key Industrial Applications of wet wipe manufacturer

| Industry/Sector | Specific Application of Wet Wipe Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Medical Disinfection Wipes | Ensures hygiene and reduces infection rates | Compliance with health regulations and certifications |

| Food Service | Food Contact Surface Wipes | Promotes safety and cleanliness in food handling | Food-grade materials and adherence to safety standards |

| Personal Care | Cosmetic and Personal Hygiene Wipes | Enhances customer convenience and satisfaction | Skin-friendly formulations and hypoallergenic options |

| Automotive | Interior Cleaning Wipes | Maintains vehicle cleanliness and customer appeal | Compatibility with various materials and surfaces |

| Industrial Cleaning | Heavy-Duty Industrial Wipes | Efficient removal of tough stains and contaminants | Durability and strength suitable for industrial applications |

How Are Wet Wipes Utilized in the Healthcare Sector?

In the healthcare sector, wet wipes are vital for maintaining hygiene and preventing the spread of infections. Medical disinfection wipes are used to sanitize surfaces and equipment in hospitals and clinics. These wipes must meet stringent health regulations and certifications to ensure they are effective against pathogens. International buyers should prioritize manufacturers that comply with local and international health standards, ensuring that their products are safe for use in sensitive environments.

What Role Do Wet Wipes Play in Food Service Applications?

In food service, wet wipes serve as essential tools for cleaning food contact surfaces. These wipes help businesses maintain high standards of cleanliness, thereby reducing the risk of foodborne illnesses. When sourcing wet wipes for this application, buyers must ensure that the materials used are food-safe and compliant with health regulations. Additionally, wipes should be effective in removing grease and residues without leaving harmful residues behind.

How Are Wet Wipes Beneficial in the Personal Care Industry?

The personal care industry utilizes wet wipes for cosmetic and personal hygiene purposes. These wipes provide convenience for consumers, allowing for quick and easy cleansing on the go. Buyers in this sector should look for hypoallergenic formulations and skin-friendly ingredients to cater to diverse customer needs. Manufacturers that offer customizable packaging and formulations can provide a competitive edge in this market.

What Are the Advantages of Using Wet Wipes in Automotive Cleaning?

In the automotive industry, interior cleaning wipes are crucial for maintaining vehicle cleanliness. These wipes help remove dirt, dust, and spills, enhancing the overall customer experience. When sourcing these products, businesses should consider the compatibility of the wipes with various materials, such as leather and plastic, to prevent damage. Additionally, the durability of the wipes is essential for effective cleaning in high-use environments.

How Do Industrial Cleaning Wipes Solve Challenges in Heavy-Duty Applications?

Industrial cleaning wipes are designed for heavy-duty applications, providing efficient solutions for removing tough stains and contaminants. These wipes are essential in manufacturing and construction settings, where quick and effective cleaning is critical. Buyers should focus on sourcing wipes that offer high durability and absorbency, ensuring they can withstand rigorous use. Manufacturers should also provide options tailored to specific industrial needs, such as chemical resistance and extra strength.

3 Common User Pain Points for ‘wet wipe manufacturer’ & Their Solutions

Scenario 1: Inconsistent Quality Across Different Suppliers

The Problem:

B2B buyers often face the challenge of inconsistent quality when sourcing wet wipes from various manufacturers. This inconsistency can lead to product complaints from customers, potential damage to brand reputation, and financial losses. For example, a buyer might receive a shipment of wipes that are too thin, lack sufficient moisture, or have an unpleasant scent, which can frustrate end-users and lead to negative reviews. This is particularly critical in regions like Africa and South America, where consumer expectations are rapidly evolving, and product quality is paramount for market penetration.

The Solution:

To mitigate quality inconsistencies, B2B buyers should establish rigorous supplier assessment protocols. Start by creating a detailed specification sheet outlining the desired quality standards, including material thickness, moisture content, and fragrance. Implement a vendor qualification process that includes requesting samples and conducting quality audits before placing large orders. Additionally, consider engaging in long-term partnerships with a select few manufacturers who have proven their reliability. This not only builds trust but also allows for better control over production processes and consistency. Regularly scheduled quality checks and open communication channels will further enhance product reliability, ensuring that the wipes meet the expected standards before reaching the market.

Scenario 2: Difficulty in Meeting Diverse Regulatory Standards

The Problem:

International B2B buyers often struggle with navigating the myriad of regulatory standards that vary by country, especially in the wet wipes industry. For instance, wipes sold in Europe might need to comply with stringent EU regulations regarding chemical content and environmental impact, while those marketed in the Middle East may have different requirements. This complexity can lead to delays in product launches and costly fines if products do not meet local regulations.

The Solution:

To address this regulatory challenge, B2B buyers should invest time in understanding the specific regulatory frameworks of their target markets. Collaborate with local legal experts or compliance consultants who specialize in product regulations. When sourcing wet wipes, inquire about the manufacturer’s compliance with international standards, such as ISO certifications, and request documentation to support their claims. Additionally, consider working with manufacturers who have a proven track record of navigating these regulations successfully. Creating a compliance checklist that outlines necessary certifications and tests required for each market will streamline the sourcing process and reduce the risk of non-compliance.

Scenario 3: Sustainability Concerns and Environmental Impact

The Problem:

With increasing global awareness around sustainability, B2B buyers are increasingly concerned about the environmental impact of wet wipes, particularly those that are non-biodegradable. In regions like Europe, consumers are pushing for more eco-friendly products, and companies that fail to meet these expectations risk losing market share. This presents a dilemma for buyers who want to provide effective cleaning solutions without contributing to environmental degradation.

The Solution:

To respond to sustainability concerns, B2B buyers should prioritize sourcing from wet wipe manufacturers that offer biodegradable or sustainably sourced materials. Engage in discussions with suppliers about their sustainability practices, including raw material sourcing, manufacturing processes, and end-of-life disposal options for their products. Buyers can also request certifications that verify a product’s eco-friendliness, such as FSC certification for paper products or compliance with the EN 13432 standard for compostability. By aligning with manufacturers who prioritize sustainability, buyers can position their brands as environmentally responsible, appealing to a growing segment of eco-conscious consumers and differentiating themselves in a competitive market.

Strategic Material Selection Guide for wet wipe manufacturer

When selecting materials for wet wipes, manufacturers must consider a variety of factors that impact product performance, compliance with international standards, and market preferences. Below are analyses of four commonly used materials in wet wipe manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Spunlace Nonwoven Fabric?

Spunlace nonwoven fabric is a popular choice for wet wipes due to its excellent absorbency and softness. This material is created by entangling fibers through high-pressure water jets, resulting in a fabric that is both durable and gentle on the skin. Key properties include high tensile strength, good moisture retention, and compatibility with a wide range of cleaning agents.

Pros: Spunlace is highly versatile and can be used in various applications, including personal care and household cleaning. It offers a soft touch, making it suitable for sensitive skin. Additionally, it is biodegradable, appealing to environmentally conscious consumers.

Cons: The manufacturing process can be complex and costly, which may increase the final product price. It may also have limitations in terms of chemical resistance, particularly with harsh solvents.

Impact on Application: Spunlace is compatible with a variety of media, including alcohol and surfactants, making it suitable for disinfecting wipes.

International Considerations: Buyers in Africa, South America, the Middle East, and Europe should ensure compliance with local regulations and standards, such as ASTM for material safety and performance.

How Does Polypropylene Compare in Wet Wipe Manufacturing?

Polypropylene is another widely used material in wet wipes, known for its excellent chemical resistance and durability. This thermoplastic polymer is lightweight and can be produced in various thicknesses, making it adaptable to different applications.

Pros: Polypropylene is cost-effective and offers good moisture barrier properties, making it ideal for wipes that require longer shelf life. It is also resistant to a wide range of chemicals, enhancing its usability in various cleaning formulations.

Cons: While durable, polypropylene can be less soft compared to spunlace, which may not be suitable for all personal care applications. Additionally, it is not biodegradable, which could deter environmentally conscious consumers.

Impact on Application: This material is particularly effective in industrial and heavy-duty wipes, where chemical resistance is paramount.

International Considerations: Buyers should consider the environmental impact and local regulations regarding non-biodegradable materials, especially in regions with strict waste management policies.

What are the Benefits of Rayon in Wet Wipe Production?

Rayon, a semi-synthetic fiber made from cellulose, is often used in wet wipes for its superior absorbency and softness. It can be blended with other materials to enhance performance.

Pros: Rayon offers excellent liquid absorption and a soft texture, making it ideal for personal care products. Its natural fiber content can appeal to consumers looking for more sustainable options.

Cons: Rayon can be more expensive than synthetic alternatives and may not be as durable in heavy-duty applications. Additionally, its production process can be less environmentally friendly than other options.

Impact on Application: Rayon is particularly effective in wipes designed for sensitive skin, such as baby wipes and facial cleansing wipes.

International Considerations: B2B buyers should ensure that rayon products meet local safety and environmental regulations, as well as consumer preferences for sustainable materials.

How Does Polyester Fit into the Wet Wipe Material Landscape?

Polyester is a synthetic fiber that is commonly used in wet wipes due to its strength and durability. It can be engineered to have various properties, including moisture wicking and quick-drying capabilities.

Pros: Polyester is highly durable and resistant to wear and tear, making it suitable for heavy-duty applications. It is also relatively inexpensive compared to natural fibers.

Cons: Polyester can be less absorbent than other materials, which may limit its effectiveness in certain applications. Additionally, it is not biodegradable, raising environmental concerns.

Impact on Application: Polyester is often used in industrial wipes and applications where durability is critical, such as automotive cleaning.

International Considerations: B2B buyers should evaluate the environmental impact of polyester and consider consumer preferences for biodegradable options in their respective markets.

Summary Table of Material Selection for Wet Wipe Manufacturing

| Material | Typical Use Case for wet wipe manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Spunlace Nonwoven | Personal care and household cleaning | Soft, biodegradable, versatile | Complex manufacturing process | Medium |

| Polypropylene | Industrial and heavy-duty wipes | Cost-effective, chemical resistant | Less soft, non-biodegradable | Low |

| Rayon | Baby wipes and facial cleansing wipes | Excellent absorbency, soft texture | More expensive, less durable | High |

| Polyester | Automotive and industrial cleaning wipes | Highly durable, inexpensive | Less absorbent, non-biodegradable | Low |

This guide provides a comprehensive overview of material options for wet wipe manufacturers, highlighting key considerations for international B2B buyers. By understanding the properties and implications of each material, buyers can make informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for wet wipe manufacturer

What Are the Main Stages of the Manufacturing Process for Wet Wipes?

The manufacturing process of wet wipes involves several critical stages, each of which ensures that the final product meets quality and safety standards. Understanding these stages is vital for B2B buyers, especially those looking to source wet wipes from international manufacturers.

1. Material Preparation

Material preparation is the foundational step in the manufacturing of wet wipes. This stage involves sourcing high-quality nonwoven fabrics, which are typically made from materials such as polyester, polypropylene, or a blend of both. Buyers should ensure that the materials comply with safety regulations, particularly for products intended for sensitive skin, such as baby wipes.

In addition to the fabric, the formulation of the liquid solution is crucial. This solution may include various ingredients such as moisturizers, preservatives, and fragrances. B2B buyers should inquire about the sourcing and safety of these ingredients, particularly in compliance with international standards such as REACH in Europe.

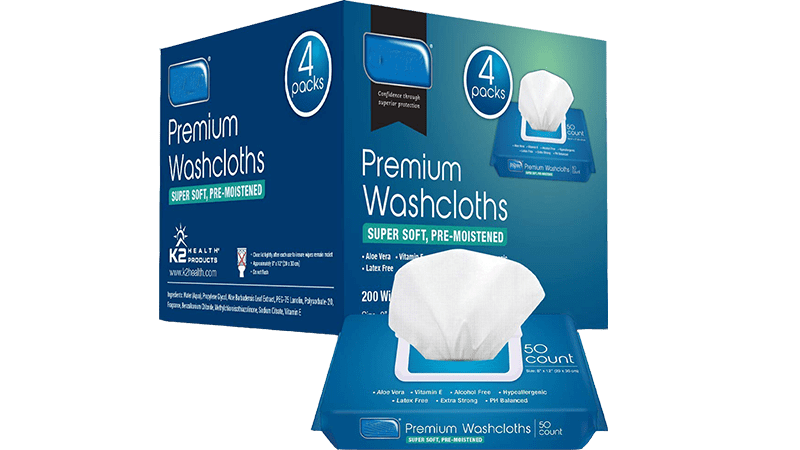

A stock image related to wet wipe manufacturer.

2. Forming

The next step is forming, where the prepared nonwoven material is cut into the desired sizes. This is typically done using advanced cutting machines that ensure precision. The fabric is then saturated with the liquid solution, which can be done through various techniques such as spraying or soaking.

For B2B buyers, it’s essential to understand the technology used in this stage, as it can impact the product’s quality and shelf life. Manufacturers using automated systems often achieve higher consistency and reduced contamination risks.

3. Assembly

During the assembly phase, the saturated wipes are folded and packaged. This process often involves the use of automated machines that can produce large quantities efficiently. The packaging is designed to maintain moisture and prevent contamination, which is particularly important for products like disinfectant wipes.

Buyers should assess the packaging materials used, as they should be environmentally friendly and comply with local regulations. Additionally, it is beneficial to inquire about the manufacturer‘s ability to customize packaging for specific markets.

4. Finishing

The final stage in the manufacturing process is finishing. This includes quality checks, labeling, and preparing the product for shipment. Quality checks at this stage ensure that the wipes meet the required specifications and are free from defects.

How Do Quality Assurance Processes Work in Wet Wipe Manufacturing?

Quality assurance (QA) is a critical component of wet wipe manufacturing, ensuring that the final products are safe, effective, and compliant with various regulations. B2B buyers should understand the QA processes in place to guarantee product reliability.

Relevant International Standards for Quality Assurance

Manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific standards like CE marking (for products sold in the European market) and API (for pharmaceutical-grade products) are essential.

For B2B buyers, verifying compliance with these standards can provide confidence in a manufacturer’s commitment to quality. Requesting documentation of certifications and compliance reports can be a valuable step in the sourcing process.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are critical in ensuring that products meet defined standards at various stages of production. The main checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials before they enter the production process. Ensuring that materials meet specifications is crucial for product quality.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing checks are performed to monitor processes and detect any deviations from quality standards.

-

Final Quality Control (FQC): After production, the finished products undergo comprehensive testing to ensure they meet all quality and safety standards before packaging and shipping.

What Common Testing Methods Are Used in Wet Wipe Quality Assurance?

Common testing methods in the wet wipe manufacturing process include microbiological testing, chemical analysis, and physical testing.

-

Microbiological Testing: This ensures that the wipes are free from harmful bacteria and pathogens, which is especially important for products intended for personal care.

-

Chemical Analysis: Testing for the presence of harmful chemicals or allergens is crucial, particularly for products like baby wipes.

-

Physical Testing: This includes assessing the strength, absorbency, and moisture content of the wipes, ensuring they perform as expected.

B2B buyers should inquire about the specific testing methods used by manufacturers and request access to testing reports to validate quality.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

Verifying a supplier’s quality assurance practices is critical for B2B buyers looking to establish long-term partnerships. Here are actionable steps to ensure reliability:

Conducting Audits

Regular audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should consider scheduling onsite audits to review production facilities and QC procedures.

Reviewing Quality Control Reports

Requesting quality control reports from manufacturers can offer transparency regarding their QA processes. These reports should detail the results of various tests conducted on raw materials and finished products.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can add an extra layer of assurance. These independent organizations can conduct unannounced inspections and provide unbiased evaluations of the manufacturer’s practices.

What Nuances Should International B2B Buyers Consider in Quality Assurance?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several nuances in quality assurance:

-

Regulatory Compliance: Different regions may have varying regulations concerning product safety and quality. Understanding these regulations is vital to avoid compliance issues.

-

Cultural Sensitivities: Buyers should be aware of cultural preferences and sensitivities when selecting ingredients and packaging. For example, certain fragrances or materials may not be suitable for all markets.

-

Supply Chain Transparency: Ensuring transparency in the supply chain can help mitigate risks associated with sourcing materials and maintaining quality standards.

By understanding the manufacturing processes and quality assurance practices of wet wipe manufacturers, B2B buyers can make informed decisions that align with their needs and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wet wipe manufacturer’

In the competitive landscape of wet wipe manufacturing, international B2B buyers must navigate numerous factors to ensure they select the right supplier. This practical sourcing guide provides a step-by-step checklist tailored for buyers from Africa, South America, the Middle East, and Europe. Follow these actionable steps to streamline your procurement process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for sourcing wet wipes that meet your needs. Consider aspects such as the type of material (e.g., non-woven vs. woven), size, and intended use (e.g., personal care, industrial).

– Key considerations:

– Material Composition: Ensure the material is suitable for its intended application.

– Additives: Specify any required antibacterial or moisturizing agents.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable wet wipe manufacturers. Utilize online platforms, industry directories, and trade shows to compile a list of potential suppliers.

– What to look for:

– Experience: Prefer suppliers with a proven track record in the wet wipe industry.

– Geographic Location: Consider suppliers in regions with favorable trade agreements or logistics.

Step 3: Evaluate Supplier Certifications

Before proceeding with a supplier, verify their certifications and compliance with industry standards. This ensures the manufacturer adheres to quality and safety regulations.

– Important certifications include:

– ISO Certification: Indicates adherence to quality management standards.

– FDA Approval (if applicable): Necessary for personal care products in certain regions.

Step 4: Request Samples

Obtaining product samples allows you to assess the quality and performance of the wet wipes before placing a bulk order. This step is crucial to ensure that the products meet your specifications.

– What to evaluate:

– Durability: Check if the wipes hold up under use.

– Moisture Content: Ensure the wipes are adequately saturated for their intended purpose.

Step 5: Conduct Pricing Analysis

Analyze pricing structures from different suppliers to ensure competitive rates. Consider not just the unit price but also shipping costs, minimum order quantities, and payment terms.

– Factors to evaluate:

– Bulk Discounts: Look for suppliers that offer incentives for larger orders.

– Total Cost of Ownership: Assess the long-term costs, including potential reorders and warranty services.

Step 6: Assess Supply Chain Capabilities

Understanding a supplier’s supply chain capabilities is vital to ensure timely delivery and consistent product availability. Evaluate their production capacity and logistics network.

– Questions to ask:

– Lead Times: What are the expected lead times for orders?

– Contingency Plans: Does the supplier have measures in place for potential disruptions?

Step 7: Establish Communication and Support Channels

Effective communication is critical for successful long-term partnerships. Ensure that the supplier provides adequate support and is responsive to inquiries.

– What to prioritize:

– Dedicated Account Managers: Having a specific point of contact can streamline communication.

– After-Sales Support: Verify the availability of customer service for any post-purchase issues.

By following this structured checklist, international B2B buyers can make informed decisions when sourcing wet wipes, ultimately enhancing their procurement strategy and ensuring product quality.

Comprehensive Cost and Pricing Analysis for wet wipe manufacturer Sourcing

What Are the Key Cost Components for Wet Wipe Manufacturing?

When sourcing wet wipes, understanding the cost structure is crucial. The main components include:

-

Materials: The primary materials for wet wipes are non-woven fabrics and liquid formulations. The cost of these materials can vary significantly based on quality and sourcing locations. For example, sourcing from local suppliers in Africa may reduce costs but could affect quality compared to suppliers in Europe.

-

Labor: Labor costs are influenced by local wage rates and the complexity of the manufacturing process. In regions with lower labor costs, such as parts of South America and Africa, manufacturers can offer more competitive pricing.

-

Manufacturing Overhead: This encompasses costs associated with running a factory, including utilities, maintenance, and indirect labor. It’s essential to consider how efficient the production facility is when evaluating total costs.

-

Tooling: Specialized equipment for producing custom wet wipes can lead to significant initial investments. These costs can be amortized over larger production runs, making it vital to assess volume commitments.

-

Quality Control (QC): Implementing stringent quality control processes ensures compliance with international standards, which may increase costs but reduce the risk of product recalls or customer dissatisfaction.

-

Logistics: Shipping and handling costs, including freight and insurance, significantly impact the final price. Incoterms play a crucial role in determining who bears these costs and risks during transportation.

-

Margin: Manufacturers typically add a margin to cover profit and reinvestment. This margin can vary based on market dynamics and competition.

How Do Price Influencers Affect Wet Wipe Sourcing?

Several factors can influence the pricing of wet wipes, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for larger orders. Understanding the supplier’s MOQ can help negotiate better pricing.

-

Specifications and Customization: Customized wipes, such as those infused with specific chemicals or designed for unique applications, may incur additional costs. It’s essential to clarify specifications upfront.

-

Materials: The choice of materials directly affects pricing. For example, biodegradable or hypoallergenic materials may cost more but cater to a growing market demand.

-

Quality and Certifications: Products that meet international quality standards (e.g., ISO, FDA) often command higher prices. Buyers should consider the importance of these certifications in their markets.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a history of quality may charge a premium.

-

Incoterms: Understanding Incoterms is vital for international transactions. These terms define the responsibilities of buyers and sellers, which can affect overall costs and pricing structures.

What Are the Best Negotiation Tips for B2B Buyers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following tips to enhance their negotiation strategies:

-

Research and Benchmarking: Gather market intelligence on pricing and costs from multiple suppliers to establish a competitive baseline.

-

Focus on Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors like logistics, potential tariffs, and quality assurance costs when evaluating offers.

-

Leverage Volume Commitments: If feasible, promise larger orders to secure better pricing. Suppliers are often more willing to negotiate on price with guaranteed volume.

-

Be Prepared to Walk Away: Establish a maximum budget and be willing to seek other suppliers if the terms do not meet your expectations.

-

Establish Long-Term Relationships: Building a rapport with suppliers can lead to better pricing and terms in the long run.

What Should Buyers Keep in Mind Regarding Pricing Nuances?

Pricing in the wet wipe manufacturing sector can be complex. Buyers should remain aware of fluctuations in raw material prices and changes in labor costs due to economic conditions. Additionally, exchange rate volatility can impact international purchasing decisions, making it essential to factor in currency risk when negotiating contracts.

Disclaimer: The prices and cost structures mentioned are indicative and can vary based on specific supplier agreements, regional economic conditions, and market demand. Always conduct thorough due diligence when sourcing.

Alternatives Analysis: Comparing wet wipe manufacturer With Other Solutions

Introduction to Alternative Solutions for Wet Wipes

As the demand for efficient cleaning and hygiene products continues to rise globally, B2B buyers are increasingly exploring alternative solutions to wet wipes. Understanding these alternatives is essential for making informed purchasing decisions that align with specific operational needs. This analysis provides a comparative overview of wet wipes against other viable solutions, including disinfectant sprays and reusable cleaning cloths, helping buyers assess which option best suits their requirements.

Comparison Table of Wet Wipe Manufacturer and Alternatives

| Comparison Aspect | Wet Wipe Manufacturer | Disinfectant Spray | Reusable Cleaning Cloths |

|---|---|---|---|

| Performance | High; quick drying and effective against germs | High; effective against a range of pathogens | Moderate; depends on cleaning solution used |

| Cost | Higher initial cost due to packaging and materials | Lower cost per use, but ongoing purchase needed | Economical long-term; initial investment in cloths |

| Ease of Implementation | Simple; ready-to-use packaging | Requires proper application technique | Requires laundering and maintenance |

| Maintenance | Low; disposable after use | Low; needs proper storage and usage guidelines | Moderate; requires regular washing and drying |

| Best Use Case | On-the-go cleaning, healthcare settings | General disinfection, home and commercial use | Eco-friendly cleaning, repeated use in various settings |

Detailed Breakdown of Alternatives

Disinfectant Spray

Disinfectant sprays offer a practical alternative to wet wipes, particularly in environments where surface disinfection is essential. They are often less expensive on a per-use basis compared to wet wipes, making them a cost-effective solution for high-traffic areas. However, their effectiveness relies on proper application and dwell time on surfaces to eliminate pathogens. For businesses in healthcare or food service industries, the need for proper training in usage can complicate implementation. Additionally, the risk of overspray can lead to waste and potential damage to sensitive surfaces.

Reusable Cleaning Cloths

Reusable cleaning cloths are an eco-friendly option that appeals to organizations looking to reduce waste. These cloths can be used with various cleaning solutions, making them versatile for different cleaning tasks. While the initial investment may be higher, the long-term cost savings are significant, as they can be laundered and reused multiple times. However, they require maintenance, such as regular washing and proper drying, which can be a logistical challenge for businesses with high cleaning demands. Furthermore, their effectiveness is contingent on the cleaning solution used, which may vary in performance.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between a wet wipe manufacturer and alternative cleaning solutions, B2B buyers must consider their specific operational needs, budget constraints, and environmental goals. Wet wipes are ideal for quick, on-the-go cleaning in sectors like healthcare, where hygiene is paramount. Conversely, disinfectant sprays and reusable cloths may be better suited for businesses focused on cost-effectiveness and sustainability. By thoroughly evaluating performance, cost, ease of use, and maintenance requirements, buyers can make informed decisions that enhance their cleaning protocols and align with their organizational values.

Essential Technical Properties and Trade Terminology for wet wipe manufacturer

What Are the Essential Technical Properties for Wet Wipe Manufacturing?

When selecting wet wipe manufacturers, it’s crucial for B2B buyers to understand the technical specifications that impact product quality, performance, and compliance. Here are some key properties:

1. Material Grade

Wet wipes are typically made from non-woven fabrics, which can be composed of various materials such as polyester, polypropylene, or a blend. The choice of material affects the durability, absorbency, and softness of the wipes. Higher-grade materials often provide better performance, but they can also increase the overall cost. Buyers should assess the material grade based on their target market’s preferences and regulatory requirements.

2. Absorbency Rate

The absorbency rate indicates how much liquid a wet wipe can retain. This property is critical for applications ranging from personal hygiene to industrial cleaning. A higher absorbency rate means the wipes can be more effective at cleaning or disinfecting surfaces, which is particularly valuable for B2B clients in sectors like healthcare and hospitality. Understanding absorbency can help buyers determine the suitability of wipes for specific tasks.

3. Biodegradability

As environmental concerns grow, the biodegradability of wet wipes has become a key factor for many buyers. Products that decompose more readily are often favored, especially in regions with strict environmental regulations. Manufacturers that can provide certifications regarding the biodegradability of their products are more likely to attract environmentally conscious businesses.

4. pH Level

The pH level of the solution used in wet wipes is vital, particularly for personal care products. A balanced pH level ensures skin compatibility and minimizes irritation. B2B buyers in the cosmetic or healthcare sectors should ensure that the pH levels align with industry standards to avoid adverse reactions among end-users.

5. Tolerance Levels

Tolerance refers to the permissible variation in dimensions and properties of the wipes. For example, the thickness of the wipes must be consistent to ensure uniform performance. High tolerance levels can lead to product inconsistencies, which may affect customer satisfaction and brand reputation. Buyers should inquire about the manufacturer’s tolerance standards to ensure quality control.

What Are Common Trade Terms Used in Wet Wipe Manufacturing?

Understanding trade terminology is essential for effective communication and negotiation with manufacturers. Here are some common terms relevant to the wet wipe industry:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of wet wipes, an OEM may manufacture the wipes while another brand labels and sells them. Understanding OEM relationships can help buyers identify potential partners for private label products.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to produce or sell. This term is significant for B2B buyers as it can affect inventory costs and supply chain management. Buyers should negotiate MOQs that align with their business needs, especially when entering new markets.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request prices for specific products from suppliers. This process is critical for obtaining competitive pricing and understanding the cost structure of potential manufacturers. Buyers should be precise in their RFQs to ensure accurate quotes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers regarding the delivery of goods. They cover aspects such as shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international buyers, as they help clarify the terms of trade and reduce the risk of misunderstandings.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. For wet wipe manufacturers, lead times can vary based on production schedules and material availability. Understanding lead times is crucial for B2B buyers to plan inventory and meet customer demands effectively.

A stock image related to wet wipe manufacturer.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when selecting wet wipe manufacturers, ensuring that they align with their business goals and market needs.

Navigating Market Dynamics and Sourcing Trends in the wet wipe manufacturer Sector

What Are the Key Market Dynamics and Trends in the Wet Wipe Manufacturing Sector?

The global wet wipe manufacturing market has been experiencing robust growth, driven by increasing demand across various sectors such as personal care, healthcare, and household cleaning. Key market dynamics include the rising awareness of hygiene and cleanliness, particularly in the wake of the COVID-19 pandemic. This shift has led to heightened demand for antibacterial and disinfectant wipes, appealing to health-conscious consumers and businesses alike. Additionally, the growing trend of convenience in personal care products is propelling wet wipes into mainstream use, with consumers favoring single-use items for their practicality.

Emerging B2B technology trends also play a crucial role in shaping the wet wipe sector. Automation and smart manufacturing techniques are enhancing production efficiency and reducing costs, making it easier for manufacturers to respond to fluctuating market demands. Furthermore, digital transformation is enabling improved supply chain management, allowing international buyers to track shipments and manage inventory more effectively. For buyers in Africa, South America, the Middle East, and Europe, understanding these trends is vital for making informed purchasing decisions and identifying reliable suppliers.

How Can Sustainability and Ethical Sourcing Impact Your B2B Decisions in the Wet Wipe Sector?

Sustainability is becoming increasingly important in the wet wipe manufacturing sector, as buyers are more conscious of the environmental impacts of their purchases. Traditional wet wipes often contain non-biodegradable materials, contributing to significant waste. In response, manufacturers are shifting towards more sustainable options, such as biodegradable and compostable wipes, which appeal to eco-conscious consumers and businesses.

Ethical sourcing is also critical, as international buyers are increasingly seeking suppliers that prioritize fair labor practices and responsible sourcing of materials. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 (Environmental Management) are becoming essential for demonstrating a commitment to sustainability. For B2B buyers, ensuring that suppliers uphold these standards not only mitigates risk but also enhances brand reputation in the market.

How Has the Wet Wipe Manufacturing Sector Evolved Over Time?

The evolution of the wet wipe manufacturing sector can be traced back to the introduction of disposable hygiene products in the late 20th century. Initially popularized in the healthcare industry for infection control, wet wipes quickly gained traction in personal care and household cleaning markets. Innovations in materials and formulations have led to a diverse array of products catering to specific needs, from baby wipes to disinfectant wipes for industrial use.

The sector has witnessed significant technological advancements, including the integration of automated production lines and enhanced packaging solutions that prolong shelf life and maintain product integrity. Today, wet wipes are not only viewed as convenience items but also as essential tools for maintaining hygiene, reflecting broader societal shifts towards health and wellness. For international B2B buyers, understanding this historical context can provide valuable insights into current market offerings and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of wet wipe manufacturer

-

How do I find a reliable wet wipe manufacturer for my business?

To locate a trustworthy wet wipe manufacturer, begin by conducting thorough market research to identify potential suppliers. Utilize online B2B platforms such as Alibaba, Global Sources, or TradeIndia, which feature verified manufacturers. Attend trade shows and industry exhibitions to meet manufacturers in person and assess their products. Additionally, check reviews and testimonials from other businesses that have sourced from these manufacturers. Request samples to evaluate quality before making a commitment. -

What is the best way to assess the quality of wet wipes?

Quality assessment of wet wipes should include a few key factors: material composition, moisture content, and effectiveness. Request product samples to evaluate the texture, thickness, and fragrance. Ensure that the wipes are dermatologically tested and free from harmful chemicals, especially if they are intended for sensitive skin. Consider certifications such as ISO or CE, which indicate adherence to international quality standards. Conduct laboratory testing if necessary to ensure they meet your specific requirements. -

How can I customize wet wipes to suit my brand?

Most manufacturers offer customization options for wet wipes, including size, fragrance, and packaging. When discussing customization, provide specific details about your brand’s requirements, such as desired ingredients, packaging design, and labeling. Collaborate closely with the manufacturer during the development phase to ensure that the final product aligns with your branding and meets regulatory standards in your target market. Keep communication open for adjustments throughout the production process. -

What are the typical minimum order quantities (MOQs) for wet wipes?

Minimum order quantities (MOQs) for wet wipes can vary significantly based on the manufacturer and the level of customization required. Generally, MOQs can range from 5,000 to 50,000 units. It is essential to discuss your needs directly with potential suppliers, as some may offer flexible MOQs for first-time buyers or bulk orders. Understanding your market demand can help you negotiate better terms while ensuring you meet your inventory needs. -

What payment terms should I expect when sourcing from a wet wipe manufacturer?

Payment terms can differ among manufacturers but typically include options like a deposit followed by a balance payment before shipment. Commonly, a 30% deposit is required upfront, with the remaining 70% due upon completion of production. It’s advisable to negotiate terms that align with your cash flow and risk management strategies. Consider utilizing secure payment methods such as letters of credit or escrow services to protect your investment. -

How do I ensure compliance with international trade regulations for wet wipes?

To ensure compliance with international trade regulations, familiarize yourself with the import/export laws in your country and the country of the manufacturer. This includes understanding labeling requirements, ingredient regulations, and safety standards. Work closely with your supplier to obtain necessary certifications and documentation, such as a Certificate of Origin or compliance with FDA regulations, if applicable. Consulting with a trade compliance expert can provide additional guidance tailored to your specific market. -

What logistics considerations should I keep in mind when sourcing wet wipes?

Logistics play a crucial role in the timely delivery of wet wipes. Consider factors such as shipping methods (air vs. sea), transit times, and customs clearance processes. Evaluate the manufacturer’s location and shipping capabilities to minimize delays. Additionally, factor in warehousing needs and distribution logistics to ensure smooth operations upon receiving the goods. Establishing a reliable freight forwarder can also facilitate efficient transport and customs handling. -

How can I build a long-term relationship with my wet wipe manufacturer?

Building a long-term relationship with your wet wipe manufacturer involves consistent communication and transparency. Provide feedback on product quality and delivery times, and address any concerns promptly. Regularly engage with the manufacturer to discuss upcoming needs and potential product innovations. Consider visiting their facility to strengthen the partnership and gain insights into their operations. Establishing trust and collaboration can lead to better pricing, priority service, and tailored solutions that benefit both parties.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for wet wipe manufacturer

In the evolving landscape of the wet wipe manufacturing industry, strategic sourcing emerges as a critical factor for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe. By prioritizing supplier partnerships that align with sustainability practices and quality standards, businesses can enhance their competitive edge. Understanding regional market dynamics is essential, as consumer preferences and regulatory requirements vary significantly across these areas.

What are the key benefits of effective strategic sourcing in wet wipe procurement? It not only mitigates risks associated with supply chain disruptions but also fosters innovation through collaboration with manufacturers who are at the forefront of technological advancements. Engaging with suppliers who demonstrate flexibility and responsiveness can lead to cost efficiencies and improved product offerings.

Looking ahead, the demand for eco-friendly and biodegradable wet wipes is set to rise. International buyers should seize this opportunity to align their procurement strategies with sustainable practices, ensuring they are well-positioned to meet future market demands. As the industry progresses, now is the time to engage with reputable wet wipe manufacturers that can support your long-term business goals. Take the next step in your strategic sourcing journey to cultivate valuable partnerships that drive growth and sustainability in your operations.