Discover Top Bicycle Part Manufacturers: A Complete Guide (2025)

Introduction: Navigating the Global Market for bicycle part manufacturer

As international B2B buyers seek to source high-quality bicycle parts, navigating the complexities of the global market can be daunting. The challenge lies not only in identifying reliable manufacturers but also in understanding the diverse applications and specifications that different markets demand. This comprehensive guide to bicycle part manufacturers serves as a valuable resource, addressing the key aspects of sourcing, including types of parts, applications, supplier vetting processes, and cost considerations.

In the rapidly evolving bicycle industry, buyers from regions such as Africa, South America, the Middle East, and Europe—specifically countries like Argentina and Spain—must be equipped with the right knowledge to make informed purchasing decisions. This guide empowers you by providing insights into the latest trends, quality standards, and logistical challenges faced in the procurement of bicycle components.

By delving into the intricacies of supplier evaluation and pricing strategies, this resource aims to streamline your procurement process and enhance your competitive edge. Whether you are looking to expand your product line or seeking cost-effective solutions, understanding the dynamics of the global bicycle parts market is crucial. With this guide, you can confidently navigate your sourcing journey, ensuring that you select the best suppliers that align with your business goals and customer expectations.

Understanding bicycle part manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM Manufacturers | Produce parts for brands under their own specifications. | Large-scale bicycle production. | Pros: High quality, consistency. Cons: Minimum order quantities can be high. |

| Aftermarket Suppliers | Provide replacement or upgrade parts not made by OEMs. | Retail shops, repair services. | Pros: Variety of options, often cheaper. Cons: Quality may vary significantly. |

| Custom Fabricators | Create bespoke parts tailored to specific client needs. | Specialized bikes, unique projects. | Pros: Tailored solutions, flexibility. Cons: Higher costs and longer lead times. |

| Component Assemblers | Focus on assembling parts from various suppliers. | Bicycle manufacturers, large retailers. | Pros: Streamlined sourcing, efficiency. Cons: May lack specialization in certain components. |

| Niche Specialty Producers | Manufacture specialized parts for specific bicycle types. | High-end markets, custom builds. | Pros: Expertise in niche products. Cons: Limited availability and higher prices. |

What Are the Characteristics of OEM Manufacturers?

OEM (Original Equipment Manufacturer) manufacturers are key players in the bicycle part industry, producing components that adhere strictly to the specifications of established bicycle brands. These manufacturers focus on large-scale production, ensuring consistent quality across their product lines. B2B buyers often engage with OEMs for their reliability and ability to meet high-volume demands. However, the downside is that they typically require minimum order quantities, which can be a barrier for smaller businesses or startups.

How Do Aftermarket Suppliers Differ from OEMs?

Aftermarket suppliers offer an alternative to OEM parts, providing replacement or upgrade components that are not produced by the original manufacturers. These parts are widely used in retail shops and repair services, making them essential for businesses focused on maintenance and customization. The primary advantage of sourcing from aftermarket suppliers is the extensive variety and often lower prices. However, buyers should be cautious as the quality of these parts can be inconsistent, necessitating careful evaluation before purchasing.

What Are the Benefits of Custom Fabricators?

Custom fabricators are ideal for B2B buyers seeking bespoke bicycle parts tailored to specific requirements. These manufacturers excel in creating unique components for specialized bicycles or unique projects, allowing for a high degree of customization. The main benefits include tailored solutions and flexibility in design. However, buyers should be aware that custom fabrication often comes with higher costs and longer lead times, which can impact project timelines.

How Do Component Assemblers Streamline the Sourcing Process?

Component assemblers play a crucial role in the bicycle manufacturing supply chain by focusing on assembling parts sourced from various suppliers. This approach is particularly beneficial for bicycle manufacturers and large retailers who need to streamline their sourcing processes. The efficiency gained from working with assemblers can reduce lead times and simplify inventory management. However, buyers may find that assemblers lack specialization in certain components, which could affect the overall quality of the final product.

What Should Buyers Know About Niche Specialty Producers?

Niche specialty producers focus on manufacturing specific parts designed for particular types of bicycles, catering to high-end markets and custom builds. Their expertise in niche products can be a significant advantage for businesses looking to differentiate themselves in the market. While these producers offer high-quality components, buyers must consider the limited availability and potentially higher prices associated with these specialized products. Understanding the market demand for niche components can help buyers make informed decisions.

Related Video: Jagwire Inline Cable Adjusters – Installation and Adjustment – Bicycle Maintenance

Key Industrial Applications of bicycle part manufacturer

| Industry/Sector | Specific Application of Bicycle Part Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation | Manufacturing of bicycle components for urban mobility | Enhanced mobility solutions, reduced traffic congestion | Quality standards, local regulations, and supply chain reliability |

| Recreational Sports | Production of high-performance bicycle parts for racing | Increased market competitiveness and product differentiation | Material quality, customization options, and performance testing |

| Tourism and Leisure | Development of bicycles for eco-tourism initiatives | Promotion of sustainable tourism and improved customer experience | Sustainability certifications, design aesthetics, and durability |

| Healthcare and Rehabilitation | Creation of specialized bicycles for therapy and rehabilitation | Improved patient outcomes and expanded service offerings | Compliance with health regulations, ergonomic design, and safety standards |

| Education and Training | Supply of bicycles and parts for educational programs | Enhanced learning opportunities and community engagement | Cost-effectiveness, educational partnerships, and local support |

How Are Bicycle Part Manufacturers Impacting the Transportation Sector?

In the transportation sector, bicycle part manufacturers provide essential components that contribute to urban mobility solutions. With increasing urbanization, cities are looking for sustainable transport alternatives to alleviate traffic congestion and reduce carbon emissions. Bicycle manufacturers can offer lightweight frames, efficient gear systems, and reliable braking components tailored to local regulations. International buyers, particularly from regions like Africa and South America, should consider quality standards and the reliability of supply chains to ensure timely deliveries and compliance with local laws.

What Role Do Bicycle Parts Play in Recreational Sports?

In the realm of recreational sports, high-performance bicycle parts are crucial for competitive cycling. Manufacturers supply advanced gear systems, aerodynamic frames, and lightweight materials that enhance speed and handling. This not only gives businesses a competitive edge but also attracts enthusiasts looking for quality. Buyers in Europe, especially in cycling-centric countries like Spain, must evaluate the material quality and customization options available to meet specific performance needs.

How Are Bicycle Components Supporting Eco-Tourism?

Bicycle part manufacturers are increasingly collaborating with tourism operators to create bikes designed for eco-tourism. These bicycles are engineered for durability and comfort, enabling tourists to explore natural landscapes sustainably. By investing in these bicycles, businesses can enhance their customer experience while promoting environmental stewardship. Buyers should prioritize sustainability certifications and design aesthetics that align with eco-tourism values when sourcing these products.

What Are the Applications of Bicycle Parts in Healthcare and Rehabilitation?

Bicycle parts play a significant role in the healthcare sector, particularly in rehabilitation and therapy. Specialized bicycles designed for therapeutic purposes help patients regain mobility and strength. Manufacturers must ensure compliance with health regulations and focus on ergonomic designs that cater to diverse patient needs. International buyers in this sector should be aware of safety standards and the importance of providing a comfortable user experience.

How Can Bicycle Parts Enhance Educational Programs?

Bicycle part manufacturers also contribute to educational initiatives by supplying bicycles and components for training programs. These partnerships can foster community engagement and promote cycling as a sustainable transport option. Businesses involved in these programs should focus on cost-effectiveness and building strong local partnerships to ensure sustainability and support. Buyers from various regions, including the Middle East, should seek manufacturers that can provide robust support for educational initiatives.

Related Video: What is Industrial Automation?

3 Common User Pain Points for ‘bicycle part manufacturer’ & Their Solutions

Scenario 1: Inconsistent Quality of Bicycle Parts

The Problem:

B2B buyers often encounter the frustrating issue of inconsistent quality in bicycle parts from manufacturers. This inconsistency can lead to delays in production, increased costs due to returns or replacements, and ultimately harm the reputation of the buyer’s business. For example, a bicycle manufacturer may source frames that vary in weight and strength, leading to safety concerns and dissatisfaction among end customers.

The Solution:

To mitigate quality inconsistencies, international B2B buyers should prioritize sourcing from reputable bicycle part manufacturers with established quality control protocols. Before finalizing a supplier, buyers should request samples of the parts and conduct thorough inspections to verify quality. Additionally, implementing a robust supplier evaluation process, including a review of certifications and past performance, can help in selecting manufacturers that adhere to high standards. Utilizing quality assurance services or third-party inspections can further ensure that the parts meet specified standards before shipment. This proactive approach can save time and costs in the long run and maintain the integrity of the buyer’s brand.

Scenario 2: Delayed Shipping and Supply Chain Disruptions

The Problem:

International buyers frequently face challenges related to delayed shipping and supply chain disruptions, which can significantly affect production schedules. For instance, a bicycle retailer in South America may rely on timely deliveries of components from Europe. If shipments are delayed due to customs issues or logistical failures, it can lead to stock shortages, missed sales opportunities, and frustrated customers.

The Solution:

To combat shipping delays, buyers should establish clear communication channels with their suppliers and logistics partners. It’s advisable to create a detailed shipping timeline that includes buffer periods to accommodate potential delays. Additionally, buyers can negotiate contracts that include penalties for late deliveries, incentivizing manufacturers to adhere to agreed timelines. Exploring alternative logistics options, such as expedited shipping or local suppliers for critical components, can also help maintain a steady supply chain. Regularly reviewing and adjusting supply chain strategies based on market conditions will enable businesses to be more resilient against disruptions.

Scenario 3: Lack of Customization Options for Unique Products

The Problem:

Many B2B buyers struggle with the inability to customize bicycle parts according to their specific requirements. For instance, a bicycle company in Africa looking to create a unique line of mountain bikes may find that their chosen manufacturer only offers standard parts, which limits their ability to differentiate their products in a competitive market.

The Solution:

To address this issue, buyers should actively seek out bicycle part manufacturers that specialize in custom solutions. Engaging in early discussions about customization possibilities can help identify manufacturers that are willing to collaborate on bespoke designs. Buyers can also leverage digital tools such as CAD software to create prototypes, enabling manufacturers to visualize and understand their specific needs. Establishing long-term partnerships with manufacturers who have a flexible approach to production will not only facilitate customization but also foster innovation and responsiveness to market trends. Networking within industry forums and attending trade shows can also help buyers discover new manufacturers that offer tailored solutions.

Strategic Material Selection Guide for bicycle part manufacturer

When selecting materials for bicycle part manufacturing, it is crucial for international B2B buyers to understand the properties, advantages, and limitations of common materials. This knowledge enables informed decisions that align with product performance, cost-effectiveness, and regional compliance standards. Below, we analyze four prevalent materials used in the industry.

What Are the Key Properties of Aluminum in Bicycle Manufacturing?

Aluminum is a popular choice for bicycle frames and components due to its lightweight nature and strength. It typically exhibits excellent corrosion resistance, which is vital for bicycles exposed to various weather conditions. Aluminum can withstand moderate temperatures and pressures, making it suitable for various applications.

Pros and Cons: The primary advantages of aluminum include its low weight, high strength-to-weight ratio, and resistance to rust. However, it can be more expensive than steel and may require more complex manufacturing processes, such as welding or anodizing, which can increase production costs.

Impact on Application: Aluminum is compatible with a wide range of media, including water and oils, making it suitable for various bicycle components, such as frames, handlebars, and rims.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local availability and cost fluctuations of aluminum. Compliance with standards such as ASTM or EN for quality assurance is essential, especially in European markets like Spain.

How Does Steel Compare as a Material for Bicycle Parts?

Steel is another widely used material, particularly for entry-level bicycles. It offers high strength and durability, making it ideal for components that undergo significant stress, such as frames and forks.

Pros and Cons: The advantages of steel include its toughness, lower cost compared to aluminum, and ease of manufacturing. However, steel is heavier and more prone to rust if not properly treated, which can affect long-term performance.

Impact on Application: Steel’s compatibility with various media is generally good, but its susceptibility to corrosion requires protective coatings, particularly in humid climates.

Considerations for International Buyers: Buyers in the Middle East may prefer steel for its cost-effectiveness, while those in Europe might focus on corrosion-resistant treatments to comply with local standards.

What Are the Benefits of Carbon Fiber in Bicycle Manufacturing?

Carbon fiber is increasingly popular in high-performance bicycles due to its exceptional strength and lightweight properties. It is particularly advantageous for racing and high-end models.

Pros and Cons: The primary advantage of carbon fiber is its superior strength-to-weight ratio, allowing for lightweight designs without compromising performance. However, it is significantly more expensive and requires specialized manufacturing processes, which can limit accessibility for some manufacturers.

Impact on Application: Carbon fiber is compatible with various media and is resistant to corrosion, making it ideal for components exposed to moisture.

Considerations for International Buyers: Buyers from Europe and South America should be aware of the high costs associated with carbon fiber and the need for compliance with specific manufacturing standards to ensure quality and safety.

What Role Does Titanium Play in Bicycle Parts Manufacturing?

Titanium is known for its high strength, low weight, and excellent corrosion resistance, making it an ideal choice for premium bicycle components.

Pros and Cons: Titanium’s key advantages include its durability and resistance to fatigue, which is crucial for high-performance applications. However, it is one of the most expensive materials, and its manufacturing processes can be complex and labor-intensive.

Impact on Application: Titanium is compatible with a range of media and is particularly suited for high-end bicycle frames and components that require longevity and performance.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should consider the investment required for titanium components and ensure compliance with international standards to justify the cost.

Summary Table of Material Selection for Bicycle Parts

| Material | Typical Use Case for bicycle part manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frames, handlebars, rims | Lightweight and corrosion-resistant | Higher cost than steel | Medium |

| Steel | Entry-level frames, forks | Tough and cost-effective | Heavier and prone to rust | Low |

| Carbon Fiber | High-performance racing bikes | Superior strength-to-weight ratio | High cost and complex manufacturing | High |

| Titanium | Premium frames and components | Excellent durability and corrosion resistance | Very high cost and complex processes | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed choices that align with their specific market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for bicycle part manufacturer

What Are the Main Stages of Manufacturing Bicycle Parts?

Manufacturing bicycle parts is a complex process that involves several key stages, each critical to ensuring the quality and performance of the final product. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Bicycle Part Manufacturing?

Material preparation is the first step in the manufacturing process. This involves selecting high-quality raw materials, such as aluminum, steel, or carbon fiber, based on the specific part being produced. Suppliers often conduct rigorous testing on these materials to ensure they meet industry standards. For B2B buyers, verifying the material specifications through supplier documentation is essential. Look for certifications that confirm the materials comply with international standards such as ISO 9001 or specific regional standards relevant to your market.

What Forming Techniques Are Commonly Used in Bicycle Parts Manufacturing?

Once materials are prepared, the forming stage begins. This can involve various techniques such as:

- Stamping: Used for creating flat parts from sheet metal.

- Machining: Precision cutting of materials to create intricate shapes.

- Forging: Involves shaping metal using compressive forces, resulting in stronger parts.

- Extrusion: For creating long, uniform shapes from materials like aluminum.

Each technique has its advantages, and the choice depends on the part’s design and required specifications. B2B buyers should inquire about the forming techniques used by suppliers to ensure they align with their quality and performance expectations.

How Are Bicycle Parts Assembled and Finished?

The assembly stage is where components come together to form a complete part. This process often involves welding, riveting, or using adhesives, depending on the design requirements. Following assembly, finishing processes such as painting, anodizing, or plating are applied to enhance aesthetics and protect against corrosion.

B2B buyers should pay attention to the finishing processes as they can significantly affect the durability and performance of the parts. Requesting samples or detailed descriptions of the finishing techniques can provide insights into the supplier’s capabilities.

What Quality Assurance Measures Are Essential for Bicycle Parts?

Quality assurance (QA) is a critical component of bicycle part manufacturing, ensuring that products meet defined standards and customer expectations. B2B buyers should familiarize themselves with the relevant international standards and the specific quality control processes employed by manufacturers.

Which International Standards Should B2B Buyers Be Aware Of?

One of the most recognized quality management standards is ISO 9001, which outlines criteria for establishing an effective quality management system (QMS). Compliance with ISO 9001 indicates that a manufacturer consistently meets customer and regulatory requirements.

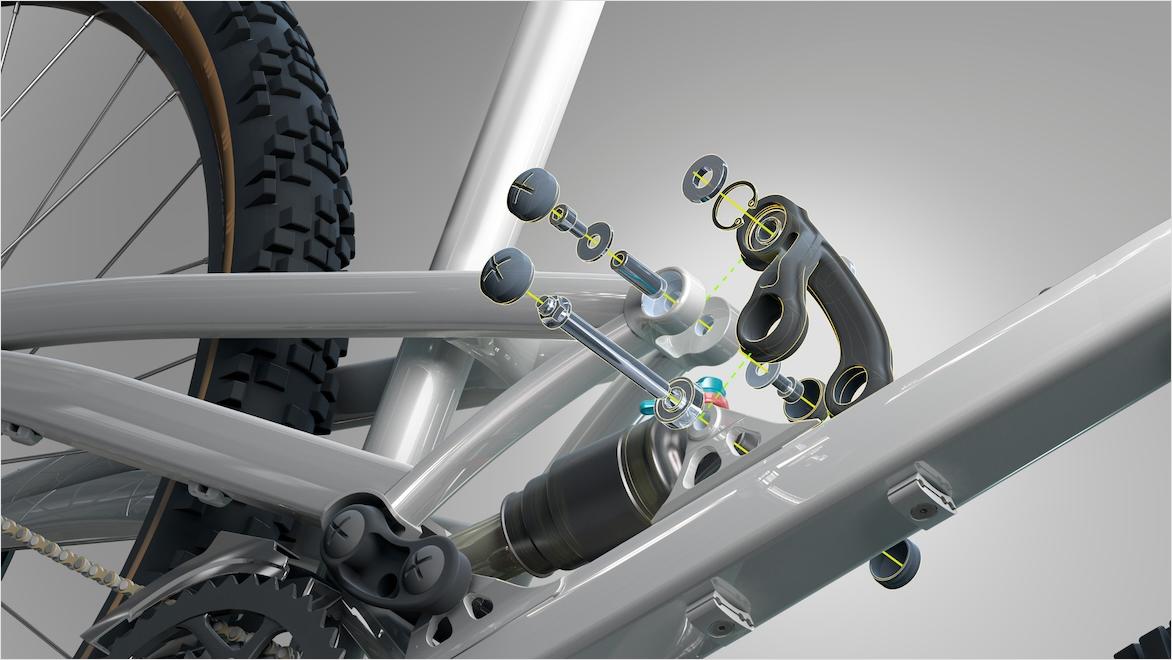

A stock image related to bicycle part manufacturer.

In addition to ISO standards, specific certifications may apply to bicycle parts, such as:

- CE Marking: Required in the European Union for certain products to indicate compliance with health, safety, and environmental protection standards.

- API Standards: Relevant for parts that may interact with other mechanical systems, ensuring they meet specific performance criteria.

B2B buyers from regions like Africa, South America, the Middle East, and Europe should verify these certifications when selecting suppliers.

What Are the Key Quality Control Checkpoints in Bicycle Part Manufacturing?

Quality control involves several checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): Inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring processes during production to catch defects early.

- Final Quality Control (FQC): Conducting thorough inspections of finished products before shipment.

B2B buyers should request documentation of these quality checkpoints to ensure that robust QA practices are in place. This documentation can include inspection reports and testing results, providing confidence in the supplier’s ability to deliver quality products.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is crucial for ensuring product reliability. B2B buyers can adopt several strategies to assess supplier quality:

What Role Do Audits and Third-Party Inspections Play?

Conducting supplier audits is one of the most effective ways to evaluate a manufacturer’s quality assurance practices. These audits can focus on the supplier’s adherence to international standards, their manufacturing processes, and their overall operational effectiveness.

Additionally, engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspectors can conduct on-site evaluations and testing, offering a comprehensive report on the manufacturer’s capabilities.

How Important Are Quality Control Reports?

Requesting quality control reports from suppliers is another way for B2B buyers to verify product quality. These reports should detail the results of various inspections and tests conducted during the manufacturing process. Buyers should look for clear metrics and compliance with standards, which can be instrumental in ensuring that the parts meet their specifications.

What Are the Unique Quality Control Nuances for International B2B Buyers?

B2B buyers from Africa, South America, the Middle East, and Europe should be aware of several nuances related to quality control that may vary by region. Different markets may have specific regulatory requirements, and understanding these can help in selecting the right supplier.

How Do Regional Standards Impact Quality Assurance?

For example, European buyers may place significant emphasis on CE marking and compliance with EU regulations, while buyers in Africa and South America might prioritize local certifications that reflect regional quality expectations. It is essential for international buyers to communicate their quality requirements clearly and ensure that suppliers can meet these expectations.

What Should Buyers Consider Regarding Cultural Differences in Quality Practices?

Cultural differences can also influence quality control practices. Understanding a supplier’s approach to quality—whether it is proactive or reactive—can impact the overall partnership. Engaging in open communication and establishing clear quality expectations can help bridge any gaps.

Conclusion

A thorough understanding of manufacturing processes and quality assurance is essential for B2B buyers in the bicycle parts industry. By focusing on the key stages of manufacturing, relevant quality standards, and effective verification methods, international buyers can make informed decisions that ensure they partner with reliable suppliers. This knowledge not only enhances product quality but also fosters long-term business relationships built on trust and excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bicycle part manufacturer’

In the competitive landscape of bicycle manufacturing, sourcing the right bicycle parts is vital for ensuring product quality and supply chain efficiency. This practical sourcing guide outlines a step-by-step checklist designed for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. By following these steps, you can streamline your procurement process and establish fruitful relationships with suppliers.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes the types of bicycle parts needed, such as frames, wheels, or brakes, and their specific features, such as material, size, and compliance with industry standards. Precise specifications not only help in identifying suitable suppliers but also prevent miscommunication and ensure that the products meet your quality expectations.

- Consider creating a detailed product specification document.

- Include any regulatory compliance requirements relevant to your target market.

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify potential suppliers who specialize in bicycle parts. Utilize online platforms, trade shows, and industry directories to compile a list of manufacturers. This step is crucial to ensure you have a diverse pool of suppliers to evaluate, which can enhance your bargaining power and lead to better pricing.

- Look for suppliers with a strong online presence and positive customer reviews.

- Consider their experience in exporting to your specific region.

Step 3: Evaluate Supplier Capabilities

Once you have a shortlist of potential suppliers, assess their manufacturing capabilities. Inquire about their production capacity, technology, and quality control processes. Understanding their capabilities is essential to ensure they can meet your demand and maintain consistent quality.

- Request detailed information on their manufacturing processes and equipment.

- Ask about their lead times and flexibility in accommodating changes in order volume.

Step 4: Verify Supplier Certifications

It is essential to verify that potential suppliers hold relevant certifications, such as ISO or other quality management standards. These certifications indicate a commitment to quality and can significantly reduce the risk of receiving subpar products.

- Request copies of their certifications and check their validity.

- Look for any industry-specific certifications that may apply to bicycle parts.

Step 5: Request Samples for Quality Assessment

Before placing a bulk order, always request samples of the bicycle parts you intend to purchase. This allows you to assess the quality, durability, and compliance with your specifications firsthand. Evaluating samples can prevent costly mistakes and help you gauge the supplier’s reliability.

- Test the samples under real-world conditions if possible.

- Assess packaging and labeling as part of your quality review.

Step 6: Negotiate Terms and Conditions

Once you are satisfied with the suppliers and their samples, negotiate terms and conditions. This includes pricing, payment terms, delivery schedules, and return policies. Effective negotiation can lead to better deals and minimize risks associated with international trade.

- Ensure all agreements are documented in a formal contract.

- Discuss potential penalties for delays or quality issues.

Step 7: Establish a Communication Plan

Finally, establish a clear communication plan with your chosen suppliers. Regular updates on production status, shipping timelines, and any potential issues are crucial for maintaining a smooth supply chain. Open lines of communication foster better relationships and can enhance collaboration.

- Schedule regular check-ins or updates via email or video calls.

- Utilize project management tools for tracking orders and deadlines.

By following this structured checklist, B2B buyers can enhance their sourcing strategy for bicycle parts, ensuring they select reliable suppliers that align with their business needs.

Comprehensive Cost and Pricing Analysis for bicycle part manufacturer Sourcing

What Are the Key Cost Components in Bicycle Part Manufacturing?

When sourcing bicycle parts, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components typically include:

-

Materials: The choice of raw materials significantly impacts overall costs. High-quality metals, plastics, and composites often lead to higher prices but can improve product longevity and performance.

-

Labor: Labor costs vary by region and manufacturing processes. In regions with lower labor costs, such as parts of Africa and South America, you may find competitive pricing. However, skilled labor may demand higher wages, affecting overall costs.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and equipment depreciation. Efficient manufacturing practices can help lower overhead costs, making it essential to assess the operational efficiency of potential suppliers.

-

Tooling: Initial tooling costs can be substantial, particularly for custom parts. These expenses need to be amortized over the production volume, so larger orders can reduce the tooling cost per unit.

-

Quality Control (QC): Implementing rigorous QC processes is vital for ensuring product reliability. However, these processes incur additional costs. Buyers should weigh the costs against the benefits of higher quality and reduced returns.

-

Logistics: Transportation and shipping costs can vary widely depending on the distance and mode of transport. Understanding Incoterms and logistics options can lead to significant savings.

-

Margin: Manufacturers typically build a profit margin into their pricing. This can vary based on competition, brand reputation, and market demand.

How Do Price Influencers Impact Bicycle Parts Sourcing?

Several factors influence the pricing of bicycle parts, and understanding these can help you negotiate better deals:

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing. Higher volumes usually lead to lower per-unit costs, making it advantageous to consolidate orders if possible.

-

Specifications and Customization: Custom designs or specific material requirements can drive up costs. Be clear about your needs to avoid unexpected expenses.

-

Material Quality and Certifications: Parts that meet international quality standards (e.g., ISO certifications) may come at a premium. However, these certifications can be crucial for market entry, especially in Europe.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can influence pricing. It’s beneficial to conduct due diligence on potential suppliers.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for calculating total costs, including shipping, insurance, and customs duties.

What Are the Best Negotiation Tips for B2B Buyers in Bicycle Parts?

-

Research and Benchmarking: Before negotiations, research market rates and benchmark prices from multiple suppliers. This information can provide leverage during discussions.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better terms, discounts, and priority treatment for future orders.

-

Emphasize Total Cost of Ownership: When discussing pricing, highlight the importance of total cost of ownership (TCO), which includes purchase price, maintenance, and operational costs. Suppliers may be more inclined to offer competitive pricing if they understand your long-term perspective.

-

Flexibility with Specifications: Be open to alternative materials or designs that may reduce costs without compromising quality. This flexibility can often lead to better pricing.

-

Long-Term Contracts: Offering to commit to long-term contracts can encourage suppliers to provide better pricing, as it guarantees them consistent business.

Why Is It Important to Understand Pricing Nuances for International B2B Buyers?

Navigating the intricacies of international sourcing requires a keen understanding of pricing nuances. Different regions may have varying cost structures due to labor laws, material availability, and economic conditions. For buyers from Africa, South America, the Middle East, and Europe, it’s essential to consider these regional factors to avoid unexpected costs and ensure a smooth procurement process.

Disclaimer on Pricing

A stock image related to bicycle part manufacturer.

Prices discussed in this analysis are indicative and can fluctuate based on market conditions, supplier negotiations, and specific requirements. Always consult directly with suppliers for the most accurate and current pricing information tailored to your needs.

Alternatives Analysis: Comparing bicycle part manufacturer With Other Solutions

Understanding the Need for Alternatives in Bicycle Parts Manufacturing

In the dynamic landscape of bicycle parts manufacturing, it’s essential for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, to explore alternatives. While traditional bicycle part manufacturers provide reliable solutions, alternative technologies and methods can offer unique advantages that align with specific business needs, such as cost-efficiency, ease of implementation, and performance.

Comparison Table of Bicycle Part Manufacturer and Alternatives

| Comparison Aspect | Bicycle Part Manufacturer | 3D Printing Technology | Local Artisans & Craftsmen |

|---|---|---|---|

| Performance | High durability and consistency | Variable, can achieve high precision | Often unique but may vary in quality |

| Cost | Moderate to high | Potentially lower for small batches | Often lower, but varies widely |

| Ease of Implementation | Established processes | Requires initial investment in technology | Generally easy, but depends on skills available |

| Maintenance | Regular maintenance required | Minimal once set up | Varies based on the artisan’s skill |

| Best Use Case | Large-scale production | Custom or limited runs | Unique, handcrafted parts |

In-Depth Analysis of Alternatives

How Does 3D Printing Technology Compare to Traditional Manufacturing?

3D printing technology presents a transformative alternative to traditional bicycle part manufacturing. It allows for rapid prototyping and customization, enabling manufacturers to create bespoke parts tailored to specific customer needs. The initial investment in 3D printing technology can be offset by the cost savings in materials and labor, especially for small production runs. However, the quality of printed parts can vary, and maintaining consistent performance might be challenging. Buyers should weigh the benefits of customization against the potential variability in product quality.

What Are the Advantages of Using Local Artisans and Craftsmen?

Engaging local artisans and craftsmen offers a unique approach to sourcing bicycle parts. This method supports local economies and can yield one-of-a-kind designs that stand out in the marketplace. Costs can be significantly lower, especially for small quantities, making it an attractive option for niche markets. However, the quality and durability of the parts can be inconsistent, and the availability of skilled artisans may vary by region. This option is best suited for businesses looking for unique aesthetics or custom solutions rather than mass production.

How to Choose the Right Solution for Your Business Needs

When deciding between traditional bicycle part manufacturing and alternative solutions, B2B buyers should consider several factors. Assess the scale of production required, the need for customization, and budget constraints. If your business demands high volume and consistent quality, sticking with established manufacturers may be advisable. Conversely, for businesses looking to innovate or cater to niche markets, exploring 3D printing or working with local artisans could provide distinct advantages. Ultimately, the best choice will depend on your specific operational goals, market demands, and resource availability.

Essential Technical Properties and Trade Terminology for bicycle part manufacturer

What Are the Key Technical Properties for Bicycle Part Manufacturing?

When sourcing bicycle parts, understanding critical technical properties is essential for ensuring quality and performance. Here are some key specifications to consider:

1. Material Grade

Material grade indicates the quality and type of materials used in manufacturing bicycle parts. Common materials include aluminum alloys, carbon fiber, and high-tensile steel. Each material has unique properties affecting weight, durability, and cost. For instance, carbon fiber is lightweight and strong, making it ideal for high-performance bicycles, while steel is more economical and offers greater durability for everyday use. B2B buyers should select materials that align with their product specifications and market demands.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension or measured value. It is crucial in ensuring parts fit together correctly and function as intended. Tight tolerances may be necessary for high-performance components, while broader tolerances may suffice for less critical parts. Understanding tolerance specifications helps buyers avoid compatibility issues and ensure that their products meet safety and performance standards.

3. Surface Finish

The surface finish of bicycle parts affects both aesthetics and performance. Various finishes, such as anodizing, powder coating, or polishing, can enhance corrosion resistance, reduce friction, and improve appearance. Buyers should consider the intended use of the bicycle parts when selecting the appropriate surface finish, as it can impact maintenance requirements and longevity.

4. Weight

Weight is a critical specification in the cycling industry, especially for competitive cyclists. Lighter components can enhance performance by improving acceleration and handling. Buyers should evaluate weight specifications in conjunction with material choices, as heavier materials may reduce performance but could provide better durability or cost savings.

5. Load Capacity

Load capacity indicates the maximum weight a component can safely support. This is particularly important for parts such as frames, wheels, and brakes. Buyers must ensure that the load capacity of components aligns with the expected usage scenarios to prevent failures during operation.

What Trade Terminology Should B2B Buyers Know in Bicycle Part Manufacturing?

Familiarity with industry jargon can facilitate smoother negotiations and transactions. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In bicycle manufacturing, this often refers to companies that create components for major bike brands. Understanding the OEM landscape allows buyers to identify reliable suppliers and assess the quality of parts.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. This term is significant for buyers looking to manage inventory costs and negotiate pricing. Knowing the MOQ helps buyers plan their purchases effectively and avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products or services. This process is crucial for comparing offers from multiple suppliers and ensuring competitive pricing. Buyers should clearly outline their specifications in an RFQ to receive accurate and relevant quotations.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping responsibilities, risk management, and cost allocation. For instance, “FOB” (Free On Board) indicates that the seller is responsible for transporting goods to the shipping port, while the buyer assumes responsibility once the goods are on board.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for inventory management and meeting customer demand. Buyers should account for lead times when planning their production schedules to avoid delays.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring their bicycle part manufacturing processes are efficient and cost-effective.

Navigating Market Dynamics and Sourcing Trends in the bicycle part manufacturer Sector

What Are the Key Market Dynamics and Sourcing Trends in the Bicycle Part Manufacturer Sector?

The bicycle part manufacturing sector is undergoing significant transformation driven by various global dynamics. One major driver is the increasing popularity of cycling as a sustainable mode of transportation, particularly in urban areas across Africa, South America, the Middle East, and Europe. This trend is prompting manufacturers to innovate and diversify their product offerings to meet the demand for high-quality, durable components that enhance cycling experiences. In addition, the rise of e-commerce platforms is reshaping how international B2B buyers source bicycle parts, allowing for easier access to suppliers and competitive pricing.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are also influencing sourcing trends. Manufacturers are increasingly adopting smart manufacturing techniques to optimize production processes, reduce lead times, and enhance quality control. This is particularly relevant for B2B buyers looking for reliable suppliers who can guarantee timely delivery and superior product standards. Furthermore, the integration of data analytics is enabling manufacturers to better understand market demands and customer preferences, allowing for tailored solutions that meet specific regional needs.

How Important is Sustainability and Ethical Sourcing in the Bicycle Parts Industry?

Sustainability and ethical sourcing are becoming paramount in the bicycle part manufacturing industry. The environmental impact of production processes, such as carbon emissions and waste generation, is under scrutiny, prompting manufacturers to adopt greener practices. This includes utilizing sustainable materials like recycled metals and eco-friendly composites, which not only reduce environmental harm but also appeal to increasingly eco-conscious consumers.

For international B2B buyers, engaging with suppliers that prioritize ethical supply chains is crucial. This involves understanding the sourcing of raw materials and ensuring that they come from responsible sources that do not exploit labor or harm communities. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as important indicators of a supplier’s commitment to sustainability. By prioritizing suppliers with these certifications, buyers can not only mitigate risks but also enhance their brand’s reputation in a market that values ethical practices.

How Has the Bicycle Parts Manufacturing Sector Evolved Over Time?

The bicycle parts manufacturing sector has seen significant evolution over the decades, transitioning from traditional craftsmanship to advanced industrial processes. In the early days, parts were largely handmade, focusing on durability and functionality. However, the introduction of mass production techniques in the late 20th century allowed for increased efficiency and reduced costs, making bicycles more accessible to the general public.

In recent years, the focus has shifted towards innovation and customization. Manufacturers now leverage technology to produce specialized components for various cycling disciplines, from mountain biking to urban commuting. This evolution reflects the broader changes in consumer preferences and the growing demand for personalized cycling experiences. For B2B buyers, understanding this historical context is essential for making informed purchasing decisions and identifying suppliers that align with contemporary market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of bicycle part manufacturer

-

How do I choose the right bicycle parts manufacturer for my business?

Choosing the right bicycle parts manufacturer involves evaluating their experience, product quality, and customer service. Begin by researching manufacturers who specialize in the specific bicycle parts you need, such as frames, wheels, or components. Look for certifications, reviews, and case studies that reflect their reliability and quality. Additionally, consider their production capacity to meet your demand and their ability to provide customization options that align with your brand’s needs. -

What are the benefits of sourcing bicycle parts from manufacturers in Africa or South America?

Sourcing bicycle parts from Africa or South America can offer several advantages, including reduced shipping costs due to proximity, access to unique materials, and potential for lower labor costs. Additionally, local manufacturers may have better insights into regional market trends and preferences, allowing for more tailored products. Establishing partnerships in these regions can also help diversify your supply chain, mitigating risks associated with sourcing from a single area. -

What should I consider when negotiating payment terms with a bicycle parts manufacturer?

When negotiating payment terms, consider factors such as the size of your order, your relationship with the supplier, and your cash flow needs. Common terms include a deposit upfront, followed by payment upon delivery or net terms (e.g., 30 or 60 days). Ensure you clarify the consequences of late payments and any discounts for early settlement. It’s advisable to have a clear agreement in writing to avoid any misunderstandings. -

How can I verify the quality of bicycle parts before making a bulk purchase?

To verify the quality of bicycle parts, request samples before placing a bulk order. Conduct thorough testing for durability, performance, and compliance with industry standards. Additionally, consider visiting the manufacturer’s facility, if possible, to assess their production processes and quality control measures. Look for certifications, such as ISO, that indicate adherence to quality management standards. -

What are the typical minimum order quantities (MOQs) for bicycle parts?

Minimum order quantities (MOQs) can vary significantly based on the manufacturer and the type of bicycle parts you are sourcing. Generally, MOQs for custom parts may range from 100 to 1,000 units, while standard components might have lower MOQs. Discuss your specific needs with manufacturers to find a suitable arrangement, especially if you are a small business or just starting out. -

How do I ensure timely delivery of bicycle parts from international suppliers?

To ensure timely delivery, establish clear communication with your supplier about production timelines and shipping methods. Opt for reliable logistics partners and consider using freight forwarders experienced in handling international shipments. It’s also beneficial to track shipments actively and maintain flexibility in your inventory management to accommodate potential delays. -

What customization options should I look for in a bicycle parts manufacturer?

Look for manufacturers that offer a range of customization options, including materials, colors, sizes, and branding elements. The ability to create custom designs or modifications can differentiate your product in the competitive market. Discuss your specific requirements upfront to ensure the manufacturer can meet your expectations and timelines. -

What quality assurance practices should I expect from a reputable bicycle parts manufacturer?

A reputable bicycle parts manufacturer should have robust quality assurance practices in place, including regular inspections during the production process, testing of finished products, and adherence to international quality standards. Ask about their quality control procedures, such as batch testing and certifications, to ensure they meet your specifications and industry requirements. Regular audits and feedback loops can also help maintain product quality over time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for bicycle part manufacturer

What Are the Key Takeaways for B2B Buyers in Bicycle Parts Manufacturing?

As we conclude our exploration of strategic sourcing in the bicycle parts manufacturing sector, it is crucial for international B2B buyers to recognize the importance of building robust supply chain relationships. Effective strategic sourcing not only enhances cost efficiency but also improves product quality and delivery timelines, which are vital in meeting the demands of a competitive market. For buyers in regions such as Africa, South America, the Middle East, and Europe, understanding local sourcing capabilities and global market trends can lead to significant competitive advantages.

How Can Strategic Sourcing Shape the Future of Bicycle Parts Procurement?

Looking ahead, buyers should leverage technological advancements and data analytics to refine their sourcing strategies. Emphasizing sustainability and ethical sourcing will resonate well with increasingly conscious consumers, particularly in European markets. By engaging with manufacturers who prioritize these values, companies can enhance their brand reputation and foster customer loyalty.

What Steps Should B2B Buyers Take Next?

In summary, strategic sourcing is not just a procurement function; it’s a pathway to innovation and growth. International B2B buyers are encouraged to proactively evaluate their sourcing strategies, build partnerships with reliable manufacturers, and stay informed about market shifts. Take action today to align your sourcing strategies with future market demands and position your business for long-term success in the bicycle parts industry.