Discover Top Butterfly Valve Manufacturers: Save Costs Today (2025)

Introduction: Navigating the Global Market for Butterfly Valve Manufacturers

Navigating the intricate landscape of global sourcing for butterfly valve manufacturers can pose significant challenges for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. With diverse applications ranging from water management to industrial processes, selecting the right butterfly valve is crucial for operational efficiency and safety. This comprehensive guide serves as a vital resource, addressing key aspects such as various types of butterfly valves, their applications across industries, and essential criteria for vetting suppliers.

By delving into cost considerations, performance specifications, and regulatory compliance, this guide empowers buyers to make informed purchasing decisions that align with their specific needs. Whether you’re a procurement officer in Kenya or a project manager in Germany, understanding the nuances of butterfly valve sourcing will enhance your ability to select high-quality products that meet both technical and budgetary requirements.

Ultimately, this guide aims to demystify the process of sourcing butterfly valves, providing actionable insights that enable B2B buyers to navigate the complexities of international markets with confidence. By leveraging the information presented here, businesses can streamline their procurement strategies, minimize risks, and foster long-term partnerships with reliable manufacturers.

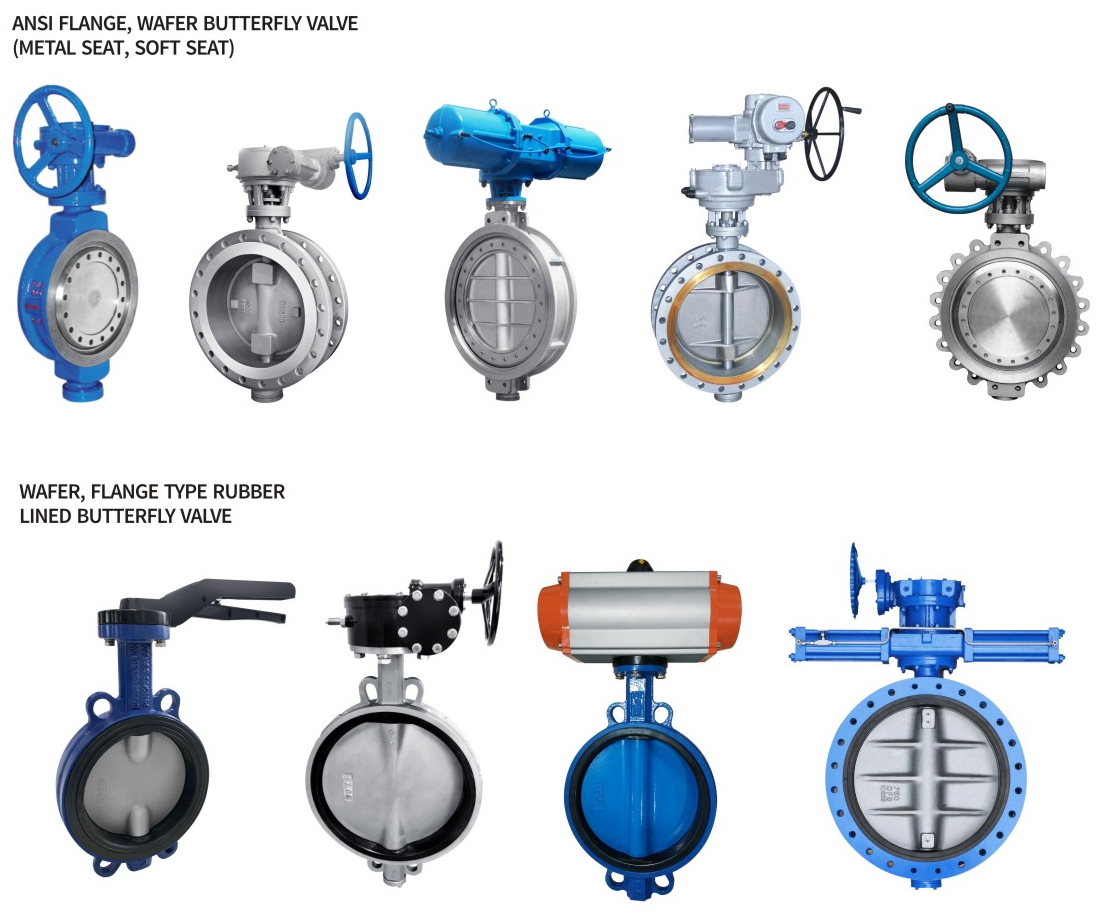

Understanding Butterfly Valve Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wafer Butterfly Valves | Compact design, installed between flanges | Water treatment, HVAC systems | Pros: Lightweight, easy to install. Cons: Limited pressure ratings. |

| Lug Butterfly Valves | Two sets of threaded holes for mounting | Oil & gas pipelines, chemical plants | Pros: Easy maintenance, can be serviced without line shutdown. Cons: Bulkier than wafer types. |

| Double Flanged Butterfly Valves | Flanged ends for direct connection | Power generation, waste management | Pros: High pressure and temperature ratings. Cons: More expensive and heavier. |

| Electric Butterfly Valves | Automated operation with electric actuator | Automation in manufacturing, water control | Pros: Reduced labor costs, precise control. Cons: Requires electrical infrastructure. |

| Manual Butterfly Valves | Operated by handwheel or lever | General industrial applications | Pros: Simple operation, low cost. Cons: Slower response time compared to automated options. |

What are Wafer Butterfly Valves and Their Applications?

Wafer butterfly valves are designed with a compact structure that fits between two flanges, making them ideal for space-constrained applications. These valves are particularly suitable for water treatment facilities and HVAC systems where weight and ease of installation are critical. When purchasing wafer butterfly valves, buyers should consider the fluid type, pressure ratings, and the valve’s compatibility with existing systems to ensure optimal performance.

How Do Lug Butterfly Valves Differ from Other Types?

Lug butterfly valves feature two sets of threaded holes, allowing for easy mounting and maintenance without requiring a complete system shutdown. They are commonly used in oil and gas pipelines and chemical plants, where safety and reliability are paramount. Buyers should evaluate the valve’s size, material, and pressure ratings to match their specific operational requirements, ensuring a secure and efficient installation.

Why Choose Double Flanged Butterfly Valves?

Double flanged butterfly valves offer robust construction with flanged ends that provide direct connection to pipelines, making them suitable for high-pressure and high-temperature applications like power generation and waste management. The key considerations for B2B buyers include the valve’s material, pressure rating, and compatibility with the intended application, as these factors can significantly impact the valve’s performance and longevity.

What Are the Benefits of Electric Butterfly Valves?

Electric butterfly valves are equipped with electric actuators that allow for automated operation, making them ideal for applications requiring precise control, such as in manufacturing and water management systems. While they reduce labor costs and improve operational efficiency, B2B buyers must ensure the availability of electrical infrastructure and consider the initial investment costs associated with automation.

When Should Manual Butterfly Valves Be Used?

Manual butterfly valves are operated through a handwheel or lever, making them a straightforward choice for general industrial applications. They are favored for their simplicity and low cost, though they may not provide the rapid response needed for more dynamic systems. Buyers should assess their operational needs and consider the trade-offs between manual and automated options to determine the best fit for their applications.

Related Video: Valves Explained – Control Valve Types (Gate Valve, Globe Valve, Ball Valve, Butterfly Valve, etc.)!

Key Industrial Applications of Butterfly Valve Manufacturers

| Industry/Sector | Specific Application of Butterfly Valve Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Flow regulation in water treatment plants | Efficient control of water supply and quality | Material compatibility with water, pressure ratings |

| Oil & Gas | Isolation in pipeline systems | Safety and operational efficiency | Compliance with industry standards, corrosion resistance |

| Food & Beverage | Control of liquid flow in processing lines | Hygiene and quality assurance | FDA compliance, ease of cleaning |

| Power Generation | Regulation of steam and cooling water in power plants | Enhanced energy efficiency and reliability | Temperature tolerance, sealing effectiveness |

| Chemical Processing | Flow control in chemical reactors | Precise control of reactions and safety management | Material compatibility with chemicals, pressure ratings |

How Are Butterfly Valves Used in Water Treatment?

In water treatment facilities, butterfly valves are integral for regulating flow and maintaining water quality. They enable precise control over the water supply, ensuring it meets safety standards. For international buyers, particularly from regions like Africa and South America, sourcing butterfly valves that are compatible with local water conditions and regulatory requirements is crucial. Buyers should prioritize materials that resist corrosion and ensure high-pressure ratings to withstand varying water conditions.

What Role Do Butterfly Valves Play in Oil & Gas Applications?

In the oil and gas sector, butterfly valves are primarily used for isolation in pipeline systems. They provide a reliable method to control the flow of oil or gas, enhancing safety and operational efficiency. Buyers in the Middle East, where oil and gas are predominant industries, must consider sourcing valves that comply with stringent industry standards and offer corrosion resistance due to harsh environmental conditions. Understanding the specific pressure and temperature ratings required for their applications is also essential.

Why Are Butterfly Valves Important in the Food & Beverage Industry?

Butterfly valves are critical in the food and beverage industry for controlling the flow of liquids in processing lines. They ensure hygiene and quality assurance, which are paramount in this sector. B2B buyers, especially from Europe, should ensure that the valves meet FDA compliance and are easy to clean to maintain sanitation standards. Selecting valves made from materials that do not leach harmful substances into food products is also a key consideration.

How Do Butterfly Valves Enhance Efficiency in Power Generation?

In power generation, butterfly valves regulate steam and cooling water, contributing to enhanced energy efficiency and reliability. These valves help maintain optimal operating conditions within power plants. For buyers in Europe and other regions with advanced power generation systems, sourcing valves with high-temperature tolerance and effective sealing is critical. Understanding the specific operational requirements and maintenance needs of these valves can significantly impact plant performance.

What Are the Applications of Butterfly Valves in Chemical Processing?

Butterfly valves are widely used in chemical processing for flow control in reactors. They allow for precise management of chemical reactions, which is vital for safety and efficiency. International B2B buyers, particularly from South America, should focus on sourcing valves that are compatible with the specific chemicals being processed and that meet the required pressure ratings. Ensuring material compatibility to prevent chemical degradation is crucial for maintaining operational integrity.

Related Video: Assembly of the Pratt Industrial BF Series Butterfly Valve

3 Common User Pain Points for ‘Butterfly Valve Manufacturers’ & Their Solutions

Scenario 1: Difficulty Sourcing High-Quality Butterfly Valves

The Problem:

B2B buyers often struggle to find reliable suppliers of butterfly valves that meet their specific quality standards and regulatory requirements. This issue is particularly pronounced in regions like Africa and South America, where local manufacturing capabilities may be limited, leading to reliance on international suppliers. Buyers frequently face challenges related to inconsistent quality, lack of certification compliance, and prolonged lead times, which can disrupt project timelines and increase costs.

The Solution:

To effectively source high-quality butterfly valves, buyers should prioritize suppliers with proven track records and reputable certifications such as ISO 9001 or API 609. Engaging in thorough supplier audits and site visits can provide insights into their manufacturing processes and quality control measures. Utilizing online platforms and industry-specific forums to gather reviews and testimonials can also help in making informed decisions. Furthermore, establishing long-term relationships with suppliers can lead to better pricing and priority in production schedules, ensuring timely delivery of high-quality products.

Scenario 2: Understanding Technical Specifications for Optimal Performance

The Problem:

Another common pain point for B2B buyers is the complexity of technical specifications associated with butterfly valves. Buyers often find themselves overwhelmed by technical jargon and the variety of options available, such as different materials, pressure ratings, and valve designs. This lack of understanding can lead to purchasing decisions that do not align with operational requirements, resulting in inefficiencies or equipment failures in the field.

The Solution:

To navigate the technical specifications effectively, buyers should invest time in training sessions or workshops that focus on the fundamentals of butterfly valve technology. Collaborating with engineers or technical consultants can also provide valuable insights into the specific needs of the project. Additionally, buyers should utilize resources such as manufacturer datasheets and technical documentation to compare different products side by side. Establishing a checklist of essential specifications relevant to their applications—such as temperature tolerance, media compatibility, and actuator types—can streamline the decision-making process, ensuring that the selected valves meet operational demands.

Scenario 3: Managing After-Sales Support and Service Issues

The Problem:

After-sales support is a significant concern for B2B buyers of butterfly valves. Many manufacturers offer limited support or fail to respond promptly to service requests, leaving buyers stranded when they encounter issues post-installation. This lack of support can lead to increased downtime, costly repairs, and frustration for companies that rely on these components for their operations.

The Solution:

To mitigate after-sales support issues, buyers should prioritize manufacturers that offer comprehensive warranties and robust customer service. Before making a purchase, it’s essential to inquire about the manufacturer’s support policies, including response times for service requests and availability of replacement parts. Buyers can also establish service level agreements (SLAs) that outline expected response times and support commitments. Furthermore, joining industry associations or networks can provide access to shared experiences and recommendations for reliable manufacturers known for their exceptional after-sales service, thereby enhancing the overall purchasing experience.

Strategic Material Selection Guide for Butterfly Valve Manufacturers

When selecting materials for butterfly valves, manufacturers must consider various factors that directly affect performance, durability, and cost-effectiveness. Here, we analyze four common materials used in butterfly valve production: cast iron, stainless steel, PVC, and bronze. Each material has unique properties, advantages, and limitations that influence their suitability for different applications, especially for international B2B buyers.

What Are the Key Properties of Cast Iron for Butterfly Valves?

Cast iron is a widely used material for butterfly valves, particularly in water and wastewater applications. Its key properties include excellent strength and durability, with a temperature rating typically up to 200°C (392°F) and pressure ratings around 150 psi. Cast iron is also resistant to corrosion in non-aggressive environments, making it suitable for various media.

Pros: The advantages of cast iron include its low cost and ease of manufacturing, which can lead to lower overall production costs. It also provides good sealing capabilities and is suitable for large valve sizes.

Cons: However, cast iron is relatively brittle and can crack under high-stress conditions. It is also not suitable for highly corrosive environments, which can limit its application scope.

Impact on Application: Cast iron valves are commonly used in municipal water systems and irrigation, where the media is generally non-corrosive.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM or DIN, for cast iron specifications, especially for water quality regulations.

How Does Stainless Steel Enhance Butterfly Valve Performance?

Stainless steel is another popular choice for butterfly valves, particularly in industries that require high corrosion resistance, such as food processing and pharmaceuticals. Its key properties include a high temperature rating (up to 400°C or 752°F) and excellent pressure resistance.

Pros: The primary advantage of stainless steel is its superior durability and resistance to corrosion, making it ideal for harsh environments. It also offers a clean finish, which is essential in sanitary applications.

Cons: On the downside, stainless steel is more expensive than cast iron and can be more challenging to machine, leading to higher manufacturing costs.

Impact on Application: Stainless steel valves are suitable for a wide range of media, including aggressive chemicals and high-pressure steam.

Considerations for International Buyers: Buyers in Europe, particularly Germany, should be aware of compliance with strict European standards for food-grade materials, such as the FDA and EU regulations.

What Are the Advantages of Using PVC in Butterfly Valves?

PVC (Polyvinyl Chloride) is a lightweight, cost-effective material often used for butterfly valves in low-pressure applications. Its key properties include a temperature rating of up to 60°C (140°F) and excellent chemical resistance.

Pros: The main advantage of PVC is its low cost and resistance to a wide range of chemicals, making it suitable for water treatment and irrigation systems.

Cons: However, PVC is not suitable for high-temperature applications and can become brittle over time when exposed to UV light.

Impact on Application: PVC valves are commonly used in irrigation and chemical processing where the media is not corrosive and the pressure is low.

Considerations for International Buyers: Buyers from the Middle East should consider the impact of high temperatures on PVC performance and ensure compliance with local standards for plastic materials.

Why Choose Bronze for Butterfly Valves?

Bronze is a traditional material for butterfly valves, especially in marine and industrial applications. Its key properties include good corrosion resistance and a temperature rating of up to 250°C (482°F).

Pros: Bronze offers excellent durability and resistance to seawater, making it ideal for marine applications. It also has good machinability, allowing for precise manufacturing.

Cons: The main disadvantage of bronze is its higher cost compared to other materials, and it can be prone to dezincification if not properly alloyed.

Impact on Application: Bronze valves are often used in shipbuilding, marine applications, and industrial processes involving corrosive media.

Considerations for International Buyers: Buyers from South America should ensure that the bronze used meets local corrosion resistance standards, particularly in coastal regions.

Summary Table of Material Selection for Butterfly Valves

| Material | Typical Use Case for Butterfly Valve Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Municipal water systems, irrigation | Low cost and good sealing | Brittle, limited corrosive resistance | Low |

| Stainless Steel | Food processing, pharmaceuticals | Superior durability and corrosion resistance | Higher cost, challenging to machine | High |

| PVC | Irrigation, low-pressure chemical processing | Low cost and chemical resistance | Not suitable for high temperatures | Low |

| Bronze | Marine applications, industrial processes | Excellent corrosion resistance | Higher cost, prone to dezincification | Medium |

This guide provides valuable insights for international B2B buyers, helping them make informed decisions based on material properties, application suitability, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for Butterfly Valve Manufacturers

What Are the Typical Manufacturing Processes for Butterfly Valve Manufacturers?

Manufacturing butterfly valves involves a series of well-defined stages that ensure the final product meets rigorous performance and quality standards. Understanding these processes can help B2B buyers make informed decisions when selecting suppliers.

What Are the Main Stages of Butterfly Valve Manufacturing?

-

Material Preparation

– Selection of Raw Materials: The primary materials used for butterfly valves include cast iron, stainless steel, and PVC. The choice depends on the application, such as pressure, temperature, and the type of fluid being controlled.

– Material Testing: Before production begins, raw materials undergo rigorous testing for chemical composition and mechanical properties to ensure they meet industry standards. -

Forming

– Casting or Forging: Butterfly valve bodies are typically manufactured through casting or forging. Casting allows for complex shapes, while forging enhances strength.

– Machining: Post-casting or forging, components are machined to precise dimensions using CNC (Computer Numerical Control) equipment. This includes drilling, milling, and turning operations to achieve the desired tolerances. -

Assembly

– Component Assembly: The valve’s internal components, such as the disc, seat, and stem, are assembled. Attention to detail is crucial during this stage to ensure proper fit and function.

– Sealing: Gaskets and seals are installed to prevent leaks. The choice of sealing materials can significantly affect the valve’s performance and longevity. -

Finishing

– Surface Treatment: After assembly, the valve undergoes surface treatments such as coating or plating to enhance corrosion resistance and aesthetics.

– Final Inspection: Each valve is subject to a final inspection to verify that it meets the specifications before it is packaged and shipped.

How Is Quality Assurance Implemented in Butterfly Valve Manufacturing?

Quality assurance (QA) is critical in ensuring that butterfly valves perform reliably under various operating conditions. The QA process typically aligns with international standards and industry-specific regulations.

What International Standards Should Buyers Be Aware Of?

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). Manufacturers certified under ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: In Europe, CE marking indicates that a product meets safety, health, and environmental protection standards. This is particularly important for valves used in critical applications.

- API Standards: The American Petroleum Institute (API) has specific standards for valves used in oil and gas applications. Compliance with these standards can be a key requirement for buyers in these industries.

What Are the Key Quality Control Checkpoints?

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Ensuring that materials meet specifications is crucial for the quality of the final product.

-

In-Process Quality Control (IPQC): During manufacturing, various checkpoints are established to monitor processes and identify defects early. This can include dimensional checks and functional tests at different stages of production.

-

Final Quality Control (FQC): Before shipment, each valve undergoes a comprehensive final inspection. This includes pressure testing, functional testing, and visual inspections to ensure compliance with specifications.

What Common Testing Methods Are Used in Quality Assurance?

- Pressure Testing: Valves are subjected to pressure tests to verify their ability to withstand operating conditions without leaking.

- Functional Testing: This involves checking the valve’s operation under simulated working conditions to ensure it opens and closes smoothly.

- Material Testing: Techniques such as hardness testing and tensile testing are used to evaluate the mechanical properties of the materials used in the valve.

How Can B2B Buyers Verify Supplier Quality Control?

- Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess the manufacturing processes and quality assurance practices firsthand. This is particularly important for buyers from regions like Africa and South America, where manufacturing standards may vary.

- Quality Reports: Requesting detailed quality control reports can provide insights into the supplier’s QA processes and any issues encountered during production.

- Third-Party Inspections: Engaging independent inspection agencies to evaluate the manufacturing processes and final products can ensure an unbiased assessment of quality.

What Are the Quality Control and Certification Nuances for International Buyers?

B2B buyers from different regions must consider specific quality control and certification nuances when sourcing butterfly valves. For instance:

- Regional Regulations: Buyers from the Middle East may need to comply with local standards, such as the Gulf Cooperation Council (GCC) regulations, which could differ from European standards.

- Documentation Requirements: Ensuring that suppliers provide adequate documentation, including test reports and compliance certificates, is essential for international transactions.

- Cultural Considerations: Understanding the cultural context in which suppliers operate can help buyers navigate potential challenges in communication and expectations regarding quality.

Conclusion

A comprehensive understanding of the manufacturing processes and quality assurance practices for butterfly valves is essential for international B2B buyers. By familiarizing themselves with the main stages of production, relevant standards, quality checkpoints, and verification methods, buyers can make informed decisions and establish reliable partnerships with manufacturers across Africa, South America, the Middle East, and Europe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Butterfly Valve Manufacturers’

To effectively source butterfly valves for your business, it is crucial to follow a structured approach that ensures quality, compliance, and value. This checklist is designed for international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, who seek reliable manufacturers of butterfly valves.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly define the technical requirements of the butterfly valves you need. This includes size, material, pressure ratings, and any specific features such as actuators or coatings.

– Why It’s Important: Precise specifications help ensure that the product meets your operational needs and reduces the risk of compatibility issues later in the procurement process.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential butterfly valve manufacturers. Look for companies that specialize in your required specifications and have a strong market presence.

– What to Consider:

– Company reputation and history in the industry.

– Reviews and feedback from other buyers in similar sectors.

Step 3: Evaluate Supplier Certifications

✅ Verify Supplier Certifications to ensure compliance with international standards such as ISO 9001 for quality management systems.

– Why It’s Important: Certifications indicate that the manufacturer adheres to quality control processes, which can significantly reduce the risk of product failure and ensure reliability in your operations.

Step 4: Request Samples and Product Documentation

Before making a bulk purchase, request samples of the butterfly valves along with detailed product documentation.

– What to Look For:

– Material certifications and test reports.

– Installation manuals and operational guidelines.

Step 5: Assess Lead Times and Production Capacity

Inquire about the lead times for production and delivery, as well as the manufacturer’s capacity to meet your order volumes.

– Why It’s Important: Understanding lead times allows you to plan your inventory and operations effectively, preventing potential delays in your projects.

Step 6: Negotiate Payment Terms and Pricing

Discuss pricing and payment terms with potential suppliers to ensure you get the best deal without compromising on quality.

– What to Consider:

– Look for flexible payment options such as milestones based on delivery stages.

– Assess the total cost of ownership, including shipping and potential tariffs.

Step 7: Establish Communication Protocols

Set clear communication channels and protocols with your selected supplier to facilitate smooth interactions.

– Why It’s Important: Open lines of communication can help address any issues promptly and ensure that both parties are aligned throughout the sourcing process.

By following this checklist, you can streamline your sourcing process and make informed decisions when procuring butterfly valves, ensuring that you partner with manufacturers who meet your quality and operational needs.

Comprehensive Cost and Pricing Analysis for Butterfly Valve Manufacturers Sourcing

What Are the Key Cost Components in Butterfly Valve Manufacturing?

When sourcing butterfly valves, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials include cast iron, stainless steel, and PVC, with prices varying based on quality and market demand. For instance, high-grade stainless steel valves will typically command higher prices than their cast iron counterparts.

-

Labor: Labor costs can vary widely depending on the region and the complexity of the valve design. Manufacturers in regions with higher labor costs, such as Western Europe, may have to price their products higher than those in lower-cost regions like parts of Africa or South America.

-

Manufacturing Overhead: This includes indirect costs associated with the production process, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help mitigate these overhead costs.

-

Tooling: The cost of tooling is a significant factor, especially for custom or high-specification valves. Initial tooling investments may be high, but they can be amortized over larger production runs.

-

Quality Control (QC): Ensuring product quality often involves additional costs related to inspection, testing, and certifications. This is particularly critical for industries like oil and gas, where safety standards are stringent.

-

Logistics: Shipping and handling costs should not be overlooked, especially for international buyers. These costs can fluctuate based on distance, shipping method, and any tariffs or import duties.

A stock image related to Butterfly Valve Manufacturers.

- Margin: Finally, manufacturers will include a profit margin that reflects their business model and market positioning. This margin can vary significantly based on the competitive landscape and the perceived value of the product.

How Do Price Influencers Affect Butterfly Valve Costs?

Several factors can influence the pricing of butterfly valves, making it crucial for international buyers to consider these when sourcing:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to discounts. Understanding the MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Customized valves that meet specific operational needs may incur additional costs. Buyers should be clear about their requirements to avoid unexpected expenses.

-

Material Selection: The choice of materials not only affects the initial cost but also the long-term durability and maintenance costs of the valves.

-

Quality and Certifications: Higher quality and certified valves (such as ISO or API certifications) can command premium prices, but they often lead to lower Total Cost of Ownership (TCO) in the long run.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established manufacturers may offer higher quality but at a premium.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can greatly affect the final price.

What Negotiation Tips Can Help International Buyers Achieve Cost-Efficiency?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can significantly impact the overall cost:

-

Conduct Market Research: Understanding the average market prices and competitor offerings can empower buyers during negotiations.

-

Leverage Volume Purchases: If feasible, consolidating orders can lead to lower prices per unit and better terms.

-

Explore Long-term Partnerships: Building relationships with manufacturers can lead to better pricing, priority service, and favorable terms over time.

-

Discuss Total Cost of Ownership (TCO): Highlighting the importance of TCO can shift the focus from upfront costs to long-term savings, which may lead suppliers to offer better terms.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures influenced by local demand, economic conditions, and logistical factors. Understanding these nuances can guide negotiation strategies.

Disclaimer on Indicative Prices

Prices for butterfly valves can fluctuate based on numerous factors, including market conditions, supplier pricing strategies, and geopolitical factors. Therefore, it is advisable for buyers to obtain current quotes directly from manufacturers or suppliers to ensure accurate budgeting and financial planning.

Alternatives Analysis: Comparing Butterfly Valve Manufacturers With Other Solutions

When considering the procurement of butterfly valves, it’s essential to evaluate the alternatives available in the market. Understanding how these alternatives stack up against traditional butterfly valve manufacturers can significantly impact decision-making for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. This analysis will highlight key alternatives, enabling buyers to make informed choices that align with their operational needs and budget constraints.

Comparison Table of Butterfly Valve Manufacturers and Alternatives

| Comparison Aspect | Butterfly Valve Manufacturers | Electric Actuated Valves | Gate Valve Manufacturers |

|---|---|---|---|

| Performance | High flow capacity, quick operation | Precise control, faster response time | Good for on/off service, limited throttling |

| Cost | Moderate to high initial investment | Higher initial cost due to electric components | Generally lower initial cost |

| Ease of Implementation | Simple installation and integration | Requires electrical setup, more complex | Straightforward installation |

| Maintenance | Low maintenance, durable materials | Moderate maintenance, requires power source | Regular maintenance needed, susceptible to wear |

| Best Use Case | Ideal for large volume, low-pressure applications | Best for automated systems requiring precise control | Suitable for high-pressure systems and isolation |

In-Depth Analysis of Alternatives

What Are Electric Actuated Valves and Their Advantages?

Electric actuated valves are designed for automated control in various industrial applications. Their primary advantage lies in their ability to provide precise control over flow rates and pressure, making them ideal for processes that demand high levels of accuracy. However, they come with a higher initial cost and require a reliable power source, which may not be feasible in all regions, particularly in areas with inconsistent electricity supply. Regular maintenance is also necessary to ensure the actuator functions correctly, which can add to operational costs.

How Do Gate Valve Manufacturers Compare?

Gate valves are a traditional solution for controlling the flow of fluids. They are particularly effective in high-pressure applications and are often less expensive than butterfly valves. Gate valves excel in providing a tight seal when fully closed, making them suitable for applications that require complete isolation. However, they are not designed for throttling, which limits their versatility in flow control. Additionally, they may require more frequent maintenance due to wear and tear, especially in high-frequency operations.

Conclusion: How to Choose the Right Valve Solution for Your Needs?

Selecting the right valve solution hinges on understanding the specific requirements of your application. For buyers in Africa, South America, the Middle East, and Europe, it is crucial to assess factors such as the operational environment, budget constraints, and maintenance capabilities. Butterfly valves offer a balance of performance and ease of use for large volume applications, while electric actuated valves provide precision for automated systems, albeit at a higher cost. Gate valves may serve well in isolation applications but lack the versatility needed for dynamic flow control. Ultimately, a thorough evaluation of these factors will guide B2B buyers in choosing the most effective and economical solution for their operations.

Essential Technical Properties and Trade Terminology for Butterfly Valve Manufacturers

What Are the Essential Technical Properties of Butterfly Valves?

Understanding the critical specifications of butterfly valves is vital for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Here are some key properties that manufacturers focus on:

1. Material Grade

The material grade of a butterfly valve significantly affects its performance and durability. Common materials include ductile iron, stainless steel, and PVC. The choice of material depends on factors such as the medium being transported (water, gas, chemicals) and environmental conditions (corrosion, temperature). For instance, stainless steel valves are preferred for corrosive environments, while ductile iron is suitable for water applications. Selecting the right material ensures longevity and reduces maintenance costs.

2. Pressure Rating

Pressure rating indicates the maximum pressure a valve can withstand without failing. It is typically expressed in pounds per square inch (PSI) or bar. Understanding pressure ratings is crucial for buyers to ensure that the valve can operate effectively within their system’s pressure requirements. For example, a valve rated for 150 PSI may not be suitable for high-pressure applications, leading to potential failures or safety hazards.

3. Size and Diameter

Butterfly valves come in various sizes, and selecting the correct diameter is essential for flow efficiency. The size affects the flow rate and pressure drop across the valve. Buyers must consider the pipe size and the specific requirements of their application when determining the appropriate valve diameter. A miscalculation can result in insufficient flow or excessive pressure loss, impacting system performance.

4. Tolerance Levels

A stock image related to Butterfly Valve Manufacturers.

Tolerance refers to the permissible limit or limits of variation in a physical dimension. For butterfly valves, tight tolerances are critical for ensuring proper fit and function within a piping system. Higher tolerance levels can enhance sealing and reduce the risk of leaks. Buyers should inquire about tolerance specifications, especially for applications requiring precise control, such as in chemical processing or food and beverage industries.

5. Actuation Type

Butterfly valves can be manually operated or automated, with actuation types including electric, pneumatic, and hydraulic. The choice of actuation affects response time, control precision, and operational efficiency. For instance, automated valves are ideal for remote operations and applications requiring frequent adjustments, while manual valves may suffice for simpler, less frequent tasks.

What Are Common Trade Terms in the Butterfly Valve Industry?

Familiarizing yourself with industry terminology can streamline your purchasing process and improve communication with suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components that are used in another company’s end products. In the context of butterfly valves, buyers may work directly with OEMs for custom solutions that fit specific system requirements. Understanding this term helps in identifying potential suppliers who can meet specialized needs.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand as it can affect inventory management and cash flow. Knowing the MOQ can help buyers plan their orders effectively, particularly when dealing with international suppliers who may have different standards.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a price quote on specific products or services. It typically includes details such as specifications, quantities, and delivery timelines. For buyers, issuing an RFQ is an essential step in the procurement process, enabling them to compare offers and negotiate terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers to navigate shipping, insurance, and customs regulations effectively. For instance, terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for costs and risks during transportation.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing butterfly valves, ensuring compatibility and efficiency in their applications.

Navigating Market Dynamics and Sourcing Trends in the Butterfly Valve Manufacturers Sector

What Are the Current Market Dynamics and Sourcing Trends in the Butterfly Valve Manufacturers Sector?

The butterfly valve market is experiencing significant growth, driven by increasing demand across various industries such as water treatment, oil and gas, and chemical processing. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe navigate this market, understanding the underlying dynamics is crucial. Key trends include the integration of smart technologies, which enhance the functionality of butterfly valves through real-time monitoring and automation. Additionally, there is a notable shift towards digital sourcing platforms that streamline procurement processes and foster better supplier relationships.

Emerging technologies such as the Internet of Things (IoT) and Artificial Intelligence (AI) are reshaping sourcing strategies. These innovations enable predictive maintenance and optimize inventory management, reducing operational costs for buyers. Furthermore, sustainability concerns are prompting manufacturers to adopt eco-friendly materials and processes, aligning with the growing global emphasis on reducing environmental footprints. For instance, the use of lightweight materials not only conserves resources but also improves transport efficiency, which is particularly beneficial for buyers in remote areas.

International buyers should also be aware of regional market dynamics. In Africa, the emphasis is on infrastructure development, while Europe focuses on regulatory compliance and innovation. Understanding these variations allows buyers to tailor their sourcing strategies effectively, ensuring they remain competitive in an evolving landscape.

How Is Sustainability and Ethical Sourcing Shaping the Butterfly Valve Manufacturers Sector?

Sustainability has become a central theme in the butterfly valve manufacturing sector, with increasing pressure on companies to demonstrate environmental responsibility. The environmental impact of valve production and operation is significant, and buyers are now prioritizing suppliers who can provide transparency in their supply chains. This includes adherence to regulations, waste management practices, and the overall carbon footprint of their operations.

Ethical sourcing is also gaining traction among international B2B buyers. Companies are expected to procure materials from suppliers who uphold fair labor practices and contribute positively to their communities. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential benchmarks for buyers assessing potential suppliers. These certifications not only ensure compliance but also reflect a commitment to sustainable practices.

Moreover, the use of ‘green’ materials, such as recycled or sustainably sourced metals, is increasingly favored. Buyers can enhance their corporate social responsibility profiles by sourcing from manufacturers who prioritize sustainability. This trend not only meets regulatory requirements but also resonates with end consumers, leading to enhanced brand loyalty and market competitiveness.

What Is the Historical Context of Butterfly Valve Manufacturing and Its Impact on B2B Sourcing?

The evolution of butterfly valve manufacturing dates back to the early 20th century when the need for efficient flow control in industrial applications became apparent. Initially, these valves were primarily made of cast iron and were limited in application. However, advancements in materials science and manufacturing techniques have transformed butterfly valves into versatile components used in various sectors.

Today, butterfly valves are constructed from a range of materials, including stainless steel, plastic, and exotic alloys, which cater to diverse operational conditions. This evolution has not only expanded the market but also increased competition among manufacturers. For B2B buyers, understanding the historical context helps in recognizing the importance of selecting suppliers who have adapted to technological advancements and market demands. This ensures that they are sourcing products that are not only reliable but also innovative and suited for modern applications.

In conclusion, as international B2B buyers continue to explore the butterfly valve market, staying informed about market dynamics, sustainability trends, and the historical context of manufacturing will empower them to make strategic sourcing decisions that align with their operational goals and values.

Frequently Asked Questions (FAQs) for B2B Buyers of Butterfly Valve Manufacturers

- How do I select the right butterfly valve manufacturer for my project?

Choosing the right butterfly valve manufacturer involves evaluating several key factors. Start by assessing their industry experience and specialization in your sector, whether it’s oil and gas, water treatment, or food processing. Look for manufacturers with certifications like ISO 9001, which ensures quality management systems. Request samples and references from previous clients, particularly those in similar geographical regions or industries. Finally, consider their responsiveness and willingness to provide support, as effective communication is crucial for successful international transactions.

-

What is the typical lead time for butterfly valves from manufacturers?

Lead times for butterfly valves can vary significantly based on several factors, including the manufacturer’s location, the complexity of the valve design, and the order size. Generally, lead times can range from 4 to 12 weeks. For customized valves, expect longer delays due to the additional design and manufacturing processes involved. To ensure timely delivery, communicate your project timelines clearly during negotiations and consider manufacturers with established logistics networks that can expedite shipping. -

What are the common payment terms offered by butterfly valve manufacturers?

Payment terms can vary widely among butterfly valve manufacturers and may depend on the buyer’s location and the manufacturer’s policies. Common terms include upfront deposits (typically 30-50%) with the balance due upon shipment. Some manufacturers may offer credit terms for established clients. It’s essential to negotiate these terms early in the procurement process and ensure they are documented in the contract to avoid misunderstandings later on. -

How do I ensure quality assurance in my butterfly valve order?

To ensure quality assurance, request detailed specifications and certifications from the manufacturer, such as material certifications and test reports. Many manufacturers conduct rigorous quality checks throughout the production process, including pressure testing and dimensional inspections. Additionally, consider arranging third-party inspections or audits, especially for large orders. Clear communication regarding your quality standards upfront can help prevent issues and ensure the final product meets your requirements.

- What customization options are available for butterfly valves?

Customization options for butterfly valves can include size, material, and design features such as seat types and actuator integration. Many manufacturers can tailor their products to specific operational conditions, such as high temperatures or corrosive environments. When discussing your needs, provide as much detail as possible about the application and any unique challenges. This helps manufacturers offer the best solutions tailored to your requirements.

-

What is the minimum order quantity (MOQ) for butterfly valves?

Minimum order quantities (MOQ) for butterfly valves vary among manufacturers and can depend on the valve type and complexity. Some manufacturers may have an MOQ of 10 to 50 units, while others may accept smaller orders. It’s advisable to discuss your needs during the initial inquiry phase. If your order quantity is below the MOQ, some manufacturers may still accommodate you but may charge a premium or combine your order with others to meet production requirements. -

How can I effectively vet a butterfly valve supplier before making a purchase?

Effective vetting involves researching the supplier’s reputation and credibility. Check for industry certifications, customer reviews, and case studies that demonstrate their experience and reliability. Engage in direct communication to assess their responsiveness and willingness to address your concerns. Additionally, consider visiting their facility if possible or requesting a virtual tour to better understand their production capabilities. Networking with other businesses in your industry can also provide valuable insights into potential suppliers. -

What logistics considerations should I keep in mind when sourcing butterfly valves internationally?

When sourcing butterfly valves internationally, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Choose a manufacturer with experience in international shipping to ensure compliance with local laws and regulations. Understand the import duties and taxes that may apply to your shipment. Collaborating with a freight forwarder can help streamline the logistics process and provide insights into the best shipping options based on cost and urgency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Butterfly Valve Manufacturers

In the evolving landscape of butterfly valve manufacturing, strategic sourcing emerges as a critical element for international B2B buyers. By prioritizing relationships with reputable manufacturers, buyers can ensure access to high-quality products that meet specific industry standards and regulatory requirements. This approach not only reduces procurement risks but also enhances supply chain efficiency, particularly for buyers operating in diverse markets across Africa, South America, the Middle East, and Europe.

Moreover, understanding the local market dynamics and leveraging technology can provide significant advantages. For instance, utilizing data analytics can inform purchasing decisions and optimize inventory management. As the demand for sustainable and innovative valve solutions grows, aligning sourcing strategies with manufacturers who prioritize eco-friendly practices can also enhance brand reputation and compliance with international regulations.

Looking ahead, international B2B buyers should actively seek partnerships that foster innovation and adaptability. Engaging with manufacturers who are committed to research and development will not only yield immediate benefits but also position businesses for future growth in a competitive marketplace. Therefore, now is the time to evaluate your sourcing strategies and make informed decisions that will drive long-term success.