Discover Top Cable Assembly Manufacturers: Save Costs Today (2025)

Introduction: Navigating the Global Market for cable assembly manufacturers

Navigating the global market for cable assembly manufacturers presents a unique set of challenges for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. As businesses increasingly rely on complex electronic systems, sourcing high-quality cable assemblies has become crucial for ensuring reliability and performance. This guide aims to simplify the process of finding reputable manufacturers by exploring various types of cable assemblies, their applications across industries, and essential supplier vetting criteria.

In this comprehensive resource, buyers will gain insights into the diverse applications of cable assemblies, including automotive, telecommunications, and industrial sectors, allowing them to make informed decisions tailored to their specific needs. Additionally, the guide addresses critical factors such as pricing structures, quality certifications, and logistical considerations that can influence procurement strategies.

By leveraging the actionable insights provided herein, B2B buyers can enhance their sourcing processes, mitigate risks, and establish long-term partnerships with trustworthy manufacturers. Whether you’re operating in bustling markets like Nigeria or navigating the complex regulatory landscapes in Europe, this guide is designed to empower you with the knowledge needed to make confident purchasing decisions in the cable assembly sector.

Understanding cable assembly manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Cable Assemblies | Tailored designs, specific lengths and connectors | Aerospace, automotive, medical devices | Pros: Highly specific solutions; Cons: Higher costs and longer lead times. |

| Standard Cable Assemblies | Pre-manufactured designs, common specifications | Consumer electronics, telecommunications | Pros: Cost-effective; Cons: Limited customization options. |

| Fiber Optic Cable Assemblies | Utilizes glass or plastic fibers for data transmission | Data centers, telecommunications | Pros: High-speed data transfer; Cons: Fragile and requires careful handling. |

| Coaxial Cable Assemblies | Central conductor surrounded by insulation and shielding | Broadcasting, CCTV systems | Pros: Excellent signal quality; Cons: Bulkier than other options. |

| Specialty Cable Assemblies | Unique materials or configurations for specific needs | Industrial machinery, robotics | Pros: Designed for specific environments; Cons: May have higher minimum order quantities. |

What Are Custom Cable Assemblies and When Should You Use Them?

Custom cable assemblies are designed to meet specific requirements in terms of length, connector type, and functionality. They are particularly beneficial for industries such as aerospace and medical devices where precision and compliance with regulatory standards are critical. When purchasing, consider the additional costs and longer lead times associated with custom solutions. It’s crucial to work closely with manufacturers to ensure that the design meets all necessary specifications.

How Do Standard Cable Assemblies Compare in Cost and Flexibility?

Standard cable assemblies are mass-produced and available in common lengths and connector types. These are ideal for applications in consumer electronics and telecommunications where cost-effectiveness and speed of delivery are essential. While they offer a lower price point and quicker turnaround times, buyers should be aware that customization options are limited, which may not meet all specific needs.

What Advantages Do Fiber Optic Cable Assemblies Provide?

Fiber optic cable assemblies utilize glass or plastic fibers to transmit data at high speeds, making them indispensable in data centers and telecommunications. Their ability to support high bandwidth and long-distance transmission without signal degradation is a significant advantage. However, buyers must consider the fragility of these cables and the need for specialized installation and handling techniques.

Why Choose Coaxial Cable Assemblies for Broadcasting?

Coaxial cable assemblies are designed to provide excellent signal quality, making them a preferred choice for broadcasting and CCTV systems. They consist of a central conductor, insulation, and a shielding layer, which protects the signal from interference. While they deliver reliable performance, their bulkier design may limit flexibility in tight installation spaces.

When to Opt for Specialty Cable Assemblies?

Specialty cable assemblies are tailored for unique applications, often using specific materials or configurations to withstand extreme environments or particular functionalities. Industries like industrial machinery and robotics often require these specialized solutions. While they offer targeted benefits, buyers should be prepared for higher minimum order quantities and potentially longer lead times, making thorough planning essential.

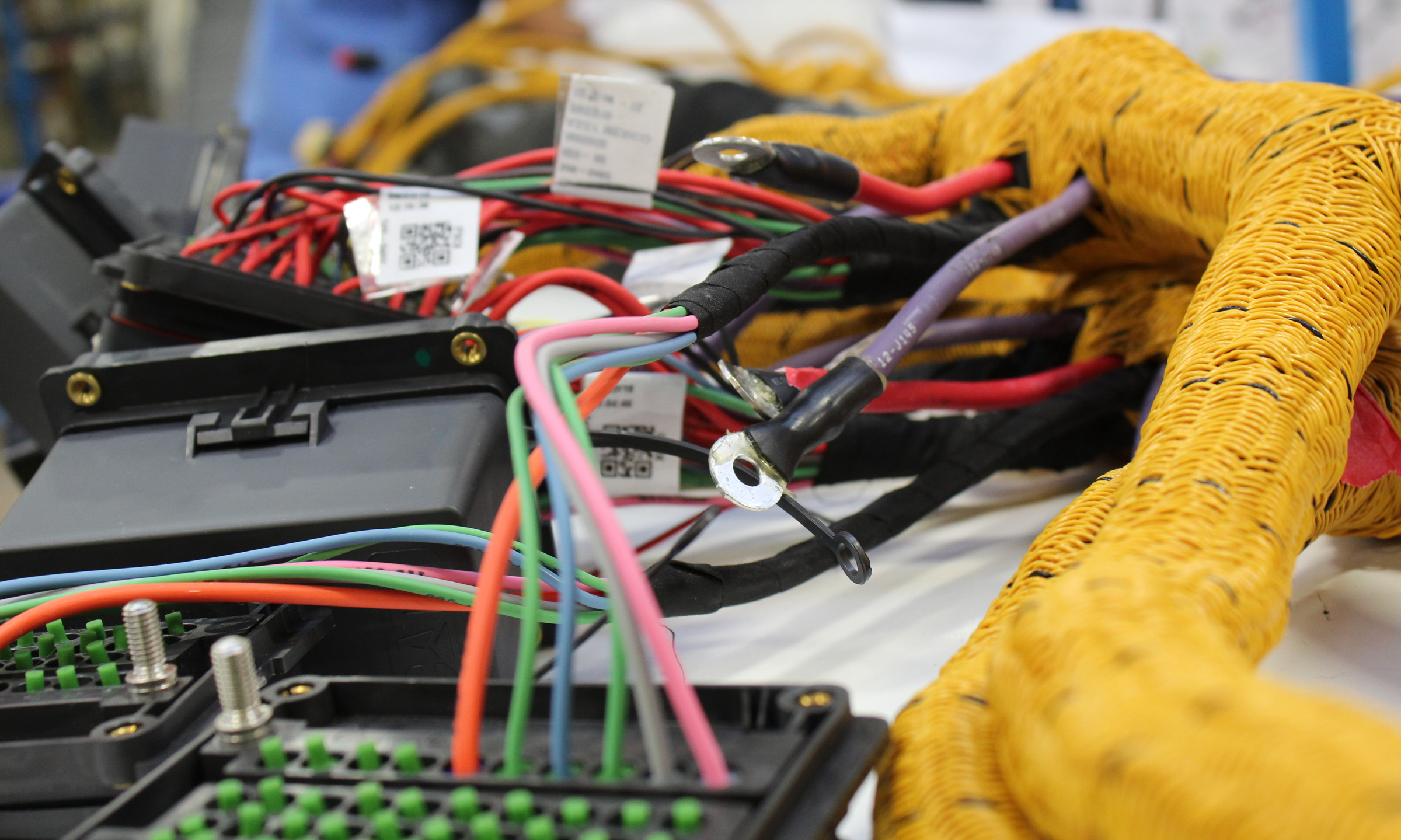

Related Video: Nangudi Wire Harness And Cable Assemblies Manufacturer Production Process

Key Industrial Applications of cable assembly manufacturers

| Industry/Sector | Specific Application of cable assembly manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom wiring harnesses for electric vehicles | Enhanced vehicle performance and safety | Compliance with automotive standards; robust testing results |

| Telecommunications | Fiber optic cable assemblies for data transmission | High-speed data transfer and reliability | Durability; environmental resistance; scalability |

| Industrial Automation | Cable assemblies for robotic systems | Improved operational efficiency and automation | Compatibility with existing systems; customization options |

| Medical Devices | Medical cable assemblies for diagnostic equipment | Precision and reliability in medical diagnostics | Regulatory compliance; biocompatibility; traceability |

| Consumer Electronics | Cable assemblies for audio and visual devices | Enhanced user experience and product performance | Quality assurance; design flexibility; supply chain reliability |

How Are Cable Assembly Manufacturers Used in the Automotive Industry?

In the automotive sector, cable assembly manufacturers provide custom wiring harnesses specifically designed for electric vehicles (EVs). These harnesses are crucial for connecting various components, including batteries, motors, and electronic control units. By utilizing high-quality materials and adhering to automotive standards, manufacturers ensure safety and performance. International buyers, particularly from Africa and South America, should prioritize suppliers who can demonstrate compliance with local regulations and provide robust testing results to prevent failures in critical systems.

What Role Do Cable Assemblies Play in Telecommunications?

In telecommunications, cable assembly manufacturers produce fiber optic cable assemblies that facilitate high-speed data transmission. These assemblies are essential for connecting network infrastructure, enabling reliable internet and communication services. The demand for high bandwidth and low latency makes quality a priority in sourcing. Buyers from the Middle East and Europe must consider the durability and environmental resistance of these cables, especially in regions with extreme weather conditions, to ensure long-term functionality.

How Are Cable Assemblies Integral to Industrial Automation?

Cable assemblies are vital in industrial automation, particularly for robotic systems. They connect various sensors and actuators, enabling seamless communication and control between components. This application improves operational efficiency and supports automation processes in manufacturing. Buyers should focus on sourcing assemblies that are compatible with existing systems and offer customization options to meet specific operational needs. This is especially important for businesses in emerging markets that may have unique infrastructure challenges.

Why Are Cable Assemblies Important for Medical Devices?

In the medical field, cable assembly manufacturers supply assemblies for diagnostic and imaging equipment. These assemblies must meet stringent regulatory requirements and ensure precision and reliability in diagnostics. International buyers, particularly from Europe and Africa, should prioritize suppliers who can provide evidence of regulatory compliance, biocompatibility, and traceability of materials. This is crucial for maintaining high standards in patient care and equipment reliability.

How Do Cable Assemblies Enhance Consumer Electronics?

In consumer electronics, cable assembly manufacturers create assemblies for audio and visual devices, enhancing user experience and product performance. High-quality assemblies can reduce signal loss and improve sound and image clarity. Buyers should look for manufacturers that offer quality assurance and design flexibility to cater to evolving consumer preferences. Ensuring a reliable supply chain is essential, particularly for businesses in fast-growing markets like South America, where demand for consumer electronics is rapidly increasing.

3 Common User Pain Points for ‘cable assembly manufacturers’ & Their Solutions

Scenario 1: Quality Control Issues in Cable Assemblies

The Problem: B2B buyers often face significant challenges regarding the quality of cable assemblies. These issues can arise from inconsistent manufacturing processes, leading to defects that compromise the performance of electronic devices. For example, a buyer sourcing cable assemblies for medical equipment may discover that the assemblies have poor insulation or incorrect wiring configurations. This not only delays project timelines but also poses serious safety risks and financial losses due to recalls or compliance failures.

The Solution: To mitigate quality control issues, buyers should implement a rigorous vetting process for cable assembly manufacturers. This includes requesting certifications such as ISO 9001 to ensure that the manufacturer adheres to international quality management standards. Moreover, buyers should consider conducting on-site visits to manufacturing facilities to assess processes and quality assurance protocols. Establishing clear specifications and performance standards before production can help ensure that the final product meets expectations. Additionally, maintaining an open line of communication with the manufacturer throughout the production process can facilitate quick resolutions to any quality concerns.

Scenario 2: Complex Supply Chain Management

The Problem: Managing a supply chain for cable assemblies can be daunting, particularly for buyers in regions with less reliable logistics networks. For instance, a buyer in Africa might experience delays due to customs issues or transportation inefficiencies, causing disruptions in their production schedules. These delays can lead to increased costs and strained relationships with clients who expect timely delivery.

The Solution: Buyers can alleviate supply chain challenges by partnering with cable assembly manufacturers who have a robust logistics framework. It’s essential to choose manufacturers who have experience working in the buyer’s region and understand the local customs and regulations. Additionally, leveraging technology such as supply chain management software can help buyers track shipments in real time and identify potential bottlenecks before they become significant issues. Creating contingency plans, such as sourcing from multiple manufacturers or establishing local inventory, can also provide a buffer against unforeseen delays.

Scenario 3: Difficulty in Customization of Cable Assemblies

The Problem: Many B2B buyers require customized cable assemblies to fit specific applications, but they often encounter resistance from manufacturers who may not be flexible or responsive to custom requests. This issue can be particularly frustrating for buyers in sectors like automotive or telecommunications, where precision and customization are critical for functionality. A buyer may find themselves stuck with standard products that do not meet their unique needs, leading to suboptimal performance and potential project failures.

The Solution: To address customization challenges, buyers should prioritize manufacturers known for their flexibility and willingness to collaborate on custom solutions. When initiating contact, buyers should clearly articulate their requirements, including specifications for materials, lengths, connectors, and other critical features. It can be beneficial to work with manufacturers who have a dedicated engineering team capable of providing insights and suggestions on design improvements. Establishing a prototype phase before full production allows buyers to test and refine their designs, ensuring that the final product aligns with their expectations. Regular feedback loops during the development process can further enhance collaboration and result in a more satisfactory outcome.

Strategic Material Selection Guide for cable assembly manufacturers

When selecting materials for cable assemblies, manufacturers must consider a variety of factors that directly influence performance, durability, and cost. Below, we analyze four common materials used in cable assembly manufacturing, providing insights that are particularly relevant for international B2B buyers from Africa, South America, the Middle East, and Europe.

A stock image related to cable assembly manufacturers.

What Are the Key Properties of PVC in Cable Assemblies?

A stock image related to cable assembly manufacturers.

Polyvinyl Chloride (PVC) is one of the most widely used materials in cable assemblies. It offers excellent insulation properties, flexibility, and resistance to moisture and chemicals. PVC can operate effectively within a temperature range of -10°C to 70°C, making it suitable for various environments.

Pros: PVC is cost-effective and easy to manufacture, which helps keep production costs low. Its durability and resistance to abrasion also make it a popular choice for many applications.

Cons: However, PVC is less resistant to high temperatures and can degrade under prolonged exposure to sunlight. This makes it less suitable for outdoor applications without additional protective measures.

Impact on Application: PVC is compatible with a wide range of media, including water and oils, but it may not be suitable for high-temperature or high-pressure applications.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding PVC use, particularly in regions with stringent environmental standards. Common standards like ASTM D3032 and DIN 47200 should be referenced.

How Does XLPE Compare for High-Performance Cable Assemblies?

Cross-Linked Polyethylene (XLPE) is another material that is gaining traction, particularly for high-performance cable assemblies. XLPE offers superior thermal resistance, withstanding temperatures up to 90°C continuously and 130°C intermittently.

Pros: XLPE is highly resistant to chemicals and moisture, making it ideal for harsh environments. Its mechanical strength and flexibility also contribute to its durability.

Cons: The manufacturing process for XLPE is more complex and costly compared to PVC, which can increase the final product price.

Impact on Application: XLPE is particularly effective in applications involving high voltage and temperature, making it suitable for industrial and utility applications.

Considerations for International Buyers: Buyers must consider the specific certifications required for XLPE cables, such as IEC 60502 and UL 44, especially when dealing with electrical installations in different regions.

What Are the Benefits of Using Teflon in Cable Assemblies?

Teflon (PTFE) is renowned for its exceptional chemical resistance and high-temperature tolerance, making it a premium choice for specialized cable assemblies. It can operate effectively in temperatures ranging from -200°C to 260°C.

Pros: Teflon’s low friction properties contribute to excellent signal integrity, and it is highly resistant to various chemicals, making it suitable for demanding applications.

Cons: The primary drawback of Teflon is its high cost, which can be a limiting factor for budget-sensitive projects. Additionally, its manufacturing complexity can lead to longer lead times.

Impact on Application: Teflon is ideal for applications requiring high-frequency signals and extreme environmental conditions, such as aerospace and medical devices.

Considerations for International Buyers: Buyers should verify compliance with standards like ASTM D3308 and JIS C 3102, especially in industries where safety and performance are critical.

Why Is Copper Still the Preferred Choice for Conductors?

Copper remains the standard for electrical conductors in cable assemblies due to its excellent electrical conductivity and thermal properties. It can handle high currents and has a melting point of approximately 1,085°C.

Pros: Copper cables are highly durable and have a long lifespan, making them a reliable choice for various applications.

Cons: However, copper is susceptible to corrosion, particularly in saline environments, and is also more expensive than alternatives like aluminum.

Impact on Application: Copper is suitable for a wide range of applications, from residential wiring to industrial machinery, but its weight can be a consideration in specific designs.

Considerations for International Buyers: Buyers should be aware of the varying standards for copper quality and conductivity, such as ASTM B3 and IEC 60228, to ensure compliance with local regulations.

Summary Table of Material Selection for Cable Assembly Manufacturers

| Material | Typical Use Case for cable assembly manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General-purpose cable insulation | Cost-effective and durable | Limited temperature resistance | Low |

| XLPE | High-voltage and industrial applications | Excellent thermal and chemical resistance | Higher manufacturing complexity | Medium |

| Teflon | Aerospace and medical applications | Superior chemical resistance and signal integrity | High cost and complex manufacturing | High |

| Copper | Electrical conductors in various applications | Excellent conductivity and durability | Susceptible to corrosion | Medium |

This strategic material selection guide provides essential insights for B2B buyers in diverse regions, enabling informed decisions that align with their specific application requirements and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cable assembly manufacturers

What Are the Main Stages of Manufacturing for Cable Assembly Manufacturers?

The manufacturing process for cable assemblies is a multi-stage operation that requires precision and adherence to specific standards. Understanding these stages can help B2B buyers from regions such as Africa, South America, the Middle East, and Europe (e.g., Nigeria and Thailand) make informed decisions when selecting suppliers.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials such as copper, aluminum, and various types of insulation. Suppliers should provide certifications for the materials used, ensuring compliance with international standards. Buyers should request documentation that includes material specifications and supplier certifications to verify quality.

-

Forming: After material preparation, the next step is forming the wires and cables. This involves cutting the raw materials to the required lengths and applying processes such as stripping insulation and twisting wires together. Advanced machinery is often employed to ensure consistency and accuracy in dimensions.

-

Assembly: During the assembly phase, the formed wires are connected with connectors, terminals, or other components. This step may also include soldering or crimping techniques, which are critical for ensuring reliable electrical connectivity. Buyers should inquire about the equipment and technology used in this process, as modern techniques can significantly enhance the quality of the final product.

-

Finishing: The finishing stage includes applying protective coatings, labeling, and packaging. It’s essential that these steps adhere to industry standards for durability and safety. Buyers should evaluate whether the manufacturer employs quality control measures during this stage, such as visual inspections and automated testing.

How Is Quality Assurance Implemented in Cable Assembly Manufacturing?

Quality assurance (QA) is a crucial aspect of cable assembly manufacturing, ensuring that products meet both customer expectations and regulatory requirements. For international B2B buyers, understanding the QA processes can provide confidence in the reliability of their suppliers.

-

International Standards and Certifications: Many cable assembly manufacturers comply with international quality management systems, such as ISO 9001. This certification demonstrates a commitment to consistent quality and continuous improvement. Additionally, industry-specific standards, such as CE marking for the European market or API standards for oil and gas applications, should be verified by buyers.

-

Quality Control Checkpoints: Manufacturers typically implement several quality control checkpoints throughout the production process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, various tests are conducted to ensure that processes are being followed correctly and that products are being made to specification.

– Final Quality Control (FQC): This final inspection checks the completed cable assemblies for defects and ensures they meet all relevant standards before shipment. -

Common Testing Methods: Cable assemblies undergo various testing methods, such as electrical continuity tests, insulation resistance tests, and environmental stress tests. Each of these tests helps to verify that the assembly can withstand operational conditions without failure. B2B buyers should ask potential suppliers about their testing protocols and the results of these tests.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly from regions like Africa and South America, ensuring the quality of cable assembly manufacturers is essential. Here are actionable steps to verify supplier quality control:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This can include on-site visits to evaluate facilities, equipment, and adherence to quality standards.

-

Requesting Quality Reports: Buyers should request quality assurance documentation, including test reports and compliance certificates. This documentation can offer transparency regarding the quality control measures employed by the manufacturer.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a manufacturer’s capabilities. These services can conduct audits, inspect products, and provide certifications that assure quality and compliance.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing from cable assembly manufacturers, international buyers should be aware of specific nuances related to quality control:

-

Cultural and Regulatory Differences: Different regions may have varying expectations regarding quality standards. Buyers from Europe may prioritize compliance with CE marking, while those in Africa might focus on local certification requirements. Understanding these differences can help buyers set clear expectations with suppliers.

-

Communication and Documentation: Clear communication is vital. Buyers should ensure that all quality expectations are documented in contracts and agreements. This includes specifying quality standards, testing methods, and compliance requirements.

-

Post-Delivery Support: Quality control does not end at the point of delivery. Buyers should discuss post-delivery support and warranty policies with suppliers. This can include product recalls, replacement parts, and technical support, which are crucial for maintaining long-term supplier relationships.

In conclusion, understanding the manufacturing processes and quality assurance measures in cable assembly manufacturing is critical for B2B buyers. By focusing on the stages of manufacturing, quality control standards, and verification methods, buyers can make informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cable assembly manufacturers’

To successfully procure cable assembly manufacturing services, international B2B buyers must follow a structured approach. This checklist provides actionable insights tailored for buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements of your cable assemblies. Consider factors such as wire gauge, insulation type, connector specifications, and environmental resistance. Precise specifications help potential suppliers understand your needs and ensure that the final product meets quality standards.

- Tip: Include tolerances and any industry standards (e.g., UL, IEC) relevant to your application.

Step 2: Research and Shortlist Potential Manufacturers

Conduct thorough research to identify reputable cable assembly manufacturers. Utilize online directories, industry associations, and trade shows to compile a list of potential suppliers.

- Tip: Focus on manufacturers with experience in your specific industry or application, as they will be better equipped to meet your needs.

Step 3: Evaluate Supplier Certifications and Compliance

Verify the certifications and compliance of potential suppliers. Look for ISO certifications, RoHS compliance, and any other relevant industry standards.

- Tip: Certifications ensure that manufacturers adhere to quality management systems and environmental regulations, which can impact product reliability and safety.

Step 4: Request Samples and Prototypes

Before making a large order, request samples or prototypes of the cable assemblies. This allows you to evaluate the quality, functionality, and compatibility of the products with your systems.

- Tip: Assess not only the physical product but also the responsiveness and communication of the supplier during the sample phase.

Step 5: Conduct a Cost Analysis

Analyze the total cost of ownership, not just the initial purchase price. Consider factors such as shipping costs, tariffs, lead times, and potential for bulk discounts.

- Tip: Engage in negotiations based on your analysis to ensure you are receiving the best value for your investment.

Step 6: Assess Manufacturing Capabilities and Capacity

Inquire about the manufacturer’s production capabilities and capacity to ensure they can meet your demand. Understand their lead times and flexibility in scaling production for future orders.

- Tip: A manufacturer with modern equipment and technology is more likely to produce high-quality products efficiently.

Step 7: Establish Clear Communication Channels

Effective communication is vital for successful collaboration. Establish clear communication channels and protocols to facilitate ongoing discussions regarding project updates, changes, and feedback.

- Tip: Choose a supplier that is responsive and has a dedicated point of contact to address your inquiries promptly.

By following this structured checklist, B2B buyers can streamline their sourcing process for cable assembly manufacturers, ensuring they partner with suppliers that meet their technical, quality, and logistical requirements.

Comprehensive Cost and Pricing Analysis for cable assembly manufacturers Sourcing

What Are the Key Cost Components in Cable Assembly Manufacturing?

When sourcing from cable assembly manufacturers, understanding the cost structure is crucial for international B2B buyers. The primary components influencing the overall cost include:

-

Materials: The choice of materials—such as copper, insulation, and connectors—directly affects the cost. High-quality materials may increase initial expenses but can lead to better performance and durability.

-

Labor: Labor costs vary significantly by region. For instance, manufacturers in Africa and South America may have lower labor costs compared to those in Europe. Understanding local wage rates can help buyers assess total costs.

-

Manufacturing Overhead: This includes the costs associated with running the manufacturing facility, such as utilities, rent, and equipment maintenance. Manufacturers with higher overhead may pass these costs on to buyers.

-

Tooling: Initial tooling costs can be substantial, particularly for custom cable assemblies. Buyers should inquire about tooling costs, especially if they require unique specifications.

-

Quality Control (QC): Implementing stringent QC processes is essential for ensuring product reliability. However, these processes incur additional costs, which can vary based on the manufacturer’s quality standards and certifications.

-

Logistics: Shipping and handling costs are significant, especially for international buyers. Factors such as distance, Incoterms, and shipping methods can influence the final cost.

-

Margin: Manufacturers typically include a profit margin in their pricing. Understanding the typical margins in the industry can help buyers gauge the fairness of quotes.

How Do Price Influencers Affect Sourcing Decisions?

Several factors can influence pricing, making it essential for buyers to consider these elements when negotiating:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs. Buyers should evaluate their needs and aim to meet MOQs to benefit from lower prices.

-

Specifications and Customization: Custom cable assemblies tailored to specific requirements can significantly increase costs. Clearly defining requirements upfront can help in obtaining accurate quotes.

-

Material Choices: The quality and type of materials selected will impact pricing. Buyers should weigh the benefits of high-quality materials against their budgets.

-

Quality Certifications: Manufacturers with internationally recognized quality certifications may charge higher prices. However, these certifications can ensure product reliability, making them worth the investment.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established manufacturers may command higher prices due to their proven track record.

-

Incoterms: Understanding Incoterms is crucial for international shipping. They determine who is responsible for costs at various points in the shipping process, affecting the total price.

What Are Effective Buyer Tips for Negotiating Prices?

International B2B buyers should consider the following strategies to optimize their sourcing:

-

Negotiate Terms: Don’t hesitate to negotiate pricing and terms. Presenting a strong case for volume orders or long-term partnerships can lead to better deals.

-

Focus on Cost-Efficiency: Look beyond the sticker price. Evaluate the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and potential downtime.

-

Research Market Prices: Familiarize yourself with market prices for similar products. This knowledge can empower you during negotiations.

-

Consider Local Suppliers: For buyers in Africa, South America, and the Middle East, sourcing from local manufacturers can reduce shipping costs and lead times.

-

Request Detailed Quotes: Obtain itemized quotes that break down costs into components. This transparency allows for better comparison and negotiation.

Conclusion

Navigating the complexities of sourcing from cable assembly manufacturers requires a thorough understanding of cost structures, price influencers, and effective negotiation tactics. By focusing on these areas, international B2B buyers can make informed decisions that enhance their supply chain efficiency and cost-effectiveness. Always remember that prices can vary significantly based on numerous factors, so thorough research and negotiation are key to achieving the best outcomes.

Alternatives Analysis: Comparing cable assembly manufacturers With Other Solutions

In the fast-evolving landscape of B2B solutions, international buyers often face the challenge of selecting the most appropriate technology or method for their needs. Cable assembly manufacturers are a popular choice for creating customized solutions, but there are alternative approaches worth considering. Understanding these options can help businesses make informed decisions that align with their operational goals and budget.

| Comparison Aspect | Cable Assembly Manufacturers | Alternative 1: Prefabricated Cable Assemblies | Alternative 2: Fiber Optic Solutions |

|---|---|---|---|

| Performance | High reliability and durability, tailored to specific applications | Moderate performance, suitable for general uses | High-speed data transmission, excellent for long distances |

| Cost | Higher upfront investment due to customization | Lower cost, economies of scale | Variable costs, often higher for installation and equipment |

| Ease of Implementation | Requires design input and longer lead times | Quick to deploy, minimal setup required | Complex installation, may need specialized skills |

| Maintenance | Regular maintenance needed for optimal performance | Minimal maintenance due to standardization | Higher maintenance, especially with connection points |

| Best Use Case | Industrial applications requiring bespoke solutions | General-purpose applications where customization isn’t critical | Telecommunications and data centers needing high-speed connections |

What are the Advantages and Disadvantages of Prefabricated Cable Assemblies?

Prefabricated cable assemblies are a practical alternative for businesses looking for quick and cost-effective solutions. They are manufactured in bulk, which reduces costs and allows for fast delivery. However, their limitations lie in customization; they may not meet specific requirements for all applications. This makes them ideal for companies that have standard needs or those that prioritize speed and budget over tailored solutions.

How Do Fiber Optic Solutions Compare to Cable Assembly Manufacturers?

Fiber optic solutions offer high-speed data transmission and are essential in environments where bandwidth is crucial. They excel in performance, particularly over long distances, making them suitable for telecommunications and data centers. However, the complexity of installation and higher costs associated with fiber optics can deter some buyers. Additionally, maintenance can be a challenge due to the fragility of fiber connections. Companies should weigh these factors against their specific needs for speed and capacity.

How Can International B2B Buyers Choose the Right Solution?

When selecting the right solution, international B2B buyers should consider their specific operational requirements, budget constraints, and long-term strategic goals. If customization is paramount for unique applications, cable assembly manufacturers might be the best fit despite the higher costs and longer lead times. Conversely, for businesses needing rapid deployment with standard requirements, prefabricated assemblies can provide a more economical and timely solution. Lastly, organizations in need of high-speed connectivity over extensive networks should evaluate fiber optic solutions, keeping in mind the installation complexities and maintenance demands. Each alternative presents unique advantages and challenges, making it essential for buyers to align their choice with their operational priorities and market dynamics.

Essential Technical Properties and Trade Terminology for cable assembly manufacturers

What Are the Key Technical Properties for Cable Assemblies?

When selecting cable assemblies, international B2B buyers should pay close attention to several critical technical properties that directly impact performance and compliance with industry standards.

1. Material Grade: Why Is It Important?

The material grade of a cable assembly significantly influences its durability and performance. Common materials include copper, aluminum, and various plastics. For instance, copper is favored for its excellent conductivity, while PVC is popular for its insulation properties. Selecting the right material ensures that the cable assembly meets specific electrical and mechanical requirements, which is crucial for applications in industries such as automotive, telecommunications, and industrial machinery.

2. Tolerance: How Does It Affect Performance?

Tolerance refers to the permissible limit of variation in a physical dimension. In cable assemblies, it is essential for ensuring compatibility with connectors and devices. For example, a tolerance of ±0.1mm might be standard for certain applications. Tight tolerances can enhance reliability, reduce the risk of connection failure, and improve overall system performance. Buyers should ensure that manufacturers can meet the specified tolerances to avoid costly errors in assembly or installation.

3. Voltage Rating: What Should Buyers Consider?

The voltage rating indicates the maximum voltage a cable can handle safely without risk of breakdown. It’s vital to select cable assemblies with appropriate voltage ratings for their intended application. Exceeding the voltage rating can lead to insulation failure, which may result in short circuits or even fires. B2B buyers must verify that the voltage rating aligns with their operational requirements to ensure safety and compliance with regulations.

4. Temperature Rating: Why Is It Critical?

Temperature rating specifies the maximum and minimum temperatures at which a cable can operate effectively. This property is especially important in industries exposed to extreme conditions, such as oil and gas, aerospace, and automotive. A cable with inadequate temperature ratings may degrade quickly, leading to failure and expensive downtime. Buyers should assess the operating environment and ensure that the temperature rating meets their needs.

5. Shielding: What Role Does It Play?

Shielding in cable assemblies protects against electromagnetic interference (EMI) and radio frequency interference (RFI). It is crucial for maintaining signal integrity in sensitive applications such as data transmission and audio/video equipment. Buyers should inquire about the type of shielding used (e.g., foil or braided) and its effectiveness in mitigating interference. Proper shielding can enhance performance and reliability, especially in complex electrical environments.

What Are Common Trade Terms in the Cable Assembly Industry?

Understanding trade terminology is essential for effective communication and negotiation in the cable assembly sector.

1. OEM (Original Equipment Manufacturer): What Does It Mean?

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the cable assembly industry, buyers often work with OEMs to develop custom solutions tailored to specific applications. Understanding this term helps B2B buyers identify potential partners for sourcing specialized cable assemblies.

2. MOQ (Minimum Order Quantity): How Does It Impact Purchasing?

MOQ refers to the minimum number of units a supplier is willing to sell. This term is crucial for B2B buyers as it affects budgeting and inventory management. Knowing the MOQ helps buyers make informed decisions about their purchasing strategies, especially when negotiating with manufacturers from different regions.

3. RFQ (Request for Quotation): Why Is It Necessary?

An RFQ is a document used by buyers to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. For international buyers, issuing an RFQ can streamline the procurement process and ensure that they receive competitive pricing from multiple manufacturers.

4. Incoterms (International Commercial Terms): How Do They Affect Shipping?

Incoterms define the responsibilities of buyers and sellers in international trade, particularly concerning shipping and logistics. Understanding these terms is vital for B2B buyers to clarify shipping costs, risk transfer, and delivery obligations. Misunderstandings around Incoterms can lead to unexpected expenses and delays.

5. Certification Standards: Why Are They Important?

Certification standards, such as ISO or UL, indicate that a product meets specific safety and quality benchmarks. For B2B buyers, verifying these certifications is essential to ensure compliance with industry regulations and to mitigate risks associated with product quality and safety.

Navigating Market Dynamics and Sourcing Trends in the cable assembly manufacturers Sector

What Are the Key Market Dynamics and Trends in the Cable Assembly Manufacturing Sector?

The cable assembly manufacturing sector is witnessing significant evolution driven by various global factors. Emerging technologies such as automation, IoT (Internet of Things), and advancements in telecommunications are reshaping sourcing and production strategies. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The growing demand for customized cable assemblies tailored to specific applications—ranging from automotive to renewable energy—is creating an opportunity for manufacturers to innovate. Additionally, shifts towards just-in-time manufacturing processes allow buyers to optimize inventory management and reduce holding costs.

Another key trend is the increasing integration of digital platforms for sourcing and procurement. B2B buyers can now leverage online marketplaces and supplier networks to gain better visibility into product offerings, pricing, and supplier reliability. This digital transformation is particularly beneficial for buyers in emerging markets, enabling them to access global suppliers and competitive pricing. Furthermore, the rise of nearshoring and reshoring practices is prompting manufacturers to rethink their supply chains, ensuring they can meet local demand promptly while minimizing risks associated with global logistics.

How Is Sustainability Influencing Sourcing Decisions in Cable Assembly Manufacturing?

Sustainability is becoming a cornerstone of sourcing strategies in the cable assembly manufacturing sector. International buyers are increasingly prioritizing environmentally friendly practices, pushing manufacturers to adopt sustainable materials and processes. The environmental impact of cable production is significant, often involving the use of non-renewable resources and generating waste. As a response, many manufacturers are now seeking to implement ‘green’ certifications and utilize recyclable materials in their products.

For B2B buyers, understanding the importance of ethical sourcing is paramount. Suppliers who demonstrate commitment to sustainability not only enhance their brand reputation but also attract customers who are conscious of their environmental footprint. Certifications such as ISO 14001 for environmental management systems and RoHS compliance for hazardous substances can serve as valuable indicators of a supplier’s commitment to sustainability. Buyers should look for suppliers who engage in transparent reporting on their sustainability practices, as this can also mitigate risks associated with regulatory compliance and consumer backlash.

What Is the Historical Context of Cable Assembly Manufacturing?

The cable assembly manufacturing industry has evolved significantly over the past few decades. Initially dominated by simple wire and connector assemblies, the sector has transformed into a complex ecosystem that supports high-tech applications in telecommunications, automotive, and industrial sectors. The introduction of computer-aided design (CAD) technologies in the 1980s revolutionized the way cable assemblies are designed and produced, allowing for greater precision and customization.

In recent years, the shift towards automation and digitalization has accelerated, enabling manufacturers to streamline their operations and improve efficiency. This historical context is essential for B2B buyers to appreciate the advancements that have shaped the current landscape of cable assembly manufacturing. Understanding these developments helps buyers make informed decisions, aligning their sourcing strategies with suppliers that are not only technologically advanced but also responsive to market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of cable assembly manufacturers

-

How do I ensure the quality of cable assemblies from manufacturers?

To ensure quality, request detailed certifications such as ISO 9001, which indicates adherence to quality management standards. Conduct factory audits, either virtually or in-person, to assess the manufacturing processes and quality control measures. Additionally, ask for samples before placing large orders and consider third-party testing to verify performance against your specifications. Establishing a clear quality assurance agreement in your contract can also safeguard against defects. -

What are the key factors to consider when choosing a cable assembly manufacturer?

Key factors include the manufacturer’s experience in your specific industry, their production capacity, and technological capabilities. Assess their history of delivering on time and their ability to customize products based on your requirements. Furthermore, evaluate their compliance with international standards, the flexibility in order quantities, and their responsiveness to communication. These factors are crucial for ensuring a reliable partnership. -

What is the best way to communicate my specific needs to a cable assembly manufacturer?

Effective communication starts with detailed documentation. Provide specifications, including drawings, material requirements, and expected performance standards. Use clear and concise language, and consider including visual aids or prototypes if possible. Regular follow-ups during the design phase can help clarify any misunderstandings and ensure that the manufacturer fully understands your requirements before production begins. -

How can I verify the legitimacy of a cable assembly manufacturer?

To verify legitimacy, conduct thorough research on the manufacturer’s background, including checking their business registration and financial health. Request references from previous clients and look for reviews or testimonials online. You can also utilize platforms like LinkedIn to gauge their industry presence. Additionally, consider third-party verification services that specialize in supplier audits. -

What are the typical minimum order quantities (MOQ) for cable assemblies?

Minimum order quantities can vary significantly based on the manufacturer and the complexity of the cable assembly. Generally, MOQs can range from a few hundred to several thousand units. For specialized or custom assemblies, manufacturers may have higher MOQs due to setup costs. Always discuss your specific needs upfront to negotiate terms that suit your business requirements, especially if you are a smaller buyer. -

What payment terms should I expect when sourcing from cable assembly manufacturers?

Payment terms can differ widely, but common practices include a deposit (typically 30-50%) upon order confirmation, with the balance due before shipment. Some manufacturers may offer credit terms for established clients. Be sure to discuss payment methods (such as wire transfers, letters of credit, etc.) and ensure they align with your financial capabilities. Always get these terms documented in your contract to avoid misunderstandings. -

How do logistics and shipping impact my sourcing of cable assemblies?

Logistics play a crucial role in the timely delivery of your cable assemblies. Consider the manufacturer’s location relative to shipping routes and potential tariffs or customs delays. Discuss shipping options, including air freight for speed or sea freight for cost-effectiveness. Ensure that the manufacturer has a reliable logistics partner and that you are clear on who bears the shipping costs and responsibilities for customs clearance. -

What customization options are available when working with cable assembly manufacturers?

Customization options vary by manufacturer but may include choices in materials, lengths, connector types, and insulation. Some manufacturers can also accommodate unique specifications such as color coding, labeling, and packaging. When discussing customization, provide clear specifications and be open to suggestions from the manufacturer, as they may have insights on optimal designs that can enhance performance and reduce costs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cable assembly manufacturers

In today’s competitive landscape, strategic sourcing remains a cornerstone for cable assembly manufacturers aiming to optimize operations and enhance supply chain resilience. By focusing on long-term relationships with suppliers and leveraging local sourcing opportunities, B2B buyers can significantly reduce costs while ensuring high-quality materials. This is particularly vital for international buyers from regions like Africa, South America, the Middle East, and Europe, where market dynamics and regulatory environments differ vastly.

How can B2B buyers effectively implement strategic sourcing strategies? Begin by conducting thorough supplier evaluations, considering factors such as reliability, production capacity, and compliance with international standards. Engaging in collaborative partnerships can also foster innovation and adaptability, essential traits in today’s fast-evolving technology landscape.

As we look ahead, the emphasis on sustainability and digital transformation will shape the future of cable assembly manufacturing. Buyers are encouraged to explore suppliers who prioritize eco-friendly practices and advanced manufacturing technologies. By doing so, they not only enhance their competitive edge but also contribute positively to the global supply chain’s sustainability goals.

Take the next step in your sourcing journey—connect with cable assembly manufacturers who align with your strategic objectives and embrace a forward-thinking approach that benefits both your business and the broader community.