Discover Top Camera Len Manufacturers: Your Complete Guide (2025)

Introduction: Navigating the Global Market for camera len manufacturer

As the demand for high-quality imaging technology continues to rise, sourcing camera lens manufacturers presents a unique challenge for international B2B buyers. This guide serves as a comprehensive resource for understanding the intricate landscape of camera lens manufacturing, catering specifically to the needs of businesses in Africa, South America, the Middle East, and Europe. By exploring various types of camera lenses, their applications across diverse industries, and critical supplier vetting processes, this guide aims to empower buyers to make informed purchasing decisions.

Navigating the global market for camera lens manufacturers can be daunting, especially when considering factors such as cost, quality, and technological advancements. Buyers must not only assess the specifications and performance of camera lenses but also understand the reputation and reliability of potential suppliers. This guide will delve into essential topics, including the latest trends in lens technology, strategies for effective supplier evaluation, and tips for negotiating favorable terms.

By providing actionable insights and practical advice, this resource is designed to equip international B2B buyers with the knowledge needed to enhance their sourcing strategies. Whether you are based in bustling urban centers or emerging markets, understanding the nuances of the camera lens manufacturing industry will enable you to harness the full potential of this critical technology, ultimately driving innovation and success in your business endeavors.

Understanding camera len manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Prime Lenses | Fixed focal length, high optical quality | Photography, Cinematography | Pros: Excellent image quality, wide apertures. Cons: Limited versatility. |

| Zoom Lenses | Variable focal lengths, versatile composition | Events, Sports, Wildlife | Pros: Flexibility in framing, fewer lenses needed. Cons: Generally heavier and can be more expensive. |

| Macro Lenses | Designed for extreme close-ups, high magnification | Product Photography, Scientific | Pros: Exceptional detail capture. Cons: Limited working distance, can be specialized. |

| Telephoto Lenses | Long focal lengths, compresses distance | Wildlife, Sports, Surveillance | Pros: Ideal for distant subjects, shallow depth of field. Cons: Bulkier, requires stability. |

| Wide-Angle Lenses | Short focal lengths, broader field of view | Architecture, Landscape Photography | Pros: Captures more in frame, enhances perspective. Cons: Distortion at edges, can be challenging to use. |

What Are the Characteristics of Prime Lenses for B2B Buyers?

Prime lenses are characterized by their fixed focal length, which often results in superior optical quality compared to zoom lenses. They are highly valued in professional photography and cinematography for their ability to produce sharp images with minimal distortion. B2B buyers should consider prime lenses when image quality is paramount, such as in commercial photography or high-end video production. However, the limitation of a single focal length may require businesses to invest in multiple lenses for varied shooting scenarios.

How Do Zoom Lenses Benefit Businesses?

Zoom lenses offer the flexibility of variable focal lengths, allowing photographers to adjust their framing without changing lenses. This versatility is particularly beneficial for event photography, sports, and wildlife shooting, where conditions can change rapidly. B2B buyers should weigh the advantages of having a single lens that covers multiple focal lengths against the potential drawbacks of increased weight and cost. For businesses that prioritize adaptability in dynamic environments, zoom lenses are an excellent investment.

Why Are Macro Lenses Important for Specific Industries?

Macro lenses are specialized for capturing extreme close-ups, making them essential for product photography and scientific applications. They enable businesses to showcase intricate details, such as textures and small components, which can enhance marketing materials or research presentations. Buyers must consider the limited working distance and specialized nature of macro lenses, which may not be suitable for general photography needs. Investing in macro lenses can significantly elevate the quality of close-up imagery.

What Role Do Telephoto Lenses Play in B2B Applications?

Telephoto lenses are designed for long-distance photography, making them indispensable in wildlife, sports, and surveillance photography. They compress distances, providing a unique perspective on distant subjects while allowing for a shallow depth of field. B2B buyers should consider the bulkiness of telephoto lenses and the need for stability, as these lenses can be heavier and often require tripods for optimal use. For businesses needing to capture action from afar, telephoto lenses are a worthwhile investment.

How Do Wide-Angle Lenses Enhance Business Photography?

Wide-angle lenses are known for their short focal lengths and ability to capture broader scenes, making them ideal for architecture and landscape photography. They create a sense of depth and can make spaces appear larger, which is advantageous for real estate and venue marketing. However, buyers should be aware of potential edge distortion, which can affect image quality. For businesses focused on capturing expansive views or unique perspectives, wide-angle lenses can be an essential part of their equipment arsenal.

Related Video: Camera Lenses Explained For Beginners (What Do The Numbers Mean?)

Key Industrial Applications of camera len manufacturer

| Industry/Sector | Specific Application of Camera Lens Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Security & Surveillance | High-resolution surveillance cameras for public safety | Enhanced security monitoring and crime deterrence | Reliability, low-light performance, and durability in harsh environments |

| Automotive | Advanced driver-assistance systems (ADAS) cameras | Improved road safety and reduced accident rates | Compliance with automotive standards and integration capabilities |

| Medical Devices | Imaging systems for diagnostics and surgeries | Accurate diagnostics leading to better patient outcomes | Precision, compliance with health regulations, and sterility |

| Consumer Electronics | Smartphone and tablet cameras | Enhanced user experience and competitive advantage | Size, weight, and integration with existing technology |

| Industrial Automation | Machine vision systems for quality control | Increased efficiency and reduced waste | Customization options and compatibility with existing systems |

How Are Camera Lens Manufacturers Used in Security & Surveillance?

Camera lens manufacturers play a crucial role in the security and surveillance sector by providing high-resolution lenses that enhance the capabilities of surveillance cameras. These lenses help in capturing clear images in various lighting conditions, which is essential for effective monitoring. For international B2B buyers, especially in regions like Africa and the Middle East, sourcing durable lenses that can withstand extreme weather conditions is vital. Additionally, understanding local regulations and compliance standards is necessary to ensure the equipment meets safety and operational requirements.

What Are the Applications of Camera Lenses in Automotive Industry?

In the automotive industry, camera lens manufacturers supply lenses for advanced driver-assistance systems (ADAS). These cameras are integral for features such as lane-keeping assistance, adaptive cruise control, and collision avoidance systems. For buyers in Europe and South America, it is important to consider lenses that comply with stringent automotive safety standards. Furthermore, the ability to integrate seamlessly with existing vehicle systems is a critical factor in the procurement process, ensuring that safety features function reliably.

How Do Camera Lenses Benefit Medical Devices?

In the medical field, camera lenses are essential for imaging systems used in diagnostics and surgical procedures. High-quality lenses allow for precise imaging, which is crucial for accurate diagnoses and successful surgeries. International B2B buyers must ensure that the lenses sourced comply with healthcare regulations and standards. Additionally, the ability to provide sterile and biocompatible products is a key requirement, particularly for applications in surgery and diagnostics in hospitals across Africa and Europe.

How Are Camera Lenses Utilized in Consumer Electronics?

Camera lens manufacturers significantly impact the consumer electronics market, particularly through smartphone and tablet cameras. High-quality lenses enhance the photographic capabilities of these devices, providing users with superior image quality. For B2B buyers in South America and Europe, considerations include the size and weight of the lenses, as these factors directly affect the design and portability of consumer devices. Moreover, keeping up with the latest trends in mobile photography is essential for maintaining a competitive edge.

What Role Do Camera Lenses Play in Industrial Automation?

In industrial automation, camera lenses are utilized in machine vision systems for quality control and inspection processes. These lenses help in identifying defects in products, ensuring that only high-quality items reach the market. B2B buyers should focus on sourcing lenses that offer customization options to fit specific machinery and production lines. Compatibility with existing systems is also crucial, as it ensures a smooth integration process, thereby enhancing operational efficiency and reducing waste in manufacturing processes.

Related Video: Top 10 applications of drones

3 Common User Pain Points for ‘camera len manufacturer’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Camera Lens for Specific Applications

The Problem:

International B2B buyers often face challenges when selecting camera lenses that meet their specific application needs. Whether they are in the film industry, security surveillance, or medical imaging, the variety of lens options available can be overwhelming. Buyers might struggle to determine which lens specifications—such as focal length, aperture, and image stabilization features—are crucial for their intended use. This confusion can lead to poor purchasing decisions, resulting in wasted resources and unmet project requirements.

The Solution:

To address this challenge, B2B buyers should conduct a thorough needs assessment before engaging with camera lens manufacturers. Start by outlining the specific application requirements and the environment in which the lens will be used. For instance, if the lens is needed for low-light conditions, prioritize lenses with larger apertures (f/1.4 or wider). Collaborate with manufacturers or suppliers who offer customized solutions or technical consultations. Additionally, leverage sample products or trial periods to test lens performance in real-world scenarios. This proactive approach ensures that the chosen lens aligns perfectly with the project demands, thus minimizing the risk of costly errors.

Scenario 2: Managing Supply Chain Disruptions in Camera Lens Procurement

The Problem:

B2B buyers in regions such as Africa and South America often experience significant supply chain disruptions that affect the timely procurement of camera lenses. Factors such as political instability, logistical challenges, and limited local supplier networks can lead to delays and increased costs. This situation not only hampers project timelines but can also affect the overall operational efficiency of businesses relying on high-quality imaging solutions.

The Solution:

To mitigate supply chain risks, B2B buyers should diversify their supplier base by establishing relationships with multiple camera lens manufacturers across different regions. This strategy helps ensure a steady supply, even if one supplier encounters difficulties. Buyers should also consider engaging with manufacturers who offer direct shipping options or have local distribution centers in their region. Implementing an inventory management system that tracks stock levels and lead times can further enhance procurement processes. By proactively managing supply chain dynamics, businesses can reduce downtime and maintain consistent workflow efficiency.

Scenario 3: Ensuring Compatibility Between Camera Lenses and Existing Equipment

The Problem:

Another common pain point for B2B buyers is the compatibility of new camera lenses with existing camera systems and other equipment. Many buyers invest in state-of-the-art lenses only to discover that they do not seamlessly integrate with their current camera bodies or mounting systems. This incompatibility can lead to additional costs for adapters or even necessitate the purchase of new camera systems altogether.

The Solution:

To avoid compatibility issues, B2B buyers should meticulously research and verify the specifications of both the camera lenses and the camera bodies they intend to use. It is beneficial to consult with technical experts or the manufacturer’s support team to clarify any doubts regarding compatibility. Buyers should also consider investing in lenses that offer interchangeable mounts or those that are universally compatible across multiple camera brands. Keeping abreast of the latest advancements in camera technology can also help buyers make informed decisions, ensuring that new purchases align with their existing infrastructure. By focusing on compatibility from the outset, businesses can prevent unforeseen expenses and ensure smoother integration of new equipment.

Strategic Material Selection Guide for camera len manufacturer

What Are the Key Materials for Camera Lens Manufacturing?

When selecting materials for camera lens manufacturing, it is crucial for international B2B buyers to understand the properties, advantages, and limitations of various materials. This knowledge not only aids in product performance but also influences manufacturing processes, costs, and compliance with international standards.

Glass: The Traditional Choice for Camera Lenses

Key Properties: Glass is renowned for its optical clarity and ability to withstand high temperatures. It typically has a high refractive index, which allows for greater light transmission and minimal distortion.

Pros & Cons: The primary advantage of glass is its superior optical quality, making it ideal for high-end camera lenses. However, glass is relatively heavy and can be fragile, which may complicate shipping and handling. Additionally, the manufacturing process for glass lenses can be complex and time-consuming, leading to higher costs.

Impact on Application: Glass lenses are compatible with a variety of media, including digital sensors, and are often used in professional photography and cinematography due to their high performance.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider the fragility of glass during transport. Compliance with international standards, such as ASTM and DIN, is essential for quality assurance.

Polycarbonate: A Lightweight Alternative

Key Properties: Polycarbonate is a thermoplastic material known for its impact resistance and lightweight nature. It can withstand a wide range of temperatures and is resistant to UV radiation.

Pros & Cons: The main advantage of polycarbonate is its durability and lightweight characteristics, making it suitable for portable devices. However, it may not offer the same optical clarity as glass, which can be a drawback for high-end applications.

Impact on Application: Polycarbonate lenses are often used in consumer-grade cameras and action cameras, where weight and durability are more critical than absolute optical performance.

Considerations for International Buyers: Buyers in the Middle East and Europe may prefer polycarbonate for its resilience in harsh environments. Understanding local regulations regarding plastics is crucial for compliance.

Acrylic: Cost-Effective and Versatile

Key Properties: Acrylic is a lightweight, shatter-resistant plastic that provides good optical clarity. It is also easier to mold than glass, allowing for more complex shapes.

Pros & Cons: Acrylic lenses are significantly less expensive to produce than glass, making them a popular choice for budget-friendly applications. However, they are more prone to scratching and may not perform as well in terms of optical quality.

Impact on Application: Commonly used in low-cost cameras and educational purposes, acrylic lenses are suitable for applications where cost is a primary concern.

Considerations for International Buyers: Buyers from regions with stringent environmental regulations, such as Europe, should ensure that acrylic materials comply with local standards.

Optical Coatings: Enhancing Performance

Key Properties: Optical coatings, typically made from various thin-film materials, enhance the performance of lenses by reducing glare, improving light transmission, and increasing scratch resistance.

Pros & Cons: The main advantage of optical coatings is their ability to significantly improve lens performance without altering the base material. However, they can add to the manufacturing complexity and cost.

Impact on Application: Coated lenses are essential in professional photography and high-end optics, where performance is critical.

Considerations for International Buyers: Compliance with international standards for coatings, such as ISO and JIS, is vital for ensuring quality and performance across different markets.

Summary Table of Materials for Camera Lens Manufacturing

| Material | Typical Use Case for camera len manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Professional cameras and cinematography | Superior optical quality | Heavy and fragile | High |

| Polycarbonate | Consumer-grade cameras and action cameras | Lightweight and impact-resistant | Lower optical clarity | Medium |

| Acrylic | Low-cost cameras and educational tools | Cost-effective and versatile | Prone to scratching | Low |

| Optical Coatings | High-end optics and professional photography | Enhances performance significantly | Adds complexity to manufacturing | Medium |

This guide provides a comprehensive overview of materials used in camera lens manufacturing, helping international B2B buyers make informed decisions based on performance, cost, and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for camera len manufacturer

What Are the Key Stages in the Manufacturing Process for Camera Lens Production?

The manufacturing process for camera lenses involves several critical stages, each designed to ensure precision and high-quality output. Understanding these stages is essential for B2B buyers looking to partner with reliable suppliers.

1. Material Preparation: What Materials Are Used in Camera Lens Manufacturing?

The first step in manufacturing camera lenses is material preparation. High-quality optical glass is the primary material used due to its transparency and refractive properties. Various types of glass, such as crown glass and flint glass, are chosen based on the lens’s required specifications.

In addition to glass, other materials like plastic and coatings are also utilized. Buyers should inquire about the source and quality of these materials, as they directly impact the lens performance. Manufacturers typically follow stringent guidelines to ensure that only top-grade materials are utilized.

2. Forming: How Are Lenses Shaped and Molded?

The forming stage involves shaping the raw glass or plastic into lens elements. This can be achieved through several techniques:

-

Grinding and Polishing: This method is used to shape the lens surfaces with high precision. Advanced CNC (Computer Numerical Control) machines are employed to achieve the required curvature and thickness.

-

Molding: For plastic lenses, injection molding is commonly used. This technique allows for mass production and can reduce costs while maintaining quality.

-

Coating Application: Anti-reflective coatings, UV filters, and other specialized coatings are applied to improve lens performance. The application of coatings must be done under controlled conditions to avoid contamination.

Understanding the specific forming techniques used by a manufacturer can help buyers assess the quality and durability of the lenses.

3. Assembly: How Are Lens Components Combined?

Once the lens elements are formed, the assembly process begins. This stage typically involves:

-

Alignment: Each lens element must be precisely aligned to ensure optimal optical performance. Misalignment can lead to image distortion.

-

Mounting: The lens elements are mounted into a barrel or housing, which may include additional components like focus mechanisms and electronic interfaces.

-

Sealing: Proper sealing is crucial to protect the internal components from dust and moisture, which can degrade performance.

Buyers should verify if the manufacturer employs automated assembly processes, as this can enhance precision and reduce errors.

4. Finishing: What Quality Checks Are Performed Post-Assembly?

The finishing stage includes final inspections and polishing to ensure that the lenses meet industry standards. This step may involve:

-

Final Polishing: Any imperfections on the lens surface are polished out to enhance clarity.

-

Quality Control Checks: Each finished lens undergoes rigorous quality checks to ensure compliance with specifications.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is a critical aspect of the manufacturing process for camera lenses. International and industry-specific standards help ensure that products meet the required quality benchmarks.

1. What International Standards Apply to Camera Lens Manufacturing?

ISO 9001 is a widely recognized standard for quality management systems (QMS) that applies to manufacturers across various industries, including optical components. Compliance with ISO 9001 indicates that a manufacturer has established a robust quality management system focused on continuous improvement and customer satisfaction.

In addition to ISO standards, certifications like CE marking (Conformité Européenne) indicate compliance with European safety and health requirements. B2B buyers should confirm that their suppliers hold relevant certifications, as this can be crucial for market entry and regulatory compliance.

2. How Do Manufacturers Conduct Quality Control?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial step involves inspecting raw materials upon receipt to ensure they meet specified criteria before processing.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are taken to check for defects and ensure processes are followed correctly.

-

Final Quality Control (FQC): After assembly, each lens is tested for optical performance, alignment, and physical integrity.

Common testing methods include optical performance tests, environmental tests (temperature and humidity), and durability assessments. Buyers should inquire about the specific QC methods employed by their suppliers.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers need to ensure their suppliers maintain high standards of quality control. Here are actionable steps to verify QC processes:

1. What Documentation Should Buyers Request?

Buyers should ask for detailed QC documentation, including:

-

Quality Assurance Manuals: These documents outline the manufacturer’s quality management processes and standards.

-

Inspection Reports: Regular inspection reports provide insights into the quality of materials and finished products.

-

Certificates of Compliance: Suppliers should provide evidence of compliance with relevant international standards.

2. How Can Buyers Conduct Audits?

Conducting on-site audits is one of the most effective ways to evaluate a supplier’s quality control processes. During an audit, buyers can:

-

Observe Manufacturing Processes: Witnessing the manufacturing processes firsthand can reveal adherence to quality standards.

-

Review QC Records: Buyers can assess the thoroughness of QC checks and historical performance data.

-

Engage with Quality Assurance Personnel: Discussions with QA staff can provide deeper insights into the supplier’s commitment to quality.

3. Should Buyers Consider Third-Party Inspections?

Engaging a third-party inspection service can add an additional layer of assurance. These independent firms can conduct thorough inspections and audits, providing unbiased evaluations of the supplier’s quality control processes.

What Are the Unique QC Considerations for International B2B Buyers?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should consider the following:

-

Regulatory Compliance: Ensure suppliers understand and comply with local regulations regarding imports and product safety.

-

Cultural and Logistical Factors: Different regions may have varying expectations for quality and delivery. Building relationships with suppliers that understand these nuances can lead to better cooperation and results.

-

Supply Chain Transparency: Buyers should prioritize suppliers that are transparent about their supply chain and quality control processes, as this can help mitigate risks associated with product quality.

By thoroughly understanding the manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting camera lens manufacturers, ensuring they partner with reliable and high-quality suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘camera len manufacturer’

The procurement process for camera lens manufacturing can be intricate, particularly for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This guide provides a practical checklist to streamline your sourcing efforts, ensuring you secure a reliable supplier that meets your technical and operational requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for aligning your needs with supplier capabilities. Consider factors such as lens type (e.g., prime, zoom), focal length, aperture size, and material quality. Detailed specifications help prevent misunderstandings and ensure that the products meet your performance expectations.

Step 2: Research Potential Suppliers

Invest time in researching potential suppliers. Utilize industry directories, trade shows, and online platforms to identify manufacturers with a solid reputation. Look for suppliers that specialize in camera lenses and have experience with your specific requirements, as this can significantly affect product quality and service reliability.

Step 3: Verify Supplier Certifications

Before proceeding with any supplier, ensure they possess relevant certifications. This could include ISO 9001 for quality management or industry-specific certifications that reflect their compliance with international standards. Certifications indicate a commitment to quality and can mitigate risks associated with product defects.

Step 4: Request Samples for Evaluation

Sampling is a critical step in the procurement process. Request samples of the camera lenses you are interested in to evaluate their quality firsthand. Pay attention to factors like optical clarity, build quality, and overall performance. This practical assessment can significantly influence your purchasing decision.

Step 5: Assess Production Capacity and Lead Times

Understanding a supplier’s production capacity and lead times is essential to ensure they can meet your demand. Inquire about their manufacturing processes and how they handle large orders. Suppliers with robust production capabilities can better accommodate fluctuations in demand, ensuring timely delivery.

Step 6: Evaluate After-Sales Support and Warranty Policies

After-sales support can be a deciding factor in your choice of supplier. Investigate their warranty policies, return processes, and customer service responsiveness. Strong after-sales support not only enhances your operational efficiency but also provides peace of mind in case of defects or issues with the products.

Step 7: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Ensure you have established clear channels for discussing your requirements, expectations, and any potential issues. Regular updates and open dialogue can foster a better working relationship, helping to resolve problems quickly and effectively.

By following this checklist, B2B buyers can make informed decisions when sourcing camera lens manufacturers, ensuring they partner with suppliers who align with their technical needs and business goals.

Comprehensive Cost and Pricing Analysis for camera len manufacturer Sourcing

What Are the Key Cost Components in Camera Lens Manufacturing?

When sourcing camera lenses, international B2B buyers must understand the intricate cost structure that affects pricing. The primary cost components include:

-

Materials: The quality of glass, coatings, and other materials significantly influences the overall cost. High-grade optical glass and specialized coatings can substantially elevate the price.

-

Labor: Skilled labor is essential in manufacturing precision optics. Labor costs can vary widely based on the geographic location of the manufacturer, with higher wages in developed countries compared to emerging markets.

-

Manufacturing Overhead: This encompasses the indirect costs of production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: The initial investment in specialized machinery and tools required for lens production is considerable. This cost is often spread across production runs, impacting unit pricing.

-

Quality Control (QC): Rigorous QC processes ensure that each lens meets strict optical standards. While this adds to costs, it is crucial for maintaining product reliability and reputation.

-

Logistics: Shipping and handling costs must be factored in, especially for international transactions. These can vary based on the shipping method, distance, and any import tariffs.

-

Margin: Manufacturers typically include a profit margin in their pricing, which can vary depending on market demand and competition.

How Do Price Influencers Impact Camera Lens Sourcing?

Several factors can influence the final pricing of camera lenses:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk discounts. Understanding the MOQ can lead to significant savings, especially for businesses planning long-term usage.

-

Specifications and Customization: Custom lenses or specific optical requirements can lead to increased costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: Lenses made from premium materials and those certified by recognized quality standards often command higher prices. Buyers should assess whether these certifications are necessary for their intended use.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established manufacturers may charge a premium, while newer entrants might offer competitive rates to build market share.

-

Incoterms: The chosen Incoterms can significantly affect total costs, including responsibilities for shipping, insurance, and tariffs. Understanding these terms is vital for accurate budgeting.

What Negotiation Tips Can Help International Buyers Optimize Costs?

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, effective negotiation strategies are essential:

-

Understand Total Cost of Ownership (TCO): Rather than focusing solely on the unit price, consider the total cost over the lens’s lifecycle, including maintenance and potential replacement costs.

-

Leverage Volume for Better Pricing: If possible, consolidate orders to meet higher volume thresholds, thus securing better pricing and terms.

-

Request Detailed Quotes: Ensure quotes include a breakdown of costs associated with materials, labor, and logistics. This transparency can aid in negotiations and budget planning.

-

Evaluate Multiple Suppliers: Gathering quotes from various manufacturers can provide leverage during negotiations. It also allows buyers to compare quality and service levels.

-

Stay Informed on Market Trends: Understanding current market conditions and pricing trends can empower buyers to negotiate more effectively and recognize fair pricing.

Conclusion and Disclaimer on Pricing

While the information provided offers a comprehensive view of the cost and pricing landscape for camera lens manufacturing, it is important to note that prices can fluctuate based on market dynamics, supplier negotiations, and geopolitical factors. Buyers should conduct thorough due diligence and engage in open dialogue with suppliers to achieve the best outcomes tailored to their specific needs.

Alternatives Analysis: Comparing camera len manufacturer With Other Solutions

Introduction: Why Consider Alternatives to Camera Lens Manufacturers?

In the rapidly evolving world of imaging technology, international B2B buyers must evaluate not only the traditional offerings of camera lens manufacturers but also alternative solutions that might better meet their specific needs. Whether the goal is to enhance image quality, reduce costs, or streamline implementation processes, understanding the competitive landscape is crucial for making informed purchasing decisions.

Comparison Table of Camera Lens Manufacturer and Alternatives

| Comparison Aspect | Camera Lens Manufacturer | Alternative 1: Smartphone Cameras | Alternative 2: Action Cameras |

|---|---|---|---|

| Performance | High optical quality, specialized for various applications. | Moderate; suitable for casual use but lacks professional features. | Good for dynamic environments; designed for rugged use. |

| Cost | Higher investment; varies by brand and specifications. | Generally lower; many options available in the consumer market. | Mid-range; offers durability at a reasonable price. |

| Ease of Implementation | Requires specific mounting and setup; potentially complex. | User-friendly; integrated into smartphones, easy to use. | Simple setup; designed for on-the-go use. |

| Maintenance | Regular cleaning and calibration needed; can be costly. | Minimal maintenance; software updates are often automatic. | Rugged design reduces maintenance needs; waterproof options available. |

| Best Use Case | Professional photography, cinematography, and specialized applications. | Everyday use, social media content creation, and casual photography. | Action sports, outdoor activities, and travel vlogging. |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of Smartphone Cameras as an Alternative?

Smartphone cameras have revolutionized the way individuals and businesses approach photography. With advancements in technology, many smartphones now boast multi-lens systems and advanced imaging software, making them viable for various casual applications.

Pros:

– Cost-effective and widely accessible.

– Easy to use, requiring no specialized knowledge or equipment.

– Integrated software allows for quick editing and sharing.

Cons:

– Limited optical performance compared to dedicated camera lenses.

– Not suitable for professional applications where image quality is paramount.

– Dependence on battery life and device performance.

How Do Action Cameras Compare to Traditional Camera Lens Solutions?

Action cameras are designed for capturing high-quality footage in dynamic and challenging conditions. They are compact and durable, making them ideal for outdoor adventures.

Pros:

– Robust and often waterproof, ideal for extreme conditions.

– Simple to operate, allowing for quick capture of moments.

– Versatile mounting options available for diverse scenarios.

Cons:

– Optical quality may not match that of specialized camera lenses.

– Limited manual controls and features compared to traditional cameras.

– Best suited for specific use cases, such as sports and travel.

Conclusion: How to Choose the Right Imaging Solution for Your Business Needs

When considering alternatives to traditional camera lens manufacturers, B2B buyers should carefully assess their specific requirements. Factors such as intended use, budget constraints, and the desired level of image quality play crucial roles in the decision-making process. While camera lens manufacturers offer high performance for professional applications, alternatives like smartphone cameras and action cameras can provide sufficient quality and convenience for less demanding uses. Ultimately, a clear understanding of the trade-offs involved will help buyers make informed choices that align with their operational goals.

Essential Technical Properties and Trade Terminology for camera len manufacturer

What Are the Essential Technical Properties for Camera Lens Manufacturers?

When sourcing camera lenses, understanding the technical properties is crucial for making informed purchasing decisions. Here are some key specifications to consider:

1. Material Grade: How Does It Affect Lens Quality?

Camera lenses are typically made from high-quality optical glass or plastic. The material grade directly influences the lens’s clarity, durability, and weight. Higher-grade materials reduce distortion and enhance light transmission, essential for achieving high-resolution images. For B2B buyers, selecting lenses made from superior materials can lead to better end-product performance and customer satisfaction.

2. Tolerance: Why Is Precision Important?

Tolerance refers to the allowable deviation from a specified dimension in the lens manufacturing process. Tight tolerances are crucial for maintaining image quality and ensuring that lenses fit perfectly in their intended applications. For manufacturers and buyers, understanding tolerance levels is essential to avoid compatibility issues and ensure optimal performance, particularly in high-precision environments like medical imaging or professional photography.

3. Coating Types: What Are Their Benefits?

Lens coatings, such as anti-reflective, UV, and scratch-resistant coatings, significantly enhance lens performance. Anti-reflective coatings reduce glare and increase light transmission, while UV coatings protect against harmful rays. Buyers should evaluate the types of coatings offered, as they can impact both the quality of images produced and the longevity of the lenses.

4. Focal Length: How Does It Influence Use Cases?

Focal length determines the lens’s field of view and magnification capabilities. Shorter focal lengths provide wider angles, ideal for landscapes or architecture, while longer focal lengths are suited for portraits or wildlife photography. B2B buyers need to align focal lengths with their specific application requirements to ensure the lenses meet their operational needs.

5. Aperture: What Role Does It Play in Image Quality?

The aperture, measured in f-stops, controls the amount of light entering the lens. A wider aperture (lower f-stop number) allows more light, resulting in better performance in low-light conditions and providing a shallower depth of field for artistic effects. Understanding aperture specifications helps buyers choose lenses that will excel in their intended lighting environments.

What Are the Common Trade Terms Used in Camera Lens Manufacturing?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B contexts. Here are some common terms:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to companies that produce components that are used in another company’s end products. In the context of camera lenses, an OEM might supply lenses to camera manufacturers. Understanding OEM relationships can help buyers identify quality sources for lens procurement and ensure compatibility with their equipment.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers as it affects budgeting and inventory management. Knowing the MOQ can help businesses plan their purchases effectively, ensuring they meet demand without overcommitting resources.

3. RFQ (Request for Quotation): How Can It Streamline Purchasing?

An RFQ is a document sent to suppliers requesting pricing for specific products or services. For camera lens manufacturers, issuing an RFQ can streamline the procurement process, allowing buyers to compare prices and terms from multiple suppliers, thereby ensuring they get the best deal.

4. Incoterms: What Are They and Why Do They Matter?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. For B2B buyers from different regions, understanding Incoterms is crucial for avoiding misunderstandings and ensuring smooth logistics.

5. Lead Time: How Does It Impact Project Timelines?

Lead time refers to the time taken from placing an order to receiving the goods. In the camera lens industry, lead times can vary significantly based on production schedules and shipping methods. Buyers must consider lead times when planning projects to avoid delays that could impact their operations or product launches.

Understanding these technical properties and trade terms can significantly enhance the decision-making process for B2B buyers in the camera lens manufacturing industry, ensuring they procure the best products suited to their needs.

Navigating Market Dynamics and Sourcing Trends in the camera len manufacturer Sector

What Are the Current Market Dynamics in the Camera Lens Manufacturing Sector?

The camera lens manufacturing sector is experiencing dynamic shifts driven by technological advancements, increasing consumer demand for high-quality imaging, and the rise of applications in industries like security, healthcare, and automotive. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly influenced by these trends. As digital photography and videography continue to evolve, the demand for specialized lenses, such as wide-angle, macro, and telephoto, is increasing. Moreover, innovations in optical design and materials are enabling manufacturers to produce lenses that are lighter, more durable, and capable of higher performance in various lighting conditions.

Another significant trend is the integration of artificial intelligence and smart technologies in lens manufacturing processes. This includes automated quality control systems that enhance production efficiency and reduce waste. Additionally, buyers are increasingly seeking suppliers who offer customization options to meet specific project needs. As a result, manufacturers who can leverage these technologies and provide tailored solutions are more likely to capture market share.

Furthermore, the global supply chain is undergoing transformations due to geopolitical factors and trade policies, which can impact sourcing strategies. Buyers must stay informed about these changes to navigate potential disruptions effectively. By understanding these market dynamics, B2B buyers can make informed decisions, ensuring that they partner with manufacturers who are not only technologically advanced but also capable of adapting to the ever-evolving landscape.

How Are Sustainability and Ethical Sourcing Impacting the Camera Lens Manufacturing Sector?

Sustainability is becoming a cornerstone of the camera lens manufacturing industry, driven by increasing consumer awareness and regulatory pressures. International B2B buyers are now prioritizing suppliers who adhere to ethical sourcing practices and minimize environmental impact. This shift is evident in the growing demand for “green” certifications, such as ISO 14001, which demonstrate a commitment to environmental management and sustainability.

Manufacturers are adopting eco-friendly materials and processes, such as using recycled plastics and low-impact production methods. By doing so, they not only reduce their carbon footprint but also appeal to B2B buyers who are looking to enhance their own sustainability profiles. For instance, lenses made from sustainable materials not only perform well but also align with the ethical values of companies in diverse sectors—from photography to telecommunications.

Moreover, transparency in supply chains is becoming increasingly important. Buyers are encouraged to engage with manufacturers who can provide detailed information about their sourcing practices, including labor conditions and material origins. This transparency fosters trust and helps buyers mitigate risks associated with unethical practices. As sustainability becomes a key differentiator, B2B buyers who prioritize ethical sourcing will be better positioned to build long-term relationships with suppliers and enhance their brand reputation.

What Is the Brief Evolution of the Camera Lens Manufacturing Sector?

The evolution of the camera lens manufacturing sector is marked by significant technological advancements and shifts in consumer preferences. Initially, camera lenses were primarily made from glass and featured basic designs that limited their versatility. However, with the advent of digital photography in the late 20th century, there was a surge in demand for high-performance lenses that could meet the needs of both professional and amateur photographers.

In the early 2000s, the introduction of new materials, such as high-index plastics, revolutionized lens design by allowing for lighter and more compact constructions without compromising optical quality. The integration of computer-aided design (CAD) and advanced manufacturing techniques further enabled manufacturers to create lenses with complex geometries, enhancing their performance across various applications.

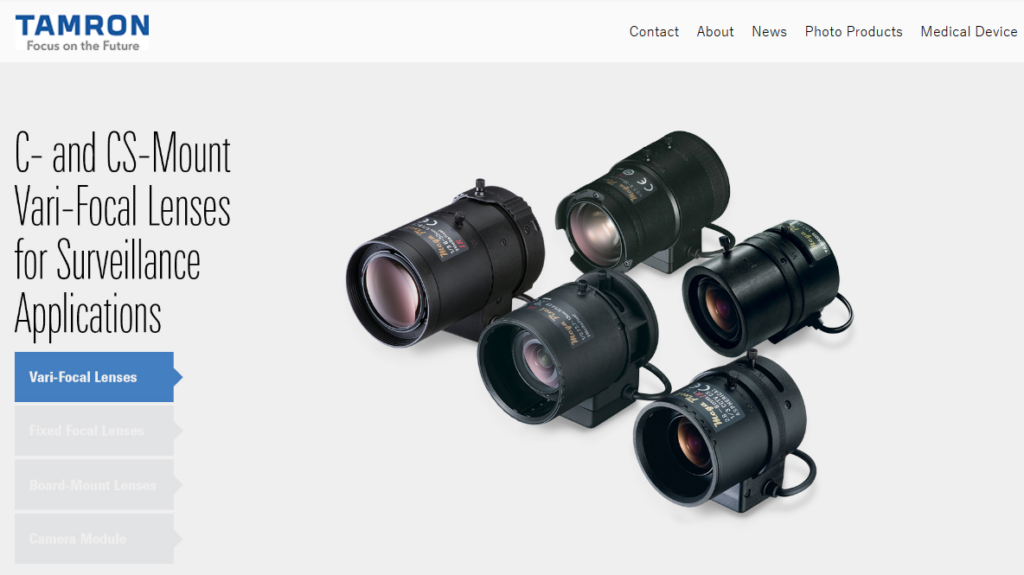

A stock image related to camera len manufacturer.

Today, the sector is witnessing a convergence of traditional optics with emerging technologies, including artificial intelligence and smart features, which are reshaping product offerings. As the demand for high-quality imaging continues to grow across different industries, the camera lens manufacturing sector is poised for continued innovation and expansion, providing ample opportunities for international B2B buyers to explore new partnerships and sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of camera len manufacturer

-

How do I evaluate the quality of camera lenses from a manufacturer?

To assess the quality of camera lenses, consider requesting samples from potential suppliers. Evaluate these samples under different lighting conditions and at various focal lengths. Additionally, check for optical clarity, color accuracy, and build quality. Certifications such as ISO 9001 can also indicate a manufacturer’s commitment to quality. Engaging with existing customers for reviews and feedback can provide deeper insights into the manufacturer’s reliability and the performance of their lenses. -

What are the best camera lenses for professional photography?

The best camera lenses for professional photography often include prime lenses with wide apertures (like f/1.4 or f/1.8) for low-light performance and depth of field control. Zoom lenses with versatile focal lengths (like 24-70mm) are also popular for their flexibility. Additionally, consider specialized lenses such as macro or fisheye lenses based on specific photography needs. Always align your choice with the camera body specifications and intended use, ensuring compatibility and optimal performance. -

What should I consider when sourcing camera lenses from international manufacturers?

When sourcing camera lenses internationally, consider factors like the manufacturer’s reputation, production capabilities, and adherence to international quality standards. Evaluate their experience in exporting to your region, as familiarity with customs regulations can expedite the process. Additionally, assess their communication skills and customer service, which are critical for resolving potential issues during the sourcing process. Lastly, consider the geographical location for shipping costs and timelines. -

What are the minimum order quantities (MOQs) for camera lenses?

Minimum order quantities (MOQs) for camera lenses can vary significantly depending on the manufacturer and the type of lens. Typically, MOQs can range from 100 to 1,000 units. It’s essential to discuss these requirements upfront with suppliers to ensure they align with your purchasing capabilities. Some manufacturers may offer flexibility on MOQs for first-time buyers or larger orders, so negotiation may be possible. -

How can I customize camera lenses to fit my specific needs?

Customization options for camera lenses may include adjustments in focal length, aperture size, coatings, and physical design. When approaching a manufacturer, clearly outline your specifications and intended applications. Many suppliers offer design services and may provide prototypes for testing before final production. Additionally, ensure that the manufacturer has the capability to produce customized lenses at scale and within your desired timeline.

A stock image related to camera len manufacturer.

-

What are typical payment terms for international camera lens purchases?

Payment terms for international purchases of camera lenses often include options such as advance payment, letter of credit, or payment upon delivery. It’s common for manufacturers to require a deposit (typically 30-50%) before production begins, with the remaining balance due upon shipment. Always clarify payment terms in the contract to avoid misunderstandings. Consider using secure payment methods to protect against fraud, especially when dealing with new suppliers. -

How do I ensure quality assurance (QA) when sourcing camera lenses?

To ensure quality assurance when sourcing camera lenses, establish a clear QA process with your supplier. This may include pre-production samples, in-process inspections, and final product evaluations. Request documentation such as test reports and certifications that confirm adherence to quality standards. Additionally, consider conducting on-site inspections or hiring third-party inspection services to verify product quality before shipment. -

What logistics considerations should I keep in mind when importing camera lenses?

When importing camera lenses, logistics considerations include shipping methods (air freight vs. sea freight), customs duties, and delivery timelines. Assess the reliability of your shipping partner and ensure they have experience with international shipments. It’s vital to understand the import regulations in your country, including any restrictions on electronic goods. Additionally, plan for potential delays and ensure that your supply chain can accommodate these factors to maintain inventory levels.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for camera len manufacturer

In today’s competitive landscape, strategic sourcing has emerged as a critical component for international B2B buyers in the camera lens manufacturing sector. By prioritizing supplier relationships and focusing on quality, innovation, and cost efficiency, businesses can enhance their product offerings and improve market positioning. Buyers from regions such as Africa, South America, the Middle East, and Europe must leverage these strategies to navigate the complexities of global trade and supply chain management effectively.

What are the key benefits of strategic sourcing for camera lens manufacturers? By employing a thorough sourcing strategy, companies can identify reliable suppliers who adhere to international quality standards while also offering competitive pricing. This not only minimizes risks associated with supply chain disruptions but also fosters long-term partnerships that can lead to collaborative innovation.

Looking ahead, the demand for high-quality camera lenses is expected to grow, driven by advancements in technology and increasing consumer expectations. B2B buyers are encouraged to engage proactively with manufacturers, exploring opportunities for customization and co-development. Embrace strategic sourcing as a means to not only meet current market demands but also to position your business for future success. Take the next step in your sourcing journey and explore the vast potential of partnerships in the camera lens manufacturing industry.