Discover Top Catalyst Suppliers: A Complete Sourcing Guide (2025)

Introduction: Navigating the Global Market for catalyst supplier

In today’s interconnected world, international B2B buyers face the critical challenge of sourcing high-quality catalyst suppliers that can meet their specific needs across diverse applications. As industries increasingly rely on catalysts to enhance productivity and sustainability, understanding the global landscape of catalyst suppliers becomes essential. This guide serves as a comprehensive resource for navigating the complexities of sourcing catalysts, covering vital aspects such as types of catalysts, their applications in various industries, supplier vetting processes, and cost considerations.

For buyers in regions such as Africa, South America, the Middle East, and Europe—including Poland and the UK—this guide empowers you to make informed purchasing decisions. With detailed insights into market trends and supplier capabilities, you will learn how to assess potential partners based on quality, reliability, and compliance with international standards.

Additionally, the guide addresses common questions such as “What factors should I consider when evaluating catalyst suppliers?” and “How can I ensure cost-effectiveness while maintaining quality?” By leveraging this information, you will be better equipped to navigate the global market for catalyst suppliers, ultimately driving efficiency and innovation in your operations. Through strategic sourcing and supplier relationships, you can enhance your competitive edge and contribute to sustainable industrial practices in your region.

Understanding catalyst supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Chemical Catalyst Suppliers | Specialize in catalysts for chemical reactions; often provide custom formulations. | Petrochemical, pharmaceuticals | Pros: Tailored solutions; high expertise. Cons: Higher costs; longer lead times. |

| Environmental Catalyst Suppliers | Focus on catalysts that reduce emissions and enhance sustainability. | Waste management, energy production | Pros: Eco-friendly solutions; regulatory compliance. Cons: Limited options for specific applications. |

| Biocatalyst Suppliers | Utilize biological materials for catalysis; often biodegradable. | Food processing, pharmaceuticals | Pros: Sustainable; efficient under mild conditions. Cons: May require specific handling and storage. |

| Heterogeneous Catalyst Suppliers | Provide catalysts that are in a different phase than the reactants, enhancing reaction efficiency. | Oil refining, chemical synthesis | Pros: High activity and selectivity; easier separation. Cons: Can be expensive; may need specific reactors. |

| Homogeneous Catalyst Suppliers | Supply catalysts that are in the same phase as reactants, offering uniform distribution. | Fine chemicals, agrochemicals | Pros: Effective for complex reactions; improved reaction rates. Cons: Difficult separation; potential contamination. |

What Are the Characteristics of Chemical Catalyst Suppliers?

Chemical catalyst suppliers are key players in industries such as petrochemicals and pharmaceuticals. They offer a range of catalysts tailored to specific chemical reactions, often providing customized formulations to meet unique client needs. When considering suppliers in this category, B2B buyers should assess the supplier’s expertise in the desired chemical process, as well as their ability to provide consistent quality and reliability. However, it’s important to note that these suppliers may come with higher costs and longer lead times due to the customization involved.

How Do Environmental Catalyst Suppliers Enhance Sustainability?

Environmental catalyst suppliers specialize in catalysts designed to minimize emissions and improve the sustainability of industrial processes. These catalysts are crucial for applications in waste management and energy production, helping companies comply with increasingly stringent environmental regulations. Buyers should evaluate the supplier’s track record in environmental compliance and the efficacy of their products in real-world applications. While these solutions often provide significant ecological benefits, the range of options available may be limited for specific applications.

What Are the Advantages of Biocatalyst Suppliers?

Biocatalyst suppliers utilize biological materials, such as enzymes, to facilitate chemical reactions. These catalysts are particularly effective in food processing and pharmaceuticals, offering a sustainable alternative to traditional chemical catalysts. B2B buyers should consider the efficiency of biocatalysts under mild conditions, which can lead to lower energy costs. However, they must also be mindful of the specific handling and storage requirements that biocatalysts may entail, as improper management can affect their effectiveness.

What Makes Heterogeneous Catalyst Suppliers Unique?

Heterogeneous catalyst suppliers provide catalysts that exist in a different phase than the reactants, which enhances reaction efficiency and simplifies product separation. This type of catalyst is widely used in oil refining and chemical synthesis. For B2B buyers, the advantages include high activity and selectivity, which can lead to improved yield and lower processing costs. However, potential buyers should be aware that these catalysts can be more expensive and may require specific reactor designs to optimize performance.

Why Choose Homogeneous Catalyst Suppliers for Complex Reactions?

Homogeneous catalyst suppliers offer catalysts that are in the same phase as the reactants, resulting in uniform distribution and effective reaction rates. These catalysts are commonly used in the production of fine chemicals and agrochemicals, making them suitable for complex reactions. When selecting a supplier, buyers should assess the supplier’s ability to provide consistent quality and support for complex processes. However, challenges such as difficult separation of products and the risk of contamination should be carefully considered.

Related Video: Simplified, scalable and clean production of Catalyst Coated Membranes for green hydrogen

Key Industrial Applications of catalyst supplier

| Industry/Sector | Specific Application of Catalyst Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Petrochemical | Catalysts in Crude Oil Refining | Enhances yield and purity of refined products | Regulatory compliance, local supply chain logistics |

| Chemical Manufacturing | Catalysts for Polymer Production | Increases production efficiency and quality | Compatibility with existing processes, supplier reliability |

| Environmental Management | Catalysts in Waste Treatment Processes | Reduces environmental impact and complies with regulations | Certification and performance data, technology transfer |

| Automotive | Catalysts in Emission Control Systems | Meets regulatory emissions standards, improves vehicle performance | Testing and validation, regional emissions regulations |

| Pharmaceuticals | Catalysts in Active Pharmaceutical Ingredient (API) Synthesis | Improves synthesis efficiency and reduces costs | Intellectual property concerns, sourcing of rare materials |

How Are Catalysts Used in the Petrochemical Industry?

In the petrochemical sector, catalysts play a crucial role in crude oil refining processes, such as hydrocracking and catalytic reforming. By facilitating chemical reactions that convert crude oil into valuable products like gasoline and diesel, catalysts enhance the yield and purity of these refined products. For international buyers, especially those in Africa and South America, sourcing catalysts that comply with local regulations and ensuring a reliable supply chain are essential to maintain operational efficiency.

What Role Do Catalysts Play in Chemical Manufacturing?

Catalysts are indispensable in the production of polymers within the chemical manufacturing industry. They help improve the efficiency of chemical reactions, leading to higher yields and better quality of the final products. Buyers from the Middle East and Europe should focus on suppliers that offer catalysts compatible with their existing processes and can guarantee consistent performance, as this can significantly impact production timelines and costs.

How Are Catalysts Used in Environmental Management?

In environmental management, catalysts are employed in waste treatment processes to facilitate the breakdown of hazardous materials. They help in reducing the environmental impact of industrial waste, ensuring compliance with stringent regulations. For international B2B buyers, it’s vital to source catalysts that come with certifications and proven performance data to meet both local and international environmental standards.

Why Are Catalysts Important in Automotive Applications?

Catalysts are critical components of emission control systems in vehicles, helping to convert harmful pollutants into less harmful emissions. This application is particularly important for automotive manufacturers in Europe, where stringent emissions regulations are in place. Buyers need to ensure that their catalyst suppliers can provide testing and validation services, along with a deep understanding of regional emissions regulations to ensure compliance and enhance vehicle performance.

How Do Catalysts Enhance Pharmaceutical Production?

In the pharmaceutical industry, catalysts are used in the synthesis of Active Pharmaceutical Ingredients (APIs) to improve efficiency and reduce production costs. They enable complex chemical reactions that are essential for producing high-quality pharmaceuticals. International buyers, especially in Europe, should consider suppliers that address intellectual property concerns and can source rare materials required for specific catalysts, ensuring that the production process remains efficient and compliant with industry standards.

Related Video: Uses of Metals – Science 9

3 Common User Pain Points for ‘catalyst supplier’ & Their Solutions

Scenario 1: Understanding Catalyst Quality and Specifications

The Problem: One of the most significant challenges faced by B2B buyers in the catalyst market is ensuring the quality and specifications of catalysts meet their production needs. Many buyers are unsure of the precise requirements for their processes, leading to the risk of procuring subpar catalysts that do not perform effectively. This can result in production delays, increased costs, and ultimately, a negative impact on profitability. Buyers from regions like Africa and South America may particularly struggle with this due to varying standards and limited access to reliable information about suppliers.

The Solution: To address this issue, buyers should conduct thorough due diligence on potential catalyst suppliers. Start by specifying your process requirements in detail, including temperature ranges, pressure conditions, and desired reaction outcomes. This information will help suppliers provide you with tailored catalyst options. Engage in discussions with multiple suppliers to compare their offerings and request samples for testing. Additionally, consider suppliers with certifications and quality assurances, such as ISO standards, which can provide confidence in the consistency and reliability of their products. Establishing a strong line of communication with the supplier can also facilitate better understanding and adjustments based on performance feedback.

Scenario 2: Navigating Supply Chain Challenges in Catalyst Procurement

The Problem: Buyers often face significant supply chain disruptions, especially when sourcing catalysts from international suppliers. Issues like shipping delays, customs clearance, and unexpected tariffs can lead to inventory shortages, halting production lines and resulting in financial losses. This is particularly relevant for businesses in the Middle East and Europe, where geopolitical factors may further complicate logistics.

The Solution: To mitigate supply chain risks, buyers should diversify their supplier base to avoid dependence on a single source. Establish relationships with multiple catalyst suppliers across different regions to ensure alternatives are available if one supplier encounters issues. Additionally, consider local suppliers or those with regional distribution centers to reduce shipping times and costs. Implementing just-in-time inventory management practices can also help maintain adequate stock levels without overcommitting resources. Lastly, staying informed about geopolitical developments and trade regulations can enable buyers to proactively adjust their sourcing strategies.

Scenario 3: Ensuring Compliance with Environmental Regulations

The Problem: B2B buyers must navigate an increasingly complex landscape of environmental regulations concerning catalyst use and disposal. In Europe, for instance, stringent regulations surrounding emissions and waste disposal can pose significant challenges for manufacturers. Buyers may find it difficult to source catalysts that not only meet performance criteria but also comply with local environmental laws, leading to potential legal liabilities and reputational damage.

The Solution: Buyers should prioritize suppliers who demonstrate a commitment to sustainability and compliance with environmental regulations. When evaluating catalyst suppliers, inquire about their adherence to local and international environmental standards, such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) in Europe. Request documentation that outlines their environmental policies and practices, including information on catalyst life cycle, recycling options, and waste management. Engaging suppliers in discussions about their sustainability initiatives can also provide insight into their operational practices and help you align your procurement strategy with your organization’s environmental goals. Additionally, consider conducting a risk assessment to evaluate the potential environmental impact of your catalyst choices, ensuring that compliance is a cornerstone of your procurement process.

Strategic Material Selection Guide for catalyst supplier

What Are the Key Materials Used in Catalyst Production?

In the realm of catalyst suppliers, the selection of materials is critical for ensuring optimal performance and longevity of catalysts in various industrial applications. Below, we analyze four common materials used in catalyst production, highlighting their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Do Precious Metals Perform as Catalysts?

Key Properties: Precious metals such as platinum, palladium, and rhodium exhibit excellent catalytic activity and high resistance to thermal degradation. They can operate effectively under extreme temperatures and pressures, making them suitable for a variety of catalytic processes.

Pros & Cons: The primary advantage of precious metals is their exceptional catalytic efficiency and durability. However, they come with high costs and can be challenging to source, particularly for buyers in regions with limited access to these materials. Additionally, their high manufacturing complexity can lead to longer lead times.

Impact on Application: Precious metals are particularly effective in automotive catalytic converters and chemical synthesis processes. Their ability to withstand harsh environments makes them ideal for applications involving corrosive media.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of compliance with standards such as ASTM and ISO regarding precious metal content. Sourcing from certified suppliers is crucial to ensure quality and compliance.

What Role Do Transition Metals Play in Catalysis?

Key Properties: Transition metals like nickel, cobalt, and copper are known for their good thermal stability and moderate resistance to corrosion. They can catalyze a wide range of reactions, including hydrogenation and oxidation.

Pros & Cons: Transition metals are generally more affordable than precious metals, making them attractive for large-scale applications. However, they may have lower catalytic activity and can be more susceptible to poisoning, which can limit their effectiveness in certain environments.

Impact on Application: These metals are commonly used in petrochemical processing and hydrogen production. Their compatibility with various media makes them versatile, but their performance can vary significantly based on the specific application.

Considerations for International Buyers: Buyers should consider the regional availability of these metals and their compliance with local regulations. Understanding the specific catalytic requirements of their applications is essential for selecting the right transition metal.

How Do Metal Oxides Function as Catalysts?

Key Properties: Metal oxides, such as titanium dioxide and zinc oxide, are known for their high surface area and thermal stability. They are often used as supports for other catalytic materials due to their ability to enhance catalytic activity.

Pros & Cons: Metal oxides are generally cost-effective and exhibit good durability. However, their catalytic performance can be lower compared to precious metals. Additionally, the manufacturing process can be complex, requiring precise control over conditions to achieve the desired properties.

Impact on Application: Metal oxides are widely used in oxidation reactions and environmental applications, such as air and water purification. Their compatibility with a variety of media makes them suitable for diverse applications.

Considerations for International Buyers: Buyers must ensure that the metal oxides they source comply with international standards and regulations. Awareness of local environmental regulations is also crucial, particularly in regions with strict emissions controls.

What Advantages Do Zeolites Offer as Catalysts?

Key Properties: Zeolites are microporous, aluminosilicate minerals that provide high surface area and tunable pore sizes. They are particularly effective in catalytic cracking and hydrocracking processes.

Pros & Cons: The primary advantage of zeolites is their ability to selectively catalyze reactions based on molecular size and shape. However, they can be sensitive to temperature and moisture, which may limit their application in certain environments.

Impact on Application: Zeolites are commonly used in the petrochemical industry and for environmental applications. Their unique structure allows for effective separation and catalysis, making them invaluable in refining processes.

Considerations for International Buyers: Buyers should evaluate the sourcing of zeolites based on their local availability and compliance with industry standards. Understanding the specific catalytic processes they intend to use is essential for selecting the appropriate zeolite type.

Summary Table of Catalyst Materials

| Material | Typical Use Case for catalyst supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Precious Metals | Automotive catalytic converters, chemical synthesis | Exceptional catalytic efficiency | High cost, sourcing challenges | High |

| Transition Metals | Petrochemical processing, hydrogen production | More affordable than precious metals | Lower catalytic activity, poisoning susceptibility | Medium |

| Metal Oxides | Oxidation reactions, environmental applications | Cost-effective, good durability | Lower performance compared to precious metals | Low |

| Zeolites | Catalytic cracking, hydrocracking | Selective catalysis based on molecular size | Sensitive to temperature and moisture | Medium |

This comprehensive analysis equips international B2B buyers with actionable insights to make informed decisions when selecting materials for catalysts, ensuring compatibility with their specific applications and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for catalyst supplier

What Are the Main Stages of Catalyst Manufacturing Processes?

The manufacturing of catalysts involves several critical stages that ensure the end product meets the required performance specifications. Understanding these stages is crucial for international B2B buyers looking to source high-quality catalysts.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage in catalyst manufacturing is material preparation. This involves the selection of high-purity raw materials, such as metal oxides and supports, which are essential for catalyst performance. Buyers should inquire about the sourcing of these materials, as the purity and origin significantly influence the catalyst’s effectiveness.

Common practices include grinding, milling, and sieving to achieve the desired particle size and distribution. A thorough understanding of these processes helps buyers assess the quality of the raw materials used.

Forming: What Techniques Are Used to Shape Catalysts?

Once materials are prepared, the next step is forming. This stage often employs techniques such as extrusion, pelletization, or spray drying to create the desired shape and surface area.

For instance, extrusion is commonly used to produce cylindrical pellets, while spray drying can create fine powders. Each method has implications for the catalyst’s performance in specific applications. Buyers should ask suppliers about the forming techniques used and their impact on the final product.

Assembly: How Are Catalysts Assembled for Optimal Performance?

In the assembly stage, different catalyst components are combined to create the final product. This may include the addition of promoters or stabilizers to enhance the catalyst’s activity and longevity.

Understanding the assembly process allows buyers to evaluate the potential performance of the catalyst in their applications. It is advisable to request detailed specifications about the assembly process to ensure compatibility with existing systems.

Finishing: What Final Steps Ensure Catalyst Quality?

The finishing stage involves drying, calcination, and surface treatment. These processes are crucial for developing the catalyst’s final properties, such as surface area, porosity, and thermal stability.

Buyers should be aware of the specific finishing techniques employed, as they can significantly affect the catalyst’s efficiency. Verification through supplier documentation or certifications can provide assurance of quality during this phase.

How Is Quality Control Integrated into the Catalyst Manufacturing Process?

Quality control (QC) is a fundamental aspect of catalyst manufacturing, ensuring that products meet international standards and customer specifications. Understanding QC processes can help B2B buyers from Africa, South America, the Middle East, and Europe make informed purchasing decisions.

What International Standards Guide Catalyst Quality Assurance?

Catalyst suppliers typically adhere to several international standards to ensure product quality. The ISO 9001 standard is widely recognized and focuses on quality management systems. Compliance with ISO 9001 indicates that a supplier has established processes to consistently meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications like CE marking for European markets or API certification for the oil and gas sector may apply. Buyers should verify that their suppliers hold relevant certifications to ensure compliance with local regulations and industry practices.

What Are the Key QC Checkpoints in Catalyst Production?

Quality control is integrated at various checkpoints throughout the manufacturing process, commonly categorized as Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

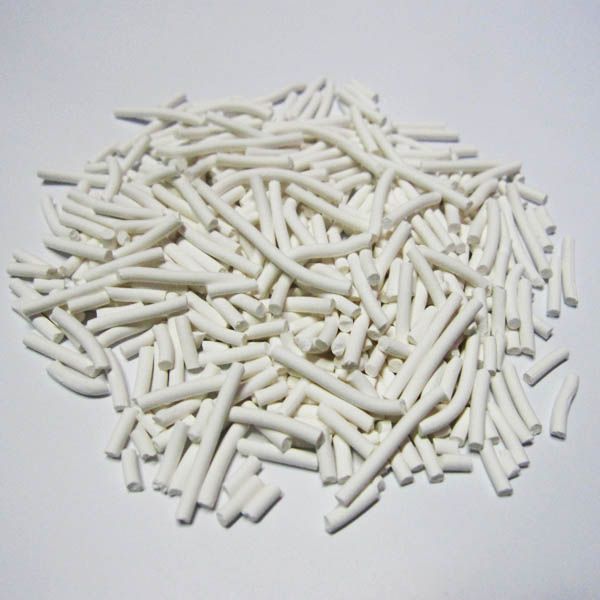

A stock image related to catalyst supplier.

-

Incoming Quality Control (IQC): This involves inspecting raw materials before production. Buyers should inquire about the criteria used for accepting or rejecting materials and whether suppliers perform regular audits of their suppliers.

-

In-Process Quality Control (IPQC): During production, samples are taken at different stages to ensure that processes are running within specified parameters. Buyers can ask about the frequency of these checks and the measures taken if deviations occur.

-

Final Quality Control (FQC): This stage involves comprehensive testing of the finished product against specifications. Common testing methods include surface area analysis, porosity measurement, and activity testing. Buyers should request information on the specific tests conducted and their results.

How Can B2B Buyers Verify Supplier Quality Control?

Ensuring that a catalyst supplier adheres to rigorous quality control processes is essential for B2B buyers. Here are effective methods for verifying supplier QC:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should conduct thorough supplier audits to assess quality control practices. During audits, buyers can evaluate the supplier’s adherence to quality standards, inspect production facilities, and review documentation related to quality processes.

Additionally, requesting quality reports, including test results and compliance certificates, can provide insights into the supplier’s performance. Buyers should ensure that these documents are up-to-date and reflect the latest manufacturing practices.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can offer an impartial assessment of a supplier’s quality control measures. These inspections can cover everything from raw material sourcing to final product testing, giving buyers confidence in the supplier’s capabilities.

By utilizing third-party inspections, buyers can identify potential issues that might not be apparent during supplier audits, thereby mitigating risks associated with poor-quality catalysts.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control that may affect their purchasing decisions.

How Do Regional Regulations Impact Quality Standards?

Each region may have unique regulatory requirements that influence catalyst quality assurance. For instance, buyers in Europe must comply with REACH regulations, which govern the use of chemicals. Understanding these regional regulations can help buyers navigate compliance issues and avoid legal complications.

What Are the Challenges of Sourcing Catalysts Internationally?

Sourcing catalysts internationally may pose challenges, such as differences in quality standards, shipping delays, and variations in supplier reliability. Buyers should consider these factors when selecting suppliers and may benefit from building relationships with multiple vendors to mitigate risks.

By focusing on manufacturing processes and quality assurance, B2B buyers can make informed decisions when selecting catalyst suppliers, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘catalyst supplier’

The following guide is designed to assist international B2B buyers in effectively sourcing catalyst suppliers. Navigating the complexities of international procurement can be daunting, but this checklist provides a structured approach to ensure you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for catalysts. This includes the type of catalyst needed, its intended application, and performance criteria. By having precise specifications, you minimize misunderstandings and ensure that suppliers can meet your exact needs.

- Identify the catalyst type: Is it heterogeneous or homogeneous?

- Determine the application: What chemical processes will it be used in?

- Set performance benchmarks: What are the required efficiency and lifespan?

Step 2: Conduct Market Research

Understanding the market landscape is essential. Research potential suppliers and their reputations within the industry. This helps you gauge which companies are well-regarded and can meet your quality and service expectations.

- Utilize industry reports: Look for insights on market leaders and emerging players.

- Engage in forums and networks: Join industry-specific groups to gather feedback from peers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; seek out third-party reviews and testimonials to validate their claims.

- Check for industry certifications: Ensure suppliers meet relevant quality standards.

- Review their production capabilities: Can they scale production to meet your demand?

Step 4: Assess Supplier Financial Stability

Supplier reliability is closely tied to their financial health. Review their financial statements and credit ratings to ensure they can sustain operations and fulfill long-term contracts. This step is particularly important for large orders and ongoing partnerships.

- Request financial documents: Look for profitability, liquidity, and debt levels.

- Consider their market position: A supplier with a strong market presence is less likely to face disruptions.

Step 5: Negotiate Terms and Conditions

Once you’ve identified suitable suppliers, initiate negotiations on pricing, delivery schedules, and payment terms. Clear communication in this phase can prevent disputes later on and ensure both parties have aligned expectations.

- Discuss bulk pricing: Can you secure discounts for larger orders?

- Establish delivery timelines: Ensure they align with your project schedules.

Step 6: Verify Regulatory Compliance

Ensure that the suppliers comply with local and international regulations relevant to catalysts. This is particularly important for buyers in regions like Europe, where compliance standards are stringent. Verify their adherence to safety, environmental, and quality regulations.

- Request documentation: Ensure they provide proof of compliance with regulations.

- Check for sustainability practices: Are they following eco-friendly practices in production?

Step 7: Establish Communication Protocols

Good communication is key to a successful supplier relationship. Set up clear lines of communication regarding updates, order status, and potential issues. Establish regular check-ins to discuss performance and any adjustments needed.

- Choose communication tools: Determine preferred platforms for updates.

- Schedule regular reviews: Set periodic meetings to assess performance and address concerns.

By following this step-by-step checklist, B2B buyers can streamline their sourcing process for catalyst suppliers, ensuring they find reliable partners that meet their specific needs while minimizing risks.

Comprehensive Cost and Pricing Analysis for catalyst supplier Sourcing

What Are the Key Cost Components in Catalyst Supplier Sourcing?

When sourcing catalysts, understanding the cost structure is essential for making informed purchasing decisions. The primary components of cost include:

-

Materials: The choice of raw materials significantly influences pricing. High-purity metals and specialized chemicals often come at a premium, impacting overall costs.

-

Labor: Skilled labor is necessary for manufacturing catalysts. Labor costs can vary widely based on geographical location, skill level, and labor laws. In regions like Europe, labor costs may be higher than in Africa or South America.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: Specialized tools and equipment are often required for catalyst production. Investment in advanced tooling can lead to better quality and efficiency but also adds to the initial cost.

-

Quality Control (QC): Rigorous QC processes are vital to ensure the catalysts meet industry standards. While this may increase upfront costs, it can prevent costly failures and recalls in the long run.

-

Logistics: Transportation and handling costs are critical, especially for international shipments. Factors like distance, shipping mode, and customs duties can heavily influence logistics expenses.

-

Margin: Suppliers typically add a margin to cover their risks and profits. This margin varies based on market conditions and competition.

How Do Price Influencers Impact Catalyst Sourcing Decisions?

Several factors can influence pricing strategies when sourcing catalysts:

-

Volume/MOQ: Minimum Order Quantities (MOQ) can lead to price breaks. Larger orders often result in lower per-unit costs, making it advantageous for buyers to consolidate purchases.

-

Specifications and Customization: Customized catalysts tailored to specific applications can command higher prices. Clearly defining specifications can help buyers negotiate better deals.

-

Material Quality and Certifications: Higher quality materials often yield better performance and durability. Certifications such as ISO or industry-specific standards can also affect pricing, as they assure buyers of product reliability.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge more due to their perceived value and trustworthiness.

-

Incoterms: Understanding International Commercial Terms (Incoterms) is essential for international buyers. These terms define the responsibilities of buyers and sellers regarding shipping, risk, and costs, which can influence the final price.

What Are Some Negotiation Tips for B2B Buyers in Catalyst Sourcing?

Negotiation is a crucial skill for buyers aiming to optimize costs and enhance value. Here are some actionable tips:

-

Research Market Prices: Understand the market landscape to establish a baseline for negotiations. Utilize industry reports and peer networks to gather insights.

-

Focus on Total Cost of Ownership (TCO): Instead of solely looking at the purchase price, consider the TCO, which includes maintenance, operational costs, and disposal. A cheaper catalyst may lead to higher long-term costs if it requires frequent replacement or leads to operational inefficiencies.

-

Leverage Volume: If possible, consolidate purchases across multiple projects or departments to negotiate better pricing. Suppliers are often willing to provide discounts for larger orders.

-

Build Relationships: Developing strong relationships with suppliers can lead to better terms, flexibility, and potential access to exclusive deals or innovations.

-

Be Mindful of Cultural Differences: When negotiating with suppliers from different regions, be aware of cultural nuances that may affect communication and negotiation styles. Respect and adaptability can foster better partnerships.

Final Thoughts on Pricing Nuances for International Buyers

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of catalyst pricing is vital. Always approach negotiations with a comprehensive understanding of the cost components, price influencers, and the broader market context.

Disclaimer: Prices for catalysts can fluctuate based on various factors, including market demand and geopolitical events. Always seek updated quotations and conduct due diligence before finalizing any agreements.

Alternatives Analysis: Comparing catalyst supplier With Other Solutions

Understanding the Importance of Evaluating Alternatives in Catalyst Supply

When considering catalyst suppliers for industrial applications, it’s crucial to evaluate various alternatives that can meet your operational needs. The market offers a range of solutions, each with unique benefits and drawbacks. By comparing these options, international B2B buyers can make informed decisions that align with their strategic goals.

Comparison Table of Catalyst Supplier and Alternatives

| Comparison Aspect | Catalyst Supplier | Chemical Catalyst Alternatives | Biocatalyst Solutions |

|---|---|---|---|

| Performance | High efficiency in specific reactions | Varies by chemical nature; can be optimized | Effective in specific biological processes |

| Cost | Moderate to high initial investment | Often lower, but can vary widely | Generally lower operational costs, but may require more time |

| Ease of Implementation | Requires technical expertise for setup | Often straightforward if chemicals are available | May need specialized training and conditions |

| Maintenance | Regular monitoring needed; can be complex | Lower maintenance but chemical stability issues may arise | Minimal maintenance; however, sensitive to environmental conditions |

| Best Use Case | Ideal for high-volume industrial processes | Suitable for a range of chemical reactions | Best for sustainable processes and specific biochemical reactions |

What Are the Benefits and Drawbacks of Chemical Catalyst Alternatives?

Chemical catalysts represent a broad category of alternatives that can be used in various industrial applications. They are often less expensive than traditional catalyst suppliers, making them attractive for companies looking to reduce initial investment costs. However, the performance can vary significantly based on the type of chemical used, and they may not be as efficient in highly specialized reactions. Additionally, while implementation may seem easier, the need for proper chemical handling and potential stability issues can complicate their use in the long term.

How Do Biocatalyst Solutions Compare in Terms of Efficiency and Cost?

Biocatalysts, which include enzymes and microorganisms, offer a sustainable alternative to traditional catalysts. They are particularly effective in biochemical processes and can operate under milder conditions, reducing energy costs. The operational costs tend to be lower, but they may require longer processing times and specific environmental conditions to maintain effectiveness. While the maintenance is generally minimal, the need for specialized training to handle biocatalysts can be a barrier for some businesses.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right catalyst solution involves assessing your specific operational requirements, budget constraints, and the scalability of the technology. Buyers should conduct a thorough analysis of their production processes and consider factors such as the volume of production, desired efficiency, and the environmental impact of each alternative. Engaging with suppliers for demonstrations or pilot tests can also provide valuable insights into performance and compatibility with existing systems. Ultimately, the goal is to choose a solution that not only meets immediate needs but also aligns with long-term strategic objectives, including sustainability and cost-effectiveness.

Essential Technical Properties and Trade Terminology for catalyst supplier

What Are the Key Technical Properties of Catalysts in B2B Transactions?

Understanding the essential technical properties of catalysts is crucial for international B2B buyers, particularly in industries such as petrochemicals, pharmaceuticals, and environmental technologies. Here are some critical specifications to consider:

-

Material Grade

Material grade refers to the composition and purity of the catalyst materials. Different grades can significantly impact performance, durability, and cost. Buyers should evaluate material grades to ensure compatibility with specific industrial applications. For instance, higher-grade catalysts may offer enhanced activity or selectivity, which can lead to improved yield and lower operational costs. -

Particle Size Distribution

The particle size of a catalyst affects its surface area and reactivity. A narrower particle size distribution often leads to more uniform catalytic performance. In B2B negotiations, discussing particle size is essential as it can influence the overall efficiency of the catalytic process, especially in applications requiring precise reactions. -

Surface Area

The surface area of a catalyst is a critical factor that determines its effectiveness. Higher surface areas typically lead to increased catalytic activity due to more active sites available for chemical reactions. For buyers, understanding surface area specifications can help in selecting the right catalyst for specific processes, ensuring optimal performance and cost-effectiveness. -

Thermal Stability

Thermal stability defines how well a catalyst can withstand high temperatures without degrading. This property is vital for processes that involve extreme conditions. Buyers should prioritize catalysts with high thermal stability to avoid frequent replacements, which can be costly and disruptive to production schedules. -

Tolerance Levels

Tolerance levels indicate the permissible variations in catalyst performance parameters. Understanding these tolerances is essential for ensuring that the catalyst meets the specific needs of the application without compromising efficiency. Buyers should communicate their tolerance requirements clearly to suppliers to avoid issues during the production phase.

What Are Common Trade Terms That B2B Buyers Should Know?

Familiarity with industry jargon can streamline communication and enhance negotiations. Here are some commonly used terms in the catalyst supply industry:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, knowing if a catalyst supplier is an OEM can signify reliability and quality assurance, as OEMs typically adhere to stringent manufacturing standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to manage inventory and cash flow effectively. This term helps in planning purchases and ensuring that the procurement aligns with production schedules. -

RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers to request pricing and terms for specific products. For international buyers, crafting a detailed RFQ can lead to better responses from suppliers, ensuring that all necessary specifications and requirements are clearly communicated. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is crucial for buyers to avoid misunderstandings and ensure smooth logistics when sourcing catalysts from different regions. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. For B2B buyers, knowing the lead time is essential for effective supply chain management, helping to align procurement with production needs. -

Technical Data Sheet (TDS)

A TDS provides detailed information about a product’s specifications, handling, and applications. Buyers should always request a TDS to ensure that the catalysts meet their technical requirements and to facilitate informed decision-making.

By grasping these technical properties and trade terminologies, B2B buyers can enhance their procurement strategies, ensuring they select the right catalysts for their needs while navigating the complexities of international trade effectively.

Navigating Market Dynamics and Sourcing Trends in the catalyst supplier Sector

What Are the Current Market Dynamics and Key Trends in the Catalyst Supplier Sector?

The catalyst supplier sector is experiencing transformative changes driven by globalization, technological advancements, and evolving buyer demands. International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, need to stay informed about these dynamics to make strategic sourcing decisions. A significant driver in this market is the increasing demand for catalysts that enhance process efficiency and reduce emissions, aligning with global sustainability goals.

Emerging technologies, such as artificial intelligence and machine learning, are reshaping how suppliers and buyers engage. For instance, predictive analytics can help buyers forecast demand and optimize inventory, while digital marketplaces facilitate easier access to a broader range of suppliers. Furthermore, the rise of e-commerce platforms is enabling buyers to source catalysts from various regions, ensuring competitive pricing and improved supply chain transparency.

Regional market dynamics also play a crucial role. In Europe, stringent regulations on emissions are pushing companies to adopt more innovative and environmentally friendly catalysts. Meanwhile, in Africa and South America, the focus is on developing local supply chains to reduce dependence on imports and promote economic growth. Understanding these trends is vital for buyers looking to establish reliable partnerships and secure high-quality catalysts.

How Can Sustainability and Ethical Sourcing Impact Your B2B Catalyst Supply Chain?

Sustainability is no longer a buzzword; it is a critical consideration for B2B buyers in the catalyst supplier sector. The environmental impact of catalyst production and usage is significant, making ethical sourcing paramount. Suppliers are increasingly adopting sustainable practices, such as using recycled materials and minimizing waste during production. For buyers, aligning with suppliers committed to sustainability can enhance brand reputation and meet regulatory requirements.

Moreover, certifications such as ISO 14001 for environmental management and other ‘green’ certifications are becoming essential for buyers seeking to validate their suppliers’ commitments to sustainability. These certifications provide assurance that the supplier adheres to recognized environmental standards, which can be a deciding factor when evaluating potential partners.

Investing in catalysts with a lower environmental footprint not only contributes to global sustainability efforts but also often leads to cost savings in the long run. Buyers should prioritize suppliers who demonstrate transparency in their sourcing practices and offer products that minimize ecological impacts.

What Is the Historical Context Behind Current Trends in the Catalyst Supplier Market?

The catalyst supplier sector has evolved significantly over the past few decades. Initially dominated by a few key players, the market has expanded with the entry of numerous specialized suppliers, particularly from emerging economies. This diversification has led to increased competition and innovation, allowing buyers more options and driving down prices.

Historically, the focus was primarily on performance and cost-efficiency. However, as environmental concerns have risen, the industry has shifted toward sustainable practices. This evolution reflects broader societal changes where both consumers and businesses are increasingly prioritizing ethical considerations in their purchasing decisions.

A stock image related to catalyst supplier.

Understanding this historical context helps B2B buyers appreciate the current landscape and anticipate future trends, enabling them to make informed sourcing decisions that align with their long-term strategic goals.

Frequently Asked Questions (FAQs) for B2B Buyers of catalyst supplier

-

How do I select the right catalyst supplier for my business needs?

Choosing the right catalyst supplier involves several critical steps. First, assess your specific application requirements, including the type of reactions you are conducting and the performance characteristics you need. Research potential suppliers’ expertise and track record in your industry, focusing on their product offerings and technological capabilities. Additionally, request samples for testing and consider conducting site visits to evaluate their production facilities. Finally, seek references from existing customers to gain insights into reliability, support, and service levels. -

What are the key factors to consider when evaluating catalyst quality?

When evaluating catalyst quality, several factors should be prioritized. Look for certifications and compliance with international standards, such as ISO or ASTM. Performance metrics, including activity, selectivity, and durability, are essential; request data sheets or independent test results. Additionally, consider the supplier’s quality assurance processes and their ability to provide documentation for batch traceability. Lastly, assess the consistency of their products over time, as this can significantly impact your operations. -

What customization options should I expect from a catalyst supplier?

Many catalyst suppliers offer customization options tailored to specific client needs. This may include variations in catalyst composition, particle size, and shape, as well as modifications to enhance selectivity or activity for particular reactions. Discuss your requirements in detail with potential suppliers to explore the extent of their customization capabilities. It’s also beneficial to inquire about their R&D support for developing new formulations that align with your operational goals. -

What are the typical minimum order quantities (MOQs) for catalysts?

Minimum order quantities (MOQs) can vary significantly among catalyst suppliers based on their production capabilities and the type of catalyst. Generally, MOQs may range from a few kilograms for specialized catalysts to several tons for bulk products. Always clarify MOQs upfront during negotiations to avoid any misunderstandings. Additionally, consider the impact of MOQs on your inventory management and cash flow, especially if you’re working with limited budgets or require infrequent supplies. -

What payment terms should I negotiate with my catalyst supplier?

Negotiating payment terms is crucial in establishing a successful supplier relationship. Common terms include payment upfront, net 30, or even longer periods depending on the order size and supplier trust. Ensure to discuss options for partial payments upon order confirmation and the balance upon delivery. It’s also advisable to evaluate the supplier’s flexibility in terms of payment methods, including bank transfers, credit terms, or letters of credit, especially for international transactions. -

How can I ensure quality assurance in catalyst procurement?

To ensure quality assurance in catalyst procurement, start by requesting detailed documentation from suppliers, including product specifications, quality control protocols, and any relevant certifications. Consider suppliers that conduct third-party testing to validate their claims. Establish a clear communication channel for addressing quality issues and ensure that there is a robust return policy in place. It may also be beneficial to implement a sampling process to test the catalyst before full-scale procurement. -

What are the logistics considerations for importing catalysts?

When importing catalysts, logistics play a crucial role in ensuring timely delivery and compliance with regulations. Understand the shipping methods available and their associated costs, including freight, insurance, and customs duties. Familiarize yourself with the import regulations specific to your country, as well as any documentation required for customs clearance. It’s also wise to partner with logistics providers experienced in handling chemical products to mitigate risks during transit. -

How do I handle potential supply chain disruptions in catalyst sourcing?

To manage potential supply chain disruptions in catalyst sourcing, diversification of suppliers is key. Establish relationships with multiple suppliers across different regions to reduce dependency on a single source. Implement a robust inventory management system that includes safety stock levels to cushion against delays. Additionally, stay informed about global market trends and geopolitical issues that may affect supply chains, and develop contingency plans for alternative sourcing strategies if necessary.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for catalyst supplier

In today’s competitive landscape, the significance of strategic sourcing for catalyst suppliers cannot be overstated. By prioritizing supplier partnerships and understanding regional market dynamics, international B2B buyers can enhance their procurement strategies. Buyers from Africa, South America, the Middle East, and Europe should focus on identifying suppliers that not only meet quality standards but also align with their sustainability goals. This alignment is crucial in fostering long-term relationships that yield cost-effective solutions and reliable supply chains.

What should B2B buyers consider when selecting catalyst suppliers? The answer lies in evaluating suppliers based on their technological capabilities, innovation in product development, and responsiveness to market demands. Buyers are encouraged to leverage digital tools for supply chain visibility and risk management, ensuring that their sourcing decisions are informed and strategic.

Looking ahead, the catalyst industry is poised for growth, driven by advancements in technology and increasing environmental regulations. It is essential for international buyers to remain agile and proactive in their sourcing strategies. Embrace collaboration, seek out innovative suppliers, and stay informed about market trends to secure your position in this evolving landscape. Your commitment to strategic sourcing will not only enhance operational efficiency but also contribute to sustainable business growth.