Discover Top CD Suppliers: Your Guide to Quality Choices (2025)

Introduction: Navigating the Global Market for cd supplier

In the ever-evolving landscape of global trade, sourcing reliable CD suppliers can present a significant challenge for international B2B buyers. Whether you are in South Africa, Mexico, or the Middle East, navigating the complexities of supplier relationships, product quality, and pricing can be daunting. This guide aims to simplify the process of sourcing CD suppliers by providing a thorough exploration of various types of CDs, their applications across different industries, and the critical steps involved in supplier vetting.

Understanding the nuances of pricing and cost structures is essential for making informed purchasing decisions, especially for businesses looking to maximize their ROI while ensuring product quality. By delving into these aspects, this guide empowers B2B buyers to identify trustworthy suppliers and negotiate favorable terms that align with their business goals.

With a focus on actionable insights tailored for international buyers from Africa, South America, Europe, and the Middle East, this comprehensive resource will equip you with the necessary tools and knowledge to confidently engage with suppliers. From assessing supplier credentials to understanding market trends, you’ll find valuable information that can help streamline your procurement process and enhance your competitive edge in the global market.

Understanding cd supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bulk CD Suppliers | Offer large quantities at discounted rates | Manufacturing, distribution, and retail | Pros: Cost-effective, consistent supply. Cons: Minimum order quantities may be high. |

| Custom CD Suppliers | Provide tailored solutions such as branding | Promotional products, corporate gifts | Pros: Unique branding options, high customization. Cons: Higher costs, longer lead times. |

| Digital CD Suppliers | Focus on digital distribution and replication | Software distribution, digital media | Pros: Fast delivery, lower storage needs. Cons: Limited physical product appeal. |

| Eco-friendly CD Suppliers | Use sustainable materials and processes | Green businesses, environmentally conscious brands | Pros: Positive brand image, compliance with regulations. Cons: Potentially higher costs. |

| Local CD Suppliers | Operate within specific geographic regions | Local businesses, niche markets | Pros: Faster shipping, local support. Cons: Limited product range compared to larger suppliers. |

What Are the Characteristics of Bulk CD Suppliers?

Bulk CD suppliers are characterized by their ability to provide large quantities of CDs at competitive prices. They cater primarily to businesses that require a consistent and reliable supply of CDs for various applications, such as manufacturing and retail. When considering bulk suppliers, B2B buyers should evaluate their minimum order requirements, as these can be substantial, impacting cash flow and storage. Bulk suppliers are ideal for companies looking to reduce costs through economies of scale.

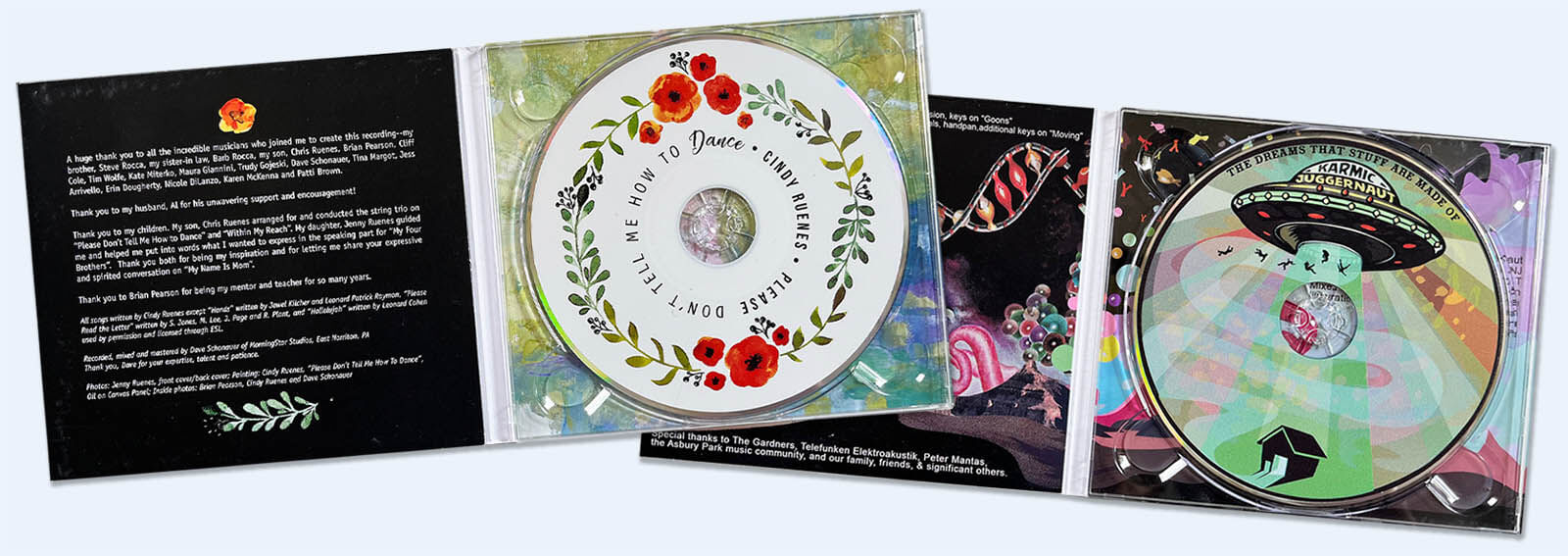

A stock image related to cd supplier.

How Do Custom CD Suppliers Cater to Unique Needs?

Custom CD suppliers specialize in creating CDs that meet specific branding and design requirements. They allow businesses to customize labels, packaging, and even the content of the CDs for promotional purposes. This type of supplier is particularly beneficial for companies in marketing and advertising sectors. However, buyers should be prepared for potentially higher costs and longer lead times, as customization often requires more resources and production time.

What Are the Advantages of Digital CD Suppliers?

Digital CD suppliers focus on the digital replication and distribution of CDs, making them a popular choice for software companies and digital media producers. Their services typically include fast turnaround times and lower storage requirements since they often deal with digital files rather than physical inventory. B2B buyers should consider the implications of digital-only products, which may not appeal to all consumer segments, especially those seeking tangible products.

Why Choose Eco-friendly CD Suppliers?

A stock image related to cd supplier.

Eco-friendly CD suppliers prioritize sustainability by using recyclable materials and environmentally responsible production processes. This approach is appealing to businesses that want to enhance their brand image and comply with environmental regulations. While these suppliers may charge a premium for their products, the long-term benefits include attracting environmentally conscious customers and potentially reducing regulatory risks. B2B buyers should weigh the cost against the potential for increased brand loyalty.

What Are the Benefits of Local CD Suppliers?

Local CD suppliers operate within specific regions, offering businesses the advantage of faster shipping and personalized service. This is particularly beneficial for local businesses and niche markets that require quick turnaround times. However, B2B buyers should consider the limited product range that local suppliers may have compared to larger, national suppliers. Overall, local suppliers can provide significant value in terms of convenience and support.

Related Video: The Genius Behind Bach’s Goldberg Variations: CANONS

Key Industrial Applications of cd supplier

| Industry/Sector | Specific Application of cd supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics Manufacturing | Supply of cadmium for batteries | Enhanced battery performance and longevity | Ensure compliance with local regulations and quality standards. |

| Renewable Energy | Use in thin-film solar cells | Improved energy conversion efficiency | Consider sourcing from suppliers with sustainable practices. |

| Aerospace | Production of high-performance alloys | Increased durability and reduced weight | Verify certifications and material traceability. |

| Chemical Industry | Catalyst in chemical reactions | Enhanced reaction rates and product yields | Assess supplier’s capability to meet specific chemical purity requirements. |

| Automotive | Use in high-strength steel production | Improved vehicle safety and fuel efficiency | Evaluate the supplier’s ability to deliver consistent quality and volume. |

How is Cadmium Used in Electronics Manufacturing?

In the electronics manufacturing sector, cadmium is primarily used in the production of rechargeable batteries, particularly nickel-cadmium (NiCd) batteries. These batteries are valued for their reliability and longevity in powering various devices, from portable electronics to power tools. For international buyers, especially in regions like Africa and South America where battery demand is growing, it is essential to source cadmium that complies with local environmental regulations. Buyers should prioritize suppliers who can provide certifications for both product quality and environmental safety.

What Role Does Cadmium Play in Renewable Energy?

Cadmium is a crucial component in the production of thin-film solar cells, which are known for their lightweight and flexibility. This application is particularly beneficial for solar panel manufacturers looking to enhance energy conversion efficiency. International buyers in Europe, where renewable energy initiatives are robust, must ensure that their suppliers adhere to sustainability practices and provide cadmium sourced responsibly. Understanding the supplier’s production methods and environmental impact is vital for compliance with stringent European regulations.

How is Cadmium Utilized in the Aerospace Industry?

In the aerospace sector, cadmium is used in the production of high-performance alloys that are essential for aircraft components. These alloys provide increased durability and reduced weight, which are critical for enhancing fuel efficiency and safety in aviation. For B2B buyers from the Middle East and Europe, it is crucial to verify that suppliers possess the necessary certifications and quality assurance processes to meet aerospace standards. Establishing a relationship with suppliers who have a proven track record in aerospace applications can significantly mitigate risks.

What is the Importance of Cadmium in the Chemical Industry?

Cadmium serves as an effective catalyst in various chemical reactions, improving reaction rates and product yields. This application is particularly valuable for chemical manufacturers aiming to optimize production processes. International buyers should assess the supplier’s ability to meet specific purity requirements, as contaminants can adversely affect chemical reactions. Sourcing from reputable suppliers who can guarantee high-quality cadmium is essential for maintaining production efficiency and product integrity.

How is Cadmium Applied in the Automotive Sector?

In the automotive industry, cadmium is utilized in the production of high-strength steel, which enhances vehicle safety and fuel efficiency. This application is increasingly important as manufacturers strive to meet safety regulations and fuel economy standards. Buyers from regions like South Africa and Europe should evaluate suppliers based on their ability to deliver consistent quality and volume, as fluctuations can impact production schedules. Additionally, understanding the supplier’s compliance with automotive industry standards is critical for ensuring the reliability of the sourced materials.

Related Video: Uses and Gratifications Theory

3 Common User Pain Points for ‘cd supplier’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges with CD Suppliers

The Problem: B2B buyers often face significant challenges when it comes to ensuring the quality of CDs from suppliers. This is particularly true for businesses in emerging markets like South Africa and Mexico, where the standards of production may vary. Poor quality CDs can lead to defective products, resulting in returns, dissatisfied customers, and ultimately a damaged reputation. Buyers may also struggle to find reliable suppliers who can consistently meet quality requirements without extensive oversight.

The Solution: To overcome quality assurance challenges, B2B buyers should establish a rigorous vetting process for potential CD suppliers. This involves requesting samples and conducting quality audits before entering into a contractual agreement. Buyers should also inquire about the supplier’s quality control processes, certifications, and previous client references. Additionally, implementing a quality assurance agreement that outlines expectations, inspection protocols, and penalties for non-compliance can help ensure that suppliers maintain high standards. Regular communication with suppliers about quality expectations and feedback on product performance will also foster a collaborative relationship focused on continuous improvement.

Scenario 2: Overcoming Communication Barriers with International CD Suppliers

The Problem: International B2B transactions often come with communication barriers, especially when dealing with suppliers from different cultural backgrounds or languages. This can lead to misunderstandings regarding product specifications, delivery timelines, and payment terms. For buyers in regions like the Middle East or South America, where nuances in language and business etiquette vary, these barriers can impede effective collaboration and lead to costly delays.

The Solution: To mitigate communication issues, B2B buyers should prioritize establishing clear and open lines of communication from the outset. Utilizing professional translation services can ensure that language differences do not hinder negotiations or order specifications. Buyers should also develop a comprehensive project brief that includes detailed descriptions of product requirements, timelines, and terms of service, which can serve as a reference throughout the partnership. Regular check-ins via video calls or collaborative platforms can help maintain alignment and facilitate a deeper understanding of expectations. Finally, fostering a relationship built on trust and transparency will encourage suppliers to communicate proactively about any challenges they encounter.

Scenario 3: Managing Lead Time and Delivery Issues with CD Suppliers

The Problem: Lead time and delivery reliability are critical concerns for B2B buyers sourcing CDs, particularly when they operate within tight schedules or rely on just-in-time inventory systems. In regions like Europe, where market competition is fierce, delays can result in lost sales opportunities and strained relationships with end customers. Buyers may find that suppliers do not always provide accurate lead times, or they may encounter unexpected delays due to logistical challenges.

The Solution: To address lead time and delivery issues, buyers should conduct thorough research on potential suppliers’ logistics capabilities and delivery performance history. Establishing a clear timeline for production and delivery at the outset is crucial; buyers should request detailed production schedules and shipping timelines. Incorporating flexibility into contracts—such as penalties for missed deadlines—can incentivize suppliers to adhere to agreed-upon timelines. Additionally, working with suppliers who have robust logistics partners or those located closer to the buyer can reduce transit times and enhance reliability. Implementing a tracking system for shipments can also provide real-time updates and allow buyers to anticipate any potential delays, enabling them to adjust their operations accordingly.

Strategic Material Selection Guide for cd supplier

When selecting materials for a CD supplier, it is essential to understand the properties, advantages, disadvantages, and specific considerations that each material presents. This knowledge not only aids in optimizing product performance but also ensures compliance with regional standards and buyer preferences.

What Are the Key Properties of Common Materials Used in CD Supply?

1. Polycarbonate (PC)

Polycarbonate is a widely used material in the production of CDs due to its excellent optical clarity and impact resistance. It typically has a high-temperature rating of around 120°C and offers good resistance to UV light and various chemicals.

Pros & Cons:

– Advantages: Polycarbonate is lightweight, durable, and can be easily molded into complex shapes, making it suitable for various designs.

– Disadvantages: It can be more expensive than other plastics, and while it has good scratch resistance, it is not entirely scratch-proof.

Impact on Application: Polycarbonate’s optical clarity makes it ideal for data storage applications, ensuring high-quality data retrieval.

Considerations for International Buyers: Buyers should ensure that the polycarbonate used complies with international standards such as ASTM D256 for impact resistance and ASTM D635 for flammability, particularly in regions with stringent safety regulations.

2. Polyvinyl Chloride (PVC)

PVC is another common material used in CD production, known for its versatility and cost-effectiveness. It has a temperature rating of approximately 60°C and is resistant to various chemicals.

Pros & Cons:

– Advantages: PVC is relatively low-cost and easy to manufacture, making it an attractive option for mass production.

– Disadvantages: It has lower durability compared to polycarbonate and can become brittle over time, especially under UV exposure.

Impact on Application: PVC is suitable for applications where cost is a significant factor, but it may not perform as well in high-stress environments.

Considerations for International Buyers: Buyers in regions such as Africa and South America should be aware of environmental regulations regarding PVC, as its production and disposal can have ecological impacts.

3. Acrylonitrile Butadiene Styrene (ABS)

ABS is a thermoplastic that combines strength and impact resistance, making it a suitable choice for CD packaging and cases. It has a temperature rating of around 80°C and offers good chemical resistance.

Pros & Cons:

– Advantages: ABS is robust, lightweight, and can be easily colored, allowing for various aesthetic options.

– Disadvantages: It is less transparent than polycarbonate, which may affect optical performance in some applications.

Impact on Application: ABS is often used for CD cases where durability and aesthetics are crucial, though it may not be the best choice for optical discs themselves.

Considerations for International Buyers: Buyers should ensure that ABS complies with relevant standards such as ISO 527 for tensile properties, particularly in Europe where compliance with EU regulations is critical.

4. Glass

While less common, glass is sometimes used in high-end applications due to its excellent optical properties and durability. It can withstand high temperatures and is resistant to scratching.

Pros & Cons:

– Advantages: Glass offers superior clarity and durability, making it ideal for high-performance applications.

– Disadvantages: It is heavier and more fragile than plastic alternatives, which can complicate shipping and handling.

Impact on Application: Glass is suitable for specialized applications where optical quality is paramount, such as in archival storage.

Considerations for International Buyers: Buyers should consider the fragility of glass and ensure compliance with shipping regulations, especially in regions with strict import guidelines.

Summary Table of Material Selection for CD Supplier

| Material | Typical Use Case for cd supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Optical discs | Excellent optical clarity and impact resistance | Higher cost than other plastics | High |

| Polyvinyl Chloride | CD packaging | Cost-effective and versatile | Lower durability and brittleness | Low |

| Acrylonitrile Butadiene Styrene | CD cases | Strong and lightweight | Less transparent than polycarbonate | Medium |

| Glass | High-end optical discs | Superior clarity and durability | Heavier and more fragile | High |

This guide provides a comprehensive overview of the materials used in CD supply, highlighting the importance of selecting the right material based on performance, cost, and compliance with international standards. By understanding these factors, international B2B buyers can make informed decisions that align with their specific needs and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for cd supplier

What Are the Main Stages of the Manufacturing Process for CD Suppliers?

The manufacturing process for compact discs (CDs) involves several crucial stages that ensure the final product meets industry standards and customer expectations. Understanding these stages can help B2B buyers from regions like Africa, South America, the Middle East, and Europe make informed decisions when selecting suppliers.

1. Material Preparation: What Materials Are Used in CD Manufacturing?

The first step in the manufacturing process is material preparation. CDs are primarily made from polycarbonate plastic, which is used for the disc substrate. Additionally, a reflective layer, typically made of aluminum, is applied, followed by a protective lacquer coating.

- Polycarbonate Resin: It’s essential to select high-quality polycarbonate resin to avoid defects such as warping or poor transparency.

- Reflective Layer: The choice of aluminum or alternative materials affects the disc’s durability and data integrity.

- Lacquer Coating: This layer is critical for protecting the reflective layer and ensuring the longevity of the CD.

B2B buyers should inquire about the sourcing and quality of these materials to ensure they meet industry standards.

2. Forming: How Are CDs Shaped and Structured?

In the forming stage, the prepared materials are molded into the shape of a disc. This involves injection molding, where molten polycarbonate is injected into a mold that shapes it into a CD.

- Injection Molding Process: This process requires precision to ensure that each disc is uniform in size and shape. Variations can lead to issues during playback.

- Quality Control During Molding: It is crucial to monitor the temperature and pressure during molding to prevent defects. Suppliers should provide data on their molding processes.

Buyers should consider suppliers that use advanced molding technologies to guarantee high-quality outputs.

3. Assembly: What Steps Are Involved in Assembling CDs?

Once the discs are formed, the next step is assembly, which includes the application of the reflective layer and the protective lacquer.

- Reflective Layer Application: This is typically done using a vacuum deposition process that ensures even coverage across the disc surface.

- Lacquer Coating: After the reflective layer is applied, the lacquer is spun onto the disc, which is then cured under ultraviolet light.

Understanding the assembly techniques can help buyers evaluate the efficiency and reliability of potential suppliers.

4. Finishing: How Is the Final Product Prepared for Distribution?

The final stage involves finishing processes, which may include printing labels and packaging.

- Label Printing: High-quality printing techniques ensure that labels are durable and resistant to fading. Suppliers should use methods that adhere to industry standards.

- Packaging: Proper packaging is critical to prevent damage during shipping. Buyers should inquire about the supplier’s packaging methods and materials.

What International Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is paramount in the manufacturing of CDs. Suppliers should adhere to international standards to ensure product consistency and safety.

ISO 9001: Why Is This Standard Important for CD Suppliers?

ISO 9001 certification is an essential indicator of a supplier’s commitment to quality management systems. It involves ongoing audits and improvement processes to ensure that products consistently meet customer and regulatory requirements.

- Benefits of ISO Certification: B2B buyers can trust that ISO-certified suppliers have established processes to manage quality, which can significantly reduce risks associated with product defects.

CE Marking and Other Industry-Specific Certifications: What Do They Mean?

In addition to ISO 9001, suppliers may need to comply with regional certifications, such as CE marking in Europe, which indicates conformity with health, safety, and environmental protection standards.

- Understanding CE Marking: For buyers in Europe, ensuring that suppliers have CE marking is essential for compliance with local laws and regulations.

- API Certification: For specialized CDs, such as those used in medical or industrial applications, API certification may be required.

How to Verify Supplier Quality Control Processes?

B2B buyers must implement due diligence when verifying the quality control processes of potential suppliers. Here are several methods to ensure that suppliers maintain high standards.

What Are the Key QC Checkpoints in CD Manufacturing?

Quality control checkpoints during the manufacturing process include:

- Incoming Quality Control (IQC): Inspection of raw materials before production.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages.

- Final Quality Control (FQC): Comprehensive testing of the finished product before shipment.

These checkpoints help in identifying defects early, thereby reducing waste and ensuring product reliability.

What Common Testing Methods Are Used for CDs?

Common testing methods include:

- Playback Testing: Ensures that the discs can be read by standard CD players without errors.

- Durability Testing: Checks the physical resilience of the discs against scratches and environmental factors.

- Data Integrity Testing: Verifies that the data stored on the CD is accurate and retrievable.

B2B buyers should request detailed testing reports from suppliers to confirm these processes are in place.

How Can Buyers Conduct Supplier Audits and Inspections?

Conducting supplier audits and inspections is crucial for verifying that quality control measures are effective. Buyers can consider the following approaches:

- On-Site Audits: Visiting the supplier’s facility to assess their manufacturing processes and quality assurance practices.

- Third-Party Inspections: Engaging independent inspectors to evaluate the supplier’s compliance with international standards and regulations.

- Reviewing Quality Reports: Requesting access to quality control reports and certifications can provide insights into the supplier’s performance and reliability.

Conclusion: What Should B2B Buyers Look for in a CD Supplier?

For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance standards for CD suppliers is crucial. By evaluating suppliers based on their manufacturing stages, adherence to international standards, and quality control practices, buyers can make informed decisions that align with their business needs.

Investing time in supplier evaluation not only mitigates risks but also enhances the overall quality of products offered to end customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cd supplier’

To successfully procure a reliable CD supplier, international B2B buyers must follow a structured approach. This checklist aims to streamline the sourcing process, ensuring that you select a supplier who meets your business needs while maintaining quality and compliance standards.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the CDs you require. This includes the type of CD (e.g., CD-R, CD-RW), capacity (e.g., standard 700MB), and any additional features such as printability or packaging options. Having precise specifications helps narrow down potential suppliers who can meet your exact needs.

Step 2: Conduct Market Research for Suppliers

Engage in thorough market research to identify potential CD suppliers across your target regions, such as Africa, South America, the Middle East, and Europe. Utilize online platforms, trade shows, and industry associations to gather a list of reputable suppliers. This step is crucial as it sets the foundation for your supplier selection process and helps you understand the competitive landscape.

Step 3: ✅ Verify Supplier Certifications

Before proceeding with a supplier, ensure they possess the necessary certifications that guarantee quality and compliance. Look for ISO certifications, environmental certifications, and industry-specific standards. Verifying these credentials not only safeguards your business against subpar products but also enhances your company’s credibility.

Step 4: Request Samples and Test Quality

Always request samples from potential suppliers to evaluate the quality of their CDs firsthand. Testing for durability, clarity, and performance is vital, particularly if you plan to use these CDs for critical business applications. Assessing samples allows you to make informed decisions and mitigate risks associated with poor quality.

Step 5: Evaluate Supplier Production Capacity and Lead Times

Assess the production capacity of the suppliers to ensure they can meet your volume demands within your required time frames. Inquire about their lead times and any potential bottlenecks in their manufacturing process. Understanding their capabilities helps prevent future supply chain disruptions and ensures timely delivery of your orders.

Step 6: Check References and Past Performance

Request references from other clients who have worked with the supplier, particularly those in your industry or region. This insight into their past performance, reliability, and customer service will help gauge whether they are a good fit for your needs. A supplier with a proven track record is more likely to meet your expectations.

Step 7: Negotiate Terms and Conditions

Once you have selected a preferred supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Ensure that all agreements are documented clearly to avoid misunderstandings later. Strong negotiation can lead to better pricing and terms, ultimately benefiting your bottom line.

By following this checklist, international B2B buyers can navigate the complexities of sourcing CD suppliers effectively, ensuring they secure high-quality products that align with their business objectives.

Comprehensive Cost and Pricing Analysis for cd supplier Sourcing

What Are the Key Cost Components in CD Supplier Sourcing?

When sourcing from CD suppliers, understanding the cost structure is crucial for international B2B buyers. The primary cost components typically include:

-

Materials: The quality and type of raw materials used in CD production significantly influence costs. For instance, higher-quality substrates or specialized coatings will increase the material cost.

-

Labor: Labor costs vary depending on the supplier’s location and the skill level required for production. Regions with lower labor costs may offer more competitive pricing but could compromise on quality.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and factory operations. Efficient suppliers often have lower overhead costs, which can reflect in their pricing.

-

Tooling: Initial setup costs for molds and machinery can be significant, especially for custom CD designs. Understanding these costs is vital, particularly for buyers with specific requirements.

-

Quality Control (QC): Ensuring that products meet quality standards incurs additional costs. Suppliers with rigorous QC processes may charge more but can provide better reliability.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location and the destination. Consideration of freight costs, insurance, and customs duties is essential.

-

Margin: Suppliers typically add a profit margin to their costs. Understanding how this margin correlates with the supplier’s value proposition can guide your sourcing decision.

How Do Price Influencers Impact CD Supplier Sourcing?

Several factors can influence the pricing of CDs from suppliers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to discounts per unit. Negotiating favorable terms based on projected needs can significantly reduce costs.

-

Specifications and Customization: Custom CDs with specific artwork or features typically incur higher costs. Buyers should assess whether customization adds value or if standard options suffice.

-

Materials: The choice of materials can greatly affect the price. Higher-grade materials or eco-friendly options may come at a premium but can appeal to specific market segments.

-

Quality and Certifications: Suppliers with certifications (e.g., ISO) may charge more due to their commitment to quality and sustainability. Buyers should weigh the benefits of these certifications against potential cost increases.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium, but their reliability can mitigate risks associated with supply chain disruptions.

-

Incoterms: Understanding the implications of Incoterms (e.g., FOB, CIF) is essential as they dictate the responsibilities of buyers and suppliers regarding shipping costs and risk transfer.

What Are Effective Buyer Tips for Cost-Efficiency in CD Supplier Sourcing?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, here are actionable insights:

-

Negotiate: Always negotiate terms, including pricing, delivery schedules, and payment terms. Building a strong relationship with suppliers can lead to better deals.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the total cost, including shipping, tariffs, and potential costs related to delays or quality issues.

-

Research Pricing Nuances: Different regions may have varying pricing structures due to local economic factors. Understanding these nuances can help you identify competitive suppliers.

-

Leverage Volume Discounts: If your business can project consistent demand, leverage this to negotiate better pricing or terms with suppliers.

-

Perform Due Diligence: Always assess potential suppliers for reliability and quality. Request samples and verify their certifications to ensure they meet your standards.

-

Stay Informed on Market Trends: Keeping abreast of industry trends and shifts in material costs can provide leverage during negotiations and sourcing decisions.

Disclaimer on Indicative Prices

Pricing for CD supplier sourcing can fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. Always seek updated quotes and conduct thorough market research to ensure you are making informed purchasing decisions.

Alternatives Analysis: Comparing cd supplier With Other Solutions

When considering solutions for your business needs, it’s crucial to evaluate all available alternatives alongside the primary offering. In this analysis, we will compare ‘cd supplier’ with two viable alternatives: ‘digital distribution platforms’ and ‘local print services.’ This comparison will highlight performance, cost, ease of implementation, maintenance, and best use cases, providing actionable insights for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

Comparison Table

| Comparison Aspect | Cd Supplier | Digital Distribution Platforms | Local Print Services |

|---|---|---|---|

| Performance | High-quality physical CDs | Instant delivery, variable quality | Variable quality, longer turnaround |

| Cost | Moderate (bulk discounts) | Subscription-based fees or per sale | Generally higher due to materials |

| Ease of Implementation | Moderate (requires setup) | Easy (mostly online) | Moderate (depends on order size) |

| Maintenance | Low (once set up, minimal) | Low (platform manages updates) | Moderate (inventory management required) |

| Best Use Case | Large volume physical sales | Digital products and streaming | Small runs or localized sales |

What Are the Pros and Cons of Digital Distribution Platforms?

Digital distribution platforms, such as Bandcamp or DistroKid, offer a compelling alternative for businesses looking to distribute their content electronically.

Pros:

– Instant Delivery: Products can be delivered to customers within minutes, enhancing customer satisfaction.

– Lower Overhead Costs: Eliminates the need for physical storage, shipping, and inventory management.

– Global Reach: Easily accessible to international buyers without additional shipping costs.

Cons:

– Quality Variability: The quality of digital downloads can be inconsistent, depending on the platform used.

– Dependence on Internet Connectivity: Requires reliable internet access, which might be a limitation in certain regions.

How Do Local Print Services Compare to ‘cd supplier’?

Local print services provide an alternative for businesses that need physical products quickly and on a smaller scale.

Pros:

– Customization: Allows for tailored products that meet specific customer needs.

– Quick Turnaround: Local providers can often produce and deliver products faster than global suppliers.

Cons:

– Higher Costs: The per-unit cost is typically higher due to materials and labor.

– Inventory Management Challenges: Businesses must manage inventory, which can lead to excess or shortages.

Conclusion: How Can B2B Buyers Choose the Right Solution?

For B2B buyers, the choice between ‘cd supplier,’ digital distribution platforms, and local print services hinges on specific business needs and customer expectations. If your business relies heavily on physical products and aims for bulk sales, ‘cd supplier’ is likely the most efficient choice. Conversely, if your audience is shifting towards digital consumption, investing in a digital distribution platform may yield better returns. For businesses that require flexibility and rapid response times, local print services can provide the needed customization. Ultimately, assessing your operational capabilities, budget, and target market will guide you to the right solution that aligns with your strategic goals.

Essential Technical Properties and Trade Terminology for cd supplier

What Are the Key Technical Properties of a CD Supplier?

When engaging with a CD supplier, understanding the essential technical properties is crucial for ensuring product quality and compatibility with your needs. Below are several critical specifications to consider:

1. Material Grade: What Material Should You Expect?

The material grade refers to the quality of the raw materials used in producing CDs. Common grades include polycarbonate for the disc substrate, which should meet industry standards like ISO 9001. High-grade materials ensure durability and longevity, reducing the risk of data loss or physical damage. For B2B buyers, selecting a supplier that uses superior materials can translate into better product performance and customer satisfaction.

2. Tolerance: Why Is Precision Important?

Tolerance indicates the allowable deviation from specified dimensions during manufacturing. For CDs, tolerances in thickness and diameter are critical, as even minor discrepancies can affect compatibility with players and drives. A standard tolerance for CDs is ±0.1 mm. Understanding tolerance is vital for B2B buyers to ensure that the CDs will function flawlessly in their intended applications, thus minimizing return rates and warranty claims.

3. Data Capacity: How Much Information Can It Hold?

Data capacity, typically measured in megabytes (MB) or gigabytes (GB), determines how much information a CD can store. Standard CDs typically hold 700 MB, while DVDs and Blu-rays offer larger capacities. Knowing the data capacity helps businesses select the right media for their specific needs, whether for software distribution, data archiving, or multimedia storage.

4. Durability and Lifespan: How Long Will the Product Last?

Durability refers to the physical resilience of the CD against scratches, environmental factors, and general wear and tear. A high-quality CD should last 10 years or more if properly stored. For B2B buyers, investing in durable products reduces the frequency of replacements and enhances the overall value of the purchase.

5. Surface Finish: What Affects Readability?

The surface finish of a CD can impact its readability and compatibility with various devices. Common finishes include glossy and matte. Glossy finishes often provide better aesthetics but may be more prone to scratches. B2B buyers should assess the intended use of the CDs to choose an appropriate finish that balances durability with visual appeal.

What Are Common Trade Terms You Should Know When Dealing with CD Suppliers?

In addition to understanding technical properties, familiarizing yourself with industry terminology can facilitate smoother transactions and negotiations. Here are some essential terms:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to companies that produce components that are used in the products of another company. In the context of CDs, an OEM supplier provides discs that are branded and sold by another company. Understanding OEM relationships can help B2B buyers identify potential suppliers who can meet specific branding requirements.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ indicates the smallest quantity of product that a supplier is willing to sell. For CD suppliers, MOQs can vary significantly and affect your purchasing strategy. Knowing the MOQ helps businesses plan their inventory and budget accordingly, ensuring they meet supplier requirements without overcommitting resources.

3. RFQ (Request for Quotation): How Do You Get Pricing Information?

An RFQ is a document that a buyer sends to suppliers to request pricing for specific products. Including details such as quantity, specifications, and delivery timelines helps suppliers provide accurate quotes. This process is essential for B2B buyers to compare costs effectively and make informed purchasing decisions.

4. Incoterms: What Are They and Why Do They Matter?

Incoterms (International Commercial Terms) are a set of predefined international rules that clarify the responsibilities of buyers and sellers in shipping goods. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) outline who bears the risk and costs at various stages of transport. Familiarity with Incoterms enables B2B buyers to negotiate better shipping agreements and understand their obligations.

5. Lead Time: How Long Will It Take?

Lead time refers to the amount of time from placing an order to receiving the products. Understanding lead times is crucial for B2B buyers to plan their production schedules and inventory levels. Longer lead times can affect project timelines, so it’s essential to clarify these details upfront with suppliers.

By grasping these technical specifications and industry terms, B2B buyers can make more informed decisions, ensuring that they select the right CD suppliers to meet their business needs.

Navigating Market Dynamics and Sourcing Trends in the cd supplier Sector

What Are the Current Market Dynamics and Key Trends in the CD Supplier Sector?

The global CD supplier market is experiencing a transformative phase driven by technological advancements and shifting consumer preferences. As international B2B buyers, especially from Africa, South America, the Middle East, and Europe, navigate these dynamics, several key trends have emerged. Firstly, the integration of digital tools such as e-commerce platforms and AI-driven analytics is revolutionizing sourcing strategies. These technologies enable buyers to efficiently compare suppliers, manage orders, and streamline logistics, enhancing overall procurement efficiency.

Moreover, sustainability is becoming a central theme in sourcing decisions. Buyers are increasingly looking for suppliers who prioritize environmentally friendly practices. The rise of digital supply chain management solutions allows for better tracking of sustainability metrics, enabling buyers to make informed choices. Additionally, there is a growing demand for transparency in supply chains, with buyers seeking detailed information on supplier practices, certifications, and sourcing origins. This trend is particularly pronounced in regions such as Europe, where regulatory frameworks are tightening around sustainability and ethical sourcing.

Another significant dynamic is the localization of supply chains. Given the disruptions caused by global events, including the pandemic and geopolitical tensions, many B2B buyers are reconsidering their sourcing strategies to favor local suppliers. This shift not only reduces transportation costs but also mitigates risks associated with international logistics.

How Is Sustainability and Ethical Sourcing Influencing CD Suppliers?

The importance of sustainability in the CD supplier sector cannot be overstated. Environmental impact concerns are leading buyers to prioritize suppliers who demonstrate a commitment to ethical sourcing practices. This includes the use of eco-friendly materials, waste reduction strategies, and adherence to fair labor practices. For instance, suppliers that utilize recycled or sustainably sourced materials are becoming increasingly attractive to buyers who are conscious of their carbon footprint.

Incorporating sustainability into the supply chain is not just a trend; it is a necessity for long-term viability. Certifications such as ISO 14001 (Environmental Management) and Fair Trade are becoming essential for suppliers aiming to attract international buyers. These certifications provide assurance that suppliers adhere to recognized environmental and ethical standards, which is particularly critical for buyers in Europe and North America.

Furthermore, the demand for ‘green’ certifications is influencing product development within the CD supplier sector. Suppliers are innovating by developing materials that are both high-quality and environmentally friendly, catering to buyers who are looking for sustainable options without compromising on performance.

What Is the Brief Evolution and History of the CD Supplier Sector?

The CD supplier sector has evolved significantly since the inception of compact discs in the late 20th century. Initially dominated by a few key players, the market has diversified over the years with the advent of digital media and changing consumption patterns. The shift towards digital formats in the early 2000s posed challenges for traditional CD suppliers, forcing them to adapt by enhancing production efficiencies and exploring new business models.

In recent years, the resurgence of physical media among niche markets, such as collectors and audiophiles, has revitalized the sector. This evolution has led to increased competition and innovation among suppliers, particularly in areas like customized packaging and limited-edition releases. As international B2B buyers engage with this sector, understanding its historical context helps illuminate current trends and the importance of sustainability and ethical sourcing in shaping future business strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of cd supplier

- How do I choose the right CD supplier for my business needs?

Selecting the right CD supplier involves assessing several key factors. Start by evaluating their product quality, production capabilities, and industry reputation. Request samples to gauge the quality of their CDs. Additionally, consider their experience in your specific market, as suppliers familiar with regional demands can better meet your needs. Finally, analyze their customer service responsiveness and support, as a reliable supplier can significantly impact your business operations.

-

What are the common minimum order quantities (MOQs) for CD suppliers?

Minimum order quantities (MOQs) can vary widely among CD suppliers, typically ranging from 100 to several thousand units. Suppliers in regions like Africa and South America may have lower MOQs to accommodate smaller businesses. Always clarify MOQs during initial discussions to ensure they align with your purchasing capabilities. Additionally, inquire if there are benefits for larger orders, such as discounts or reduced shipping costs. -

What payment terms should I expect when sourcing CDs internationally?

Payment terms for international CD purchases can vary based on supplier policies and your negotiation skills. Common terms include payment upfront, 30% deposit with the balance upon delivery, or net 30/60 days after invoice. It’s crucial to clarify these terms before finalizing any agreements to avoid misunderstandings. Also, consider using secure payment methods like letters of credit to protect your transaction, especially when dealing with new suppliers. -

How can I ensure the quality of CDs from my supplier?

To ensure the quality of CDs, establish clear quality assurance (QA) protocols with your supplier. Request detailed specifications regarding materials and production processes. It’s advisable to conduct quality checks at various stages of production, including pre-production samples and final inspections. Additionally, consider visiting the supplier’s facility if feasible or hiring a third-party inspection service to verify quality standards before shipment. -

What logistics considerations should I be aware of when sourcing CDs?

Logistics is a critical aspect of sourcing CDs internationally. Factors to consider include shipping methods, transit times, and customs regulations. Discuss with your supplier the best shipping options based on your delivery timelines and budget. Be aware of any import duties and taxes that may apply when the goods arrive in your country. Collaborating with a freight forwarder can streamline the logistics process and help navigate customs procedures effectively. -

Can I customize the CDs I order from a supplier?

Many CD suppliers offer customization options, including printing labels, packaging designs, and even unique formats. When discussing your order, clearly communicate your customization needs and any specific design files required. Some suppliers may have limitations on customization based on order quantities or production capabilities, so it’s essential to confirm these details early in the negotiation process to avoid delays. -

What certifications should I look for in a CD supplier?

When sourcing CDs, look for suppliers with relevant certifications that ensure compliance with industry standards. Common certifications include ISO 9001 for quality management and ISO 14001 for environmental management. Additionally, certifications related to data protection and copyright compliance can be crucial, especially if you’re distributing content. These certifications provide assurance that the supplier adheres to best practices and can deliver high-quality products. -

What are the risks of working with a new CD supplier, and how can I mitigate them?

Working with a new CD supplier can pose risks such as quality inconsistencies, delayed shipments, or financial instability. To mitigate these risks, conduct thorough due diligence before entering into agreements. Research the supplier’s history, read customer reviews, and request references. Start with a smaller order to evaluate their performance before committing to larger contracts. Establish clear communication and contract terms to protect your interests throughout the sourcing process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cd supplier

In summary, effective strategic sourcing is a critical component for international B2B buyers looking to partner with reliable CD suppliers. As we have explored, understanding market dynamics, leveraging technology, and fostering strong supplier relationships are essential strategies to maximize procurement efficiency and reduce costs. Buyers from Africa, South America, the Middle East, and Europe should prioritize transparency and communication when evaluating potential suppliers, ensuring alignment on quality standards and delivery timelines.

How Can B2B Buyers Prepare for Future Sourcing Challenges?

As the global market continues to evolve, buyers must remain agile and responsive to shifting trends and demands. Embracing digital tools and data analytics can enhance decision-making processes and supplier evaluations. Furthermore, diversifying the supply base not only mitigates risks but also opens avenues for innovation and competitive advantage.

What’s Next for B2B Buyers in the Global Market?

Moving forward, it is crucial for international B2B buyers to cultivate a proactive approach in their sourcing strategies. Engage with suppliers who demonstrate sustainability and ethical practices, aligning with the increasing demand for responsible sourcing. By doing so, you will not only enhance your brand reputation but also contribute to a more sustainable global economy. Take action today to optimize your sourcing strategy and position your business for future success.