Discover Top CNC Machining Suppliers: Your Essential Guide (2025)

Introduction: Navigating the Global Market for cnc machining supplier

In an increasingly interconnected global market, sourcing a reliable CNC machining supplier can be a daunting task for international B2B buyers. With the complexity of supply chains and varying quality standards across regions, making informed decisions is crucial. This guide aims to navigate the intricate landscape of CNC machining suppliers, offering insights into various types of suppliers, applications of CNC machining, effective supplier vetting processes, and cost considerations.

By understanding the nuances of CNC machining—from precision engineering to mass production—buyers from Africa, South America, the Middle East, and Europe, including nations like France and Saudi Arabia, can enhance their procurement strategies. This comprehensive resource empowers B2B buyers to identify reputable suppliers who not only meet their technical requirements but also align with their budgetary constraints.

Additionally, we delve into best practices for assessing supplier capabilities, evaluating production quality, and fostering long-term partnerships. The aim is to equip buyers with actionable insights that streamline their sourcing processes, ultimately leading to more efficient operations and enhanced competitiveness in their respective markets. Whether you are a small enterprise looking for specialized components or a large manufacturer seeking bulk production, this guide serves as your roadmap to making informed, strategic purchasing decisions in the CNC machining realm.

Understanding cnc machining supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Job Shop CNC Suppliers | Flexible production capabilities for small batches | Prototyping, custom parts manufacturing | Pros: Customization, quick turnaround. Cons: Higher costs per unit, longer lead times for larger orders. |

| Contract CNC Manufacturers | Focus on large-scale production under contract | Mass production, OEM parts | Pros: Economies of scale, lower per-unit costs. Cons: Less flexibility, potential for longer lead times. |

| Specialized CNC Suppliers | Expertise in specific materials or processes | Aerospace, medical devices, automotive | Pros: High precision, specialized knowledge. Cons: Limited to certain industries, potentially higher costs. |

| Online CNC Services | Digital platforms for quoting and ordering | Small businesses, startups | Pros: Accessibility, competitive pricing. Cons: Limited customization options, variable quality control. |

| In-House CNC Machining | Integrated CNC machining within a larger operation | High-volume production, R&D | Pros: Full control over production, immediate adjustments. Cons: High initial investment, requires skilled labor. |

What Are Job Shop CNC Suppliers and When Should You Use Them?

Job shop CNC suppliers are known for their flexibility in production, catering primarily to small batches and custom orders. These suppliers are ideal for businesses looking to prototype or manufacture unique components. When considering a job shop, buyers should evaluate their need for customization against potential higher costs per unit and longer lead times for larger orders.

How Do Contract CNC Manufacturers Operate?

Contract CNC manufacturers focus on producing large quantities of parts under contract agreements. They are suited for businesses needing mass production of components, such as OEM parts. Buyers benefit from economies of scale, which can significantly lower per-unit costs. However, they should be aware that this model may offer less flexibility and potentially longer lead times.

What Makes Specialized CNC Suppliers Unique?

Specialized CNC suppliers possess expertise in specific materials or processes, making them indispensable for industries such as aerospace, medical devices, and automotive. These suppliers provide high precision and specialized knowledge, which is crucial for applications requiring strict adherence to industry standards. However, buyers should consider that such specialization might limit options for other industries and could lead to higher costs.

Why Consider Online CNC Services for Your Business?

Online CNC services leverage digital platforms for quoting and ordering, making them accessible to small businesses and startups. These services are particularly appealing due to their competitive pricing and ease of use. However, buyers should be cautious about limited customization options and potential variability in quality control, which can affect the final product.

What Are the Advantages of In-House CNC Machining?

In-house CNC machining refers to the integration of CNC capabilities within a larger operation, allowing for high-volume production and R&D activities. This approach gives businesses full control over their production processes, enabling immediate adjustments based on changing requirements. Despite these advantages, buyers must weigh the high initial investment and the need for skilled labor against the benefits of enhanced control and responsiveness.

Related Video: INCREDIBLE 9-Axis CNC Machining Process in Stainless

Key Industrial Applications of cnc machining supplier

| Industry/Sector | Specific Application of CNC Machining Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision component manufacturing | High accuracy and reliability in critical parts | Certification standards, lead times, and material sourcing |

| Automotive | Prototype and production of vehicle parts | Reduced time-to-market for new models | Cost efficiency, scalability, and tooling capabilities |

| Medical Devices | Custom implants and surgical instruments | Enhanced patient safety through precision manufacturing | Compliance with health regulations and material biocompatibility |

| Electronics | Enclosures and circuit board components | Improved product performance and durability | Supply chain reliability and technological capabilities |

| Oil & Gas | Custom drilling and extraction tools | Increased operational efficiency and reduced downtime | Material strength, resistance to harsh environments, and lead times |

How is CNC Machining Supplier Used in Aerospace and What Are the Benefits?

In the aerospace industry, CNC machining suppliers are critical for manufacturing precision components such as turbine blades, brackets, and housings. These components require high accuracy to ensure safety and performance in flight. By utilizing CNC machining, aerospace manufacturers can achieve tight tolerances and repeatability, which are essential for compliance with stringent industry standards. International buyers, particularly from regions like Europe and the Middle East, must consider suppliers that meet specific certification requirements, such as AS9100, and can deliver on time without compromising quality.

What Are the Applications of CNC Machining in Automotive Manufacturing?

CNC machining plays a vital role in both the prototyping and production phases of automotive manufacturing. Suppliers can produce complex parts, such as engine components and chassis elements, quickly and cost-effectively, reducing the overall time-to-market for new vehicle models. For B2B buyers in South America and Africa, sourcing from CNC suppliers that offer scalability and flexibility is crucial, especially when introducing new models or adapting to market demands. Cost efficiency in production is also a key consideration, as it directly impacts the final pricing of vehicles.

How Does CNC Machining Enhance Medical Device Manufacturing?

In the medical device sector, CNC machining suppliers provide custom solutions for implants and surgical instruments that require high precision and biocompatibility. The ability to produce intricate designs ensures that devices fit perfectly and function as intended, significantly enhancing patient safety. Buyers in regions like Africa and the Middle East must prioritize suppliers who comply with health regulations and can demonstrate a track record of quality and reliability. Additionally, understanding the material properties and their implications for patient health is essential when sourcing these products.

What Are the Benefits of CNC Machining in Electronics?

CNC machining is extensively used in the electronics industry for producing enclosures and circuit board components. The precision offered by CNC machining ensures that electronic devices perform reliably and have a longer lifespan. B2B buyers from Europe, particularly France, should focus on suppliers who can guarantee high-quality finishes and durability in their components. Additionally, sourcing from suppliers with robust supply chains and advanced technological capabilities can lead to better product outcomes and innovation in electronics design.

How is CNC Machining Applied in the Oil & Gas Industry?

In the oil and gas sector, CNC machining is essential for creating custom drilling and extraction tools designed to withstand harsh environmental conditions. The precision and strength of these tools can significantly enhance operational efficiency and reduce downtime during critical extraction processes. International buyers, especially from the Middle East, should consider suppliers that specialize in high-strength materials and have experience working in the oil and gas industry. Understanding lead times and the supplier’s ability to deliver under pressure is also vital for maintaining operational continuity.

Related Video: What is CNC Machining and How Does it Work?

3 Common User Pain Points for ‘cnc machining supplier’ & Their Solutions

Scenario 1: Navigating Quality Assurance in CNC Machining

The Problem:

B2B buyers often face challenges in ensuring the quality of the parts produced by CNC machining suppliers. This issue is exacerbated when sourcing from suppliers located internationally, such as those in Africa or South America, where regulatory standards may vary significantly. A buyer might receive parts that do not meet the specified tolerances or material specifications, leading to costly rework or product failures in their operations.

The Solution:

To mitigate quality assurance concerns, buyers should implement a comprehensive supplier evaluation process. Start by establishing clear quality criteria and specifications before engaging suppliers. Request detailed documentation of their quality control processes, including ISO certifications and examples of previous work. Additionally, consider visiting the supplier’s facility if feasible or conducting virtual audits to assess their capabilities firsthand. Implement a pilot run of parts before full-scale production, allowing for adjustments based on initial outcomes. This proactive approach ensures that the supplier understands your quality expectations and enables you to build a collaborative relationship focused on continuous improvement.

Scenario 2: Managing Lead Times and Delivery Schedules

The Problem:

Timely delivery of CNC machined parts is critical for maintaining production schedules. However, many buyers experience delays that disrupt their operations. This issue can arise due to various factors, such as unexpected machine downtimes, supply chain disruptions, or inefficient project management by the supplier. For international buyers from regions like the Middle East or Europe, these delays can lead to significant financial repercussions and damage to client relationships.

The Solution:

To address lead time challenges, buyers should establish clear communication channels with their CNC machining suppliers. It is essential to set realistic timelines that account for potential disruptions. Implementing a contract that includes penalties for late deliveries can incentivize suppliers to prioritize your orders. Additionally, consider diversifying your supplier base by identifying multiple CNC machining suppliers across different regions. This strategy not only provides backup options but also encourages competition among suppliers, improving overall service levels. Regularly review and discuss delivery performance metrics with your suppliers to foster accountability and encourage adherence to schedules.

Scenario 3: Customization and Flexibility Challenges

The Problem:

B2B buyers often require custom CNC machining solutions tailored to specific project requirements. However, many suppliers struggle to provide the necessary flexibility, leading to a mismatch between the buyer’s needs and the supplier’s offerings. This problem can be particularly acute for buyers in fast-paced industries such as automotive or aerospace, where innovation and rapid prototyping are essential.

The Solution:

To enhance customization capabilities, buyers should engage suppliers who demonstrate a willingness to collaborate on design and engineering processes. Initiate discussions about your specific needs early in the project lifecycle, and provide detailed specifications, including CAD models and material preferences. Look for suppliers that offer design assistance services, as this can lead to more efficient production methods and improved outcomes. Consider establishing long-term partnerships with a select few suppliers who have proven their ability to adapt to your evolving requirements. This collaborative approach not only fosters innovation but also streamlines communication, resulting in more agile responses to market demands.

Strategic Material Selection Guide for cnc machining supplier

When selecting materials for CNC machining, international B2B buyers must consider various factors such as material properties, application suitability, and compliance with regional standards. Below, we analyze four common materials used in CNC machining, highlighting their key properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Aluminum in CNC Machining?

Aluminum is a lightweight metal known for its excellent corrosion resistance and good thermal conductivity. It typically has a temperature rating of around 150°C and can withstand moderate pressure. Its low density makes it ideal for applications where weight is a concern, such as in the aerospace and automotive industries.

Pros: Aluminum is durable, easy to machine, and offers a good strength-to-weight ratio. It is also cost-effective compared to other metals.

Cons: While aluminum is resistant to corrosion, it can be less durable under high-stress conditions. Additionally, its lower melting point can limit its use in high-temperature applications.

Impact on Application: Aluminum is compatible with various media, including water and air, making it suitable for a range of applications from automotive components to consumer electronics.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B221 (for aluminum extrusions) and consider local preferences for aluminum grades (e.g., 6061, 7075) based on application needs.

How Does Steel Compare as a Material for CNC Machining?

Steel is a widely used material in CNC machining, known for its high strength and durability. Depending on the alloy, steel can withstand high temperatures (up to 300°C) and pressures, making it suitable for heavy-duty applications.

Pros: Steel’s strength and toughness make it ideal for structural components and tools. It is also versatile, with various grades available for different applications.

Cons: Steel can be more challenging to machine compared to softer metals like aluminum, leading to increased manufacturing complexity and costs. It is also prone to corrosion unless treated.

Impact on Application: Steel is well-suited for applications requiring high strength and wear resistance, such as in construction equipment and industrial machinery.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM A36 (for structural steel) and consider local regulations regarding the use of specific steel grades.

What Are the Advantages of Using Plastic in CNC Machining?

Plastics, such as polycarbonate and nylon, are increasingly used in CNC machining due to their lightweight and corrosion-resistant properties. They can typically withstand temperatures up to 120°C, depending on the type.

Pros: Plastics are easy to machine and can be produced at a lower cost than metals. They also offer excellent chemical resistance and can be molded into complex shapes.

Cons: Plastics may not provide the same strength and durability as metals, which can limit their application in high-stress environments. They are also more susceptible to UV degradation.

Impact on Application: Plastics are ideal for applications in consumer products, medical devices, and automotive interiors, where weight and corrosion resistance are critical.

Considerations for International Buyers: Buyers should ensure compliance with standards like ISO 9001 for quality management and consider the specific properties of different plastic types to meet their application needs.

How Does Titanium Stand Out in CNC Machining?

Titanium is known for its exceptional strength-to-weight ratio and corrosion resistance, often used in aerospace and medical applications. It can withstand high temperatures (up to 600°C) and is highly resistant to various chemicals.

Pros: Titanium’s strength and lightweight nature make it ideal for high-performance applications. It is also biocompatible, making it suitable for medical implants.

Cons: Titanium is more expensive than other materials and can be challenging to machine, leading to higher manufacturing costs.

Impact on Application: Titanium is well-suited for applications in aerospace, automotive, and medical industries, where performance and durability are paramount.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM F136 for titanium alloys used in medical devices and consider the implications of cost and machining challenges.

Summary Table of Material Selection for CNC Machining

| Material | Typical Use Case for CNC Machining Supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Less durable under high stress | Medium |

| Steel | Structural components, industrial machinery | High strength and toughness | Challenging to machine, prone to corrosion | Medium |

| Plastic | Consumer products, medical devices | Easy to machine, low cost | Limited strength, UV degradation | Low |

| Titanium | Aerospace, medical implants | Exceptional strength-to-weight ratio | High cost, difficult to machine | High |

By understanding these materials’ properties, advantages, and limitations, B2B buyers can make informed decisions that align with their specific application requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc machining supplier

What Are the Main Stages of CNC Machining Manufacturing Processes?

CNC machining is a sophisticated process that converts raw materials into finished products using computer-controlled machinery. Understanding the typical manufacturing stages is crucial for international B2B buyers looking to ensure quality and efficiency from their suppliers.

Material Preparation: How Do Suppliers Select and Process Raw Materials?

The first step in the CNC machining process involves selecting appropriate raw materials. Suppliers often utilize metals such as aluminum, steel, and titanium, as well as plastics and composites, depending on the specific application.

Once materials are selected, they undergo preparation which includes cutting to size, deburring, and cleaning to remove any contaminants. This initial phase is critical, as the quality of raw materials directly influences the final product’s performance. B2B buyers should inquire about the suppliers’ sourcing policies to ensure compliance with international standards.

Forming: What Techniques Are Used in CNC Machining?

In the forming stage, CNC machines execute precise operations based on programmed instructions. Techniques commonly employed include:

- Milling: This process involves removing material from a workpiece using rotary cutters, ideal for creating complex shapes.

- Turning: Utilized for cylindrical parts, turning involves rotating the workpiece against a cutting tool.

- Drilling: This technique creates holes in a workpiece and is often integrated with milling for added functionality.

Buyers should assess the technology and machinery used by suppliers, as modern CNC machines offer enhanced precision and efficiency, significantly reducing lead times.

Assembly: How Do Suppliers Ensure Proper Component Integration?

After individual components are machined, they may require assembly. This could involve fitting together multiple parts or integrating additional components like fasteners or electronic systems. Effective assembly is critical to ensuring product functionality and reliability.

B2B buyers should inquire about the assembly processes used by suppliers, including any automation technologies that enhance precision and reduce human error. Verification of assembly techniques can help mitigate risks associated with product failures.

Finishing: What Are Common Techniques for Surface Treatment?

The finishing stage is essential for enhancing the aesthetic and functional properties of the machined parts. Common finishing techniques include:

- Anodizing: This electrochemical process increases corrosion resistance and surface hardness.

- Powder Coating: A dry finishing process that provides a durable and attractive finish.

- Polishing: This enhances the surface finish, improving aesthetics and reducing friction.

Buyers should ensure that suppliers offer finishing services that meet industry-specific requirements, as these can significantly impact product performance and market acceptance.

How Do Quality Assurance Processes Work in CNC Machining?

Quality assurance (QA) is a critical component of CNC machining, ensuring that products meet specified standards and customer expectations.

What International Standards Should B2B Buyers Look For?

International standards such as ISO 9001 are fundamental for suppliers aiming to demonstrate their commitment to quality management. ISO 9001 certification indicates that a supplier has established processes to consistently deliver products that meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications like CE (for European markets) and API (for oil and gas) are crucial for buyers in sectors with strict regulatory requirements. It’s essential for buyers to verify the certifications held by potential suppliers.

What Are the Key Quality Control Checkpoints in CNC Machining?

Quality control checkpoints are integral to maintaining high standards throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the machining process and detect any deviations.

- Final Quality Control (FQC): Once production is complete, a thorough inspection of finished products is conducted to ensure they meet quality standards.

Buyers should request detailed information about each of these checkpoints from suppliers to understand their quality assurance practices.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must implement strategies to verify the quality control processes of their CNC machining suppliers effectively. Here are some actionable insights:

What Role Do Audits Play in Supplier Quality Assurance?

Conducting regular audits is an effective method for buyers to assess the quality systems of their suppliers. Audits can be performed by third-party organizations or internally by the buyer’s quality assurance team. These audits should focus on evaluating compliance with international standards, process effectiveness, and overall quality performance.

How Important Are Quality Control Reports?

Quality control reports provide a detailed overview of the manufacturing process, including any defects identified, corrective actions taken, and overall product performance. Buyers should request these reports periodically to ensure continuous compliance with quality standards.

Can Third-Party Inspections Enhance Supplier Credibility?

Engaging third-party inspection services can further enhance the credibility of suppliers. Independent inspectors can provide objective assessments of product quality and compliance with international standards, giving buyers additional confidence in their purchasing decisions.

What Nuances Should International Buyers Consider in Supplier Quality Control?

B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe must navigate various cultural and regulatory nuances when evaluating supplier quality control practices.

How Do Cultural Differences Impact Quality Assurance?

Cultural differences can influence how quality assurance is perceived and implemented. For instance, suppliers in Europe may have stringent adherence to quality standards compared to those in emerging markets. Buyers should understand these cultural contexts and adjust their expectations and communication styles accordingly.

What Regulatory Considerations Should Buyers Keep in Mind?

Different regions have specific regulatory requirements that can affect product quality and safety. Buyers should familiarize themselves with these regulations to ensure their suppliers comply. For example, the CE marking is crucial for products sold in Europe, while other regions may have different standards.

By understanding these nuances, international B2B buyers can make more informed decisions when selecting CNC machining suppliers, ultimately leading to better product quality and enhanced business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc machining supplier’

Introduction

Sourcing a reliable CNC machining supplier is a critical step for businesses looking to enhance their manufacturing capabilities. This guide provides a step-by-step checklist to streamline the procurement process, ensuring you select a supplier that meets your technical specifications, quality standards, and budget requirements. By following these actionable steps, international B2B buyers from Africa, South America, the Middle East, and Europe can make informed decisions that drive operational success.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, it’s essential to clearly define your technical requirements. This includes material types, tolerances, production volume, and delivery timelines. A well-documented specification will help you communicate effectively with suppliers and ensure that they can meet your needs.

- What to Include:

- Dimensions and tolerances

- Material properties and surface finishes

- Quantity and frequency of orders

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential CNC machining suppliers. Utilize online marketplaces, industry directories, and trade shows to create a list of candidates. This step is crucial for building a pool of suppliers that can meet your specifications.

- Where to Look:

- Online B2B platforms (e.g., Alibaba, ThomasNet)

- Industry-specific trade shows and expos

- Recommendations from industry peers

Step 3: Evaluate Supplier Certifications and Compliance

Before proceeding, verify that your shortlisted suppliers possess relevant certifications and comply with international quality standards. Certifications such as ISO 9001 indicate a commitment to quality management and operational excellence.

- Key Certifications to Look For:

- ISO 9001 (Quality Management)

- ISO 13485 (Medical Devices, if applicable)

- AS9100 (Aerospace Industry)

Step 4: Request and Analyze Quotes

Once you have narrowed down your options, request detailed quotes from each supplier. Analyze these quotes not only for pricing but also for terms of delivery, payment options, and any additional costs. This step helps you gauge which supplier provides the best value for your specific needs.

- What to Compare:

- Base price and volume discounts

- Lead times and shipping costs

- Warranty and after-sales support

Step 5: Conduct Supplier Visits or Virtual Tours

If possible, visit the suppliers’ facilities or request a virtual tour to assess their manufacturing capabilities and quality control processes. This direct observation will help you evaluate the operational efficiency and technology used by the supplier, ensuring they can meet your quality standards.

- What to Observe:

- Equipment and technology used

- Cleanliness and organization of the facility

- Quality control measures in place

Step 6: Check References and Customer Feedback

Before finalizing your decision, check references and gather feedback from other customers who have worked with the supplier. This step is vital for understanding the supplier’s reliability, communication, and overall customer satisfaction.

- How to Proceed:

- Ask for client testimonials or case studies

- Research online reviews and ratings

- Contact previous clients directly for insights

Step 7: Finalize Contracts and Terms

Once you have chosen a supplier, ensure that all agreements are documented in a formal contract. This contract should outline all terms, including pricing, delivery schedules, quality standards, and penalties for non-compliance. A well-structured contract protects both parties and sets clear expectations.

- Key Elements to Include:

- Payment terms and conditions

- Detailed specifications and quality standards

- Dispute resolution procedures

By following this checklist, B2B buyers can effectively navigate the sourcing process for CNC machining suppliers, ensuring they select a partner that aligns with their business goals and quality expectations.

Comprehensive Cost and Pricing Analysis for cnc machining supplier Sourcing

What Are the Key Cost Components in CNC Machining Supplier Pricing?

When sourcing CNC machining services, understanding the cost structure is crucial for international B2B buyers. The primary cost components typically include:

-

Materials: The type and quality of materials used significantly affect pricing. Premium materials may incur higher costs, while bulk purchasing could offer discounts.

-

Labor: Skilled labor is essential for CNC machining. Labor costs vary by region, with countries in Europe generally having higher labor rates compared to those in Africa or South America.

-

Manufacturing Overhead: This encompasses operational costs such as utilities, maintenance, and facility management. High overhead costs in developed regions can increase the overall price.

-

Tooling: The initial investment in tooling can be substantial. Custom tooling for specific projects will add to the cost, while standard tooling may reduce expenses.

-

Quality Control (QC): Implementing stringent QC measures ensures product quality but also adds to the cost. Certifications (like ISO) can further increase expenses.

-

Logistics: Shipping costs, including tariffs and taxes, are crucial in the pricing equation, especially for international shipments. Understanding Incoterms is vital for managing these costs effectively.

-

Margin: Suppliers will include a profit margin that varies based on their operational costs, market position, and the competitive landscape.

How Do Price Influencers Affect CNC Machining Costs?

Several factors influence CNC machining prices, and international buyers should consider these when sourcing suppliers:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes typically lead to lower per-unit costs. Suppliers often offer discounts for bulk orders, making it essential to evaluate your needs.

-

Specifications and Customization: Complex or highly customized parts require more time and resources, increasing costs. Clearly defined specifications can help manage expectations and pricing.

-

Material Choices: Different materials have varying costs. For example, titanium will be more expensive than aluminum. Buyers should weigh the benefits against the costs when selecting materials.

-

Quality and Certifications: Parts requiring high precision or specific certifications will incur higher costs due to additional QA processes. Suppliers with recognized certifications might charge a premium.

-

Supplier Factors: The supplier’s location, reputation, and operational efficiency can influence pricing. Suppliers in regions with lower labor costs may provide more competitive pricing.

-

Incoterms: Understanding shipping terms (FOB, CIF, etc.) is vital for estimating total costs. The chosen terms can significantly impact logistics expenses and delivery times.

What Are the Best Negotiation Strategies for CNC Machining Suppliers?

International B2B buyers can adopt several strategies to negotiate better terms and pricing with CNC machining suppliers:

-

Understand Total Cost of Ownership (TCO): Calculate not just the upfront costs but also maintenance, operational, and logistics costs. A lower initial price may lead to higher long-term expenses.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQ requirements for better pricing. Suppliers are often more willing to negotiate on larger contracts.

-

Communicate Clearly: Provide detailed specifications and expectations upfront. This minimizes misunderstandings that could lead to additional costs.

-

Compare Multiple Suppliers: Obtain quotes from various suppliers to understand the market rate. This competitive insight can strengthen your negotiation position.

-

Build Relationships: Establishing a long-term relationship with suppliers can lead to better pricing, priority service, and flexibility.

-

Negotiate Payment Terms: Discuss favorable payment terms such as extended payment periods or discounts for early payment to improve cash flow.

Conclusion: Navigating CNC Machining Pricing for International Buyers

In summary, understanding the cost components and price influencers in CNC machining is vital for international B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe. By employing strategic negotiation techniques and being aware of the total cost of ownership, buyers can make informed decisions that lead to cost-effective sourcing. Always remember that prices can fluctuate based on market conditions, so it’s prudent to seek indicative quotes rather than fixed prices.

Alternatives Analysis: Comparing cnc machining supplier With Other Solutions

Understanding the Alternatives to CNC Machining Suppliers

When considering manufacturing solutions, it’s crucial to evaluate alternatives to CNC machining suppliers. This analysis focuses on comparing CNC machining with other viable manufacturing methods, providing B2B buyers with insights into their options. Here, we will explore two notable alternatives: 3D Printing and Traditional Manual Machining.

Comparison Table of CNC Machining and Alternatives

| Comparison Aspect | Cnc Machining Supplier | 3D Printing | Traditional Manual Machining |

|---|---|---|---|

| Performance | High precision and repeatability | Good for complex geometries | Variable precision, depends on skill |

| Cost | Higher initial investment | Lower for small batches | Low initial, but variable costs |

| Ease of Implementation | Requires skilled operators | User-friendly software | Requires skilled artisans |

| Maintenance | Regular maintenance needed | Minimal maintenance | High maintenance depending on tools |

| Best Use Case | Mass production of precise parts | Prototyping and low-volume runs | Custom, one-off projects |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of 3D Printing?

3D printing, also known as additive manufacturing, is a method that creates objects layer by layer from digital models.

Pros:

– Flexibility: 3D printing allows for the creation of complex geometries that might be impossible or costly with CNC machining.

– Cost-Effective for Low Volumes: For small production runs or prototyping, 3D printing can be significantly cheaper than CNC machining, eliminating the need for expensive tooling.

– Rapid Prototyping: It enables quick iterations and modifications to designs without the time-consuming setup associated with traditional machining.

Cons:

– Material Limitations: While the range of materials is growing, not all materials can be 3D printed, which can limit applications.

– Surface Finish: The finish quality may not match the high precision and smoothness achieved by CNC machining, requiring post-processing.

How Does Traditional Manual Machining Compare?

Traditional manual machining involves using hand-operated tools to shape and fabricate parts.

Pros:

– Lower Initial Investment: The setup costs can be significantly lower compared to CNC machining, making it accessible for smaller businesses or startups.

– Versatility: Skilled machinists can adapt to different tasks quickly, allowing for customized solutions.

Cons:

– Skill Dependent: The quality and precision of the output heavily rely on the skill and experience of the machinist, which can lead to variability in results.

– Time-Consuming: Manual processes are generally slower than automated CNC machining, making them less suitable for large-scale production.

Making the Right Choice: How Should B2B Buyers Decide?

Choosing the right manufacturing solution depends on various factors, including production volume, required precision, and budget constraints. For high-volume, precision-dependent projects, CNC machining remains a leading choice due to its repeatability and speed. However, for businesses focused on rapid prototyping or low-volume production, 3D printing presents a flexible and cost-effective alternative. On the other hand, traditional manual machining may suit smaller operations looking for custom, one-off projects without significant upfront investment.

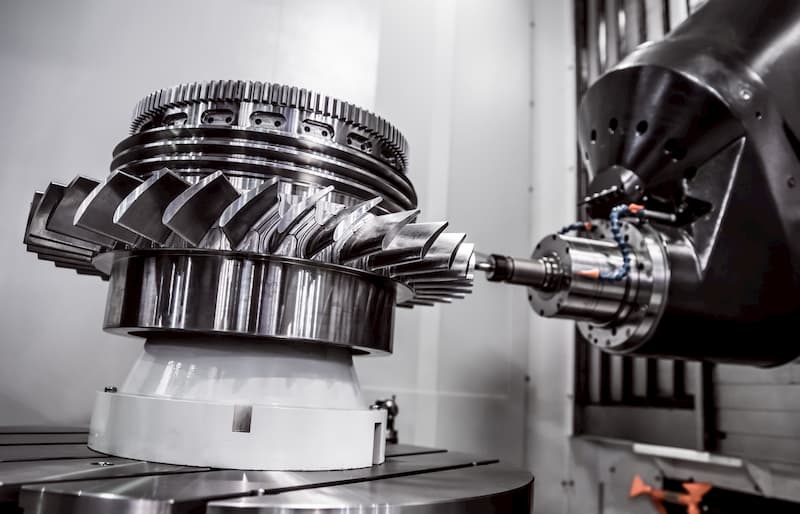

A stock image related to cnc machining supplier.

Ultimately, B2B buyers should assess their specific needs, including the nature of the product, production goals, and available resources, to make an informed decision that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for cnc machining supplier

What Are the Essential Technical Properties for CNC Machining Suppliers?

When engaging with CNC machining suppliers, understanding the technical properties of products is crucial for making informed purchasing decisions. Below are some of the key specifications that international B2B buyers should consider:

1. Material Grade: Why Does It Matter?

Material grade refers to the type of material used in the manufacturing process, which significantly affects the part’s performance and durability. Common materials include aluminum, stainless steel, and titanium. The choice of material can influence the cost, weight, and strength of the final product. For example, titanium is lightweight yet strong, making it suitable for aerospace applications, while stainless steel is often preferred for its corrosion resistance in medical devices.

2. Tolerance: What Is Its Role in Precision Machining?

Tolerance defines the allowable deviation from a specified dimension. It is a critical factor in CNC machining as it determines how accurately a part can be manufactured. Tight tolerances (e.g., ±0.01 mm) are essential for high-precision applications like aerospace or automotive components. Understanding the required tolerances helps buyers assess the supplier’s capability to meet their quality standards.

3. Surface Finish: How Does It Impact Performance?

Surface finish refers to the texture and smoothness of a manufactured part’s surface. It can affect everything from aesthetic appeal to functionality, such as reducing friction in moving parts. Common surface finishes include anodizing, polishing, and sandblasting. Buyers should specify their requirements for surface finish to ensure that the final product meets both functional and aesthetic criteria.

4. Machining Process: What Methods Are Commonly Used?

Different CNC machining processes (like milling, turning, and grinding) are used to achieve various shapes and features. Each process has its advantages and limitations regarding precision, speed, and cost. For example, milling is ideal for complex geometries, while turning is better for cylindrical parts. Understanding the machining processes available will help buyers select the right supplier for their specific needs.

5. Lead Time: Why Is It Critical for Project Management?

Lead time refers to the duration from placing an order to the delivery of the finished product. In B2B environments, understanding lead times is essential for project planning and inventory management. Suppliers may offer different lead times based on their production capacity and workload. Buyers should discuss lead times upfront to ensure alignment with their project schedules.

What Are Common Trade Terms Used in CNC Machining?

Familiarity with industry jargon can greatly enhance communication and negotiation with CNC machining suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In CNC machining, an OEM might design a component that a supplier manufactures. Understanding OEM relationships helps buyers clarify responsibilities regarding design and production.

2. MOQ (Minimum Order Quantity): Why Should You Care?

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it impacts inventory levels and cash flow. Buyers should negotiate MOQs that align with their production needs without overcommitting financially.

3. RFQ (Request for Quotation): How to Use It Effectively?

An RFQ is a document sent to suppliers to solicit pricing and terms for a specific project. Including detailed specifications in an RFQ helps suppliers provide accurate quotes. Buyers should ensure their RFQs are comprehensive to avoid misunderstandings later in the process.

4. Incoterms: What Are They and Why Are They Important?

Incoterms (International Commercial Terms) are standard trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who pays for shipping, insurance, and tariffs, which is vital for budgeting and logistics planning. Understanding Incoterms can prevent disputes and ensure smooth transactions.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of the CNC machining industry more effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the cnc machining supplier Sector

What Are the Key Market Dynamics and Trends Affecting CNC Machining Suppliers?

A stock image related to cnc machining supplier.

The CNC machining supplier sector is experiencing significant growth, driven by globalization, technological advancements, and evolving manufacturing needs. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of several key trends.

Firstly, automation and Industry 4.0 technologies are reshaping the landscape. CNC machines are increasingly integrated with IoT devices, allowing for real-time monitoring and predictive maintenance. This not only enhances operational efficiency but also reduces downtime and operational costs, making it critical for buyers to assess suppliers based on their technological capabilities.

Secondly, there is a rising demand for customized solutions. As industries such as aerospace, automotive, and medical devices require more complex and precise components, CNC suppliers that offer tailored machining services are becoming more attractive. Buyers should look for suppliers who can demonstrate flexibility and adaptability in their production processes.

Additionally, sourcing from local suppliers is gaining traction, particularly in light of recent supply chain disruptions. Buyers in Africa and South America may find it beneficial to partner with regional suppliers to mitigate risks associated with global logistics. This trend also aligns with the growing emphasis on reducing lead times and enhancing supply chain transparency.

How Important Is Sustainability and Ethical Sourcing for CNC Machining Suppliers?

Sustainability has become a critical consideration in the sourcing decisions of international B2B buyers. The CNC machining sector is no exception, as environmental impact and ethical supply chains take center stage. Suppliers that prioritize sustainable practices—such as energy-efficient manufacturing processes and responsible waste management—are increasingly favored by buyers.

Buyers should also consider suppliers that have obtained ‘green’ certifications, which can serve as a benchmark for assessing a supplier’s commitment to sustainability. Materials sourced from recycled or renewable origins are becoming essential, particularly in Europe and the Middle East, where regulatory pressures are high.

Furthermore, ethical sourcing is paramount. Buyers must ensure that their suppliers adhere to fair labor practices and comply with international labor standards. Engaging with suppliers who are transparent about their sourcing methods fosters trust and long-term partnerships, which is crucial for maintaining a competitive edge in the market.

What Is the Brief Evolution of CNC Machining and Its Relevance to Today’s B2B Context?

The evolution of CNC machining has been remarkable since its inception in the 1950s. Initially, CNC (Computer Numerical Control) technology was designed to automate machine tools, significantly enhancing precision and efficiency in manufacturing. Over the decades, advancements in computing power and software have transformed CNC machines into sophisticated systems capable of executing complex designs with minimal human intervention.

Today, CNC machining is integral to various industries, ranging from automotive to aerospace and medical manufacturing. This historical context is vital for B2B buyers as it highlights the ongoing innovation within the sector. Understanding the evolution of CNC technology allows buyers to appreciate the capabilities and reliability of modern suppliers, ensuring they make informed decisions when sourcing machining services.

In conclusion, navigating the CNC machining supplier landscape requires a keen understanding of current market dynamics, a commitment to sustainability, and an appreciation of the technology’s historical progression. By focusing on these aspects, international B2B buyers can enhance their sourcing strategies and foster successful partnerships.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc machining supplier

-

How do I choose the right CNC machining supplier for my business?

Choosing the right CNC machining supplier involves evaluating several key factors. First, assess their experience and expertise in your specific industry, as this can influence the quality of the products. Next, check their certifications and quality assurance processes to ensure they meet international standards. It’s also beneficial to request samples of their previous work to evaluate their machining capabilities. Finally, consider their production capacity and lead times to ensure they can meet your demand, especially if you require large quantities. -

What are the typical minimum order quantities (MOQs) for CNC machining suppliers?

Minimum order quantities (MOQs) can vary significantly among CNC machining suppliers, often depending on the complexity of the parts and the materials used. Many suppliers set MOQs to optimize their production efficiency; common MOQs can range from 50 to 100 units for standard parts. However, some suppliers may offer flexibility for smaller orders, especially for prototyping or initial runs. It’s advisable to discuss your specific needs directly with the supplier to negotiate terms that work for both parties. -

What payment terms should I expect when working with a CNC machining supplier?

Payment terms for CNC machining can differ widely based on the supplier’s policies and your negotiation. Common terms include a 30% deposit upfront, with the balance due upon completion or delivery. Some suppliers may offer favorable terms for repeat customers or larger orders, such as extended payment periods. Always ensure that payment terms are clearly defined in the contract to avoid misunderstandings. It’s also wise to inquire about accepted payment methods, especially for international transactions, which may include bank transfers or letters of credit. -

How can I ensure quality assurance when sourcing from CNC machining suppliers?

To ensure quality assurance, request detailed information about the supplier’s quality control processes. Look for suppliers who are ISO certified, as this indicates adherence to international quality standards. Additionally, ask about their inspection methods, including in-process and final inspections, and whether they use certified measuring tools. It may also be beneficial to conduct an on-site visit or engage third-party inspection services to verify compliance with your quality requirements before placing a large order. -

What customization options are typically available with CNC machining?

CNC machining offers extensive customization options, including the ability to create complex geometries, use various materials, and apply specific finishes. Most suppliers can accommodate custom designs based on your CAD files, allowing for precise modifications tailored to your needs. Furthermore, inquire about the availability of additional services such as surface treatment, assembly, or packaging, which can streamline your production process. Discussing your requirements in detail with the supplier can help you understand the full range of customization options they offer. -

What logistics considerations should I keep in mind when sourcing from international CNC machining suppliers?

When sourcing from international CNC machining suppliers, consider logistics factors such as shipping costs, delivery times, and customs regulations. Establish a clear understanding of who is responsible for freight and insurance, and whether the supplier can handle logistics arrangements. Additionally, be aware of potential delays due to customs clearance, especially if you are importing parts into regions with strict regulations. Utilizing a reliable freight forwarder can help navigate these complexities and ensure timely delivery of your products. -

How do I handle communication and time zone differences with international CNC suppliers?

Effective communication is crucial when working with international CNC suppliers, especially across different time zones. Utilize tools like email, video conferencing, and project management software to facilitate collaboration. Establish a clear schedule for regular updates and meetings to address any issues promptly. Additionally, consider assigning a point of contact within your organization who can manage communications and ensure that messages are conveyed accurately and timely, minimizing misunderstandings due to language or cultural differences. -

What are the common challenges faced when sourcing CNC machined parts internationally?

Common challenges when sourcing CNC machined parts internationally include quality control issues, language barriers, and differing manufacturing standards. Additionally, fluctuations in shipping costs and potential delays due to customs can complicate logistics. It is essential to conduct thorough due diligence on your supplier, including checking references and reviewing their production capabilities. Establishing clear contracts with defined quality expectations and timelines can help mitigate these risks and ensure a smoother sourcing process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc machining supplier

In today’s competitive landscape, the strategic sourcing of CNC machining suppliers is essential for international B2B buyers aiming to enhance operational efficiency and product quality. By prioritizing suppliers that demonstrate reliability, technological prowess, and compliance with international standards, businesses can secure a competitive edge. Key takeaways include the importance of conducting thorough supplier evaluations, leveraging technology for better communication, and ensuring alignment with local market needs, especially in regions like Africa, South America, the Middle East, and Europe.

Investing in strategic sourcing not only reduces costs but also fosters long-term partnerships that drive innovation and responsiveness to market changes. As global supply chains continue to evolve, buyers must remain agile, adapting their sourcing strategies to navigate challenges and seize opportunities.

Looking forward, the demand for CNC machining will continue to rise, driven by advancements in technology and increasing manufacturing capabilities. International B2B buyers should proactively engage with suppliers to explore new solutions that enhance productivity and quality. Start building your strategic sourcing framework today to position your business for success in this dynamic market.