Discover Top Dental Chair Manufacturers: Your Ultimate Guide (2025)

Introduction: Navigating the Global Market for dental chair manufacturers

In the competitive landscape of dental chair manufacturers, sourcing high-quality, ergonomically designed dental chairs that enhance patient comfort and practitioner efficiency can be a daunting challenge for international B2B buyers. This guide is crafted specifically for dental practices and distributors across Africa, South America, the Middle East, and Europe, including key markets like Colombia and Mexico. It offers a comprehensive analysis of various dental chair types, their applications, and the latest innovations in the industry.

Understanding the nuances of dental chair procurement is essential for making informed purchasing decisions. This guide will delve into critical aspects such as supplier vetting processes, cost considerations, and maintenance requirements. Moreover, it will highlight the importance of compliance with local regulations and standards, which vary significantly across regions. By addressing these challenges, we aim to empower buyers with actionable insights that facilitate effective sourcing strategies.

As you navigate this global market, the information presented here will serve as a valuable resource, equipping you with the knowledge needed to select the right dental chairs that align with your specific operational needs and budget constraints. Whether you are looking to enhance your clinic’s offerings or expand your product line as a distributor, this guide is designed to streamline your decision-making process and ultimately drive your business success.

Understanding dental chair manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Dental Chairs | Manual adjustment, basic ergonomic design | General dental practices | Pros: Affordable, easy maintenance. Cons: Limited features, less comfort for patients. |

| Electric Dental Chairs | Automated adjustments, advanced ergonomic design | Specialty clinics, cosmetic dentistry | Pros: Increased efficiency, enhanced patient comfort. Cons: Higher initial cost, requires power source. |

| Pediatric Dental Chairs | Child-friendly design, adjustable for smaller sizes | Pediatric dental practices | Pros: Engaging design for children, safety features. Cons: Limited use beyond pediatric dentistry. |

| Surgical Dental Chairs | Enhanced stability, specific for surgical procedures | Oral surgery, implantology clinics | Pros: High durability, specialized functions. Cons: Heavier and less portable, higher price point. |

| Portable Dental Chairs | Lightweight, collapsible design for easy transport | Mobile dental clinics, outreach programs | Pros: Versatile, ideal for remote locations. Cons: May lack some features of stationary chairs. |

What Are Standard Dental Chairs and Their Benefits for B2B Buyers?

Standard dental chairs are the most common type found in general dental practices. They typically feature manual adjustments that allow dentists to modify the chair’s height and angle. While they are budget-friendly and easy to maintain, buyers should consider their limitations in terms of patient comfort and the lack of advanced functionalities. For practices focused on cost-effectiveness, these chairs serve as a reliable choice, but they may not meet the needs of more specialized applications.

How Do Electric Dental Chairs Enhance the Dental Experience?

Electric dental chairs offer automated adjustments, which significantly improve the efficiency of dental procedures. Their advanced ergonomic designs provide enhanced comfort for patients, making them ideal for cosmetic and specialty clinics. While the initial investment is higher compared to standard chairs, the long-term benefits, such as reduced strain on dental professionals and increased patient satisfaction, often justify the cost. B2B buyers should evaluate their practice type and patient demographics to determine the suitability of electric chairs.

Why Choose Pediatric Dental Chairs for Child Patients?

Pediatric dental chairs are specifically designed to cater to the needs of children, featuring engaging designs and safety features. These chairs are adjustable to accommodate smaller sizes, ensuring a comfortable and secure experience for young patients. While they are perfect for pediatric dental practices, their use is limited outside this field. B2B buyers should consider the potential for patient retention and the impact on children’s anxiety during dental visits when investing in these specialized chairs.

What Makes Surgical Dental Chairs Essential for Specialized Practices?

Surgical dental chairs are built for stability and support during complex procedures. They often include features tailored for oral surgery and implantology clinics, such as adjustable armrests and enhanced durability. Though these chairs come with a higher price tag and are less portable, their specialized functions can significantly improve surgical outcomes. Buyers in specialized fields should weigh the benefits of these features against their practice’s specific needs and budget constraints.

How Do Portable Dental Chairs Support Mobile Practices?

Portable dental chairs are designed for easy transport and setup, making them ideal for mobile dental clinics and outreach programs. Their lightweight, collapsible design allows for versatility in various settings, including community events and remote locations. However, buyers should note that portable chairs may lack some advanced features found in stationary models. For B2B buyers focused on expanding their reach and providing services in underserved areas, investing in portable dental chairs can enhance service delivery while maintaining patient comfort.

Related Video: Dental Office Duties

Key Industrial Applications of dental chair manufacturers

| Industry/Sector | Specific Application of Dental Chair Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Ergonomic dental chairs for patient comfort and accessibility | Enhances patient experience, leading to increased retention | Look for chairs with adjustable features and durable materials |

| Hospitals | Multi-functional dental chairs for surgical procedures | Increases operational efficiency and patient throughput | Ensure compatibility with surgical equipment and easy sanitation |

| Mobile Dental Units | Compact, portable dental chairs for on-site services | Expands service reach, particularly in underserved areas | Focus on lightweight design and easy setup |

| Educational Institutions | Specialized chairs for dental training programs | Provides realistic training environments for students | Seek chairs that mimic real-world usage and offer durability |

| Research Facilities | Advanced dental chairs with integrated diagnostic tools | Facilitates innovative research and development | Prioritize technological features and adaptability for studies |

How Are Dental Chairs Utilized in Dental Clinics?

In dental clinics, ergonomic dental chairs are essential for providing patient comfort during treatments. These chairs often come equipped with adjustable features that allow dental practitioners to optimize positioning for various procedures. This not only enhances the patient experience but also contributes to better clinical outcomes. For international buyers, particularly in regions like Africa and South America, sourcing chairs that are durable and easy to maintain is crucial, given the potential for varied infrastructure and service capabilities.

What Are the Benefits of Dental Chairs in Hospitals?

Hospitals utilize multi-functional dental chairs that are designed for surgical procedures. These chairs often feature advanced positioning capabilities and are compatible with various dental equipment, enhancing operational efficiency. By improving patient throughput, hospitals can maximize their service delivery. Buyers from the Middle East and Europe should consider sourcing chairs that meet international safety and hygiene standards, ensuring they are suitable for high-demand environments.

How Do Mobile Dental Units Leverage Dental Chairs?

Mobile dental units use compact and portable dental chairs to provide on-site services, particularly in rural or underserved areas. The lightweight design of these chairs allows for easy transportation and quick setup, enabling dental professionals to expand their service reach. For B2B buyers in regions like Colombia or Mexico, it is vital to focus on sourcing chairs that are not only portable but also robust enough to withstand frequent movement and usage.

Why Are Dental Chairs Important in Educational Institutions?

In educational institutions, specialized dental chairs are utilized for training dental students. These chairs mimic real-world usage, providing a realistic environment for practice. The durability and functionality of these chairs can significantly impact the quality of training. International buyers should prioritize sourcing chairs that offer a balance of realism and resilience, ensuring that they can withstand the rigors of frequent use in training programs.

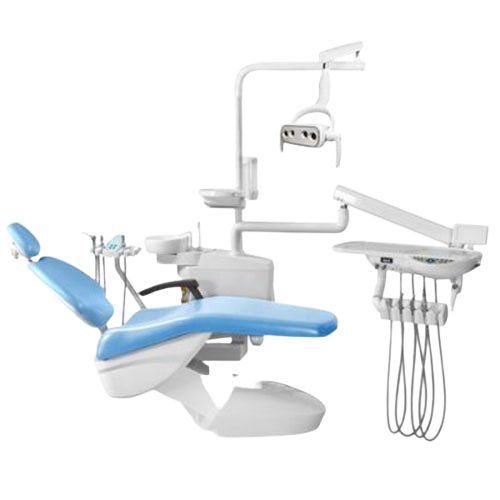

A stock image related to dental chair manufacturers.

How Do Research Facilities Benefit from Advanced Dental Chairs?

Research facilities benefit from advanced dental chairs that integrate diagnostic tools, facilitating innovative research and development in dental science. These chairs enable researchers to conduct detailed studies, contributing to advancements in dental care. When sourcing for such applications, it is essential to prioritize chairs with technological features that can adapt to various research needs, ensuring they support the evolving landscape of dental research.

Related Video: Dental Handpiece Maintenance

3 Common User Pain Points for ‘dental chair manufacturers’ & Their Solutions

Scenario 1: Challenges with Ergonomics and Patient Comfort

The Problem: B2B buyers often face significant challenges in ensuring that dental chairs are ergonomically designed for both the dentist and the patient. In regions like Africa and South America, where healthcare budgets can be tight, the focus may often shift to cost rather than comfort and functionality. As a result, dental practices might invest in chairs that lead to discomfort for patients or strain for practitioners, ultimately impacting the quality of care and patient satisfaction.

The Solution: To overcome this issue, buyers should prioritize sourcing dental chairs from manufacturers that emphasize ergonomic design and patient comfort. This involves conducting thorough research on product specifications, including adjustable features, lumbar support, and materials used. Engaging in discussions with manufacturers about the chair’s design philosophy can provide insights into how these elements enhance usability. Furthermore, consider seeking out user reviews or testimonials from other dental professionals in similar markets to gauge real-world performance. By prioritizing ergonomic solutions, dental practices can improve patient experiences and reduce the risk of occupational strain for staff.

Scenario 2: Difficulty in Maintenance and Durability

The Problem: Another prevalent pain point for B2B buyers is the maintenance and durability of dental chairs. Frequent repairs or replacements can be a significant financial burden, particularly in regions where replacement parts are not readily available. Many buyers report issues with the longevity of cheaper models, leading to costly downtime and disruptions in service.

The Solution: To address this concern, buyers should invest time in evaluating the long-term durability of dental chairs by asking manufacturers about their materials and construction processes. Opt for chairs with warranties that cover extended periods, as this can be an indicator of quality. Additionally, buyers should inquire about the availability of spare parts and the manufacturer’s service support in their region. Establishing a relationship with the manufacturer can also provide buyers with access to maintenance tips and best practices, ensuring that their investment lasts longer and operates efficiently.

Scenario 3: Navigating Compliance and Regulatory Standards

The Problem: Compliance with local health regulations and standards can be a daunting task for B2B buyers, especially in regions with evolving healthcare laws, such as in the Middle East and Europe. Buyers may struggle to find dental chairs that meet both international and local standards, leading to potential fines or, worse, the inability to operate their practice legally.

The Solution: To mitigate compliance issues, it is essential for buyers to engage directly with dental chair manufacturers about their certifications and compliance with local regulations. Request documentation that verifies adherence to standards such as ISO or CE marking, which are crucial in many markets. Additionally, buyers should stay informed about local regulations by consulting with professional dental associations or regulatory bodies in their regions. This proactive approach not only ensures that the dental chairs meet necessary standards but also fosters trust and transparency between buyers and manufacturers, leading to better long-term partnerships.

Strategic Material Selection Guide for dental chair manufacturers

When selecting materials for dental chairs, manufacturers must consider a variety of factors that influence performance, durability, and compliance with international standards. Here, we analyze four common materials used in the production of dental chairs: steel, aluminum, plastic, and upholstery fabrics. Each material has distinct properties, advantages, and limitations that can significantly affect the end product.

What are the Key Properties of Steel for Dental Chairs?

A stock image related to dental chair manufacturers.

Steel is a popular choice for dental chair frames due to its strength and durability. It typically has a high temperature and pressure rating, making it suitable for environments where sterilization is crucial. Additionally, steel exhibits excellent corrosion resistance when properly treated, which is vital in a dental setting where exposure to moisture and cleaning agents is frequent.

Pros & Cons of Steel:

– Pros: High durability, excellent structural integrity, and easy to weld and fabricate.

– Cons: Heavier than other materials, which may complicate mobility. It can also be prone to rust if not adequately coated.

Impact on Application:

Steel is particularly compatible with various dental equipment that requires stable support. Its robustness ensures that the chair can withstand the rigors of daily use.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure that the steel used complies with ASTM standards for strength and corrosion resistance. In Europe and the Middle East, adherence to EN standards is crucial.

How Does Aluminum Compare as a Material for Dental Chairs?

Aluminum is another common choice, known for its lightweight properties and resistance to corrosion. It typically has a lower pressure rating than steel but is still suitable for dental applications where weight reduction is beneficial.

Pros & Cons of Aluminum:

– Pros: Lightweight, corrosion-resistant, and aesthetically pleasing with various finishes available.

– Cons: Less durable than steel and may require more frequent replacement in high-use environments.

Impact on Application:

Aluminum is ideal for mobile dental chairs that need to be easily maneuvered. Its lightweight nature allows for easy adjustments and repositioning during procedures.

Considerations for International Buyers:

Buyers should look for aluminum that meets JIS standards, particularly in regions like Asia and the Middle East, to ensure quality and safety.

What Role Does Plastic Play in Dental Chair Design?

Plastic is often utilized in dental chairs for components such as armrests and seat covers due to its versatility and ease of cleaning. It can be molded into complex shapes and is generally resistant to chemicals.

Pros & Cons of Plastic:

– Pros: Lightweight, cost-effective, and available in various colors and textures.

– Cons: Less durable than metal options and can become discolored or brittle over time.

Impact on Application:

Plastic components are suitable for areas that require frequent cleaning and disinfection, making them ideal for dental environments.

Considerations for International Buyers:

It is essential to select plastics that comply with FDA regulations and local health standards, especially in regions with stringent health regulations like Europe.

How Do Upholstery Fabrics Affect Dental Chair Functionality?

Upholstery fabrics are crucial for patient comfort and hygiene. High-quality fabrics are often treated to be resistant to stains and easy to clean, which is essential in a dental setting.

Pros & Cons of Upholstery Fabrics:

– Pros: Provides comfort, available in various designs, and can be treated for antimicrobial properties.

– Cons: Can wear out over time, requiring replacement, and may be more expensive than other materials.

Impact on Application:

The right upholstery enhances patient experience, making it a vital consideration for dental practices focused on patient comfort.

Considerations for International Buyers:

Buyers should ensure upholstery materials meet local fire safety standards and are compliant with health regulations in their respective regions.

Summary Table of Material Selection for Dental Chairs

| Material | Typical Use Case for Dental Chair Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chair frames and structural components | High durability and strength | Heavier, potential rust issues | Medium |

| Aluminum | Mobile dental chairs and lightweight components | Lightweight and corrosion-resistant | Less durable than steel | Medium |

| Plastic | Armrests, seat covers, and non-structural components | Cost-effective and easy to clean | Less durable, can discolor | Low |

| Upholstery Fabrics | Chair padding and patient contact surfaces | Comfort and aesthetic variety | Wear over time, may require replacement | High |

This guide provides a comprehensive overview of material selection for dental chair manufacturers, offering actionable insights for international B2B buyers. Understanding the properties, advantages, and limitations of each material can help in making informed purchasing decisions tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for dental chair manufacturers

What Are the Typical Manufacturing Processes for Dental Chair Manufacturers?

The manufacturing of dental chairs involves several critical stages that ensure the final product is functional, durable, and compliant with industry standards. Understanding these stages can significantly aid international B2B buyers in making informed purchasing decisions.

How Are Materials Prepared for Dental Chair Manufacturing?

The initial stage of the manufacturing process focuses on material preparation, which is crucial for the performance and longevity of dental chairs. Manufacturers typically utilize high-quality materials such as:

- Steel and Aluminum: Commonly used for the frame due to their strength and durability.

- Plastic and Upholstery Materials: These materials are chosen for comfort and ease of cleaning.

- Electronics: Components such as motors and controls are sourced for their reliability and performance.

Before production begins, these materials undergo thorough inspections to ensure they meet specific criteria for quality and safety. This step is vital as it minimizes the risk of defects during the later stages of manufacturing.

What Key Techniques Are Used in Forming Dental Chairs?

Once the materials are prepared, the forming stage involves shaping these materials into the components of the dental chair. Key techniques include:

- Metal Fabrication: Processes such as cutting, bending, and welding are employed to create the chair’s frame.

- Injection Molding: Used for producing plastic components that require precise shapes and durability.

- Upholstery Techniques: These techniques are applied to cover the chair with appropriate materials, ensuring comfort and aesthetics.

Each technique requires skilled labor and specialized machinery, which significantly impacts the quality of the final product.

How Is the Assembly of Dental Chairs Conducted?

The assembly process combines all the individual components into a complete dental chair. This stage typically includes:

- Sub-Assembly: Components such as the base, seat, and backrest are assembled separately before being joined together.

- Electrical Assembly: Motors and electronic controls are integrated at this stage, ensuring that all functions operate smoothly.

- Final Assembly: The complete chair is assembled, including the attachment of any additional features like armrests, headrests, and instrument trays.

Assembly lines often employ lean manufacturing principles to reduce waste and increase efficiency, which can be beneficial for international buyers seeking cost-effective solutions.

What Finishing Processes Are Important for Dental Chairs?

Finishing processes enhance the aesthetic appeal and functionality of dental chairs. These processes may include:

- Surface Treatment: Techniques such as powder coating or anodizing are used to protect metal surfaces from corrosion and wear.

- Quality Control Inspection: Before the final product is packaged, it undergoes rigorous inspections to ensure it meets design specifications and functional requirements.

These finishing touches not only improve the appearance but also extend the life of the dental chairs, which is crucial for B2B buyers looking for long-term investments.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is a critical aspect of manufacturing dental chairs, ensuring that products meet safety and performance standards. B2B buyers should be aware of the following international and industry-specific standards:

- ISO 9001: This standard outlines requirements for a quality management system, ensuring consistent product quality and customer satisfaction.

- CE Marking: Essential for products sold in the European Economic Area, this marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: Relevant for dental equipment, these standards focus on the performance and safety of medical devices.

Understanding these standards can help buyers assess the credibility and reliability of potential suppliers.

How Are Quality Control Checkpoints Implemented in the Manufacturing Process?

Quality control (QC) is an integral part of the manufacturing process, with several checkpoints to ensure that products meet established standards. Key QC checkpoints include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers must provide certifications and test reports to verify material quality.

- In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are conducted to monitor compliance with specifications. This includes verifying dimensions, material integrity, and assembly accuracy.

- Final Quality Control (FQC): Before shipping, the completed dental chairs undergo final inspections to ensure they meet all requirements and function as intended.

These checkpoints are crucial for maintaining product integrity and can significantly reduce the likelihood of defects.

What Testing Methods Are Commonly Used in Dental Chair Manufacturing?

Various testing methods are employed to ensure that dental chairs meet performance and safety standards. Common testing methods include:

- Load Testing: Assessing the chair’s ability to withstand weight and pressure without deformation.

- Electrical Safety Testing: Ensuring that all electronic components comply with safety regulations to prevent electrical hazards.

- Durability Testing: Simulating long-term use to evaluate wear and tear on upholstery and mechanical parts.

These testing methods provide buyers with assurance regarding the reliability and safety of the products they are purchasing.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are actionable steps to consider:

- Conduct Audits: Regularly auditing suppliers can provide insights into their manufacturing processes and QC measures. This can be done through onsite visits or third-party audits.

- Request Quality Reports: Suppliers should be able to provide documentation detailing their QC processes, including test results and compliance with standards.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can add an extra layer of assurance, as these firms can conduct unbiased assessments of the manufacturing processes and final products.

These practices not only enhance trust between buyers and suppliers but also help mitigate risks associated with product quality.

What Nuances Should International Buyers Be Aware of Regarding QC and Certification?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several nuances when it comes to quality control and certification:

- Regional Compliance: Different regions may have varying compliance requirements. For example, dental chairs sold in Europe must comply with CE marking, while those in the U.S. must adhere to FDA regulations.

- Cultural and Market Variations: Understanding local market expectations regarding quality can influence purchasing decisions. For example, buyers in emerging markets may prioritize cost-effectiveness over premium features.

- Language and Communication Barriers: Effective communication with suppliers is essential for clarifying quality expectations and certifications. Utilizing bilingual staff or translation services can help mitigate misunderstandings.

By being aware of these nuances, B2B buyers can navigate the complexities of international procurement more effectively, ensuring they receive high-quality dental chairs that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dental chair manufacturers’

In the ever-evolving dental equipment industry, sourcing high-quality dental chairs is crucial for dental practices aiming to provide excellent patient care. This guide outlines a step-by-step checklist for B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to streamline the procurement process and ensure they select the best dental chair manufacturers.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in the sourcing process. Consider the features that are most important for your practice, such as chair height adjustment, ergonomic design, and patient comfort. Additionally, specify the necessary electrical requirements and any integrated technologies, such as LED lights or digital controls.

Step 2: Conduct Market Research

Understanding the market landscape is vital for identifying potential suppliers. Investigate the leading dental chair manufacturers in your target regions and evaluate their product offerings. Utilize industry reports, trade publications, and online platforms to gather insights about emerging trends and customer reviews, which can guide your decision-making process.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have a proven track record of reliability and quality, and don’t hesitate to ask for testimonials from their existing clients.

Step 4: Verify Supplier Certifications

Ensure that the dental chair manufacturers comply with relevant industry standards and certifications. This could include ISO certifications, CE marking in Europe, or FDA approval in the United States. Valid certifications not only guarantee product quality but also indicate the manufacturer’s commitment to safety and regulatory compliance.

Step 5: Request Samples and Demonstrations

Once you’ve narrowed down potential suppliers, request samples or live demonstrations of their dental chairs. This step allows you to assess the quality, comfort, and functionality of the chairs firsthand. Pay attention to the materials used, ease of use, and any additional features that may enhance the patient experience.

Step 6: Discuss Pricing and Payment Terms

Engage in detailed discussions about pricing structures, payment terms, and potential discounts for bulk purchases. Understanding the total cost of ownership, including warranty and maintenance services, is essential for making a financially sound decision. Ensure that the pricing aligns with your budget while still meeting your quality requirements.

Step 7: Establish a Long-term Relationship

Building a long-term relationship with your chosen supplier can lead to better pricing, priority service, and access to new products. Communicate your expectations clearly and ensure that the supplier is willing to support your practice in the long run. Regular communication can help resolve issues quickly and foster a productive partnership.

By following these steps, B2B buyers can effectively navigate the procurement process for dental chairs, ensuring they select a manufacturer that meets their needs and enhances their practice’s capabilities.

Comprehensive Cost and Pricing Analysis for dental chair manufacturers Sourcing

What Are the Key Cost Components for Dental Chair Manufacturers?

When sourcing dental chairs, international B2B buyers must understand the various cost components that contribute to the final price. These components include:

-

Materials: The choice of materials significantly influences the cost of dental chairs. High-quality upholstery, durable metals, and advanced plastics are common in premium models. Buyers should evaluate the long-term durability of materials to ensure they align with their needs.

-

Labor Costs: Labor costs vary widely by region. Manufacturers in countries with lower labor costs may offer more competitive pricing, but this can sometimes come at the expense of quality. It’s essential to assess the skill level and training of the workforce to gauge the expected quality of the product.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. Buyers should inquire about how these costs are allocated in the pricing structure to understand the overall value being offered.

-

Tooling and Equipment: The initial investment in specialized tooling and machinery can affect pricing. Manufacturers that utilize advanced technology may have higher upfront costs but can offer better quality and more precise manufacturing.

-

Quality Control (QC): Rigorous quality control processes add to the manufacturing cost but are essential for ensuring the reliability and safety of dental chairs. Buyers should ask for details about QC measures in place to ensure product quality.

-

Logistics: Shipping and handling costs can vary based on the location of the manufacturer and the buyer. Understanding Incoterms is crucial, as they dictate who bears the costs and risks during transport.

-

Margin: Profit margins for manufacturers can vary based on competition, market demand, and brand positioning. Buyers should be aware of these margins when negotiating prices.

How Do Price Influencers Impact Dental Chair Sourcing?

Several factors can influence the pricing of dental chairs, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger quantities often leads to lower per-unit costs. Buyers should negotiate MOQs to maximize cost efficiency.

-

Specifications and Customization: Custom features and specifications can increase the cost. Buyers should clearly outline their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Chairs made from high-grade materials or those that meet specific certifications (e.g., ISO) may command higher prices. Buyers should assess the necessity of these certifications based on their market needs.

-

Supplier Factors: The reputation and reliability of the supplier play a significant role in pricing. Established manufacturers may offer better warranties and support, which can justify a higher price.

-

Incoterms: Understanding the implications of different Incoterms can help buyers manage costs effectively. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) define who pays for shipping and insurance, affecting total costs.

What Are the Best Buyer Tips for Cost-Efficient Dental Chair Sourcing?

To navigate the complexities of sourcing dental chairs, buyers should consider the following tips:

-

Negotiate Effectively: Establish a clear understanding of the cost breakdown and be prepared to negotiate terms that can lead to cost reductions. Leverage volume purchasing as a bargaining chip.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the purchase price but also the long-term costs associated with maintenance, warranties, and potential repairs. A cheaper chair might lead to higher TCO if it requires frequent servicing.

-

Understand Pricing Nuances for International Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional price differences due to local market conditions, import tariffs, and currency fluctuations. Always request indicative prices and clarify any additional costs that may arise during the procurement process.

-

Request Samples and Test Products: Before finalizing large orders, request samples to evaluate the quality firsthand. This can prevent costly mistakes and ensure that the products meet your standards.

By understanding the cost structure, price influencers, and effective negotiation strategies, international B2B buyers can make informed decisions when sourcing dental chairs, ultimately leading to better investment outcomes.

Alternatives Analysis: Comparing dental chair manufacturers With Other Solutions

Exploring Alternatives to Dental Chairs: What Are the Options for B2B Buyers?

In the dental industry, the choice of equipment is crucial for operational efficiency and patient comfort. While traditional dental chairs from established manufacturers remain the go-to solution, emerging alternatives present viable options worth considering. This section examines how dental chair manufacturers stack up against other solutions such as portable dental units and tele-dentistry technologies.

| Comparison Aspect | Dental Chair Manufacturers | Portable Dental Units | Tele-Dentistry Technologies |

|---|---|---|---|

| Performance | High stability and comfort for patients; designed for prolonged use | Moderate; suitable for short-term use in various settings | Variable; mainly for consultation and diagnosis, not physical treatment |

| Cost | Typically ranges from $2,000 to $10,000 depending on features | Generally lower, ranging from $500 to $3,000 | Cost-effective for consultations; subscription models may apply |

| Ease of Implementation | Requires installation and dedicated space; can be complex | Easy to set up and transport; minimal installation needed | Requires internet access and basic tech setup |

| Maintenance | Regular maintenance needed; parts may be expensive | Low maintenance; fewer parts to manage | Minimal maintenance; software updates required |

| Best Use Case | Ideal for established dental practices with high patient volumes | Excellent for mobile dentistry, outreach programs, or temporary setups | Best for remote consultations and follow-ups, especially in underserved areas |

What Are the Pros and Cons of Portable Dental Units?

Portable dental units provide a flexible alternative to traditional dental chairs, especially beneficial in mobile dentistry settings. Their main advantage lies in their cost-effectiveness and ease of transport. Practices that require equipment for outreach or temporary clinics can significantly benefit from these units. However, they may lack the stability and comfort associated with traditional dental chairs, making them less suitable for prolonged procedures. Additionally, the limited workspace can hinder complex dental treatments.

How Do Tele-Dentistry Technologies Compare?

Tele-dentistry technologies represent a groundbreaking alternative to conventional dental setups, allowing for remote consultations and diagnostics. This method has gained traction, especially in regions with limited access to dental care. The primary benefits include cost savings and the ability to reach patients in remote locations. However, tele-dentistry cannot replace in-person treatment and is primarily useful for consultations, follow-ups, and minor assessments. This limitation may necessitate a hybrid approach, combining tele-dentistry with traditional methods.

Conclusion: Choosing the Right Solution for Your Dental Practice

When evaluating alternatives to dental chair manufacturers, B2B buyers should consider their specific operational needs, patient demographics, and budget constraints. While traditional dental chairs offer unmatched stability and comfort for extensive procedures, portable units and tele-dentistry present innovative solutions for practices seeking flexibility or access to underserved populations. Ultimately, the decision should align with the practice’s goals, whether it’s enhancing patient experience, expanding reach, or optimizing costs. By carefully analyzing these options, buyers can make informed decisions that best fit their unique circumstances.

Essential Technical Properties and Trade Terminology for dental chair manufacturers

What Are the Key Technical Properties of Dental Chairs?

When sourcing dental chairs, understanding the technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

1. Material Grade

The materials used in dental chairs significantly impact durability and hygiene. High-grade materials like stainless steel and medical-grade plastics are preferred due to their resistance to corrosion and ease of cleaning. For B2B buyers, selecting chairs made from high-quality materials ensures longevity and compliance with health regulations, which is particularly important in regions like Africa and the Middle East, where durability against various climatic conditions is essential.

2. Weight Capacity

Weight capacity is a critical specification that indicates how much load a dental chair can safely support. Typical chairs can accommodate between 120 kg to 200 kg, depending on their design and construction. This specification is vital for dental practices that serve diverse patient demographics, ensuring safety and comfort for all users. Buyers should prioritize chairs with higher weight capacities to cater to a broader range of patients.

3. Adjustability and Ergonomics

Dental chairs should offer various adjustments, including height, backrest angle, and leg support. Ergonomic designs reduce strain on dental professionals during procedures and enhance patient comfort. For international buyers, especially in Europe, where regulations on workplace ergonomics are stringent, investing in adjustable chairs can lead to improved staff well-being and productivity.

4. Tolerance Levels

Tolerance refers to the acceptable variation in dimensions and performance of the dental chair components. High tolerance levels ensure that parts fit together seamlessly, enhancing the chair’s functionality and safety. For B2B buyers, understanding tolerance specifications is essential to ensure compatibility with other dental equipment and to maintain operational efficiency in dental practices.

5. Electrical Specifications

Most modern dental chairs are equipped with electrical systems for functions such as reclining and operating dental tools. It’s crucial to consider voltage and power requirements, especially for buyers in regions with varying electrical standards. Ensuring compatibility with local electrical systems can prevent operational issues and enhance the usability of the equipment.

What Are Common Trade Terms in Dental Chair Manufacturing?

Understanding industry jargon is key to navigating the procurement process effectively. Here are some commonly used trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships is crucial when sourcing dental chairs, as it impacts the quality and warranty of the equipment. It’s advisable to inquire about the OEM status of the dental chair to ensure reliability and support.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for international buyers in Africa and South America, where budget constraints may dictate purchasing decisions. Understanding MOQ can help in negotiating better terms and ensuring that inventory levels align with demand.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers. For B2B buyers, submitting an RFQ can lead to competitive pricing and better terms. It’s beneficial to detail specific requirements in the RFQ to receive tailored quotes that align with operational needs.

4. Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for buyers to understand shipping costs, delivery timelines, and liability. Different Incoterms can significantly affect the overall cost of dental chairs, making it crucial for buyers to clarify these terms during negotiations.

5. Warranty and Service Agreements

These terms outline the manufacturer’s commitment to repair or replace defective products within a specified period. Understanding warranty conditions is essential for buyers to mitigate risks associated with equipment failure. It’s advisable to review warranty terms carefully to ensure adequate coverage and support for the dental chairs.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions when sourcing dental chairs, ultimately enhancing their purchasing efficiency and operational success.

Navigating Market Dynamics and Sourcing Trends in the dental chair manufacturers Sector

What Are the Current Market Dynamics and Key Trends in the Dental Chair Manufacturing Sector?

The dental chair manufacturing sector is experiencing significant transformations driven by technological advancements and shifting market demands. Global factors such as rising healthcare expenditure, an increasing aging population, and greater awareness of oral health are propelling market growth. In regions like Africa and South America, the expansion of dental services and clinics is leading to heightened demand for efficient and ergonomic dental chairs.

Emerging technologies such as tele-dentistry and smart dental solutions are reshaping the landscape. For instance, integration of IoT in dental chairs allows for real-time monitoring of equipment performance, enhancing maintenance and reducing downtime. Additionally, manufacturers are increasingly adopting automation in their production processes, which not only improves efficiency but also ensures consistent quality.

B2B buyers, particularly in Europe, the Middle East, and Latin America, should be aware of the trend towards modular designs that offer flexibility in clinic layouts and can accommodate various dental procedures. This adaptability is crucial for practices looking to optimize space and functionality. Furthermore, the rise of e-commerce platforms for sourcing dental equipment is making it easier for international buyers to access a wider range of products and suppliers, fostering competitive pricing and innovation.

How Is Sustainability and Ethical Sourcing Influencing the Dental Chair Manufacturing Sector?

Sustainability is becoming a cornerstone in the dental chair manufacturing industry, with an increasing emphasis on reducing environmental impact. B2B buyers are encouraged to consider manufacturers who prioritize eco-friendly materials and sustainable production practices. This includes the use of recyclable materials and processes that minimize waste and energy consumption.

Ethical sourcing is also gaining traction, as buyers seek to establish supply chains that reflect their values. Certifications such as ISO 14001 for environmental management and FSC (Forest Stewardship Council) for responsible sourcing are becoming essential criteria in supplier selection. By choosing manufacturers who adhere to these standards, buyers not only enhance their corporate social responsibility but also appeal to environmentally-conscious consumers.

In the context of dental chairs, manufacturers are exploring biodegradable materials and low-impact manufacturing processes. This shift not only benefits the planet but can also lead to cost savings in the long run as waste management and compliance costs decrease. B2B buyers should actively inquire about the sustainability credentials of suppliers to ensure alignment with their own ethical sourcing goals.

What Is the Brief History and Evolution of Dental Chair Manufacturing?

The dental chair has evolved significantly since its inception in the late 19th century. Initially designed for basic functionality, these chairs have transformed into sophisticated pieces of equipment that enhance the efficiency and comfort of dental procedures. Early models were manually operated, providing little in terms of patient comfort or ergonomic design.

The introduction of electric dental chairs in the mid-20th century marked a pivotal shift, allowing for easier adjustments and improved patient accessibility. Over the years, advancements in materials and technology have enabled manufacturers to produce chairs that are not only more durable but also customizable to meet the specific needs of various dental practices.

Today, dental chairs are equipped with features such as integrated lighting, adjustable positions, and even built-in entertainment systems for patients. This evolution reflects a broader trend in healthcare towards enhancing patient experience while also improving operational efficiency for dental practitioners. As this sector continues to innovate, B2B buyers must stay informed about the latest developments to make strategic sourcing decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of dental chair manufacturers

-

How do I choose the right dental chair manufacturer for my practice?

Choosing the right dental chair manufacturer involves assessing several factors. Start by evaluating the manufacturer’s reputation and experience in the market. Check for certifications and compliance with international standards, particularly if you are sourcing from regions like Africa or South America, where regulations may vary. Additionally, consider the manufacturer’s product range and customization options to ensure they can meet your specific needs. Reading reviews and testimonials from other B2B buyers can provide valuable insights into product quality and customer service. -

What features should I look for in a dental chair?

When selecting a dental chair, prioritize ergonomic design, adjustability, and patient comfort. Look for features such as multi-function controls, easy-to-clean materials, and compatibility with dental equipment. An integrated delivery system and adequate weight capacity are also essential. For international buyers, inquire about local service support and warranty terms, as these can greatly impact long-term satisfaction and operational efficiency in your practice. -

What are the typical minimum order quantities (MOQ) for dental chairs?

Minimum order quantities (MOQ) for dental chairs can vary significantly based on the manufacturer and your location. Typically, MOQs range from 1 to 10 units for smaller manufacturers, while larger manufacturers might have higher MOQs. It’s advisable to discuss your requirements directly with the manufacturer to negotiate terms that suit your purchasing needs, especially if you are a startup or a smaller clinic. Keep in mind that bulk orders may also lead to discounts. -

What payment terms should I expect when purchasing dental chairs internationally?

Payment terms can vary among manufacturers, but common practices include advance payment, partial upfront payments, or letter of credit arrangements. For international transactions, it’s crucial to clarify currency, payment methods (bank transfer, credit card, etc.), and any additional fees (like customs duties). Establishing clear payment terms upfront can help avoid misunderstandings and ensure a smooth transaction. -

How can I ensure the quality of dental chairs from international suppliers?

To ensure product quality from international suppliers, request detailed specifications and certifications that verify compliance with international standards (such as ISO or CE). Conducting factory visits or third-party inspections can also be beneficial. Additionally, ask for samples before placing a large order, and establish a clear quality assurance process to address any defects or issues that may arise during shipping. -

What logistics considerations should I keep in mind when importing dental chairs?

When importing dental chairs, consider shipping methods, timelines, and customs regulations specific to your country. Evaluate the total landed cost, including shipping, taxes, and duties, to avoid unexpected expenses. Partnering with a logistics provider experienced in medical equipment can simplify the process and ensure compliance with local regulations. Lastly, ensure that your chairs are properly packaged to prevent damage during transit. -

How can I customize dental chairs to fit my practice’s branding?

Customization options for dental chairs often include color choices, upholstery materials, and additional features tailored to your practice’s needs. Many manufacturers offer bespoke solutions, so it’s essential to communicate your requirements clearly during the inquiry process. Be sure to ask about lead times for custom orders, as they may differ from standard models. This customization can enhance your practice’s branding and improve patient experience. -

What are the common warranty terms for dental chairs?

Warranty terms for dental chairs typically range from one to five years, covering defects in materials and workmanship. Be sure to clarify what the warranty includes, such as parts and labor, and understand the claim process. For international buyers, inquire about the availability of local service centers to facilitate repairs and maintenance. A robust warranty can provide peace of mind and protect your investment in high-quality dental equipment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dental chair manufacturers

The global landscape for dental chair manufacturing is evolving rapidly, driven by technological advancements and changing buyer preferences. Strategic sourcing has emerged as a vital approach for international B2B buyers looking to optimize their procurement processes. Key takeaways include the importance of evaluating suppliers not just on price, but also on quality, innovation, and after-sales support. For buyers in Africa, South America, the Middle East, and Europe, understanding local market dynamics and supplier capabilities can significantly enhance sourcing strategies.

How can B2B buyers leverage strategic sourcing for better outcomes? Engaging in thorough market research, establishing clear communication with suppliers, and prioritizing long-term partnerships will yield better results. As the demand for high-quality dental equipment continues to grow, buyers should not only focus on immediate needs but also consider future trends and sustainability practices.

Looking ahead, the dental chair manufacturing sector is set for continued innovation. International buyers are encouraged to stay informed about emerging technologies and regulatory changes that could impact their sourcing decisions. By embracing a proactive sourcing strategy, B2B buyers can position themselves for success in this competitive market.