Discover Top Diesel Generator Manufacturers: Your Guide (2025)

Introduction: Navigating the Global Market for diesel generator manufacturer

In today’s rapidly evolving global market, sourcing reliable diesel generators can be a daunting challenge for international B2B buyers. With diverse applications ranging from industrial power supply to emergency backup systems, understanding the nuances of different manufacturers is essential. This guide serves as a comprehensive resource, addressing critical aspects such as types of diesel generators, their applications, supplier vetting processes, and cost considerations.

International buyers from regions like Africa, South America, the Middle East, and Europe—especially in countries like Saudi Arabia and Germany—face unique challenges in identifying the right diesel generator manufacturer that aligns with their operational needs and budget constraints. The complexities of logistics, regulatory compliance, and market dynamics can complicate the purchasing process.

By leveraging the insights provided in this guide, you will be empowered to make informed purchasing decisions that enhance operational efficiency and reliability. From understanding the technical specifications to evaluating supplier credentials, this resource is designed to facilitate strategic sourcing and foster long-term partnerships with trusted manufacturers. Whether you are looking to invest in a single unit or a large fleet, navigating the global market for diesel generators has never been more accessible and actionable.

Understanding diesel generator manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Open-Frame Diesel Generators | Lightweight, portable, minimal noise insulation | Construction, Events, Temporary Power | Pros: Cost-effective, easy transport. Cons: Limited noise reduction, less durable. |

| Enclosed Diesel Generators | Soundproof casing, robust construction | Industrial, Commercial, Backup Power | Pros: Quiet operation, weather-resistant. Cons: Heavier, higher initial cost. |

| Mobile Diesel Generators | Trailer-mounted, high mobility | Mining, Oil & Gas, Remote Sites | Pros: Versatile, can be towed. Cons: Requires towing vehicle, may have limited fuel capacity. |

| Stationary Diesel Generators | Fixed installation, high capacity | Hospitals, Data Centers, Manufacturing | Pros: High efficiency, reliable power. Cons: Installation costs, less flexible. |

| Hybrid Diesel Generators | Combines diesel with renewable energy sources | Sustainable Projects, Remote Areas | Pros: Eco-friendly, reduced fuel costs. Cons: Complex maintenance, higher upfront investment. |

What Are the Key Characteristics of Open-Frame Diesel Generators?

Open-frame diesel generators are characterized by their lightweight and portable design, making them ideal for temporary power solutions. These generators are often used in construction sites, outdoor events, and other scenarios where mobility is a priority. When considering an open-frame generator, buyers should evaluate the balance between portability and noise, as these units typically offer minimal noise insulation, which may not be suitable for all environments.

How Do Enclosed Diesel Generators Differ from Other Types?

Enclosed diesel generators feature a soundproof casing that significantly reduces noise levels, making them suitable for industrial and commercial applications. Their robust construction protects the engine from environmental factors, ensuring durability and longevity. B2B buyers should consider the higher initial investment against the benefits of quieter operation and increased weather resistance, especially in urban settings or areas with stringent noise regulations.

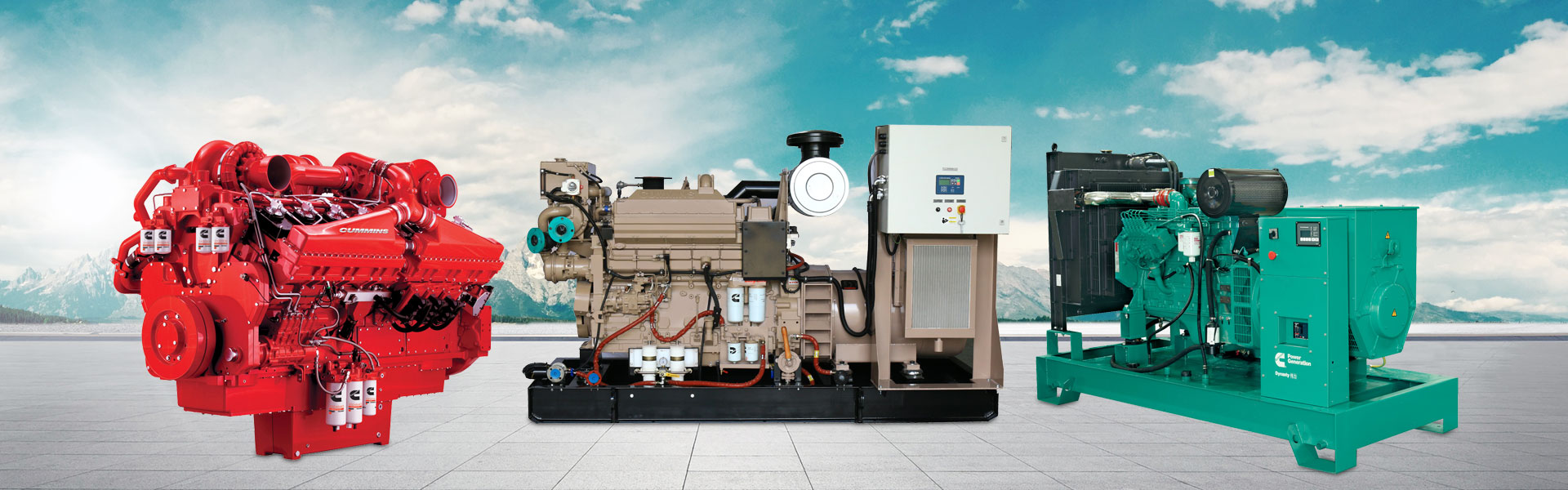

A stock image related to diesel generator manufacturer.

What Makes Mobile Diesel Generators a Flexible Choice for B2B Buyers?

Mobile diesel generators are designed for high mobility, often mounted on trailers for easy transport. They are particularly valuable in sectors like mining, oil & gas, and remote site operations, where power needs can change rapidly. When purchasing mobile generators, companies should assess the towing capabilities and fuel capacity, as these factors can impact operational efficiency and logistics.

Why Are Stationary Diesel Generators Preferred for Large Operations?

Stationary diesel generators are fixed installations known for their high capacity and reliability, making them the go-to choice for critical operations like hospitals and data centers. Their efficiency in providing consistent power can justify the installation costs for businesses that require uninterrupted energy supply. Buyers should consider the long-term operational costs and maintenance needs, as these factors play a crucial role in total ownership costs.

How Do Hybrid Diesel Generators Support Sustainable Practices?

A stock image related to diesel generator manufacturer.

Hybrid diesel generators combine traditional diesel engines with renewable energy sources, such as solar or wind power. This innovative approach is particularly appealing to businesses focused on sustainability and reducing carbon footprints. While hybrid systems may involve a higher upfront investment and complex maintenance, the potential for lower fuel costs and environmental benefits makes them a compelling choice for projects in remote areas or those aiming for green certifications. B2B buyers should weigh these factors against their operational needs and sustainability goals.

Related Video: 5KW to 10KW Air Cooled Silent Diesel Generator for home Reliable and low cost generator

Key Industrial Applications of diesel generator manufacturer

| Industry/Sector | Specific Application of Diesel Generator Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Powering construction sites during outages | Ensures uninterrupted operations and project timelines | Fuel efficiency, power output, and mobility capabilities |

| Mining | Providing reliable power for remote mining operations | Enhances productivity and safety in isolated locations | Durability, ease of maintenance, and service availability |

| Telecommunications | Backup power for cell towers and data centers | Maintains connectivity and service reliability | Load capacity, emissions standards, and noise levels |

| Agriculture | Supporting irrigation systems and processing facilities | Boosts productivity and reduces crop losses | Fuel availability, adaptability to local conditions, and cost-effectiveness |

| Healthcare | Emergency power for hospitals and clinics | Guarantees critical care and patient safety | Compliance with health regulations, reliability, and service support |

How Are Diesel Generators Used in the Construction Industry?

In the construction sector, diesel generators are vital for powering equipment and tools on-site, especially in regions with unreliable electricity. They provide a reliable power source that helps keep projects on schedule, preventing costly delays. International buyers must consider factors such as fuel efficiency and output capacity to ensure that the generators can handle the demands of various construction equipment. Additionally, mobility features are crucial for transporting generators between different project sites.

What Role Do Diesel Generators Play in Mining Operations?

In the mining industry, diesel generators are indispensable for powering machinery in remote locations where grid power is unavailable. They enhance productivity by providing a constant energy supply for drilling, crushing, and processing operations. Buyers in this sector should prioritize the durability and maintenance ease of the generators, as they often operate in harsh environments. Furthermore, access to reliable service and parts is essential to minimize downtime and maintain operational efficiency.

Why Are Diesel Generators Critical for Telecommunications?

Telecommunications companies rely on diesel generators to ensure uninterrupted service during power outages. These generators are essential for powering cell towers and data centers, which must maintain connectivity at all times. For international buyers, sourcing generators with adequate load capacity and low emissions is vital to comply with environmental regulations. Additionally, noise levels should be considered, particularly in urban areas where regulations may restrict sound output.

How Do Diesel Generators Benefit the Agriculture Sector?

In agriculture, diesel generators support irrigation systems and processing facilities, ensuring that crops receive the necessary water and that processing does not halt due to power failures. This reliability boosts productivity and reduces the risk of crop losses due to equipment downtime. Buyers should focus on the adaptability of generators to local conditions, such as fuel availability and the specific energy needs of agricultural operations. Cost-effectiveness is also a key consideration for maximizing return on investment.

What Is the Importance of Diesel Generators in Healthcare Settings?

Healthcare facilities depend on diesel generators for emergency power supply to maintain critical operations during outages. These generators ensure that life-saving equipment remains operational, safeguarding patient care and safety. When sourcing generators for healthcare, compliance with health regulations is non-negotiable. Buyers must also evaluate the reliability of the equipment and the availability of service support to ensure that any issues can be addressed promptly, thereby minimizing risks to patient safety.

Related Video: HOW A DIESEL GENERATOR WORKS -ANIMATION

3 Common User Pain Points for ‘diesel generator manufacturer’ & Their Solutions

Scenario 1: Difficulty in Sizing the Diesel Generator for Specific Needs

The Problem: Many B2B buyers struggle with accurately sizing diesel generators for their operational requirements. This often leads to purchasing a unit that is either too small to meet energy demands or too large, resulting in unnecessary costs and inefficiencies. For example, a manufacturing facility in South America might miscalculate its peak load needs, leading to frequent power shortages or wasted fuel costs due to an oversized generator. This sizing dilemma not only impacts operational efficiency but can also lead to significant financial losses.

The Solution: To overcome this issue, buyers should engage in a thorough load analysis before selecting a diesel generator. This involves assessing the total power requirements by examining all electrical loads, including peak and continuous loads. Buyers can collaborate with an experienced diesel generator manufacturer who offers consulting services, ensuring they provide accurate calculations. Additionally, utilizing advanced software tools that simulate load demands can aid in making informed decisions. It’s advisable to consider future expansion plans and potential load increases when sizing the generator, ensuring that the selected model can accommodate growth without the need for immediate replacement.

Scenario 2: Concerns Over Generator Reliability and Maintenance

The Problem: Reliability is a top concern for B2B buyers, especially in regions like Africa and the Middle East where power outages can severely disrupt business operations. Buyers often fear that a diesel generator may fail during critical times, leading to costly downtimes. For instance, a healthcare facility in Saudi Arabia could face dire consequences if its backup generator fails during a power outage, jeopardizing patient care and safety.

The Solution: To ensure reliability, buyers should prioritize sourcing generators from manufacturers with a strong reputation for quality and reliability. Look for models that come with extended warranties and comprehensive maintenance plans. It’s also beneficial to establish a preventive maintenance schedule, which includes regular inspections, oil changes, and component checks. Buyers can also consider investing in telemetry systems that provide real-time performance monitoring, alerting them to potential issues before they lead to failure. Engaging with local service providers who specialize in diesel generator maintenance can ensure that support is readily available, further enhancing reliability.

Scenario 3: Environmental Regulations and Compliance Issues

The Problem: As environmental regulations become increasingly stringent across Europe and other regions, B2B buyers face challenges in ensuring their diesel generators comply with local emissions standards. For instance, a construction company in Germany may find itself at risk of fines if its diesel generators exceed allowable emission limits, hindering their ability to operate efficiently and legally.

The Solution: To navigate these regulatory challenges, buyers should proactively research the specific emissions standards applicable in their region. Engaging with manufacturers that specialize in environmentally friendly technologies, such as low-emission engines or hybrid systems, can provide solutions that meet compliance requirements without sacrificing performance. Additionally, buyers should look for generators equipped with advanced emission control technologies like selective catalytic reduction (SCR) and diesel particulate filters (DPF). Establishing a relationship with a knowledgeable distributor can also be invaluable, as they can provide insights on upcoming regulations and help ensure that the chosen generator remains compliant throughout its lifecycle. Regular training for staff on compliance and operational best practices can further mitigate risks associated with environmental regulations.

Strategic Material Selection Guide for diesel generator manufacturer

When selecting materials for diesel generators, manufacturers must consider several factors that impact performance, durability, and compliance with international standards. Below is an analysis of four common materials used in diesel generator manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What are the Key Properties of Steel in Diesel Generators?

Steel is a widely used material in diesel generator construction due to its strength and versatility. It typically offers high tensile strength, making it suitable for heavy-duty applications. Steel components can withstand high temperatures and pressures, which is essential for generator operation. Additionally, corrosion-resistant coatings can enhance its longevity in harsh environments.

Pros: Steel is durable, relatively inexpensive, and can be easily fabricated into complex shapes. It is also widely available, making it a practical choice for manufacturers.

Cons: The primary downside is its susceptibility to corrosion if not properly treated. This can lead to maintenance challenges, particularly in humid or coastal environments.

Impact on Application: Steel is compatible with various media, including diesel fuel and lubricants, but requires protective coatings in corrosive environments.

Considerations for International Buyers: Buyers from regions like Saudi Arabia and South America should ensure compliance with local standards such as ASTM or DIN for steel quality. Additionally, understanding local availability and fabrication capabilities is crucial.

How Does Aluminum Benefit Diesel Generator Manufacturing?

Aluminum is another popular choice for diesel generator components, particularly for housing and enclosures. Its lightweight nature reduces the overall weight of the generator, which can be a significant advantage for mobile applications. Aluminum also has good corrosion resistance, especially when anodized.

Pros: The lightweight characteristic of aluminum aids in transportation and installation, while its resistance to corrosion extends the lifespan of components.

Cons: Aluminum is generally more expensive than steel and may not offer the same level of strength, making it less suitable for high-stress applications.

Impact on Application: Aluminum is compatible with diesel fuel and can withstand moderate temperature variations, but it may require careful design to avoid issues related to thermal expansion.

Considerations for International Buyers: Buyers from Europe, particularly Germany, should consider the environmental impact of aluminum production and seek suppliers with sustainable practices. Compliance with EU regulations on materials can also influence purchasing decisions.

What Role Does Copper Play in Diesel Generator Components?

Copper is primarily used in electrical components of diesel generators, such as wiring and connectors, due to its excellent electrical conductivity. It also has good thermal conductivity, which helps in heat dissipation.

Pros: Copper’s superior conductivity ensures efficient power transmission, while its malleability allows for easy shaping and installation.

Cons: Copper is more expensive than other materials and is prone to corrosion if not properly protected. In certain environments, it may require additional coatings to maintain performance.

Impact on Application: Copper is essential for components that require high electrical performance, but its use in corrosive environments must be carefully managed to avoid degradation.

Considerations for International Buyers: Buyers in the Middle East should be aware of the implications of copper prices, which can fluctuate significantly. Compliance with international electrical standards is also critical for ensuring safety and performance.

Why is Composite Material Gaining Popularity in Diesel Generators?

Composite materials, such as fiberglass reinforced plastics, are becoming increasingly popular in diesel generator manufacturing. These materials offer a unique combination of strength, lightweight properties, and corrosion resistance.

Pros: Composites are highly resistant to corrosion and can be molded into complex shapes, making them ideal for custom applications. They are also lighter than metals, which can reduce transportation costs.

Cons: The main limitation is the higher initial cost and complexity in manufacturing processes. Additionally, composites may not have the same mechanical strength as metals in high-stress applications.

Impact on Application: Composites are particularly suitable for enclosures and non-structural components, where weight savings and corrosion resistance are priorities.

Considerations for International Buyers: Buyers from Africa should evaluate the availability of composite materials and the expertise of local manufacturers in working with these materials. Compliance with international standards for composites is also essential.

Summary Table of Material Selection for Diesel Generators

| Material | Typical Use Case for diesel generator manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, frames | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Housings, enclosures | Lightweight and corrosion-resistant | Higher cost, lower strength | High |

| Copper | Electrical wiring and connectors | Excellent conductivity | Expensive, prone to corrosion | High |

| Composite | Non-structural components, enclosures | Corrosion-resistant, lightweight | Higher initial cost, complex mfg | Medium to High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions that align with performance requirements and compliance standards in their respective regions.

In-depth Look: Manufacturing Processes and Quality Assurance for diesel generator manufacturer

What Are the Key Stages in the Manufacturing Process of Diesel Generators?

The manufacturing of diesel generators involves several critical stages, each contributing to the final product’s reliability and performance. Understanding these stages will empower international B2B buyers to make informed decisions when selecting suppliers.

1. Material Preparation

The first stage involves sourcing high-quality raw materials, such as steel for the frame, copper for windings, and specialized alloys for components like pistons and valves. Manufacturers often establish relationships with certified suppliers to ensure material quality. Buyers should inquire about the supplier’s sourcing strategies and material certifications, as these factors significantly impact the generator’s durability.

2. Forming

In this stage, raw materials are shaped into components through processes such as casting, machining, and stamping. For example, engine blocks are typically cast from high-grade iron or aluminum. It’s crucial for buyers to understand the forming techniques used, as different processes yield varying levels of strength and precision. Manufacturers often employ CNC (Computer Numerical Control) machines for high precision, which can be a point of differentiation among suppliers.

3. Assembly

The assembly phase is where the components come together to form the diesel generator. This stage includes the installation of the engine, alternator, control panel, and cooling systems. A systematic assembly line is often employed, with skilled technicians overseeing the integration of components. Buyers should assess the assembly processes and workforce qualifications when evaluating potential suppliers, as these factors can influence the generator’s overall performance and reliability.

4. Finishing

Finishing processes, such as painting and coating, protect the generator from environmental factors and enhance its aesthetic appeal. Additionally, quality checks are performed during this stage to ensure that all components are correctly installed and functioning. It’s advisable for buyers to request information on the finishing materials and techniques used, as these can affect the generator’s lifespan and maintenance needs.

How Do Diesel Generator Manufacturers Ensure Quality Assurance?

Quality assurance is paramount in the manufacturing of diesel generators. International B2B buyers should be aware of various standards and practices that ensure product reliability and performance.

Relevant International Standards

Manufacturers typically adhere to recognized international standards, such as ISO 9001 for quality management systems. This certification indicates a commitment to consistent quality and customer satisfaction. Additionally, specific industry standards like CE marking (for compliance with European safety regulations) and API standards (for products related to the oil and gas industry) may also apply. Buyers should verify these certifications during the supplier selection process.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated into the manufacturing process to ensure that every component meets the required specifications. Key QC checkpoints include:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet predefined quality standards.

-

In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help catch defects early. This includes monitoring tolerances during machining and ensuring proper assembly techniques.

-

Final Quality Control (FQC): A comprehensive inspection is conducted before the product leaves the facility, including performance testing and visual inspections.

Buyers should inquire about the QC processes a manufacturer employs and the frequency of these checks.

Common Testing Methods for Diesel Generators

Testing methods are crucial for validating the performance and safety of diesel generators. Common methods include:

-

Load Testing: Ensuring the generator can handle its rated load and perform under stress conditions.

-

Vibration Analysis: Identifying potential mechanical issues that could lead to failure.

-

Thermal Imaging: Detecting overheating components to prevent failure during operation.

Buyers should request detailed test reports and certifications from manufacturers to verify compliance with industry standards.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for mitigating risks associated with subpar products. Here are actionable steps that buyers can take:

Conduct Supplier Audits

Buyers should consider conducting on-site audits of potential suppliers. This involves assessing their manufacturing processes, quality assurance practices, and adherence to international standards. Audits can reveal valuable insights into a supplier’s operational capabilities and commitment to quality.

Review Quality Control Reports

Requesting access to quality control reports can provide transparency regarding the supplier’s QC practices. These reports should detail the results of IQC, IPQC, and FQC processes, as well as any corrective actions taken in case of non-conformance.

Engage Third-Party Inspection Services

Utilizing third-party inspection services can offer an unbiased evaluation of the manufacturing process. These services can conduct inspections at various stages of production, ensuring adherence to the agreed specifications and standards.

What Are the Quality Control and Certification Nuances for International Buyers?

When sourcing diesel generators from international suppliers, B2B buyers should be aware of specific nuances related to quality control and certification:

-

Regional Standards Compliance: Different regions may have varying regulatory requirements. For example, generators sold in Europe must comply with CE marking, while those in the Middle East may need to meet GSO standards. Buyers should ensure that suppliers are familiar with and compliant with the regulations applicable to their target markets.

-

Documentation for Customs Clearance: Quality certifications and test reports may be required for customs clearance in certain countries. Buyers should confirm that suppliers can provide the necessary documentation to avoid delays in shipping.

-

Language and Communication Barriers: Engaging with suppliers from different regions may present language challenges. Buyers should ensure that there is clear communication regarding quality expectations and standards to avoid misunderstandings.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions, ensuring they partner with reliable diesel generator manufacturers who meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diesel generator manufacturer’

This guide serves as a practical checklist for international B2B buyers looking to source diesel generators from manufacturers. By following these steps, you can streamline your procurement process, ensuring that you select a supplier who meets your technical requirements, budget, and compliance needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for the diesel generator. Consider factors such as power output, fuel efficiency, noise levels, and emissions standards. This step is crucial to ensure that the generator meets your operational needs and complies with local regulations.

Step 2: Research Potential Manufacturers

Conduct thorough research to identify reputable diesel generator manufacturers. Utilize industry directories, trade shows, and online platforms to compile a list of potential suppliers. Pay attention to manufacturers who have a strong presence in your region, as they are likely to understand local market demands and compliance requirements.

Step 3: Verify Supplier Certifications and Compliance

It is essential to verify that potential suppliers hold the necessary certifications and comply with international standards. Look for certifications such as ISO 9001 for quality management and ISO 14001 for environmental management. Compliance ensures that the manufacturer adheres to safety and environmental regulations, which is especially important in regions with strict laws.

Step 4: Evaluate Supplier Experience and Reputation

Investigate the experience and reputation of each manufacturer on your shortlist. Look for customer testimonials, case studies, and references from similar industries. A supplier with a proven track record is more likely to deliver reliable products and services, reducing the risk of procurement issues down the line.

Step 5: Request Detailed Quotations

Once you have narrowed down your options, request detailed quotations from your selected manufacturers. Ensure that these quotations include not only the pricing but also terms of delivery, warranty conditions, and after-sales support. Comparing comprehensive quotes will help you make an informed decision and avoid hidden costs.

Step 6: Assess After-Sales Support and Maintenance Services

After-sales support is a critical factor in your decision-making process. Inquire about the availability of spare parts, maintenance services, and technical support. A manufacturer that offers robust after-sales services can significantly enhance the longevity and performance of your diesel generator.

Step 7: Negotiate Terms and Finalize the Agreement

Once you have selected a supplier, it’s time to negotiate the terms of the agreement. Discuss payment terms, delivery schedules, and any specific requirements you might have. Clear communication during this phase is vital to establish a mutually beneficial relationship and ensure that both parties have aligned expectations.

By following this step-by-step checklist, B2B buyers can effectively navigate the sourcing process for diesel generators, ultimately leading to a successful procurement experience.

Comprehensive Cost and Pricing Analysis for diesel generator manufacturer Sourcing

What Are the Key Cost Components in Diesel Generator Manufacturing?

Understanding the cost structure of diesel generator manufacturing is essential for international B2B buyers to make informed sourcing decisions. The primary cost components include:

-

Materials: The core materials, such as engines, alternators, and control panels, significantly influence the overall cost. High-quality materials can increase durability but may also raise the price.

-

Labor: Labor costs vary by region and can impact the final pricing. Skilled labor is often required for assembly and quality control, leading to higher costs in areas with stringent labor standards.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses. Efficient factories with optimized processes can help keep these costs down, benefiting buyers through more competitive pricing.

-

Tooling: Initial setup costs for specialized tools and machinery can be substantial. Buyers should consider whether the manufacturer has the necessary tooling to meet specific requirements without incurring excessive costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to the manufacturing cost. Certifications such as ISO can also influence pricing as they demonstrate compliance with international standards.

-

Logistics: Transportation costs, including shipping and customs duties, must be factored in, especially for international buyers. The choice of shipping method (air vs. sea) can also significantly impact costs.

-

Margin: Manufacturers typically add a profit margin to cover their risks and investments. Understanding the expected margin can help buyers negotiate better terms.

How Do Price Influencers Affect Diesel Generator Sourcing?

Several factors can influence the pricing of diesel generators, which are crucial for B2B buyers to consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs and negotiate bulk pricing.

-

Specifications and Customization: Customized generators tailored to specific applications may incur additional costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Higher quality materials and certifications can enhance performance but also increase costs. Buyers should balance quality with budget constraints.

-

Supplier Factors: Supplier reputation and reliability can affect pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is critical for assessing total costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift responsibilities and costs between buyers and sellers.

What Are the Best Negotiation Tips for International B2B Buyers?

Effective negotiation strategies can lead to better pricing and terms for diesel generator purchases:

-

Research Market Prices: Knowledge of current market rates helps in setting realistic expectations and strengthens negotiation positions.

-

Leverage Volume Discounts: If feasible, consolidating purchases with fewer suppliers can lead to significant cost savings.

-

Request Transparent Pricing: Ask suppliers for detailed breakdowns of costs to identify areas for potential savings.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs, including maintenance, fuel efficiency, and potential downtime.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better deals and more favorable terms in future transactions.

What Pricing Nuances Should Buyers from Africa, South America, the Middle East, and Europe Consider?

International buyers should be aware of regional pricing nuances when sourcing diesel generators:

-

Africa: Currency fluctuations and import tariffs can significantly affect costs. Buyers should factor these into their pricing models.

-

South America: Local regulations and environmental standards can influence specifications and costs. Buyers should ensure compliance to avoid additional expenses.

-

Middle East: The demand for reliable power sources often drives prices up. Buyers should be prepared for competitive bidding.

-

Europe: Stricter regulations may lead to higher upfront costs due to compliance requirements, but they can also result in lower operational costs over time.

Disclaimer on Indicative Prices

It’s important to note that prices for diesel generators can vary widely based on the aforementioned factors. Buyers should request quotes from multiple suppliers to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing diesel generator manufacturer With Other Solutions

Understanding the Importance of Exploring Alternatives to Diesel Generators

When considering energy solutions for business operations, it is vital to assess not only the primary option, such as diesel generators, but also alternative technologies that may provide similar benefits. This analysis will help international B2B buyers from regions such as Africa, South America, the Middle East, and Europe evaluate the best fit for their unique circumstances, including budget constraints, environmental regulations, and energy reliability needs.

Comparison Table of Diesel Generators and Alternative Solutions

| Comparison Aspect | Diesel Generator Manufacturer | Solar Power Systems | Natural Gas Generators |

|---|---|---|---|

| Performance | High reliability; capable of providing consistent power in remote areas | Dependent on sunlight; effective for on-grid and off-grid solutions | High efficiency; stable output, but location-dependent |

| Cost | Moderate upfront and operational costs; fuel price volatility | Higher initial investment; low operational costs; incentives available | Moderate initial costs; fluctuating fuel prices |

| Ease of Implementation | Easy to deploy; requires fuel supply chain | Requires space and infrastructure; installation can be complex | Requires existing natural gas infrastructure; simpler than solar |

| Maintenance | Regular maintenance needed; fuel management required | Low maintenance; occasional panel cleaning | Regular maintenance; less frequent than diesel |

| Best Use Case | Remote locations with high energy demand | Sustainable energy solutions; ideal for sunny regions | Areas with existing gas supply; environmentally conscious firms |

What Are the Advantages and Disadvantages of Solar Power Systems?

Solar power systems harness energy from the sun and convert it into electricity. One of the most significant advantages is their low operational costs after installation, as sunlight is free. Additionally, solar energy is environmentally friendly, which can enhance a company’s sustainability profile. However, solar systems may not perform well in areas with limited sunlight and can require a substantial initial investment for installation and infrastructure. Businesses in sunny regions can benefit greatly, but those in less favorable climates may find the reliability of solar power lacking.

How Do Natural Gas Generators Compare in Performance and Cost?

Natural gas generators offer a cleaner alternative to diesel generators, producing lower emissions while providing reliable power. They tend to have a lower operational cost compared to diesel, especially in regions where natural gas is readily available. The initial investment is moderate, but operational costs can fluctuate based on gas prices. However, the implementation of natural gas generators can be limited by the need for existing natural gas infrastructure, which may not be present in all locations. Companies that prioritize environmental sustainability and have access to gas lines may find this option appealing.

Conclusion: How Can B2B Buyers Choose the Right Energy Solution?

Choosing the right energy solution involves evaluating the specific needs of your business, including power requirements, budget constraints, and sustainability goals. While diesel generators provide reliability and immediate power, alternatives like solar power and natural gas generators may offer long-term cost savings and environmental benefits. B2B buyers should consider factors such as location, energy demand, and future scalability when making their decision. A thorough analysis of the pros and cons of each option will ultimately guide buyers in selecting the most appropriate energy solution for their operational needs.

Essential Technical Properties and Trade Terminology for diesel generator manufacturer

What Are the Key Technical Properties of Diesel Generators?

When evaluating diesel generators for procurement, understanding their technical specifications is crucial. Here are several essential properties that B2B buyers should consider:

1. Power Output Rating (kW or kVA)

The power output rating indicates the maximum electrical power a generator can produce. This is typically measured in kilowatts (kW) or kilovolt-amperes (kVA). For B2B buyers, selecting a generator with the appropriate power output is vital to ensure that it meets the operational needs without overloading the system.

2. Fuel Consumption Efficiency

Fuel consumption efficiency is often expressed in liters per hour or gallons per hour at a specified load. This specification is significant for buyers aiming to minimize operational costs. A generator with lower fuel consumption can lead to substantial savings over time, especially in regions where fuel prices fluctuate, such as in parts of Africa and South America.

3. Noise Level (dB)

The noise level of a diesel generator is measured in decibels (dB) and is crucial for compliance with local regulations and community standards. Buyers must consider the noise output, especially if the generator will be used in residential or sensitive environments. Selecting a quieter model can prevent potential disturbances and enhance the generator’s acceptance in urban settings.

4. Cooling System Type

The type of cooling system (air-cooled or liquid-cooled) affects both the operational efficiency and maintenance needs of the generator. Liquid-cooled systems generally provide better performance and longevity, making them preferable for heavy-duty applications. Understanding the cooling system can help buyers choose a generator that aligns with their operational environment and maintenance capabilities.

5. Durability and Material Grade

The material grade of the generator components, such as the engine and chassis, influences its durability and longevity. Common materials include cast iron and high-grade steel. Buyers should assess the material specifications to ensure that the generator can withstand harsh conditions, particularly in regions with extreme climates like the Middle East.

What Are Common Trade Terms Used in the Diesel Generator Industry?

Understanding industry jargon can facilitate smoother negotiations and clearer communication. Here are some key terms that B2B buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, engaging with an OEM can ensure that they receive high-quality, reliable components, which is essential for the longevity of the diesel generator.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. Understanding the MOQ is crucial for buyers, as it can impact budget planning and inventory management. Buyers should negotiate MOQs based on their operational needs and storage capabilities.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It is an essential step in the procurement process, allowing buyers to compare offers and ensure they receive competitive pricing. Crafting a detailed RFQ can lead to better pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital for B2B buyers to understand shipping costs, risks, and insurance obligations.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for B2B buyers to manage project timelines effectively. Buyers should communicate their deadlines clearly to suppliers to avoid delays in project implementation.

By grasping these technical specifications and trade terms, international B2B buyers can make informed decisions when procuring diesel generators, ensuring they select the right products for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the diesel generator manufacturer Sector

What Are the Key Market Drivers Influencing the Diesel Generator Manufacturing Sector?

The diesel generator manufacturing sector is experiencing significant shifts driven by both global economic factors and technological advancements. Key market drivers include the increasing demand for reliable power supply in regions with unstable grids, particularly in Africa and South America. Economic growth in these areas is leading to heightened industrial activity, which in turn boosts the need for diesel generators. Additionally, the rise in data centers and telecommunications infrastructure, especially in the Middle East and Europe, is pushing the demand for uninterrupted power solutions.

Emerging B2B technologies such as IoT integration in diesel generators are transforming how businesses monitor and manage power systems. Smart generators equipped with remote monitoring capabilities allow for predictive maintenance, reducing downtime and operational costs. Moreover, the trend towards hybrid solutions—combining diesel with renewable energy sources—reflects a growing inclination toward energy diversification. International buyers should consider these technologies as they evaluate potential suppliers, ensuring they align with current sourcing trends.

How Can International Buyers Adapt to Sustainability and Ethical Sourcing in the Diesel Generator Sector?

Sustainability and ethical sourcing have become paramount in the global diesel generator market. The environmental impact of diesel generators, particularly in terms of emissions, has prompted manufacturers to innovate towards greener solutions. International B2B buyers must prioritize suppliers that are committed to reducing their carbon footprint and implementing sustainable practices throughout their supply chains.

The importance of ethical sourcing cannot be overstated, as businesses increasingly seek to enhance their corporate social responsibility profiles. Buyers should look for manufacturers that are certified by recognized green certifications such as ISO 14001, which focuses on effective environmental management systems. Additionally, sourcing materials from suppliers who adhere to sustainable practices—such as using recycled components or biofuels—can significantly contribute to a company’s overall sustainability goals. By aligning purchasing decisions with these principles, international buyers can foster positive relationships with stakeholders and enhance their brand reputation.

What Is the Evolution of the Diesel Generator Manufacturing Sector Relevant to B2B Buyers?

The diesel generator manufacturing sector has evolved significantly over the past few decades, shaped by technological advancements and changing market demands. Initially, diesel generators were primarily viewed as backup power solutions. However, with the rise of industrialization and urbanization, particularly in developing regions, their role has expanded to become essential for primary power supply in many sectors, including construction, telecommunications, and healthcare.

In recent years, the focus has shifted towards enhancing efficiency and reducing emissions, leading to innovations in generator design and fuel technology. For B2B buyers, understanding this evolution is crucial as it highlights the importance of selecting suppliers who are not only responsive to current market needs but also proactive in adopting future trends. This insight enables buyers to make informed decisions that align with both their operational requirements and sustainability objectives, ensuring they remain competitive in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of diesel generator manufacturer

-

How do I determine the right diesel generator capacity for my needs?

Selecting the right diesel generator capacity involves assessing your power requirements. Calculate the total wattage of all the equipment you plan to run simultaneously. Consider peak loads, as certain machinery may require more power during startup. It’s advisable to choose a generator with a capacity 20-30% higher than your calculated needs to ensure efficiency and longevity. Engaging with a knowledgeable supplier can also help clarify your requirements based on regional factors like climate and power outages. -

What are the key specifications to look for in a diesel generator?

When sourcing a diesel generator, focus on specifications such as power output (measured in kVA), fuel consumption, noise levels, and emission standards. Ensure it complies with the regulations in your region, especially in Europe, where emission laws are stringent. Additionally, check for features like automatic voltage regulation, durability, and ease of maintenance. A generator with an efficient cooling system can also prolong its lifespan, making it a wise investment. -

What customization options are available when sourcing diesel generators?

Many manufacturers offer customization options, allowing you to tailor the generator to your specific needs. These may include modifications for size, power output, fuel tank capacity, and additional features like soundproof enclosures or mobile trailers. Discussing your requirements with the manufacturer can lead to tailored solutions that enhance performance, particularly in challenging environments typical in regions like Africa and the Middle East. -

What are the common minimum order quantities (MOQ) for diesel generators?

Minimum order quantities can vary widely among manufacturers, typically ranging from one unit to several dozen. Larger manufacturers may offer flexibility for smaller orders, while others might have strict MOQs due to production efficiencies. It’s essential to communicate your needs clearly during the sourcing process, as some manufacturers may be willing to accommodate smaller orders, especially for first-time buyers or trial purchases. -

What payment terms should I expect when purchasing a diesel generator?

Payment terms can differ significantly based on the manufacturer and your relationship with them. Common practices include upfront deposits (usually 30-50%) with the balance due upon delivery or after installation. Some suppliers may offer financing options or extended payment plans for larger orders. It’s crucial to negotiate terms that align with your budget and cash flow, ensuring clarity in all transactions to avoid potential disputes. -

How can I ensure quality assurance when sourcing diesel generators internationally?

To ensure quality assurance, request certifications such as ISO 9001 from manufacturers, which indicates a commitment to quality management systems. Inquire about their testing procedures and warranty offerings. Additionally, consider third-party inspections or certifications from recognized bodies in your region. Establishing a strong communication channel with the manufacturer can also help in monitoring quality throughout the production and delivery processes. -

What logistics considerations should I keep in mind when importing diesel generators?

Logistics play a crucial role in the importation of diesel generators. Consider shipping methods, customs regulations, and the potential for delays in transit. Ensure you have a reliable freight forwarder familiar with international shipping and customs clearance in your region. Additionally, factor in transportation costs to your final destination, as well as potential duties and taxes that may apply upon arrival. -

How do I vet potential diesel generator suppliers effectively?

Vetting suppliers involves conducting thorough research and due diligence. Start by reviewing their business credentials, customer testimonials, and case studies. Ask for references from previous clients, particularly those in your industry or region. Visiting the manufacturing facility, if possible, can provide insights into their operations. Additionally, assess their responsiveness and willingness to address your concerns, which can indicate their level of service and commitment to customer satisfaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for diesel generator manufacturer

The strategic sourcing of diesel generators is essential for international buyers looking to optimize performance, cost, and reliability in their operations. By understanding the unique requirements of diverse markets across Africa, South America, the Middle East, and Europe, businesses can make informed decisions that align with their operational needs. Key takeaways include the importance of evaluating supplier capabilities, ensuring compliance with regional regulations, and leveraging technological advancements to enhance generator efficiency.

How can B2B buyers leverage strategic sourcing for competitive advantage? By fostering strong relationships with manufacturers and suppliers, companies can negotiate better terms, access innovative products, and secure long-term support. This proactive approach not only mitigates risks but also positions businesses to respond swiftly to market changes.

As we look to the future, the demand for reliable power solutions will continue to grow, driven by economic development and increased energy needs. International buyers are encouraged to explore diverse sourcing options, prioritize sustainability, and stay abreast of industry trends. By embracing these strategies, businesses can secure a robust supply chain that meets their operational demands while contributing to a more sustainable energy landscape.