Discover Top Display Rack Suppliers: Your Complete Guide (2025)

Introduction: Navigating the Global Market for display rack supplier

In the competitive landscape of international trade, sourcing a reliable display rack supplier is crucial for businesses aiming to enhance their product presentation and storage solutions. The challenge often lies in identifying suppliers that not only meet quality standards but also understand the diverse needs of markets across Africa, South America, the Middle East, and Europe, including countries like Italy and Germany. This comprehensive guide is designed to equip B2B buyers with actionable insights into the global market for display racks, addressing key considerations such as types of display racks, applications across various industries, supplier vetting processes, and cost analysis.

With the increasing demand for efficient and aesthetically pleasing display solutions, understanding the nuances of sourcing display racks becomes imperative. This guide empowers international buyers to make informed purchasing decisions by providing detailed evaluations of potential suppliers, highlighting the importance of quality certifications, and offering tips on negotiating favorable terms. Additionally, it delves into the latest trends and innovations in the display rack market, ensuring that businesses stay ahead of the curve. By navigating the complexities of sourcing display racks, you can enhance your operational efficiency and drive sales growth in your respective markets.

Understanding display rack supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gondola Display Racks | Double-sided, adjustable shelves, often used in retail settings | Grocery stores, supermarkets | Pros: Versatile, maximizes space. Cons: Can be bulky. |

| Pallet Racks | Heavy-duty, designed for bulk storage, typically in warehouses | Warehouses, distribution centers | Pros: High load capacity, efficient for large items. Cons: Requires significant floor space. |

| Wall-Mounted Racks | Space-saving, fixed to walls, customizable design options | Showrooms, boutiques | Pros: Saves floor space, aesthetically pleasing. Cons: Limited load capacity. |

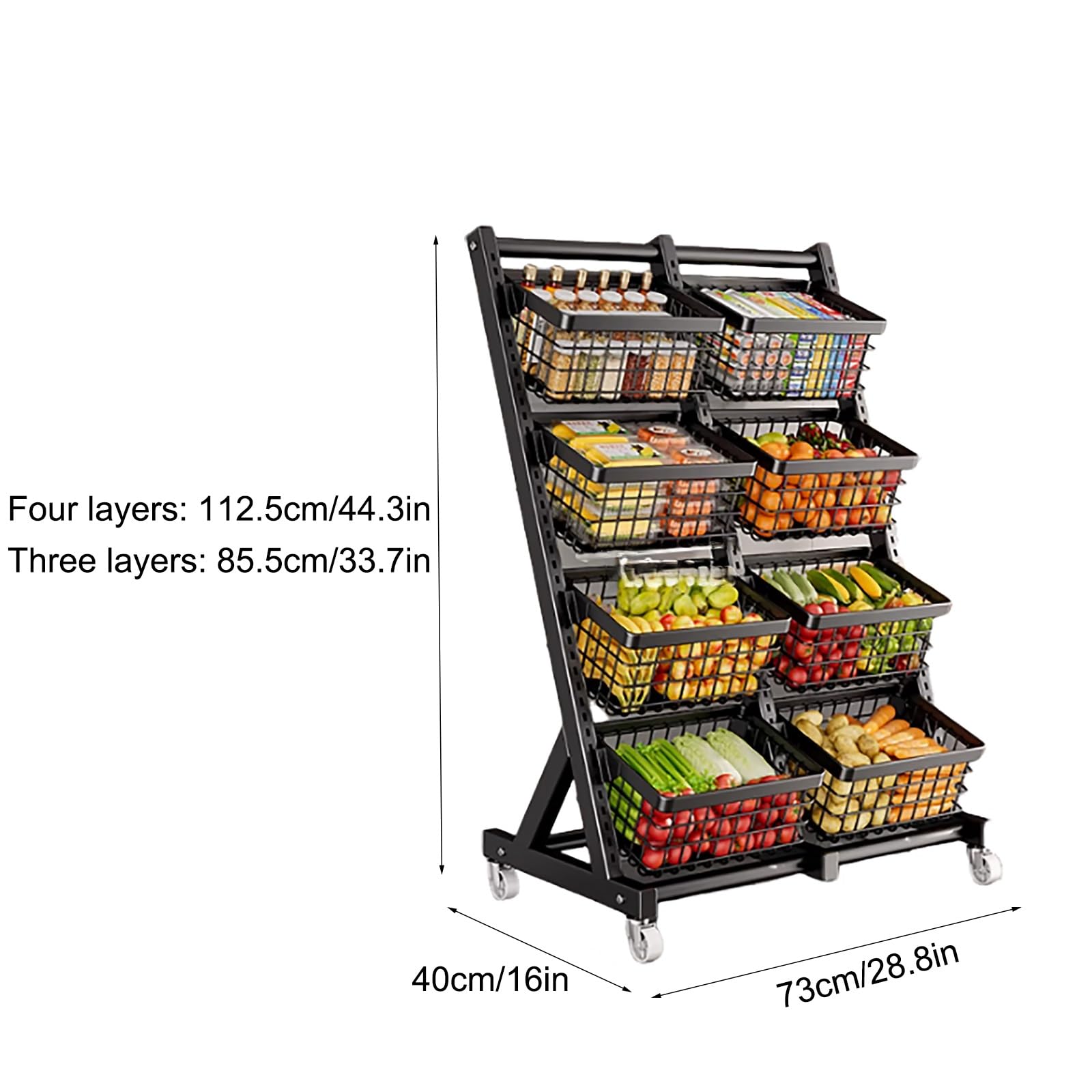

| Mobile Display Racks | Portable, often on wheels, adjustable height and configuration | Trade shows, exhibitions | Pros: Flexible, easy to transport. Cons: May be less stable. |

| Retail Display Stands | Eye-catching designs, often used for promotional purposes | Retail stores, events | Pros: Attracts customer attention, enhances branding. Cons: May have lower durability. |

What Are Gondola Display Racks and Their Key Characteristics?

Gondola display racks are versatile, double-sided shelving units primarily used in retail environments. They feature adjustable shelves, allowing businesses to customize the height and arrangement according to their inventory needs. Suitable for grocery stores and supermarkets, these racks maximize floor space while providing easy access to products. When considering a gondola rack, B2B buyers should evaluate their store layout, product types, and the potential need for future adjustments.

How Do Pallet Racks Serve B2B Buyers?

Pallet racks are heavy-duty storage systems ideal for warehouses and distribution centers. They are designed to hold large quantities of goods, making them perfect for bulk storage. Their key features include adjustable beams and high load capacities, which allow for efficient inventory management. Buyers should consider the available floor space and the specific weight requirements of their products when investing in pallet racks, as they can require substantial room.

What Are the Advantages of Wall-Mounted Racks?

Wall-mounted racks are an excellent solution for businesses looking to save floor space while displaying products attractively. These racks are fixed to walls and can be customized in various designs to match the aesthetic of retail spaces like showrooms and boutiques. While they are visually appealing and functional, buyers must consider their limited load capacity and ensure they can accommodate their display needs without overloading.

Why Choose Mobile Display Racks for Flexibility?

Mobile display racks are designed for flexibility and ease of use, making them ideal for trade shows and exhibitions. These racks often come with wheels, allowing for easy transportation and rearrangement. Their adjustable height and configuration options cater to diverse display needs. B2B buyers should assess the stability and durability of mobile racks, especially if they plan to use them frequently in dynamic environments.

How Do Retail Display Stands Enhance Branding?

Retail display stands are specifically designed to catch the attention of customers and promote products effectively. They come in various shapes and sizes, making them suitable for retail stores and events. While these stands can significantly enhance branding and visibility, buyers should weigh their durability against the promotional benefits they provide, as some stands may not withstand heavy use over time.

Related Video: Display Rack / (Garment Store/Medical Store/Grocery Store)

Key Industrial Applications of display rack supplier

| Industry/Sector | Specific Application of Display Rack Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | In-store Product Display Racks | Enhances product visibility and customer engagement | Durability, design flexibility, and customization options |

| Warehousing & Logistics | Heavy-Duty Storage Racks | Maximizes storage efficiency and space optimization | Load capacity, material quality, and safety certifications |

| Manufacturing | Tool and Parts Storage Racks | Improves organization and accessibility of tools | Size specifications, modularity, and ease of assembly |

| Food & Beverage | Refrigerated Display Racks | Maintains product quality and extends shelf life | Temperature control features, energy efficiency, and hygiene standards |

| Healthcare | Medical Supply Storage Racks | Ensures quick access and organization of medical supplies | Compliance with health regulations, material safety, and ease of cleaning |

How Can Retailers Benefit from Display Racks?

In the retail sector, display racks are critical for showcasing products effectively. Suppliers provide various designs, from simple shelving to elaborate, eye-catching displays, which can significantly enhance product visibility and customer engagement. Retailers looking to source display racks should consider durability and the ability to customize designs to fit their brand aesthetics. Additionally, understanding the local market’s preferences in Africa, South America, the Middle East, and Europe can guide better procurement decisions.

What Advantages Do Warehousing and Logistics Gain from Heavy-Duty Racks?

In warehousing and logistics, heavy-duty storage racks are essential for maximizing space and improving operational efficiency. These racks allow businesses to store a greater volume of goods without sacrificing accessibility. When sourcing these racks, companies must evaluate load capacity and material quality, ensuring they meet safety certifications. For international buyers, factors such as shipping costs and local regulations in their respective regions are crucial considerations.

How Do Manufacturing Facilities Utilize Tool and Parts Storage Racks?

Manufacturers benefit from tool and parts storage racks by enhancing organization and accessibility. These racks streamline workflows, reducing time spent searching for tools and components. Buyers should focus on size specifications and modularity when sourcing, as these factors can directly impact the efficiency of operations. Additionally, ease of assembly can be a significant advantage, especially in regions where skilled labor may be limited.

What Role Do Refrigerated Display Racks Play in the Food and Beverage Sector?

Refrigerated display racks are vital in the food and beverage industry, helping maintain product quality while extending shelf life. These racks not only keep products at optimal temperatures but also attract customers with appealing designs. When sourcing, businesses should prioritize temperature control features and energy efficiency, as these can lead to substantial cost savings. Compliance with hygiene standards is also a critical factor, particularly in regions with stringent health regulations.

How Are Medical Supply Storage Racks Important in Healthcare?

In healthcare settings, medical supply storage racks ensure quick access to essential supplies, which can be critical during emergencies. These racks help organize medical tools and medications, enhancing operational efficiency. Buyers must consider compliance with health regulations and choose materials that are easy to clean and maintain. In regions like Africa and South America, where healthcare infrastructure may vary, understanding local compliance requirements is essential for successful sourcing.

Related Video: Warnerwoods Company uses a perpetual Inventory System

3 Common User Pain Points for ‘display rack supplier’ & Their Solutions

Scenario 1: Difficulty in Customization for Unique Spaces

The Problem: Many B2B buyers face the challenge of finding display racks that fit unique spatial requirements in their retail or warehouse environments. Standard display racks may not align with the dimensions or aesthetic needs of their businesses. This can lead to wasted investment in racks that do not serve their intended purpose, resulting in frustration and delays in product displays.

The Solution: To overcome this problem, buyers should prioritize suppliers that offer customizable display solutions. When sourcing a display rack supplier, inquire about their capability to provide tailored designs that meet specific measurements and design preferences. It’s advisable to provide detailed specifications, including dimensions, weight capacities, and any additional features needed (like wheels for mobility or modular components). Engaging in an initial consultation can also help clarify your needs, allowing the supplier to recommend the best options. By ensuring that the supplier understands your unique space requirements, you can achieve a display solution that maximizes your space and enhances product visibility.

Scenario 2: Concerns Over Durability and Quality

The Problem: Buyers often worry about the durability and quality of display racks, especially in high-traffic environments or when displaying heavy items. Subpar materials can lead to rapid wear and tear, posing safety risks and incurring additional costs for replacements or repairs. This concern is particularly pressing in industries such as retail or logistics, where the integrity of display solutions is paramount.

The Solution: To address durability concerns, it is crucial to conduct thorough research on potential suppliers. Look for suppliers who provide detailed information about the materials used in their display racks, including load capacities and manufacturing standards. Request samples or references from previous clients to gauge the performance of their products in similar environments. Additionally, consider suppliers that offer warranties or guarantees on their products, which can provide peace of mind regarding quality. By selecting a supplier that prioritizes durability, you can ensure that your investment will withstand the test of time and heavy usage.

Scenario 3: Challenges with Assembly and Installation

The Problem: Many B2B buyers encounter difficulties with the assembly and installation of display racks, especially if the racks are complex or require special tools. This can lead to increased labor costs and extended timelines, disrupting business operations. Buyers may feel overwhelmed by the prospect of setting up a new display system without adequate support from their suppliers.

The Solution: To mitigate assembly challenges, buyers should actively seek suppliers who offer comprehensive installation support. This can include detailed assembly instructions, video tutorials, or even on-site installation services. Before finalizing a purchase, inquire about the level of support provided and whether the supplier has a dedicated team for installation assistance. Additionally, consider suppliers that provide modular or easy-to-assemble options, which can significantly reduce the complexity and time required for setup. By choosing a supplier that supports the installation process, you can streamline the integration of display racks into your operations, minimizing disruptions and enhancing efficiency.

Strategic Material Selection Guide for display rack supplier

When selecting materials for display racks, international B2B buyers must consider various factors that influence performance, cost, and compliance with regional standards. Here, we analyze four common materials used in the manufacturing of display racks: steel, aluminum, wood, and plastic. Each material has distinct properties, advantages, and limitations that can impact the overall effectiveness of display solutions in diverse markets.

What are the Key Properties of Steel for Display Racks?

Steel is a widely used material for display racks, known for its strength and durability. It typically has a high-temperature rating and excellent corrosion resistance, especially when treated with coatings such as galvanization.

Pros & Cons: The primary advantage of steel is its exceptional load-bearing capacity, making it suitable for heavy-duty applications. However, it is relatively heavy, which can complicate transportation and installation. Additionally, the manufacturing complexity can lead to higher costs compared to other materials.

Impact on Application: Steel is compatible with various media types, including heavy merchandise and electronic displays. However, it may require additional treatments to ensure compatibility with specific environments, such as humid or corrosive settings.

Considerations for International Buyers: Buyers from regions like Europe must ensure compliance with standards such as DIN for structural steel. In Africa and South America, corrosion resistance may be particularly important due to varying climates.

How Does Aluminum Compare as a Material for Display Racks?

Aluminum is another popular choice, known for its lightweight properties and resistance to corrosion. It typically performs well in moderate temperature ranges but is less robust than steel under heavy loads.

Pros & Cons: The key advantage of aluminum is its lightweight nature, which simplifies installation and reduces shipping costs. However, its lower strength can be a limitation for heavy-duty applications. Additionally, aluminum may be more expensive than steel, impacting budget considerations.

Impact on Application: Aluminum is ideal for lightweight displays, such as those used in retail environments for showcasing fashion or electronics. Its resistance to corrosion makes it suitable for outdoor applications.

Considerations for International Buyers: Buyers in the Middle East and Europe should consider the specific alloy used, as different grades offer varying levels of strength and corrosion resistance. Compliance with standards such as ASTM is also crucial.

What Role Does Wood Play in Display Rack Construction?

Wood offers a unique aesthetic appeal, making it a favored choice for retail environments focused on design. It generally has a lower temperature tolerance and can be susceptible to warping in humid conditions.

Pros & Cons: The primary advantage of wood is its versatility and visual appeal, allowing for creative designs. However, it is less durable than metal options and can be prone to damage from moisture and pests, which could lead to higher maintenance costs.

Impact on Application: Wood is particularly well-suited for high-end retail displays and environments where aesthetics are paramount. However, it may not be ideal for heavy or outdoor displays.

Considerations for International Buyers: Buyers in Europe may need to ensure compliance with sustainability standards, such as FSC certification. In regions like Africa, sourcing locally can reduce costs and support local economies.

Why Consider Plastic for Display Racks?

Plastic is a lightweight and cost-effective material that can be molded into various shapes. It typically has a lower temperature and pressure rating compared to metals.

Pros & Cons: The main advantage of plastic is its affordability and ease of manufacturing, which can lead to lower overall costs. However, it may not offer the same durability or load-bearing capacity as metal options.

Impact on Application: Plastic is suitable for lightweight displays, such as promotional stands or temporary setups. Its compatibility with various media types is generally high, but it may not withstand heavy or long-term use.

Considerations for International Buyers: Buyers should be aware of regional regulations regarding plastic use and recycling, especially in Europe where sustainability is a significant concern.

Summary Table of Material Selection for Display Racks

| Material | Typical Use Case for display rack supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty racks for retail and industrial use | Exceptional load-bearing capacity | Heavy and complex to manufacture | High |

| Aluminum | Lightweight displays in retail environments | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Wood | High-end retail displays and custom designs | Aesthetic appeal and versatility | Susceptible to moisture and pests | Medium |

| Plastic | Temporary displays and promotional stands | Cost-effective and easy to manufacture | Less durable than metal options | Low |

This strategic material selection guide provides B2B buyers with critical insights into choosing the right materials for display racks, ensuring they meet both performance and compliance requirements in their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for display rack supplier

What Are the Key Stages in the Manufacturing Process of Display Racks?

The manufacturing process of display racks involves several critical stages that ensure both functionality and aesthetic appeal. Understanding these stages is essential for international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe.

Material Preparation: What Materials Are Typically Used for Display Racks?

The first stage in manufacturing display racks is material preparation. Common materials include metal (steel or aluminum), wood, and plastic. For metal racks, sheets are often cut to size and treated to resist corrosion. Wood may be sourced from sustainable forests, and plastics are typically selected for their durability and aesthetic qualities. Buyers should inquire about the supplier‘s sourcing practices, especially regarding compliance with international sustainability standards.

Forming: What Techniques Are Used to Shape Display Racks?

After materials are prepared, the forming process takes place. This may involve techniques such as bending, welding, and stamping for metal racks. For wooden racks, cutting, sanding, and joining techniques are employed. Advanced suppliers may utilize CNC (Computer Numerical Control) machinery to ensure precision in forming. International buyers should look for suppliers that employ modern techniques, as these not only improve quality but also enhance production efficiency.

Assembly: How Are Display Racks Assembled?

The assembly stage is crucial for ensuring the structural integrity of display racks. Components are carefully joined, often using screws, bolts, or adhesives, depending on the material. For metal racks, welding is a common method, while wooden racks may require dowels or screws. It’s vital for buyers to understand the assembly processes used by suppliers, as this can significantly impact the durability and load-bearing capacity of the racks.

A stock image related to display rack supplier.

Finishing: What Finishing Techniques Are Commonly Applied?

Finishing processes enhance the visual appeal and longevity of display racks. Techniques may include painting, powder coating, or varnishing, which provide both aesthetic value and protection against wear and tear. A high-quality finish is essential for B2B buyers who prioritize branding and customer experience. Suppliers should be able to demonstrate their finishing processes and the types of finishes they offer to meet diverse market needs.

What International Quality Assurance Standards Should Buyers Consider?

Quality assurance is a critical aspect of the manufacturing process, particularly for international B2B buyers who must ensure compliance with various standards.

What Are the Key International Standards for Display Rack Manufacturing?

ISO 9001 is one of the most recognized quality management standards globally. It outlines requirements for a quality management system (QMS) and emphasizes continuous improvement. Suppliers certified to ISO 9001 are more likely to deliver consistent quality products. Additionally, depending on the market, certifications like CE (European Conformity) or API (American Petroleum Institute) may be relevant, especially for specialized display racks used in specific industries.

What Are the Quality Control Checkpoints During Manufacturing?

Quality control (QC) is implemented at various stages of the manufacturing process to ensure that products meet specified requirements.

How Do Incoming Quality Control (IQC) Checks Work?

Incoming Quality Control (IQC) involves assessing raw materials before they enter the production process. This stage is critical for identifying defects early and ensuring that only high-quality materials are used. Buyers can request IQC reports to verify that materials meet their specifications.

What Is In-Process Quality Control (IPQC) and Its Importance?

In-Process Quality Control (IPQC) occurs during the manufacturing stages. This involves periodic inspections and tests to ensure that the assembly processes are being followed correctly. IPQC helps to catch issues in real-time, reducing waste and ensuring that products meet quality standards before moving to the next stage.

How Is Final Quality Control (FQC) Conducted?

Final Quality Control (FQC) is the last checkpoint before products are shipped. This stage often includes comprehensive testing of the finished racks to assess their strength, stability, and finish quality. Buyers should inquire about the specific tests performed during FQC, such as load testing and visual inspections, to ensure the racks meet safety and quality standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is essential for international B2B buyers to mitigate risks and ensure product quality.

What Audit Processes Should Buyers Consider?

Buyers can conduct audits of potential suppliers to assess their manufacturing processes and quality control systems. This can include site visits or remote audits via video conferencing. During audits, buyers should focus on the supplier’s adherence to international standards and their internal quality control measures.

How Important Are Quality Reports and Documentation?

Quality reports, including IQC, IPQC, and FQC documentation, provide insight into a supplier’s manufacturing consistency and reliability. Buyers should request these reports to evaluate the supplier’s commitment to quality. Furthermore, understanding the documentation process will help buyers ensure compliance with their own regional regulations.

Should Buyers Consider Third-Party Inspections?

Engaging third-party inspectors can provide an unbiased evaluation of a supplier’s manufacturing processes and quality control measures. This is particularly beneficial for international buyers who may be unfamiliar with local practices. Third-party inspections can help validate that suppliers meet the necessary quality standards before shipment.

What Are the Unique Quality Control Considerations for Different Regions?

Quality control nuances can vary significantly between regions, affecting how international B2B buyers approach supplier selection.

How Do Cultural Differences Influence Quality Expectations?

A stock image related to display rack supplier.

Cultural differences can influence quality expectations and communication styles between buyers and suppliers. For instance, European buyers may prioritize detailed documentation, while suppliers in Africa or South America may focus on flexibility and adaptability. Buyers should consider these differences and adjust their communication strategies accordingly.

What Regulatory Compliance Should Buyers Be Aware Of?

Different regions have unique regulatory requirements that impact quality assurance. Buyers from Europe should be well-versed in CE marking requirements, while those in the Middle East might need to comply with local standards. Understanding these regulations can guide buyers in selecting suppliers that meet their specific needs.

By thoroughly evaluating the manufacturing processes and quality assurance practices of display rack suppliers, international B2B buyers can make informed decisions that enhance their operational efficiency and product quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘display rack supplier’

To successfully procure display racks for your business, it’s essential to follow a structured sourcing approach. This guide provides a step-by-step checklist to help you navigate the complexities of selecting a reliable display rack supplier, ensuring that you make informed decisions that cater to your specific needs.

Step 1: Define Your Display Rack Requirements

Before reaching out to suppliers, clearly outline your requirements. Consider factors such as the type of display racks needed (e.g., shelving, stand-alone), dimensions, weight capacity, and materials. This clarity will help you communicate effectively with suppliers and ensure they can meet your specifications.

Step 2: Conduct Market Research for Suppliers

Start your search by researching potential suppliers in your target markets—Africa, South America, the Middle East, and Europe. Utilize online platforms, trade shows, and industry publications to create a list of suppliers. Look for those with a proven track record and positive customer reviews, as this can indicate reliability and quality.

Step 3: Evaluate Supplier Credentials and Certifications

Verify that potential suppliers have the necessary certifications and credentials. This may include ISO certifications, quality management standards, and compliance with local regulations. Understanding their certifications will give you confidence in their ability to deliver products that meet safety and quality benchmarks.

Step 4: Request Samples and Product Catalogs

Once you’ve narrowed down your options, request product samples and catalogs from your shortlisted suppliers. Assess the quality of materials, craftsmanship, and design. Additionally, review their product range to ensure they offer options that align with your business needs.

Step 5: Compare Pricing and Payment Terms

Analyze pricing structures from various suppliers. Be cautious of prices that seem too low, as they may indicate inferior quality. Look for transparent pricing models and favorable payment terms, such as credit options or discounts for bulk orders. This will help you manage your budget effectively while securing the best value.

Step 6: Check References and Past Projects

Before finalizing your decision, ask for references from previous clients, particularly those in your industry or region. Inquire about their experiences with the supplier regarding product quality, delivery times, and customer service. This firsthand feedback can provide valuable insights into what you can expect.

Step 7: Negotiate Contract Terms and Delivery Schedules

Once you’ve selected a supplier, negotiate the contract terms, including delivery schedules, warranties, and after-sales support. Clear agreements on these aspects will help prevent misunderstandings and ensure that you receive your display racks on time and in accordance with your quality expectations.

By following this structured checklist, B2B buyers can effectively navigate the sourcing process for display racks, ensuring that they partner with suppliers who meet their specific needs and standards.

Comprehensive Cost and Pricing Analysis for display rack supplier Sourcing

What Are the Key Cost Components in Display Rack Sourcing?

When sourcing display racks, international B2B buyers must consider a variety of cost components that contribute to the overall price. These components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials for display racks include wood, metal, and plastic. Buyers should assess the durability and aesthetics of materials that align with their branding and usage.

-

Labor: Labor costs vary by region. In countries with higher wage standards, labor can constitute a significant portion of the overall cost. Understanding local labor rates can help buyers anticipate expenses accurately.

-

Manufacturing Overhead: This includes costs related to factory operations such as utilities, rent, and equipment maintenance. Suppliers may pass these costs onto buyers, so it’s essential to inquire about overhead rates.

-

Tooling: Custom display racks often require specific tooling, which can add to the initial costs. Tooling expenses should be factored into the budget, especially for bespoke designs.

-

Quality Control (QC): Implementing stringent QC measures can increase production costs but ensures product reliability. Buyers should discuss QC standards with suppliers to balance cost and quality effectively.

-

Logistics: Shipping and handling costs can vary widely based on the origin and destination. Factors such as distance, volume, and shipping method should be evaluated to avoid unexpected expenses.

-

Margin: Supplier margins can fluctuate based on their operational costs and market conditions. Understanding typical margin rates within the industry can help buyers gauge the competitiveness of supplier pricing.

How Do Price Influencers Impact Display Rack Costs?

Several factors influence the pricing of display racks, and international buyers should be aware of these to negotiate effectively:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs. Buyers should consider their inventory needs and negotiate MOQs to optimize pricing.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should weigh the benefits of customization against their budget constraints and explore standard alternatives when possible.

-

Material Quality and Certifications: High-quality materials and certifications (e.g., ISO, CE) can enhance product value but also increase costs. Buyers should assess the necessity of certifications based on their market requirements.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can affect pricing. Established suppliers may charge more due to their experience and quality assurance.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects shipping responsibilities and costs. Understanding these terms can help buyers manage logistics expenses and risks.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should adopt strategic approaches to maximize value in their sourcing efforts:

-

Negotiate Wisely: Leverage your purchasing power by negotiating not just on price but also on payment terms and delivery schedules. Building a relationship with suppliers can lead to better terms over time.

-

Focus on Total Cost of Ownership (TCO): Instead of only considering the purchase price, evaluate the total cost over the product’s lifecycle, including maintenance, potential returns, and resale value.

-

Understand Pricing Nuances for International Markets: Currency fluctuations, import duties, and local market conditions can impact costs significantly. Buyers should stay informed about these factors to make more accurate budgeting decisions.

-

Conduct Market Research: Familiarize yourself with regional pricing standards and compare multiple suppliers to ensure competitive pricing.

-

Request Indicative Pricing: Always ask for indicative pricing to gauge market rates. However, remember that prices can vary based on specific requirements, so use this as a starting point for negotiation.

Understanding these elements will empower B2B buyers to make informed decisions when sourcing display racks, ensuring they achieve the best possible balance between cost, quality, and functionality.

Alternatives Analysis: Comparing display rack supplier With Other Solutions

In the competitive landscape of retail and storage solutions, understanding the various options available to businesses is crucial for making informed purchasing decisions. While display rack suppliers offer specialized products for showcasing merchandise, several alternatives can also serve similar purposes. This analysis will compare display racks with two viable alternatives: modular shelving systems and mobile display units.

Comparison Table

| Comparison Aspect | Display Rack Supplier | Modular Shelving Systems | Mobile Display Units |

|---|---|---|---|

| Performance | High durability, tailored for various products | Flexible layout options, can support diverse product types | High mobility, adaptable for events and sales promotions |

| Cost | Moderate to high, depending on customization | Generally cost-effective, especially in bulk | Higher upfront costs but savings in labor and transport |

| Ease of Implementation | Requires assembly, can be complex for custom designs | Simple to install, often comes with user-friendly instructions | Quick setup, often designed for immediate use |

| Maintenance | Low maintenance, durable materials | Moderate maintenance, may require adjustments over time | Regular checks needed for mobility components |

| Best Use Case | Permanent retail settings, warehouses | Flexible retail environments, stock rooms | Trade shows, pop-up stores, seasonal promotions |

What are the Benefits and Drawbacks of Modular Shelving Systems?

Modular shelving systems offer a flexible alternative to traditional display racks. They are designed to be easily reconfigured, allowing businesses to adapt their display setups as product lines change. This flexibility can be particularly beneficial for retailers who frequently update their merchandise. However, while modular shelving can be more cost-effective in bulk, it may lack the tailored aesthetics that custom display racks provide, potentially impacting brand presentation.

How Do Mobile Display Units Enhance Retail Flexibility?

Mobile display units are an excellent choice for businesses that participate in trade shows or require temporary displays for promotions. These units are designed for easy transport and quick setup, making them ideal for events where speed and flexibility are crucial. However, they typically come with a higher initial cost and may require more frequent maintenance to ensure that wheels and other moving parts remain functional. Their primary advantage lies in their ability to quickly adapt to changing sales environments.

Conclusion: Which Solution is Right for Your Business Needs?

Choosing the right display solution depends heavily on your specific business requirements. If your focus is on a permanent retail environment where durability and aesthetics are paramount, partnering with a display rack supplier may be the best option. Conversely, if your business model involves frequent changes in product offerings or participation in temporary sales events, modular shelving systems or mobile display units may be more suitable. Evaluate your operational needs, budget constraints, and the nature of your merchandise to determine the most effective solution for your business.

Essential Technical Properties and Trade Terminology for display rack supplier

What Are the Key Technical Properties of Display Racks?

When sourcing display racks, understanding the essential technical specifications is crucial for ensuring that the products meet your business needs. Here are some critical properties to consider:

1. Material Grade

The material used for display racks can significantly influence their durability and aesthetics. Common materials include steel, aluminum, wood, and plastic. Steel is often favored for heavy-duty applications due to its strength, while wood may be preferred for its visual appeal in retail environments. For B2B buyers, selecting the right material is essential to balance cost, strength, and visual impact.

2. Load Capacity

This specification refers to the maximum weight a display rack can safely hold. It is vital for ensuring that the racks can support the intended products without risk of failure. Buyers should assess the weight of their merchandise and match it with the load capacity of the display racks. An inadequate load capacity can lead to accidents and financial loss.

3. Dimensions and Tolerance

Understanding the dimensions of display racks—height, width, and depth—is critical for fitting them into designated spaces. Tolerance refers to the allowable deviation in these measurements. Accurate dimensions ensure that the racks fit perfectly in your store or warehouse, while appropriate tolerances allow for minor adjustments during installation.

4. Finish Type

The finish of a display rack affects both its durability and appearance. Common finishes include powder coating, galvanizing, and varnishing. Powder coating, for instance, provides a durable and aesthetically pleasing surface that resists scratches and corrosion. Choosing the right finish is vital for maintaining the visual appeal and longevity of the racks, especially in high-traffic environments.

5. Assembly Requirements

Display racks may come pre-assembled or require assembly. Understanding the assembly process and the tools needed can save time and reduce labor costs. Buyers should inquire about assembly instructions and whether the supplier offers assembly services, especially when purchasing large quantities.

What Are Common Trade Terms Used in Display Rack Procurement?

Navigating the procurement process requires familiarity with specific trade terminology. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM produces components or products that are used in another company’s end product. In the context of display racks, OEM suppliers may provide customized racks tailored to a buyer’s specifications. Understanding OEM relationships can help buyers negotiate better pricing and terms.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. This term is crucial for buyers, particularly those in emerging markets, as it can affect inventory management and cash flow. Knowing the MOQ can help businesses plan their purchases and avoid overstock situations.

3. RFQ (Request for Quotation)

An RFQ is a formal document issued by buyers to solicit price quotes from suppliers for specific products or services. Including detailed specifications in an RFQ can lead to more accurate pricing and better supplier responses. B2B buyers should ensure their RFQs are comprehensive to facilitate competitive bidding.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international sales contracts that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms helps buyers understand the costs and risks associated with transportation, insurance, and customs clearance.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the goods are delivered. This term is crucial for planning inventory and sales strategies. Buyers should always inquire about lead times to align their operations with supplier capabilities.

Understanding these technical properties and trade terms will empower international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to make informed purchasing decisions regarding display racks. By leveraging this knowledge, buyers can optimize their procurement processes, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the display rack supplier Sector

What Are the Current Market Dynamics and Key Trends in the Display Rack Supplier Sector?

The display rack supplier sector is experiencing a transformative phase driven by several global factors. First, the rise of e-commerce has significantly altered retail environments, necessitating innovative display solutions that enhance product visibility and customer engagement. In regions like Africa and South America, where urbanization and consumer spending are on the rise, the demand for versatile and space-efficient display racks is surging. Additionally, technological advancements, such as smart displays integrated with IoT capabilities, are becoming increasingly popular, allowing retailers to optimize inventory management and enhance customer interaction.

Another notable trend is the shift towards customization. International buyers, particularly from Europe and the Middle East, are seeking tailored solutions that align with their brand aesthetics and operational needs. This demand for personalized products is prompting suppliers to adopt flexible manufacturing processes. Furthermore, the trend of omnichannel retailing is pushing suppliers to offer display solutions that are adaptable for both physical stores and online environments, creating a seamless shopping experience for consumers.

As sustainability becomes a priority globally, display rack suppliers are also adapting to eco-friendly practices. This includes utilizing recyclable materials and reducing waste during the manufacturing process. Such initiatives not only cater to the growing consumer preference for sustainable products but also enhance the brand image of suppliers, making them more appealing to conscious buyers across all markets.

How Important Is Sustainability and Ethical Sourcing in the Display Rack Supplier Sector?

Sustainability and ethical sourcing are increasingly critical in the display rack supplier sector. The environmental impact of manufacturing practices is under scrutiny, compelling suppliers to prioritize eco-friendly materials and processes. For international buyers, particularly in Europe, the emphasis on green certifications is paramount. Certifications such as FSC (Forest Stewardship Council) for wood-based products or ISO 14001 for environmental management systems can significantly influence purchasing decisions.

Moreover, ethical supply chains are becoming a focal point for B2B buyers. Transparency in sourcing practices not only reflects a company’s commitment to social responsibility but also mitigates risks associated with labor violations and environmental degradation. Suppliers who can demonstrate ethical sourcing practices are likely to build stronger relationships with buyers, fostering trust and loyalty.

The integration of sustainable materials, such as recycled metals and biodegradable plastics, is becoming more prevalent among display rack suppliers. This shift not only addresses environmental concerns but also appeals to a growing segment of consumers who prefer products that minimize ecological footprints. By prioritizing sustainability, suppliers can differentiate themselves in a competitive marketplace and appeal to ethically-minded B2B buyers across Africa, South America, the Middle East, and Europe.

How Has the Display Rack Supplier Sector Evolved Over Time?

The evolution of the display rack supplier sector can be traced back to the early days of retail when simple wooden shelves and racks were the norm. Over the decades, as retail environments became more sophisticated, so did the design and functionality of display racks. The introduction of metal and plastic materials allowed for more durable and aesthetically pleasing solutions.

In the late 20th century, the emergence of modular and customizable display systems marked a significant turning point, enabling retailers to adapt their display solutions to changing inventory and consumer preferences. The digital age has since ushered in smart technology, allowing for innovative displays that integrate digital signage and interactive elements, enhancing the consumer experience.

Today, the focus is not only on functionality and aesthetics but also on sustainability and ethical practices, showcasing how the sector has adapted to meet modern challenges and consumer expectations. International buyers can benefit from this evolution by sourcing products that not only fulfill their immediate needs but also align with their long-term sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of display rack supplier

-

How do I determine the right display rack supplier for my business needs?

To select the ideal display rack supplier, first assess your specific requirements such as size, weight capacity, and design preferences. Research potential suppliers by checking their product range and past client reviews. Networking in industry-specific forums can provide insights into supplier reliability and service quality. Additionally, consider the supplier’s capacity for customization and their experience in international shipping, especially if you are sourcing from Africa, South America, the Middle East, or Europe. -

What is the best type of display rack for retail stores?

The best type of display rack for retail stores often depends on the products being displayed. For heavy items, consider using gondola or pallet racks, while lighter items may benefit from shelving or wire racks. Additionally, modular display racks provide versatility, allowing for reconfiguration as inventory changes. Always prioritize durability and aesthetics to enhance the shopping experience and align with your brand identity. -

What should I look for in terms of customization options from a display rack supplier?

When seeking customization options, inquire about material choices, colors, and designs that align with your brand image. A good supplier should offer tailored solutions such as adjustable shelving heights and configurations that can adapt to various product sizes. Additionally, ask about the supplier’s ability to integrate branding elements, such as signage or logos, into the display racks for a cohesive look in your retail space. -

What are typical minimum order quantities (MOQs) when sourcing display racks?

Minimum order quantities (MOQs) for display racks can vary significantly between suppliers. Generally, international suppliers may have higher MOQs due to shipping costs and production runs. It’s crucial to discuss MOQs upfront, as some suppliers may offer flexibility for first-time buyers or smaller businesses. Establishing a good relationship with your supplier may also lead to better terms on future orders. -

What payment terms should I expect when sourcing display racks internationally?

Payment terms can vary, but common practices include deposits ranging from 30% to 50% upfront, with the balance due upon shipment or delivery. Some suppliers may offer credit terms for established clients. Always clarify payment methods accepted, such as bank transfers, letters of credit, or online payment platforms, and ensure you have a clear understanding of any potential fees associated with currency conversion or international transactions. -

How can I ensure quality assurance when sourcing display racks?

To ensure quality assurance, request product samples before finalizing orders. Establish clear specifications and standards that the supplier must meet. Conducting factory audits or inspections during production can help verify quality control processes. Utilizing third-party inspection services can also provide additional assurance, especially for international transactions, ensuring that the products meet your expectations before shipping. -

What logistics considerations should I be aware of when importing display racks?

When importing display racks, consider shipping methods (air vs. sea), lead times, and customs regulations specific to your region. Ensure that your supplier provides necessary documentation, such as invoices and shipping manifests, for customs clearance. Additionally, factor in storage and handling upon arrival, as well as potential duties and taxes that may apply to your order, especially when dealing with suppliers from different continents. -

How do I handle disputes with a display rack supplier?

In case of disputes with a display rack supplier, first attempt to resolve the issue amicably through direct communication. Clearly document all correspondence and agreements. If resolution isn’t possible, refer to the contract terms regarding dispute resolution, which may include mediation or arbitration. Engaging a legal professional knowledgeable in international trade can also provide guidance on navigating complex situations effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for display rack supplier

As international B2B buyers navigate the complexities of sourcing display racks, understanding the strategic sourcing process remains paramount. By leveraging strategic sourcing, companies can optimize their supply chains, reduce costs, and enhance product quality. A thorough evaluation of suppliers, including their capabilities, certifications, and past performance, is essential for making informed decisions that align with your business goals.

How Can Strategic Sourcing Impact Your Business?

Investing time in strategic sourcing provides a competitive edge. It allows buyers to build strong relationships with suppliers, fostering collaboration and innovation. This is particularly vital for businesses in Africa, South America, the Middle East, and Europe, where market dynamics can vary significantly. Tailoring sourcing strategies to local nuances not only improves product accessibility but also ensures compliance with regional regulations.

What’s Next for International Buyers of Display Racks?

Looking ahead, international B2B buyers should focus on integrating sustainable practices into their sourcing strategies. This approach not only meets the increasing demand for eco-friendly solutions but also positions companies favorably in the eyes of consumers and partners alike.

In conclusion, as you embark on your sourcing journey, prioritize strategic partnerships with display rack suppliers that understand your unique market needs. Engage proactively with potential suppliers to explore innovative solutions that can enhance your offerings. The future of your business hinges on these strategic decisions—make them count.