Discover Top Eclipse Glasse Manufacturers: A Buying Guide (2025)

Introduction: Navigating the Global Market for eclipse glasse manufacturer

In the competitive landscape of the global market for eclipse glasses manufacturing, international B2B buyers face significant challenges in sourcing high-quality, compliant products that meet the diverse needs of their regions. Whether you are looking for solar eclipse glasses for educational purposes, promotional items, or retail distribution, understanding the nuances of this niche market is crucial. This guide delves into the various types of eclipse glasses available, their applications across different sectors, and essential supplier vetting processes to ensure quality and safety compliance.

Navigating the complexities of sourcing eclipse glasses requires a comprehensive approach that includes evaluating potential suppliers, understanding pricing structures, and recognizing the unique requirements of diverse markets in Africa, South America, the Middle East, and Europe, including countries like Poland and Thailand. By leveraging the insights provided in this guide, buyers can make informed purchasing decisions that align with their business objectives, ultimately enhancing customer satisfaction and driving sales.

This resource is designed to empower you with actionable information, from identifying reputable manufacturers to understanding the critical safety standards that eclipse glasses must meet. With this knowledge, you can confidently navigate the global market, ensuring that your sourcing strategies yield high-quality products that resonate with your target audience.

Understanding eclipse glasse manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Eclipse Glasses | Basic design, often made from cardboard or plastic, with simple solar filters. | Educational events, public viewings, casual use. | Pros: Affordable, widely available. Cons: Limited durability and protection. |

| Premium Eclipse Glasses | Higher quality materials, often with multi-layered solar filters for better vision. | Astronomy clubs, professional events, high-end retail. | Pros: Enhanced clarity, more durable. Cons: Higher cost compared to standard options. |

| Custom-Branded Eclipse Glasses | Personalized designs with company logos or unique artwork. | Promotional events, corporate giveaways, marketing campaigns. | Pros: Brand visibility, unique marketing tool. Cons: Longer lead times for production. |

| Solar Viewer Filters | Designed to attach to telescopes or binoculars, offering enhanced viewing experiences. | Professional astronomy, educational institutions, observatories. | Pros: Superior optical performance, safe for telescopes. Cons: Requires additional equipment for use. |

| Children’s Eclipse Glasses | Specifically designed for kids, often with fun designs and enhanced safety features. | Schools, family events, educational programs. | Pros: Engaging for children, safety-focused. Cons: May not withstand rough handling as well as adult versions. |

What Are the Characteristics of Standard Eclipse Glasses?

Standard eclipse glasses are typically made from lightweight materials such as cardboard or plastic. They feature simple solar filters that are adequate for casual viewing of solar events. These glasses are ideal for educational events or large public gatherings where affordability is key. However, their limited durability and protective capabilities may not meet the needs of serious observers.

Why Choose Premium Eclipse Glasses?

Premium eclipse glasses are crafted from higher-quality materials and often include multi-layered solar filters that provide superior optical clarity. They are suitable for astronomy clubs and professional events, where visual quality is paramount. While they come at a higher price point, the investment is justified for those seeking a better viewing experience.

How Do Custom-Branded Eclipse Glasses Benefit Businesses?

Custom-branded eclipse glasses allow companies to showcase their logos or unique designs, making them a popular choice for promotional events and corporate giveaways. They serve as effective marketing tools that enhance brand visibility. However, businesses should be aware of the longer lead times for production, which can affect event planning.

What Are the Advantages of Solar Viewer Filters?

Solar viewer filters are designed for use with telescopes and binoculars, providing a safe and enhanced viewing experience. These filters are ideal for professional astronomers and educational institutions that require high-quality optical performance. While they offer superior safety for telescope use, they necessitate additional equipment, which may not be suitable for casual users.

Why Are Children’s Eclipse Glasses Important?

Children’s eclipse glasses are designed with fun, engaging designs and enhanced safety features to cater to younger audiences. They are perfect for schools and family events, ensuring that kids can safely observe solar phenomena. However, buyers should consider that these glasses may not be as robust as adult versions, potentially affecting their longevity in active environments.

Related Video: How to Make Your Own Solar Eclipse Glasses – Easy and Free DIY

Key Industrial Applications of eclipse glasse manufacturer

| Industry/Sector | Specific Application of Eclipse Glasses Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Solar Energy | Protective eyewear for solar panel installation | Enhances safety during installation processes | Certifications for UV protection and durability |

| Automotive | Windshield and visor manufacturing | Improved visibility and safety for drivers | Compliance with regional safety standards |

| Construction | Safety glasses for construction workers | Reduces risk of eye injuries on-site | Bulk purchasing options and custom branding |

| Electronics Manufacturing | Protective eyewear for assembly line workers | Minimizes risk of injuries from debris | Ergonomic design and comfort for long wear |

| Mining and Heavy Industry | Specialized eyewear for hazardous environments | Protects against dust and chemical exposure | Certification for impact resistance and clarity |

How Are Eclipse Glasses Used in the Solar Energy Sector?

In the solar energy industry, eclipse glasses are crucial for the safety of workers during the installation of solar panels. They provide essential eye protection against harmful UV rays and glare, which can lead to severe eye damage. International buyers should prioritize sourcing glasses that are certified for UV protection and durability to meet safety regulations specific to their region. Additionally, bulk purchasing options can help reduce costs while ensuring that all workers are adequately protected.

What Role Do Eclipse Glasses Play in Automotive Manufacturing?

Eclipse glasses are increasingly utilized in the automotive sector, particularly in the production of windshields and visors. These glasses enhance visibility and safety for drivers by reducing glare and providing a clearer view of the road. Buyers from Europe, Africa, and South America should focus on suppliers that comply with regional safety standards, as well as those that offer innovative designs that cater to the latest automotive trends. Sourcing glasses that can withstand high temperatures and impact is also essential for ensuring quality.

Why Are Eclipse Glasses Important in Construction?

In the construction industry, protective eyewear is vital for safeguarding workers from potential eye injuries caused by flying debris, dust, and other hazards. Eclipse glasses manufactured for this sector not only provide essential protection but also enhance worker productivity by allowing for better visibility in bright conditions. When sourcing these products, buyers should consider options for bulk purchases and custom branding, which can help promote safety culture on-site while also being cost-effective.

How Are Eclipse Glasses Beneficial in Electronics Manufacturing?

Eclipse glasses are used in electronics manufacturing to protect assembly line workers from eye injuries caused by small debris and bright lights from equipment. The ergonomic design of these glasses ensures comfort during long hours of wear, which is crucial for maintaining productivity. International buyers should look for suppliers that offer glasses with anti-fog and scratch-resistant features, as these will enhance the usability and longevity of the eyewear in a fast-paced manufacturing environment.

What Are the Applications of Eclipse Glasses in Mining and Heavy Industry?

In mining and heavy industries, specialized eclipse glasses are essential for protecting workers from hazardous environments where dust and chemicals pose significant risks. These glasses are designed to provide maximum visibility while ensuring protection against impact and chemical splashes. Buyers in this sector should prioritize sourcing glasses that come with certifications for impact resistance and clarity, which are crucial for maintaining safety standards in challenging working conditions.

Related Video: What are all the Laboratory Apparatus and their uses?

3 Common User Pain Points for ‘eclipse glasse manufacturer’ & Their Solutions

Scenario 1: Navigating Quality Assurance for Eclipse Glasses

The Problem: International B2B buyers often face significant challenges in ensuring the quality of eclipse glasses, especially when sourcing from unfamiliar manufacturers. In regions such as Africa and South America, where local suppliers may not adhere to global safety standards, buyers worry about the potential risks associated with poor-quality products. This is particularly concerning given that eclipse glasses must meet specific ISO requirements to protect users’ eyes during solar events. The lack of transparency in manufacturing processes can lead to distrust and hesitation in placing large orders.

The Solution: To mitigate these concerns, buyers should prioritize manufacturers who can provide verifiable certifications and compliance documentation. Before finalizing any order, request samples of the eclipse glasses and conduct rigorous testing, ideally in collaboration with a local lab that specializes in optical safety. Additionally, consider establishing a long-term relationship with manufacturers who have a proven track record and positive reviews from other buyers in your industry. Engage in direct communication with manufacturers to discuss their quality control processes and ensure they align with your expectations for safety and durability.

Scenario 2: Overcoming Supply Chain Disruptions for Eclipse Glasses

The Problem: Supply chain disruptions can significantly affect the timely delivery of eclipse glasses, particularly in regions like the Middle East and Europe, where demand can spike dramatically around solar events. B2B buyers may find themselves scrambling for reliable suppliers who can deliver products on short notice, leading to potential financial losses and missed opportunities. This problem is exacerbated by fluctuating shipping costs and customs delays, which can further complicate international procurement.

The Solution: To navigate these challenges, buyers should diversify their supply chain by establishing relationships with multiple manufacturers across different regions. This strategy not only reduces reliance on a single supplier but also allows for flexibility in sourcing. Additionally, consider leveraging local distributors who can stock eclipse glasses in anticipation of demand surges. Implementing a just-in-time inventory system can help manage cash flow while ensuring you have adequate stock on hand. Regularly review shipping options and work with logistics partners who have experience in international shipping to streamline the process and minimize delays.

Scenario 3: Addressing Regulatory Compliance Challenges in Different Markets

The Problem: B2B buyers of eclipse glasses often encounter complex regulatory environments that vary significantly across regions such as Europe, Africa, and South America. Different countries have distinct requirements for safety, labeling, and certification of eclipse glasses, which can create confusion and hinder market entry. Buyers risk facing legal penalties or product recalls if they do not fully comply with local regulations, leading to potential reputational damage.

The Solution: To ensure compliance, buyers should conduct thorough research on the regulatory frameworks governing eclipse glasses in their target markets. Collaborate with local legal experts or compliance consultants who can provide insights into the specific requirements for each region. Establish partnerships with manufacturers that are familiar with these regulations and can assist in navigating the compliance landscape. Additionally, consider obtaining certifications from recognized bodies that can enhance your product’s credibility and facilitate smoother entry into various markets. Regular training and updates on regulatory changes for your procurement team will also help maintain compliance and avoid pitfalls.

Strategic Material Selection Guide for eclipse glasse manufacturer

When selecting materials for manufacturing eclipse glasses, it is crucial to consider properties that directly affect product performance, compliance with international standards, and the specific needs of various markets. Here, we analyze four common materials used in the production of eclipse glasses, focusing on their key properties, advantages and disadvantages, and implications for international buyers, particularly from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polycarbonate in Eclipse Glasses?

Polycarbonate is a popular choice for eclipse glasses due to its high impact resistance and optical clarity. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for various environmental conditions. Additionally, polycarbonate has excellent UV protection, blocking up to 99.9% of harmful rays.

Pros: Polycarbonate is lightweight, shatter-resistant, and offers superior optical quality. Its manufacturing process is relatively straightforward, allowing for mass production.

Cons: While durable, polycarbonate can scratch easily and may require additional coatings to enhance its surface hardness. It is also more expensive than some alternatives.

Impact on Application: Polycarbonate is compatible with various media, including inks and coatings, which can be crucial for branding and customization.

Considerations for International Buyers: Buyers must ensure that polycarbonate used in eclipse glasses meets relevant safety standards, such as ASTM F659, which governs the use of materials in solar viewing devices.

How Does Glass Compare to Other Materials for Eclipse Glasses?

Glass is another common material used in eclipse glasses, particularly for high-end models. It offers excellent optical clarity and scratch resistance, making it ideal for prolonged use.

Pros: Glass provides superior optical properties and is less prone to scratching compared to polycarbonate. It can also be treated to enhance its UV-blocking capabilities.

Cons: Glass is heavier and more fragile than polycarbonate, increasing the risk of breakage during handling and transportation. Its manufacturing process can also be more complex and costly.

Impact on Application: Glass is suitable for high-quality solar filters but may not be ideal for environments where durability is critical.

Considerations for International Buyers: Compliance with international standards such as ISO 12312-2 is essential for glass eclipse glasses, particularly in regions with strict safety regulations.

What Are the Advantages of Using Mylar in Eclipse Glasses?

Mylar, a type of polyester film, is often used in eclipse glasses for its affordability and lightweight properties. It can effectively block harmful UV rays and is relatively easy to manufacture.

Pros: Mylar is cost-effective, lightweight, and can be produced in large quantities. It is also flexible, allowing for various designs.

Cons: Mylar is less durable than polycarbonate and glass, making it more susceptible to tearing and damage. Its optical clarity may not match that of glass or high-quality polycarbonate.

Impact on Application: Mylar is suitable for short-term use and is often preferred for promotional or disposable eclipse glasses.

Considerations for International Buyers: Buyers should verify that Mylar meets safety standards such as ANSI Z80.3, particularly in regions where consumer safety is heavily regulated.

How Does Acrylic Perform as a Material for Eclipse Glasses?

Acrylic, or polymethyl methacrylate (PMMA), is another alternative for eclipse glasses. It offers good optical clarity and is more impact-resistant than glass.

Pros: Acrylic is lightweight, shatter-resistant, and can be produced in various colors and finishes. It provides good UV protection and is easier to mold into complex shapes.

Cons: Acrylic can scratch more easily than glass and polycarbonate, requiring protective coatings. Its thermal stability is lower, making it less suitable for extreme temperatures.

Impact on Application: Acrylic is often used in environments where weight is a concern, but its durability may limit its use in harsher conditions.

Considerations for International Buyers: Compliance with standards such as EN 166 is crucial for acrylic eclipse glasses, especially in European markets.

Summary Table of Material Selection for Eclipse Glasses

| Material | Typical Use Case for eclipse glasse manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | General-purpose eclipse glasses | High impact resistance and UV protection | Scratches easily without coatings | Medium |

| Glass | High-end eclipse glasses | Superior optical clarity and scratch resistance | Heavier and more fragile | High |

| Mylar | Disposable or promotional eclipse glasses | Cost-effective and lightweight | Less durable and lower optical quality | Low |

| Acrylic | Lightweight eclipse glasses for various designs | Shatter-resistant and good UV protection | Scratches easily and lower thermal stability | Medium |

This guide provides a comprehensive overview of materials used in eclipse glasses manufacturing, aiding international B2B buyers in making informed decisions tailored to their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for eclipse glasse manufacturer

What Are the Key Stages in the Manufacturing Process for Eclipse Glasses?

The manufacturing process for eclipse glasses is a meticulous endeavor that involves several critical stages to ensure both performance and safety. B2B buyers should familiarize themselves with these stages to make informed purchasing decisions.

1. Material Preparation

The first step involves sourcing and preparing the right materials. Eclipse glasses must utilize specialized solar filters that meet specific optical standards to safely view solar events. Common materials include polycarbonate and mylar, which are lightweight yet durable. Buyers should ensure that suppliers use materials that comply with international safety standards, such as ISO 12312-2, which pertains to the optical filters for direct viewing of the sun.

2. Forming

Once materials are prepared, the forming stage begins. This typically involves cutting the solar filter material into the required shapes and sizes. Advanced techniques like precision laser cutting may be employed to achieve exact specifications. The forming process is crucial, as any inaccuracies can compromise the glasses’ effectiveness in protecting users’ eyes.

3. Assembly

The assembly stage integrates the formed filters with the frame components. Frames can be made from various materials, including plastic and cardboard, depending on the product’s intended use and target market. During this stage, it is essential to ensure that the solar filters are securely attached to the frames to prevent detachment during use. Buyers should inquire about the assembly techniques used and whether they involve automated processes that can enhance consistency and quality.

4. Finishing

The finishing stage involves applying final touches, such as branding and packaging. This is also where the glasses undergo a visual inspection to ensure they meet aesthetic and functional standards. B2B buyers should request information about any coatings or treatments applied, which can enhance durability and resistance to scratches.

How Is Quality Assurance Implemented in Eclipse Glass Manufacturing?

Quality assurance (QA) is paramount in the production of eclipse glasses, given the potential risks associated with improper use. Understanding the QA measures in place can help buyers assess supplier reliability.

Relevant International Standards for Quality Assurance

International standards play a vital role in the quality assurance of eclipse glasses. Buyers should look for compliance with:

- ISO 9001: This standard ensures that manufacturers maintain a quality management system that is effective and efficient.

- ISO 12312-2: Specifically tailored for solar viewing filters, this standard addresses safety requirements and performance criteria.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated into various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, this checkpoint ensures that every stage meets quality benchmarks.

- Final Quality Control (FQC): A comprehensive inspection of the finished product before packaging, focusing on both functional and aesthetic qualities.

Which Testing Methods Are Commonly Used for Eclipse Glasses?

Various testing methods are employed to verify the safety and quality of eclipse glasses. B2B buyers should be aware of these methods to evaluate supplier capabilities:

- Optical Density Testing: Measures the amount of light that passes through the solar filter, ensuring it meets safety standards for solar viewing.

- Durability Testing: Assesses the resistance of the glasses to scratches, impacts, and environmental factors.

- Thermal Testing: Evaluates how the glasses perform under varying temperature conditions, which is crucial for outdoor use.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to stringent quality control measures, B2B buyers can take several proactive steps:

- Conduct Audits: Regular audits can provide insights into a supplier’s manufacturing practices and adherence to quality standards. Buyers should request audit reports to assess compliance.

- Request QC Reports: Suppliers should provide detailed QC reports that outline the testing methods used, results obtained, and any corrective actions taken.

- Engage Third-Party Inspectors: Utilizing independent inspectors can offer an unbiased evaluation of the supplier’s quality control processes and product safety.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers, particularly from Africa, South America, the Middle East, and Europe, must navigate several nuances when it comes to quality control:

- Understanding Regional Standards: Different regions may have varying standards for solar viewing products. Buyers should familiarize themselves with local regulations and ensure suppliers comply accordingly.

- Cultural Considerations: Communication styles and business practices may differ across cultures. Establishing clear expectations and maintaining open lines of communication can facilitate smoother transactions.

- Supply Chain Transparency: Inquire about the entire supply chain to understand where materials are sourced and how they are processed. Transparency can significantly impact product quality and safety.

Conclusion: The Importance of Rigorous Manufacturing and Quality Assurance

For B2B buyers seeking eclipse glasses, understanding the manufacturing processes and quality assurance protocols is crucial. By focusing on these aspects, buyers can make informed decisions, ensuring they procure safe and effective products that meet international standards. Engaging with reliable suppliers who prioritize quality control will ultimately benefit businesses, fostering trust and long-term partnerships in the competitive market of eclipse glasses.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘eclipse glasse manufacturer’

Introduction: How to Effectively Source Eclipse Glasses

Sourcing eclipse glasses for your business requires careful planning and execution to ensure you obtain high-quality products that meet safety standards. This checklist provides a step-by-step approach, enabling B2B buyers—particularly from Africa, South America, the Middle East, and Europe—to navigate the complexities of the procurement process effectively.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to outline the specific requirements for the eclipse glasses. Consider factors such as optical density, material durability, and certification standards.

- Optical Density: Ensure the glasses meet the ISO 12312-2 standard, which specifies the level of protection required for direct solar viewing.

- Durability: Look for materials that can withstand various environmental conditions, especially if you plan to sell them in outdoor settings.

Step 2: Research and Identify Potential Suppliers

Start by compiling a list of potential manufacturers and suppliers who specialize in eclipse glasses. Utilize online directories, trade shows, and industry publications to gather data on reputable companies.

- Online Directories: Websites like Alibaba or ThomasNet can help you find manufacturers with positive reviews.

- Trade Shows: Attend industry events to meet suppliers in person and evaluate their offerings.

Step 3: Evaluate Potential Suppliers

Before making a commitment, conduct a thorough evaluation of the shortlisted suppliers. Request detailed company profiles, product samples, and references from other clients.

- Company Profiles: Assess their experience in manufacturing eclipse glasses and their market reputation.

- Client References: Contact previous buyers to gain insights into their experiences with product quality and customer service.

Step 4: Verify Supplier Certifications

It is crucial to ensure that your chosen supplier holds the necessary certifications for safety and quality standards. This step protects your business from liability and enhances customer trust.

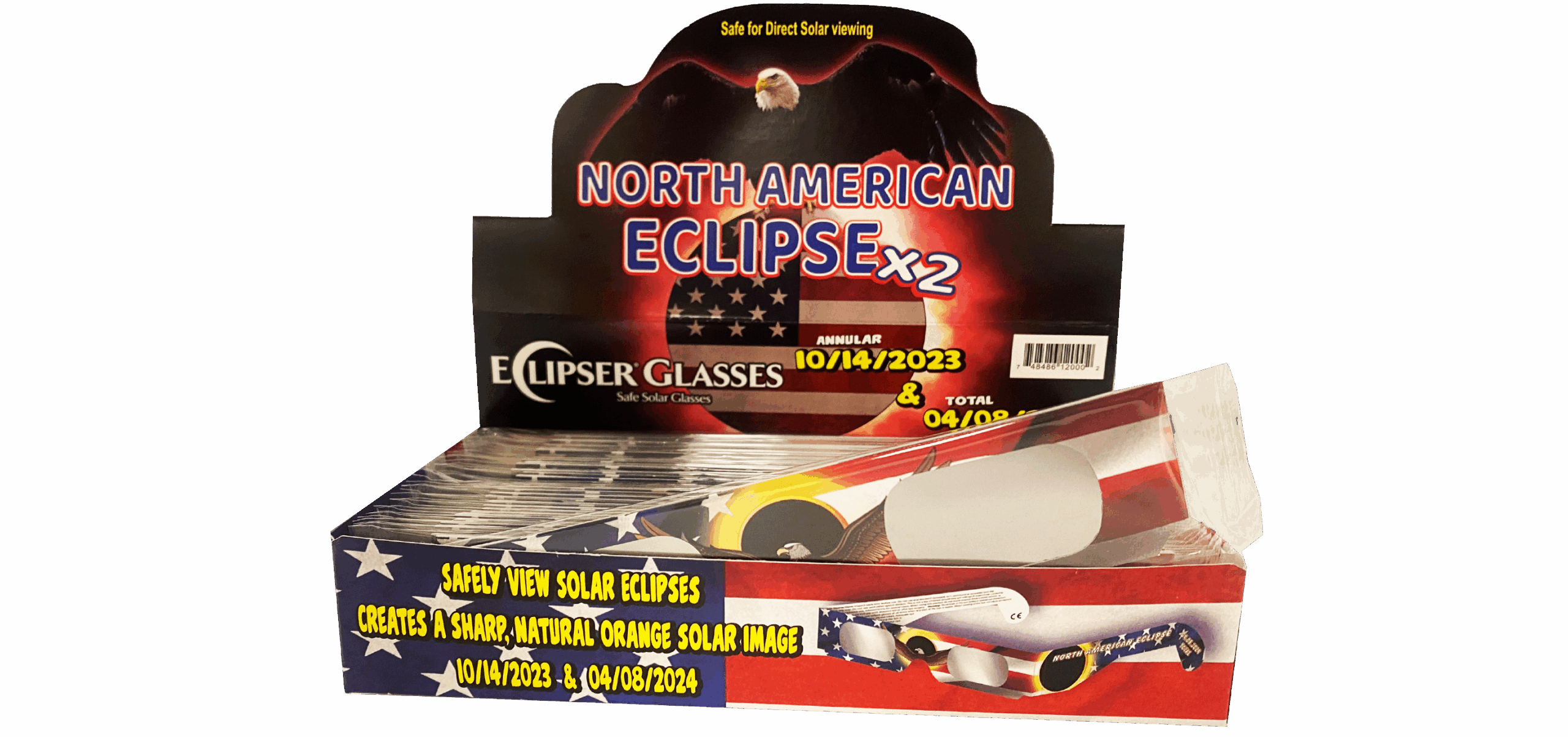

A stock image related to eclipse glasse manufacturer.

- ISO Certification: Confirm that the supplier is ISO certified, indicating adherence to international quality standards.

- Safety Compliance: Check for compliance with local regulations and safety standards relevant to your target market.

Step 5: Request Samples for Testing

Once you have narrowed down your options, request samples of the eclipse glasses. This allows you to assess the quality and usability before placing a larger order.

- Quality Assessment: Examine the samples for optical clarity, comfort, and build quality.

- User Feedback: If possible, gather feedback from potential customers regarding their impressions of the product.

Step 6: Negotiate Terms and Pricing

Engage in negotiations with the selected supplier to establish favorable terms, including pricing, payment schedules, and delivery timelines.

- Volume Discounts: Inquire about pricing adjustments for bulk orders to maximize profitability.

- Payment Terms: Discuss flexible payment options that align with your cash flow needs.

Step 7: Finalize the Purchase Agreement

After agreeing on terms, finalize the purchase agreement to formalize the transaction. Ensure that all details, including delivery schedules and after-sales support, are clearly outlined in the contract.

- Clarity in Terms: A well-defined agreement minimizes misunderstandings and protects both parties.

- After-Sales Support: Confirm that the supplier offers adequate support for any product issues post-purchase.

By following this comprehensive checklist, B2B buyers can navigate the procurement process for eclipse glasses with confidence, ensuring they source quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for eclipse glasse manufacturer Sourcing

What Are the Key Cost Components in Sourcing Eclipse Glasses?

When sourcing eclipse glasses, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects the overall cost. High-quality optical-grade filters, which provide adequate protection against harmful UV rays, are essential. Buyers should consider sourcing from manufacturers who use compliant materials that meet safety standards.

-

Labor: Labor costs vary by region. Countries with lower labor costs can offer competitive pricing, but buyers should ensure that quality is not compromised. Skilled labor is vital for precise manufacturing, especially when dealing with safety-related products.

-

Manufacturing Overhead: This includes utilities, rent, and administrative costs associated with production. Buyers should inquire about the manufacturer’s overhead to understand how it impacts pricing.

-

Tooling: The initial investment in tooling can be significant, especially for custom designs. This cost is typically amortized over the production run, meaning larger orders can benefit from lower per-unit costs.

-

Quality Control (QC): Robust QC processes are necessary to ensure safety and compliance. Manufacturers with stringent QC practices may charge higher prices, but this often results in better product reliability.

-

Logistics: Shipping and handling costs can vary widely based on the destination and shipping method. For international buyers, understanding Incoterms is crucial to determine who bears the cost and risk during transit.

-

Margin: The manufacturer’s profit margin will also influence the final price. Buyers should seek transparency in pricing to evaluate the fairness of the margin applied.

How Do Price Influencers Affect Sourcing Decisions?

Several factors can influence the pricing of eclipse glasses:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs to find a balance between inventory needs and pricing benefits.

-

Specifications and Customization: Custom designs may incur additional costs. Buyers should assess whether customization is essential for their target market and weigh it against potential cost increases.

-

Material Quality and Certifications: Higher quality materials and relevant safety certifications can increase costs. However, they are critical for compliance and customer satisfaction.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality may charge more, but the risk of defects or non-compliance is lower.

-

Incoterms: Understanding the implications of Incoterms (e.g., FOB, CIF) can help buyers manage costs effectively. Each term defines the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs.

What Are the Best Negotiation Strategies for B2B Buyers?

For international buyers, especially from Africa, South America, the Middle East, and Europe, effective negotiation can significantly impact the total cost of ownership (TCO):

-

Research and Benchmarking: Conduct thorough market research to understand typical pricing structures. Use this information as leverage in negotiations.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms. Open communication fosters trust and encourages suppliers to offer competitive rates.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price, but also the costs associated with shipping, storage, and potential defects. A slightly higher price with better quality may result in lower overall costs.

-

Flexible Payment Terms: Negotiate payment terms that can ease cash flow constraints. Options like staggered payments or extended payment periods can be advantageous.

-

Evaluate Multiple Suppliers: Don’t settle for the first offer. Comparing multiple suppliers can reveal significant price differences and provide negotiation leverage.

Conclusion: What Should Buyers Keep in Mind?

While sourcing eclipse glasses, it is essential for international buyers to navigate the complex cost structures and pricing factors effectively. Understanding the components that contribute to the total cost, leveraging negotiation strategies, and focusing on long-term value can lead to successful sourcing decisions. Keep in mind that prices can vary widely based on regional factors and market conditions, so always request indicative pricing and be prepared for fluctuations.

Alternatives Analysis: Comparing eclipse glasse manufacturer With Other Solutions

In the ever-evolving market for eclipse glasses, international B2B buyers must consider various options beyond the traditional offerings. Understanding the available alternatives can help businesses make informed decisions that align with their specific needs, budget constraints, and operational requirements.

Comparison Table of Eclipse Glasses Solutions

| Comparison Aspect | Eclipse Glasses Manufacturer | Solar Viewing Filters | Pinhole Projectors |

|---|---|---|---|

| Performance | High UV protection, durable | Excellent for direct viewing, lightweight | Safe for indirect viewing, low cost |

| Cost | Medium to high | Low to medium | Very low |

| Ease of Implementation | Requires manufacturing setup | Easy to distribute | Simple DIY assembly |

| Maintenance | Low maintenance required | Minimal upkeep | No maintenance needed |

| Best Use Case | Commercial events, schools | Astronomy clubs, outdoor events | Educational purposes |

What Are the Advantages and Disadvantages of Solar Viewing Filters?

Solar viewing filters provide an effective alternative to traditional eclipse glasses, offering high levels of UV protection and clarity for direct solar viewing. They are generally lightweight and easy to distribute, making them ideal for use in events like astronomy clubs and outdoor gatherings. However, the cost can vary, and they may require some training for users to ensure proper handling and use. While they are a great choice for direct viewing, they may not provide the same level of durability as glasses manufactured specifically for prolonged use.

How Do Pinhole Projectors Compare as a Safe Viewing Method?

Pinhole projectors represent a low-cost solution for viewing solar events indirectly. They can be easily constructed from everyday materials, making them an accessible option for educational purposes. The simplicity of the design means that there is no maintenance required, and they can be a fun project for schools and community groups. However, the viewing experience is not as engaging as using eclipse glasses or solar filters, and they are not suitable for direct viewing, which limits their application in commercial settings.

What Should B2B Buyers Consider When Choosing Between These Options?

When selecting the right solution for eclipse viewing, B2B buyers should assess their specific needs against the features of each alternative. Key considerations include the intended use case—whether for commercial events, educational purposes, or casual viewing—along with budget constraints and ease of implementation.

For businesses focused on high-quality experiences, investing in eclipse glasses manufactured to stringent safety standards might be worthwhile despite the higher cost. Conversely, organizations with budget limitations or looking for educational tools might find solar viewing filters or pinhole projectors to be more aligned with their objectives.

Conclusion

Navigating the options for eclipse viewing solutions requires careful evaluation of each alternative’s performance, cost, and ease of use. By understanding the unique benefits and limitations of eclipse glasses, solar viewing filters, and pinhole projectors, international B2B buyers can make strategic decisions that best fit their operational needs and enhance their offerings during solar events. Ultimately, the right choice will depend on a thorough assessment of the specific context in which the solution will be applied.

Essential Technical Properties and Trade Terminology for eclipse glasse manufacturer

What Are the Essential Technical Properties for Eclipse Glass Manufacturing?

When sourcing eclipse glasses, understanding the technical properties of the materials used is crucial for ensuring safety and compliance with international standards. Here are some key specifications to consider:

1. Material Grade

Eclipse glasses must be made from certified solar viewing materials, such as polycarbonate or optical glass. The material grade affects the glasses’ ability to filter out harmful UV and infrared radiation. High-quality materials ensure durability and effectiveness, which is vital for international compliance and consumer safety.

2. Optical Density

Optical density (OD) measures the amount of light that can pass through the material. For eclipse glasses, a minimum OD of 5 is required, meaning they block 99.999% of sunlight. This property is critical for protecting users’ eyes during solar events, and failure to meet this standard can result in legal liabilities.

3. Tolerance Levels

Tolerance refers to the permissible limits of variation in the dimensions and characteristics of the glasses. For instance, the frame size and lens thickness must adhere to specific tolerances to ensure a proper fit and comfort for users. This specification is essential for manufacturers to maintain quality control and customer satisfaction.

4. Impact Resistance

Eclipse glasses should possess a high level of impact resistance to withstand accidental drops or pressure. This property is particularly important in regions where transportation and handling can be rough. Ensuring that glasses meet impact resistance standards can reduce product returns and enhance brand reputation.

5. Coating and Finish

The coatings applied to eclipse glasses can enhance their durability and performance. Anti-scratch coatings are vital for maintaining clarity, while anti-fog treatments improve visibility. This aspect is important for B2B buyers looking to differentiate their products in a competitive market.

What Are Common Trade Terms in the Eclipse Glass Industry?

Familiarity with industry terminology can facilitate smoother transactions and negotiations. Here are several key trade terms that every buyer should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or products that are used in another company’s end products. For eclipse glasses, working with OEMs can help buyers ensure that they receive high-quality components tailored to their specifications.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage their inventory effectively and negotiate better pricing with manufacturers, especially when entering new markets.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. Submitting a well-structured RFQ can lead to more accurate quotes and better supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping, insurance, and risk management associated with their purchases.

5. Lead Time

Lead time is the amount of time between placing an order and receiving it. Knowing the lead time is crucial for B2B buyers to plan their inventory and sales strategies effectively, ensuring that they can meet customer demand without overstocking.

A stock image related to eclipse glasse manufacturer.

Understanding these technical properties and trade terms will empower international B2B buyers to make informed decisions when sourcing eclipse glasses, ensuring safety, compliance, and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the eclipse glasse manufacturer Sector

What Are the Key Market Trends Impacting the Eclipse Glasses Manufacturing Sector?

The global demand for eclipse glasses is witnessing a significant surge, driven by the increasing awareness of solar events and the need for protective eyewear. This trend is further amplified by the growth of social media and digital platforms, which facilitate the dissemination of information about upcoming solar eclipses. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing.

One of the key market dynamics is the technological advancement in materials used for eclipse glasses. Manufacturers are increasingly investing in high-quality, durable materials that provide better UV protection and optical clarity. Moreover, the integration of digital technologies in the manufacturing process is improving efficiency and reducing lead times, which is beneficial for B2B buyers looking for timely deliveries.

Emerging trends also include the rise of e-commerce platforms that allow manufacturers to reach global markets directly. This shift not only expands the supplier base for buyers but also offers competitive pricing options. Buyers from regions like Poland and Thailand can leverage these platforms to source products that meet their specific requirements while ensuring compliance with international safety standards.

How Is Sustainability Influencing the Sourcing of Eclipse Glasses?

Sustainability has become a pivotal consideration for B2B buyers in the eclipse glasses manufacturing sector. The environmental impact of production processes and materials used in eclipse glasses is under scrutiny, prompting manufacturers to adopt greener practices. For buyers, understanding the sustainability credentials of suppliers is essential in making informed purchasing decisions.

Ethical sourcing practices are increasingly being prioritized, with many manufacturers seeking certifications that validate their commitment to sustainability. Certifications such as FSC (Forest Stewardship Council) for paper products and ISO 14001 for environmental management systems are becoming vital for establishing credibility. By sourcing from certified manufacturers, international buyers can ensure that their supply chains are not only compliant but also contribute positively to environmental conservation.

Additionally, the use of recycled materials is gaining traction in the production of eclipse glasses. Buyers looking to align with sustainability goals can benefit from partnering with manufacturers who incorporate eco-friendly materials into their products. This not only enhances brand reputation but also appeals to a growing consumer base that values environmental responsibility.

What Is the Historical Context of the Eclipse Glasses Manufacturing Sector?

The manufacturing of eclipse glasses has evolved significantly over the past few decades. Initially, these glasses were produced using basic materials that provided minimal protection. However, with advancements in technology and a better understanding of solar radiation’s effects on the eyes, the industry has undergone a transformation.

In the late 20th century, the introduction of high-quality solar filters marked a turning point for the sector. This innovation led to the development of safer and more effective eclipse glasses, making them accessible to a broader audience. The rise of the internet and e-commerce platforms has further revolutionized the market, allowing manufacturers to reach international buyers more efficiently.

As the global awareness of solar events continues to grow, the eclipse glasses manufacturing sector is poised for further innovation and expansion. Understanding this historical context can provide B2B buyers with insights into the reliability and safety of products in today’s market.

Frequently Asked Questions (FAQs) for B2B Buyers of eclipse glasse manufacturer

-

How do I find reliable eclipse glasses manufacturers for international trade?

Finding reliable eclipse glasses manufacturers requires thorough research. Start by leveraging online B2B marketplaces like Alibaba or Global Sources, where you can filter suppliers based on ratings and reviews. Attend trade shows focused on safety products or eyewear, as these events allow for direct interaction with manufacturers. Additionally, consider seeking recommendations from industry contacts or using platforms like LinkedIn to connect with professionals who have experience sourcing eclipse glasses. -

What certifications should I look for in eclipse glasses manufacturers?

When sourcing eclipse glasses, it’s vital to ensure that manufacturers comply with international safety standards. Look for ISO certification, which indicates quality management practices. Additionally, check for compliance with the American National Standards Institute (ANSI) Z80.3 or similar international standards, which confirm that the glasses meet safety requirements for solar viewing. Request documentation of these certifications to ensure product safety. -

What is the minimum order quantity (MOQ) for eclipse glasses, and how does it vary by supplier?

Minimum order quantities (MOQ) for eclipse glasses can vary significantly between suppliers. Typically, MOQs range from 100 to several thousand units, depending on the manufacturer and their production capabilities. Smaller manufacturers may offer lower MOQs, while larger companies may require bulk orders for competitive pricing. Always clarify MOQs during initial discussions, and negotiate terms that suit your business needs. -

What are the typical payment terms for international orders of eclipse glasses?

Payment terms for international orders can vary widely among manufacturers. Common arrangements include a 30% deposit upfront, with the remaining 70% due before shipping. Some suppliers may offer more flexible terms based on your order size or payment history. It’s advisable to discuss and agree on payment terms in writing, and consider using secure payment methods like letters of credit or escrow services to mitigate risks. -

How can I ensure the quality of eclipse glasses before purchasing?

To ensure the quality of eclipse glasses, request samples from potential manufacturers before placing a bulk order. Conduct visual inspections and, if possible, test the glasses for compliance with safety standards. Additionally, inquire about the manufacturer’s quality assurance processes and certifications. Establishing a clear communication channel regarding quality expectations can help in maintaining standards throughout the production run. -

What customization options are available for eclipse glasses?

Many manufacturers offer customization options for eclipse glasses, including branding, colors, and packaging. Discuss your specific requirements with the supplier and ask for examples of previous custom projects. Customization may impact MOQs and lead times, so be prepared for potential adjustments in pricing and delivery schedules. Clear communication of your design specifications will help ensure that the final product meets your expectations. -

What logistics considerations should I keep in mind when importing eclipse glasses?

When importing eclipse glasses, consider logistics factors such as shipping costs, delivery times, and customs regulations. Choose a reliable freight forwarder who is familiar with importing goods into your country. Be aware of any import duties or taxes that may apply, and ensure that the supplier provides accurate shipping documentation to facilitate a smooth customs clearance process. -

How can I build a long-term relationship with eclipse glasses manufacturers?

Building a long-term relationship with eclipse glasses manufacturers involves regular communication and transparency. After your initial order, provide feedback on the product quality and service, and express interest in future collaboration. Consider visiting the manufacturer’s facility if feasible, as face-to-face interactions can strengthen partnerships. Establishing mutual trust and understanding can lead to better pricing, priority during production, and collaborative product development in the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for eclipse glasse manufacturer

What Are the Key Takeaways for International B2B Buyers of Eclipse Glasses?

As we conclude this exploration of strategic sourcing for eclipse glasses, it is essential to emphasize the significance of a tailored procurement strategy. International buyers, particularly from Africa, South America, the Middle East, and Europe, must prioritize partnerships with manufacturers that not only guarantee quality but also adhere to sustainable practices. This commitment to sustainability is increasingly becoming a deciding factor in buyer preferences, enhancing brand reputation and consumer trust.

How Can Strategic Sourcing Enhance Your Competitive Edge?

Strategic sourcing not only improves cost-efficiency but also fosters innovation and adaptability in response to market demands. Establishing strong relationships with reliable suppliers can lead to better negotiation terms, reduced lead times, and access to cutting-edge technologies. This proactive approach allows businesses to stay ahead of competitors and respond swiftly to the dynamic market landscape.

What Should Be Your Next Steps in Sourcing Eclipse Glasses?

Looking ahead, international B2B buyers should actively seek out suppliers who demonstrate a commitment to quality and innovation in eclipse glass manufacturing. Engage with manufacturers that provide transparent sourcing practices and can offer certifications for quality assurance. By prioritizing these factors, buyers can ensure they are well-prepared for the upcoming demand surges surrounding solar events. Embrace this opportunity to enhance your sourcing strategies, and position your business for success in the global marketplace.