Discover Top Fiber Optic Cable Manufacturers: A Complete Guide (2025)

Introduction: Navigating the Global Market for Fiber Optic Cable Manufacturers

In today’s interconnected world, sourcing high-quality fiber optic cables is critical for businesses aiming to enhance their communication infrastructure. However, international B2B buyers often face challenges in navigating the complex global market for fiber optic cable manufacturers. This comprehensive guide addresses these challenges by providing in-depth insights into various types of fiber optic cables, their applications, and the vital aspects of supplier vetting. From understanding the differences between single-mode and multi-mode fibers to evaluating the cost-effectiveness of different suppliers, this resource equips buyers with the knowledge necessary for informed purchasing decisions.

The guide also delves into the latest trends in fiber optics, including advancements in technology and sustainability practices, which are increasingly important to buyers in regions such as Africa, South America, the Middle East, and Europe. By focusing on specific markets like Argentina and Egypt, we highlight regional considerations that can impact sourcing decisions. Additionally, this guide offers actionable tips for negotiating contracts and ensuring compliance with international standards, empowering buyers to make strategic choices that align with their business goals. Whether you’re enhancing your telecommunications network or investing in new infrastructure, understanding the fiber optic landscape is essential for driving success in the digital age.

Understanding Fiber Optic Cable Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Mode Fiber (SMF) | Small core diameter (~8-10 microns), supports long-distance transmission | Telecommunications, data centers | Pros: High bandwidth, low signal loss over long distances. Cons: More expensive, requires precise installation. |

| Multi-Mode Fiber (MMF) | Larger core diameter (50-62.5 microns), supports multiple light modes | Local area networks (LANs), short distances | Pros: Cost-effective for short distances, easier to install. Cons: Higher signal loss over distance, limited to shorter runs. |

| Armored Fiber Optic Cable | Reinforced with protective layers, resistant to physical damage | Industrial applications, outdoor installations | Pros: Durable, resistant to harsh environments. Cons: Heavier and more expensive than standard cables. |

| Ribbon Fiber Optic Cable | Contains multiple fibers in a flat ribbon structure, space-efficient | High-density applications, data centers | Pros: Space-saving, high fiber count per unit area. Cons: More complex splicing, requires specialized installation. |

| Specialty Fiber Optics | Custom-designed fibers for specific applications (e.g., photonic crystal fibers) | Medical devices, sensing applications | Pros: Tailored performance, unique capabilities. Cons: Typically high cost and longer lead times. |

What are the Characteristics of Single-Mode Fiber (SMF)?

Single-Mode Fiber (SMF) features a small core diameter, typically between 8 to 10 microns, which allows only one mode of light to propagate. This design minimizes signal attenuation, making SMF ideal for long-distance communications, such as telecommunications and data centers. When considering SMF for purchase, buyers should evaluate their long-term bandwidth needs, installation capabilities, and compatibility with existing systems. Although the initial investment may be higher, the reduced signal loss can lead to cost savings over time.

How Does Multi-Mode Fiber (MMF) Differ in Application?

Multi-Mode Fiber (MMF) has a larger core diameter (50-62.5 microns), allowing multiple light modes to travel simultaneously. This characteristic makes MMF suitable for short-distance applications, such as local area networks (LANs) and within buildings. Buyers should consider the intended application’s distance requirements and budget, as MMF is generally more cost-effective for shorter runs. However, its higher signal loss over longer distances may limit its effectiveness in expansive networks.

What Advantages Does Armored Fiber Optic Cable Provide?

Armored Fiber Optic Cables are designed with additional protective layers to withstand physical stress and environmental hazards. These cables are particularly beneficial in industrial settings or outdoor installations where exposure to harsh conditions is a concern. Buyers should assess the specific environmental risks and installation challenges they face. While armored cables offer durability, they can be heavier and more costly than standard options, impacting installation logistics and overall project budgets.

Why Choose Ribbon Fiber Optic Cable?

Ribbon Fiber Optic Cables feature multiple fibers arranged in a flat ribbon structure, allowing for a high fiber count in a compact design. This type is particularly advantageous in high-density applications, such as data centers, where space is at a premium. When considering ribbon cables, buyers should evaluate their splicing capabilities and the need for specialized installation equipment. Although they provide significant space-saving benefits, the complexity of splicing may require additional training or resources.

What are the Benefits of Specialty Fiber Optics?

Specialty Fiber Optics are custom-designed to meet specific application requirements, such as photonic crystal fibers used in medical devices or sensing applications. These fibers can offer unique performance characteristics tailored to niche markets. Buyers looking into specialty fibers should consider their unique project needs, as well as the potential for higher costs and longer lead times associated with custom production. While they may not be suitable for all applications, their specialized capabilities can provide significant advantages in targeted uses.

Related Video: Fiber Optic Networking Lesson 1: How to Choose the Right Fiber Optic Cable -A Beginner’s Guide

Key Industrial Applications of Fiber Optic Cable Manufacturers

| Industry/Sector | Specific Application of Fiber Optic Cable Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | High-speed internet infrastructure deployment | Enhanced data transmission speeds and reliability | Compliance with local regulations, quality certifications |

| Healthcare | Medical imaging and telemedicine systems | Improved diagnostic capabilities and remote patient care | Compatibility with existing systems, stringent quality standards |

| Oil & Gas | Monitoring and control systems for pipelines | Real-time data collection and reduced downtime | Resistance to harsh environments, custom lengths and designs |

| Smart Cities | Smart grid and urban infrastructure connectivity | Increased efficiency and better resource management | Scalability, integration with IoT technologies |

| Transportation | Fiber optic systems for signaling and communication in railways | Enhanced safety and operational efficiency | Durability, installation support, and maintenance services |

How Are Fiber Optic Cable Manufacturers Used in Telecommunications?

In the telecommunications sector, fiber optic cables are essential for deploying high-speed internet infrastructure. They facilitate the transmission of vast amounts of data over long distances with minimal loss. For international B2B buyers, especially in regions like Africa and South America, sourcing high-quality fiber optics can help overcome challenges related to connectivity and bandwidth limitations. Buyers must consider local compliance and the supplier’s ability to provide reliable technical support.

What Role Do Fiber Optic Cables Play in Healthcare?

Fiber optic cables are increasingly used in healthcare for medical imaging and telemedicine systems. These cables enable high-resolution imaging and the transfer of large data files, improving diagnostic capabilities and patient outcomes. For buyers in the healthcare sector, particularly in the Middle East and Europe, it is crucial to ensure that the cables meet stringent quality standards and are compatible with existing medical equipment.

How Are Fiber Optic Cables Applied in the Oil & Gas Industry?

In the oil and gas sector, fiber optic cables are utilized for monitoring and control systems in pipelines. They provide real-time data on pipeline conditions, allowing for quick responses to potential leaks or other issues. For B2B buyers in regions like Egypt and Argentina, sourcing durable fiber optic solutions that can withstand harsh environmental conditions is essential. Custom lengths and designs may also be required to fit specific operational needs.

What Benefits Do Fiber Optic Cables Offer in Smart Cities?

Fiber optic cables are critical for connecting smart grid technologies and urban infrastructure in smart cities. They enhance communication between various city services, leading to improved efficiency and resource management. For buyers in Europe and the Middle East, sourcing scalable solutions that can integrate with IoT technologies is vital to future-proof urban development projects.

How Are Fiber Optic Cables Used in Transportation Systems?

In transportation, particularly railways, fiber optic cables are integral to signaling and communication systems. They improve safety and operational efficiency by allowing for real-time communication between trains and control centers. Buyers in this sector should prioritize sourcing durable fiber optic systems that offer installation support and ongoing maintenance services to ensure long-term reliability.

Related Video: Fiber optic cable manufacturing process / Ftth drop cable factory / Jera line

3 Common User Pain Points for ‘Fiber Optic Cable Manufacturers’ & Their Solutions

Scenario 1: Overcoming High Installation Costs for Fiber Optic Networks

The Problem: One of the most significant challenges faced by B2B buyers, especially in emerging markets like Africa and South America, is the high cost associated with installing fiber optic networks. These expenses can arise from multiple sources, including the physical installation of cables, the need for specialized labor, and the requirement for advanced equipment. For businesses looking to expand their connectivity, these costs can be prohibitive, leading to delayed projects and lost opportunities.

The Solution: To mitigate installation costs, buyers should consider engaging with local fiber optic cable manufacturers who understand the regional market and can provide cost-effective solutions. It’s essential to request bulk pricing and explore options for financing or leasing the necessary equipment. Additionally, buyers can benefit from partnering with manufacturers that offer comprehensive training for local technicians. By investing in local talent, companies can reduce labor costs and minimize the need for expensive foreign expertise. Furthermore, leveraging pre-terminated fiber optic solutions can significantly cut down installation times and associated costs, as they eliminate the need for on-site splicing.

Scenario 2: Navigating Supply Chain Disruptions in Fiber Optic Cable Procurement

The Problem: International B2B buyers often face unpredictable supply chain disruptions that can delay their projects and affect service delivery. This is particularly true in regions like the Middle East and Africa, where logistical challenges can be compounded by geopolitical issues or natural disasters. The inability to secure timely delivery of fiber optic cables can lead to project overruns and increased operational costs.

The Solution: To combat supply chain issues, buyers should establish strong relationships with multiple manufacturers and suppliers to diversify their sourcing options. This strategy not only mitigates risks associated with relying on a single supplier but also allows businesses to negotiate better terms and prices. Implementing a just-in-time inventory system can help maintain optimal stock levels while reducing excess inventory costs. Additionally, buyers should actively monitor market trends and geopolitical developments to anticipate potential disruptions and adjust their procurement strategies accordingly. Investing in technology solutions that provide real-time tracking of shipments can further enhance supply chain visibility and responsiveness.

Scenario 3: Ensuring Compatibility and Future-Proofing Fiber Optic Infrastructure

The Problem: As technology evolves, businesses need to ensure that their fiber optic infrastructure can support future upgrades without requiring complete overhauls. Buyers often struggle with selecting the right type of fiber optic cables, such as single-mode versus multi-mode, and ensuring compatibility with existing systems. This can lead to costly retrofitting or replacements if the wrong choices are made.

The Solution: To future-proof fiber optic networks, buyers should conduct a thorough needs assessment that considers current and anticipated bandwidth requirements. Engaging with fiber optic cable manufacturers early in the planning process can provide valuable insights into the most suitable cable types and configurations. It’s also beneficial to opt for modular systems that allow for easy upgrades and scalability. Buyers should prioritize manufacturers that offer a range of products compatible with industry standards and provide clear documentation on specifications. Regular training and updates on technological advancements can also empower buyers to make informed decisions about their infrastructure as new options become available.

Strategic Material Selection Guide for Fiber Optic Cable Manufacturers

What Are the Key Materials Used in Fiber Optic Cable Manufacturing?

Fiber optic cables are essential in modern telecommunications, and the choice of materials significantly affects their performance, durability, and cost. Below, we analyze four common materials used in fiber optic cable manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

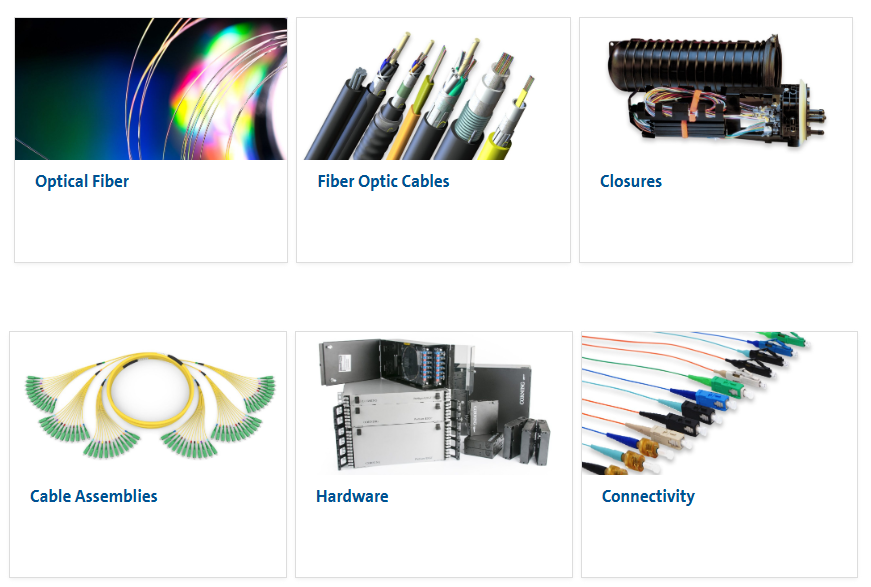

A stock image related to Fiber Optic Cable Manufacturers.

Glass Fiber: The Standard for High-Performance Cables

Key Properties: Glass fibers are known for their exceptional light transmission capabilities, with low attenuation rates (as low as 0.2 dB/km). They can operate effectively across a wide temperature range, typically from -40°C to +85°C, and are resistant to moisture and chemical corrosion.

Pros & Cons: The primary advantage of glass fibers is their high performance in data transmission, making them suitable for long-distance communication. However, they are more fragile than other materials, which can complicate installation and increase the risk of breakage during handling. Additionally, glass fibers can be more expensive to produce.

Impact on Application: Glass fibers are ideal for high-bandwidth applications, such as internet backbone connections and data centers. Their compatibility with various media makes them a preferred choice for telecommunications.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM and IEC to guarantee quality. The fragility of glass fibers necessitates careful handling and installation practices.

Plastic Optical Fiber (POF): A Cost-Effective Alternative

Key Properties: POF is made from polymer materials, typically polymethyl methacrylate (PMMA). It is lightweight and has a larger core diameter than glass fibers, which allows for easier coupling with light sources. POF operates efficiently at lower data rates and is less sensitive to bending.

Pros & Cons: The main advantage of POF is its lower cost and ease of installation, making it suitable for short-distance applications. However, its performance diminishes over longer distances, with higher attenuation rates compared to glass fibers. POF is also less durable in harsh environmental conditions.

Impact on Application: POF is commonly used in consumer electronics, automotive applications, and home networking. Its flexibility makes it suitable for environments where installation space is limited.

Considerations for International Buyers: Buyers should consider the local infrastructure and application requirements when choosing POF. Compliance with regional standards, such as DIN in Europe, is essential for ensuring product reliability.

Armored Fiber: Enhancing Durability in Harsh Environments

Key Properties: Armored fiber cables are designed with an additional layer of protection, typically made from steel or aluminum. This enhances their resistance to physical damage, moisture, and rodent attacks, making them suitable for outdoor and industrial applications.

Pros & Cons: The key advantage of armored fiber is its durability, which reduces the need for frequent replacements. However, the added protection increases manufacturing complexity and cost, making them more expensive than standard cables.

Impact on Application: Armored fiber is ideal for applications in harsh environments, such as outdoor installations, military applications, and industrial settings where cables are exposed to potential damage.

Considerations for International Buyers: Buyers in the Middle East and Africa should consider the local environmental conditions when selecting armored fiber. Compliance with standards like JIS is crucial for ensuring product effectiveness.

Low Smoke Zero Halogen (LSZH) Cable: Safety in Enclosed Spaces

Key Properties: LSZH cables are made from materials that emit low smoke and no halogen when exposed to fire. This property significantly enhances safety in enclosed spaces, such as buildings and public transport systems.

Pros & Cons: The primary advantage of LSZH cables is their safety profile, making them ideal for indoor installations. However, they may be more expensive than standard cables and can have a lower performance in terms of flexibility and temperature resistance.

Impact on Application: LSZH cables are commonly used in commercial buildings, airports, and public transport systems, where safety is a paramount concern.

Considerations for International Buyers: Buyers in Europe and South America should prioritize LSZH cables in applications where fire safety is critical. Compliance with local fire safety standards is essential.

Summary Table of Material Selection for Fiber Optic Cable Manufacturers

| Material | Typical Use Case for Fiber Optic Cable Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass Fiber | Long-distance telecommunications and data centers | High performance with low attenuation | Fragility can complicate installation | High |

| Plastic Optical Fiber (POF) | Consumer electronics and home networking | Cost-effective and easy to install | Higher attenuation over long distances | Low |

| Armored Fiber | Outdoor and industrial applications | Enhanced durability against damage | Increased cost and manufacturing complexity | Medium |

| Low Smoke Zero Halogen (LSZH) | Indoor installations in public spaces | Improved safety in fire situations | Higher cost and lower flexibility | Medium |

This analysis provides international B2B buyers with a comprehensive understanding of the materials used in fiber optic cable manufacturing, enabling informed decisions that align with their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for Fiber Optic Cable Manufacturers

What are the Main Stages of the Manufacturing Process for Fiber Optic Cables?

The manufacturing process for fiber optic cables involves several critical stages that ensure the final product meets the required standards for performance and quality. Understanding these stages is essential for international B2B buyers looking to procure high-quality fiber optic cables.

-

Material Preparation

The first stage involves sourcing high-purity silica or plastic materials. Silica is the primary material used in glass fiber production, while plastic is utilized for polymer optical fibers. Suppliers must ensure that the raw materials meet specific purity levels to minimize attenuation during light transmission. Buyers should inquire about the sourcing practices of manufacturers and the traceability of materials. -

Forming the Fiber

The actual fiber is formed using processes such as the Modified Chemical Vapor Deposition (MCVD) or the Outside Vapor Deposition (OVD) methods. These techniques allow manufacturers to create the core and cladding of the fiber with precise refractive indices. The process involves heating silica rods and depositing layers of glass that will form the fiber. Buyers should understand the techniques employed by manufacturers, as they directly impact the fiber’s performance characteristics. -

Assembly of the Cable

Once the fiber is formed, it is bundled with protective materials and additional components such as strength members and outer jackets. This stage often includes applying protective coatings and ensuring that the fibers are properly aligned. The assembly process must adhere to strict standards to ensure durability and reliability in various environments. -

Finishing Processes

The final stage involves cutting the cables to specific lengths, applying connectors, and testing the completed assemblies. This may also include labeling and packaging for shipment. Quality control checks are critical during this stage to ensure that all products meet the specifications outlined in customer orders.

How is Quality Assurance Implemented in Fiber Optic Cable Manufacturing?

Quality assurance (QA) is vital for ensuring that fiber optic cables perform reliably in their intended applications. Here’s how manufacturers implement QA throughout the production process:

-

What International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 for quality management systems are crucial benchmarks for fiber optic cable manufacturers. Compliance with these standards demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific certifications such as CE marking for European markets or API standards for specific applications can be significant indicators of quality. -

What are the Key Quality Control Checkpoints?

Quality control in fiber optic manufacturing typically includes several checkpoints:

– Incoming Quality Control (IQC): Raw materials are tested upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps catch defects early.

– Final Quality Control (FQC): Finished products undergo rigorous testing to verify performance metrics, including attenuation and bandwidth capabilities. -

Which Testing Methods are Commonly Used?

Several testing methods are employed to assess the quality of fiber optic cables:

– Optical Time Domain Reflectometry (OTDR): Used to measure the light loss in the fiber.

– Insertion Loss Testing: Verifies the amount of signal loss when the fiber is connected to a light source.

– Visual Inspection: Ensures that connectors and terminations are free from defects.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, ensuring that suppliers maintain high-quality standards is essential. Here are actionable steps to verify supplier quality control processes:

-

Conduct Supplier Audits

Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. Buyers should request access to audit reports and certifications to assess compliance with international standards. -

Request Quality Control Reports

Buyers can ask suppliers for detailed quality control reports, including test results and failure analysis. These documents should outline the methodologies used for testing and the outcomes of those tests. -

Engage Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These services can conduct inspections at various stages of production and provide detailed reports on compliance with specifications.

What Are the Nuances of Quality Control for International B2B Buyers?

Understanding the nuances of quality control in different regions is crucial for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

-

Regional Standards and Regulations

Each region may have specific standards that must be adhered to. For example, buyers in Europe must consider CE marking, while those in the Middle East may need to comply with Gulf Standards Organization (GSO) regulations. Understanding these requirements can help buyers avoid compliance issues. -

Cultural Factors Affecting Quality Control

Different regions may have varying approaches to quality assurance, influenced by local practices and norms. Buyers should be aware of these cultural differences when evaluating suppliers and their practices. -

Logistics and Supply Chain Considerations

Quality control doesn’t stop at manufacturing; it extends to logistics and distribution. B2B buyers should inquire about how suppliers maintain quality during transportation and storage, as these factors can significantly affect product performance.

By understanding the manufacturing processes and quality assurance measures in place, international B2B buyers can make informed decisions when selecting fiber optic cable manufacturers. This knowledge not only enhances supplier relationships but also ensures the procurement of high-quality, reliable products that meet specific business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Fiber Optic Cable Manufacturers’

In the rapidly evolving telecommunications industry, sourcing fiber optic cable manufacturers requires a strategic approach to ensure quality and reliability. This guide provides a practical checklist to streamline your procurement process, helping you make informed decisions tailored to your specific needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is crucial for effective sourcing. Determine the type of fiber optic cables you need, such as single-mode or multi-mode, and specify the required bandwidth, length, and environmental conditions. Understanding these details will enable you to communicate effectively with potential suppliers and ensure they can meet your needs.

Step 2: Conduct Market Research for Suppliers

Researching potential suppliers is essential to identify reputable manufacturers. Utilize industry directories, online forums, and trade shows to compile a list of candidates. Pay attention to suppliers with a strong presence in your region, as they may have better insight into local regulations and market demands.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with a proven track record of delivering high-quality products and excellent customer service.

- Assess their experience: Consider the number of years they have been in business and their expertise in manufacturing fiber optic cables.

- Check for compliance: Ensure that the suppliers adhere to international standards and regulations relevant to your market.

Step 4: Verify Supplier Certifications

Certifications are a testament to a manufacturer’s commitment to quality and reliability. Verify that your chosen suppliers possess relevant certifications, such as ISO 9001 for quality management systems or TL 9000 specific to the telecommunications industry.

- Inquire about testing: Ask if they conduct regular quality tests on their products to ensure compliance with industry standards.

- Review documentation: Request copies of their certifications to confirm their validity.

Step 5: Request Samples for Testing

Always request samples before making a bulk purchase. Testing samples allows you to evaluate the quality and performance of the fiber optic cables firsthand.

- Conduct performance tests: Assess parameters like attenuation, bandwidth capacity, and durability under various environmental conditions.

- Evaluate compatibility: Ensure the samples are compatible with your existing systems and infrastructure.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, it’s time to negotiate terms. Discuss pricing, payment terms, delivery schedules, and warranty conditions.

- Consider total cost of ownership: Look beyond the initial purchase price and evaluate long-term costs associated with installation, maintenance, and potential upgrades.

- Seek flexibility: Ensure the supplier is open to adjustments in order quantity or delivery timelines as your needs may evolve.

Step 7: Establish a Long-term Relationship

Building a lasting relationship with your fiber optic cable supplier can lead to better pricing, priority service, and access to new products.

- Communicate regularly: Keep the lines of communication open for updates on product developments and industry trends.

- Provide feedback: Share your experiences and suggestions for improvement, fostering a collaborative partnership.

By following this comprehensive checklist, international B2B buyers can effectively navigate the sourcing process for fiber optic cable manufacturers, ensuring they select a reliable partner that meets their technical and operational needs.

Comprehensive Cost and Pricing Analysis for Fiber Optic Cable Manufacturers Sourcing

Understanding the cost structure and pricing dynamics of fiber optic cable manufacturers is crucial for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. Below, we break down the key components influencing costs and pricing strategies, alongside actionable insights for buyers.

What Are the Key Cost Components in Fiber Optic Cable Manufacturing?

-

Materials Costs

The primary materials used in fiber optic cables include silica glass and plastic. Silica, being abundant, keeps costs relatively low, but fluctuations in raw material prices can affect the overall cost. Buyers should be aware of market trends in material sourcing, particularly from suppliers in regions like Asia and Europe. -

Labor Costs

Labor costs vary significantly by region. Countries with lower wage standards may offer more competitive pricing. However, labor quality and expertise in fiber optic technology are essential. Ensure that the supplier employs skilled labor to maintain high manufacturing standards. -

Manufacturing Overhead

This includes utilities, facility maintenance, and indirect labor costs. Manufacturers with advanced automation technologies may enjoy lower overhead costs, translating to better pricing for buyers. Inquire about the production technology used by suppliers to gauge efficiency. -

Tooling and Equipment

Initial investments in specialized tooling and machinery can be substantial. Suppliers who invest in state-of-the-art equipment often yield higher-quality products, which can justify higher prices. Buyers should weigh the upfront costs against long-term benefits. -

Quality Control (QC)

Effective QC processes ensure that products meet industry standards and certifications, which are critical for reliability. Manufacturers with rigorous QC protocols may charge a premium, but this often results in lower failure rates and better overall performance. -

Logistics Costs

Transportation and handling costs can vary based on the location of the manufacturer and the destination market. International buyers should consider the impact of logistics on total costs, including tariffs and shipping fees. -

Profit Margin

Manufacturers typically apply a markup based on their costs, competitive landscape, and perceived value of their products. Understanding the typical margins in your target market can aid in negotiations.

What Influences Pricing in Fiber Optic Cable Sourcing?

-

Volume and Minimum Order Quantity (MOQ)

Larger orders typically attract better pricing due to economies of scale. Buyers should assess their purchasing strategy to maximize cost savings. -

Specifications and Customization

Custom specifications, such as cable length and type (single-mode vs. multi-mode), can significantly affect pricing. Buyers should clearly define their requirements to avoid unexpected costs. -

Quality and Certifications

Products that meet international standards (e.g., ISO, IEC) may command higher prices. Buyers should prioritize quality certifications to ensure compliance with local regulations. -

Supplier Factors

The reputation and reliability of the supplier can influence pricing. Established suppliers with a proven track record may charge a premium, but they often provide better support and service. -

Incoterms

The choice of Incoterms (e.g., FOB, CIF) can affect the total landed cost of goods. Understanding these terms will help buyers negotiate better shipping arrangements and manage risks effectively.

What Are the Best Practices for Negotiating Fiber Optic Cable Prices?

-

Leverage Total Cost of Ownership (TCO)

When negotiating, consider not just the purchase price but the TCO, which includes installation, maintenance, and potential downtime costs. A higher upfront cost may result in lower long-term expenses. -

Conduct Market Research

Stay informed about market conditions and competitor pricing to strengthen your negotiation position. Knowledge of regional pricing trends can be a powerful tool. -

Build Relationships with Suppliers

Establishing a strong relationship with suppliers can lead to better pricing and terms over time. Open communication about your needs and expectations can foster trust and collaboration. -

Consider Alternative Suppliers

Don’t hesitate to explore multiple suppliers to compare pricing and service levels. This can provide leverage in negotiations. -

Be Prepared for Fluctuations

Prices can vary based on market demand, supply chain disruptions, and geopolitical factors. Buyers should be flexible and ready to adapt their sourcing strategies accordingly.

Disclaimer on Indicative Prices

Prices for fiber optic cables can fluctuate based on various factors, including raw material costs, manufacturing processes, and market demand. It is advisable for buyers to obtain quotes from multiple suppliers to ensure competitive pricing and assess the overall value offered.

Alternatives Analysis: Comparing Fiber Optic Cable Manufacturers With Other Solutions

Understanding Alternatives in Fiber Optic Solutions

When evaluating fiber optic cable manufacturers, it’s essential to consider alternative technologies that can achieve similar communication goals. This analysis not only highlights the strengths of fiber optics but also provides insight into viable alternatives, enabling international B2B buyers from regions like Africa, South America, the Middle East, and Europe to make informed decisions based on their specific needs.

Comparison Table of Fiber Optic Cable Manufacturers and Alternatives

| Comparison Aspect | Fiber Optic Cable Manufacturers | Copper Cable Solutions | Wireless Communication Technologies |

|---|---|---|---|

| Performance | High bandwidth, low latency | Moderate bandwidth, higher latency | Variable, dependent on signal strength and distance |

| Cost | Higher initial investment, long-term savings | Lower initial cost, higher long-term costs | Varies widely; can be cost-effective for short distances |

| Ease of Implementation | Requires specialized installation | Easier to install and terminate | Generally easier, but affected by environmental factors |

| Maintenance | Low maintenance needs | Moderate maintenance requirements | Variable; can require frequent maintenance |

| Best Use Case | Long-distance, high-demand applications | Short-distance, residential or office use | Mobile applications, temporary setups, or areas with difficult access |

Detailed Breakdown of Alternatives

Copper Cable Solutions

Copper cables have been a traditional choice for networking and telecommunications for decades. They offer a lower initial investment compared to fiber optics, making them appealing for smaller businesses or projects with limited budgets. However, they suffer from limitations in bandwidth and are more susceptible to electromagnetic interference. Over long distances, signal loss and latency can become significant issues, making copper less suitable for high-demand applications. Thus, while copper may be a practical choice for short-distance connections, it may not meet the needs of businesses planning for future growth or high-performance applications.

Wireless Communication Technologies

Wireless technologies, including Wi-Fi and cellular networks, provide flexibility and ease of deployment, particularly in environments where cabling is impractical. The initial setup can be less expensive than installing fiber optics, and they allow for mobility, making them ideal for temporary setups or remote areas. However, performance can vary significantly based on environmental factors such as distance from the transmitter, physical obstructions, and interference from other devices. For businesses requiring reliable, high-speed data transfer, especially over long distances, wireless solutions may fall short compared to fiber optics, which consistently deliver superior performance.

Conclusion: Choosing the Right Solution for Your Needs

When deciding between fiber optic cable manufacturers and alternative solutions like copper or wireless technologies, B2B buyers must assess their specific requirements. Factors such as performance needs, budget constraints, installation capabilities, and maintenance considerations play crucial roles in this decision-making process. For businesses in rapidly developing regions like Africa and South America, investing in fiber optics may provide the long-term benefits of scalability and reliability, while copper or wireless solutions might be suitable for more immediate or budget-conscious needs. Ultimately, understanding the strengths and limitations of each option will empower buyers to make choices that align with their operational goals and future growth plans.

Essential Technical Properties and Trade Terminology for Fiber Optic Cable Manufacturers

What Are the Key Technical Properties of Fiber Optic Cables?

A stock image related to Fiber Optic Cable Manufacturers.

Understanding the essential technical properties of fiber optic cables is crucial for B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. Here are the key specifications you should consider:

-

Material Grade

– Fiber optic cables are primarily made from glass or plastic. The grade of these materials affects their performance, durability, and cost. High-grade silica fibers, for example, offer lower attenuation (signal loss) and are more suitable for long-distance communication. Buyers should prioritize high-quality materials to ensure reliability in their network infrastructure. -

Core Diameter

– The core diameter of a fiber optic cable determines its mode of transmission. Single-mode fibers, typically with a core diameter of about 8-10 microns, allow only one mode of light to propagate, making them ideal for long-distance communication with minimal loss. In contrast, multi-mode fibers, which have a core diameter greater than 50 microns, support multiple light paths but are better suited for shorter distances. Understanding this property helps buyers select the right type for their specific applications. -

Attenuation Rate

– Attenuation refers to the reduction in signal strength as light travels through the fiber. Measured in decibels per kilometer (dB/km), a lower attenuation rate indicates a better quality fiber that can transmit data over longer distances without significant loss. For B2B buyers, selecting cables with low attenuation is essential for maintaining signal integrity, particularly in extensive networks. -

Bandwidth Capacity

– Bandwidth capacity refers to the amount of data that can be transmitted over the fiber optic cable in a given time. This is crucial for applications requiring high-speed data transfer, such as video streaming and large data transfers. Buyers should assess the bandwidth needs of their operations to choose cables that can accommodate future growth. -

Temperature and Environmental Resistance

– Fiber optic cables must be rated for their ability to withstand various environmental conditions, including temperature extremes and moisture. Buyers should consider the installation environment (e.g., outdoor, underground) to ensure the selected cable can endure the specific conditions without degrading performance.

What Are Common Trade Terms in the Fiber Optic Industry?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common trade terms relevant to fiber optic cable procurement:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the fiber optic industry, this term often refers to manufacturers who produce cables for brands that sell them under their label. Understanding OEM relationships can help buyers negotiate better pricing and quality assurance. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for buyers to understand as it can affect inventory costs and procurement strategies. Buyers should clarify MOQs with suppliers to ensure they align with their purchasing capabilities. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing an RFQ helps in comparing prices and services from multiple manufacturers, facilitating better purchasing decisions. -

Incoterms (International Commercial Terms)

– Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) related to international commercial law. They define the responsibilities of buyers and sellers in transactions, including delivery methods and risk management. Understanding these terms can help buyers mitigate risks and understand their obligations in international shipping. -

Lead Time

– Lead time refers to the time taken from placing an order to its delivery. For fiber optic cables, lead time can vary based on manufacturing capabilities and logistics. Buyers should factor in lead times to align with project schedules and avoid delays. -

Fiber Optic Splicing

– This term refers to the process of joining two fiber optic cables together. Splicing is critical in network construction and maintenance. Understanding this term helps buyers evaluate the skills and equipment needed for installation and repair, ensuring proper handling of their cable investments.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they select the right fiber optic cables to meet their operational needs while optimizing costs and performance.

Navigating Market Dynamics and Sourcing Trends in the Fiber Optic Cable Manufacturers Sector

What Are the Key Trends Shaping the Fiber Optic Cable Manufacturing Market?

The global fiber optic cable market is experiencing a significant transformation driven by several key factors. Rapid advancements in telecommunications technology, the increasing demand for high-speed internet, and the expansion of smart cities are major market drivers. In regions like Africa and South America, where internet penetration is still growing, there is a surge in infrastructure development projects aimed at enhancing connectivity. These projects are often supported by government initiatives and international investments, creating ample opportunities for international B2B buyers to source high-quality fiber optic cables.

Emerging trends in sourcing include the integration of advanced technologies such as artificial intelligence and machine learning in supply chain management. This allows manufacturers to optimize production processes and reduce lead times, making sourcing more efficient for buyers. Additionally, there is a notable shift towards multi-modal fiber optic cables that offer greater flexibility and performance in various applications, which is particularly beneficial for buyers looking to diversify their product offerings.

Buyers from the Middle East and Europe are also increasingly focused on suppliers that can provide customized solutions tailored to specific industry needs, such as data centers or telecommunications. This demand for customization is coupled with a preference for suppliers who demonstrate agility in responding to market changes, which is crucial for maintaining competitive advantage in the fast-paced telecommunications landscape.

How Is Sustainability Impacting Fiber Optic Cable Manufacturing?

Sustainability is becoming a cornerstone of sourcing decisions in the fiber optic cable manufacturing sector. The environmental impact of production processes, particularly in terms of energy consumption and waste generation, is under scrutiny. International B2B buyers are increasingly prioritizing suppliers who adhere to sustainable practices and can demonstrate a commitment to reducing their carbon footprint.

Ethical sourcing has gained traction, with buyers seeking manufacturers that utilize ‘green’ materials and processes. Certifications such as ISO 14001 for environmental management systems and other ‘green’ certifications are becoming essential for suppliers aiming to attract environmentally conscious buyers. These certifications not only validate a manufacturer’s commitment to sustainability but also provide assurance to buyers that they are engaging in responsible sourcing practices.

Moreover, the use of recyclable materials in fiber optic cable production is on the rise. Buyers are encouraged to inquire about the lifecycle of products and the potential for recycling at the end of their use. This not only aligns with global sustainability goals but can also enhance brand reputation and customer loyalty in increasingly eco-conscious markets.

What Is the Historical Context of Fiber Optic Cable Manufacturing?

The fiber optic cable manufacturing sector has evolved significantly since its inception in the late 20th century. Initially developed for military and aerospace applications, fiber optics has transitioned into mainstream telecommunications technology due to its superior performance over traditional copper cables. The invention of low-loss fibers in the 1970s catalyzed this shift, allowing for longer transmission distances and higher data rates.

Over the decades, technological advancements have led to the miniaturization and cost reduction of fiber optic cables, making them more accessible for various applications. The rise of the internet in the 1990s further propelled demand, as telecommunications companies sought to upgrade infrastructure to support growing data traffic. Today, fiber optics is integral to global communications, with ongoing innovations in materials and design continuing to shape the landscape.

For B2B buyers, understanding this historical evolution provides valuable context for current market dynamics and sourcing trends, enabling them to make informed decisions when selecting suppliers in this rapidly changing sector.

Frequently Asked Questions (FAQs) for B2B Buyers of Fiber Optic Cable Manufacturers

-

How do I choose the right fiber optic cable manufacturer for my business needs?

Selecting the right fiber optic cable manufacturer involves evaluating several factors. Look for suppliers with proven industry experience and positive customer reviews. Assess their product range to ensure they offer the specific types of fiber optic cables you need, such as single-mode or multi-mode options. Additionally, verify their certifications and compliance with international standards, as this ensures quality and reliability. Engaging in direct communication can also provide insights into their customer service and support capabilities. -

What are the key quality assurance practices to look for in fiber optic cable manufacturers?

Quality assurance practices are crucial when sourcing fiber optic cables. Check if the manufacturer follows industry standards such as ISO 9001. Additionally, inquire about their testing processes, including attenuation tests, bandwidth tests, and environmental testing. Manufacturers should provide documentation of their quality control procedures, and it’s beneficial to request samples for independent testing before placing large orders. A transparent QA process can significantly impact the reliability and performance of the cables. -

What customization options are available for fiber optic cables?

Many manufacturers offer customization options to meet specific business requirements. Common customizations include cable length, jacket material, fiber count, and connector types. Discuss your project needs with potential suppliers to understand their capabilities in creating tailored solutions. Customization not only ensures compatibility with your existing infrastructure but also enhances overall performance, making it vital for specialized applications in various industries. -

What minimum order quantities (MOQs) should I expect from fiber optic cable manufacturers?

Minimum order quantities can vary widely among manufacturers based on their production capabilities and the type of cables required. Some suppliers may have low MOQs, making it easier for small businesses to place orders, while others may require larger quantities for cost-effective production. Before committing, clarify the MOQ with the manufacturer and assess if it aligns with your project needs. Consider the potential for future orders, as establishing a relationship with a reliable supplier can lead to more favorable terms. -

What payment terms are commonly offered by fiber optic cable suppliers?

Payment terms can differ significantly among suppliers, influenced by factors such as order size and the buyer’s creditworthiness. Common terms include upfront payment, net 30, or net 60 days. Some manufacturers may offer payment plans or financing options for larger orders. It’s essential to discuss and negotiate payment terms during the procurement process to ensure they fit your cash flow needs. Always confirm the accepted payment methods, including wire transfers, credit cards, or escrow services. -

How can I ensure timely logistics and delivery for my fiber optic cable orders?

Ensuring timely logistics starts with selecting a manufacturer that has a robust supply chain and shipping processes. Discuss delivery timelines upfront and consider suppliers who offer tracking capabilities for your shipments. It’s also wise to understand their shipping methods and whether they can accommodate expedited options if needed. Building a relationship with your supplier can facilitate better communication regarding any potential delays or issues, ensuring that your project timelines remain on track. -

What certifications should I look for in international fiber optic cable suppliers?

When sourcing fiber optic cables internationally, ensure that suppliers possess relevant certifications that indicate compliance with safety and quality standards. Look for certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, and RoHS compliance for restriction of hazardous substances. These certifications not only assure product quality but also demonstrate a commitment to environmentally friendly practices, which can be an important factor for many businesses. -

How do I vet potential fiber optic cable manufacturers before making a purchase?

Vetting potential manufacturers involves several steps. Start by researching their reputation in the industry, checking customer reviews and testimonials. Request references from previous clients to gain insights into their experiences. Additionally, conduct a site visit if possible to assess their manufacturing capabilities and quality control processes. Engaging in detailed discussions about their products, warranties, and after-sales support can also help you determine if they are a reliable partner for your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Fiber Optic Cable Manufacturers

As the demand for high-speed internet and robust communication networks continues to rise globally, strategic sourcing in fiber optic cable manufacturing becomes crucial for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. By leveraging strong supplier relationships and understanding the intricacies of fiber optic technology, businesses can enhance their operational efficiency and reduce costs.

Buyers should focus on identifying manufacturers that offer high-quality materials and innovative solutions tailored to their specific needs. This not only ensures superior performance but also positions companies to capitalize on emerging markets and technological advancements. Additionally, understanding the different types of fiber optics, such as single-mode and multi-mode fibers, will empower buyers to make informed decisions that align with their strategic objectives.

Looking ahead, the future of fiber optic technology is bright, with advancements paving the way for faster and more reliable connections. International B2B buyers are encouraged to engage with manufacturers who prioritize sustainability and innovation, ensuring their investments contribute to a greener and more connected world. Take the next step in enhancing your supply chain by exploring partnerships with leading fiber optic cable manufacturers today.