Discover Top Gas Generator Suppliers: Your Complete Guide (2025)

Introduction: Navigating the Global Market for gas generator supplier

In the dynamic landscape of global trade, sourcing reliable gas generator suppliers can be a daunting challenge for international B2B buyers. As businesses across Africa, South America, the Middle East, and Europe (including key markets like France and Mexico) seek to enhance their operational efficiencies and reduce downtime, the demand for high-quality gas generators continues to rise. This guide is designed to equip you with the necessary insights to navigate this complex market, helping you make informed decisions that align with your unique business needs.

Throughout this comprehensive resource, we will explore various types of gas generators, their applications across different industries, and the critical factors to consider when vetting potential suppliers. Understanding the nuances of pricing structures and the total cost of ownership is essential for maximizing your investment. Additionally, we will provide actionable strategies to identify reputable suppliers and negotiate favorable terms, ensuring that you secure the best value for your business.

By empowering international B2B buyers with in-depth knowledge and practical tools, this guide aims to streamline your procurement process, enhance supplier relationships, and ultimately drive your business success. Whether you are a seasoned procurement professional or new to the industry, you will find valuable insights tailored to your region and market demands, enabling you to confidently navigate the global market for gas generators.

Understanding gas generator supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Natural Gas Generators | Uses natural gas as fuel; higher efficiency | Power generation, industrial applications | Pros: Lower emissions, cost-effective; Cons: Infrastructure dependent on gas supply |

| Biogas Generators | Utilizes organic waste; renewable energy source | Agriculture, waste management | Pros: Sustainable, reduces waste; Cons: Variable output, initial setup costs |

| Propane Generators | Uses propane gas; portable options available | Remote sites, construction | Pros: Flexible fuel choice, easy transport; Cons: Higher emissions than natural gas |

| Dual-Fuel Generators | Operates on both natural gas and diesel | Emergency backup, critical operations | Pros: Versatile fuel options; Cons: More complex maintenance requirements |

| Industrial Gas Generators | High-capacity units for large-scale needs | Manufacturing, large facilities | Pros: High efficiency, reliability; Cons: Higher upfront investment, space requirements |

What Are the Characteristics of Natural Gas Generators?

Natural gas generators are designed to run on natural gas, making them a popular choice for businesses seeking energy-efficient solutions. Their high efficiency and lower emissions appeal to companies focused on sustainability. These generators are particularly suitable for power generation in urban areas where natural gas infrastructure is well-established. When purchasing, buyers should consider the reliability of gas supply, local regulations regarding emissions, and the generator’s capacity to meet their energy needs.

How Do Biogas Generators Work for B2B Applications?

Biogas generators convert organic waste into energy, making them an excellent option for agricultural businesses and waste management facilities. They not only produce electricity but also help in waste reduction, aligning with circular economy principles. B2B buyers should evaluate the availability of feedstock, the technology used for gas production, and the potential for government incentives for renewable energy projects. Initial setup costs can be significant, but the long-term savings and environmental benefits can justify the investment.

Why Choose Propane Generators for Remote Operations?

Propane generators are known for their portability and flexibility, making them ideal for remote job sites or construction projects. They can be easily transported and set up, providing a reliable power source where grid access is limited. When considering propane generators, buyers should assess the availability of propane, the generator’s fuel efficiency, and its emissions profile. While they offer convenience, it is essential to weigh their higher emissions against the need for mobility and immediate power supply.

What Are the Advantages of Dual-Fuel Generators?

Dual-fuel generators can operate on both natural gas and diesel, providing businesses with versatility in fuel choice. This adaptability is particularly beneficial for operations that require reliable backup power, such as data centers and critical infrastructure. Buyers should focus on the generator’s switching capabilities, maintenance requirements, and overall efficiency. While dual-fuel systems offer flexibility, they may come with more complex maintenance needs, necessitating a knowledgeable service team.

What Makes Industrial Gas Generators Suitable for Large Facilities?

Industrial gas generators are designed for high-capacity and continuous operation, making them suitable for manufacturing plants and large facilities. They are typically more robust and efficient than smaller models, allowing businesses to meet substantial power demands. When purchasing, B2B buyers should consider the generator’s operational costs, space requirements, and integration with existing systems. While the upfront investment is higher, the long-term reliability and efficiency can lead to significant operational savings.

Related Video: Emergency Standby Generator Install, DIY Start to Finish. Generac 24kW Backup Generator.

Key Industrial Applications of gas generator supplier

| Industry/Sector | Specific Application of gas generator supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Emergency power supply for hospitals | Ensures continuous operation of critical systems | Compliance with health regulations and reliability |

| Manufacturing | Backup power for production lines | Minimizes downtime and maximizes productivity | Fuel availability and generator capacity |

| Construction | Powering construction sites | Provides reliable energy for tools and equipment | Mobility and durability of the generator |

| Agriculture | Powering irrigation systems | Enhances crop yield and operational efficiency | Fuel efficiency and environmental impact |

| Data Centers | Uninterruptible power supply (UPS) | Protects data integrity and minimizes outages | Scalability and integration with existing systems |

How is a gas generator supplier used in the healthcare industry?

In healthcare, gas generators are crucial for maintaining an uninterrupted power supply to hospitals and clinics, especially during emergencies. They ensure that critical systems such as ventilators, lighting, and surgical equipment remain operational. International B2B buyers in this sector should prioritize suppliers that comply with stringent health regulations and offer reliable products that can withstand varying power demands. Additionally, service and maintenance support is essential to avoid any disruptions in service.

What role do gas generators play in the manufacturing sector?

Manufacturing facilities often rely on gas generators to provide backup power for production lines. In scenarios where grid power fails, these generators minimize downtime, which is vital for maintaining productivity and meeting production targets. Buyers from regions like Africa and South America should consider the availability of fuel and the generator’s capacity to handle peak loads. Understanding the generator’s maintenance requirements is also crucial to ensure continuous operation.

How do gas generators support construction projects?

On construction sites, gas generators are indispensable for powering tools, machinery, and temporary lighting. They provide a reliable energy source that facilitates various tasks, from concrete pouring to site inspections. Buyers should focus on the mobility and durability of generators, as construction environments can be harsh. It’s also important to evaluate the generator’s fuel consumption and emissions, especially in regions with strict environmental regulations.

In what ways do gas generators enhance agricultural operations?

In agriculture, gas generators are utilized to power irrigation systems, which are essential for enhancing crop yields and ensuring efficient water management. They enable farmers to operate pumps and other equipment reliably, regardless of grid availability. For international buyers, considerations such as fuel efficiency and the generator’s environmental impact are critical, particularly in regions where sustainability is a growing concern. Suppliers should also provide solutions tailored to specific agricultural needs.

Why are gas generators vital for data centers?

Data centers require an uninterruptible power supply (UPS) to protect sensitive information and ensure seamless operations. Gas generators serve as a backup power source that kicks in during outages, safeguarding data integrity and minimizing service interruptions. Buyers in this sector, particularly in Europe and the Middle East, should look for scalable solutions that can integrate with existing power systems. Additionally, the reliability and efficiency of the generator are paramount to maintaining operational continuity.

Related Video: The Siemens SGT-800 A 50-MW-class industrial gas turbine

3 Common User Pain Points for ‘gas generator supplier’ & Their Solutions

Scenario 1: Unexpected Downtime Due to Equipment Failure

The Problem: For B2B buyers, particularly in regions with unstable electricity supplies like parts of Africa and the Middle East, relying on gas generators is often critical for operations. However, unexpected equipment failures can lead to significant downtime. This situation not only disrupts business operations but also leads to financial losses and reputational damage. Buyers may find it challenging to identify reliable suppliers who can provide high-quality generators with robust customer support and maintenance services.

The Solution: To mitigate the risk of unexpected downtime, buyers should prioritize suppliers that offer comprehensive warranty and service agreements. When sourcing a gas generator, inquire about the supplier’s history of reliability and customer support. Opt for suppliers that provide regular maintenance checks and a responsive customer service team. Additionally, consider investing in a generator monitoring system that can alert you to potential issues before they result in failure. This proactive approach will ensure that you maintain operational efficiency and minimize disruptions.

Scenario 2: Difficulty in Sizing the Right Generator for Specific Needs

The Problem: Sizing a gas generator correctly is crucial, yet many buyers struggle with this aspect. A generator that is too small won’t meet the energy needs of the operation, while an oversized unit can lead to inefficiencies and increased fuel consumption. This common issue is particularly evident in sectors like manufacturing or agriculture in South America and Europe, where operational demands vary significantly.

The Solution: To effectively size a gas generator, buyers should conduct a thorough energy audit of their operations. This involves calculating the total wattage required to power all necessary equipment, including peak loads. Collaborate with your gas generator supplier to provide them with detailed information about your operational requirements. Many reputable suppliers offer tools or consulting services to assist with this process. Furthermore, consider future expansion plans; opting for a generator with a little extra capacity can provide flexibility as your energy needs grow.

Scenario 3: Navigating Regulatory Compliance and Environmental Standards

The Problem: International B2B buyers often face the challenge of ensuring that their gas generators comply with local regulations and environmental standards. This issue can be particularly daunting in regions like Europe, where regulations are stringent, and non-compliance can result in hefty fines or operational shutdowns. Buyers may feel overwhelmed by the varying standards across different countries, especially if they are sourcing equipment from abroad.

The Solution: To navigate regulatory compliance, it is essential to partner with a gas generator supplier that is well-versed in local regulations and environmental standards. Before finalizing any purchase, conduct research on the specific compliance requirements in your target market. Request documentation from suppliers that verifies their generators meet these standards. Additionally, consider suppliers who provide eco-friendly options, such as generators designed for lower emissions. Engaging with local industry associations or regulatory bodies can also provide valuable insights into compliance requirements, ensuring that your operations remain lawful and environmentally responsible.

Strategic Material Selection Guide for gas generator supplier

When selecting materials for gas generators, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below, we analyze four common materials used in gas generator manufacturing: Steel, Aluminum, Copper, and Composite Materials. Each material has distinct properties, advantages, and limitations that can significantly affect the operational efficiency and longevity of gas generators.

What are the Key Properties of Steel in Gas Generators?

Steel is a widely used material in gas generators due to its exceptional strength and durability. It typically has high-temperature and pressure ratings, making it suitable for high-performance applications. Steel also exhibits good corrosion resistance when treated or coated, which is crucial for generators operating in harsh environments.

Pros & Cons of Steel:

The primary advantage of steel is its strength, which allows for robust construction and longevity. However, steel can be heavier than other materials, which may impact the overall weight of the generator. Additionally, while steel is generally cost-effective, the need for protective coatings can increase manufacturing complexity and costs.

Impact on Application:

Steel is compatible with various media, including natural gas and biogas, making it versatile for different applications. Buyers must ensure that the steel grade selected meets the specific environmental conditions of the intended use.

Considerations for International Buyers:

Buyers from regions like Africa and the Middle East should ensure compliance with local standards, such as ASTM or DIN, especially when sourcing steel components. Understanding the local availability of specific steel grades can also influence procurement decisions.

How Does Aluminum Perform in Gas Generator Applications?

Aluminum is another popular choice for gas generator components, especially in applications where weight reduction is critical. It has a lower density than steel, which can lead to lighter designs without sacrificing performance. Aluminum also offers good corrosion resistance, particularly when anodized.

Pros & Cons of Aluminum:

The key advantage of aluminum is its lightweight nature, which can enhance portability and ease of installation. However, aluminum has a lower strength-to-weight ratio compared to steel, which may limit its use in high-stress applications. Additionally, aluminum can be more expensive than steel, affecting overall project budgets.

Impact on Application:

Aluminum is suitable for applications involving clean gases but may not be ideal for environments with high abrasive particles, as it can be more prone to wear.

Considerations for International Buyers:

Buyers in Europe, particularly in countries like France, should consider the EU regulations on aluminum sourcing and recycling. Understanding local market conditions can help in negotiating better pricing.

Why Choose Copper for Electrical Components in Gas Generators?

Copper is primarily used in gas generators for electrical wiring and components due to its excellent electrical conductivity and thermal properties. It can withstand high temperatures and has good corrosion resistance, especially in non-oxidizing environments.

Pros & Cons of Copper:

The main advantage of copper is its superior conductivity, which ensures efficient energy transfer. However, copper is relatively expensive compared to other metals, which can increase the overall cost of the generator. Additionally, it is heavier than aluminum, which may impact design considerations.

Impact on Application:

Copper is ideal for applications requiring reliable electrical connections, such as ignition systems and control panels. However, it may not be suitable for environments with high humidity or corrosive gases without proper protection.

Considerations for International Buyers:

B2B buyers should be aware of the fluctuating copper prices and ensure compliance with international standards for electrical components. Understanding local sourcing options can also lead to cost savings.

What Role Do Composite Materials Play in Gas Generators?

Composite materials, often made from a combination of fibers and resins, are increasingly used in gas generators due to their lightweight and high-strength characteristics. They can be engineered to provide excellent thermal and chemical resistance.

Pros & Cons of Composites:

The key advantage of composites is their ability to reduce weight while maintaining strength, making them suitable for advanced applications. However, the manufacturing process can be complex and costly, which may limit their use in budget-sensitive projects.

Impact on Application:

Composites are particularly effective in environments with extreme temperatures and corrosive substances, making them suitable for specialized gas generator applications.

Considerations for International Buyers:

Buyers from South America and the Middle East should consider the availability of composite materials and the expertise required for their fabrication. Compliance with international standards for composites is also essential.

Summary Table of Material Selection for Gas Generators

| Material | Typical Use Case for gas generator supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components | High strength and durability | Heavier and requires protective coatings | Medium |

| Aluminum | Lightweight components | Low weight | Lower strength and higher cost | High |

| Copper | Electrical wiring | Excellent conductivity | Expensive and heavier | High |

| Composite | Specialized components | Lightweight and high-strength | Complex manufacturing process | High |

This guide serves as a strategic resource for international B2B buyers, enabling informed material selection that aligns with operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for gas generator supplier

What Are the Main Stages in the Manufacturing Process of Gas Generators?

The manufacturing of gas generators involves several critical stages that ensure product reliability and performance. Understanding these stages can help international B2B buyers make informed decisions when selecting suppliers.

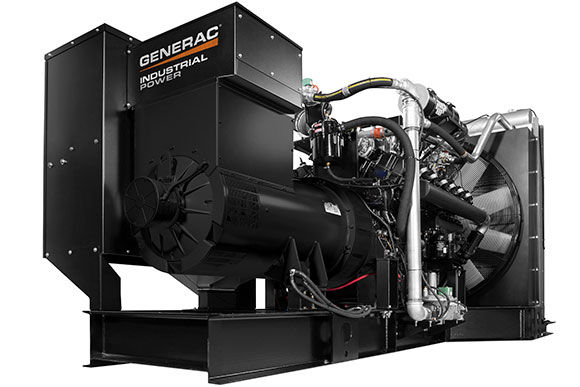

A stock image related to gas generator supplier.

-

Material Preparation

The process begins with the careful selection and preparation of raw materials. Common materials include high-quality steel and aluminum alloys, which are chosen for their durability and resistance to corrosion. Suppliers often conduct thorough inspections of incoming materials to ensure they meet specific standards before they are processed. -

Forming

The forming stage includes techniques such as cutting, bending, and welding. Advanced machinery like CNC (Computer Numerical Control) machines are frequently used to achieve precision. This stage is crucial for shaping components such as engine casings and frames, which must adhere to stringent specifications to ensure optimal performance. -

Assembly

During assembly, various components—including engines, alternators, and control systems—are integrated. This stage often employs automated assembly lines to enhance efficiency and reduce human error. Skilled technicians oversee the process to ensure that all parts are correctly aligned and connected, which is vital for the generator’s operational integrity. -

Finishing

The finishing stage includes surface treatment processes like painting and coating, which protect against environmental factors. Quality assurance checks are conducted at this stage to confirm that the finished product meets aesthetic and functional standards.

How Is Quality Assurance Implemented in Gas Generator Manufacturing?

Quality assurance is a cornerstone of the manufacturing process, ensuring that gas generators meet both international and industry-specific standards.

What Are the Relevant International Standards for Quality Control?

International standards such as ISO 9001 are critical for gas generator suppliers. ISO 9001 focuses on quality management systems, ensuring that organizations consistently meet customer and regulatory requirements. Additionally, suppliers may adhere to industry-specific standards, such as:

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Standards: Applicable for suppliers involved in the oil and gas sector, ensuring that products meet safety and operational criteria.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. The primary QC checkpoints include:

-

Incoming Quality Control (IQC)

This initial stage involves inspecting raw materials and components upon arrival. Suppliers typically check for defects, dimensions, and compliance with specifications. -

In-Process Quality Control (IPQC)

During manufacturing, IPQC is employed to monitor the production process. Operators conduct regular checks to identify any deviations from the specified processes, allowing for immediate corrective actions. -

Final Quality Control (FQC)

FQC occurs after assembly and finishing. It involves comprehensive testing of the completed generators, including functionality tests, load tests, and safety checks. This ensures that each unit operates as intended before shipping.

What Common Testing Methods Are Used for Gas Generators?

Testing methods play a vital role in verifying the quality and performance of gas generators. Common techniques include:

- Load Testing: Assessing the generator’s performance under various load conditions to ensure reliability.

- Vibration Analysis: Monitoring vibrations during operation to detect potential mechanical issues.

- Thermal Imaging: Identifying hot spots and ensuring that temperature thresholds are maintained.

These methods help ensure that the final product is safe, efficient, and ready for deployment in various applications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are actionable steps to ensure compliance and reliability:

-

Conduct Supplier Audits

Regular audits help assess a supplier’s adherence to quality standards. Buyers should request an audit of the manufacturing facility to evaluate their QC processes firsthand. -

Request Quality Assurance Reports

Suppliers should provide documentation detailing their quality control procedures and results from recent tests. These reports should include data from IQC, IPQC, and FQC stages. -

Engage Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s products. This is particularly important for buyers in regions with stringent import regulations.

What Are the Quality Control and Certification Nuances for International Buyers?

When sourcing gas generators, international B2B buyers should be aware of specific nuances related to quality control and certification:

-

Regional Compliance: Different regions may have varying compliance requirements. For example, European buyers must ensure that products are CE certified, while buyers in the Middle East may require compliance with local standards.

-

Documentation and Traceability: Buyers should ensure that suppliers maintain thorough documentation and traceability for all materials and processes. This is essential for accountability and for addressing any potential issues that may arise post-purchase.

-

Cultural and Communication Considerations: Effective communication is vital when dealing with international suppliers. Buyers should be aware of cultural differences that may impact negotiation and quality assurance discussions.

Conclusion

Understanding the manufacturing processes and quality assurance practices of gas generator suppliers is crucial for international B2B buyers. By focusing on the main stages of manufacturing, relevant quality standards, testing methods, and verification strategies, buyers can make informed decisions that enhance their procurement processes. Prioritizing these elements will help ensure the reliability and performance of gas generators, ultimately contributing to business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gas generator supplier’

In the competitive landscape of sourcing gas generators, particularly for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, a structured approach is essential. This guide provides a step-by-step checklist to streamline your procurement process, ensuring that you select the right supplier to meet your operational needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is crucial before initiating the sourcing process. Consider factors such as generator capacity, fuel type, and operational environment. This clarity will help you communicate effectively with potential suppliers and ensure that their offerings align with your expectations.

- Generator Capacity: Determine the power output needed based on your operations.

- Fuel Type: Specify whether you require natural gas, propane, or biogas options.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a solid reputation in the gas generator market. Utilize online platforms, industry directories, and trade shows to compile a list of potential candidates. Understanding the supplier landscape will help you make informed decisions.

- Industry Reviews: Look for reviews or testimonials from previous clients.

- Market Presence: Evaluate how long suppliers have been in the industry and their geographic reach.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is critical to ensure compliance with international standards and regulations. Check for ISO certifications, safety standards, and any other relevant accreditations that validate the quality of their products.

- ISO 9001 Certification: Indicates a commitment to quality management.

- Environmental Compliance: Ensure that the supplier adheres to environmental regulations relevant to your region.

Step 4: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that outline pricing, terms, and conditions. This step is vital for comparing offers and understanding the total cost of ownership, which includes installation, maintenance, and operational costs.

- Breakdown of Costs: Ensure that the quote includes all associated costs, not just the initial purchase price.

- Payment Terms: Clarify payment schedules and any financing options available.

Step 5: Assess After-Sales Support and Warranty

After-sales support is a key factor that can significantly impact your operational efficiency. Investigate the warranty terms and the level of support provided, such as maintenance services, spare parts availability, and technical assistance.

- Warranty Duration: Look for warranties that cover both parts and labor for an extended period.

- Response Time: Assess the supplier’s commitment to response times for service requests.

Step 6: Conduct Site Visits or Virtual Tours

If feasible, visiting the supplier’s facilities can provide invaluable insights into their operations, quality control processes, and overall credibility. If a physical visit is not possible, request virtual tours or video presentations.

- Production Capabilities: Observe the manufacturing processes and quality assurance practices.

- Employee Expertise: Assess the qualifications and experience of the staff involved in production.

Step 7: Finalize Contractual Agreements

Before finalizing your purchase, ensure that all terms are clearly defined in a written contract. This should include delivery timelines, payment terms, warranties, and service agreements. A well-drafted contract protects both parties and clarifies expectations.

- Legal Review: Consider having a legal professional review the contract to safeguard your interests.

- Dispute Resolution: Include clauses that outline procedures for resolving potential disputes.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing gas generators effectively, ensuring that they secure reliable and quality suppliers tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for gas generator supplier Sourcing

When sourcing gas generators, understanding the cost structure is vital for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Here’s a detailed analysis of the cost components and pricing dynamics that can influence your procurement strategy.

What Are the Key Cost Components in Gas Generator Manufacturing?

-

Materials: The primary cost driver in gas generator production is the materials used. High-quality metals, components for electrical systems, and durable casings significantly impact the overall cost. Prices for these materials can fluctuate based on global supply and demand, so it’s essential to stay informed about market trends.

-

Labor: Labor costs vary widely depending on the geographical location of the manufacturing facility. For instance, manufacturers in Europe may have higher labor costs compared to those in South America or Africa. Understanding the local labor market conditions can help in negotiating better pricing.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. Efficient manufacturers often optimize these overhead costs, which can be reflected in their pricing. Buyers should seek suppliers with streamlined operations to benefit from lower overhead costs.

-

Tooling: The initial investment in tooling can be substantial, especially for customized or specialized gas generators. Buyers should consider whether the supplier includes tooling costs in the quoted price or if they are additional.

-

Quality Control (QC): Effective quality control processes are essential to ensure the reliability and safety of gas generators. Suppliers that invest in rigorous QC practices may charge higher prices, but this can result in reduced long-term costs due to fewer failures or warranty claims.

-

Logistics: Transportation costs can vary significantly based on the distance from the supplier to the buyer and the chosen shipping method. Import duties and taxes also play a crucial role, especially for international buyers. Understanding the logistics landscape can help in negotiating more favorable terms.

-

Margin: Suppliers will typically add a margin to cover their profit. This can vary based on competition, brand reputation, and the complexity of the product. Knowing the market average for margins can provide leverage in negotiations.

How Do Price Influencers Affect Your Sourcing Strategy?

-

Volume and Minimum Order Quantity (MOQ): Ordering in larger volumes often results in reduced per-unit costs. However, be mindful of your storage capabilities and cash flow when negotiating MOQs.

-

Specifications and Customization: Customized gas generators typically command higher prices due to the additional design and manufacturing processes involved. Clearly defining your specifications upfront can minimize unexpected costs later.

-

Material Quality and Certifications: Higher quality materials and certifications (like ISO) can increase the initial purchase price but may lead to lower maintenance and operational costs. Assess the long-term benefits of investing in higher-quality products.

-

Supplier Reputation and Reliability: Established suppliers with a strong track record may charge premium prices. However, the assurance of reliability and support can offset the higher costs, especially for critical operations.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) used in your contracts can significantly affect the total cost. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) will determine who bears the shipping costs and risks.

What Are Effective Buyer Tips for Gas Generator Sourcing?

-

Negotiate Wisely: Use your understanding of cost components and price influencers to negotiate better terms. Highlight your potential for repeat business to encourage suppliers to offer discounts.

-

Focus on Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operation, and potential downtime costs to evaluate the true cost of the generator over its lifecycle.

-

Understand Pricing Nuances: Be aware that pricing can differ based on regional market conditions. For instance, European suppliers may offer different pricing structures compared to those in Africa or South America due to varying labor and material costs.

-

Market Research: Stay informed about market trends and fluctuations in material costs. This knowledge will empower you to negotiate effectively and make informed purchasing decisions.

Disclaimer

Prices and cost structures can vary significantly based on numerous factors, including market conditions, supplier capabilities, and specific project requirements. Always seek multiple quotes and conduct thorough due diligence before making sourcing decisions.

Alternatives Analysis: Comparing gas generator supplier With Other Solutions

When evaluating energy solutions for businesses, it is essential to consider various alternatives to gas generators. Each option presents unique advantages and challenges, which can significantly affect operational efficiency, cost, and sustainability. By analyzing these alternatives, international B2B buyers can make informed decisions that align with their strategic goals.

| Comparison Aspect | Gas Generator Supplier | Solar Energy Systems | Diesel Generators |

|---|---|---|---|

| Performance | Reliable power source; can operate continuously | Dependent on sunlight; effective in sunny regions | High power output; suitable for heavy loads |

| Cost | Moderate initial investment; variable fuel costs | High upfront costs; low operational costs | Lower initial investment; high fuel costs |

| Ease of Implementation | Generally straightforward; requires proper site assessment | Requires space and infrastructure; long installation time | Simple setup; requires fuel storage and handling |

| Maintenance | Regular maintenance needed; parts can be costly | Low maintenance; occasional inverter servicing | High maintenance; fuel system complexity |

| Best Use Case | Remote locations with stable fuel supply | Off-grid applications and sustainable initiatives | Construction sites and emergency power needs |

What Are the Advantages and Disadvantages of Solar Energy Systems?

Solar energy systems harness sunlight to generate electricity, making them an attractive alternative for businesses looking to reduce their carbon footprint. The primary advantage of solar systems is their sustainability and low operational costs after installation. They require minimal maintenance, primarily focusing on inverter checks and panel cleaning. However, the initial investment can be substantial, and energy production is highly dependent on geographical location and weather conditions. Businesses in sunny regions with ample space for solar panels will find this option particularly beneficial.

How Do Diesel Generators Compare to Gas Generators?

Diesel generators are a traditional alternative to gas generators, especially for applications requiring high power output. They are known for their robustness and ability to handle heavy loads, making them suitable for construction sites and industrial operations. Diesel generators typically have a lower initial investment compared to gas generators but come with high fuel costs and maintenance requirements. Their fuel systems can be complex, requiring more frequent servicing. B2B buyers should consider the operational costs and the environmental regulations in their regions, as diesel generators may face stricter emissions standards.

Conclusion: How Can B2B Buyers Choose the Right Energy Solution?

Selecting the right energy solution involves analyzing specific business needs, budget constraints, and sustainability goals. Gas generators provide reliability in fuel-rich areas but can have fluctuating fuel costs. Solar energy systems offer long-term savings and environmental benefits, particularly for businesses committed to sustainability. Diesel generators, while robust, may incur higher ongoing costs. By carefully assessing these factors and considering the operational context—such as location and energy requirements—international B2B buyers can make strategic choices that enhance their operational efficiency and align with their corporate responsibility objectives.

Essential Technical Properties and Trade Terminology for gas generator supplier

Understanding the key technical properties and trade terminology associated with gas generators is crucial for international B2B buyers. This section aims to equip decision-makers from Africa, South America, the Middle East, and Europe with the necessary knowledge to make informed purchasing decisions.

What Are the Critical Technical Properties of Gas Generators?

1. Output Power Rating (kW or MW)

The output power rating indicates the maximum electrical power the gas generator can produce. This specification is essential for determining whether a generator can meet the energy demands of your operations. Buyers should assess their energy requirements carefully to select a generator that provides adequate power without oversizing, which can lead to inefficiencies.

2. Fuel Type Compatibility

Gas generators can operate on various fuel types, including natural gas, propane, and biogas. Understanding fuel compatibility is vital, as it affects operational costs and availability. Buyers in regions with limited fuel options should prioritize generators that can efficiently use locally available fuels to reduce dependence on imports.

3. Noise Level (dB)

Noise level is often a critical consideration, especially for generators used in residential or noise-sensitive areas. Measured in decibels (dB), a lower noise rating indicates a quieter operation. Buyers should evaluate local regulations and community standards to ensure compliance and avoid potential conflicts.

4. Emission Standards

Compliance with regional environmental regulations is crucial for gas generators. Different countries have varying standards for emissions, such as nitrogen oxides (NOx) and carbon monoxide (CO). Buyers must verify that the generator meets the emission requirements specific to their market to avoid legal complications and penalties.

5. Efficiency Rating

The efficiency rating indicates how well a generator converts fuel into usable energy. Higher efficiency means lower operational costs and reduced environmental impact. Buyers should compare efficiency ratings across different models to identify options that provide the best value in terms of fuel consumption and operational performance.

What Are the Common Trade Terms in the Gas Generator Industry?

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the role of OEMs is essential for buyers looking for specific components or replacement parts, as they can impact warranty and service quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers, as it affects inventory management and initial investment costs. Buyers should negotiate MOQs based on their specific needs to optimize cash flow and storage capacity.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits pricing and delivery information from suppliers. It is a critical step in the purchasing process, allowing buyers to compare offers and negotiate terms. An effective RFQ should include detailed specifications to ensure accurate quotes.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for understanding shipping costs, risk transfer, and delivery timelines. Buyers should clarify which Incoterms apply to their purchase to avoid misunderstandings.

5. Warranty and Service Agreements

These terms outline the support and repair services provided by the supplier. Understanding warranty conditions and service agreements is vital to ensure long-term support and maintenance for the gas generator, reducing unexpected costs and downtime.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of sourcing gas generators effectively, ensuring they select the right equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the gas generator supplier Sector

What Are the Current Market Dynamics and Key Trends Affecting Gas Generator Suppliers?

The global gas generator market is experiencing significant growth, driven by increasing energy demands, particularly in developing regions like Africa and South America. Key trends include the rising adoption of hybrid systems that combine gas generators with renewable energy sources, enhancing efficiency and reducing costs. Moreover, technological advancements such as IoT integration are paving the way for smarter generator systems, enabling real-time monitoring and predictive maintenance. For international B2B buyers, understanding these technological shifts is crucial, as they can lead to more reliable and efficient energy solutions.

In Europe, regulatory frameworks are increasingly favoring cleaner energy solutions, prompting a surge in demand for low-emission gas generators. This trend is mirrored in the Middle East, where diversification efforts away from oil dependency are encouraging investments in gas-powered technologies. Buyers from these regions should prioritize suppliers that not only comply with local regulations but also demonstrate a commitment to innovation and sustainability.

Furthermore, the competitive landscape is evolving, with new entrants and established players vying for market share. This presents an opportunity for B2B buyers to negotiate better terms and explore innovative financing options, such as leasing models, which can mitigate upfront costs. Staying informed about these market dynamics will empower buyers to make strategic sourcing decisions that align with their operational needs and sustainability goals.

How Important Is Sustainability and Ethical Sourcing in the Gas Generator Supplier Sector?

Sustainability is no longer a buzzword; it has become a fundamental criterion for B2B buyers in the gas generator sector. The environmental impact of gas generators, while lower than traditional diesel generators, still warrants attention. Buyers must evaluate suppliers based on their emissions profiles and their commitment to reducing carbon footprints. This includes assessing the use of cleaner fuels, advanced emission control technologies, and overall energy efficiency.

Ethical sourcing practices are equally vital. B2B buyers should ensure that their suppliers adhere to fair labor practices and source materials responsibly. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to ethical practices. Additionally, as sustainability becomes a key differentiator in the market, suppliers that can showcase their ‘green’ credentials—through certifications or the use of sustainable materials—are likely to gain a competitive edge.

For international buyers, particularly in regions like Africa and South America where regulatory environments are evolving, partnering with suppliers who prioritize sustainability can enhance corporate reputation and align with governmental incentives aimed at promoting green energy solutions.

What Is the Brief Evolution of the Gas Generator Supplier Industry?

The gas generator supplier industry has evolved significantly over the past few decades. Initially dominated by traditional fossil fuels, the sector has seen a gradual shift towards more efficient and environmentally friendly options. The introduction of natural gas as a primary fuel source has marked a turning point, offering a cleaner alternative to diesel and heavy fuel oil.

In recent years, technological advancements have further transformed the landscape. The integration of digital technologies has enabled remote monitoring and management, improving operational efficiencies and reducing downtime. As global energy demands continue to rise, the evolution of gas generators reflects a broader transition towards sustainable energy solutions, making it essential for B2B buyers to remain informed and proactive in their sourcing strategies. Understanding this evolution can provide insights into future trends and innovations that will shape the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of gas generator supplier

-

How do I choose the right gas generator supplier for my business needs?

Choosing the right gas generator supplier involves assessing several factors including product quality, supplier reliability, and industry experience. Research potential suppliers by checking their certifications, customer reviews, and case studies relevant to your region (e.g., Africa, South America). Engage in direct discussions to gauge their understanding of your specific requirements, such as power output, fuel type, and environmental regulations. Request samples or references to ensure they can meet your quality expectations. -

What is the best type of gas generator for industrial applications?

The best type of gas generator for industrial applications typically depends on the specific energy needs of your operations. For continuous power, consider high-capacity generators, such as those with a power range of 100 kW to 2 MW. For backup power, look for reliable models with quick start-up capabilities. Additionally, assess whether you need dual-fuel generators that can operate on natural gas or propane, providing flexibility and cost savings, particularly in regions with variable fuel availability. -

What should I consider when negotiating payment terms with a gas generator supplier?

When negotiating payment terms, consider factors such as your cash flow, the supplier’s payment policies, and the total order value. Common terms include upfront deposits, milestone payments during production, and final payments upon delivery. Ensure that terms are clearly stated in the contract to avoid misunderstandings. Additionally, explore options for financing or trade credit that can ease your purchasing process, especially if you are sourcing from international suppliers. -

What are the minimum order quantities (MOQs) for gas generators?

Minimum order quantities (MOQs) for gas generators can vary widely depending on the supplier and the specific model. Typically, MOQs may range from a single unit for smaller suppliers to several units for larger manufacturers. It’s essential to communicate your needs upfront to the supplier, as some may offer flexibility on MOQs for long-term partnerships or bulk orders. Understanding MOQs can help you plan your budget and inventory effectively. -

How can I ensure quality assurance (QA) in my gas generator purchase?

To ensure quality assurance in your gas generator purchase, request detailed documentation of the supplier’s QA processes, including certifications like ISO 9001. Inquire about the testing protocols for their products, including performance, emissions, and safety tests. Consider arranging for third-party inspections before shipment, especially for large orders. Building a relationship with the supplier allows for ongoing communication regarding quality standards and potential issues.

A stock image related to gas generator supplier.

-

What logistics considerations should I keep in mind when importing gas generators?

When importing gas generators, logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder familiar with importing heavy machinery to navigate customs clearance efficiently. Be aware of import duties, taxes, and any compliance requirements specific to your country. Additionally, ensure that the supplier provides proper documentation, including certificates of origin and compliance with local standards to facilitate a smooth import process. -

How can I customize my gas generator to meet specific operational needs?

Customization options for gas generators often include modifications to power output, fuel type, and control systems. Discuss your specific operational requirements with the supplier, such as the need for automatic start/stop functions or noise reduction features. Some suppliers may offer bespoke solutions tailored to unique applications, such as mobile generators for remote locations. Make sure to review the costs and timelines associated with these customizations to ensure they align with your project goals. -

What are the environmental considerations when selecting a gas generator supplier?

When selecting a gas generator supplier, consider their commitment to environmental sustainability. Look for suppliers who adhere to international environmental standards and regulations, such as emissions limits. Evaluate their product offerings for energy efficiency and technologies that reduce greenhouse gas emissions. Additionally, inquire about their recycling policies for used equipment and any initiatives they may have for sustainable manufacturing practices. This ensures that your purchase aligns with your company’s environmental goals and responsibilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for gas generator supplier

In navigating the complexities of sourcing gas generators, international B2B buyers must prioritize a strategic approach to maximize value. Key takeaways from this guide highlight the importance of evaluating suppliers based on reliability, technological innovation, and after-sales support. Establishing long-term relationships with reputable suppliers can significantly enhance operational efficiency and reduce downtime, which is critical in regions such as Africa and the Middle East, where energy reliability is paramount.

How can strategic sourcing enhance your procurement process for gas generators? By leveraging data-driven insights and market trends, buyers can make informed decisions that align with their operational goals. This approach not only ensures compliance with local regulations but also fosters a competitive edge in diverse markets, including Europe and South America.

Looking ahead, the demand for sustainable and efficient energy solutions will only grow. B2B buyers are encouraged to stay abreast of technological advancements and evolving market conditions. By adopting a proactive sourcing strategy, international buyers can secure the best gas generator solutions tailored to their unique needs. Engage with suppliers today to explore innovative options that will power your operations into the future.