Discover Top Generator Suppliers: Your Complete Buying Guide (2025)

Introduction: Navigating the Global Market for generator supplier

Navigating the global market for generator suppliers can be a daunting task for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. With a diverse range of generator types available—from portable models for outdoor activities to robust industrial generators for power outages—understanding the specific needs of your business is crucial. This guide aims to demystify the complexities of sourcing reliable generator suppliers, providing insights into the various applications, types, and technologies available in the market today.

In this comprehensive resource, we will explore essential factors such as supplier vetting processes, cost considerations, and compliance with local regulations. We will also address how to identify reputable manufacturers and distributors, ensuring that you make informed purchasing decisions tailored to your unique operational requirements. Whether you’re a construction firm in Turkey seeking backup power solutions or a hospitality business in Colombia needing portable generators for events, this guide empowers you to navigate the intricacies of the generator market with confidence.

By equipping you with actionable insights and practical strategies, we aim to enhance your procurement process, helping you secure high-quality products that align with your business goals. With the right information at your fingertips, you can avoid common pitfalls and achieve optimal efficiency in your power supply needs.

Understanding generator supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Generators | Lightweight, compact, often fueled by gasoline or diesel | Outdoor events, construction sites | Pros: Easy to transport; Cons: Limited power output. |

| Standby Generators | Automatically activates during power outages, larger capacity | Hospitals, data centers, and manufacturing | Pros: Reliable backup; Cons: Higher initial investment. |

| Industrial Generators | High-capacity, designed for continuous operation | Large-scale construction, mining, utilities | Pros: Durable and powerful; Cons: Requires significant space and maintenance. |

| Solar Generators | Utilizes solar panels for power generation | Remote locations, sustainable projects | Pros: Eco-friendly; Cons: Dependent on sunlight availability. |

| Inverter Generators | Produces clean, stable power, suitable for sensitive electronics | Events, camping, and home use | Pros: Quiet operation; Cons: Typically more expensive. |

What Are the Characteristics of Portable Generators?

Portable generators are designed for mobility and convenience, making them ideal for temporary power needs. They are typically fueled by gasoline or diesel and can generate enough electricity to power tools, lights, and small appliances. These generators are widely used in outdoor events, construction sites, and emergency situations. When purchasing, consider fuel efficiency, noise levels, and the total wattage needed to support your equipment, especially in markets across Africa and South America where portability is often essential due to infrastructure challenges.

How Do Standby Generators Function in B2B Settings?

Standby generators are permanently installed systems that automatically provide power during outages. They are crucial for businesses that require uninterrupted power supply, such as hospitals, data centers, and manufacturing facilities. These generators are typically larger and more powerful than portable options. When evaluating standby generators, buyers should consider fuel type, installation requirements, and maintenance services. The upfront costs can be significant, but the investment is often justified by the reliability and peace of mind they provide, particularly in regions with unstable power grids.

What Makes Industrial Generators Suitable for Large-Scale Operations?

Industrial generators are designed for high-capacity and continuous operation, making them suitable for large-scale applications such as construction, mining, and utilities. These generators can handle significant power loads and are built to withstand harsh environments. Key purchasing considerations include fuel type, maintenance requirements, and the generator’s capacity to meet peak demand. Buyers should also factor in the total cost of ownership, including installation and service contracts, especially in regions like the Middle East where industrial activities are prevalent.

Why Choose Solar Generators for Sustainable Projects?

Solar generators harness solar energy to produce electricity, making them an eco-friendly option for businesses focused on sustainability. These generators are particularly useful in remote locations where traditional power sources are unavailable. Their applications range from powering small devices to providing electricity for entire facilities. When considering solar generators, evaluate the solar panel efficiency, battery storage capacity, and overall system integration. This type of generator is gaining traction in Europe, where there is a strong push towards renewable energy solutions.

What Are the Advantages of Inverter Generators for Sensitive Equipment?

Inverter generators are designed to produce clean and stable power, making them ideal for sensitive electronics such as computers and medical equipment. They are compact, quieter than traditional generators, and often equipped with advanced technology that allows for variable speed operation, enhancing fuel efficiency. B2B buyers should consider power output, weight, and noise levels when selecting inverter generators. While they may come at a higher price point, the reliability and quality of power they provide make them a worthwhile investment for businesses in sectors like IT and healthcare.

Related Video: Voith: Functioning of a hydropower generator (EN)

Key Industrial Applications of generator supplier

| Industry/Sector | Specific Application of generator supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Temporary power supply for construction sites | Ensures continuous operations during power outages | Fuel type, noise level, portability, and emissions compliance |

| Healthcare | Backup power for medical facilities | Protects critical medical equipment from outages | Reliability, maintenance support, and compliance with health regulations |

| Agriculture | Power for irrigation systems and machinery | Enhances productivity and reduces crop loss risk | Fuel efficiency, output capacity, and service availability |

| Events and Entertainment | Power supply for outdoor events and festivals | Provides reliable energy for lighting and sound | Mobility, noise restrictions, and rental options |

| Telecommunications | Power for remote cell towers and installations | Maintains network uptime and service reliability | Scalability, fuel type, and integration capabilities |

How Are Generators Used in the Construction Industry?

In the construction sector, generator suppliers provide temporary power solutions essential for various tasks, from operating heavy machinery to powering site offices. These generators ensure that work proceeds uninterrupted, especially in regions prone to power outages. Buyers in this industry should consider generators that are portable, fuel-efficient, and compliant with local emissions regulations to minimize their environmental impact while maximizing productivity.

What Role Do Generators Play in Healthcare Settings?

Healthcare facilities rely on generator suppliers to provide backup power, ensuring that critical medical devices and systems remain operational during outages. This is particularly crucial for hospitals and clinics where life-support systems depend on a continuous power supply. When sourcing generators, healthcare buyers must prioritize reliability, ease of maintenance, and adherence to health and safety regulations to safeguard patient care.

How Do Generators Benefit Agricultural Operations?

In agriculture, generator suppliers offer solutions for powering irrigation systems and agricultural machinery, especially in remote areas where grid access is limited. These generators help maintain optimal growing conditions and can significantly reduce crop loss due to power failures. Buyers should focus on fuel efficiency and output capacity to ensure that their operations remain sustainable and productive throughout the growing season.

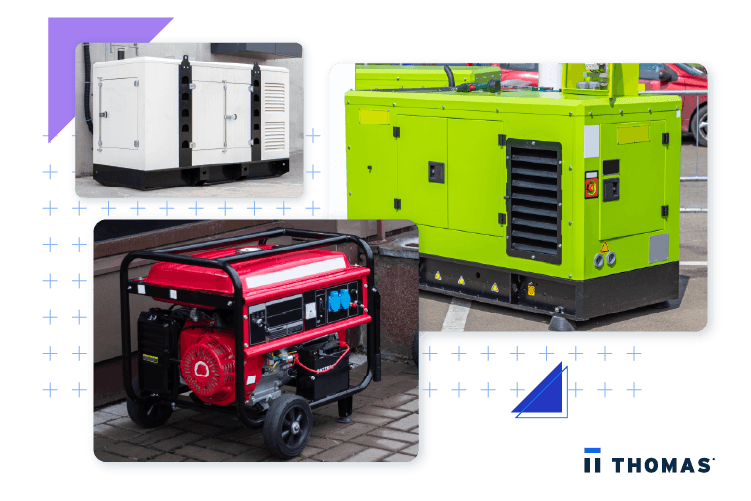

A stock image related to generator supplier.

Why Are Generators Important for Events and Entertainment?

A stock image related to generator supplier.

For the events and entertainment industry, generator suppliers provide essential power for outdoor festivals, concerts, and exhibitions. These generators support lighting, sound systems, and other electronic equipment, ensuring that events run smoothly. Buyers should consider mobility and noise restrictions, as well as rental options, to accommodate different event sizes and locations while adhering to local regulations.

How Are Generators Used in Telecommunications?

Generator suppliers are critical for telecommunications, providing power to remote cell towers and installations where grid power is unavailable. This ensures that communication networks remain operational, particularly in emergencies. When sourcing generators, telecommunications buyers need to evaluate scalability, fuel type, and integration capabilities to ensure that their power solutions can grow with their network demands.

Related Video: How a hydro generator works

3 Common User Pain Points for ‘generator supplier’ & Their Solutions

Scenario 1: Unexpected Downtime Due to Generator Failures

The Problem: Many B2B buyers in sectors such as construction, event management, or agriculture face unexpected downtime due to generator failures. In regions like Africa or South America, where access to reliable power sources is limited, a malfunctioning generator can halt operations, leading to lost revenue and damaged client relationships. The challenge is further exacerbated by a lack of immediate access to technical support or spare parts, leaving businesses vulnerable during critical projects.

The Solution: To mitigate the risk of generator failures, buyers should prioritize sourcing from reputable suppliers who provide comprehensive warranty and support services. When selecting a generator supplier, inquire about the availability of local technical support and spare parts. Implementing a robust maintenance schedule is also crucial. Establish a preventive maintenance agreement with the supplier to ensure regular inspections and timely repairs. Additionally, consider investing in generators equipped with real-time monitoring technology that can alert operators to potential issues before they escalate into failures.

Scenario 2: Difficulty in Selecting the Right Generator for Specific Needs

The Problem: B2B buyers often struggle with selecting the right generator that meets their unique operational needs. In diverse markets across the Middle East and Europe, the requirements can vary significantly based on usage scenarios—such as powering heavy machinery at a construction site or providing backup power for medical facilities. This challenge is compounded by the overwhelming variety of generator types, specifications, and features available in the market.

The Solution: To simplify the selection process, buyers should start by conducting a detailed needs assessment. Evaluate the power requirements of all equipment that the generator will support and consider factors like load types (e.g., inductive vs. resistive loads) and the duration of use. Suppliers often provide expert consultation services—take advantage of these to gain insights into the best fit for your specific application. Additionally, request product demos or trial periods to assess performance in real-world conditions before making a substantial investment. Leveraging online resources, such as comparison tools or user reviews, can also aid in making an informed decision.

Scenario 3: Navigating Compliance and Regulatory Requirements

The Problem: International buyers, especially from regions with stringent environmental regulations like Europe, face challenges in ensuring that their generators comply with local laws regarding emissions and noise levels. Non-compliance can lead to hefty fines, operational shutdowns, and reputational damage, making it essential for businesses to navigate these regulations effectively.

The Solution: Buyers should familiarize themselves with the relevant compliance standards in their region, such as the EU’s Stage V emissions regulations or similar guidelines in other markets. When sourcing generators, prioritize suppliers who demonstrate a clear understanding of these regulations and offer products that meet or exceed compliance standards. Request detailed documentation on emissions certifications and noise level measurements for each generator model. Furthermore, consider engaging with local environmental consultants or legal experts who can provide guidance on compliance and help you stay informed about any upcoming regulatory changes. This proactive approach not only protects your investment but also enhances your company’s reputation as a responsible business.

Strategic Material Selection Guide for generator supplier

When selecting materials for generators, international B2B buyers must consider various factors that affect performance, durability, and compliance with regional standards. Here, we analyze four common materials used in generator manufacturing, focusing on their properties, advantages, disadvantages, and implications for buyers from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Steel in Generator Manufacturing?

Steel is a widely used material in generator construction due to its excellent strength-to-weight ratio and durability. It typically has a high temperature and pressure rating, making it suitable for various applications. Corrosion-resistant steel variants, such as stainless steel, are often employed in environments where exposure to moisture and chemicals is prevalent.

Pros & Cons:

Steel offers high durability and resistance to mechanical stress, making it ideal for heavy-duty applications. However, it can be relatively heavy, which may complicate transportation and installation. Additionally, while the cost of carbon steel is generally low, stainless steel can be more expensive due to its alloying elements.

Impact on Application:

Steel’s compatibility with various media, including fuel and oil, makes it a versatile choice for generators. However, buyers must consider the specific environmental conditions, such as humidity and temperature fluctuations, which may necessitate additional protective coatings.

Considerations for International Buyers:

Steel compliance with standards such as ASTM and DIN is crucial for international buyers. In regions like Africa and South America, where environmental conditions may be harsher, selecting corrosion-resistant steel can enhance the longevity of the generator.

How Does Aluminum Benefit Generator Suppliers?

Aluminum is increasingly favored in generator manufacturing due to its lightweight and corrosion-resistant properties. It typically has a lower density than steel, which can lead to easier handling and reduced shipping costs.

Pros & Cons:

The primary advantage of aluminum is its resistance to corrosion, making it suitable for outdoor applications. However, it has a lower strength compared to steel, which may limit its use in high-stress environments. While aluminum is generally more expensive than carbon steel, its weight savings can offset some of the initial costs.

Impact on Application:

Aluminum’s compatibility with various fuels and lubricants makes it a suitable choice for portable generators. However, buyers should be cautious about using aluminum in high-temperature applications, as it may deform under extreme heat.

Considerations for International Buyers:

Buyers in Europe and the Middle East should ensure that aluminum components meet relevant standards, such as JIS or EN, to guarantee product reliability and safety.

What Role Does Copper Play in Generator Efficiency?

Copper is a critical material for electrical components in generators due to its excellent electrical conductivity and thermal properties. It is often used in windings and connectors, significantly impacting the efficiency of power generation.

Pros & Cons:

Copper’s high conductivity ensures minimal energy loss, enhancing overall generator efficiency. However, it is relatively expensive compared to other metals, which can increase production costs. Additionally, copper is susceptible to corrosion, necessitating protective coatings in certain environments.

Impact on Application:

In applications where high electrical performance is essential, copper is indispensable. Its compatibility with various electrical systems makes it a preferred choice for generator manufacturers.

Considerations for International Buyers:

Buyers should be aware of the fluctuations in copper prices and consider sourcing strategies that mitigate cost increases. Compliance with international standards is also essential for ensuring the reliability of copper components.

Why is Composite Material Gaining Popularity in Generators?

Composite materials, often a combination of plastic and fiberglass, are becoming popular in generator manufacturing due to their lightweight and corrosion-resistant properties. They are particularly useful in components that do not require high strength.

Pros & Cons:

The main advantage of composites is their resistance to corrosion and lightweight nature, making them ideal for portable generators. However, they may not withstand high temperatures or mechanical stress as effectively as metals. The manufacturing process for composites can also be more complex, leading to higher production costs.

Impact on Application:

Composites are suitable for non-structural components, such as casings and covers, where weight savings are crucial. However, their limitations in high-stress applications must be considered.

Considerations for International Buyers:

Buyers should verify that composite materials meet relevant safety and performance standards, particularly in regions like Africa and South America, where environmental conditions can be unpredictable.

Summary Table of Material Selection for Generator Suppliers

| Material | Typical Use Case for generator supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components | High strength and durability | Heavy, may require corrosion protection | Medium |

| Aluminum | Portable generators | Lightweight and corrosion-resistant | Lower strength than steel | High |

| Copper | Electrical windings and connectors | Excellent conductivity and efficiency | Expensive, susceptible to corrosion | High |

| Composite | Non-structural components | Lightweight and corrosion-resistant | Limited high-temperature performance | Medium |

This analysis provides international B2B buyers with actionable insights into material selection for generators, emphasizing the importance of understanding the properties, advantages, and limitations of each material in relation to their specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for generator supplier

What Are the Main Stages of the Manufacturing Process for Generators?

The manufacturing process for generators involves several critical stages that ensure the final product meets quality and performance standards. Understanding these stages is essential for B2B buyers looking to source reliable generator suppliers.

1. Material Preparation

The first step in generator manufacturing is material preparation. This involves selecting high-quality raw materials such as steel, copper, and various plastics. The choice of materials significantly impacts the generator’s durability and efficiency. Suppliers typically use advanced software to calculate material requirements and optimize usage, minimizing waste. Buyers should inquire about the sourcing of materials, as compliance with international standards (like ISO 14001 for environmental management) can indicate a supplier’s commitment to sustainability.

2. Forming

Once materials are prepared, they undergo forming processes. This includes cutting, bending, and shaping components using techniques such as stamping, machining, and welding. For example, the generator’s frame may be stamped from a sheet of steel, while the rotor and stator are machined to precise specifications. Manufacturers may use Computer Numerical Control (CNC) machines for high precision, which is crucial for performance and efficiency. B2B buyers should assess the technology used in forming processes, as advanced techniques often correlate with higher quality outputs.

3. Assembly

The assembly stage involves combining various components to create the generator. This process can be manual or automated, depending on the scale of production. Key components include the engine, alternator, control panel, and fuel system. During assembly, manufacturers must adhere to strict guidelines to ensure that all parts fit and function correctly. Buyers should look for suppliers who implement lean manufacturing principles to reduce waste and enhance efficiency in this phase.

4. Finishing

Finishing processes enhance the generator’s aesthetics and protect it from environmental factors. This includes painting, coating, and applying insulation materials. Finishing not only improves the appearance but also extends the generator’s lifespan by preventing corrosion. Suppliers may use powder coating or other advanced techniques to ensure durability. B2B buyers should verify that the finishing processes comply with relevant international standards, such as ISO 12944 for corrosion protection.

How Do Quality Assurance Practices Ensure Generator Reliability?

Quality assurance (QA) is integral to the manufacturing process, especially in industries where reliability is paramount, such as generator supply. Implementing robust QA practices helps ensure that products meet customer expectations and comply with international standards.

Relevant International Standards for Quality Assurance

For generator suppliers, adhering to international quality standards is essential. ISO 9001 is the most recognized standard for quality management systems, ensuring consistency and quality in production. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for oil and gas applications are critical. B2B buyers should prioritize suppliers with these certifications as they signify compliance with rigorous quality benchmarks.

What Are the Key Quality Control Checkpoints?

Effective quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint ensures that all raw materials meet specified quality standards before production begins. Suppliers should have rigorous testing protocols for materials to avoid defects downstream.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, IPQC checks are conducted at various stages to identify defects early. This can include inspections during forming, assembly, and finishing stages.

-

Final Quality Control (FQC): Before products are shipped, FQC involves comprehensive testing of the finished generators. This may include performance tests, safety checks, and compliance verifications. B2B buyers should request FQC reports to ensure product reliability.

What Testing Methods Are Commonly Used in Generator Manufacturing?

Testing is a crucial component of quality assurance in generator manufacturing. Various methods ensure that generators operate efficiently and safely.

Common Testing Methods

-

Load Testing: Generators are subjected to load testing to verify their performance under operational conditions. This ensures they can handle the required electrical load without failure.

-

Noise Level Testing: Since generators can be noisy, especially in residential areas, manufacturers often conduct noise level tests to ensure compliance with local regulations. This is particularly important for buyers in regions where noise pollution laws are stringent.

-

Vibration Testing: This test assesses how generators withstand vibrations during operation. It is essential for identifying potential mechanical issues that could lead to failures.

-

Safety Compliance Testing: Ensuring that generators meet safety standards is vital. Testing may involve checking electrical insulation, grounding, and emergency shutdown systems.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of potential suppliers is crucial for ensuring product reliability.

Effective Verification Strategies

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to evaluate manufacturing processes, quality control measures, and adherence to standards. This firsthand inspection can reveal a supplier’s commitment to quality.

-

Quality Reports: Requesting quality assurance reports and documentation from suppliers can provide insights into their QC practices. These reports should detail testing methodologies, results, and compliance with relevant standards.

-

Third-party Inspections: Engaging third-party inspection agencies to assess suppliers can add an additional layer of assurance. These agencies can provide unbiased evaluations of the supplier’s quality management systems and product compliance.

-

References and Reviews: Seeking references from other companies that have sourced from the supplier can provide valuable insights into the supplier’s reliability and product quality. Online reviews and industry reputation can also inform buyers’ decisions.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control and certification nuances when sourcing generators from different regions.

Navigating Certification Requirements

Different regions may have specific certification requirements that suppliers must meet. For example, European buyers must ensure that generators are CE certified, while buyers in the Middle East may need to consider G-Mark certification. Understanding these nuances helps buyers avoid regulatory issues and ensures the products meet local standards.

Cultural and Logistical Considerations

Cultural differences and logistical challenges can also impact quality assurance processes. For instance, communication barriers may affect the clarity of quality specifications. Buyers should establish clear communication channels and consider using translation services if necessary. Additionally, understanding the local manufacturing culture can help in setting realistic expectations regarding quality and timelines.

By comprehensively understanding the manufacturing processes and quality assurance practices of generator suppliers, B2B buyers can make informed decisions that align with their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘generator supplier’

The following guide is designed to assist international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, in sourcing reliable generator suppliers. This checklist outlines essential steps to ensure a successful procurement process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for sourcing the right generator. Consider the power output required, fuel type (diesel or gasoline), and intended use (portable, standby, or prime power). This information will help narrow down suppliers who can meet your specific needs.

- Power Requirements: Assess the total wattage needed for your operations.

- Fuel Type: Determine the most accessible and economical fuel option for your location.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers in the generator market. Utilize online directories, industry publications, and trade shows to compile a list of manufacturers and distributors.

- Reputation Check: Look for reviews and testimonials from previous customers to gauge reliability.

- Industry Experience: Focus on suppliers with a proven track record in your specific industry or region.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that suppliers hold relevant certifications and comply with international standards. This step is crucial for ensuring product quality and safety.

- Quality Standards: Check for certifications such as ISO 9001 or ISO 14001, which indicate quality management systems.

- Environmental Compliance: Ensure compliance with emissions regulations, particularly for markets in Europe and North America.

Step 4: Request Product Samples or Demonstrations

Whenever possible, request samples or demonstrations of the generators to assess their performance. This step is vital for understanding the operational efficiency and suitability of the product for your needs.

- Test Performance: Evaluate noise levels, fuel efficiency, and output reliability during the demonstration.

- Feedback from Users: If possible, gather feedback from current users of the generator model to understand real-world performance.

Step 5: Assess After-Sales Support and Warranty Terms

A strong after-sales support system is essential for maintaining generator performance over time. Review the warranty terms and after-sales services offered by potential suppliers.

- Warranty Duration: Look for comprehensive warranty coverage that protects against defects.

- Service Network: Ensure the supplier has a robust service network in your region for maintenance and repairs.

Step 6: Negotiate Pricing and Payment Terms

Once you have shortlisted suppliers, begin negotiations on pricing and payment terms. This step is critical to ensure you get the best value for your investment.

- Bulk Purchase Discounts: Inquire about discounts for larger orders or long-term contracts.

- Flexible Payment Options: Explore payment plans that suit your cash flow needs, such as installment payments.

Step 7: Finalize Contracts and Delivery Terms

Carefully review and finalize contracts with your chosen supplier. Pay close attention to delivery timelines, shipping costs, and any penalties for non-compliance.

- Clear Terms: Ensure all terms are clearly outlined, including warranties, service agreements, and delivery expectations.

- Logistics Planning: Coordinate with the supplier on logistics to ensure timely delivery to your operational site.

By following this checklist, B2B buyers can streamline their sourcing process for generator suppliers and make informed purchasing decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for generator supplier Sourcing

What Are the Key Cost Components in Generator Supplier Sourcing?

Understanding the cost structure of generator suppliers is crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The main cost components include:

-

Materials: This includes the cost of raw materials such as metals, plastics, and electronic components. High-quality materials can increase the initial cost but may lead to better durability and lower maintenance expenses over time.

-

Labor: Labor costs vary significantly by region. Countries with lower labor costs might offer cheaper generators, but this can sometimes compromise quality. Understanding the labor market in the supplier’s country can provide insights into potential quality issues.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, such as utilities, rent, and administrative expenses. Suppliers with efficient manufacturing processes can keep these costs lower, which may reflect in their pricing.

-

Tooling: The cost of specialized tools and machinery used in the production of generators can be significant. Custom designs or unique specifications often require higher tooling costs, which can be passed on to the buyer.

-

Quality Control (QC): Effective QC processes ensure the reliability and performance of generators. Suppliers with stringent QC standards may charge higher prices, but the investment can lead to reduced failure rates and lower total ownership costs.

-

Logistics: Shipping and handling costs are vital, especially for international buyers. Factors like distance, shipping method, and customs duties can significantly affect the final cost.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the typical margins in the industry can help buyers assess whether a quoted price is fair.

How Do Pricing Influencers Affect Generator Costs?

Several factors influence the pricing of generators, which buyers should consider:

-

Volume/MOQ: Purchasing in bulk often leads to lower per-unit costs. Establishing a minimum order quantity (MOQ) can also influence pricing negotiations.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should assess whether these features are essential for their operations to avoid unnecessary expenses.

-

Materials and Quality Certifications: Generators made from higher-grade materials or with specific quality certifications (like ISO) may command higher prices but can provide better performance and reliability.

-

Supplier Factors: The reputation, location, and experience of the supplier can influence costs. Established suppliers with a proven track record may charge more due to their reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial. They dictate who bears the cost and risk during shipping, impacting the total cost of ownership.

What Are the Best Buyer Tips for Negotiating Generator Prices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, effective negotiation and cost management are essential:

-

Negotiate Smartly: Leverage your position as a bulk buyer to negotiate better pricing. Discuss the possibility of discounts for larger orders or long-term contracts.

-

Focus on Cost-Efficiency: Consider the total cost of ownership rather than just the purchase price. This includes maintenance, fuel consumption, and potential downtime. A slightly higher upfront cost may lead to greater savings in the long run.

-

Understand Pricing Nuances: Familiarize yourself with local market conditions and currency fluctuations, which can affect pricing. Being aware of these factors can empower you during negotiations.

-

Request Detailed Quotes: Ask suppliers for a breakdown of costs to better understand their pricing structure. This transparency can help identify areas for negotiation.

Disclaimer on Indicative Prices

Prices for generators can vary widely based on specifications, supplier reputation, and market conditions. Buyers should always obtain multiple quotes and consider the total cost of ownership when making purchasing decisions.

Alternatives Analysis: Comparing generator supplier With Other Solutions

When evaluating energy solutions for businesses, it’s essential to consider alternatives to traditional generator suppliers. Various technologies can provide similar benefits, often with unique advantages depending on the specific needs and circumstances of the buyer. Below, we compare generator suppliers with two viable alternatives: solar power systems and battery storage solutions.

Comparison Table of Energy Solutions

| Comparison Aspect | Generator Supplier | Solar Power Systems | Battery Storage Solutions |

|---|---|---|---|

| Performance | Reliable power source; can handle high loads. | Limited by weather; requires sunlight for optimal performance. | Provides power on demand; dependent on prior charging. |

| Cost | Initial investment can be high; ongoing fuel costs. | High initial setup cost; low ongoing maintenance costs. | Moderate initial costs; long-term savings on energy bills. |

| Ease of Implementation | Quick setup; requires fuel supply. | Requires space for panels; installation can be complex. | Simple installation; can be integrated into existing systems. |

| Maintenance | Regular maintenance needed; fuel management required. | Minimal maintenance; occasional cleaning and inspections. | Low maintenance; periodic checks needed for battery health. |

| Best Use Case | Emergency power, construction sites, and remote areas. | Long-term energy savings, sustainable operations, and off-grid locations. | Backup power for critical systems and energy management in commercial settings. |

What Are the Advantages and Disadvantages of Solar Power Systems?

Solar power systems harness energy from the sun, converting it into electricity. They are particularly advantageous in regions with abundant sunlight, making them an attractive option for businesses in Africa and South America. The initial investment can be substantial, but the long-term savings on electricity bills and maintenance costs can offset this. However, solar systems are highly dependent on weather conditions, which can limit their effectiveness during cloudy or rainy days. Additionally, the installation process can be complex, requiring specialized expertise.

How Do Battery Storage Solutions Compare to Generator Suppliers?

Battery storage solutions provide an innovative way to store energy for later use, allowing businesses to utilize electricity when it’s most needed. These systems can be charged using grid power or renewable sources like solar and wind. The main advantage is their flexibility and ability to provide power on demand, which is critical for businesses requiring uninterrupted operations. However, the efficiency and lifespan of batteries can vary, and users must consider their energy management strategies to maximize benefits. While the initial investment is moderate, businesses can save significantly on energy costs in the long run.

Conclusion: Which Energy Solution is Right for Your Business?

Choosing the right energy solution requires a thorough understanding of your specific operational needs and the context in which your business operates. For companies in regions with unstable power supply or frequent outages, a generator supplier may offer the most reliable immediate solution. Conversely, businesses looking for sustainability and long-term cost savings might find solar power systems or battery storage solutions more beneficial. Ultimately, the decision should align with your business goals, financial considerations, and operational requirements.

Essential Technical Properties and Trade Terminology for generator supplier

What Are the Essential Technical Properties of Generators for B2B Buyers?

When evaluating generator suppliers, understanding the technical specifications is crucial. Here are key properties to consider:

1. Power Output (kW or kVA)

The power output indicates the generator’s capacity to supply electricity. Measured in kilowatts (kW) or kilovolt-amperes (kVA), this specification is vital for ensuring that the generator can meet the energy needs of your operations. For instance, a 10 kW generator is suitable for small businesses, while larger industries may require 100 kW or more. B2B buyers should assess their power requirements carefully to avoid over or under-specifying.

2. Fuel Type and Efficiency

Generators can run on various fuels, including diesel, gasoline, natural gas, and even renewable sources like biodiesel. Each fuel type has its implications for efficiency, cost, and environmental impact. Diesel generators, for example, are known for their durability and fuel efficiency, making them ideal for continuous operation in regions with unstable power supply, such as parts of Africa and South America.

3. Noise Level (dB)

Noise levels, measured in decibels (dB), are essential, especially in urban areas or residential settings. Many modern generators feature noise-reduction technology, making them quieter and more acceptable for various applications. Understanding the noise specifications helps buyers ensure compliance with local regulations and community standards, particularly in Europe, where noise pollution laws are strict.

4. Compliance Standards

Generators often must comply with local and international environmental regulations, such as the EU’s Stage V or the U.S. Tier 4 Final emissions standards. These compliance standards dictate the acceptable levels of emissions and can significantly affect a generator’s operational costs and marketability. B2B buyers should prioritize suppliers who adhere to these standards, ensuring long-term sustainability and legal compliance.

5. Control Systems

Modern generators come equipped with advanced control systems that enhance operational efficiency and reliability. These systems allow for remote monitoring, automatic start/stop functions, and diagnostics that can predict maintenance needs. Understanding the features of these control systems can help businesses optimize their generator usage and reduce downtime.

What Are Common Trade Terms Used in the Generator Industry?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the generator industry, understanding whether you’re purchasing from an OEM or a reseller can impact warranty conditions and product support. B2B buyers should seek OEM suppliers for better reliability and service continuity.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cost calculations. Knowing the MOQ helps businesses gauge whether a supplier can meet their purchasing needs without incurring unnecessary costs.

3. RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to solicit price offers from suppliers for specific products or services. When purchasing generators, sending an RFQ can help buyers compare pricing and terms from multiple suppliers, ensuring competitive rates and favorable conditions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to determine who is responsible for shipping, insurance, and tariffs, especially when importing generators from overseas suppliers.

5. Warranty and Service Agreements

Warranty terms outline the supplier’s responsibilities regarding repairs and replacements of defective products. Service agreements typically provide ongoing support and maintenance. B2B buyers should always clarify these terms to avoid unexpected costs and ensure long-term operational reliability.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when selecting generator suppliers, ultimately optimizing their operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the generator supplier Sector

What Are the Current Market Dynamics and Key Trends in the Generator Supplier Sector?

The generator supplier sector is witnessing significant transformation driven by global economic growth, increased energy demands, and the need for reliable power solutions. Key market drivers include the surge in renewable energy projects, particularly in Africa and South America, where off-grid solutions are essential. In regions like the Middle East, the push for infrastructure development fuels demand for both portable and stationary generators.

Emerging B2B technology trends, such as the integration of IoT in generators, allow for real-time monitoring and predictive maintenance, enhancing efficiency and reliability. This is particularly valuable for international buyers looking to minimize downtime and optimize operational costs. Additionally, a growing preference for hybrid generators, which combine traditional fuel sources with renewable energy, reflects an evolving landscape that prioritizes sustainability while meeting energy needs.

The competitive landscape also emphasizes the importance of compliance with international standards, such as ISO certifications and emission regulations. Buyers from Europe, for example, are increasingly demanding products that meet stringent environmental criteria, which has prompted suppliers to innovate and adapt their offerings. Understanding these dynamics is crucial for international B2B buyers to make informed sourcing decisions and align with market trends.

How Can Sustainability and Ethical Sourcing Impact Your B2B Procurement Strategy?

Sustainability has become a cornerstone of procurement strategies within the generator supplier sector. The environmental impact of generator production and operation is significant, especially concerning emissions and resource consumption. B2B buyers are increasingly focusing on suppliers that prioritize sustainable practices, including the use of eco-friendly materials and processes.

Ethical sourcing is not just a trend but a necessity for companies looking to enhance their corporate social responsibility (CSR) initiatives. This includes ensuring that supply chains are transparent and that raw materials are sourced responsibly. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming critical in supplier evaluations.

Furthermore, the demand for ‘green’ certifications is on the rise. Products that comply with eco-labels or have been certified as energy-efficient can significantly enhance a supplier’s marketability. Buyers should prioritize suppliers that demonstrate a commitment to sustainability, as this can lead to long-term cost savings and a positive brand reputation in increasingly eco-conscious markets.

What Is the Evolution of the Generator Supplier Sector?

The generator supplier sector has evolved significantly over the past few decades, shaped by technological advancements and changing consumer needs. Initially dominated by diesel-powered generators, the market has diversified to include gas, solar, and hybrid systems, reflecting the growing emphasis on renewable energy solutions.

In the early 2000s, the introduction of portable generators made it easier for consumers and businesses to access power in remote areas, particularly in regions with unreliable electricity grids. As global awareness of climate change increased, manufacturers began to innovate more sustainable options, leading to the rise of eco-friendly and energy-efficient generators.

Today, the sector is characterized by a blend of traditional and modern technologies, with a strong focus on IoT and smart solutions that improve efficiency and user experience. This evolution is crucial for international B2B buyers to understand, as it directly impacts sourcing strategies and the overall market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of generator supplier

-

How do I choose the right generator supplier for my business needs?

Selecting the right generator supplier involves assessing your specific requirements such as power capacity, fuel type, and intended use (e.g., construction, events, or backup power). Research suppliers based on their industry experience, product range, and customer reviews. Request detailed specifications and certifications to ensure compliance with local regulations. Additionally, consider suppliers who offer after-sales support and maintenance services, as this will enhance the longevity and reliability of your investment. -

What are the key factors to consider when sourcing a generator?

When sourcing a generator, consider power output, fuel efficiency, noise levels, and portability. Assess the generator’s intended application, such as whether it will be used in remote locations or urban settings, which influences your choice of model. Additionally, evaluate the supplier’s warranty, service agreements, and availability of spare parts to ensure long-term support. Lastly, factor in your budget and look for options that provide the best value for your specific needs. -

What payment terms should I expect from generator suppliers?

Payment terms can vary significantly among generator suppliers, but common practices include upfront payments, partial deposits, or payment upon delivery. International buyers should clarify these terms before finalizing contracts. Consider negotiating terms that align with your cash flow, such as extended payment periods or financing options. Additionally, ensure that the supplier provides secure payment methods, which can reduce the risk of fraud in international transactions. -

How can I verify the credibility of a generator supplier?

To verify the credibility of a generator supplier, conduct thorough background research. Check for company registration, industry certifications, and customer testimonials. Request references from previous clients and assess the supplier’s reputation in online forums and social media. Moreover, consider visiting their manufacturing facility if possible, or engage third-party inspection services to evaluate product quality before making a purchase. -

What customization options are available when ordering generators?

Many generator suppliers offer customization options to meet specific business needs. Customization may include adjustments to power output, fuel type, size, or additional features like noise reduction technology or automatic transfer switches. Discuss your requirements with the supplier early in the negotiation process to understand what modifications are feasible and any associated costs or lead times for these customizations. -

What is the typical minimum order quantity (MOQ) for generators?

Minimum order quantities (MOQs) for generators can vary widely based on the supplier and the type of generators being ordered. While some suppliers may allow single-unit purchases, others may require bulk orders to meet production efficiencies. It’s advisable to inquire about MOQs during your initial discussions and explore options for smaller orders if your business is just starting or if you are testing the market. -

How do I ensure quality assurance when sourcing generators?

Ensuring quality assurance involves establishing clear quality standards and conducting thorough inspections before accepting delivery. Request documentation such as quality certificates, compliance with international standards (e.g., ISO), and detailed test reports. Some suppliers may offer warranties or guarantees that cover defects or performance issues. Additionally, consider working with suppliers who have a solid reputation for quality and reliability in the industry. -

What logistics considerations should I keep in mind when importing generators?

Logistics play a crucial role in importing generators, especially regarding shipping methods, lead times, and customs regulations. Understand the shipping options available, whether by sea or air, and factor in transit times when planning your order. Ensure compliance with import regulations in your country, including tariffs, taxes, and necessary permits. Engaging a reliable freight forwarder can simplify the logistics process and help you navigate any challenges that may arise during shipping.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for generator supplier

As the demand for reliable power solutions continues to grow across various sectors, strategic sourcing of generator suppliers becomes crucial for international B2B buyers. By prioritizing partnerships with manufacturers that offer high-quality, compliant products, buyers can ensure operational efficiency and minimize downtime. Key factors to consider include the supplier’s production capabilities, adherence to international standards, and their commitment to sustainability through eco-friendly technologies.

How can international B2B buyers leverage strategic sourcing in generator procurement? Buyers should focus on building long-term relationships with suppliers who demonstrate flexibility and innovation, as these traits can lead to better pricing models and tailored solutions. Additionally, engaging with suppliers that have a global footprint can facilitate smoother logistics and support in navigating local regulations, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

Looking ahead, the generator market is poised for significant evolution, driven by advancements in technology and renewable energy integration. Buyers are encouraged to actively explore these opportunities and invest in partnerships that align with their strategic goals. The time to act is now—secure your power needs and future-proof your operations by sourcing wisely.