Discover Top Heating Elements Suppliers: Your Ultimate Guide (2025)

Introduction: Navigating the Global Market for heating elements supplier

In today’s global marketplace, sourcing high-quality heating elements can be a significant challenge for international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe. The demand for reliable heating solutions spans various industries, from manufacturing to food processing, and navigating this landscape requires a comprehensive understanding of supplier capabilities and market dynamics. This guide aims to empower B2B buyers by providing actionable insights into the diverse types of heating elements available, their applications, and the critical factors to consider when vetting suppliers.

Understanding the nuances of different heating element technologies—such as resistive, induction, and infrared—is essential for making informed purchasing decisions. Additionally, buyers will gain insights into the importance of supplier reliability, compliance with international standards, and the impact of logistics and costs on procurement strategies. By addressing these critical aspects, this guide serves as a valuable resource for decision-makers seeking to enhance their supply chain and improve operational efficiency.

Whether you are a buyer in Spain looking for innovative heating solutions or a procurement officer in South America aiming to streamline sourcing processes, this guide equips you with the knowledge needed to make strategic choices that align with your business objectives. Through careful analysis and informed decision-making, international buyers can navigate the complexities of the heating elements market with confidence.

Understanding heating elements supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Resistive Heating Elements | Simple design; converts electrical energy into heat through resistance. | Industrial heating, manufacturing processes, food service equipment. | Pros: Cost-effective, straightforward installation. Cons: Less efficient at high temperatures. |

| Induction Heating Elements | Uses electromagnetic fields to heat conductive materials directly. | Metalworking, cooking appliances, and automotive applications. | Pros: Fast heating, energy-efficient. Cons: Higher initial investment, requires compatible cookware. |

| Infrared Heating Elements | Emits infrared radiation to directly heat objects without heating the air. | Space heating, drying processes, and curing applications. | Pros: Quick heat-up time, minimal heat loss. Cons: Limited range, can be uneven heating in large spaces. |

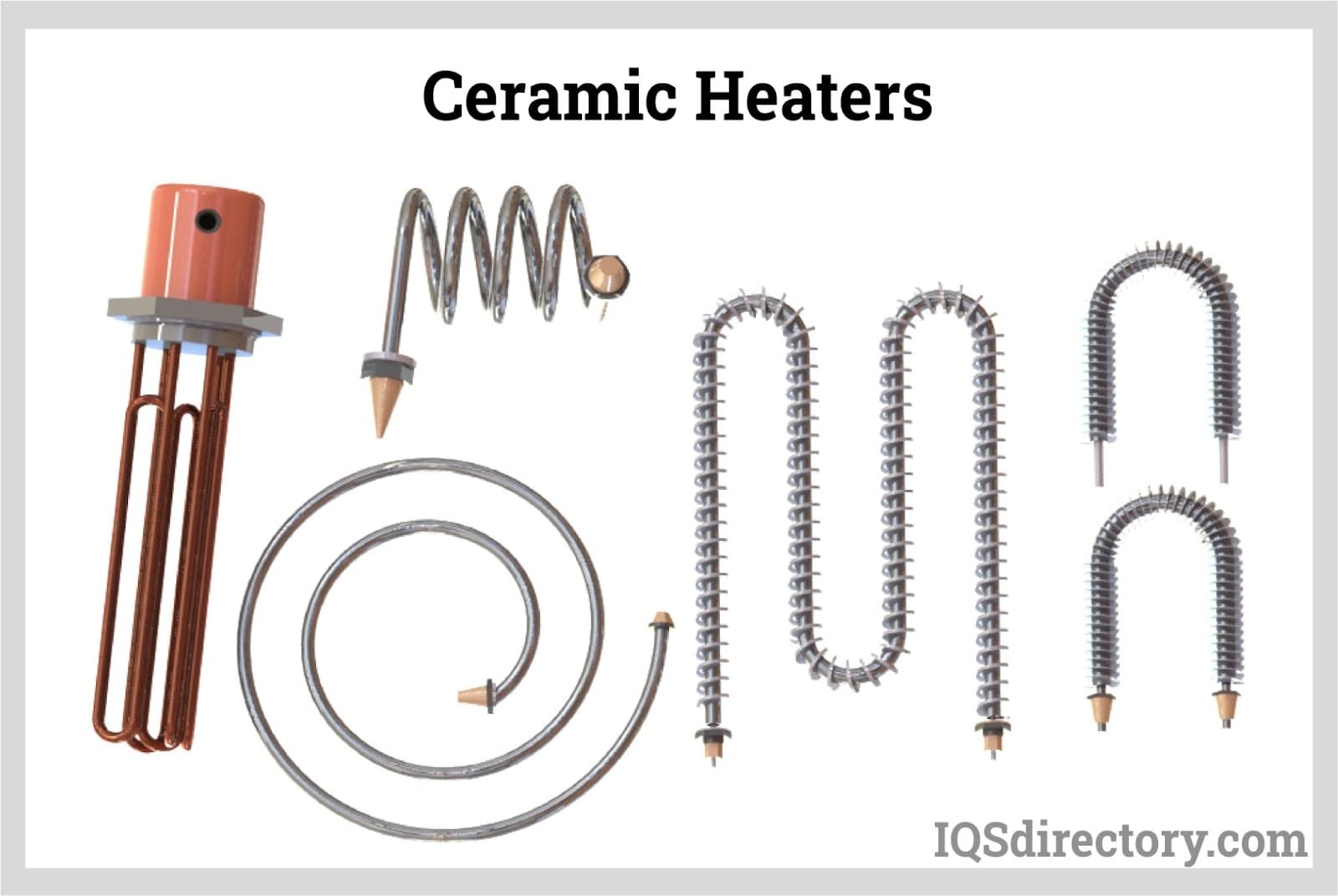

| Ceramic Heating Elements | Made from ceramic materials; provides uniform heating. | HVAC systems, home appliances, and industrial ovens. | Pros: High durability, good thermal efficiency. Cons: Heavier and bulkier than other types. |

| Silicone Rubber Heating Elements | Flexible, lightweight, and can be customized for various shapes. | Medical equipment, food processing, and aerospace. | Pros: Versatile, easy to install, and adaptable. Cons: Limited temperature range compared to others. |

What are Resistive Heating Elements and Their Suitability for B2B Buyers?

Resistive heating elements are widely used in various industries due to their simple design and functionality. They operate by converting electrical energy into heat through resistance. This type is particularly suitable for industrial heating applications, such as manufacturing processes and food service equipment. When considering a purchase, B2B buyers should evaluate the installation costs and the element’s efficiency at high temperatures, as these factors can influence long-term operational costs.

How Do Induction Heating Elements Work and Their Applications?

Induction heating elements utilize electromagnetic fields to heat conductive materials directly, making them highly efficient for specific applications. Commonly found in metalworking and cooking appliances, they provide fast heating times and energy efficiency. However, the initial investment can be higher than resistive elements, and buyers must ensure compatibility with the materials they intend to heat. Understanding the specific requirements of their application will help buyers make informed decisions.

What are Infrared Heating Elements and Their Benefits for B2B Uses?

Infrared heating elements work by emitting infrared radiation, which heats objects directly rather than the surrounding air. This makes them ideal for space heating, drying processes, and curing applications. B2B buyers appreciate the quick heat-up times and minimal heat loss associated with infrared elements. However, they should consider the limited heating range and potential uneven heating in larger spaces, which can affect performance in extensive industrial settings.

What Characteristics Define Ceramic Heating Elements for B2B Buyers?

Ceramic heating elements are known for their durability and ability to provide uniform heating. They are commonly used in HVAC systems, home appliances, and industrial ovens. B2B buyers should note that while these elements offer high thermal efficiency, they can be heavier and bulkier compared to other types. Assessing the space and application requirements is crucial for buyers to ensure that ceramic elements are a suitable choice for their needs.

Why Choose Silicone Rubber Heating Elements for Versatile Applications?

Silicone rubber heating elements are flexible, lightweight, and customizable, making them suitable for various applications, including medical equipment and food processing. Their versatility and ease of installation are significant advantages for B2B buyers. However, it is essential to be aware of the limited temperature range these elements can operate within, which may affect their applicability in high-heat environments. Understanding these factors will aid buyers in selecting the right heating solution for their specific applications.

Related Video: HEATING ELEMENTS EXPLAINED

Key Industrial Applications of heating elements supplier

| Industry/Sector | Specific Application of heating elements supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Temperature control in ovens and fryers | Enhanced cooking efficiency and product quality | Compliance with food safety standards, energy efficiency ratings |

| Plastics Manufacturing | Melting and molding processes | Improved production speed and material quality | Material compatibility, temperature range, and durability |

| HVAC Systems | Heating and cooling systems | Increased energy efficiency and comfort | Size specifications, power ratings, and installation requirements |

| Chemical Processing | Reactant heating in reactors | Enhanced reaction rates and product yield | Resistance to corrosive materials, precise temperature control |

| Medical Equipment | Sterilization and warming of medical tools | Improved safety and effectiveness of procedures | Compliance with medical regulations, reliability, and energy use |

How Are Heating Elements Used in Food Processing?

In the food processing industry, heating elements are crucial for maintaining precise temperature control in ovens, fryers, and cooking equipment. They solve the problem of inconsistent cooking temperatures, which can affect food quality and safety. International buyers, particularly from regions like Africa and South America, need to ensure that the suppliers comply with local food safety standards and provide energy-efficient solutions to minimize operational costs.

A stock image related to heating elements supplier.

What Role Do Heating Elements Play in Plastics Manufacturing?

Heating elements are integral to melting and molding processes in plastics manufacturing. They provide the necessary heat to transform raw materials into malleable forms, improving production speed and material quality. Buyers from Europe, especially in countries like Spain, should consider the compatibility of heating elements with specific plastics and the required temperature ranges to ensure optimal performance and durability.

Why Are Heating Elements Essential for HVAC Systems?

In HVAC systems, heating elements are used for both heating and cooling applications, contributing to energy efficiency and comfort in residential and commercial buildings. They help to regulate indoor temperatures effectively, addressing issues related to temperature fluctuations. For international buyers, it is vital to assess the size specifications and power ratings of heating elements to ensure compatibility with existing systems, particularly in the diverse climates of the Middle East and Europe.

How Do Heating Elements Benefit Chemical Processing?

In chemical processing, heating elements are employed for heating reactants in reactors, significantly enhancing reaction rates and product yield. They address challenges related to temperature control, which is critical for maintaining the integrity of chemical reactions. Buyers should focus on sourcing heating elements that can withstand corrosive materials and provide precise temperature control, which is essential for consistent product quality and safety.

In What Ways Are Heating Elements Used in Medical Equipment?

Heating elements are vital in the medical field for sterilizing and warming medical tools and equipment. They ensure that tools are adequately sterilized, enhancing the safety and effectiveness of medical procedures. Buyers in the medical sector must prioritize compliance with stringent medical regulations and seek reliable heating elements that are energy-efficient and durable to meet the demands of various medical applications.

Related Video: Double Pipe Heat Exchanger Basics Explained – industrial engineering

3 Common User Pain Points for ‘heating elements supplier’ & Their Solutions

Scenario 1: Sourcing Quality Heating Elements for Diverse Applications

The Problem: B2B buyers often struggle with identifying a reliable heating elements supplier that can provide products suitable for various applications, such as manufacturing, food processing, or HVAC systems. The challenge lies in the wide array of specifications, materials, and technologies available, which can lead to confusion and the risk of selecting subpar products that do not meet operational requirements.

The Solution: To effectively source high-quality heating elements, buyers should start by defining their specific application needs, including voltage, wattage, and environmental conditions. Next, they should seek suppliers with a strong reputation and proven experience in their industry. It’s beneficial to request samples and conduct thorough testing to ensure compatibility and performance. Additionally, consider suppliers that offer customization options, as this can provide tailored solutions that perfectly fit unique operational requirements. Engaging in direct communication with suppliers about your needs and concerns can facilitate a better understanding of the products and lead to more informed purchasing decisions.

Scenario 2: Managing Lead Times and Inventory Issues

The Problem: Many B2B buyers face the issue of long lead times for heating element orders, which can disrupt production schedules and lead to costly delays. Unpredictable inventory levels and shipping challenges further complicate the situation, especially for international buyers from regions such as Africa or South America, where logistics may be less reliable.

The Solution: To mitigate lead time challenges, buyers should establish strategic relationships with multiple heating elements suppliers to diversify their supply chain. This approach allows for quicker turnaround times and more flexible inventory management. Implementing a just-in-time (JIT) inventory strategy can also help maintain optimal stock levels without overcommitting resources. Regularly reviewing and adjusting orders based on production forecasts will further enhance inventory efficiency. Lastly, leveraging digital tools for supply chain management can provide real-time visibility into order status and inventory levels, allowing buyers to make informed decisions swiftly.

Scenario 3: Ensuring Compliance with Safety Standards

The Problem: Compliance with safety and regulatory standards is a critical concern for B2B buyers, especially when it comes to heating elements used in industrial applications. Failure to adhere to these standards can result in legal repercussions, safety hazards, and damage to the company’s reputation.

The Solution: Buyers should conduct thorough research on the specific regulations that apply to their industry and region. It is essential to partner with heating element suppliers who provide documentation and certification of compliance with relevant safety standards, such as CE marking in Europe or UL certification in North America. When evaluating suppliers, ask for their quality assurance processes and how they ensure ongoing compliance. Additionally, consider suppliers who offer technical support and training on the proper installation and maintenance of heating elements, as this can enhance safety and compliance efforts. Regular audits and reviews of supplier performance can further help maintain adherence to safety regulations, ensuring that all products remain compliant throughout their lifecycle.

Strategic Material Selection Guide for heating elements supplier

When selecting materials for heating elements, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below, we analyze four common materials used in heating elements, providing insights into their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Nickel-Chromium Alloys in Heating Elements?

A stock image related to heating elements supplier.

Nickel-chromium alloys, often referred to as nichrome, are widely used in heating elements due to their excellent resistance to oxidation and high-temperature stability. These alloys can typically withstand temperatures up to 1200°C and are known for their good mechanical strength at elevated temperatures.

Pros & Cons:

Nichrome offers high durability and a relatively low manufacturing complexity, making it suitable for various applications, including industrial furnaces and toasters. However, it can be more expensive than other materials, which may impact overall project costs.

Impact on Application:

Its compatibility with air and various gaseous media makes nichrome ideal for applications that require consistent heat output.

Considerations for International Buyers:

Buyers should ensure compliance with ASTM standards, particularly ASTM B395 for wire and strip, and consider the specific temperature ratings required for their applications.

How Do Silicon Carbide Heating Elements Perform?

Silicon carbide (SiC) is another popular choice for heating elements, especially in high-temperature applications. It has a remarkable temperature rating, often exceeding 1600°C, and exhibits excellent thermal conductivity.

Pros & Cons:

The primary advantage of SiC is its ability to operate in harsh environments, including vacuum and inert atmospheres. However, the brittleness of silicon carbide can lead to challenges during handling and installation, potentially increasing manufacturing complexity.

Impact on Application:

SiC is particularly suitable for applications involving molten metals or ceramics, where high temperatures and corrosive environments are common.

Considerations for International Buyers:

Buyers should be aware of compliance with international standards such as JIS (Japanese Industrial Standards) and the need for specific handling protocols due to the material’s fragility.

What Are the Benefits of Using Stainless Steel for Heating Elements?

Stainless steel is frequently used in heating elements due to its corrosion resistance and mechanical strength. It typically performs well at temperatures up to 800°C, making it versatile for various applications.

Pros & Cons:

Stainless steel is cost-effective and readily available, which can help reduce overall project costs. However, its lower temperature rating compared to nichrome and silicon carbide may limit its use in high-temperature applications.

Impact on Application:

This material is ideal for applications involving food processing or environments where corrosion is a concern, such as in humid or saline conditions.

Considerations for International Buyers:

Buyers should verify compliance with DIN standards, particularly DIN 17440 for stainless steel grades, and assess the specific grade required for their application.

Why Choose Molybdenum for High-Temperature Applications?

Molybdenum is a high-performance material often used for heating elements in vacuum furnaces. It can withstand temperatures up to 3000°C, making it suitable for extreme applications.

Pros & Cons:

The key advantage of molybdenum is its exceptional thermal stability and strength at high temperatures. However, it is one of the more expensive materials, which may deter budget-conscious buyers.

Impact on Application:

Molybdenum is particularly effective in applications requiring rapid heating and cooling cycles, such as in semiconductor manufacturing.

Considerations for International Buyers:

Buyers should ensure that suppliers meet international standards for molybdenum, such as ASTM B386, and consider the logistics of sourcing this material, as it may not be as widely available in all regions.

Summary Table of Material Properties for Heating Elements

| Material | Typical Use Case for heating elements supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nickel-Chromium Alloy | Industrial furnaces, toasters | Excellent oxidation resistance | Higher cost compared to alternatives | High |

| Silicon Carbide | High-temperature applications, ceramics | Operates in harsh environments | Brittle, handling challenges | Med |

| Stainless Steel | Food processing, humid environments | Cost-effective and corrosion resistant | Lower temperature rating | Low |

| Molybdenum | Vacuum furnaces, semiconductor manufacturing | Exceptional thermal stability | High cost | High |

By understanding the properties and implications of each material, international B2B buyers can make informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for heating elements supplier

What Are the Main Stages of the Manufacturing Process for Heating Elements?

Manufacturing heating elements involves several critical stages that ensure the final product meets quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used in Heating Element Manufacturing?

The first step in the manufacturing process is material preparation. Common materials used for heating elements include nickel-chromium alloys, stainless steel, and ceramic materials, which are selected based on their thermal conductivity and resistance to oxidation. Proper sourcing and quality verification of these raw materials are essential. Suppliers should provide certification of material properties, ensuring they conform to international standards.

How Are Heating Elements Formed and Assembled?

The next stage is forming, where the prepared materials are shaped into the required dimensions. Techniques such as wire drawing, cutting, and bending are employed to achieve the desired profiles. For example, wire elements are often wound into coils, while flat elements may be cut and shaped to fit specific applications.

Following forming, the assembly stage involves integrating various components, such as insulation, terminal connections, and protective coatings. This stage is crucial as it impacts the heating element’s efficiency and longevity. Buyers should inquire about the assembly methods used, as automated processes can enhance consistency and reduce human error.

What Finishing Techniques Are Applied to Heating Elements?

Finishing processes, such as coating, plating, and surface treatment, are critical in enhancing durability and performance. Common finishing techniques include anodizing, which improves corrosion resistance, and insulation application to prevent heat loss. Buyers should ensure that suppliers utilize finishing methods that meet their operational environment requirements, particularly in industries subject to stringent safety regulations.

How Is Quality Assurance Implemented in Heating Element Manufacturing?

Quality assurance (QA) is integral to the manufacturing of heating elements, ensuring that products meet specified performance and safety standards. Suppliers should adhere to international quality standards such as ISO 9001, which outlines criteria for an effective quality management system.

What International Standards Are Relevant for Heating Element Suppliers?

In addition to ISO 9001, suppliers may also comply with industry-specific certifications such as CE marking for products sold in Europe, or API standards for oil and gas applications. These certifications indicate that the products have been evaluated and meet rigorous safety and performance criteria. B2B buyers should verify that suppliers possess the relevant certifications for their target markets.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): During production, continuous monitoring of parameters is essential to catch defects early.

- Final Quality Control (FQC): The final inspection ensures that the finished heating elements meet all specifications before shipping.

Implementing these checkpoints allows suppliers to identify and rectify issues promptly, significantly reducing the risk of non-compliance.

What Testing Methods Are Commonly Used for Heating Elements?

Testing methods for heating elements are crucial to ensure their reliability and performance. Common methods include:

- Electrical Testing: Verifying resistance and continuity to ensure the element operates within specified parameters.

- Thermal Testing: Assessing the heating element’s performance under various temperature conditions to ensure it meets application requirements.

- Durability Testing: Simulating operational conditions to evaluate the lifespan and reliability of heating elements.

B2B buyers should inquire about the specific testing methods used by suppliers and request access to test reports to verify compliance with quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for B2B buyers to ensure they receive high-quality products. Here are several strategies:

- Conduct Supplier Audits: Regular audits of potential suppliers can reveal their manufacturing capabilities and adherence to quality standards. Buyers should assess the supplier’s facilities, equipment, and personnel qualifications.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including inspection and testing results. This transparency helps buyers evaluate the supplier’s commitment to quality.

- Utilize Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes and product quality.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International buyers, particularly from Africa, South America, the Middle East, and Europe, must navigate various regulatory environments and quality expectations. It’s crucial to understand the local compliance requirements and how they may differ from international standards. Buyers should also consider logistical factors, such as shipping times and customs regulations, which may affect product delivery and quality assurance.

By conducting thorough due diligence, including understanding the manufacturing processes and quality assurance measures of heating element suppliers, B2B buyers can mitigate risks and ensure they receive reliable, high-quality products suited to their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heating elements supplier’

The purpose of this guide is to equip international B2B buyers with a systematic approach to sourcing heating elements from suppliers. By following these steps, you can ensure that your procurement process is efficient, cost-effective, and aligned with your technical requirements.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical requirements for the heating elements you need. This includes the type (e.g., ceramic, metal, or silicone), power ratings, voltage, and size specifications.

– Consider industry standards and compliance requirements relevant to your region.

– Document any unique features or performance metrics that are critical for your application.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Utilize online directories, trade shows, and industry-specific forums to create a shortlist.

– Look for suppliers with a solid track record and positive customer reviews.

– Pay attention to their geographical location, as this can affect shipping times and costs.

Step 3: Verify Supplier Certifications

Ensure that the suppliers you are considering possess the necessary certifications. Compliance with international standards (such as ISO 9001) can indicate a commitment to quality.

– Request copies of certifications and check their validity.

– Assess whether the supplier meets specific industry standards that apply to your intended use of the heating elements.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the heating elements to evaluate their performance and quality. This step is crucial to ensure that the products meet your specifications.

– Conduct tests to verify that the heating elements operate efficiently under your conditions.

– Evaluate factors such as durability, heat distribution, and energy consumption.

Step 5: Assess Pricing and Payment Terms

Compare pricing from multiple suppliers to ensure you receive a competitive rate. However, be cautious of prices that seem too good to be true, as they may indicate lower quality.

– Inquire about bulk purchase discounts, shipping costs, and payment terms.

– Clarify any hidden fees or costs associated with importing products to your region.

Step 6: Evaluate Supplier Communication and Support

Effective communication is vital for a successful partnership. Assess how responsive and helpful the supplier is during your inquiries.

– Look for suppliers who provide clear answers and demonstrate a willingness to assist with technical support.

– Consider their ability to handle after-sales service, warranty claims, and replacement parts.

Step 7: Finalize Agreements and Place Orders

Once you have selected a supplier that meets all your criteria, finalize the terms of the agreement. Ensure that all aspects, including delivery timelines, quality assurance processes, and warranty conditions, are documented.

– Review contracts carefully before signing, ensuring that they align with your expectations and requirements.

– Maintain open lines of communication with the supplier throughout the order process to address any concerns promptly.

By following this checklist, you can streamline your sourcing process for heating elements, ensuring that you partner with a supplier that meets your technical and business needs.

Comprehensive Cost and Pricing Analysis for heating elements supplier Sourcing

What Are the Key Cost Components in Heating Elements Supplier Sourcing?

When sourcing heating elements, understanding the cost structure is crucial for international B2B buyers. Key cost components include:

-

Materials: The type of materials used significantly impacts the price. Common materials include metals like stainless steel and nickel, which can fluctuate based on market conditions.

-

Labor: Labor costs vary by region. Suppliers in regions with higher labor costs may charge more, while those in emerging markets might offer competitive pricing.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Buyers should inquire about how these costs are calculated and factored into pricing.

-

Tooling: Custom tooling for specific heating elements can add to costs. Buyers should consider whether they need standard products or customized solutions, as this will influence tooling expenses.

-

Quality Control (QC): Effective QC processes ensure product reliability and compliance with industry standards. Suppliers with stringent QC measures may charge higher prices, reflecting the value of quality assurance.

-

Logistics: Shipping costs can vary widely depending on the origin, destination, and mode of transport. Understanding the logistics involved in sourcing heating elements is essential for accurate budgeting.

-

Margin: Suppliers typically add a profit margin on top of their costs. This can vary based on competition and market demand.

How Do Price Influencers Affect Heating Elements Sourcing?

Several factors can influence pricing when sourcing heating elements:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in reduced per-unit costs. Buyers should negotiate MOQs to optimize pricing.

-

Specifications and Customization: Custom specifications can lead to higher costs due to specialized manufacturing processes. Clear communication of requirements can help manage costs effectively.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO or CE) may increase costs but also enhance product reliability. Buyers should weigh the benefits of quality against budget constraints.

-

Supplier Factors: Established suppliers with a track record of reliability may charge more due to their reputation. Evaluating multiple suppliers can provide leverage in negotiations.

-

Incoterms: Understanding the chosen Incoterms (International Commercial Terms) can impact overall costs. Buyers must be aware of who bears the shipping risk and costs, which can affect the total price.

What Tips Can Help B2B Buyers Negotiate Better Prices?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Always negotiate pricing, especially for larger orders. Leverage competitor pricing to secure better deals.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs, including maintenance and operational expenses. This comprehensive view can justify higher upfront costs for better quality products.

-

Pricing Nuances: Be aware of regional differences in pricing structures. For instance, suppliers in Europe might have different pricing compared to those in Asia due to varying labor costs and regulatory compliance.

-

Research and Benchmarking: Conduct thorough market research to understand standard pricing and supplier offerings. This knowledge can provide a foundation for negotiations.

-

Supplier Relationship Management: Build strong relationships with suppliers. A good relationship can lead to better pricing, priority on orders, and flexibility on terms.

Conclusion: Understanding Indicative Prices

While prices can vary widely based on the factors discussed, it is essential for buyers to request quotes and breakdowns from multiple suppliers to gain a clear understanding of costs. Each supplier will have its unique pricing structure based on the aforementioned components and influences, making it imperative to conduct due diligence before making purchasing decisions.

Alternatives Analysis: Comparing heating elements supplier With Other Solutions

When evaluating heating solutions for industrial applications, understanding the alternatives to traditional heating elements suppliers is crucial. Various technologies can achieve similar heating objectives, each with its unique advantages and drawbacks. This section provides a comparative analysis of heating elements suppliers against alternative solutions, empowering international B2B buyers to make informed decisions.

Comparison Table of Heating Solutions

| Comparison Aspect | Heating Elements Supplier | Induction Heating System | Infrared Heating Technology |

|---|---|---|---|

| Performance | High efficiency, uniform heating | Rapid heating, very precise | Quick response time, suitable for various materials |

| Cost | Moderate initial investment, variable operating costs | Higher initial costs, lower operating costs | Moderate to high initial investment, energy-efficient |

| Ease of Implementation | Simple installation, requires electrical infrastructure | Requires specialized installation | Generally easy to implement, but needs careful calibration |

| Maintenance | Low maintenance, long lifespan | Low maintenance, durable | Moderate maintenance, needs regular cleaning |

| Best Use Case | General industrial applications | Metalworking, cooking | Heating surfaces, drying applications |

What Are the Advantages and Disadvantages of Induction Heating Systems?

Induction heating systems are known for their rapid heating capabilities and precision. This technology uses electromagnetic fields to heat conductive materials directly, resulting in high efficiency. One of the main advantages is the reduction in energy costs over time, as these systems can be more energy-efficient than traditional heating methods. However, the initial investment can be significantly higher, which might be a barrier for some companies, particularly in emerging markets.

How Does Infrared Heating Technology Compare?

Infrared heating technology provides quick response times and is versatile, making it suitable for a variety of applications, including surface heating and drying processes. Infrared heaters emit radiant heat, which directly warms objects rather than the air, leading to energy savings. While the installation is generally straightforward, the technology requires careful calibration to achieve optimal performance. Maintenance is moderate, as infrared heaters may require cleaning to maintain efficiency.

Conclusion: How Should B2B Buyers Choose the Right Heating Solution?

When selecting a heating solution, B2B buyers should consider several factors, including their specific application requirements, budget constraints, and long-term operational costs. For companies focused on precision and speed, induction heating may be the best option despite the higher initial costs. Conversely, if the goal is to provide general heating across various industrial applications, traditional heating elements suppliers may offer a more cost-effective and straightforward solution. Infrared technology can be a compelling choice for applications requiring rapid heating and energy efficiency. Ultimately, evaluating each alternative against your operational needs will lead to the most beneficial investment.

Essential Technical Properties and Trade Terminology for heating elements supplier

What are the Key Technical Properties for Heating Elements?

When sourcing heating elements, international B2B buyers should be well-versed in several critical specifications that impact performance, safety, and longevity. Understanding these properties helps in making informed purchasing decisions.

1. Material Grade

The material grade of heating elements significantly affects their durability and thermal efficiency. Common materials include nickel-chromium alloys, stainless steel, and ceramic. Each material has unique properties, such as resistance to oxidation and heat conductivity, which are vital for specific applications. Selecting the appropriate material grade ensures optimal performance and extends the lifespan of heating elements.

2. Tolerance Levels

Tolerance levels refer to the permissible limits of variation in the dimensions and performance of heating elements. These specifications are crucial for ensuring that the heating elements fit correctly into the intended application. For example, precise tolerances are necessary in manufacturing processes that require exact heat outputs. Buyers must understand the tolerance requirements to avoid complications during installation and operation.

3. Power Rating

The power rating, usually measured in watts, indicates the amount of energy a heating element consumes. It directly correlates with the element’s heating capacity and efficiency. Buyers should assess the power requirements of their applications to ensure that the heating elements they purchase can meet operational demands without overheating or failing.

4. Operating Temperature Range

The operating temperature range defines the minimum and maximum temperatures at which a heating element can function effectively. This property is critical for applications that involve extreme conditions, such as industrial heating processes. Buyers need to ensure that the heating elements can withstand the specific temperature ranges of their operations to maintain safety and efficiency.

5. Insulation Type

The type of insulation used in heating elements plays a significant role in energy efficiency and safety. Different insulation materials, such as mineral insulation or silicone rubber, offer varying levels of thermal resistance and electrical safety. Understanding insulation types helps buyers select heating elements that align with their safety standards and energy efficiency goals.

What are Common Trade Terms in the Heating Elements Industry?

Familiarity with industry jargon is essential for effective communication and negotiation with suppliers. Here are several key terms every international buyer should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the heating elements industry, buyers often deal with OEMs for custom heating solutions tailored to their specific requirements. Understanding OEM relationships can facilitate better sourcing strategies.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and cost. Buyers should inquire about MOQs when negotiating with suppliers to ensure they can meet their production needs without incurring excess costs.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting a price quote for specific products or services. This term is essential for buyers looking to compare prices and terms from multiple suppliers. A well-prepared RFQ can lead to better pricing and terms, ultimately benefiting the buyer’s bottom line.

4. Incoterms

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of buyers and sellers in international trade. They specify who pays for shipping, insurance, and tariffs, which can significantly affect the overall cost of procurement. Understanding Incoterms is vital for international buyers to avoid unexpected expenses and ensure smooth transactions.

5. Lead Time

Lead time refers to the amount of time it takes for a supplier to fulfill an order after it has been placed. This term is critical for planning and inventory management. Buyers should always clarify lead times to ensure that they can meet their production schedules and avoid delays.

By understanding these essential technical properties and trade terms, international B2B buyers can navigate the heating elements supply chain more effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the heating elements supplier Sector

What Are the Key Market Dynamics and Trends Influencing Heating Elements Suppliers?

The heating elements supplier sector is undergoing significant transformations driven by a combination of technological advancements, regulatory changes, and shifting consumer preferences. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are navigating a landscape marked by increasing demand for energy efficiency and sustainable solutions. As industries globally aim to reduce carbon footprints, suppliers that offer innovative heating solutions—such as electric heating elements and advanced thermal management systems—are becoming increasingly competitive.

Emerging technologies like IoT (Internet of Things) are revolutionizing how heating elements are manufactured and utilized. Smart heating solutions enable real-time monitoring and control, providing businesses with the ability to optimize energy consumption and minimize waste. Furthermore, the rise of automation in production processes is enhancing efficiency and reducing lead times, which is crucial for B2B buyers requiring quick turnaround times.

Regional dynamics also play a significant role. In Europe, for example, stringent energy regulations are pushing manufacturers toward greener technologies, while in Africa and South America, there is a growing emphasis on affordable and accessible heating solutions. B2B buyers should remain vigilant about these regional trends to align their sourcing strategies with local market demands.

How Important Is Sustainability and Ethical Sourcing in the Heating Elements Supplier Sector?

Sustainability and ethical sourcing have become paramount considerations for B2B buyers in the heating elements supplier sector. The environmental impact of production processes and the materials used in manufacturing heating elements cannot be overlooked. Suppliers are increasingly expected to demonstrate transparency in their supply chains, showcasing their commitment to reducing environmental harm.

Green certifications, such as ISO 14001 (Environmental Management) and Energy Star ratings, are becoming essential for suppliers. These certifications not only validate the sustainability practices of a supplier but also assure buyers that they are investing in environmentally friendly products. Additionally, the use of recyclable materials and the implementation of circular economy principles in manufacturing processes are gaining traction, appealing to buyers who prioritize sustainability.

Ethical sourcing is closely linked to sustainability. International buyers must ensure that their suppliers adhere to fair labor practices and do not engage in exploitative practices. This is particularly important for buyers in regions where labor laws may be less stringent. By prioritizing suppliers with robust ethical standards, B2B buyers can contribute to a more sustainable and equitable global supply chain.

What Is the Historical Context Behind Current Trends in Heating Elements Supply?

The evolution of the heating elements supplier sector has been shaped by various industrial revolutions, technological advancements, and environmental considerations. Historically, heating elements were primarily used in industrial applications, with limited focus on efficiency and sustainability. However, the energy crises of the 1970s sparked a shift toward more energy-efficient heating solutions, which set the stage for modern innovations.

The introduction of electric heating elements revolutionized the sector by providing cleaner and more efficient alternatives to traditional heating methods. As environmental awareness grew in the late 20th century, manufacturers began to explore sustainable materials and processes, leading to the development of products that not only meet performance standards but also align with ecological values.

In recent years, the push for smart technology and IoT integration has further transformed the landscape, allowing for enhanced user control and energy management. This historical context highlights how past trends have paved the way for the current focus on sustainability, efficiency, and technological advancement in the heating elements supplier sector, offering valuable insights for today’s B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of heating elements supplier

-

How do I identify a reliable heating elements supplier for international sourcing?

To identify a reliable heating elements supplier, start by researching their reputation in the industry. Look for online reviews, testimonials, and case studies. Verify their certifications and compliance with international quality standards, such as ISO 9001. Engage in direct communication to assess their responsiveness and willingness to provide references. Attending trade shows or industry expos can also help you connect with trustworthy suppliers who have a proven track record. -

What factors should I consider when choosing heating elements for my specific application?

When selecting heating elements, consider factors such as the required temperature range, material compatibility, and energy efficiency. Evaluate the heating element’s power rating and its suitability for your operational environment, including moisture and chemical exposure. Customization options may be necessary to meet specific dimensions or voltage requirements. Consulting with suppliers about their technical expertise can also help ensure you choose the right product for your application. -

What is the minimum order quantity (MOQ) for heating elements, and how does it vary by supplier?

Minimum order quantities (MOQ) for heating elements can vary significantly by supplier, often ranging from 50 to several hundred units. Larger suppliers may offer lower MOQs due to their production capabilities, while smaller manufacturers might have higher MOQs. Always clarify MOQ details during initial discussions to ensure they align with your purchasing needs and budget constraints. Some suppliers may also be open to negotiation based on your long-term commitment. -

What payment terms should I negotiate with my heating elements supplier?

When negotiating payment terms, consider options such as upfront payments, net 30, or net 60 days. It’s advisable to establish a payment structure that balances your cash flow with the supplier’s need for security. Additionally, inquire about discounts for early payment or bulk orders. Make sure to discuss the accepted payment methods, including wire transfers, letters of credit, or escrow services, to ensure a secure transaction. -

How can I ensure quality assurance (QA) when sourcing heating elements internationally?

To ensure quality assurance when sourcing heating elements, request detailed product specifications and quality control certifications from the supplier. Conduct factory audits or arrange for third-party inspections before shipment. Establish clear criteria for product acceptance and discuss the warranty terms. Regular communication throughout the manufacturing process can also help identify and address any potential quality issues early on. -

What logistics considerations should I keep in mind when importing heating elements?

Logistics considerations for importing heating elements include shipping methods, customs regulations, and lead times. Choose a shipping method that balances cost and delivery speed, and ensure compliance with local import regulations. Factor in potential delays due to customs clearance, especially for international shipments. Collaborating with a logistics partner experienced in handling similar products can streamline the process and mitigate risks. -

Can heating elements be customized for my specific industrial needs?

Yes, many suppliers offer customization options for heating elements to meet specific industrial needs. This can include variations in size, wattage, voltage, and materials used. When discussing customization, provide detailed specifications and any unique requirements your application may have. Be sure to inquire about the lead times and costs associated with custom orders, as these can vary based on complexity and volume. -

What are the common applications for heating elements in various industries?

Heating elements are widely used across various industries, including manufacturing, food processing, HVAC, and medical equipment. Common applications include industrial ovens, water heaters, air conditioning units, and laboratory equipment. Understanding the specific requirements of your industry can help you select the most appropriate heating elements that ensure efficiency and compliance with safety standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for heating elements supplier

What Are the Key Takeaways for B2B Buyers in Heating Elements Sourcing?

In the competitive landscape of heating elements, strategic sourcing emerges as a critical approach for international B2B buyers. Key takeaways include understanding supplier capabilities, evaluating product quality, and leveraging technology for supply chain efficiency. Buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships with suppliers who demonstrate reliability and innovation, ensuring they meet the unique demands of their respective markets.

How Can Strategic Sourcing Enhance Your Business?

Embracing strategic sourcing not only reduces costs but also enhances product quality and service levels. By engaging in thorough market research and fostering relationships with multiple suppliers, businesses can mitigate risks associated with supply chain disruptions. The emphasis on sustainability and ethical sourcing is also becoming increasingly important, particularly in Europe, where regulations are stringent.

What’s Next for B2B Buyers in Heating Elements?

As we look to the future, the heating elements market is poised for growth driven by technological advancements and changing consumer preferences. B2B buyers are encouraged to stay informed about market trends and emerging technologies, such as smart heating solutions. By taking a proactive approach to sourcing, businesses can position themselves for success in an evolving landscape. Connect with reputable suppliers today to ensure your heating element needs are met with excellence and innovation.