Discover Top Label Maker Manufacturers: Your Ultimate Guide (2025)

Introduction: Navigating the Global Market for label maker manufacturer

In today’s rapidly evolving marketplace, sourcing the right label maker manufacturer can pose a significant challenge for international B2B buyers. With diverse applications across industries—from retail and logistics to manufacturing and healthcare—the demand for high-quality labeling solutions is on the rise. However, navigating the myriad of options available, particularly when considering suppliers from regions like Africa, South America, the Middle East, and Europe, can be daunting. This comprehensive guide aims to streamline the procurement process by providing actionable insights into identifying reliable manufacturers, evaluating product types, and understanding cost structures.

Throughout this guide, we will explore various types of label makers, including thermal printers, inkjet label printers, and handheld devices, along with their specific applications. We will also delve into the critical process of supplier vetting, offering strategies to ensure quality and reliability, while addressing logistical considerations that may arise in different regions. By equipping buyers with knowledge about pricing, features, and market trends, this resource empowers decision-makers to make informed purchasing choices that align with their business needs.

Whether you are a buyer in Kenya looking to enhance your packaging solutions or an importer in Argentina seeking cost-effective labeling options, this guide serves as your roadmap to successfully navigating the global market for label maker manufacturers. By leveraging the insights provided, you can confidently approach your sourcing strategy, ensuring that you select a partner that meets your operational demands and quality expectations.

Understanding label maker manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Handheld Label Makers | Portable, battery-operated, user-friendly | Retail, small businesses, inventory management | Pros: Cost-effective, easy to use. Cons: Limited printing speed and volume. |

| Desktop Label Printers | High-quality prints, connectable to PCs and networks | Warehousing, shipping, office environments | Pros: Versatile, supports various label sizes. Cons: Higher initial investment. |

| Industrial Label Printers | Heavy-duty, designed for high-volume production | Manufacturing, logistics, and large-scale operations | Pros: Fast printing, durable labels. Cons: Requires maintenance and space. |

| Specialty Label Makers | Customizable for specific industries (e.g., food, medical) | Food packaging, pharmaceuticals, electronics | Pros: Tailored solutions, compliance with regulations. Cons: Potentially higher costs. |

| Multi-Function Label Printers | Combines label printing with other functionalities (e.g., barcode printing) | Retail, inventory management, logistics | Pros: Space-saving, multifunctional. Cons: Complexity may require training. |

What Are the Characteristics of Handheld Label Makers?

Handheld label makers are compact and portable devices designed for easy use in various settings. They typically operate on batteries and are ideal for quick labeling tasks in retail and small business environments. Their user-friendly interfaces allow employees to create labels on the go, making them suitable for inventory management and price tagging. When considering a handheld label maker, B2B buyers should evaluate the battery life, label size options, and ease of use, especially if training is a concern.

How Do Desktop Label Printers Differ from Other Types?

Desktop label printers are designed for more robust labeling needs, often connecting to PCs and networks for enhanced functionality. They produce high-quality labels and are versatile enough to handle various label sizes and materials. Commonly used in warehousing and shipping, these printers are beneficial for businesses that require consistent label production. Buyers should assess the printer’s connectivity options, print speed, and compatibility with different label types to ensure it meets their operational needs.

What Advantages Do Industrial Label Printers Offer?

Industrial label printers are built for high-volume production, making them ideal for manufacturing and logistics environments. These heavy-duty machines can handle large batches of labels quickly, ensuring that operations run smoothly. They are designed to produce durable labels that withstand harsh conditions. B2B buyers should consider factors such as print speed, maintenance requirements, and the printer’s ability to handle various materials when selecting an industrial label printer.

Why Choose Specialty Label Makers for Specific Industries?

Specialty label makers cater to specific industries by offering customizable solutions that meet unique labeling requirements. For instance, these devices often comply with stringent regulations in sectors like food packaging and pharmaceuticals. They allow businesses to create labels that not only convey essential information but also adhere to safety standards. Buyers should examine the compliance features, customization options, and potential costs associated with these specialty label makers to ensure they align with their industry needs.

What Are the Benefits of Multi-Function Label Printers?

Multi-function label printers combine label printing capabilities with other features, such as barcode printing, making them a versatile addition to any business. They are particularly useful in retail and inventory management, where space-saving solutions are essential. These printers can streamline operations by consolidating equipment. B2B buyers should consider the complexity of operation, potential training needs, and the overall cost-effectiveness of integrating multiple functions into a single device when exploring multi-function label printers.

Related Video: Brother P-Touch PT-H110 Label Maker: UNBOXING, REVIEW, AND HOW TO SET IT UP

Key Industrial Applications of label maker manufacturer

| Industry/Sector | Specific Application of label maker manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Product labeling for inventory management | Improves inventory accuracy and reduces errors | Look for durability, speed, and compatibility with existing systems |

| Food and Beverage | Compliance labeling for nutritional information | Ensures compliance with regulations and enhances consumer trust | Focus on waterproof and food-safe materials |

| Pharmaceuticals | Batch and expiry date labeling | Enhances traceability and compliance with safety standards | Ensure labels meet regulatory standards and are resistant to environmental factors |

| Logistics and Warehousing | Shipping labels for parcel tracking | Streamlines logistics and improves shipment accuracy | Consider label size, print speed, and barcode capabilities |

| Retail | Price tagging and promotional labeling | Enhances customer experience and drives sales | Evaluate ease of use, label design options, and integration with POS systems |

How is Label Maker Manufacturing Utilized in the Manufacturing Sector?

In the manufacturing industry, label maker manufacturers provide essential tools for product labeling, particularly for inventory management. These labels assist in tracking materials and finished goods, significantly reducing human error in inventory control. International B2B buyers, especially from regions like Africa and South America, should seek label makers that offer durability and high-speed printing capabilities to keep pace with production demands. Compatibility with existing inventory management systems is also a critical requirement to ensure seamless integration.

What Role Does Label Making Play in the Food and Beverage Industry?

In the food and beverage sector, compliance labeling is crucial for providing nutritional information and ingredient lists. Label maker manufacturers supply devices that produce labels compliant with local and international regulations, thereby enhancing consumer trust and safety. Buyers from the Middle East and Europe should prioritize label makers that utilize waterproof and food-safe materials to withstand various environmental conditions. This not only ensures the longevity of the labels but also meets regulatory standards, which is essential for market access.

Why are Label Makers Important in Pharmaceuticals?

The pharmaceutical industry relies heavily on accurate batch and expiry date labeling to maintain compliance with health regulations. Label maker manufacturers provide specialized solutions that enhance traceability and ensure that products are safe for consumption. International buyers, particularly from Europe, should focus on sourcing label makers that adhere to strict regulatory requirements, including the use of materials that resist environmental factors such as moisture and heat. This attention to detail helps maintain product integrity throughout the supply chain.

How Do Label Makers Enhance Logistics and Warehousing Operations?

In logistics and warehousing, label makers are vital for creating shipping labels that facilitate parcel tracking. Efficient labeling streamlines the logistics process, reducing delays and improving shipment accuracy. B2B buyers, especially from emerging markets in Africa and South America, should consider label makers that offer customizable label sizes and fast print speeds. Additionally, the ability to print barcodes can significantly enhance tracking capabilities, making it easier to manage inventory and shipments.

What Benefits Do Retailers Gain from Label Making?

Retailers utilize label makers for price tagging and promotional labeling, which directly enhances the customer experience and can drive sales. Effective labeling helps in attracting customers and providing essential product information at a glance. For international B2B buyers, especially in competitive markets in Europe, evaluating label makers that offer user-friendly design options and seamless integration with Point of Sale (POS) systems is crucial. This ensures that labels can be easily updated and managed, aligning with dynamic pricing strategies and promotions.

Related Video: AP550 Label Applicator for Flat Surfaces

3 Common User Pain Points for ‘label maker manufacturer’ & Their Solutions

Scenario 1: Limited Compatibility with Existing Systems

The Problem:

Many B2B buyers encounter compatibility issues when integrating new label makers with their existing inventory management or shipping systems. For instance, a logistics company in Kenya may invest in a state-of-the-art label maker, only to discover that it does not sync with their warehouse management software. This can lead to wasted time, increased operational costs, and frustration among employees who are unable to use the new technology effectively.

The Solution:

To avoid compatibility pitfalls, buyers should conduct thorough research during the selection process. Start by clearly defining your current systems and needs. Request technical specifications from potential manufacturers and ensure that their label makers can easily integrate with your existing software. Engaging with manufacturers who provide robust customer support and integration services can also be beneficial. Additionally, consider a trial period with the label maker to test its compatibility before making a larger investment.

Scenario 2: Inadequate Customization Options for Diverse Needs

The Problem:

B2B buyers often face challenges when the label makers they choose do not offer sufficient customization options for their specific branding or operational requirements. For example, a company in Argentina that produces organic products may need to create unique labels that reflect their brand ethos and comply with local regulations. If their label maker cannot accommodate various sizes, colors, or materials, it could hinder their marketing efforts and create compliance issues.

The Solution:

When sourcing label makers, prioritize manufacturers that provide extensive customization options. Look for models that allow for adjustable label sizes and a variety of printing materials. Additionally, inquire about the availability of design software that can help you create custom labels easily. Collaborating closely with the manufacturer during the selection process can ensure that the equipment meets all branding and regulatory requirements. Request samples of labels produced on their machines to evaluate the quality and versatility before finalizing your purchase.

Scenario 3: High Operational Costs Due to Inefficient Labeling Processes

The Problem:

Another common pain point is the high operational costs associated with inefficient labeling processes. A business in the Middle East may find that their current label maker is slow and prone to errors, leading to increased labor costs and delays in shipping. This inefficiency can directly impact customer satisfaction and overall profitability.

The Solution:

To combat high operational costs, it is crucial to invest in label makers that offer high-speed printing and error reduction features. Look for manufacturers that provide advanced technology, such as thermal transfer printing, which can enhance both speed and accuracy. Additionally, consider label makers that come equipped with user-friendly interfaces and automation capabilities. Training your staff on best practices for operating the new equipment can further improve efficiency. Finally, evaluate the total cost of ownership, including maintenance and consumables, to ensure the label maker provides a solid return on investment over time.

Strategic Material Selection Guide for label maker manufacturer

When selecting materials for label makers, manufacturers must consider various factors that affect performance, durability, and cost. Below is an analysis of four common materials used in label maker production, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polypropylene in Label Makers?

Polypropylene (PP) is a popular choice for label makers due to its excellent chemical resistance and durability. It can withstand temperatures ranging from -20°C to 100°C, making it suitable for a variety of environments. Additionally, PP is lightweight, which can reduce shipping costs for international buyers. However, it has limited UV resistance, which may lead to fading in direct sunlight.

Pros: Polypropylene is cost-effective, easy to print on, and offers good moisture resistance. It is also recyclable, appealing to environmentally conscious businesses.

Cons: Its limited UV resistance can be a drawback for outdoor applications, and its mechanical properties may not be as strong as other materials.

Impact on Application: Polypropylene is ideal for indoor labeling and applications where moisture is a concern but may not be suitable for prolonged outdoor exposure.

Considerations for International Buyers: Buyers in regions with stringent environmental regulations, such as Europe, should ensure that the polypropylene used meets compliance standards like REACH. In emerging markets like Kenya and Argentina, cost-effectiveness may be prioritized.

How Does Vinyl Compare as a Material for Label Makers?

Vinyl is another widely used material in label production, known for its flexibility and durability. It can withstand a temperature range of -30°C to 80°C and offers excellent resistance to moisture and chemicals. Vinyl labels are often used in applications requiring high durability, such as industrial labeling.

Pros: Vinyl is highly resistant to tearing and fading, making it suitable for both indoor and outdoor applications. It also adheres well to a variety of surfaces.

Cons: The manufacturing process for vinyl can be more complex and costly compared to other materials, impacting the final price of the labels.

Impact on Application: Vinyl is particularly effective for outdoor labels and applications exposed to harsh conditions, making it a preferred choice for industries like logistics and manufacturing.

Considerations for International Buyers: Buyers from the Middle East, where high temperatures are common, will find vinyl suitable for their labeling needs. Compliance with local regulations regarding PVC usage is essential, particularly in Europe.

What Are the Advantages of Using Paper for Label Makers?

Paper is a traditional material used in label making, favored for its versatility and cost-effectiveness. It is suitable for a range of applications, particularly in environments where labels are not exposed to extreme conditions. Paper labels typically perform well in temperatures up to 70°C.

Pros: Paper is inexpensive and readily available, making it an attractive option for high-volume labeling needs. It is also easy to print on and can be customized easily.

Cons: Paper labels are less durable than synthetic options and may not be suitable for wet or outdoor environments. They can also be prone to tearing.

Impact on Application: Paper is ideal for short-term applications, such as product labels in retail settings, where durability is less of a concern.

Considerations for International Buyers: In regions like South America, where cost is often a primary concern, paper labels can be a viable option. However, buyers should consider the environmental impact and look for sustainably sourced paper.

How Does Polyester Enhance Label Maker Performance?

Polyester (PET) is a high-performance material known for its strength and resistance to chemicals, moisture, and UV light. It can handle temperatures from -40°C to 120°C, making it suitable for a wide range of applications.

Pros: Polyester labels are extremely durable and resistant to fading, making them ideal for long-term use in various environments. They are also compatible with a wide range of printing technologies.

Cons: The cost of polyester can be higher than other materials, which may deter some buyers, especially in price-sensitive markets.

Impact on Application: Polyester is particularly well-suited for industrial labeling, outdoor applications, and environments where labels are exposed to harsh chemicals.

Considerations for International Buyers: Buyers in Europe may find polyester labels compliant with various environmental standards, while those in Africa may need to consider the higher cost against the benefits of durability.

Summary Table of Material Selection for Label Makers

| Material | Typical Use Case for label maker manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Indoor labeling, moisture-prone applications | Cost-effective, recyclable | Limited UV resistance | Low |

| Vinyl | Outdoor labels, industrial applications | Highly durable and tear-resistant | Higher manufacturing complexity | Medium |

| Paper | Retail product labeling | Inexpensive and easy to print | Less durable, prone to tearing | Low |

| Polyester | Industrial labeling, harsh environments | Extremely durable and UV resistant | Higher cost | High |

This strategic material selection guide offers actionable insights for international B2B buyers, helping them make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for label maker manufacturer

What Are the Key Stages in the Manufacturing Process of Label Makers?

The manufacturing process of label makers typically involves several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages helps international B2B buyers assess the quality and reliability of potential suppliers.

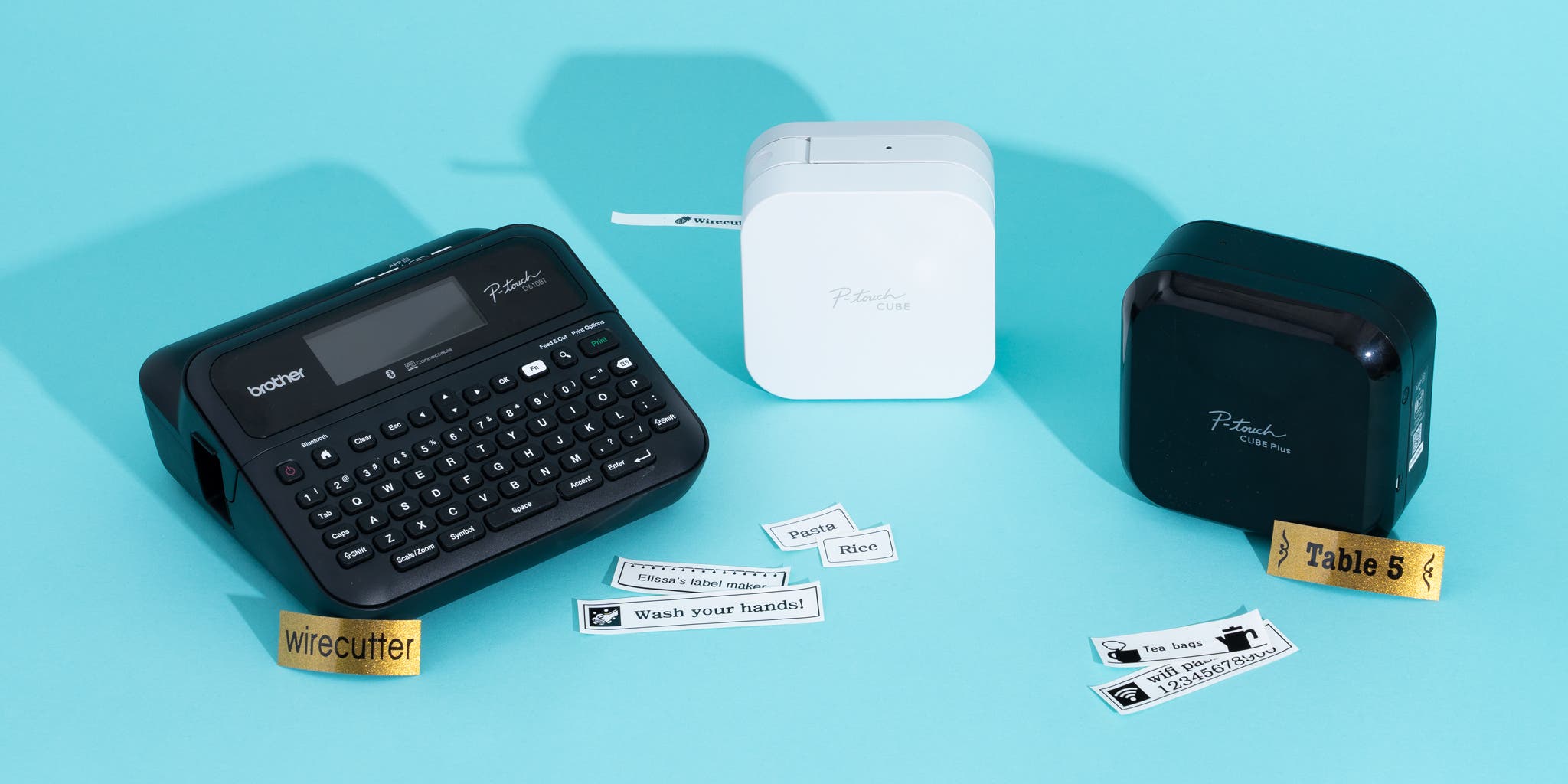

A stock image related to label maker manufacturer.

-

Material Preparation: This initial stage involves selecting high-quality materials that meet industry standards. Common materials include plastics, metals, and adhesives. Suppliers often source these materials from accredited vendors to ensure consistency and durability. For buyers, it’s essential to inquire about the origin of these materials, as this can affect both quality and compliance with international standards.

-

Forming: In this stage, raw materials are shaped into components using various techniques. Injection molding is prevalent for creating plastic parts, while metal parts may be produced through processes like stamping or machining. Buyers should look for manufacturers that utilize advanced forming techniques, as these often result in better precision and reduced waste.

-

Assembly: Once the components are formed, they undergo assembly. This can be done manually or through automated systems, depending on the complexity and scale of production. Automated assembly lines can enhance efficiency and reduce human error, which is particularly beneficial for large orders. B2B buyers should assess the assembly methods used by potential suppliers, as well as their capacity to handle custom orders.

-

Finishing: The final stage involves adding any necessary coatings, labels, or branding to the product. This step not only enhances the aesthetic appeal but also protects the label maker from wear and tear. Buyers should inquire about the finishing processes, such as painting, polishing, or applying protective films, to ensure the end product meets their expectations.

How Does Quality Assurance Impact the Manufacturing of Label Makers?

Quality assurance (QA) is a fundamental component of the manufacturing process, ensuring that each label maker meets specific standards before reaching the customer. For international B2B buyers, understanding the QA protocols of potential suppliers is crucial.

-

International Standards and Certifications: Most reputable label maker manufacturers adhere to international quality standards, such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific certifications like CE (for European markets) and API (for specific applications) are often required. Buyers should verify that suppliers possess these certifications, as they are indicators of a commitment to quality.

-

Quality Control Checkpoints: Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process. These include:

– Incoming Quality Control (IQC): Checking materials and components upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Monitoring production processes to catch defects early.

– Final Quality Control (FQC): Conducting thorough inspections of finished products before they are packaged and shipped.

B2B buyers should request information on the specific QC checkpoints used by suppliers to understand their quality assurance processes better.

- Common Testing Methods for Quality Assurance: Various testing methods are employed to ensure the functionality and durability of label makers. Common tests include:

– Performance Testing: Assessing the label maker’s speed, accuracy, and durability under different conditions.

– Safety Testing: Ensuring compliance with safety standards to prevent hazards during operation.

– Environmental Testing: Evaluating how well the product withstands environmental factors such as humidity and temperature.

Buyers should inquire about the testing methods used and whether they can access test results or certifications.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential for ensuring product reliability.

-

Conducting Supplier Audits: One of the most effective ways to verify a supplier’s quality control processes is through on-site audits. These audits allow buyers to assess the manufacturing environment, review QC practices, and ensure compliance with international standards. Buyers should establish a clear audit process and schedule regular assessments.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including inspection reports, testing results, and certifications. Buyers should review these documents to ensure they align with their quality expectations.

-

Utilizing Third-Party Inspection Services: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control measures. These services can conduct inspections at various stages of production, providing buyers with additional assurance of product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances when it comes to quality control, especially when sourcing from different regions.

-

Understanding Regional Standards: Different regions may have specific quality standards and regulations that suppliers must meet. For example, European buyers often require CE marking, while buyers in the Middle East may focus on GCC standards. Buyers should familiarize themselves with these regional requirements to ensure compliance.

-

Cultural Considerations: Cultural differences can impact communication and expectations regarding quality. Buyers should approach suppliers with an understanding of local practices and norms to foster a collaborative relationship.

-

Building Long-term Relationships: Establishing a long-term partnership with suppliers can lead to improved quality assurance over time. Regular communication, feedback, and collaboration on quality initiatives can help align expectations and enhance product quality.

In summary, understanding the manufacturing processes and quality assurance measures of label maker manufacturers is crucial for international B2B buyers. By focusing on key manufacturing stages, quality control checkpoints, and verification methods, buyers can make informed decisions and ensure they partner with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘label maker manufacturer’

Introduction

When sourcing label maker manufacturers, B2B buyers must navigate a complex landscape of options. This checklist serves as a practical guide to ensure that your procurement process is efficient and effective, addressing critical factors that influence quality, cost, and reliability. By following these steps, you can streamline your sourcing process and make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for the label maker is the first step in the sourcing process. Consider factors such as label size, print quality, materials compatibility, and production speed. Clearly defined specifications will help you communicate your needs to potential suppliers and ensure that the products you receive meet your operational requirements.

- Label Size and Type: Specify the dimensions and type of labels you need (e.g., adhesive, non-adhesive).

- Print Quality: Determine the required resolution and durability of the printed labels.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential label maker manufacturers. Use online directories, trade shows, and industry publications to compile a list of candidates. This step is crucial for finding reliable suppliers who can meet your specific needs.

- Industry Reputation: Look for reviews and ratings from previous clients to gauge supplier reliability.

- Geographic Considerations: Focus on suppliers in regions that align with your logistics and distribution strategies.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, it’s essential to verify their certifications. Certifications can indicate compliance with international quality standards and industry regulations, which is particularly important for buyers in markets such as Africa and South America.

- ISO Certifications: Check for ISO 9001 (quality management) and ISO 14001 (environmental management) certifications.

- Local Compliance: Ensure that the supplier adheres to local regulations relevant to your industry.

Step 4: Request Samples and Prototypes

Once you have shortlisted potential suppliers, request samples or prototypes of the label makers. Testing the products in real-world conditions allows you to assess their performance and suitability for your business operations.

- Quality Assessment: Evaluate the print quality, durability, and functionality of the samples.

- Compatibility Testing: Ensure that the labels work seamlessly with your existing systems and materials.

Step 5: Negotiate Terms and Conditions

Negotiation is a critical phase in the sourcing process. Discuss pricing, payment terms, delivery schedules, and warranty conditions to ensure that you are getting the best deal possible.

- Transparent Pricing: Seek clarity on all costs, including shipping and customs fees.

- Flexible Payment Options: Consider payment terms that align with your cash flow and financial strategies.

Step 6: Establish a Communication Plan

Effective communication is vital for a successful supplier relationship. Establish a communication plan that outlines how often you will check in with the supplier, the preferred channels of communication, and key contacts on both sides.

- Regular Updates: Schedule periodic meetings to discuss production status and address any concerns.

- Crisis Management: Agree on protocols for resolving issues that may arise during the sourcing process.

Step 7: Monitor Supplier Performance

After selecting a manufacturer, continuously monitor their performance to ensure they meet your expectations. Implement key performance indicators (KPIs) related to quality, delivery times, and customer service.

- Feedback Loop: Create a system for providing feedback and addressing performance issues promptly.

- Regular Reviews: Conduct periodic evaluations to assess whether the supplier continues to meet your evolving business needs.

By following this step-by-step checklist, B2B buyers can effectively source label maker manufacturers that align with their operational goals and requirements.

Comprehensive Cost and Pricing Analysis for label maker manufacturer Sourcing

What Are the Key Cost Components in Label Maker Manufacturing?

When evaluating the cost structure of label maker manufacturing, several key components contribute to the overall pricing. Understanding these elements allows international B2B buyers to make informed decisions and negotiate better deals.

-

Materials: The choice of materials significantly impacts the cost. High-quality plastics, metals, and adhesives are common in label makers. Buyers should inquire about the specific materials used and their sourcing, as this can vary by region and affect both price and quality.

-

Labor: Labor costs can vary widely depending on the manufacturer’s location. Regions with lower labor costs, such as certain areas in South America or Africa, may offer competitive pricing. However, it’s essential to consider the skill level of the workforce, as this can influence product quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Buyers should look for manufacturers who optimize their overhead to offer better pricing without compromising quality.

-

Tooling: Initial tooling costs for custom designs can be significant. Buyers should be aware of these costs upfront, especially if they require specific shapes or features in their label makers.

-

Quality Control (QC): Implementing a robust QC process is vital for ensuring product reliability. Manufacturers with stringent QC measures may charge more, but this investment can lead to long-term savings by reducing defects and returns.

-

Logistics: Shipping costs, including transportation and customs duties, can significantly affect the total cost. Understanding the logistics involved in sourcing from different regions is crucial for budget planning.

-

Margin: The manufacturer’s profit margin will vary based on their market positioning and competition. Buyers should be aware of standard margins in the industry to assess pricing fairness.

How Do Price Influencers Affect Label Maker Costs?

Several factors influence the pricing of label makers, which international buyers should consider during the sourcing process.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs. Buyers should negotiate MOQs that align with their needs while maximizing cost savings.

-

Specifications and Customization: Custom specifications can drive up costs. Buyers should clearly outline their requirements and explore whether off-the-shelf solutions are available to minimize expenses.

-

Materials and Quality Certifications: The quality of materials and any certifications (e.g., ISO standards) can affect pricing. Buyers should evaluate the importance of these factors in their purchasing decisions.

-

Supplier Factors: The manufacturer’s reputation, experience, and reliability can influence pricing. Established suppliers may charge a premium for their expertise, but they often provide better service and product quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining responsibilities in shipping and logistics. This knowledge helps buyers avoid unexpected costs and facilitates smoother transactions.

What Tips Can Help International Buyers Achieve Cost-Efficiency?

For B2B buyers from regions like Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency in sourcing label makers.

-

Negotiation Skills: Always be prepared to negotiate. Understanding the manufacturer’s cost structure can provide leverage in discussions, helping you secure better pricing or terms.

-

Total Cost of Ownership (TCO): Consider the TCO, which includes purchase price, maintenance, logistics, and potential downtime costs. A lower initial price may not always equate to better value if long-term costs are high.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, manufacturers in Europe may charge more due to higher labor costs, while those in Africa may offer competitive pricing but varying quality levels.

-

Seek Multiple Quotes: Always request quotes from multiple suppliers. This practice not only provides a benchmark for pricing but also helps in assessing different quality levels and service offerings.

-

Stay Informed on Market Trends: Understanding the latest market trends and technological advancements can aid in making informed purchasing decisions and identifying potential cost-saving opportunities.

Disclaimer on Indicative Prices

It’s important to note that pricing can fluctuate based on market conditions, exchange rates, and specific buyer requirements. Always verify current pricing with suppliers to ensure accurate budgeting.

Alternatives Analysis: Comparing label maker manufacturer With Other Solutions

Understanding Alternatives to Label Maker Manufacturers

In the fast-paced world of international business, especially for B2B buyers in regions like Africa, South America, the Middle East, and Europe, evaluating alternatives to label maker manufacturers is essential. Companies seek solutions that not only meet their labeling needs but also align with their operational efficiency, cost-effectiveness, and scalability. In this section, we will compare traditional label maker manufacturers with two viable alternatives: digital printing solutions and manual labeling methods.

Comparison Table

| Comparison Aspect | Label Maker Manufacturer | Digital Printing Solutions | Manual Labeling Methods |

|---|---|---|---|

| Performance | High-quality, consistent labels | Customizable, high-resolution prints | Variable quality, dependent on manual skill |

| Cost | Moderate initial investment, ongoing supplies | Higher upfront costs, but lower long-term | Low initial cost, labor-intensive |

| Ease of Implementation | User-friendly, requires minimal training | Requires software and printing setup | Simple but time-consuming |

| Maintenance | Regular maintenance needed for optimal performance | Low maintenance, software updates needed | Minimal maintenance |

| Best Use Case | High-volume, consistent labeling needs | Custom designs, short runs, and variable data | Low-volume, one-off labeling tasks |

What Are the Pros and Cons of Digital Printing Solutions?

A stock image related to label maker manufacturer.

Digital printing solutions offer a modern alternative to traditional label makers. One of the primary advantages is their ability to produce high-resolution, customizable labels on-demand. This is particularly beneficial for businesses requiring flexibility in design or those producing short runs of unique labels. However, the initial investment for digital printing equipment can be significant, and it may necessitate training for staff on software and hardware operation. Additionally, while digital printers offer lower maintenance needs, they do require regular software updates to ensure optimal performance.

How Do Manual Labeling Methods Compare?

Manual labeling methods are the most straightforward option, requiring minimal investment in materials like label sheets and markers. This method can be advantageous for businesses with low-volume labeling needs or those that require labels infrequently. However, the quality of manually created labels can vary significantly based on the skill of the operator, leading to inconsistencies. Furthermore, manual labeling can be time-consuming, which may hinder productivity in a fast-paced environment. While this method has its place, it may not suit companies aiming for efficiency or uniformity in their labeling processes.

Making the Right Choice for Your Business Needs

When considering which labeling solution is right for your business, it is crucial to evaluate your specific needs and resources. For organizations with high-volume requirements and a need for consistency, investing in a label maker manufacturer may be the best option. However, if customization and flexibility are priorities, digital printing solutions could offer the best return on investment. For smaller operations or one-time projects, manual labeling might suffice, although it comes with trade-offs in quality and efficiency. Ultimately, the right choice will depend on your operational goals, budget constraints, and the volume of labels required. By analyzing these factors, B2B buyers can make an informed decision that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for label maker manufacturer

Understanding the essential technical properties and trade terminology in the label maker manufacturing industry is crucial for B2B buyers, especially those from diverse markets like Africa, South America, the Middle East, and Europe. This knowledge not only aids in making informed purchasing decisions but also facilitates smoother negotiations and partnerships. Below are key specifications and terminology that every international buyer should be familiar with.

What are the Key Technical Properties of Label Makers?

1. Material Grade

Material grade refers to the quality and type of materials used in the construction of label makers. Common materials include high-impact plastics and metals, which affect durability and performance. For B2B buyers, understanding material grade is vital as it directly influences the longevity and reliability of the equipment, ultimately impacting operational costs.

2. Print Resolution

Print resolution, typically measured in dots per inch (DPI), indicates the clarity and quality of the printed labels. Higher DPI values result in sharper images and text, which is essential for businesses that require high-quality branding or detailed information on labels. Buyers should consider their specific labeling needs when assessing print resolution to ensure the label maker meets their quality standards.

3. Label Width Capacity

Label width capacity specifies the maximum width of labels that a label maker can handle. This is particularly important for businesses that produce varying sizes of labels for different applications. Understanding this property helps buyers select a machine that can accommodate their labeling requirements without the need for multiple devices, thus optimizing investment.

4. Speed of Printing

The speed of printing is measured in labels per minute (LPM) and indicates how quickly a label maker can produce labels. For companies with high-volume labeling needs, a faster machine can significantly enhance productivity. Buyers should evaluate their production volume to determine the appropriate speed that aligns with their operational efficiency.

5. Connectivity Options

Connectivity options, such as USB, Wi-Fi, or Bluetooth, refer to how the label maker interfaces with other devices, including computers and mobile devices. In a digital age, seamless connectivity is critical for integrating label printing into existing workflows. Buyers should prioritize devices that offer versatile connectivity to enhance usability and streamline processes.

What are Common Trade Terms in the Label Maker Industry?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of label makers, understanding OEM relationships can help buyers identify the source of quality and reliability in products. This is particularly important for ensuring that components are interchangeable and compatible with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For international buyers, knowing the MOQ is essential for budgeting and inventory planning. It can also affect shipping costs and lead times, especially for smaller businesses that may not have the capacity to purchase in bulk.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For B2B buyers, issuing an RFQ can help clarify costs, leading times, and other conditions, allowing for better comparison between different suppliers. This process is crucial for negotiating favorable terms and ensuring budget adherence.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to clarify shipping responsibilities, risk transfer, and cost allocation. Familiarity with Incoterms can help mitigate misunderstandings and facilitate smoother trade negotiations.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. This is a critical aspect for B2B buyers, as longer lead times can affect project timelines and inventory management. Understanding lead times from suppliers helps businesses plan better and avoid disruptions in their operations.

In conclusion, being well-versed in these technical properties and trade terms equips international B2B buyers with the knowledge necessary for making informed decisions in the label maker manufacturing sector. This understanding not only enhances purchasing strategies but also fosters better supplier relationships, ultimately leading to more successful business operations.

Navigating Market Dynamics and Sourcing Trends in the label maker manufacturer Sector

What Are the Key Market Dynamics and Trends in the Label Maker Manufacturing Sector?

The label maker manufacturing sector is currently experiencing significant transformation driven by technological advancements and changing consumer preferences. Key global drivers include the rise of e-commerce, which has increased demand for customized packaging solutions. As businesses seek to enhance their branding and operational efficiency, the integration of automation and digital printing technologies is becoming increasingly prevalent. This shift not only enhances production speed but also reduces waste, making it essential for international B2B buyers to consider suppliers that leverage these technologies.

Emerging trends include the adoption of Internet of Things (IoT) capabilities in label makers, enabling real-time tracking and inventory management. This feature is particularly beneficial for B2B buyers in Africa, South America, the Middle East, and Europe, where supply chain transparency is crucial. Additionally, the move towards multifunctional devices that combine printing, cutting, and labeling capabilities is gaining traction, allowing businesses to streamline their operations. Buyers should prioritize manufacturers who offer versatile solutions that can adapt to their specific needs.

Another dynamic to consider is the impact of regional trade agreements and tariffs, which can influence sourcing decisions. For example, buyers from the European Union may benefit from favorable trade conditions when sourcing from specific countries. Understanding these market dynamics allows international buyers to make informed decisions that align with their strategic objectives.

How Is Sustainability Shaping Sourcing Trends in the Label Maker Industry?

Sustainability has become a cornerstone of modern B2B operations, and the label maker manufacturing sector is no exception. As international buyers grow more conscious of environmental impacts, the demand for sustainable products and ethical sourcing practices is on the rise. This trend is particularly relevant for buyers in regions like Africa and South America, where environmental degradation poses significant challenges.

Ethical supply chains are paramount, and buyers should look for manufacturers that prioritize responsible sourcing of raw materials. This includes the use of recyclable and biodegradable materials for labels, which not only reduces waste but also enhances brand reputation. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 can serve as indicators of a manufacturer’s commitment to sustainability.

Moreover, buyers are increasingly seeking suppliers that incorporate energy-efficient production processes. By partnering with manufacturers that invest in renewable energy sources and sustainable practices, businesses can reduce their carbon footprint and appeal to environmentally-conscious consumers. In this context, sustainability is not just a buzzword; it is a competitive advantage that can drive long-term success in the label maker sector.

What Is the Historical Context of Label Maker Manufacturing?

The label maker manufacturing industry has evolved significantly over the past few decades, transitioning from manual processes to sophisticated automated systems. Initially, labels were produced using traditional printing methods, which were labor-intensive and time-consuming. However, the advent of digital printing technology in the late 20th century revolutionized the sector, enabling quicker production times and greater customization options.

As businesses began to recognize the importance of branding and product differentiation, the demand for high-quality labels surged. This led to the development of advanced label-making equipment that could handle a variety of materials and printing techniques. Today, manufacturers are focusing not only on efficiency and quality but also on sustainability and ethical practices, reflecting the changing priorities of international B2B buyers. Understanding this historical evolution is crucial for buyers looking to navigate the current landscape effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of label maker manufacturer

-

How do I choose the right label maker manufacturer for my business needs?

Selecting the right label maker manufacturer involves assessing several factors. Start by defining your specific requirements, such as label size, printing technology (thermal transfer vs. direct thermal), and production volume. Research manufacturers that specialize in your industry, as they will better understand your needs. Additionally, review their reputation through customer testimonials and industry reviews, and consider their ability to provide customization options that fit your branding. Lastly, request samples to evaluate quality before making a commitment. -

What are the key factors to consider when evaluating label maker manufacturers?

When evaluating label maker manufacturers, focus on quality, reliability, and customer support. Check certifications such as ISO for quality assurance and inquire about their production processes. Assess their experience in your specific market and ability to meet your volume needs. It’s also essential to understand their lead times and flexibility in scaling production. Finally, ensure they have a robust customer service structure to assist you post-purchase, especially for troubleshooting and maintenance. -

What customization options are typically available from label maker manufacturers?

Most label maker manufacturers offer a range of customization options, including label size, shape, material (e.g., paper, vinyl), color, and adhesive type. You can also request specific printing features such as barcodes, QR codes, and logos. Some manufacturers may allow for custom software solutions for label design. Before finalizing your supplier, discuss your specific customization needs to ensure they can deliver products that align with your branding and operational requirements. -

What is the minimum order quantity (MOQ) for label makers, and how does it affect pricing?

The MOQ for label makers can vary significantly between manufacturers, typically ranging from a few units to several hundred. Generally, larger MOQs may lead to lower per-unit costs, as manufacturers benefit from economies of scale. However, if your business has lower volume needs, look for manufacturers that offer flexible MOQs or tiered pricing structures. This will help you balance inventory costs with cash flow, especially when entering new markets like Africa or South America. -

What payment terms should I expect when purchasing from a label maker manufacturer?

Payment terms can vary widely among label maker manufacturers. Common arrangements include upfront payments, deposits (often 30-50%), and payment upon delivery or after inspection. For international transactions, consider the implications of currency exchange rates and potential transaction fees. It’s advisable to negotiate terms that align with your cash flow, and always ensure that the payment method is secure and traceable. Establishing a good rapport with your supplier can also lead to more favorable terms over time. -

How can I ensure quality assurance when sourcing label makers internationally?

To ensure quality assurance when sourcing label makers, start by selecting manufacturers with a strong reputation and relevant certifications (e.g., ISO 9001). Request samples to evaluate the quality of their products before placing a larger order. Implement a quality control process, including inspections at different production stages, and consider hiring third-party inspection services, especially for overseas suppliers. Establish clear quality standards and communicate them with your supplier to avoid discrepancies. -

What logistical considerations should I keep in mind when importing label makers?

Importing label makers involves several logistical considerations. First, understand the shipping methods available, such as air freight or sea freight, and choose one based on urgency and budget. Be aware of customs regulations and duties in your country, as these can significantly impact your total costs. Additionally, ensure you have a reliable freight forwarder to handle documentation and transport. Lastly, factor in lead times for production and shipping to plan your inventory effectively. -

What are the common challenges faced by international B2B buyers of label makers, and how can I mitigate them?

Common challenges include language barriers, cultural differences, and varying quality standards. To mitigate these issues, engage in thorough research and clear communication with potential suppliers. Utilize professional translation services if necessary and consider visiting suppliers to establish relationships. Additionally, leverage technology to facilitate communication and document sharing. Joining industry forums or networks can also provide insights and support from other buyers who have navigated similar challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for label maker manufacturer

In the evolving landscape of label maker manufacturing, strategic sourcing emerges as a pivotal approach for international B2B buyers. By leveraging relationships with diverse suppliers, businesses can optimize their procurement processes, ensuring access to high-quality products at competitive prices. Buyers in regions such as Africa, South America, the Middle East, and Europe should prioritize establishing partnerships with manufacturers who not only understand local market dynamics but also align with their sustainability goals and technological advancements.

How can B2B buyers enhance their sourcing strategies for label makers? Focus on conducting thorough supplier evaluations and engaging in long-term collaborations that foster innovation and reliability. This proactive stance not only mitigates risks associated with supply chain disruptions but also enhances product customization to meet specific regional requirements.

Looking ahead, the label maker industry is poised for growth, driven by increasing demand for efficient labeling solutions across various sectors. International buyers are encouraged to stay informed about emerging trends and advancements in technology to remain competitive. By embracing strategic sourcing, businesses can position themselves favorably in the market, ensuring they are not only meeting current demands but also anticipating future opportunities. Engage with manufacturers today to secure a robust supply chain that can adapt to the challenges of tomorrow.