Discover Top Lead Acid Battery Suppliers for Your Business (2025)

Introduction: Navigating the Global Market for lead acid battery supplier

Navigating the global market for lead acid battery suppliers presents unique challenges, particularly for international B2B buyers seeking reliable sources. The complexity of sourcing the right products, ensuring quality, and maintaining cost-effectiveness can be daunting. This guide aims to demystify the process by providing a comprehensive overview of lead acid batteries, including their various types, applications, and critical factors for supplier vetting.

From automotive and renewable energy applications to telecommunications, the demand for lead acid batteries is growing across Africa, South America, the Middle East, and Europe. Buyers will benefit from insights on how to assess suppliers based on quality certifications, production capabilities, and regulatory compliance. Additionally, we will explore cost considerations, enabling buyers to make informed financial decisions while minimizing risks associated with their investments.

By equipping international buyers with the necessary knowledge and tools, this guide empowers them to navigate the complexities of the lead acid battery market effectively. Understanding the nuances of supplier selection, compliance standards, and market trends is essential for making strategic purchasing decisions that align with business goals and operational requirements. Whether you are in Vietnam, France, or any other key market, this guide will serve as your resource for successful sourcing in the lead acid battery sector.

Understanding lead acid battery supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flooded Lead Acid Batteries | Liquid electrolyte, requires maintenance | Automotive, renewable energy storage | Pros: Cost-effective, reliable. Cons: Requires regular maintenance, less portable. |

| AGM (Absorbent Glass Mat) | Sealed design, low maintenance, spill-proof | Telecommunications, UPS systems | Pros: Maintenance-free, safer. Cons: Higher initial cost, sensitive to overcharging. |

| Gel Lead Acid Batteries | Gelled electrolyte, resistant to vibration | Solar energy systems, marine applications | Pros: Longer lifespan, good deep discharge capability. Cons: Limited high current discharge. |

| SLI (Starting, Lighting, Ignition) | Designed for high burst current | Automotive, motorcycles | Pros: Quick start, high power output. Cons: Shorter lifespan under deep cycle use. |

| Deep Cycle Batteries | Designed for repeated deep discharges | Electric vehicles, renewable energy storage | Pros: Longer cycle life, robust design. Cons: Heavier, requires specific charging protocols. |

What Are the Key Characteristics of Flooded Lead Acid Batteries?

Flooded lead acid batteries are characterized by their liquid electrolyte, which necessitates regular maintenance to ensure optimal performance. These batteries are commonly used in automotive applications and renewable energy storage due to their reliability and cost-effectiveness. Buyers should consider the ongoing maintenance requirements and potential space constraints, as these batteries can be bulky and require ventilation.

How Do AGM Batteries Differ from Other Types?

Absorbent Glass Mat (AGM) batteries feature a sealed design that utilizes fiberglass mats to absorb the electrolyte, making them low-maintenance and spill-proof. They are predominantly used in telecommunications and uninterruptible power supply (UPS) systems. While AGM batteries are more expensive upfront, their maintenance-free nature and safety features make them an attractive option for B2B buyers looking for reliability in critical applications.

What Advantages Do Gel Lead Acid Batteries Offer?

Gel lead acid batteries utilize a gelled electrolyte, providing superior resistance to vibration and temperature fluctuations. They are particularly suited for solar energy systems and marine applications where durability is essential. While they boast a longer lifespan and excellent deep discharge capabilities, buyers should note that gel batteries may have limitations in high current discharge scenarios, affecting their performance in certain applications.

Why Choose SLI Batteries for Automotive Needs?

Starting, Lighting, and Ignition (SLI) batteries are specifically designed for high burst current, making them ideal for automotive and motorcycle applications. Their ability to provide quick starts and high power output is crucial for vehicles. However, B2B buyers should be aware that SLI batteries generally have a shorter lifespan when subjected to deep cycle use, which may necessitate more frequent replacements.

What Makes Deep Cycle Batteries Suitable for Renewable Energy?

Deep cycle batteries are engineered for repeated deep discharges, making them a preferred choice for electric vehicles and renewable energy storage systems. Their robust design and longer cycle life provide significant advantages in applications where consistent performance is required. However, buyers must consider the weight and specific charging protocols needed for these batteries to ensure optimal operation and longevity.

Related Video: The Battery Basics: Understanding Lithium-Ion, Lead-Acid and More

Key Industrial Applications of lead acid battery supplier

| Industry/Sector | Specific Application of lead acid battery supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Starting and deep-cycle batteries for vehicles | Reliable power for starting engines and powering accessories | Compliance with international safety standards and regulations |

| Renewable Energy | Energy storage systems for solar and wind applications | Efficient energy storage, enabling renewable energy use | Battery longevity and performance under extreme conditions |

| Telecommunications | Backup power for communication networks | Ensures uninterrupted service and reliability | Capacity to meet peak demand and environmental resilience |

| Material Handling & Logistics | Power sources for forklifts and warehouse equipment | Increased operational efficiency and productivity | Weight, size, and compatibility with existing equipment |

| Emergency Services | Power supply for emergency lighting and medical equipment | Critical support in crisis situations | Fast delivery times and adherence to emergency response standards |

How are Lead Acid Batteries Used in the Automotive Industry?

Lead acid batteries are vital in the automotive sector, primarily for starting vehicles and providing power to electrical systems. They are designed to deliver high bursts of energy to start the engine and can also be used in deep-cycle applications for electric vehicles. For international B2B buyers, especially from regions like Africa and South America, sourcing reliable lead acid batteries that comply with local regulations is crucial. Factors such as battery lifespan, maintenance requirements, and environmental impact should be assessed to ensure alignment with regional automotive standards.

What Role Do Lead Acid Batteries Play in Renewable Energy Applications?

In renewable energy systems, lead acid batteries serve as effective energy storage solutions for solar and wind power installations. They store excess energy generated during peak production times, allowing for a consistent power supply even when production dips. For buyers in the Middle East and Europe, understanding the specific energy demands and climatic conditions is essential. Factors like battery cycle life, charge efficiency, and temperature tolerance will significantly influence the performance of the energy storage system.

How Do Telecommunications Companies Benefit from Lead Acid Batteries?

Telecommunications companies rely on lead acid batteries for backup power to ensure the continuity of services during outages. These batteries maintain critical communication networks, allowing for seamless operations even in emergencies. B2B buyers in this sector, particularly in regions with unstable power supply, should consider sourcing batteries that can handle high discharge rates and have a long service life. Compliance with international standards and the ability to provide rapid deployment during emergencies are also key factors.

What Are the Applications of Lead Acid Batteries in Material Handling and Logistics?

In the material handling and logistics sector, lead acid batteries power forklifts and other warehouse equipment, providing reliable energy for lifting and transporting goods. Their robustness and ability to deliver sustained power make them a preferred choice. For international buyers, especially in Europe and Africa, evaluating the compatibility of battery size and weight with existing equipment is crucial. Additionally, understanding the battery’s performance in various operating conditions will help in making informed purchasing decisions.

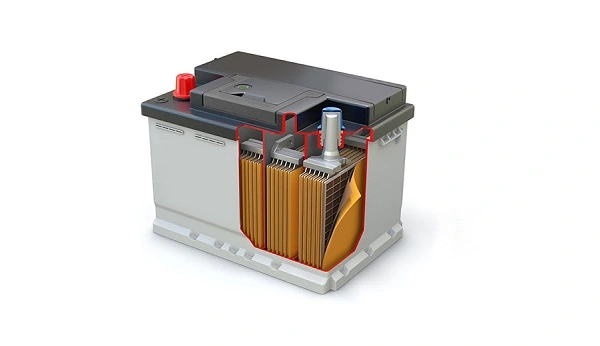

A stock image related to lead acid battery supplier.

How Are Lead Acid Batteries Critical for Emergency Services?

Emergency services utilize lead acid batteries to power essential equipment such as emergency lighting and medical devices. These batteries ensure that critical systems remain operational during power outages, directly impacting response times and service effectiveness. Buyers in this field must prioritize sourcing batteries that meet stringent safety and reliability standards. Fast delivery and the ability to provide customized battery solutions for specific emergency applications are also significant considerations.

Related Video: Lead Acid Battery – Working (Animation) | Charging & Discharging Process

3 Common User Pain Points for ‘lead acid battery supplier’ & Their Solutions

Scenario 1: Difficulty in Ensuring Battery Quality and Compliance

The Problem: International B2B buyers often face challenges in sourcing lead acid batteries that meet specific quality and safety standards. This is particularly critical in regions like Africa and the Middle East, where regulatory frameworks may differ significantly from those in Europe or South America. Buyers may encounter suppliers who provide subpar products that do not comply with international safety regulations, leading to operational failures and potential legal repercussions.

The Solution: To mitigate this issue, buyers should prioritize partnerships with suppliers who have robust quality assurance protocols and certifications. Before finalizing a purchase, it is essential to request documentation that verifies compliance with ISO standards and local regulations. Additionally, conducting factory audits or engaging third-party inspection services can ensure that the manufacturing processes align with quality expectations. Establishing clear communication channels with suppliers can facilitate transparency regarding quality control measures, enabling buyers to make informed decisions.

Scenario 2: High Costs Associated with Lead Acid Battery Maintenance

The Problem: Lead acid batteries are known for their reliability, yet they require regular maintenance to ensure optimal performance. B2B buyers often find themselves burdened with unexpected maintenance costs, which can erode profit margins, especially for companies in sectors such as telecommunications and renewable energy. Issues such as sulfation or improper charging can lead to premature battery failure, resulting in costly replacements and downtime.

The Solution: Buyers should implement a comprehensive maintenance strategy that includes regular monitoring and servicing of lead acid batteries. Investing in smart battery management systems can provide real-time data on battery health and performance, enabling proactive maintenance before issues escalate. Additionally, training staff on proper charging techniques and maintenance procedures can significantly reduce long-term costs. Partnering with suppliers who offer maintenance services or support can also help streamline this process, ensuring that batteries are kept in optimal condition without incurring excessive costs.

Scenario 3: Navigating the Environmental Impact of Lead Acid Batteries

The Problem: With increasing global emphasis on sustainability, B2B buyers face pressure to adopt environmentally friendly practices. The disposal and recycling of lead acid batteries pose significant challenges, particularly in regions with less developed waste management infrastructure. Buyers may struggle to find compliant and responsible recycling solutions, leading to potential environmental liabilities and reputational damage.

The Solution: To address these concerns, buyers should prioritize suppliers who have established recycling programs and demonstrate a commitment to sustainability. Researching local and international regulations on battery disposal can guide businesses in selecting compliant recycling partners. Additionally, buyers can engage in circular economy practices by collaborating with suppliers to design batteries that are easier to recycle or repurpose. Educating employees about proper disposal methods and the importance of recycling can also foster a culture of environmental responsibility within the organization, ultimately enhancing the company’s reputation and compliance with regulations.

Strategic Material Selection Guide for lead acid battery supplier

What Are the Common Materials Used in Lead Acid Batteries?

When selecting materials for lead acid batteries, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Here, we analyze four common materials: lead, sulfuric acid, polypropylene, and glass mat separators.

How Does Lead Impact Battery Performance?

Key Properties: Lead is the primary material used in the plates of lead acid batteries due to its excellent conductivity and ability to withstand high temperatures. Its density and malleability also contribute to the battery’s overall performance.

Pros & Cons: The durability of lead is a significant advantage, as it can endure repeated charge and discharge cycles. However, lead is heavy, which can limit the energy-to-weight ratio of the battery. Additionally, the cost of lead can fluctuate based on market conditions, impacting overall manufacturing costs.

Impact on Application: Lead’s compatibility with sulfuric acid makes it an ideal choice for lead acid batteries. However, lead’s toxicity raises environmental and health concerns, necessitating compliance with regulations in various regions.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of the regulations surrounding lead usage, including the European Union’s REACH regulations and similar standards in other regions. Ensuring compliance with ASTM and DIN standards is also crucial.

What Role Does Sulfuric Acid Play in Battery Functionality?

Key Properties: Sulfuric acid serves as the electrolyte in lead acid batteries, providing the necessary ionic conductivity for energy transfer. Its concentration can significantly affect battery performance, typically ranging from 30% to 50%.

Pros & Cons: Sulfuric acid is relatively inexpensive and widely available, making it a cost-effective choice. However, it is highly corrosive, posing risks during handling and requiring specialized containers and safety protocols.

Impact on Application: The acid’s concentration directly influences the battery’s efficiency and longevity. High concentrations can lead to faster degradation of the lead plates, while lower concentrations may reduce capacity.

Considerations for International Buyers: Buyers must ensure compliance with local hazardous material regulations when transporting sulfuric acid. Familiarity with international standards for chemical handling is essential, particularly in regions with stringent environmental regulations.

Why Is Polypropylene Used in Battery Construction?

Key Properties: Polypropylene is commonly used for the battery casing due to its excellent chemical resistance and lightweight nature. It can withstand high temperatures and is non-conductive, making it safe for use in battery applications.

Pros & Cons: The primary advantage of polypropylene is its durability and resistance to corrosion, which prolongs the battery’s lifespan. However, it may not provide the same level of structural integrity as other materials, potentially leading to issues under extreme conditions.

Impact on Application: Polypropylene’s compatibility with sulfuric acid and other battery components makes it an ideal choice for casing. However, its lower mechanical strength can be a limitation in high-stress environments.

Considerations for International Buyers: Buyers should verify that the polypropylene used meets international standards, such as ASTM D4101 for polymer materials. Understanding local regulations regarding plastic waste disposal is also vital.

How Do Glass Mat Separators Enhance Battery Performance?

Key Properties: Glass mat separators are used to prevent short circuits between the lead plates while allowing ionic flow. They are made from fine glass fibers and are highly absorbent, retaining electrolyte efficiently.

Pros & Cons: The primary advantage of glass mat separators is their ability to enhance battery performance by preventing stratification of the electrolyte. However, they can be more expensive than traditional separators, impacting overall battery cost.

Impact on Application: Glass mat separators are particularly beneficial in applications where vibration and movement are common, such as in automotive batteries. Their absorbent nature helps maintain consistent performance under varying conditions.

Considerations for International Buyers: Buyers should ensure that glass mat separators comply with relevant international standards, such as JIS and DIN. Understanding the specific performance requirements for different applications in various regions is also crucial.

Summary Table of Material Selection for Lead Acid Batteries

| Material | Typical Use Case for Lead Acid Battery Supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lead | Battery plates | Excellent conductivity and durability | Heavy and environmentally hazardous | Medium |

| Sulfuric Acid | Electrolyte | Cost-effective and widely available | Highly corrosive and hazardous | Low |

| Polypropylene | Battery casing | Lightweight and chemical resistant | Lower mechanical strength | Medium |

| Glass Mat Separators | Separators in absorbed glass mat batteries | Enhances performance and prevents stratification | Higher cost compared to traditional separators | High |

This guide provides a comprehensive overview of material selection for lead acid batteries, offering valuable insights for international B2B buyers navigating the complexities of sourcing and compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for lead acid battery supplier

What Are the Key Stages in the Manufacturing Process of Lead Acid Batteries?

The manufacturing process for lead acid batteries involves several critical stages that ensure the production of high-quality, reliable products. Understanding these stages is essential for B2B buyers seeking suppliers that adhere to international standards.

1. Material Preparation

A stock image related to lead acid battery supplier.

The first step in manufacturing lead acid batteries is the preparation of raw materials. This includes the procurement and processing of lead oxide, sulfuric acid, and separators made from materials like polyethylene.

- Lead Oxide Production: Lead is converted into lead oxide through a process called oxidation, where lead metal is exposed to oxygen at high temperatures. This is a crucial component of the battery plates.

- Sulfuric Acid Mixing: The sulfuric acid used in the battery must meet specific purity standards to ensure optimal performance and longevity.

- Separator Preparation: Separators are essential for preventing short circuits and ensuring the efficient flow of ions during the charging and discharging processes.

The quality of these materials directly impacts the battery’s performance and lifespan, making supplier reliability vital.

2. Forming Battery Plates

Once materials are prepared, the next step is forming the battery plates. This involves several techniques:

- Plate Casting: Lead oxide is mixed with a binding agent and cast into flat plates.

- Plate Pressing: The plates are pressed to achieve the desired density, which is crucial for conductivity.

- Plate Drying: Plates are dried to remove excess moisture, which can affect battery performance.

Proper forming techniques ensure that the plates have the appropriate surface area and porosity, which are critical for effective ion exchange.

3. Assembly of Battery Cells

After the plates are formed, they are assembled into cells:

- Stacking: Positive and negative plates are stacked with separators in between to form individual cells.

- Connection: Cells are connected using lead terminals to allow for current flow.

- Electrolyte Filling: The assembled cells are filled with the prepared sulfuric acid electrolyte, which facilitates the chemical reactions necessary for battery operation.

The assembly process must be carried out in a clean environment to prevent contamination that could compromise battery performance.

4. Finishing and Packaging

The final stage involves finishing and packaging the batteries:

- Formation Charge: A formation charge is applied to the assembled batteries to initiate the chemical reactions within. This step is crucial for activating the battery.

- Quality Control: Batteries undergo rigorous testing to ensure they meet quality standards before packaging. This includes checking voltage, capacity, and leak resistance.

- Labeling and Packaging: Once approved, batteries are labeled according to regulations and packaged for shipment.

Proper packaging is essential to prevent damage during transport and ensure compliance with international shipping regulations.

How Is Quality Assurance Implemented in Lead Acid Battery Manufacturing?

Quality assurance is a critical component of lead acid battery manufacturing, ensuring that the final products meet both domestic and international standards.

Relevant International Standards for Quality Assurance

International standards play a significant role in guiding the quality assurance processes for lead acid batteries. Key standards include:

- ISO 9001: This standard outlines criteria for a quality management system and is applicable to any organization. It focuses on meeting customer expectations and delivering satisfaction.

- CE Certification: For suppliers in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards.

- API Standards: In regions where API standards apply, they help ensure the quality and safety of products used in various industries.

Adhering to these standards not only enhances product reliability but also facilitates market access for international buyers.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints throughout the manufacturing process help ensure that each stage meets the required standards:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify issues before they escalate. This includes checking dimensions, weights, and chemical compositions.

- Final Quality Control (FQC): The final products undergo comprehensive testing, including performance tests and safety checks, before they are approved for shipment.

Each checkpoint serves as a safeguard against defects, ensuring that only high-quality batteries reach the market.

Common Testing Methods for Lead Acid Batteries

A variety of testing methods are employed to verify the quality and performance of lead acid batteries, including:

- Capacity Testing: Determines the battery’s ability to hold and deliver charge.

- Cycle Life Testing: Assesses how many charge/discharge cycles a battery can undergo before its capacity significantly diminishes.

- Leak Testing: Ensures that there are no leaks in the battery casing, which is crucial for safety and performance.

These tests help suppliers provide reliable products and give buyers confidence in their purchases.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are some actionable insights:

Conducting Supplier Audits

Performing audits of potential suppliers can provide a detailed understanding of their manufacturing processes and quality assurance measures. Focus on:

- Factory Visits: Observe the manufacturing environment and practices in action.

- Quality Management Systems: Review documentation related to their quality control processes and certifications.

- Employee Training: Assess the training programs in place for staff involved in production and quality assurance.

Requesting Quality Control Reports

Buyers should request detailed quality control reports from suppliers. These reports should include:

- Test Results: Documentation of performance tests conducted on the batteries.

- Non-Conformance Reports: Information on any defects found during the manufacturing process and how they were addressed.

- Compliance Certificates: Proof of adherence to international standards and any relevant regulatory requirements.

Having access to these documents can help buyers make informed decisions about their suppliers.

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These inspections can cover:

- Production Processes: A thorough examination of the manufacturing stages to ensure compliance with standards.

- Final Product Evaluation: Testing samples of finished products to verify quality before shipment.

Third-party inspections can add an extra layer of assurance for international buyers concerned about product quality.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing lead acid batteries internationally, buyers must be aware of specific nuances in quality control:

- Regulatory Compliance: Different countries have varying regulations regarding battery manufacturing and safety. Buyers should ensure that suppliers comply with both local and international regulations.

- Cultural Differences: Understanding the cultural context of suppliers can enhance communication and lead to better quality outcomes. Establishing clear expectations and maintaining open lines of communication are essential.

- Supply Chain Transparency: Buyers should seek suppliers who are transparent about their sourcing and manufacturing processes. This transparency can help mitigate risks associated with substandard materials and practices.

Navigating these nuances effectively can lead to successful partnerships and high-quality battery procurement.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lead acid battery supplier’

In the rapidly evolving market for lead-acid batteries, international B2B buyers must adopt a systematic approach to sourcing suppliers. This checklist provides actionable insights to guide you through the procurement process, ensuring you select a reliable partner who meets your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for effective sourcing. Outline the required battery types, capacities, and performance standards specific to your applications. Consider factors such as operating temperature, cycle life, and intended use (e.g., automotive, renewable energy storage). This clarity will help filter potential suppliers who can meet your exact needs.

Step 2: Conduct Market Research

Understanding the landscape of lead-acid battery suppliers is crucial. Research potential vendors in Africa, South America, the Middle East, and Europe. Use online databases, industry reports, and trade publications to identify reputable companies. Pay attention to market trends, which can inform your choice of supplier based on their technological advancements and competitive positioning.

Step 3: Verify Supplier Certifications

Before engaging with a supplier, ensure they possess relevant certifications and compliance with international standards. Look for ISO certifications, quality management systems, and environmental compliance (e.g., RoHS, REACH). These certifications demonstrate a commitment to quality and safety, reducing the risk of purchasing substandard products.

Step 4: Evaluate Supplier Financial Stability

Assessing the financial health of a potential supplier can mitigate risks associated with order fulfillment. Request financial statements or credit reports to gauge their stability and ability to meet large orders. Suppliers with strong financial backing are more likely to invest in quality and maintain consistent production levels.

Step 5: Request Samples and Conduct Quality Testing

To ensure product quality, request samples of lead-acid batteries from shortlisted suppliers. Conduct thorough testing to evaluate performance against your specifications. Look for indicators such as charge retention, discharge rates, and durability. This step is vital in identifying any potential quality issues before placing bulk orders.

Step 6: Assess Logistics and Delivery Capabilities

Understanding a supplier’s logistics and delivery capabilities is crucial for timely project execution. Inquire about their shipping methods, lead times, and ability to handle customs clearance in your region. Efficient logistics can significantly affect your supply chain’s reliability, especially when operating in diverse markets.

Step 7: Engage in Negotiations and Contracts

Once you’ve identified a suitable supplier, initiate negotiations to secure favorable terms. Discuss pricing, payment terms, and warranty conditions comprehensively. Ensure all agreements are documented in a formal contract that outlines responsibilities, delivery schedules, and recourse in the event of disputes. A well-defined contract protects both parties and fosters a long-term partnership.

By following this checklist, B2B buyers can enhance their sourcing strategy for lead-acid batteries, ensuring they partner with suppliers who align with their technical and operational requirements. This strategic approach not only mitigates risks but also contributes to building lasting supplier relationships.

Comprehensive Cost and Pricing Analysis for lead acid battery supplier Sourcing

What Are the Key Cost Components in Sourcing Lead Acid Batteries?

Understanding the cost structure of lead acid battery suppliers is essential for international B2B buyers. The primary cost components include:

-

Materials: The main raw materials for lead acid batteries are lead, sulfuric acid, and plastic. Lead prices can fluctuate significantly based on global market trends, impacting overall battery costs. Buyers should monitor lead market trends and consider suppliers that offer price stability.

-

Labor: Labor costs vary by region and can significantly influence the overall pricing. Countries with higher labor costs may reflect this in their pricing, while those with lower labor costs can offer competitive rates.

-

Manufacturing Overhead: This includes expenses related to factory operation, such as utilities, maintenance, and administrative costs. Efficient manufacturing processes can lower these costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Initial tooling and setup costs can be substantial, particularly for custom battery designs. Buyers should inquire about these costs, especially when considering bespoke solutions.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability, which can add to the cost. However, investing in QC often reduces long-term costs associated with product failures.

-

Logistics: Shipping and handling costs are critical in international sourcing. Factors such as distance, mode of transport, and customs duties can all influence logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Understanding the average margins in your target market can aid in evaluating supplier pricing.

How Do Price Influencers Affect Lead Acid Battery Costs?

Several factors can influence the pricing of lead acid batteries:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to discounts. Buyers should assess their needs and negotiate for better pricing based on order size.

-

Specifications and Customization: Customized batteries tailored to specific applications may incur additional costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO, CE) can raise costs. Buyers must decide the level of quality necessary for their applications and whether the investment aligns with their budget.

-

Supplier Factors: The reputation and reliability of a supplier can influence pricing. Established suppliers may charge a premium, but they often provide assurances regarding product quality and service.

-

Incoterms: Understanding shipping terms (Incoterms) is vital, as they dictate who bears the costs and risks during transport. Buyers should negotiate favorable terms to minimize total costs.

What Are the Best Negotiation Tips for International B2B Buyers?

When sourcing lead acid batteries, particularly from regions like Africa, South America, the Middle East, and Europe, consider the following negotiation strategies:

-

Emphasize Total Cost of Ownership (TCO): Rather than focusing solely on upfront costs, discuss the total cost of ownership, including maintenance and disposal. This broader perspective can reveal more cost-effective solutions.

-

Leverage Local Insights: Understanding local market conditions, including economic factors and supplier behaviors, can enhance negotiation power. Buyers should conduct thorough research to identify potential cost-saving opportunities.

-

Build Long-Term Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms over time. Consider creating partnerships that benefit both parties.

-

Explore Alternative Suppliers: Don’t hesitate to look beyond established suppliers. Emerging markets may offer competitive pricing without compromising quality.

-

Stay Informed on Market Trends: Keeping abreast of global lead prices and market dynamics can inform your negotiations, allowing you to time purchases strategically.

Conclusion and Disclaimer on Pricing Insights

While this analysis provides a comprehensive overview of cost structures and pricing influences in sourcing lead acid batteries, prices can vary widely based on specific circumstances, supplier negotiations, and market conditions. Therefore, it’s crucial for buyers to conduct thorough due diligence and seek multiple quotes to ensure they are getting the best value for their investment.

Alternatives Analysis: Comparing lead acid battery supplier With Other Solutions

When considering energy storage solutions, B2B buyers must evaluate various alternatives to lead acid batteries. While lead acid batteries have been widely used for decades, emerging technologies offer different advantages and drawbacks that can affect operational efficiency, cost-effectiveness, and environmental impact.

| Comparison Aspect | Lead Acid Battery Supplier | Lithium-Ion Battery Supplier | Nickel-Metal Hydride Battery Supplier |

|---|---|---|---|

| Performance | Moderate energy density; reliable for short-term use | High energy density; longer lifespan | Moderate energy density; good for hybrid applications |

| Cost | Lower initial cost but higher lifecycle costs | Higher initial investment; lower lifecycle costs | Moderate initial cost; good balance of lifespan and performance |

| Ease of Implementation | Widely available and easy to install | Requires specialized knowledge for installation | Similar to lead acid, but may require specific handling |

| Maintenance | Regular maintenance needed; prone to sulfation | Minimal maintenance; longer intervals | Requires periodic maintenance; less than lead acid |

| Best Use Case | Starting engines, backup power | Electric vehicles, renewable energy storage | Hybrid vehicles, consumer electronics |

What are the Advantages and Disadvantages of Lithium-Ion Batteries?

Lithium-ion batteries are increasingly popular due to their high energy density and longevity. They can last up to 10 years or more, reducing the frequency of replacement. However, they come with a higher initial cost, which can be a barrier for some businesses. Additionally, while they require minimal maintenance, installation may necessitate specialized knowledge, which could lead to higher upfront costs in training or hiring skilled personnel.

Why Consider Nickel-Metal Hydride Batteries?

Nickel-metal hydride (NiMH) batteries offer a middle ground between lead acid and lithium-ion technologies. They are commonly used in hybrid vehicles and consumer electronics due to their moderate energy density and good performance. The initial costs are moderate, making them an appealing option for businesses looking for a balance between cost and performance. However, they do require some maintenance, which could affect operational efficiency.

How Should B2B Buyers Choose the Right Battery Solution?

When selecting the most appropriate battery solution, B2B buyers should consider their specific use cases, budget constraints, and maintenance capabilities. Businesses focused on short-term energy storage and cost-effectiveness may still find lead acid batteries to be a suitable option. However, for those looking for long-term solutions with higher efficiency and lower maintenance needs, investing in lithium-ion or nickel-metal hydride batteries may be more beneficial in the long run. Understanding the unique strengths and weaknesses of each option can lead to informed decisions that align with organizational goals and sustainability initiatives.

Essential Technical Properties and Trade Terminology for lead acid battery supplier

What Are the Key Technical Properties of Lead Acid Batteries?

1. Material Composition: Why It Matters in Battery Performance

Lead acid batteries primarily consist of lead dioxide (PbO2) as the positive plate, sponge lead (Pb) as the negative plate, and a sulfuric acid (H2SO4) electrolyte. The purity and grade of these materials directly influence the battery’s efficiency, lifespan, and overall performance. Buyers should ensure that suppliers provide detailed specifications regarding the material grade to avoid subpar products that may lead to increased maintenance costs and reduced operational efficiency.

2. Capacity Rating: Understanding Energy Storage

The capacity of a lead acid battery is typically measured in ampere-hours (Ah). This rating indicates how much energy the battery can store and deliver over a specific period. For B2B buyers, understanding the capacity rating is crucial for selecting batteries that meet the energy demands of their applications, whether for backup power, electric vehicles, or renewable energy storage systems.

3. Cycle Life: Evaluating Longevity and Cost Efficiency

Cycle life refers to the number of complete charge and discharge cycles a battery can undergo before its capacity falls below a predetermined level (usually 80% of its original capacity). A longer cycle life translates into lower replacement costs and better value for businesses. Buyers should inquire about the cycle life under various operating conditions to ensure that the batteries will meet their long-term needs.

4. Self-Discharge Rate: Assessing Battery Maintenance Needs

Self-discharge rate indicates how quickly a lead acid battery loses its charge when not in use. A lower self-discharge rate means that batteries can hold their charge longer, which is particularly important for applications where batteries are stored for extended periods. This property helps buyers minimize maintenance and ensures readiness when the batteries are needed.

5. Temperature Tolerance: Ensuring Reliability in Diverse Environments

Lead acid batteries operate efficiently within a specific temperature range. Extreme temperatures can adversely affect performance and lifespan. Buyers should seek batteries with defined temperature tolerance specifications to ensure reliability in varied climates, especially in regions like Africa and the Middle East, where temperature fluctuations can be significant.

What Are Common Trade Terms Used by Lead Acid Battery Suppliers?

1. OEM (Original Equipment Manufacturer): What Does It Signify?

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of lead acid batteries, understanding OEM relationships helps buyers identify quality standards and compatibility with existing systems or machinery.

2. MOQ (Minimum Order Quantity): Why It Matters for B2B Buyers

MOQ is the smallest quantity of a product that a supplier is willing to sell. For buyers, knowing the MOQ is essential for budgeting and inventory management. This term can greatly influence purchasing decisions, especially for smaller businesses or those looking to test new products.

3. RFQ (Request for Quotation): How to Use This Tool

An RFQ is a document that buyers send to suppliers to request pricing and other details for specific products. This tool is vital for B2B transactions, allowing buyers to compare offers, negotiate terms, and ensure they receive the best value for their investment.

4. Incoterms (International Commercial Terms): Understanding Shipping Responsibilities

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in the shipping process. Familiarity with these terms helps buyers clarify who is responsible for shipping costs, insurance, and risk during transportation, which is crucial for international trade, particularly for buyers in Africa and South America.

5. CCA (Cold Cranking Amps): What It Indicates About Battery Performance

CCA measures a battery’s ability to start an engine in cold temperatures. This specification is particularly important for buyers in colder climates or those using batteries in automotive applications. Understanding CCA ratings helps ensure that selected batteries will perform reliably under specific conditions.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that enhance operational efficiency and reduce costs in their lead acid battery procurement processes.

Navigating Market Dynamics and Sourcing Trends in the lead acid battery supplier Sector

What Are the Current Trends Shaping the Lead Acid Battery Supplier Market?

The lead acid battery market is experiencing dynamic shifts driven by a combination of technological advancements and evolving consumer needs. Globally, the increasing demand for energy storage solutions, particularly from renewable sources, is a primary driver. Countries in Africa and South America are investing heavily in infrastructure development, leading to a surge in demand for reliable energy storage options. In the Middle East, the push for sustainable energy solutions is further accelerating the growth of the lead acid battery sector.

Emerging technologies, such as smart battery management systems and improvements in recycling processes, are reshaping the sourcing landscape. International B2B buyers should be aware of these innovations as they enhance battery efficiency and longevity. The integration of IoT (Internet of Things) in battery management is also gaining traction, providing real-time monitoring and optimization of battery performance. This trend is particularly relevant for European markets, where regulatory compliance and energy efficiency standards are stringent.

Moreover, the market dynamics are influenced by fluctuating lead prices and geopolitical factors. Buyers must navigate these complexities by establishing robust relationships with suppliers and considering diversified sourcing strategies. Building a resilient supply chain that can withstand market volatility is crucial for companies looking to maintain a competitive edge.

How Is Sustainability Impacting the Lead Acid Battery Supply Chain?

Sustainability is becoming a pivotal factor in the lead acid battery supply chain, influencing both sourcing and purchasing decisions. The environmental impact of lead mining and battery disposal has prompted a shift towards more sustainable practices. Ethical sourcing is not just a regulatory requirement but a competitive differentiator in today’s market. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers who demonstrate commitment to sustainable practices, including the use of recycled lead and adherence to environmental regulations.

The adoption of ‘green’ certifications is also gaining traction. Certifications such as ISO 14001 for environmental management systems and the Responsible Recycling (R2) certification highlight suppliers’ commitment to minimizing environmental impact. Buyers should seek out these certifications when evaluating potential suppliers, ensuring that their sourcing practices align with global sustainability standards.

Furthermore, as the demand for electric vehicles (EVs) and renewable energy solutions grows, lead acid battery manufacturers are increasingly investing in research and development for greener technologies. This focus on sustainable innovation not only addresses environmental concerns but also meets the growing consumer demand for eco-friendly products, making it a strategic consideration for B2B buyers.

What Is the Historical Context of the Lead Acid Battery Market?

The lead acid battery has a long history, dating back to its invention by French engineer Gaston Planté in 1859. Initially used for telegraphy, these batteries have evolved significantly, becoming the preferred choice for automotive applications and energy storage systems. Over the decades, the lead acid battery market has expanded to encompass various sectors, including telecommunications, uninterruptible power supplies (UPS), and renewable energy storage.

The evolution of lead acid battery technology has led to improvements in efficiency, cycle life, and safety. The introduction of absorbed glass mat (AGM) and gel battery technologies has further enhanced performance, making lead acid batteries suitable for a broader range of applications. Understanding this historical context is essential for B2B buyers, as it highlights the robustness and adaptability of lead acid technology in meeting changing energy demands.

In summary, as international B2B buyers navigate the complexities of the lead acid battery market, being informed about current trends, sustainability practices, and historical developments will empower them to make strategic sourcing decisions that align with their business objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of lead acid battery supplier

-

How can I identify a reliable lead acid battery supplier?

To identify a reliable lead acid battery supplier, start by researching their industry reputation through reviews and testimonials. Check if they have certifications such as ISO standards, which indicate adherence to quality management systems. Engage with previous clients to gauge their experiences, and ask for samples of their products to evaluate quality. Additionally, verify their financial stability and supply chain capabilities to ensure they can meet your demands consistently. -

What are the key factors to consider when sourcing lead acid batteries internationally?

When sourcing lead acid batteries internationally, consider factors such as product quality, compliance with international safety standards, and the supplier’s ability to meet your specific requirements. Evaluate shipping logistics, including costs, lead times, and customs regulations for your region. Additionally, consider currency fluctuations and payment terms that may affect your overall budget. Building a strong communication channel with the supplier is also crucial for smooth transactions. -

What is the minimum order quantity (MOQ) for lead acid batteries?

The minimum order quantity (MOQ) for lead acid batteries varies by supplier, typically ranging from 100 to 1,000 units. This depends on the supplier’s production capacity and the specific battery types you require. It’s advisable to discuss your needs directly with suppliers to negotiate favorable terms, especially if you are looking for custom solutions or if you are a first-time buyer. -

What payment terms should I expect when working with a lead acid battery supplier?

Payment terms can vary significantly among lead acid battery suppliers. Common arrangements include a deposit upfront (usually 30-50%) with the balance due upon delivery, or payment via letters of credit for larger orders. Be sure to clarify the terms before finalizing agreements, as well as any penalties for late payments or discounts for early settlements. Understanding these terms can help you manage cash flow effectively. -

How can I ensure quality assurance for lead acid batteries from suppliers?

To ensure quality assurance, request a detailed quality control plan from your supplier. This should include testing protocols for battery performance, safety, and durability. Look for suppliers that conduct regular third-party audits and have robust certification processes in place. Establishing a clear contract that outlines quality expectations and penalties for non-compliance can also safeguard your interests. -

What logistics considerations should I be aware of when importing lead acid batteries?

Importing lead acid batteries involves several logistics considerations, such as selecting the appropriate shipping method (air freight vs. sea freight) based on urgency and cost. Be aware of regulations regarding hazardous materials, as lead acid batteries are classified as such. Ensure your supplier provides all necessary documentation for customs clearance, and consider working with a logistics partner experienced in handling chemical shipments to navigate potential challenges. -

How do I assess the environmental compliance of lead acid battery suppliers?

Assessing the environmental compliance of lead acid battery suppliers involves verifying their adherence to local and international environmental regulations. Request documentation of their waste management practices and recycling programs. Suppliers should also be able to demonstrate compliance with directives like the Waste Electrical and Electronic Equipment (WEEE) Directive in Europe. Engaging with suppliers who prioritize sustainability can enhance your company’s reputation and reduce environmental impact. -

What customization options are typically available for lead acid batteries?

Many suppliers offer customization options for lead acid batteries, including variations in size, capacity, and terminal configurations to meet specific applications. You may also request custom labeling and packaging that align with your branding needs. Discuss your requirements early in the negotiation process to ensure the supplier can accommodate your requests. Be prepared to provide technical specifications to facilitate the customization process effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for lead acid battery supplier

What Are the Key Takeaways for Strategic Sourcing in Lead Acid Batteries?

In the evolving landscape of lead acid battery supply, strategic sourcing remains a pivotal element for international B2B buyers. It empowers companies to optimize their procurement processes, ensuring that they not only secure competitive pricing but also guarantee product quality and compliance with international safety standards. Understanding the health and environmental impacts of lead is crucial, particularly in regions like Africa, South America, the Middle East, and Europe, where regulatory frameworks can vary significantly.

How Can Buyers Prepare for Future Trends in Lead Acid Battery Supply?

As the demand for energy storage solutions increases, international buyers should anticipate shifts toward more sustainable and technologically advanced battery options. Engaging with suppliers who prioritize innovation and adhere to stringent safety protocols will enhance supply chain resilience. Additionally, considering suppliers’ track records in sustainability can align purchasing decisions with global environmental goals.

What Steps Should Buyers Take Next?

For B2B buyers in regions such as Vietnam and France, it is essential to remain proactive in identifying reliable suppliers that match their specific needs. Establishing partnerships based on transparency and mutual benefit will not only streamline sourcing but also foster long-term growth. Embrace the opportunity to leverage strategic sourcing as a tool for competitive advantage in the lead acid battery market. The future is bright for those who invest in the right partnerships today.