Discover Top LED Screen Manufacturers: Your Complete Guide (2025)

Introduction: Navigating the Global Market for LED Screen Manufacturers

Navigating the global market for LED screen manufacturers presents a significant challenge for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. With the rapid advancements in technology and a plethora of options available, sourcing high-quality LED screens that meet specific business needs can be daunting. This guide aims to simplify the decision-making process by providing a comprehensive overview of various LED screen types, their applications, and the nuances of supplier vetting.

In this guide, you will discover essential insights into the different categories of LED screens, including indoor and outdoor options, and their respective uses across industries such as advertising, entertainment, and retail. We delve into the critical aspects of evaluating suppliers, ensuring quality, and assessing cost implications, allowing buyers to make informed choices that align with their budgetary constraints and operational requirements.

Empowering international B2B buyers with actionable insights, this resource serves as a valuable tool in navigating the complexities of the LED screen market. By understanding the intricacies of sourcing, potential pitfalls, and best practices, businesses can enhance their procurement strategies, ultimately leading to better investment decisions and improved operational efficiency. Whether you are in Indonesia, Egypt, or any other region, this guide provides the foundation for successful sourcing and partnerships with reliable manufacturers.

Understanding LED Screen Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Indoor LED Displays | High resolution, vibrant colors, customizable sizes | Retail advertising, corporate events | Pros: Great visual impact; Cons: Higher cost for quality. |

| Outdoor LED Displays | Weather-resistant, high brightness, large formats | Billboards, stadiums, outdoor events | Pros: Visibility in sunlight; Cons: Requires robust mounting. |

| Transparent LED Screens | Semi-transparent, lightweight, aesthetic appeal | Retail windows, exhibitions | Pros: Innovative design; Cons: Limited visibility from angles. |

| Flexible LED Panels | Bendable structure, lightweight, versatile designs | Creative installations, signage | Pros: Adaptable to various shapes; Cons: May require specialized installation. |

| Mini LED Displays | Enhanced contrast, improved color accuracy | High-end retail, broadcasting | Pros: Superior image quality; Cons: Generally more expensive. |

What Are the Key Characteristics of Indoor LED Displays?

Indoor LED displays are designed for high-resolution and vibrant color output, making them ideal for environments where visual impact is paramount. They are commonly used in retail advertising and corporate events, where engaging presentations can significantly influence consumer behavior. Buyers should consider factors like pixel pitch and brightness, as these can affect clarity and visibility in different lighting conditions.

How Do Outdoor LED Displays Differ from Indoor Options?

Outdoor LED displays are built to withstand harsh weather conditions and are generally much brighter than their indoor counterparts. This makes them suitable for billboards, stadiums, and other outdoor events where visibility is crucial, even in direct sunlight. When purchasing, businesses should evaluate the durability and mounting requirements to ensure long-term performance.

What Makes Transparent LED Screens Unique for B2B Applications?

Transparent LED screens offer a semi-transparent design that allows for creative display solutions in retail windows and exhibitions. These screens can enhance aesthetic appeal while still providing advertising space. However, buyers should consider their visibility from various angles, as the effectiveness can diminish depending on the viewer’s position.

Why Choose Flexible LED Panels for Innovative Installations?

Flexible LED panels are designed to be bendable and lightweight, allowing for unique installations that can adapt to various shapes and sizes. This versatility makes them popular for creative signage and artistic displays. Businesses should account for installation complexities and potential additional costs when opting for this innovative solution.

What Advantages Do Mini LED Displays Offer Over Traditional Options?

Mini LED displays utilize advanced technology to provide enhanced contrast and improved color accuracy, making them an excellent choice for high-end retail environments and broadcasting applications. While they deliver superior image quality, potential buyers should be aware that these displays generally come at a higher price point, which may impact budget considerations.

Related Video: OLED, QLED, or Mini-LED? Which to TV Buy in 2025

Key Industrial Applications of LED Screen Manufacturers

| Industry/Sector | Specific Application of LED Screen Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Digital Signage and Advertising Displays | Enhances customer engagement and boosts sales through targeted ads. | Resolution, size, brightness, and outdoor capability. |

| Events and Entertainment | Large-Scale Video Walls for Concerts and Festivals | Provides immersive experiences, attracting larger audiences. | Portability, ease of setup, and weather resistance. |

| Transportation | Information Displays in Airports and Train Stations | Improves passenger communication and streamlines operations. | Reliability, real-time updates, and multi-language support. |

| Education | Interactive Learning Displays in Classrooms | Facilitates dynamic teaching methods and enhances student engagement. | Durability, touch capabilities, and integration with tech. |

| Corporate | Video Conferencing and Presentation Screens | Enhances communication efficiency and professionalism in meetings. | Size, resolution, and compatibility with existing systems. |

How Are LED Screen Manufacturers Used in Retail Environments?

In the retail sector, LED screens are predominantly utilized for digital signage and advertising displays. These screens allow businesses to showcase promotions, new products, and interactive content, significantly enhancing customer engagement. For international B2B buyers, particularly in regions like Africa and South America, sourcing LED screens with high brightness and resolution is critical, especially for outdoor applications where visibility in bright sunlight is essential. Additionally, businesses should consider the size and scalability of the displays to fit various retail formats.

What Are the Applications of LED Screens in Events and Entertainment?

In events and entertainment, LED screen manufacturers provide large-scale video walls that are crucial for concerts, festivals, and sporting events. These displays create immersive experiences that draw in larger crowds and enhance audience engagement. Buyers from the Middle East and Europe should prioritize features such as portability and ease of setup, ensuring that screens can be quickly deployed and taken down. Weather resistance is also vital for outdoor events, as it ensures the longevity and functionality of the displays under varying conditions.

How Do LED Screens Improve Transportation Communication?

Transportation hubs like airports and train stations utilize LED screens for information displays, providing real-time updates on schedules and services. This application significantly improves passenger communication and operational efficiency. For B2B buyers in Africa and Europe, sourcing reliable LED displays that support multi-language options can enhance the travel experience for diverse populations. It’s essential to focus on the durability and reliability of these screens, as they must operate continuously and withstand high foot traffic.

What Role Do LED Screens Play in Education?

In educational settings, LED screens are increasingly used as interactive learning displays. These screens facilitate dynamic teaching methods, making lessons more engaging for students. International buyers, especially in developing regions, should look for durable displays that can withstand heavy use and incorporate touch capabilities to support interactive learning. Integration with existing educational technologies is also a key consideration, ensuring that the displays enhance rather than complicate the learning environment.

How Are LED Screens Enhancing Corporate Communication?

In the corporate sector, LED screens are essential for video conferencing and presentations, enhancing communication efficiency and professionalism. B2B buyers from various regions need to consider the size and resolution of these displays to ensure they meet the needs of their meeting spaces. Compatibility with existing systems is crucial, as it allows for seamless integration into current communication frameworks. Investing in high-quality LED screens can significantly improve the overall effectiveness of corporate communications.

Related Video: Industrial Robots have Transformed the Manufacturing Industry – A Galco TV Tech Tip | Galco

3 Common User Pain Points for ‘LED Screen Manufacturers’ & Their Solutions

Scenario 1: Quality Control in LED Screen Manufacturing

The Problem:

B2B buyers often face significant challenges when it comes to the quality control of LED screens. Many manufacturers might promise high-quality products, but the reality can differ significantly, leading to issues such as color inconsistency, dead pixels, or inadequate brightness. This not only affects the buyer’s reputation but can also lead to substantial financial losses, especially for businesses that rely on these screens for advertising or customer engagement in critical environments like retail or events.

The Solution:

To mitigate quality issues, B2B buyers should establish a rigorous vetting process for LED screen manufacturers. This includes asking for detailed specifications and sample products before making bulk purchases. Buyers should also request third-party quality assurance certifications, such as ISO 9001, and inquire about the manufacturer’s testing procedures. Conducting factory visits or audits can provide firsthand insight into production practices. Additionally, implementing a trial period or limited initial order can help assess quality without committing to larger quantities. Forming partnerships with manufacturers that have a proven track record and can demonstrate their quality assurance processes will ensure a more reliable supply chain.

Scenario 2: Navigating Technical Specifications for LED Screens

The Problem:

International B2B buyers often struggle with the complex technical specifications associated with LED screens. Factors like pixel pitch, refresh rates, and color accuracy can be overwhelming, especially when trying to determine the right fit for specific applications. Misunderstanding these specifications can lead to purchasing products that do not meet the intended operational needs, resulting in costly returns and project delays.

The Solution:

To effectively navigate technical specifications, buyers should invest time in understanding the fundamental concepts of LED technology. Engaging with manufacturer representatives for detailed explanations can clarify how specific features impact performance in real-world scenarios. Additionally, creating a checklist of required specifications based on the intended use—whether for indoor displays, outdoor signage, or high-definition video walls—can streamline the selection process. Utilizing online resources, such as webinars or industry forums, can also enhance knowledge. Finally, collaborating with technical consultants or industry experts can provide personalized insights, ensuring the chosen LED screens align perfectly with project requirements.

Scenario 3: After-Sales Support and Service Challenges

The Problem:

Another common pain point for B2B buyers is inadequate after-sales support from LED screen manufacturers. Issues such as installation, maintenance, and troubleshooting can become significant obstacles if the manufacturer does not provide sufficient assistance. This can lead to prolonged downtime, affecting business operations and customer satisfaction.

The Solution:

Buyers should prioritize manufacturers that offer comprehensive after-sales support as part of their service package. This includes not only warranty and repair services but also technical support for installation and ongoing maintenance. Before finalizing any purchase, buyers should inquire about the manufacturer’s support structure, response times, and available resources, such as user manuals or online help centers. Establishing clear communication channels with the manufacturer for post-purchase issues can facilitate quicker resolutions. Additionally, consider negotiating service level agreements (SLAs) that outline response times and service expectations, ensuring that support is both timely and effective. By selecting manufacturers committed to robust after-sales service, buyers can protect their investments and ensure smooth operations.

Strategic Material Selection Guide for LED Screen Manufacturers

What Are the Key Materials for LED Screen Manufacturing?

When selecting materials for LED screen manufacturing, it is crucial for international B2B buyers to understand the properties, advantages, and limitations of various materials. This knowledge aids in making informed decisions that align with specific application requirements and regional standards.

Which Materials Are Commonly Used in LED Screen Manufacturing?

1. Aluminum

Key Properties:

Aluminum is known for its lightweight nature, excellent thermal conductivity, and resistance to corrosion. It typically withstands temperatures ranging from -50°C to 150°C, making it suitable for various environments.

Pros & Cons:

The primary advantage of aluminum is its strength-to-weight ratio, which allows for easier handling and installation. However, it can be more expensive compared to other metals, and its manufacturing process may require specialized equipment, increasing complexity.

Impact on Application:

Aluminum frames are often used in outdoor LED screens due to their durability and lightweight properties, making them ideal for mobile applications.

Considerations for International Buyers:

Buyers in regions like Africa and the Middle East should ensure compliance with local corrosion resistance standards, as environmental factors can significantly affect aluminum’s performance.

2. Polycarbonate

Key Properties:

Polycarbonate is a high-impact, transparent thermoplastic with excellent UV resistance and a temperature range of -40°C to 120°C. It is known for its optical clarity and durability.

Pros & Cons:

The key advantage of polycarbonate is its impact resistance, making it suitable for protective covers for LED screens. However, it can be prone to scratching and is generally more expensive than acrylic alternatives.

Impact on Application:

This material is particularly effective for outdoor LED displays, where protection against environmental factors is critical.

Considerations for International Buyers:

Compliance with standards such as ASTM for impact resistance is essential, especially for buyers in Europe, where safety regulations are stringent.

3. Glass

Key Properties:

Glass offers excellent optical clarity and is highly resistant to environmental factors. It can withstand high temperatures and is available in various thicknesses, typically ranging from 3mm to 12mm.

Pros & Cons:

While glass provides superior aesthetics and durability, it is heavier and more fragile than other materials, making installation more challenging and costly.

Impact on Application:

Glass is often used in high-end LED displays, particularly in retail and exhibition environments, where visual appeal is paramount.

Considerations for International Buyers:

Buyers in South America and Europe should consider the glass’s compliance with local safety standards, such as EN 12600, to ensure it meets impact resistance requirements.

4. Steel

Key Properties:

Steel is known for its strength and durability, with a high resistance to deformation under stress. It can handle temperatures up to 300°C, making it suitable for various industrial applications.

Pros & Cons:

The major advantage of steel is its robustness, making it ideal for structural components of LED screens. However, it is heavier and can be more susceptible to corrosion unless adequately treated, which can increase costs.

Impact on Application:

Steel is often used in the construction of large LED installations, particularly in stadiums and outdoor venues where structural integrity is critical.

Considerations for International Buyers:

International buyers should be aware of the need for corrosion-resistant coatings, especially in humid or coastal regions, to meet local standards and ensure longevity.

Summary Table of Material Selection for LED Screen Manufacturers

| Material | Typical Use Case for LED Screen Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Outdoor LED screens | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | Medium |

| Polycarbonate | Protective covers for outdoor displays | High impact resistance | Prone to scratching | High |

| Glass | High-end retail displays | Superior aesthetics | Heavy and fragile | High |

| Steel | Structural components in large installations | Excellent durability | Heavy and corrosion-prone | Medium |

This comprehensive analysis of materials provides valuable insights for international B2B buyers, enabling them to make informed decisions based on performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for LED Screen Manufacturers

What Are the Main Stages of Manufacturing LED Screens?

The manufacturing process of LED screens involves several critical stages, each requiring precision and expertise. Understanding these stages is essential for international B2B buyers looking to source high-quality LED screens.

Material Preparation: What Raw Materials Are Used?

The initial phase of LED screen manufacturing focuses on sourcing and preparing materials. Key components include:

- LED Chips: Sourced from leading semiconductor manufacturers, these chips form the core of the display.

- Substrates: Materials such as glass or plastic are prepared to house the LED chips. The choice of substrate affects the screen’s durability and performance.

- Driver ICs: Integrated circuits are essential for controlling the LED display’s brightness and color.

Buyers should ensure that suppliers source high-quality materials, as this directly impacts the final product’s performance and longevity.

How Are LED Screens Formed?

Following material preparation, the forming stage involves several processes to create the display:

- Chip Bonding: The LED chips are bonded to the substrate using advanced techniques like die bonding and wire bonding. This ensures optimal electrical conductivity.

- Optical Coating: A protective layer is applied to enhance brightness and reduce glare. This step is crucial for outdoor displays, which are exposed to varying light conditions.

- Pixel Matrix Formation: The arrangement of LEDs into a pixel matrix is performed to ensure accurate color representation and display quality.

During this stage, buyers should inquire about the technologies used, as cutting-edge methods can lead to superior display performance.

What Assembly Techniques Are Employed?

Assembly is a pivotal step where all components come together. Key activities include:

- Module Assembly: Individual LED modules are assembled, which are then combined to form the complete screen.

- Wiring: Proper wiring techniques are critical for ensuring reliable connections and functionality. This includes soldering and the use of connectors.

- Integration of Control Systems: Control systems are integrated to manage the display’s functionality, including brightness control and color adjustments.

B2B buyers should verify that suppliers employ skilled technicians in assembly to minimize defects and ensure high-quality output.

What Finishing Processes Are Involved?

The finishing stage enhances the aesthetics and functionality of the LED screen:

- Testing: Each screen undergoes rigorous testing to ensure it meets performance specifications. This includes brightness, color accuracy, and response time.

- Surface Treatment: A final surface treatment is applied to enhance durability, especially for outdoor screens that require weather resistance.

- Quality Control Checks: Final inspections are conducted to ensure that all components meet specified standards.

International buyers should request details on the finishing processes to ensure that the product meets their specific requirements.

How Is Quality Assurance Implemented in LED Screen Manufacturing?

Quality assurance (QA) is crucial for maintaining high standards in LED screen manufacturing. This involves adherence to international and industry-specific standards, as well as implementing effective quality control (QC) procedures.

What Are the Relevant International Standards for LED Screens?

LED screen manufacturers often comply with several international standards, which ensure product quality and safety. Key standards include:

- ISO 9001: This quality management system standard ensures that manufacturers consistently meet customer requirements and enhance satisfaction.

- CE Marking: Required for products sold in the European Economic Area, this certification indicates compliance with health, safety, and environmental protection standards.

- RoHS Compliance: Ensures that hazardous substances are restricted in electronic equipment, which is crucial for environmental safety.

Buyers should prioritize suppliers with these certifications, as they reflect a commitment to quality and safety.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Effective QC involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials and components are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps detect issues early.

- Final Quality Control (FQC): The finished products undergo comprehensive testing to verify that they meet all performance criteria.

Understanding these checkpoints allows buyers to assess the reliability of their suppliers’ quality assurance processes.

What Common Testing Methods Are Used for LED Screens?

Testing is vital to ensure that LED screens perform as expected. Common testing methods include:

- Visual Inspection: Technicians visually inspect the screens for defects such as dead pixels or color inconsistencies.

- Functional Testing: Screens are powered on to check for operational issues, including brightness levels and response times.

- Environmental Testing: For outdoor screens, manufacturers may conduct tests to simulate extreme weather conditions to ensure durability.

Buyers should inquire about the specific testing methods used by suppliers to understand the quality of the final product.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high standards of quality control, B2B buyers should implement several verification strategies:

What Auditing Practices Should Buyers Consider?

Buyers can conduct audits of potential suppliers to assess their manufacturing processes and quality assurance practices. Key focus areas include:

- Facility Inspections: Visiting manufacturing facilities allows buyers to evaluate equipment, cleanliness, and overall operational standards.

- Document Review: Requesting documentation related to quality control procedures, certifications, and testing results provides insight into the supplier’s commitment to quality.

How Can Buyers Leverage Third-Party Inspections?

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control practices. These agencies can perform:

- Random Sampling Inspections: Evaluating a random sample of products helps ensure that quality standards are consistently met.

- Compliance Checks: Third-party inspectors can verify that suppliers adhere to relevant international standards and regulations.

This independent verification adds an extra layer of assurance for buyers, particularly in international transactions.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must navigate specific challenges related to quality control and certification when sourcing LED screens:

- Cultural Differences: Understanding cultural nuances can affect communication and expectations regarding quality standards.

- Regulatory Compliance: Different countries have varying regulations regarding product safety and environmental standards. Buyers should ensure that their suppliers are compliant with local regulations in the markets they serve.

- Logistical Considerations: Shipping and handling can impact product quality. Buyers should discuss with suppliers how they mitigate risks during transportation.

By being proactive in verifying quality control processes and understanding certification nuances, B2B buyers can ensure they source high-quality LED screens that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘LED Screen Manufacturers’

Introduction

When sourcing LED screens for your business, particularly in emerging markets across Africa, South America, the Middle East, and Europe, it’s vital to follow a structured approach. This guide provides a step-by-step checklist to help you navigate the complexities of selecting a reliable LED screen manufacturer. By adhering to these steps, you can ensure that your procurement process is efficient, effective, and aligned with your business needs.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it’s essential to clearly outline your technical requirements. Consider factors such as screen resolution, size, brightness, and intended use (e.g., indoor vs. outdoor applications). This clarity will not only streamline your search but also enable suppliers to provide more accurate proposals tailored to your needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential LED screen manufacturers. Utilize online platforms, industry directories, and trade shows to gather information. Pay attention to their experience in the industry, product range, and market reputation. This groundwork is crucial for establishing a shortlist of suppliers who can meet your specifications.

Step 3: Evaluate Supplier Certifications

Verify the certifications and standards adhered to by the potential suppliers. Look for ISO certifications, CE marks, or RoHS compliance, which signify that the manufacturer meets international quality and safety standards. This step is vital for ensuring that you are sourcing from a reputable company that prioritizes quality and compliance.

Step 4: Request Samples and Product Demonstrations

Before making a significant investment, request samples or product demonstrations from shortlisted suppliers. This allows you to assess the quality of the LED screens firsthand. Evaluate aspects such as image clarity, color accuracy, and durability under various conditions. It’s also advisable to test the product in your intended environment to ensure compatibility.

Step 5: Assess Supplier Customer Support

Evaluate the level of customer support offered by potential suppliers. Effective communication, responsiveness, and after-sales service are crucial for a successful partnership. Inquire about their warranty policies, technical support availability, and response times to ensure that you will receive adequate assistance post-purchase.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be transparent about your budget constraints while also ensuring that the terms are favorable for both parties. A well-negotiated contract can lead to long-term savings and a stable supply chain.

Step 7: Finalize Your Order and Monitor Production

After finalizing the agreement, place your order and establish a timeline for production and delivery. Maintain open lines of communication with the supplier to monitor the progress and address any issues that may arise. Regular updates can help mitigate risks and ensure that your project stays on track.

By following this practical checklist, international B2B buyers can confidently navigate the procurement process for LED screens, ensuring that they select the right manufacturer to meet their business needs effectively.

Comprehensive Cost and Pricing Analysis for LED Screen Manufacturers Sourcing

What Are the Key Cost Components for Sourcing LED Screens?

When sourcing LED screens, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The largest portion of the cost typically involves raw materials such as LED diodes, circuit boards, and screens themselves. Prices can fluctuate based on market demand and the availability of components.

-

Labor: Labor costs vary significantly by region. For instance, sourcing from manufacturers in Asia may yield lower labor costs compared to those in Europe. Skilled labor is essential for quality assembly and testing.

-

Manufacturing Overhead: This includes costs associated with utilities, factory maintenance, and administrative expenses. Overhead can differ based on location and the scale of operations.

-

Tooling: Initial tooling costs can be high, especially for custom designs. Buyers should consider whether the tooling is a one-time investment or if it will need to be updated for future orders.

-

Quality Control (QC): Ensuring quality through rigorous testing and inspection can add to the cost but is essential for minimizing returns and maintaining customer satisfaction.

-

Logistics: Transportation costs can significantly impact the final price, especially for international shipments. Factors like shipping mode (air vs. sea), distance, and customs duties play a role.

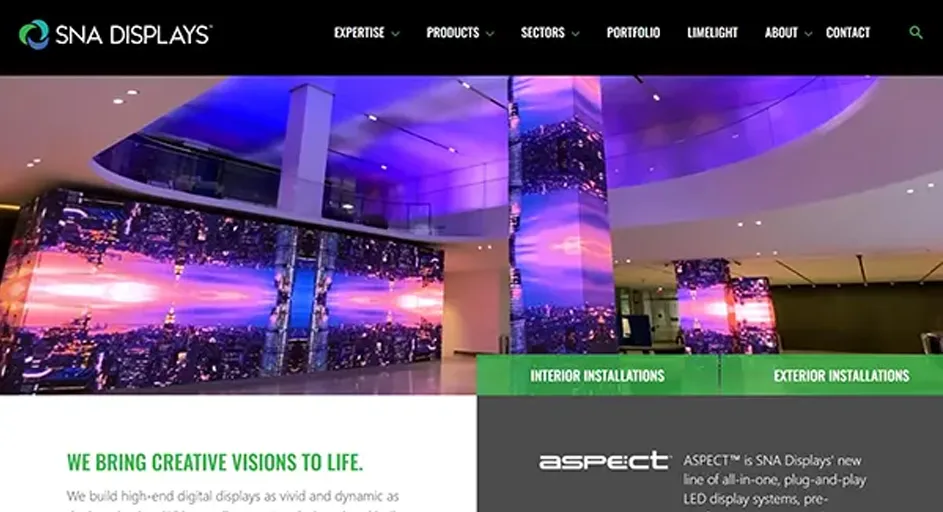

A stock image related to LED Screen Manufacturers.

- Margin: Manufacturers typically add a profit margin to cover risks and ensure sustainability. Margins can vary based on competition, demand, and market conditions.

How Do Price Influencers Affect LED Screen Sourcing?

Several factors influence the pricing of LED screens, which international buyers must consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders can lead to lower per-unit prices due to economies of scale. Understanding a supplier’s MOQ can help buyers negotiate better deals.

-

Specifications and Customization: Custom features or specific technical requirements can drive up costs. It’s vital to balance desired specifications with budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications (such as CE, RoHS) may increase costs but can also enhance the product’s marketability and lifespan.

-

Supplier Factors: The reputation and reliability of a supplier can affect pricing. Established manufacturers with a history of quality may command higher prices.

-

Incoterms: The terms of sale, including who is responsible for shipping and insurance, can affect overall costs. Familiarity with Incoterms can help buyers manage risks and expenses effectively.

What Negotiation Tips Can Help Buyers Optimize Costs?

For international B2B buyers, effective negotiation and cost management strategies are essential:

-

Understand Total Cost of Ownership (TCO): Consider all costs associated with a purchase, including shipping, customs, and potential tariffs. This comprehensive view can lead to better negotiation outcomes.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs and negotiate bulk pricing. This can lead to significant savings.

-

Build Long-term Relationships: Establishing strong relationships with suppliers can lead to better pricing, priority service, and flexibility in future orders.

-

Stay Informed on Market Trends: Being aware of fluctuations in material costs and industry trends can help buyers time their purchases for optimal pricing.

-

Utilize Competitive Bidding: Request quotes from multiple suppliers to create competition, which can drive down prices.

Conclusion and Price Disclaimer

While the above insights provide a framework for understanding costs and pricing in LED screen manufacturing, prices can vary widely based on specific requirements and market conditions. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they secure the best deal. Always remain mindful of the potential for price changes due to fluctuations in material costs and supply chain dynamics.

Alternatives Analysis: Comparing LED Screen Manufacturers With Other Solutions

Introduction: Understanding Alternatives to LED Screen Manufacturers

In the rapidly evolving landscape of visual display technology, businesses often face the dilemma of selecting the most suitable solution for their needs. While LED screens are a popular choice due to their vibrant colors and energy efficiency, there are alternative technologies that may offer distinct advantages depending on specific use cases. This section will explore these alternatives, providing B2B buyers with comprehensive insights to make informed decisions.

Comparison Table of LED Screen Manufacturers and Alternatives

| Comparison Aspect | LED Screen Manufacturers | OLED Displays | Projection Systems |

|---|---|---|---|

| Performance | High brightness and color accuracy | Superior contrast and color depth | Variable quality based on setup |

| Cost | Moderate to high | High initial investment | Generally lower initial cost |

| Ease of Implementation | Straightforward installation | Requires careful handling | Complex setup with adjustments |

| Maintenance | Low maintenance requirements | Susceptible to burn-in | Regular maintenance needed |

| Best Use Case | Retail signage, events, advertising | Home theaters, high-end displays | Large venues, presentations |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of OLED Displays?

Pros: OLED displays offer superior contrast ratios and vibrant colors thanks to their ability to control individual pixels. This results in deeper blacks and more vivid images, making them ideal for environments where visual quality is paramount, such as home theaters or high-end retail displays.

Cons: However, OLED technology comes with a high initial cost, which may not be feasible for all businesses. Additionally, OLED screens are prone to burn-in, where static images can leave a permanent mark on the display if shown for extended periods. This makes them less suitable for applications requiring static content, such as digital signage.

How Do Projection Systems Compare to LED Screens?

Pros: Projection systems typically have a lower initial cost compared to LED screens and can produce larger images, making them suitable for large venues or events. They also allow for flexible display sizes, which can be adjusted according to the space available.

Cons: However, the quality of projection systems can vary significantly based on the environment and setup. Factors such as ambient light can greatly affect visibility, making them less reliable than LED screens in brightly lit conditions. Additionally, they require regular maintenance, including bulb replacements and cleaning, which can add to long-term costs.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right display technology is crucial for achieving your business objectives. LED screen manufacturers provide a balance of performance, ease of use, and low maintenance, making them a solid choice for many applications. However, if your focus is on achieving the highest visual quality, OLED displays may be worth the investment, provided you can mitigate the risks of burn-in. Alternatively, for large-scale presentations on a budget, projection systems can be effective, albeit with some compromises in quality and maintenance requirements. Ultimately, your choice should align with your specific needs, budget constraints, and the intended application of the display technology.

Essential Technical Properties and Trade Terminology for LED Screen Manufacturers

What Are the Essential Technical Properties of LED Screens for B2B Buyers?

Understanding the technical specifications of LED screens is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Here are some critical properties to consider:

1. Material Grade: What is the Importance of LED Screen Materials?

The material grade used in LED screens affects durability, performance, and overall quality. Common materials include aluminum for frames, tempered glass for screens, and high-grade plastics for casing. A higher-grade material often means better resistance to environmental factors, such as humidity and temperature fluctuations, which is particularly relevant for outdoor installations in diverse climates.

2. Brightness Levels: Why Is Brightness Critical in LED Displays?

Brightness, measured in nits, is a key factor in display visibility, especially in outdoor or well-lit environments. For B2B applications, screens with brightness levels of 1000 nits or higher are recommended for outdoor use, ensuring that content remains visible regardless of sunlight or glare. This is especially important for advertising and public displays.

3. Resolution: How Does Resolution Impact Image Quality?

Resolution defines the clarity and detail of the images displayed. Common resolutions include Full HD (1920×1080), 4K (3840×2160), and even 8K (7680×4320). A higher resolution allows for more detailed images, which is essential for applications such as digital signage or video walls where high-quality visuals can enhance viewer engagement.

4. Refresh Rate: Why Is Refresh Rate Important for Display Performance?

The refresh rate, measured in Hertz (Hz), indicates how many times per second the image is refreshed on the screen. A higher refresh rate (e.g., 120Hz or 240Hz) is crucial for applications involving fast-moving images, such as sports broadcasting or gaming. This ensures smooth transitions and reduces motion blur, enhancing the overall viewing experience.

5. Viewing Angle: What Should Buyers Know About Viewing Angles?

Viewing angle is the maximum angle at which the screen can be viewed without significant loss of quality. A wide viewing angle (typically 160° or more) is essential for LED screens in public spaces, ensuring that all viewers, regardless of their position, can enjoy a clear and vibrant image.

6. Power Consumption: How Does Power Efficiency Affect Operational Costs?

Power consumption is a critical consideration for B2B buyers, as it directly impacts operational costs. Efficient LED screens are designed to consume less energy while providing high brightness and performance. This is especially relevant for large installations where energy costs can accumulate over time.

What Are Common Trade Terms in the LED Screen Manufacturing Industry?

Familiarity with industry terminology can facilitate smoother transactions and better negotiations. Here are several key terms:

1. OEM (Original Equipment Manufacturer): What Does OEM Mean for Buyers?

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For B2B buyers, partnering with OEMs can ensure access to high-quality components tailored to specific needs, often at competitive prices.

2. MOQ (Minimum Order Quantity): Why Is MOQ Important in Bulk Purchases?

MOQ defines the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for buyers to avoid overcommitting to large orders that may not align with their inventory needs or budget constraints.

3. RFQ (Request for Quotation): How Do RFQs Streamline Purchasing Processes?

An RFQ is a document sent to suppliers requesting pricing and terms for specific goods or services. By issuing an RFQ, buyers can compare offers and negotiate better terms, ensuring they get the best value for their investment.

4. Incoterms (International Commercial Terms): How Do Incoterms Affect Shipping Costs?

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms can help buyers understand who bears the costs and risks during transit, aiding in budgeting and logistics planning.

5. Lead Time: What Is Lead Time and Why Does It Matter?

Lead time refers to the time taken from placing an order to delivery. For B2B buyers, understanding lead times is vital for planning projects and ensuring that equipment arrives when needed, avoiding delays in deployment.

By comprehending these essential properties and trade terms, international B2B buyers can make informed decisions when sourcing LED screens, ensuring they meet their operational needs and market demands effectively.

Navigating Market Dynamics and Sourcing Trends in the LED Screen Manufacturers Sector

What Are the Key Market Dynamics and Trends in the LED Screen Manufacturing Sector?

The global LED screen manufacturing market is witnessing robust growth, driven by rapid advancements in technology and increasing demand for high-resolution displays across various sectors. Key trends include the rise of 4K and 8K resolution displays, which offer superior image quality, making them ideal for applications in advertising, entertainment, and education. Additionally, the integration of smart technologies, such as IoT capabilities, is transforming traditional LED displays into interactive platforms that enhance user engagement.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing LED screens that not only meet quality and performance standards but are also competitively priced. The trend towards direct purchasing from manufacturers rather than intermediaries is gaining traction, allowing buyers to negotiate better terms and ensure product authenticity. Moreover, the shift toward online procurement platforms is facilitating easier access to a wider range of suppliers and products, streamlining the sourcing process.

How Important Is Sustainability and Ethical Sourcing for LED Screen Manufacturers?

Sustainability is becoming a critical factor for B2B buyers in the LED screen manufacturing sector. As environmental awareness grows, companies are prioritizing suppliers that adhere to sustainable practices. This includes sourcing materials responsibly, reducing carbon footprints, and minimizing waste throughout the manufacturing process.

Ethical sourcing is also paramount, as buyers increasingly demand transparency regarding the supply chain. Certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) are becoming essential for manufacturers aiming to demonstrate their commitment to sustainability. Buyers should look for manufacturers who utilize eco-friendly materials and processes, such as recyclable components and energy-efficient production techniques, to align with their own corporate social responsibility goals. By choosing suppliers that prioritize sustainability, buyers can enhance their brand reputation and appeal to a growing segment of environmentally conscious consumers.

What Is the Brief Evolution of the LED Screen Manufacturing Industry?

The LED screen manufacturing industry has evolved significantly since its inception in the late 20th century. Initially dominated by cathode-ray tube (CRT) technology, the industry transitioned to flat-panel displays with the introduction of LED technology in the early 2000s. This shift allowed for thinner, lighter, and more energy-efficient screens, which quickly gained popularity in both consumer and commercial markets.

Over the past decade, advancements in LED technology have enabled the development of high-definition displays with improved color accuracy and brightness. The emergence of OLED and MiniLED technologies has further revolutionized the industry, offering enhanced visual experiences. Today, LED screens are ubiquitous, used in everything from large-scale outdoor advertising displays to small handheld devices. As the market continues to grow, ongoing innovation in display technology and manufacturing processes will likely shape the future of the LED screen industry, presenting new opportunities for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of LED Screen Manufacturers

-

How do I choose the right LED screen manufacturer for my business needs?

When selecting an LED screen manufacturer, consider their experience, product quality, and technology offerings. Look for manufacturers with a proven track record in your specific industry, as they will be more attuned to your requirements. Additionally, request samples to assess the quality of their products, and inquire about customization options to ensure they can meet your unique specifications. Lastly, check reviews and case studies to gauge customer satisfaction and service reliability. -

What are the key factors to consider when sourcing LED screens internationally?

Key factors include understanding import/export regulations, shipping logistics, and tariffs that may apply in your region. Evaluate the manufacturer’s compliance with international standards, such as ISO certifications, to ensure quality and safety. It’s also crucial to consider payment terms, lead times, and after-sales support. Partnering with a manufacturer that has experience in your target market can streamline the process and mitigate potential challenges. -

What customization options should I look for in LED screen manufacturers?

Many manufacturers offer customization in terms of size, resolution, brightness, and specific features like touch interactivity or waterproofing. Determine your specific needs, such as outdoor vs. indoor usage, and ensure the manufacturer can tailor their products accordingly. Ask about the flexibility of designs, software compatibility, and installation support, as these can significantly impact your project’s success. -

What minimum order quantity (MOQ) should I expect from LED screen manufacturers?

MOQs can vary significantly between manufacturers, often depending on the type of LED screens and customization requirements. Standard MOQs may range from a few units for basic models to larger quantities for customized solutions. Engage in discussions with potential suppliers to negotiate MOQs that align with your budget and project scale, and explore the possibility of trial orders for first-time purchases. -

How can I ensure quality assurance (QA) when sourcing LED screens?

To ensure quality, request detailed information about the manufacturer’s QA processes, including testing methods and certifications. Look for manufacturers who adhere to international standards like ISO 9001. Additionally, consider implementing a third-party inspection service to evaluate products before shipment. Regular communication with the supplier during production can also help address any quality concerns early. -

What payment terms should I negotiate with LED screen manufacturers?

Payment terms can vary, but common practices include a deposit upfront (typically 30-50%) with the balance due upon shipment or delivery. Negotiate terms that provide you with sufficient cash flow while ensuring the manufacturer has confidence in the transaction. Be cautious of terms that seem too favorable, as they could indicate a lack of reliability. Consider using escrow services for large orders to safeguard your investment.

A stock image related to LED Screen Manufacturers.

-

What are the logistics considerations when importing LED screens?

Logistics involve understanding shipping methods, costs, and delivery times. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your urgency. Ensure the manufacturer can provide proper packaging to prevent damage during transit. Additionally, familiarize yourself with customs procedures in your country to avoid delays and unexpected fees. Partnering with a logistics provider experienced in international shipping can simplify this process. -

How do I handle after-sales support and warranty issues with LED screen manufacturers?

Before finalizing your purchase, clarify the warranty terms and after-sales support services offered by the manufacturer. A reputable manufacturer should provide a clear warranty policy covering defects and performance issues. Inquire about technical support availability, repair services, and parts replacement. Establishing a good relationship with your supplier can facilitate quicker resolutions to any issues that arise post-purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for LED Screen Manufacturers

In conclusion, strategic sourcing plays a pivotal role in optimizing procurement processes for international B2B buyers in the LED screen manufacturing sector. By understanding the nuances of product specifications, such as resolution, panel types, and market trends, buyers can make informed decisions that align with their specific needs. Emphasizing the importance of supplier relationships, buyers from Africa, South America, the Middle East, and Europe should focus on establishing partnerships with manufacturers that demonstrate reliability and innovation.

As the global demand for high-quality LED screens continues to rise, leveraging strategic sourcing will not only enhance product offerings but also provide a competitive edge in diverse markets. Buyers are encouraged to stay abreast of technological advancements and pricing dynamics, ensuring they capitalize on opportunities as they arise.

Looking ahead, the landscape for LED screen manufacturers is ripe with potential. By engaging in proactive sourcing strategies, international buyers can secure advantageous terms and foster long-term collaborations that drive growth and success. Embrace the future of LED technology—your next strategic sourcing decision could be a game-changer for your business.