Discover Top Machinery Manufacturers: Your Complete Guide (2025)

Introduction: Navigating the Global Market for machinery manufacturer

In the rapidly evolving landscape of global trade, sourcing machinery manufacturers can pose significant challenges for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, navigating the intricate web of suppliers, quality standards, and regulatory requirements can feel overwhelming. This guide is designed to provide clarity and actionable insights for businesses seeking to procure machinery that meets their operational needs while ensuring compliance and cost-effectiveness.

Throughout this comprehensive guide, we delve into various types of machinery, their specific applications across diverse industries, and the critical factors to consider when vetting potential suppliers. From understanding the nuances of machinery specifications to evaluating supplier reliability, we equip you with the knowledge to make informed purchasing decisions.

Additionally, we address the intricacies of pricing structures and cost management strategies that are particularly relevant for buyers from regions such as Mexico and the UK. By empowering you with the tools and information necessary to assess and select the right machinery manufacturers, this guide aims to streamline your procurement process, reduce risks, and ultimately drive your business success in the global market.

Understanding machinery manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| General Machinery Manufacturers | Broad range of machinery across various industries | Construction, agriculture, manufacturing | Pros: Versatile products, wide availability. Cons: May lack specialization. |

| Custom Machinery Manufacturers | Tailored solutions based on specific client needs | Specialized industrial processes | Pros: Meets unique requirements, enhances efficiency. Cons: Higher costs, longer lead times. |

| Heavy Equipment Manufacturers | Large-scale machinery designed for heavy-duty tasks | Mining, construction, and infrastructure | Pros: Robust durability, high performance. Cons: Significant capital investment, maintenance costs. |

| Agricultural Machinery Manufacturers | Specialized in farming equipment and tools | Crop production, livestock management | Pros: Increases productivity, tailored for specific crops. Cons: Seasonal demand fluctuations. |

| Automated Machinery Manufacturers | Focus on robotics and automated systems | Manufacturing, logistics, and warehousing | Pros: Enhances efficiency, reduces labor costs. Cons: High initial investment, requires training. |

What Are the Characteristics of General Machinery Manufacturers?

General machinery manufacturers produce a diverse range of equipment applicable in various sectors, including construction, agriculture, and manufacturing. These manufacturers often offer standardized products that can be utilized across multiple industries. When purchasing from general manufacturers, B2B buyers should consider the breadth of the product line, availability of parts, and after-sales service. This type of manufacturer is suitable for businesses seeking reliable machinery without the need for specialized solutions.

How Do Custom Machinery Manufacturers Meet Unique Needs?

Custom machinery manufacturers focus on developing equipment tailored to specific client requirements, offering bespoke solutions that enhance operational efficiency. These manufacturers are ideal for businesses with unique processes that cannot be addressed by off-the-shelf machinery. B2B buyers should evaluate the manufacturer’s design capabilities, previous projects, and flexibility in modifications. While custom solutions can lead to greater productivity, they often come with higher costs and longer lead times.

What Are the Benefits of Heavy Equipment Manufacturers?

Heavy equipment manufacturers specialize in producing large-scale machinery for demanding applications such as mining, construction, and infrastructure development. Their products are known for durability and high performance, making them essential for companies requiring robust solutions. When considering heavy equipment purchases, B2B buyers should assess factors like equipment lifespan, maintenance support, and resale value. The initial investment is significant, but the long-term benefits often justify the expense.

Why Choose Agricultural Machinery Manufacturers?

Agricultural machinery manufacturers design equipment specifically for farming operations, including crop production and livestock management. These manufacturers provide tools that enhance productivity and efficiency in agricultural processes. B2B buyers should consider the adaptability of the machinery to different farming techniques and the availability of support services. While agricultural machinery can significantly improve yield, buyers must be mindful of seasonal demand fluctuations that may impact procurement.

How Do Automated Machinery Manufacturers Enhance Efficiency?

Automated machinery manufacturers focus on robotics and automated systems that streamline manufacturing and logistics processes. Their solutions are designed to enhance operational efficiency and reduce labor costs. B2B buyers must consider the initial investment and the need for training personnel to operate automated systems effectively. While the benefits of increased efficiency and productivity are clear, businesses should also evaluate the long-term return on investment and compatibility with existing processes.

Related Video: Metal Plating Process | A Complete Guide To Its Types And Technique.

Key Industrial Applications of machinery manufacturer

| Industry/Sector | Specific Application of Machinery Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Precision Farming Equipment | Increased yield and reduced resource waste | Compatibility with local crops and terrains, tech support |

| Construction | Heavy Machinery for Earthworks | Enhanced productivity and reduced project timelines | Compliance with local regulations, availability of spare parts |

| Food Processing | Automated Packaging Machinery | Improved efficiency and reduced labor costs | Adaptability to local food types, hygiene certifications |

| Mining and Minerals | Drilling and Excavation Equipment | Higher extraction rates and operational safety | Robustness to local conditions, maintenance support |

| Renewable Energy | Wind Turbine Manufacturing | Sustainable energy production and lower costs | Local infrastructure compatibility, regulatory compliance |

How is Machinery Used in Agriculture for Precision Farming?

Precision farming equipment, such as GPS-guided tractors and soil sensors, is increasingly vital in agriculture. This machinery allows farmers to monitor crop health and optimize resource use, leading to increased yields and reduced waste. For international buyers, especially from regions like Africa and South America, sourcing equipment that is compatible with local crops and terrains is crucial. Furthermore, the availability of technical support and training can significantly enhance the effectiveness of these technologies.

What Role Does Heavy Machinery Play in Construction?

Heavy machinery, including excavators and bulldozers, is essential in construction for tasks such as earthworks and site preparation. These machines enhance productivity and help meet project deadlines, which is particularly important in fast-paced markets in the Middle East and Europe. Buyers should consider local regulations regarding machinery operation and emissions, as well as the availability of spare parts and maintenance services to ensure operational continuity.

How Does Automated Packaging Machinery Benefit Food Processing?

In the food processing sector, automated packaging machinery streamlines operations, improving efficiency and reducing labor costs. This technology is critical for maintaining hygiene standards and ensuring products are packaged correctly for distribution. Buyers must evaluate the adaptability of these machines to local food types and ensure they meet necessary hygiene certifications. This is especially pertinent for international buyers looking to comply with varying regional regulations.

Why is Drilling and Excavation Equipment Important for Mining?

In the mining and minerals sector, drilling and excavation equipment is crucial for efficient resource extraction. This machinery not only increases extraction rates but also enhances operational safety in challenging environments. International B2B buyers should focus on sourcing robust equipment designed to withstand local conditions and prioritize suppliers who offer comprehensive maintenance support to minimize downtime.

What are the Advantages of Manufacturing Wind Turbines in Renewable Energy?

The manufacturing of wind turbines is an essential application of machinery in the renewable energy sector. This machinery contributes to sustainable energy production and can significantly lower energy costs over time. Buyers should consider the compatibility of the turbines with local infrastructure and ensure compliance with regional regulations concerning energy production. This is particularly relevant for international buyers in Europe, where renewable energy initiatives are strongly supported.

Related Video: Most Satisfying Industrial Manufacturing Processes with Modern Machinery.

3 Common User Pain Points for ‘machinery manufacturer’ & Their Solutions

Scenario 1: Difficulty in Finding Reliable Suppliers for Machinery

The Problem:

B2B buyers in regions such as Africa and South America often struggle with identifying trustworthy machinery manufacturers. The challenge arises from a lack of local suppliers with the necessary quality certifications, leading to potential delays in production and increased operational risks. Additionally, language barriers and differing business practices can complicate negotiations and hinder effective communication, making it hard for buyers to assess the reliability of a manufacturer.

The Solution:

To overcome this issue, B2B buyers should leverage online platforms that specialize in connecting businesses with vetted suppliers. Websites like ThomasNet, Global Sources, and Alibaba offer reviews, ratings, and detailed supplier profiles, enabling buyers to assess credibility before initiating contact. Moreover, it’s essential to conduct thorough due diligence, including requesting references and visiting the manufacturer’s facility if feasible. Developing relationships with local industry associations can also provide valuable insights into reputable suppliers in the region. Furthermore, consider utilizing third-party inspection services to evaluate machinery quality before purchase, ensuring that it meets your operational standards.

Scenario 2: Challenges with Machinery Customization and Specifications

The Problem:

Many B2B buyers face difficulties in obtaining machinery that meets specific operational needs, particularly in industries like agriculture and construction. Standardized machinery may not always align with unique production processes or local environmental conditions, leading to inefficiencies and increased costs. Buyers often find themselves frustrated when manufacturers are unable or unwilling to accommodate custom specifications, resulting in delays and increased downtime.

The Solution:

To address this pain point, buyers should engage in detailed discussions with manufacturers early in the procurement process. Clearly outlining operational requirements and desired specifications can help manufacturers understand the need for customization. Utilize design software or prototypes to visualize the required modifications and facilitate better communication. Establishing a collaborative relationship with the manufacturer can also foster innovation, allowing for co-development of tailored solutions. Moreover, consider sourcing from manufacturers with a proven track record of customization in your specific industry, as they are more likely to have the expertise and flexibility to accommodate unique needs.

Scenario 3: High Maintenance Costs and Downtime

The Problem:

Machinery can be a significant investment, and many B2B buyers are concerned about the long-term costs associated with maintenance and potential downtimes. In regions with limited access to spare parts or qualified technicians, the risk of prolonged machinery outages can severely impact production schedules and profitability. This issue is particularly prevalent in the Middle East and parts of Europe, where certain machinery may require specialized knowledge for maintenance.

The Solution:

To mitigate maintenance issues, buyers should prioritize sourcing machinery from manufacturers that offer comprehensive after-sales support, including training for local technicians and access to spare parts. Before finalizing any purchase, inquire about warranty terms and the availability of service contracts. Establishing a preventive maintenance schedule can also reduce the likelihood of unexpected breakdowns. Additionally, consider investing in machinery equipped with IoT technology that enables remote monitoring, allowing for real-time diagnostics and timely interventions before problems escalate. By fostering a proactive maintenance culture and leveraging technology, buyers can minimize downtime and extend the lifespan of their machinery investments.

Strategic Material Selection Guide for machinery manufacturer

When selecting materials for machinery manufacturing, it is critical to understand the properties, advantages, and limitations of each option. This knowledge enables international B2B buyers to make informed decisions that align with their operational needs and market standards. Below, we analyze four common materials used in machinery manufacturing, focusing on their characteristics, applications, and considerations for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Steel in Machinery Manufacturing?

Steel is one of the most widely used materials in machinery manufacturing due to its exceptional strength and versatility. It boasts high tensile strength, making it suitable for high-pressure applications. Additionally, steel can withstand elevated temperatures, which is crucial for machinery operating in harsh environments. Corrosion resistance can be enhanced through various coatings or alloying elements, such as chromium in stainless steel.

Pros & Cons: Steel’s durability and availability make it a cost-effective choice for many applications. However, it can be heavy, which may not be ideal for all machinery designs. The manufacturing complexity can vary based on the type of steel and required treatments, potentially increasing lead times.

Impact on Application: Steel is compatible with a wide range of media, including oils and fuels, making it suitable for various machinery applications. However, specific grades should be selected based on the operating environment to ensure optimal performance.

Considerations for International Buyers: Buyers should be aware of compliance with international standards such as ASTM and DIN, especially when sourcing from different regions. In Europe, for example, adherence to CE marking regulations is essential.

How Does Aluminum Compare as a Material for Machinery?

Aluminum is known for its lightweight properties and excellent corrosion resistance, making it a popular choice for machinery that requires reduced weight without sacrificing strength. It has a lower density than steel, which can enhance fuel efficiency in mobile machinery.

Pros & Cons: The primary advantage of aluminum is its weight, which can lead to lower transportation costs and improved energy efficiency. However, it generally has lower tensile strength compared to steel, which may limit its application in high-stress environments. Manufacturing processes for aluminum can also be more complex and costly.

Impact on Application: Aluminum is particularly suited for applications in corrosive environments, such as marine or chemical processing machinery. Its compatibility with various media is generally favorable, but care must be taken with certain chemicals that may cause reactions.

Considerations for International Buyers: Buyers should consider the availability of aluminum grades that meet local standards and regulations. In regions like Africa and South America, sourcing challenges may arise, so understanding local supply chains is crucial.

What Are the Advantages of Using Plastics in Machinery Manufacturing?

Plastics are increasingly being utilized in machinery manufacturing due to their lightweight nature and resistance to corrosion and chemicals. They can be engineered to meet specific performance criteria, such as temperature resistance and mechanical strength.

Pros & Cons: The key advantage of plastics is their versatility and low weight, making them suitable for a wide range of applications. However, they typically have lower strength compared to metals and may not perform well under high temperatures or pressures.

Impact on Application: Plastics are ideal for applications where weight reduction is critical, such as in consumer electronics or automotive components. They offer excellent compatibility with various chemicals but may not be suitable for high-load applications.

Considerations for International Buyers: Buyers should be aware of the different grades of plastics available and their compliance with regional standards. In Europe, for example, REACH regulations may impact the selection of certain plastic materials.

How Do Composites Enhance Machinery Performance?

Composite materials, which combine two or more constituent materials, offer unique properties that can significantly enhance machinery performance. They can be engineered for specific applications, providing high strength-to-weight ratios and excellent fatigue resistance.

Pros & Cons: Composites are lightweight and can be tailored to meet specific performance requirements, making them ideal for advanced machinery applications. However, they can be more expensive to manufacture and may require specialized processing techniques.

Impact on Application: Composites are particularly advantageous in aerospace and automotive applications where performance and weight are critical. Their compatibility with various media is generally favorable, but specific formulations should be evaluated based on the intended use.

Considerations for International Buyers: Understanding the manufacturing capabilities and certifications of composite materials is essential, especially in regions with stringent regulations, such as Europe. Buyers should ensure that suppliers can meet local compliance standards.

Summary Table of Material Selection for Machinery Manufacturing

| Material | Typical Use Case for machinery manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, structural components | High strength and durability | Heavy and manufacturing complexity | Medium |

| Aluminum | Aerospace and automotive components | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Plastics | Consumer electronics, automotive parts | Versatile and low weight | Lower strength and temperature limits | Low |

| Composites | Aerospace, high-performance automotive | Tailored properties and lightweight | Higher manufacturing costs | High |

This strategic material selection guide equips international B2B buyers with the insights needed to choose the right materials for their machinery manufacturing needs, ensuring compliance and performance across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for machinery manufacturer

What Are the Main Stages of Machinery Manufacturing Processes?

The manufacturing process for machinery involves several critical stages that ensure the final product meets the required specifications and quality standards. For international B2B buyers, understanding these stages is essential for evaluating potential suppliers effectively.

1. Material Preparation

The first stage of the manufacturing process focuses on sourcing and preparing raw materials. This includes selecting high-grade materials that meet industry standards and are suitable for the machinery’s intended use. Common materials include metals like steel and aluminum, as well as composites and plastics. Suppliers should provide certifications that guarantee the quality and origin of these materials, which is particularly important for buyers from regions with stringent import regulations, such as the European Union.

2. Forming Processes

Once materials are prepared, they undergo various forming processes. Techniques such as machining, casting, forging, and bending are prevalent in machinery manufacturing. Each method has its advantages, depending on the complexity and specifications of the machinery. For instance, CNC machining offers precision for intricate designs, while forging provides strength for load-bearing components. B2B buyers should inquire about the techniques used and the technology involved to ensure they align with their quality expectations.

3. Assembly

After forming, components are assembled into the final machinery product. This stage can vary significantly depending on the complexity of the machine. Assembly lines may employ manual labor or automated systems, such as robotic assembly, to enhance precision and efficiency. Buyers should assess the assembly process to understand how it affects the overall quality and reliability of the machinery. It’s advisable to ask for details on assembly techniques and the skill level of the workforce involved.

4. Finishing Touches

The final stage of manufacturing involves finishing processes, which may include painting, coating, and surface treatment. These processes not only enhance the aesthetic appeal of the machinery but also protect against corrosion and wear. For buyers, understanding the finishing techniques used is crucial, as they can impact the longevity and maintenance requirements of the machinery. Suppliers should provide information on the types of finishes applied and their respective benefits.

How Does Quality Assurance Fit into Machinery Manufacturing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process that ensures the machinery meets both international and industry-specific standards. For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, familiarity with these standards can aid in supplier selection.

What Are the Relevant International Standards for Quality Assurance?

International standards such as ISO 9001 provide a framework for quality management systems. This standard emphasizes continuous improvement and customer satisfaction, making it critical for machinery manufacturers. Additionally, industry-specific certifications like CE marking (for compliance with European health, safety, and environmental protection standards) and API certification (for the oil and gas sector) are essential for buyers in those regions.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically segmented into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): At this stage, raw materials and components are inspected for compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during manufacturing to identify defects early. This can include real-time inspections and automated testing.

- Final Quality Control (FQC): Upon completion, the finished machinery undergoes a comprehensive evaluation to ensure it meets all predefined standards and specifications.

B2B buyers should request detailed information on these QC checkpoints to assess the thoroughness of the supplier’s quality management practices.

What Testing Methods Are Common in Machinery Manufacturing?

Testing methods are vital for verifying the functionality and safety of machinery. Common techniques include:

- Functional Testing: Ensures that machinery operates as intended under various conditions.

- Durability Testing: Assesses the lifespan of machinery components under simulated usage.

- Safety Testing: Evaluates compliance with safety regulations to prevent hazards during operation.

Buyers should ensure that suppliers provide testing reports and certifications to validate the quality of their products.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to stringent quality standards, B2B buyers can employ several strategies:

- Audits: Conducting on-site audits of the manufacturing facilities can provide insights into the supplier’s quality management practices and production capabilities. Buyers should look for certifications that demonstrate compliance with relevant standards.

- Quality Reports: Requesting detailed quality assurance reports can help buyers understand the supplier’s QC processes, including failure rates and corrective actions taken.

- Third-Party Inspections: Engaging independent inspection services can provide an unbiased evaluation of the supplier’s quality control systems and the final product.

What Are the Nuances of Quality Control for International B2B Buyers?

Navigating quality control in international transactions can be complex. Buyers from different regions may encounter various compliance requirements, which can affect the import process. For instance, machinery imported into Europe must meet CE marking requirements, while buyers in Africa and South America may face different standards.

Understanding these nuances is essential for ensuring compliance and avoiding costly delays. B2B buyers should engage with suppliers who are well-versed in international regulations and can provide the necessary documentation to facilitate smooth importation.

Conclusion

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, a thorough understanding of the manufacturing processes and quality assurance practices in machinery manufacturing is crucial. By focusing on material preparation, forming techniques, assembly, finishing processes, and robust quality assurance measures, buyers can make informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘machinery manufacturer’

This practical sourcing guide aims to equip international B2B buyers with a structured approach to procure machinery manufacturers effectively. Whether you’re sourcing from Africa, South America, the Middle East, or Europe, following this checklist will help ensure that your procurement process is thorough and successful.

Step 1: Define Your Technical Specifications

Before starting the sourcing process, it’s essential to outline your technical requirements clearly. This includes understanding the machinery’s intended use, capacity, dimensions, and any specific features that are critical for your operations. A well-defined specification helps you communicate your needs effectively to potential suppliers and ensures that you receive relevant quotes.

Step 2: Research Potential Suppliers

Begin by compiling a list of potential machinery manufacturers. Utilize industry directories, trade shows, and online platforms to gather information. Look for suppliers with a proven track record in your specific machinery category, and consider their geographical location to optimize shipping costs and timelines.

- Consideration: Suppliers in closer proximity may offer better support and faster response times.

Step 3: Evaluate Supplier Certifications

When assessing suppliers, verifying their certifications is crucial. Certifications such as ISO 9001 or CE marking indicate adherence to international quality standards. Request documentation to confirm these credentials, as they can significantly reduce risks associated with product quality and compliance.

- Tip: Check if the supplier has any industry-specific certifications relevant to your machinery type.

Step 4: Request and Compare Quotes

Once you have a shortlist of potential suppliers, request detailed quotations. Ensure that each quote includes pricing, lead times, payment terms, and warranty information. Comparing these elements side-by-side will help you make an informed decision and negotiate better terms.

- Note: Look beyond just the price; consider the total cost of ownership, including maintenance and operational costs.

Step 5: Conduct Supplier Audits

If possible, conduct on-site audits or virtual inspections of the manufacturing facilities. This step is particularly important for buyers from regions with stringent quality requirements. An audit allows you to assess production capabilities, quality control processes, and overall operational standards.

- Action: Prepare a checklist of criteria to evaluate during the audit to ensure nothing is overlooked.

Step 6: Negotiate Contract Terms

Once you’ve selected a supplier, it’s time to negotiate the contract. Pay close attention to terms related to delivery schedules, payment structures, and after-sales support. A well-negotiated contract can protect you from unexpected costs and ensure that both parties have clear expectations.

- Advice: Consider including penalty clauses for late deliveries or quality discrepancies.

Step 7: Establish Communication Channels

Finally, establish clear communication channels with your chosen supplier. Regular updates on production status and shipment tracking are vital for maintaining a smooth procurement process. Effective communication can also help resolve any issues that may arise swiftly.

- Best Practice: Use project management tools to keep track of progress and facilitate communication.

By following these steps, international B2B buyers can streamline their procurement processes, minimize risks, and build strong, lasting relationships with machinery manufacturers. This systematic approach not only enhances operational efficiency but also contributes to long-term success in your business endeavors.

Comprehensive Cost and Pricing Analysis for machinery manufacturer Sourcing

What Are the Key Cost Components in Machinery Manufacturing?

When sourcing machinery, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects the overall cost. High-quality materials often increase the price but contribute to the durability and performance of the machinery.

-

Labor: Labor costs vary by region and can influence pricing. Countries with higher labor costs may have higher manufacturing prices, while those with lower labor costs can offer more competitive rates.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and administrative expenses. A thorough analysis of overhead can reveal potential areas for cost savings.

-

Tooling: Specialized tools and molds can add to upfront costs but may be necessary for customized machinery. Understanding tooling requirements is essential for accurate budgeting.

-

Quality Control (QC): Implementing strict QC measures is vital for ensuring product reliability and compliance with international standards. However, these measures can also increase costs.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors such as distance, mode of transport, and customs duties can significantly impact the final price.

-

Margin: Manufacturers typically include a profit margin in their pricing. Understanding the standard margins in the industry can help buyers gauge whether a price is reasonable.

What Factors Influence Pricing in Machinery Sourcing?

Several key elements can affect the pricing of machinery, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts, so understanding the supplier’s MOQ can help in negotiating better prices.

-

Specifications and Customization: Custom machinery tailored to specific needs can incur additional costs. Buyers should be clear about their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality and certified materials may come at a premium but can reduce long-term maintenance costs. Buyers should weigh the benefits against the initial investment.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their perceived value and lower risk.

-

Incoterms: Understanding the terms of delivery (such as FOB, CIF, etc.) is crucial for calculating total landed costs. Different terms can shift responsibility for shipping and customs, impacting overall pricing.

How Can International B2B Buyers Negotiate Effectively?

Negotiation is a vital skill for international buyers looking to secure the best pricing on machinery. Here are some actionable tips:

-

Leverage Volume: If possible, consolidate orders to negotiate lower unit prices. Suppliers are often willing to offer better terms for larger contracts.

-

Request Transparent Pricing: Ask suppliers for a breakdown of costs. This transparency can provide leverage in negotiations and help identify areas for potential savings.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs, including maintenance, energy consumption, and potential downtime. A higher initial price may lead to lower TCO.

-

Be Aware of Pricing Nuances: Different regions have varying pricing structures influenced by local economic conditions and currency fluctuations. Stay informed about these factors to negotiate effectively.

-

Build Relationships: Establishing a good relationship with suppliers can lead to better pricing over time. Trust can result in more favorable terms and conditions.

Disclaimer on Indicative Prices

Pricing in the machinery manufacturing sector can fluctuate based on numerous factors, including market demand, material availability, and economic conditions. Therefore, the information provided should be viewed as indicative and subject to change. It is advisable for buyers to conduct their own due diligence and obtain current quotes from suppliers to ensure accurate budgeting.

Alternatives Analysis: Comparing machinery manufacturer With Other Solutions

Understanding the Importance of Alternative Solutions in Machinery Manufacturing

When considering machinery manufacturers, it’s crucial for B2B buyers to explore alternative solutions that may better align with their operational needs and budget constraints. By comparing different technologies or methods, businesses can make informed decisions that optimize performance and cost-effectiveness. This section evaluates machinery manufacturers alongside two viable alternatives: 3D Printing Technology and Outsourcing Manufacturing Services.

Comparison Table of Machinery Manufacturer and Alternatives

| Comparison Aspect | Machinery Manufacturer | 3D Printing Technology | Outsourcing Manufacturing Services |

|---|---|---|---|

| Performance | High output and durability | Variable, dependent on design | Moderate, reliant on supplier quality |

| Cost | High initial investment | Lower initial cost, but variable material costs | Cost-effective for low-volume production |

| Ease of Implementation | Complex setup and training | User-friendly with rapid prototyping | Moderate complexity, dependent on supplier |

| Maintenance | Regular maintenance required | Minimal maintenance | No maintenance for the buyer |

| Best Use Case | Mass production of complex machinery | Custom parts and prototypes | Cost-sensitive projects with low volume |

Pros and Cons of 3D Printing Technology

3D printing technology has gained traction as a disruptive alternative to traditional machinery manufacturing. One of its primary advantages is the ability to create customized parts with minimal waste, making it ideal for prototyping and low-volume production. The initial investment is generally lower than that of purchasing heavy machinery, and it allows for rapid iterations in design. However, the performance can be inconsistent, especially with complex designs, and material costs can accumulate, impacting the overall budget. B2B buyers should consider 3D printing when they require flexibility and innovation in design but must also weigh the variability in output quality.

Evaluating Outsourcing Manufacturing Services

Outsourcing manufacturing services can be a strategic move for B2B buyers seeking to reduce costs and increase efficiency. This approach allows companies to leverage the expertise and capabilities of specialized manufacturers, especially in regions with lower labor costs. Outsourcing can be particularly beneficial for businesses that do not have the volume to justify a large machinery investment. However, this method comes with its own set of challenges, such as potential quality control issues and longer lead times. Buyers must conduct thorough due diligence on potential partners to ensure reliability and quality standards are met.

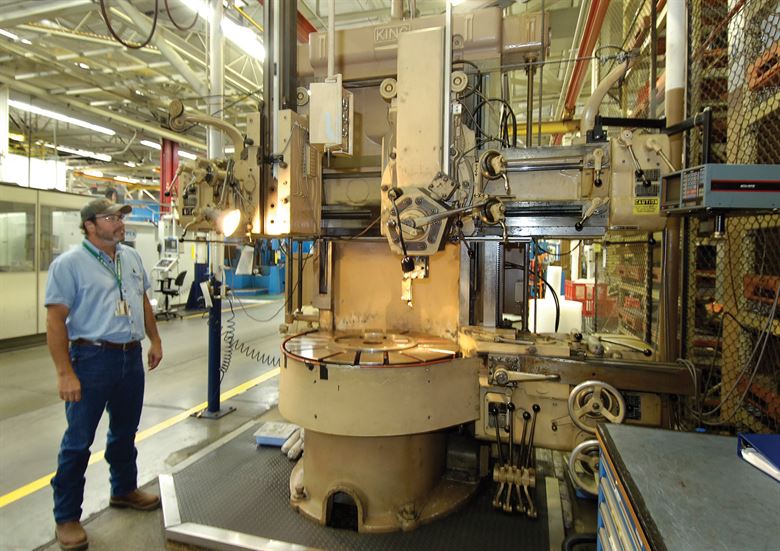

A stock image related to machinery manufacturer.

Conclusion: How to Choose the Right Solution for Your Needs

In conclusion, selecting the right manufacturing solution depends on a variety of factors, including production volume, budget, and specific operational requirements. Machinery manufacturers excel in high-output scenarios, while 3D printing offers flexibility and customization for lower volume needs. Outsourcing can provide cost savings and access to specialized skills but may introduce complexities in quality control. International B2B buyers from regions like Africa, South America, the Middle East, and Europe should carefully assess their unique circumstances and priorities to make a decision that aligns with their strategic goals and operational efficiency.

Essential Technical Properties and Trade Terminology for machinery manufacturer

What Are the Key Technical Properties in Machinery Manufacturing?

Understanding the essential technical properties of machinery is crucial for B2B buyers to ensure they select the right equipment for their operations. Here are some critical specifications that should be considered:

1. Material Grade: Why Is It Important?

Material grade refers to the quality and composition of the materials used in manufacturing machinery. Common grades include carbon steel, stainless steel, and aluminum. The choice of material affects durability, corrosion resistance, and overall performance. For instance, stainless steel is often preferred in industries that require high hygiene standards, such as food processing. Buyers should assess material grade based on their specific application needs to ensure longevity and reliability.

2. Tolerance: How Does It Impact Performance?

Tolerance defines the permissible limits of variation in a physical dimension or measured value. In machinery, tighter tolerances are often necessary for precision applications, while looser tolerances may be acceptable for less critical parts. Understanding tolerance levels is essential for ensuring parts fit and function together correctly, which can significantly affect the efficiency and safety of operations. Buyers should inquire about tolerance specifications to avoid costly assembly issues or operational failures.

3. Load Capacity: What Should Buyers Know?

Load capacity indicates the maximum load a machine can safely handle. This specification is crucial for buyers to ensure that machinery can meet the demands of their specific applications without risk of failure. For example, a crane’s load capacity will determine how much weight it can lift, impacting operational efficiency and safety. Buyers should consider their operational requirements and select machinery with an appropriate load capacity to avoid potential hazards.

4. Energy Efficiency: How Does It Affect Operating Costs?

Energy efficiency measures how effectively a machine converts energy into productive work. Higher energy efficiency can lead to significant cost savings over time, making it an essential consideration for B2B buyers. Machines with high energy efficiency ratings not only reduce operational costs but also contribute to sustainability goals. Buyers should evaluate the energy ratings of machinery to ensure they are making an environmentally and economically sound investment.

What Are Common Trade Terms in Machinery Manufacturing?

Familiarity with industry jargon is vital for effective communication and negotiation in the B2B landscape. Here are some key terms that buyers should understand:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In machinery manufacturing, understanding OEM partnerships can help buyers identify reliable sources for replacement parts or machinery. Engaging with OEMs can ensure compatibility and quality, leading to better long-term performance.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, especially those in emerging markets where budget constraints may exist. Understanding MOQ can help buyers negotiate better terms and avoid over-purchasing, ensuring they meet their operational needs without excessive expenditure.

3. RFQ (Request for Quotation): How Is It Used?

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. For buyers, issuing an RFQ can facilitate competitive bidding, helping them secure the best prices and terms. It’s a strategic tool for ensuring transparency and enabling informed decision-making.

4. Incoterms: What Are They and Why Do They Matter?

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of buyers and sellers in international trade. They clarify aspects such as who pays for shipping, insurance, and tariffs. Understanding Incoterms is essential for buyers to ensure compliance and avoid unexpected costs during international transactions.

Conclusion

A stock image related to machinery manufacturer.

By grasping these essential technical properties and trade terminologies, B2B buyers from Africa, South America, the Middle East, and Europe can make more informed purchasing decisions. Understanding material grades, tolerances, load capacities, energy efficiency, and key trade terms will empower buyers to optimize their machinery investments, ensuring operational efficiency and long-term success.

Navigating Market Dynamics and Sourcing Trends in the machinery manufacturer Sector

What Are the Key Market Dynamics Affecting Machinery Manufacturers?

The machinery manufacturing sector is currently experiencing significant transformations driven by technological advancements and evolving global demands. One of the most notable trends is the increasing adoption of Industry 4.0 technologies, which encompasses IoT, AI, and automation. These innovations are reshaping production processes, enhancing operational efficiencies, and enabling predictive maintenance, which is particularly beneficial for international B2B buyers seeking reliable machinery solutions.

Additionally, the demand for customized machinery solutions is on the rise, reflecting the unique needs of diverse markets, especially in Africa, South America, the Middle East, and Europe. This customization trend is largely influenced by the varying industrial requirements across regions. For instance, buyers from Africa may prioritize robust machinery capable of withstanding harsh conditions, while European buyers might focus on precision and efficiency.

Emerging sourcing trends highlight a shift towards digital procurement platforms, allowing buyers to easily compare suppliers and products. Furthermore, the globalization of supply chains has become more pronounced, leading to increased collaboration between manufacturers and suppliers across different continents. This trend offers B2B buyers an opportunity to source competitively priced machinery while gaining access to a wider range of innovations.

How Is Sustainability Influencing Sourcing Decisions in the Machinery Sector?

Sustainability has emerged as a crucial consideration for B2B buyers in the machinery manufacturing sector. The environmental impact of machinery production, including carbon emissions and resource depletion, is prompting buyers to seek out suppliers committed to sustainable practices. By prioritizing ethical sourcing, companies can mitigate risks associated with environmental regulations and enhance their brand reputation.

Buyers are increasingly looking for suppliers that offer ‘green’ certifications such as ISO 14001, which demonstrates an organization’s commitment to environmental management. Additionally, the use of sustainable materials, such as recycled metals and eco-friendly lubricants, is becoming a key decision factor. This shift not only reduces the environmental footprint but also resonates with end consumers who prefer environmentally responsible products.

Moreover, as international markets become more interconnected, buyers are demanding transparency in their supply chains. Understanding the origin of materials and the ethical practices of suppliers helps in making informed sourcing decisions. For buyers in regions like Africa and South America, where local regulations may vary, ensuring compliance with international sustainability standards is particularly critical.

What Has Driven the Evolution of the Machinery Manufacturing Sector?

The machinery manufacturing sector has undergone a significant evolution over the past few decades, shaped by technological advancements and globalization. Initially characterized by manual processes, the industry has progressively embraced automation and digitalization, enhancing production efficiency and accuracy.

The shift towards global supply chains has enabled manufacturers to access a broader range of resources and expertise, leading to cost reductions and innovation. In recent years, a focus on sustainability and ethical practices has further influenced the sector, prompting manufacturers to adapt their operations to meet the growing demand for environmentally friendly products.

As international B2B buyers continue to navigate these dynamics, understanding the historical context of the machinery manufacturing sector will provide valuable insights into current trends and future developments.

Frequently Asked Questions (FAQs) for B2B Buyers of machinery manufacturer

-

How do I evaluate the credibility of a machinery manufacturer?

To assess the credibility of a machinery manufacturer, start by checking their industry certifications and memberships in relevant trade organizations. Request references from previous clients, and investigate their reputation online through reviews and testimonials. Additionally, visit their production facilities if possible, and analyze their quality assurance processes. Engaging in direct communication can also provide insights into their customer service responsiveness and willingness to address your specific needs. -

What are the key factors to consider when sourcing machinery from international suppliers?

When sourcing machinery internationally, consider factors such as the manufacturer’s experience in your industry, the quality of their products, and their compliance with international standards. Evaluate their ability to provide after-sales support, including spare parts availability and technical assistance. Additionally, take into account shipping logistics, customs regulations, and potential tariffs that could impact your overall costs. Lastly, assess the manufacturer’s flexibility in terms of customization and order volume. -

What is the minimum order quantity (MOQ) when purchasing machinery?

The minimum order quantity (MOQ) varies by manufacturer and the type of machinery being ordered. Generally, larger manufacturers may have higher MOQs due to economies of scale, while smaller or specialized manufacturers may offer lower MOQs. It is essential to communicate your needs upfront to negotiate favorable terms. Keep in mind that ordering below the MOQ might lead to increased per-unit costs, which can affect your budget. -

How can I ensure the machinery meets quality standards before delivery?

To ensure machinery quality before delivery, request a detailed inspection report and certifications from the manufacturer. Engage a third-party inspection service to conduct quality assurance checks on the machinery during production. Additionally, consider arranging for a pre-shipment inspection, which allows you to verify that the machinery meets all specifications and standards. This proactive approach minimizes the risk of receiving subpar equipment and helps ensure your investment is protected. -

What are common payment terms for international machinery purchases?

Common payment terms for international machinery purchases include advance payments, letters of credit, and payment upon delivery. Many manufacturers require a deposit upfront, with the balance payable before shipping or upon receipt. Ensure that the payment terms are clearly outlined in your contract, and consider using escrow services for larger transactions to safeguard your funds. Familiarize yourself with the payment methods accepted in the country of the supplier to avoid complications. -

How do I handle logistics and shipping when sourcing machinery internationally?

Handling logistics when sourcing machinery internationally involves several steps. First, choose a reliable freight forwarder who understands customs regulations and can manage the shipping process efficiently. Determine whether you will use incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to clarify responsibilities for shipping costs and risks. Finally, ensure that all necessary documentation, including invoices, packing lists, and certificates of origin, is prepared to facilitate smooth customs clearance. -

Can machinery manufacturers customize their products to meet my specific needs?

Many machinery manufacturers offer customization options to cater to specific industry requirements or unique operational processes. Discuss your needs with the manufacturer early in the procurement process to determine the extent of customization available. Be clear about your expectations regarding performance, dimensions, and features. Keep in mind that custom solutions may require additional lead time and could impact pricing, so factor these considerations into your decision-making process. -

What are the best practices for building a long-term relationship with a machinery supplier?

Building a long-term relationship with a machinery supplier involves open communication, regular feedback, and mutual trust. Establish clear expectations from the outset and maintain a consistent dialogue about performance and service quality. Consider scheduling regular meetings or site visits to discuss ongoing projects and address any concerns. Additionally, showing loyalty through repeat business can incentivize suppliers to prioritize your needs and offer favorable terms in the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for machinery manufacturer

In the rapidly evolving landscape of machinery manufacturing, strategic sourcing remains a pivotal component for international B2B buyers. Understanding the dynamics of global supply chains allows organizations to mitigate risks, enhance operational efficiency, and leverage competitive pricing. Key takeaways include the importance of establishing robust relationships with suppliers, utilizing technology for real-time data analysis, and focusing on sustainability practices that resonate with modern market demands.

What steps can you take to enhance your sourcing strategy? By prioritizing transparency and communication with suppliers, buyers can foster trust and collaboration that leads to long-term partnerships. Additionally, exploring regional suppliers in Africa, South America, the Middle East, and Europe can unveil new opportunities and reduce dependency on single-source providers.

As we look to the future, the machinery manufacturing sector will continue to be shaped by innovations in technology and shifts in consumer preferences. International B2B buyers should remain agile, adapting their sourcing strategies to align with these changes. Embrace strategic sourcing as a proactive approach to not only meet current demands but also position your organization for future growth and sustainability. Engage with your suppliers today to unlock new efficiencies and drive your business forward.