Discover Top Milling Machine Suppliers: Your Complete Guide (2025)

Introduction: Navigating the Global Market for milling machine supplier

Navigating the global market for milling machine suppliers can be a daunting task for international B2B buyers, especially given the diverse range of products, applications, and supplier standards across different regions. One of the key challenges faced by buyers from Africa, South America, the Middle East, and Europe (including countries like Spain and Egypt) is identifying reliable suppliers that meet both their quality and budgetary requirements. This guide aims to demystify the complexities involved in sourcing milling machines, providing a comprehensive overview of the various types available, their specific applications, and critical factors to consider during supplier vetting.

From understanding the technological advancements in milling machines to evaluating cost structures and import regulations, this guide equips buyers with the essential knowledge needed to make informed purchasing decisions. You will find actionable insights on assessing supplier credibility, negotiating prices, and ensuring after-sales support, which are crucial for maintaining operational efficiency and competitiveness in your market.

By leveraging the insights provided in this guide, B2B buyers will be empowered to navigate the intricate landscape of milling machine suppliers effectively. This will not only enhance their procurement strategies but also contribute to the overall growth and sustainability of their businesses in an increasingly globalized economy.

Understanding milling machine supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vertical Milling Machine Supplier | Offers machines with vertical spindle orientation | Aerospace, automotive, and mold making | Pros: High precision; Cons: Limited to certain part geometries. |

| Horizontal Milling Machine Supplier | Features a horizontal spindle for heavier cutting | Heavy machinery and large part fabrication | Pros: Efficient for large parts; Cons: Requires more floor space. |

| CNC Milling Machine Supplier | Provides computer-controlled milling machines | Electronics, medical devices, and prototypes | Pros: High automation and precision; Cons: Higher initial investment. |

| Toolroom Milling Machine Supplier | Focuses on smaller, versatile machines for toolmaking | Tool and die shops, small batch production | Pros: Flexible for various tasks; Cons: Slower than industrial machines. |

| Specialty Milling Machine Supplier | Custom machines tailored for specific applications | Specialized industries like pharmaceuticals | Pros: Tailored solutions; Cons: Potentially longer lead times. |

What Are the Key Characteristics of Vertical Milling Machine Suppliers?

Vertical milling machine suppliers provide equipment that operates with the spindle oriented vertically. This design is ideal for machining flat surfaces, grooves, and complex shapes in various materials. These machines are widely used in aerospace, automotive, and mold-making industries due to their high precision and versatility. When purchasing, buyers should consider the machine’s rigidity, tooling options, and the supplier’s support services to ensure optimal performance.

How Do Horizontal Milling Machine Suppliers Differ?

Horizontal milling machine suppliers offer machines with a horizontal spindle, allowing for more robust cutting capabilities. These machines are particularly effective for larger workpieces and are commonly used in the heavy machinery sector. Buyers should evaluate the machine’s horsepower, table size, and the availability of accessories like rotary tables. While horizontal milling machines are efficient for large parts, they require more floor space, which can be a consideration for smaller facilities.

Why Choose CNC Milling Machine Suppliers?

CNC (Computer Numerical Control) milling machine suppliers focus on providing highly automated machines that enhance production efficiency and precision. These machines are suitable for industries such as electronics and medical devices, where precision is paramount. Buyers should assess the software compatibility, ease of programming, and the level of technical support offered. Although the initial investment is higher, the long-term benefits of reduced labor costs and increased accuracy often justify the expense.

What Are the Advantages of Toolroom Milling Machine Suppliers?

Toolroom milling machine suppliers cater to the needs of small batch production and toolmaking. These machines are designed for versatility and can handle various tasks, making them suitable for tool and die shops. Buyers should consider the machine’s footprint, ease of use, and the range of tooling available. While toolroom mills are slower than industrial counterparts, their flexibility makes them valuable for smaller operations that require quick setups and adjustments.

When to Consider Specialty Milling Machine Suppliers?

Specialty milling machine suppliers provide customized solutions tailored for specific applications within niche industries, such as pharmaceuticals. These machines often incorporate unique features to meet stringent regulatory requirements or specialized production processes. Buyers should evaluate the supplier’s experience in their industry, the customization options available, and the lead times for delivery. While specialty machines offer tailored solutions, longer lead times and potentially higher costs are important considerations for budget-conscious buyers.

Related Video: What is Milling? Parts, Operations and Types of Milling Machine

Key Industrial Applications of milling machine supplier

| Industry/Sector | Specific Application of milling machine supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision part manufacturing for aircraft components | Enhanced accuracy and reduced waste in production processes | Supplier certifications, machine accuracy, and lead times |

| Automotive | Production of engine components and transmission parts | Increased efficiency and quality control in production | Supplier reliability, after-sales support, and maintenance services |

| Metalworking | Fabrication of metal parts and tools | Improved machining capabilities and faster turnaround times | Material compatibility, tooling options, and energy efficiency |

| Construction | Manufacturing of structural components and fittings | Cost-effective production and compliance with industry standards | Local regulations, material sourcing, and delivery timelines |

| Electronics | Production of circuit board components | High precision and reduced production errors | Technology integration, scalability, and supplier reputation |

How Are Milling Machines Used in the Aerospace Industry?

In the aerospace sector, milling machines are crucial for the precision manufacturing of aircraft components such as turbine blades and fuselage parts. These machines allow for the intricate designs and tight tolerances required in aviation. For international buyers, especially from regions like Europe and the Middle East, it is essential to source suppliers that hold relevant certifications, such as AS9100, to ensure compliance with stringent aerospace standards. The challenge often lies in ensuring machine accuracy and reliability, which directly impacts safety and performance.

What Role Do Milling Machines Play in Automotive Manufacturing?

Milling machines are extensively used in the automotive industry to produce engine components, transmission parts, and other critical elements. The precision offered by modern milling technology helps manufacturers achieve high-quality outputs while minimizing waste. For buyers from South America and Africa, it’s vital to consider the supplier’s reliability and the availability of after-sales support, as these factors significantly influence long-term production efficiency. Additionally, understanding the machinery’s compatibility with various materials can streamline the sourcing process.

How Are Milling Machines Utilized in Metalworking?

In metalworking, milling machines facilitate the fabrication of various metal parts and tools. They enhance machining capabilities, allowing for complex shapes and improved surface finishes. International buyers must assess the energy efficiency of the machines, as operational costs can vary significantly. Furthermore, sourcing suppliers who offer a variety of tooling options can provide additional flexibility in production processes, enabling businesses to meet diverse customer demands.

Why Are Milling Machines Important in Construction?

For the construction industry, milling machines are integral to manufacturing structural components and fittings. They provide cost-effective production solutions while ensuring that products meet industry standards for safety and durability. Buyers from regions like Africa and Europe should be aware of local regulations that may affect sourcing decisions. Additionally, timely delivery and material sourcing are critical considerations that can influence project timelines and budgets.

How Do Milling Machines Support Electronics Manufacturing?

In electronics, milling machines are employed to produce circuit board components with high precision. The ability to achieve tight tolerances significantly reduces production errors, enhancing overall product quality. For international B2B buyers, particularly in the Middle East and Europe, the integration of advanced technology in milling processes can be a key differentiator. Evaluating the scalability of suppliers is also essential, as growing production needs must be met without compromising quality or efficiency.

Related Video: Use of the Fly Cutter on the Milling Machine

3 Common User Pain Points for ‘milling machine supplier’ & Their Solutions

Scenario 1: Difficulty in Assessing Machine Compatibility

The Problem:

B2B buyers often struggle to assess whether a milling machine from a supplier is compatible with their existing production line. This issue is particularly pronounced in industries with specialized production requirements, such as aerospace and automotive. Buyers may find themselves facing uncertainty regarding the machine’s capabilities, dimensions, and integration with current systems, leading to potential delays in production and increased costs.

The Solution:

To effectively overcome compatibility challenges, it is crucial for buyers to conduct a thorough needs assessment before engaging with milling machine suppliers. Begin by documenting specific production requirements, including the types of materials to be milled, desired precision levels, and any existing machinery specifications. Once this information is collected, communicate these needs directly to suppliers during the inquiry phase. Request detailed specifications, including CAD drawings, machine dimensions, and performance metrics.

Additionally, consider utilizing a prototyping approach where possible. This involves requesting a trial period or a demonstration of the machine’s capabilities. Not only does this enable you to evaluate the machine’s performance firsthand, but it also allows for discussions about potential modifications that could enhance compatibility. Engaging with suppliers who have a track record of successfully integrating their machines into diverse setups can also provide invaluable insights.

Scenario 2: Concerns About After-Sales Support and Maintenance

The Problem:

A prevalent concern among B2B buyers is the quality of after-sales support and maintenance services provided by milling machine suppliers. Particularly in regions such as Africa and South America, where access to technical support can be limited, buyers fear that inadequate service could lead to prolonged downtimes and losses in productivity. This uncertainty can make it challenging to commit to a supplier, impacting decision-making processes.

The Solution:

To mitigate worries regarding after-sales support, it is essential to prioritize suppliers with a robust service infrastructure. Before finalizing a purchase, inquire about the supplier’s service offerings, including response times for service requests, availability of spare parts, and the qualifications of their technicians.

Furthermore, buyers should evaluate the supplier’s reputation through references and case studies, focusing on their track record of customer service and support. Engaging with other companies in your industry can provide insights into suppliers who have excelled in after-sales service.

Also, consider negotiating a service-level agreement (SLA) that clearly outlines the expected response times and service commitments. This formal agreement can create accountability and ensure that your needs will be prioritized post-purchase.

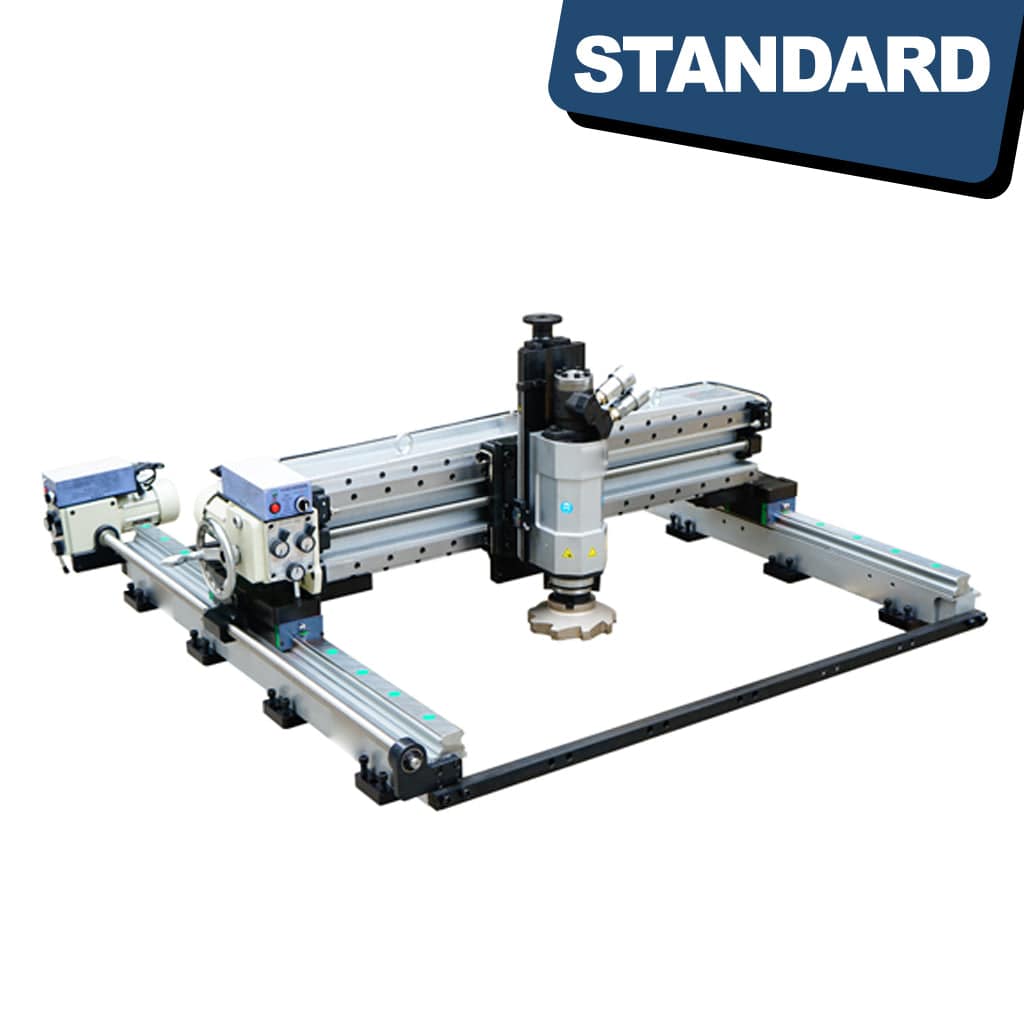

A stock image related to milling machine supplier.

Scenario 3: Pricing Transparency and Hidden Costs

The Problem:

International B2B buyers often face challenges related to pricing transparency when sourcing milling machines. Suppliers may present competitive initial prices, but buyers frequently encounter hidden costs associated with shipping, installation, training, and potential import tariffs. This lack of clarity can lead to budget overruns and hinder long-term financial planning.

The Solution:

To navigate pricing challenges effectively, buyers should adopt a comprehensive approach to cost analysis. Begin by requesting a detailed quotation that includes all potential costs associated with the purchase. This should encompass not only the base price of the milling machine but also shipping fees, installation costs, and any ancillary services such as operator training.

Engage in discussions with the supplier to clarify any uncertainties regarding additional costs. This proactive communication can help identify potential hidden fees upfront. Additionally, consider leveraging procurement platforms or third-party consultants who specialize in the milling industry to gain insights into fair pricing structures and common pitfalls.

Finally, conducting a total cost of ownership (TCO) analysis can provide a clearer financial picture. This analysis takes into account not only the purchase price but also ongoing operational costs, maintenance expenses, and the machine’s expected lifespan. By understanding the complete financial implications of the purchase, buyers can make more informed decisions and avoid surprises down the line.

Strategic Material Selection Guide for milling machine supplier

When selecting materials for milling machines, international B2B buyers must consider several factors that influence performance, cost, and compliance with industry standards. Below, we analyze four common materials used in milling machine components, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Steel in Milling Machines?

Steel is one of the most widely used materials in milling machines due to its excellent mechanical properties. It offers high strength, durability, and resistance to deformation under load. Steel can withstand high temperatures and pressures, making it suitable for heavy-duty applications.

Pros & Cons:

– Pros: Steel is cost-effective and offers good machinability. It can be heat-treated to enhance its properties, making it versatile for various applications.

– Cons: Steel is prone to corrosion if not properly treated, which can affect its longevity in humid or corrosive environments.

Impact on Application: Steel is compatible with a wide range of media, making it ideal for various milling applications. However, its susceptibility to corrosion may limit its use in environments exposed to moisture or chemicals.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM or DIN. Additionally, they should consider the availability of corrosion-resistant steel grades, especially in regions with high humidity, such as parts of Africa and South America.

How Does Aluminum Compare as a Material for Milling Machines?

A stock image related to milling machine supplier.

Aluminum is increasingly popular in milling applications due to its lightweight nature and excellent corrosion resistance. It is particularly advantageous for applications where weight reduction is critical.

Pros & Cons:

– Pros: Aluminum is lightweight and offers good machinability, which can lead to lower manufacturing costs. Its natural corrosion resistance enhances durability.

– Cons: It has lower strength compared to steel, which may limit its use in heavy-duty applications.

Impact on Application: Aluminum is suitable for applications requiring lightweight components, such as in aerospace and automotive industries. However, its lower strength may not be suitable for high-load applications.

Considerations for International Buyers: Buyers should be aware of the specific aluminum alloys available and their compliance with international standards. Regions like Europe have strict regulations regarding material properties, which should be taken into account.

What Are the Benefits of Using Cast Iron in Milling Machines?

Cast iron is known for its excellent damping properties, which help reduce vibrations during milling operations. This material is often used in machine bases and frames.

Pros & Cons:

– Pros: Cast iron is highly durable and provides excellent wear resistance. Its ability to absorb vibrations enhances machining accuracy.

– Cons: It is heavier than steel and aluminum, which may complicate transportation and installation.

Impact on Application: Cast iron is particularly effective in applications that require stability and precision. However, its weight can be a disadvantage in portable milling setups.

Considerations for International Buyers: Buyers should consider the weight implications for shipping and installation. Compliance with standards like JIS or ASTM is crucial, especially in regions with specific material requirements.

How Does Composite Material Perform in Milling Machines?

Composite materials, such as carbon fiber reinforced plastics, are gaining traction in milling applications due to their unique properties.

Pros & Cons:

– Pros: Composites are lightweight and offer excellent strength-to-weight ratios. They are resistant to corrosion and can be tailored for specific applications.

– Cons: They can be more expensive to manufacture and may require specialized machining techniques.

Impact on Application: Composites are ideal for applications where weight savings are critical without compromising strength. However, their higher cost may limit widespread adoption.

Considerations for International Buyers: Buyers should evaluate the availability of composite materials in their regions and ensure compliance with relevant standards. The cost implications should also be analyzed, particularly in budget-sensitive markets.

Summary Table of Material Selection for Milling Machines

| Material | Typical Use Case for milling machine supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, gears | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Lightweight components, automotive parts | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Cast Iron | Machine bases, frames | Excellent vibration damping | Heavy and less portable | Medium |

| Composite | Aerospace components, high-performance parts | Lightweight and customizable | Higher manufacturing cost | High |

This guide provides a comprehensive overview of material selection for milling machines, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for milling machine supplier

What Are the Main Stages of Manufacturing for Milling Machines?

When sourcing milling machines, understanding the manufacturing process is crucial. The typical stages in the production of milling machines include material preparation, forming, assembly, and finishing.

-

Material Preparation: This stage involves selecting high-quality raw materials such as steel, aluminum, or composite materials. Suppliers often conduct initial tests to verify material properties, ensuring they meet specific standards for durability and performance.

-

Forming: In this stage, materials are shaped into parts using various techniques such as casting, forging, and machining. Advanced technologies like CNC (Computer Numerical Control) machining are frequently employed to achieve precise dimensions and tolerances, which are essential for the machine’s operational efficiency.

-

Assembly: After forming, individual components are assembled. This process can be highly automated, with robotic arms and conveyor systems playing significant roles. Skilled technicians oversee the assembly to ensure that parts fit together correctly, and any potential issues are addressed in real-time.

-

Finishing: The final stage involves applying surface treatments and coatings to enhance durability and performance. Techniques such as anodizing, painting, and grinding are common. This step not only improves aesthetics but also helps protect the machine from wear and corrosion.

What Key Techniques Are Used in Milling Machine Manufacturing?

Manufacturers utilize several advanced techniques during the milling machine production process:

-

CNC Machining: This technology allows for high precision in cutting and shaping materials. It reduces human error and increases efficiency, making it a preferred method in the industry.

-

3D Printing: Emerging as a revolutionary technique, 3D printing can create complex parts that are lightweight and strong, often reducing waste and production time.

-

Robotic Automation: Robots are increasingly used for repetitive tasks, such as assembly and quality inspections, ensuring consistency and reducing labor costs.

-

Lean Manufacturing: Many suppliers adopt lean principles to minimize waste and improve efficiency. This approach not only reduces costs but also enhances the overall quality of the final product.

How Is Quality Assurance Implemented in Milling Machine Production?

Quality assurance (QA) is critical in manufacturing milling machines, ensuring that products meet international standards and customer expectations. The following aspects are essential:

-

International Standards Compliance: Many suppliers adhere to ISO 9001, which focuses on quality management systems. This certification demonstrates a commitment to quality and customer satisfaction. Additionally, industry-specific standards such as CE marking (for Europe) and API specifications (for oil and gas sectors) may apply.

-

Quality Control Checkpoints: Effective quality control involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are tested upon arrival to ensure they meet required specifications.

– In-Process Quality Control (IPQC): During production, ongoing inspections and tests are conducted to identify any deviations from quality standards.

– Final Quality Control (FQC): Once production is complete, the final product undergoes rigorous testing to ensure it meets all specifications before shipment. -

Common Testing Methods: Various testing methods are employed to verify quality, including:

– Dimensional Inspection: Using calipers and gauges to measure component dimensions.

– Functional Testing: Ensuring the machine operates correctly under simulated conditions.

– Non-Destructive Testing (NDT): Techniques like ultrasonic testing and X-ray inspections are used to detect internal flaws without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is vital. Here are actionable steps to ensure supplier reliability:

-

Conduct Supplier Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. Look for certifications and compliance with international standards.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including inspection reports and test results. This transparency can help you assess their commitment to quality.

-

Engage Third-Party Inspectors: Hiring third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes and product quality. This is particularly useful for buyers unfamiliar with local suppliers.

-

Understand Certification Nuances: Different regions may have varying standards and certifications. Buyers should familiarize themselves with local regulations and ensure that suppliers comply with them, especially when sourcing from countries with less stringent regulations.

What Are the Specific QC Challenges Faced by International B2B Buyers?

International buyers often encounter unique challenges regarding quality control. These include:

-

Cultural Differences: Varying approaches to quality assurance across cultures can lead to misunderstandings. Building strong relationships and clear communication channels with suppliers is essential.

-

Logistical Issues: Transportation delays and customs procedures can complicate quality assurance efforts. Buyers should account for these factors in their timelines and expectations.

-

Regulatory Compliance: Different countries have distinct regulations regarding product safety and quality. Buyers must ensure that their suppliers are compliant with both local and international standards to avoid legal and financial repercussions.

Conclusion: Making Informed Decisions in Milling Machine Procurement

Understanding the manufacturing processes and quality assurance practices of milling machine suppliers is essential for making informed procurement decisions. By focusing on the key stages of manufacturing, implementing robust quality control measures, and conducting thorough supplier evaluations, international B2B buyers can secure reliable and high-quality milling machines that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘milling machine supplier’

When sourcing milling machine suppliers, it’s essential to have a structured approach to ensure you make informed decisions that meet your operational needs. This checklist serves as a practical guide for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to streamline their procurement process effectively.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in sourcing a milling machine supplier. Consider the type of materials you will process, the desired precision, and the volume of production. Be specific about the machine’s capabilities, such as spindle speed, feed rates, and the size of the workpiece. This clarity helps suppliers provide accurate proposals and solutions tailored to your needs.

Step 2: Conduct Market Research for Suppliers

Engage in comprehensive market research to identify potential suppliers. Utilize online platforms such as industry-specific directories, trade shows, and B2B marketplaces. Look for suppliers that have a solid reputation and proven track record in your industry. Pay attention to customer reviews and feedback to gauge their reliability and service quality.

Step 3: Evaluate Supplier Certifications and Standards

Ensure the suppliers you consider hold relevant certifications such as ISO 9001 or CE marking. These certifications demonstrate compliance with international quality management standards and safety regulations. Additionally, inquire about their manufacturing processes and quality control measures to ensure they align with industry standards.

Step 4: Assess Production Capabilities and Lead Times

Understanding the supplier’s production capacity and lead times is crucial for planning your operations. Request information on their manufacturing capabilities, including technology used, workforce expertise, and machinery. Evaluate whether they can meet your order volume and delivery deadlines consistently, as delays can impact your business operations significantly.

Step 5: Request and Analyze Quotations

Solicit detailed quotations from multiple suppliers, ensuring they include all costs associated with the milling machines, such as shipping, installation, and after-sales support. Analyze the quotes not just on price but also on value, including warranty terms, technical support, and maintenance services. This comprehensive assessment will help you identify the best overall offer.

Step 6: Conduct Site Visits or Virtual Tours

If feasible, visit the supplier’s manufacturing facility to observe their operations firsthand. This visit allows you to assess the quality of their processes and equipment. If an on-site visit is not possible, request virtual tours or detailed videos of their production lines. This step is crucial for verifying claims and ensuring transparency.

Step 7: Establish Clear Communication Channels

Effective communication is vital for a successful supplier relationship. Set up clear channels for discussing technical details, progress updates, and any issues that may arise. Ensure that both parties understand the terms of engagement, including payment terms, delivery schedules, and service level agreements. Good communication fosters a collaborative environment and helps prevent misunderstandings.

By following this checklist, B2B buyers can navigate the complexities of sourcing milling machine suppliers effectively, ensuring they select partners that align with their operational goals and industry standards.

Comprehensive Cost and Pricing Analysis for milling machine supplier Sourcing

What Are the Key Cost Components in Sourcing Milling Machines?

When sourcing milling machines, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used in manufacturing milling machines significantly affect the price. High-grade steel or specialized alloys will increase costs but can enhance durability and performance.

-

Labor: Labor costs vary by region and can influence overall pricing. Countries with lower labor costs may offer more competitive pricing but may compromise on quality.

-

Manufacturing Overhead: This includes all indirect costs related to production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize these overhead costs.

-

Tooling: The initial investment in tooling for milling machines can be substantial. Custom tooling increases the cost but is necessary for specialized machine functions.

-

Quality Control (QC): Implementing robust QC processes ensures that the milling machines meet safety and performance standards. However, this adds to the overall cost structure.

-

Logistics: Transportation and handling costs are vital considerations, especially for international shipping. The location of the supplier and the destination can significantly influence these expenses.

-

Margin: Supplier margins can vary widely. Understanding how a supplier structures their pricing will help buyers assess value versus cost.

How Do Price Influencers Impact Milling Machine Costs?

Several factors can influence the pricing of milling machines, including:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes typically lead to lower per-unit prices. Suppliers may offer better pricing for larger orders, making it essential for buyers to negotiate MOQs.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should balance their needs for specific functionalities with budget constraints.

-

Materials Used: The choice of materials directly impacts cost. Buyers should assess whether the material quality aligns with their operational needs.

-

Quality and Certifications: Machines that comply with international standards and certifications often come at a premium. However, such machines can reduce long-term operational risks and costs.

-

Supplier Factors: The supplier’s reputation, experience, and location can affect pricing. Established suppliers with a history of reliability may charge more but offer better support and service.

-

Incoterms: Understanding the terms of shipping and delivery is essential. Costs can vary significantly based on whether the buyer is responsible for freight, insurance, and customs duties.

What Are Effective Buyer Tips for Sourcing Milling Machines?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, here are actionable tips:

-

Negotiate Effectively: Always negotiate on price and terms. Suppliers often have some flexibility, especially for larger orders.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Factor in maintenance, operational efficiency, and potential downtime costs to assess the true value.

-

Understand Pricing Nuances: Be aware that prices can fluctuate based on market demand, currency exchange rates, and geopolitical factors. Stay informed about trends in the milling machine market.

-

Conduct Thorough Research: Investigate multiple suppliers to compare pricing and offerings. Use online platforms and trade shows to gather information.

- Seek Local Representation: If possible, work with local agents or representatives who understand the market dynamics in your region. They can provide valuable insights and facilitate smoother transactions.

Disclaimer on Pricing

Pricing for milling machines can vary significantly based on the factors outlined above. The figures presented in this analysis are indicative and should be validated with suppliers for accurate quotes tailored to specific requirements. Always consider conducting a detailed cost-benefit analysis before making purchasing decisions.

Alternatives Analysis: Comparing milling machine supplier With Other Solutions

When considering the procurement of milling machines, B2B buyers often face the challenge of evaluating their options against various alternatives. The decision-making process involves analyzing not only the milling machine suppliers but also other technologies or methods that can achieve similar outcomes. This section presents a comparative analysis of milling machine suppliers alongside two viable alternatives: CNC (Computer Numerical Control) machining and manual milling.

Comparison Table of Milling Machine Solutions

| Comparison Aspect | Milling Machine Supplier | CNC Machining | Manual Milling |

|---|---|---|---|

| Performance | High precision and speed | Exceptional precision; automated processes | Moderate precision; labor-intensive |

| Cost | High upfront costs; maintenance required | Higher initial investment but lower operational costs | Low initial cost; variable labor costs |

| Ease of Implementation | Requires training and setup | Complex setup; requires skilled operators | Simple setup; minimal training needed |

| Maintenance | Regular maintenance needed | Lower maintenance due to automation | High maintenance; reliant on operator skill |

| Best Use Case | Large-scale production; high-volume tasks | Precision parts; complex designs | Prototyping; small-scale production |

What Are the Advantages and Disadvantages of CNC Machining?

CNC machining is a highly automated process that utilizes computer-controlled machines to achieve high precision in manufacturing. One of its significant advantages is its ability to produce complex parts with minimal human intervention, resulting in consistent quality and faster production times. However, the initial investment in CNC technology can be substantial, and it requires skilled operators who can program and maintain the machines. This makes it less accessible for small businesses or those with limited budgets.

How Does Manual Milling Compare in Terms of Usefulness?

Manual milling is a traditional method that involves the use of milling machines operated by skilled technicians. This approach is particularly useful for prototyping and smaller production runs, where flexibility and low initial costs are essential. The disadvantages include a higher likelihood of human error, which can affect the precision of the final product, and the need for ongoing labor costs. Manual milling is less efficient for large-scale production but can be advantageous for bespoke projects where customization is key.

Conclusion: How Can B2B Buyers Make the Right Choice?

For international B2B buyers, the choice between milling machine suppliers, CNC machining, and manual milling ultimately depends on their specific operational needs, budget constraints, and production goals. Buyers should assess their production volume, the complexity of the parts required, and the skills available within their workforce. By thoroughly evaluating these factors, businesses can make informed decisions that align with their strategic objectives and maximize their investment in manufacturing technology.

Essential Technical Properties and Trade Terminology for milling machine supplier

What Are the Essential Technical Properties of Milling Machines?

When evaluating milling machine suppliers, understanding the technical specifications is crucial for making informed purchasing decisions. Here are some key properties to consider:

1. Material Grade

The material grade of a milling machine affects its durability and performance. Common materials include high-speed steel (HSS), carbide, and tool steel. High-quality materials ensure longevity, reduce wear, and improve cutting efficiency, which is vital for maintaining production standards in industries such as manufacturing and construction.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. For milling machines, tighter tolerances lead to higher precision in manufacturing processes. This is particularly important for industries that require exact specifications, such as aerospace and automotive. Understanding the tolerance levels of a milling machine can help buyers ensure it meets their production needs.

3. Spindle Speed

The spindle speed, measured in revolutions per minute (RPM), determines how fast the milling machine can cut materials. Higher spindle speeds allow for faster processing but may generate more heat and require cooling systems. Selecting the right spindle speed is essential for optimizing production rates while ensuring quality output.

4. Power Rating

The power rating of a milling machine, usually expressed in horsepower (HP) or kilowatts (kW), indicates its ability to handle different materials and workloads. A machine with a higher power rating can perform heavier tasks and cut through tougher materials, making it suitable for more demanding applications. This specification is crucial for buyers in industries requiring robust machinery.

5. Table Size

The table size of a milling machine determines the maximum workpiece dimensions it can accommodate. Larger tables allow for bigger parts to be machined, which is important for industries like shipbuilding and heavy machinery manufacturing. Buyers should consider their specific needs when evaluating table dimensions to ensure compatibility with their projects.

6. Control Type

Modern milling machines often come with different control types, including manual, CNC (Computer Numerical Control), and PLC (Programmable Logic Controller). CNC machines offer high precision and automation, reducing the likelihood of human error. Understanding the control type is essential for buyers looking to enhance productivity and efficiency in their operations.

What Trade Terms Should B2B Buyers Understand When Purchasing Milling Machines?

Familiarity with industry jargon can significantly streamline the procurement process. Here are some common trade terms relevant to milling machine suppliers:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding whether a milling machine supplier is an OEM can help buyers assess the quality and compatibility of the machinery with their existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and procurement strategies. Buyers should negotiate MOQs based on their production needs and cash flow constraints.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. B2B buyers should prepare detailed RFQs to receive accurate pricing and terms from milling machine suppliers, ensuring they compare offers effectively.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, insurance, and risk management associated with importing milling machines.

5. Lead Time

Lead time is the time taken from the placement of an order to the delivery of the product. Understanding lead times helps buyers plan their production schedules and inventory levels, ensuring they do not face delays in their operations.

By grasping these essential technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing milling machines, ultimately enhancing their operational efficiency and productivity.

Navigating Market Dynamics and Sourcing Trends in the milling machine supplier Sector

What Are the Current Market Dynamics and Key Trends in the Milling Machine Supplier Sector?

The milling machine supplier sector is experiencing significant transformation driven by globalization, technological advancement, and changing buyer preferences. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing high-quality, efficient machinery that can enhance productivity. Key trends include the rise of Industry 4.0, where smart manufacturing and IoT-enabled machines are becoming standard. These technologies allow for real-time monitoring and data analysis, enabling manufacturers to optimize operations and reduce downtime.

Furthermore, the demand for customized solutions is growing as businesses seek to differentiate themselves in competitive markets. Suppliers that can offer tailored machinery and flexible payment terms are likely to gain a competitive edge. Emerging markets, especially in Africa and South America, show potential for growth as local industries expand and modernize their production capabilities. However, international buyers must navigate challenges such as fluctuating exchange rates and varying regulatory environments that can impact sourcing decisions.

How Is Sustainability and Ethical Sourcing Influencing the Milling Machine Supplier Sector?

Sustainability is no longer a niche consideration but a critical factor in B2B purchasing decisions. International buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing practices and environmental responsibility. This trend is particularly relevant in the milling machine sector, where the environmental impact of production processes can be significant.

Ethical supply chains are essential, as they not only enhance brand reputation but also mitigate risks associated with labor practices and environmental degradation. Buyers should seek suppliers that are certified by recognized green certifications, such as ISO 14001 or EMAS, which indicate compliance with environmental management standards. Additionally, using sustainable materials in the manufacturing process can lead to reduced waste and energy consumption, making the machines more appealing to eco-conscious buyers.

Investing in suppliers that prioritize sustainability can also result in long-term cost savings. Energy-efficient machines can reduce operational costs, while companies that adopt responsible practices are likely to avoid potential legal and reputational risks associated with unethical sourcing.

What Is the Historical Context of the Milling Machine Supplier Sector?

The milling machine sector has evolved significantly over the past century. Initially dominated by manual and semi-automated machines, the industry began to embrace automation and computer-controlled systems in the late 20th century. This shift was propelled by advancements in technology, which allowed for greater precision and efficiency in milling processes.

As industries expanded globally, the demand for milling machines surged, leading to increased competition among suppliers. The 21st century has brought forth a new era characterized by smart technology integration, with milling machines now equipped with sensors and AI capabilities to enhance productivity and decision-making. This evolution reflects broader trends in manufacturing, where efficiency, customization, and sustainability are paramount.

For B2B buyers today, understanding this historical context is crucial, as it provides insights into the capabilities and innovations that suppliers are likely to offer, helping them make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of milling machine supplier

-

How do I evaluate the reliability of a milling machine supplier?

To evaluate a milling machine supplier’s reliability, start by checking their industry reputation through customer reviews and testimonials. Look for certifications and adherence to international quality standards such as ISO. Conduct background checks on their financial stability and operational history. Additionally, request references from previous clients, particularly those from your region, to gain insights into their service quality and responsiveness. Engaging in direct communication can also reveal their professionalism and willingness to address your concerns. -

What should I consider when customizing a milling machine?

When customizing a milling machine, consider the specific requirements of your production processes, such as material types, dimensions, and tolerances. Discuss your needs with the supplier to understand their capabilities for customization, including software configurations and hardware modifications. Evaluate the potential impact on delivery timelines and costs. It’s also essential to assess how these customizations will integrate with your existing systems and workflows to ensure smooth operations. -

What are the typical minimum order quantities (MOQ) for milling machines?

Minimum order quantities (MOQ) for milling machines can vary significantly among suppliers, often ranging from a single unit for specialized machines to larger quantities for standard models. Factors influencing MOQ include the supplier’s production capacity, the complexity of the machine, and your customization requirements. When sourcing, it’s crucial to discuss MOQs upfront to avoid unexpected costs and to assess whether the supplier can accommodate smaller orders if necessary. -

What payment terms should I negotiate with a milling machine supplier?

Negotiating payment terms is critical in managing cash flow. Common terms include a deposit upfront (often 30-50%), followed by the balance upon delivery or after installation. Explore options for extended payment terms if you require more time to generate revenue from the equipment. Ensure that payment methods are secure and convenient for international transactions, and consider using escrow services for larger purchases to mitigate risks. -

How do I ensure quality assurance when purchasing milling machines?

To ensure quality assurance, request detailed specifications and quality control processes from the supplier. Ask about their testing protocols, warranty terms, and after-sales support. It’s beneficial to visit the supplier’s facility, if possible, to observe their manufacturing practices. Additionally, consider third-party inspections or certifications to verify the machine’s compliance with international quality standards before finalizing the purchase. -

What logistics considerations are important when importing milling machines?

Logistics are vital when importing milling machines, including shipping methods, customs clearance, and delivery timelines. Confirm the supplier’s ability to handle logistics and whether they offer shipping services. Understand the associated costs, including tariffs and insurance, to budget effectively. It’s also essential to ensure that the machine is adequately packaged to prevent damage during transit and to have a clear plan for installation upon arrival. -

What documentation is required for international trade of milling machines?

When engaging in international trade for milling machines, ensure you have essential documents such as the commercial invoice, bill of lading, certificate of origin, and any applicable export licenses. Familiarize yourself with the import regulations of your country, which may require additional documentation like technical specifications or compliance certificates. Collaborating with a customs broker can help navigate the complexities of international shipping and ensure compliance with all legal requirements.

- How can I build a long-term relationship with a milling machine supplier?

Building a long-term relationship with a milling machine supplier involves clear communication and trust. Start by establishing mutual expectations regarding product quality, service levels, and delivery timelines. Regularly engage with the supplier for updates, feedback, and future needs. Consider collaborating on joint development projects or sharing market insights to foster a deeper partnership. A commitment to transparency and problem-solving can significantly enhance the supplier relationship over time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for milling machine supplier

In conclusion, the strategic sourcing of milling machines is essential for international B2B buyers aiming to enhance operational efficiency and competitiveness. Key takeaways include the importance of evaluating supplier capabilities, understanding regional market dynamics, and leveraging technological advancements in milling machinery. By prioritizing strong supplier relationships and conducting thorough market research, businesses can ensure they select suppliers that align with their production needs and sustainability goals.

For buyers in Africa, South America, the Middle East, and Europe, the evolving landscape of manufacturing demands a proactive approach to sourcing. Emphasizing quality, innovation, and cost-effectiveness will not only drive immediate benefits but also foster long-term partnerships that can adapt to future industry challenges.

As we look to the future, now is the time to engage with reputable milling machine suppliers who can meet your specific requirements. Equip your business with the right tools and technologies to navigate an increasingly competitive market. Start your strategic sourcing journey today to unlock new opportunities for growth and success in your manufacturing processes.