Discover Top Module Manufacturers: A Complete Buying Guide (2025)

Introduction: Navigating the Global Market for module manufacturer

Navigating the global market for module manufacturers presents a unique set of challenges for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. One of the key hurdles buyers face is sourcing high-quality modules that meet specific application requirements while ensuring cost-effectiveness. This guide aims to simplify the procurement process by providing a comprehensive overview of module types, their applications across various industries, and essential strategies for supplier vetting.

In this guide, we delve into the intricacies of selecting the right module manufacturer, covering critical aspects such as quality assurance, pricing structures, and logistical considerations. Buyers will gain insights into the different types of modules available—ranging from electronic components to industrial applications—and how these can be tailored to their operational needs. Additionally, we will discuss best practices for evaluating potential suppliers, including assessing their production capabilities, certifications, and reliability.

By equipping international B2B buyers with the knowledge and tools necessary for informed purchasing decisions, this guide empowers them to navigate the complexities of the global market. Whether you are based in vibrant cities like Cairo or São Paulo, or established hubs in Europe like Paris, you will find actionable insights designed to enhance your sourcing strategies and drive business success.

Understanding module manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Module | Generic design, widely available, cost-effective | General computing, basic applications | Pros: Affordable, easy to source. Cons: May lack advanced features. |

| High-Performance Module | Enhanced speed, larger capacity, specialized design | Data centers, gaming, high-end computing | Pros: Superior performance, reliability. Cons: Higher cost, may require specialized installation. |

| Embedded Module | Compact design, integrated systems, low power consumption | IoT devices, automotive, consumer electronics | Pros: Space-saving, energy-efficient. Cons: Limited upgrade options. |

| Custom Module | Tailored to specific requirements, unique specifications | Specialized industries, advanced applications | Pros: Perfect fit for unique needs. Cons: Longer lead times, higher costs. |

| Industrial Module | Rugged design, durability, compliance with standards | Manufacturing, automation, harsh environments | Pros: Robust, reliable in extreme conditions. Cons: Typically more expensive than standard modules. |

What Are the Characteristics of Standard Modules?

Standard modules are the backbone of many computing environments, characterized by their generic design and wide availability. They are cost-effective and suitable for general computing tasks, making them a popular choice for businesses looking to fulfill basic application needs without significant investment. When purchasing, buyers should consider the balance between cost and performance, as these modules may not support advanced functionalities required for specialized tasks.

How Do High-Performance Modules Stand Out?

High-performance modules are designed for demanding applications, offering enhanced speed and larger capacities. These modules are commonly found in data centers and high-end gaming systems, where performance is critical. For B2B buyers, the main consideration is the return on investment, as the upfront costs are higher, but they provide significant performance benefits that can lead to increased productivity and efficiency.

What Makes Embedded Modules Suitable for IoT Applications?

Embedded modules are compact and designed for integration into smaller devices, making them ideal for IoT applications, automotive technology, and consumer electronics. Their low power consumption is a major advantage, especially in battery-operated devices. Buyers must evaluate their specific needs regarding space and energy efficiency, as these modules often have limited upgrade options, which could impact future scalability.

Why Choose Custom Modules for Specialized Needs?

Custom modules offer tailored solutions designed to meet specific business requirements, making them invaluable for specialized industries and advanced applications. The key advantage is their ability to perfectly fit unique needs, which can enhance operational efficiency. However, buyers should be prepared for longer lead times and higher costs associated with the customization process, necessitating a careful assessment of the total value offered.

What Are the Benefits of Industrial Modules in Harsh Environments?

Industrial modules are built to withstand extreme conditions, making them ideal for manufacturing and automation settings. Their rugged design ensures reliability and compliance with industry standards, which is crucial for businesses operating in harsh environments. While these modules tend to be more expensive than standard options, their durability can lead to lower maintenance costs and increased uptime, making them a wise investment for industrial applications.

Related Video: Fully automated battery module production

Key Industrial Applications of module manufacturer

| Industry/Sector | Specific Application of Module Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

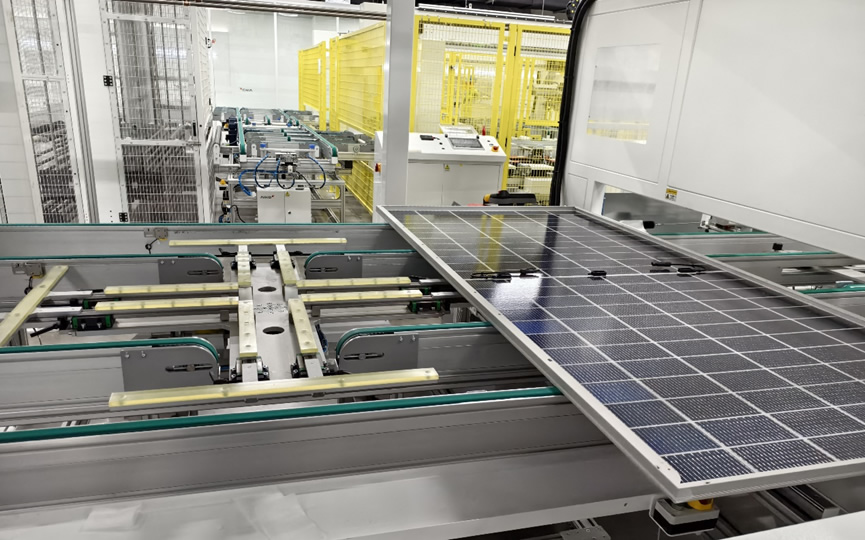

| Renewable Energy | Solar Panel Manufacturing | Reduces energy costs and enhances sustainability efforts | Quality certifications, local regulations, and supply chain reliability |

| Automotive | Electric Vehicle Battery Modules | Increases vehicle efficiency and supports green initiatives | Compatibility with existing systems and performance metrics |

| Telecommunications | Communication Module Production | Improves network reliability and speeds up data transfer | Scalability, technology compatibility, and lead times |

| Electronics | Consumer Electronics Module Assembly | Enhances product functionality and consumer satisfaction | Component sourcing, cost efficiency, and warranty support |

| Construction | Modular Building Components | Speeds up construction timelines and reduces waste | Local sourcing options, compliance with building codes, and material sustainability |

How is Module Manufacturing Used in Renewable Energy?

In the renewable energy sector, module manufacturers play a crucial role in the production of solar panels. These panels convert sunlight into electricity, providing a sustainable energy source that significantly reduces operational costs for businesses. For international buyers, particularly in regions like Africa and the Middle East, sourcing high-quality solar modules that meet local regulations and performance standards is essential. Buyers should prioritize manufacturers with proven track records and certifications to ensure reliability and efficiency.

What are the Applications of Module Manufacturing in the Automotive Industry?

The automotive industry increasingly relies on module manufacturers for electric vehicle (EV) battery modules. These modules enhance vehicle performance and energy efficiency, aligning with global green initiatives. International B2B buyers in Europe and South America should focus on sourcing from manufacturers that offer high-capacity, durable modules that comply with safety and environmental standards. It’s critical to evaluate the compatibility of these modules with existing vehicle systems to ensure seamless integration.

How Do Module Manufacturers Support Telecommunications?

In telecommunications, module manufacturers produce communication modules that are vital for network infrastructure. These modules improve data transfer speeds and enhance network reliability, which is crucial for businesses in fast-paced markets. Buyers from Africa and Europe should consider the scalability of the modules and their compatibility with existing technologies. Ensuring timely delivery and robust customer support is also essential for maintaining operational efficiency.

What Role Do Module Manufacturers Play in Electronics?

Module manufacturers are integral to the production of consumer electronics, providing essential components that enhance device functionality. This includes everything from smartphones to home appliances. For B2B buyers in South America and Europe, sourcing from manufacturers that prioritize cost efficiency and warranty support can significantly impact their bottom line. Buyers should also ensure that the modules meet specific performance criteria to maximize consumer satisfaction.

How Do Module Manufacturers Contribute to Construction?

In the construction sector, module manufacturers supply modular building components that streamline the construction process. These components allow for faster assembly and reduced waste, which can lead to significant cost savings. For international buyers, particularly in developing regions, it’s important to consider local sourcing options to minimize transportation costs and ensure compliance with local building codes. Additionally, evaluating the sustainability of materials used in these modules can enhance a company’s green credentials.

Related Video: What is Industrial Automation?

3 Common User Pain Points for ‘module manufacturer’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Module Manufacturing

The Problem: One of the most pressing challenges B2B buyers face when sourcing from module manufacturers is ensuring the quality and reliability of the products. This issue is particularly acute for businesses in regions like Africa and South America, where local standards may differ significantly from international benchmarks. Buyers often grapple with the fear of receiving subpar modules that could lead to costly downtimes, project delays, or failures in meeting regulatory compliance. The language barrier and differing manufacturing practices can further complicate quality assurance processes, leaving buyers uncertain about how to proceed.

The Solution: To mitigate quality concerns, buyers should implement a comprehensive supplier evaluation process. Start by requesting certifications such as ISO 9001, which indicates adherence to quality management principles. Engage in a dialogue with potential manufacturers about their quality control processes, including testing and inspection protocols. Conduct factory audits, either in-person or virtually, to assess their production capabilities firsthand. Leverage third-party inspection services to verify quality before shipment. Establish clear communication regarding specifications, performance standards, and warranty terms to ensure that all parties are aligned. Finally, consider building a relationship with manufacturers that have a proven track record in your region, as local partnerships can enhance trust and facilitate better quality control.

Scenario 2: Managing Supply Chain Disruptions in Module Procurement

The Problem: Supply chain disruptions can severely impact module availability, leading to unexpected project delays and increased costs. Buyers in regions like the Middle East and Europe may experience challenges such as fluctuating shipping costs, port congestion, or political instability, all of which can affect delivery timelines. This unpredictability makes it difficult for businesses to plan their projects effectively, resulting in potential revenue loss and strained client relationships.

The Solution: To better manage supply chain risks, B2B buyers should diversify their supplier base. Relying on multiple module manufacturers can provide a buffer against disruptions from any single source. Establishing relationships with suppliers from different geographical locations can also help mitigate risks associated with regional issues. Additionally, consider implementing inventory management strategies that allow for buffer stock to accommodate delays. Leveraging technology, such as supply chain management software, can enhance visibility into the supply chain and allow for proactive adjustments. Finally, negotiate flexible terms with suppliers that allow for adjustments based on market conditions, ensuring that your business can pivot quickly in response to unforeseen events.

Scenario 3: Overcoming Technical Support Gaps with Module Manufacturers

The Problem: Many B2B buyers struggle with inadequate technical support after purchasing modules, especially when integrating them into existing systems. This challenge is prevalent in markets across Europe and Africa, where technical resources may be limited. Buyers often find themselves facing installation issues or compatibility concerns without sufficient guidance from the manufacturer, which can lead to wasted time and resources.

The Solution: To address this issue, buyers should prioritize manufacturers that offer robust technical support services. Before making a purchase, inquire about the availability of technical assistance and training resources. Look for manufacturers that provide comprehensive documentation, including installation guides, troubleshooting manuals, and online support forums. Consider establishing a formal service level agreement (SLA) that outlines response times for technical inquiries and support requests. Additionally, invest in training for your team or consider working with third-party consultants who specialize in the integration of modules into existing systems. By ensuring that adequate technical support is in place, buyers can enhance the likelihood of successful implementation and minimize operational disruptions.

Strategic Material Selection Guide for module manufacturer

What Are the Key Materials Used in Module Manufacturing?

When selecting materials for module manufacturing, understanding the properties, advantages, and limitations of each material is crucial for optimizing performance and cost-effectiveness. This section analyzes four common materials: aluminum, stainless steel, copper, and thermoplastics, focusing on their suitability for various applications.

How Does Aluminum Benefit Module Manufacturers?

Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. Its temperature rating typically ranges from -60°C to 150°C, making it suitable for various environmental conditions.

Pros: Aluminum is durable and can be easily fabricated, allowing for complex shapes and designs. It is also relatively cost-effective, especially for large-scale production, and its lightweight nature reduces shipping costs.

Cons: However, aluminum can be less suitable for high-pressure applications compared to other metals. Its lower tensile strength may also necessitate thicker sections, potentially increasing material costs.

Impact on Application: Aluminum is compatible with various media, including water and air, making it ideal for HVAC modules and heat exchangers.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as EN 573 (European Standard for Aluminum) and ASTM B221 in the USA.

What Advantages Does Stainless Steel Offer for Module Manufacturing?

Stainless steel is renowned for its exceptional strength and resistance to corrosion, particularly in harsh environments. It can withstand temperatures up to 800°C, making it suitable for high-temperature applications.

Pros: The durability of stainless steel ensures a long lifespan, reducing the need for frequent replacements. Its aesthetic appeal also makes it a preferred choice for visible components.

Cons: The main drawback is its higher cost compared to aluminum and other materials. Additionally, manufacturing processes for stainless steel can be more complex and require specialized equipment.

Impact on Application: Stainless steel is ideal for modules in chemical processing and food industries due to its compatibility with aggressive media.

Considerations for International Buyers: Buyers should consider compliance with standards like ASTM A240 and DIN 1.4301, especially in regions like South America and Africa where material quality is critical.

How Does Copper Enhance Module Performance?

Copper is highly valued for its excellent electrical conductivity and thermal performance, making it a popular choice for electrical and electronic modules.

Pros: Copper’s superior conductivity ensures efficient energy transfer, which is essential for power modules. It is also highly malleable, allowing for intricate designs.

Cons: However, copper is susceptible to corrosion, particularly in moist environments, and can be more expensive than aluminum.

Impact on Application: Copper is particularly suitable for applications requiring high thermal and electrical conductivity, such as power electronics and heat exchangers.

Considerations for International Buyers: Compliance with standards like ASTM B170 is essential, especially for buyers in Europe and the Middle East, where electrical safety regulations are stringent.

What Role Do Thermoplastics Play in Module Manufacturing?

Thermoplastics, such as polycarbonate and nylon, are increasingly used in module manufacturing due to their versatility and lightweight properties.

Pros: These materials are resistant to impact and have excellent chemical resistance, making them suitable for various applications. They can be molded into complex shapes, reducing manufacturing complexity.

Cons: However, thermoplastics generally have lower thermal stability compared to metals, limiting their use in high-temperature applications.

Impact on Application: Thermoplastics are ideal for lightweight modules in consumer electronics and automotive applications, where weight savings are critical.

Considerations for International Buyers: Buyers should ensure compliance with international standards like ISO 9001, particularly in Europe and Africa, where quality assurance is paramount.

Summary Table of Material Selection for Module Manufacturing

| Material | Typical Use Case for Module Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | HVAC modules, heat exchangers | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Stainless Steel | Chemical processing, food industry | High strength and durability | Higher cost and complex fabrication | High |

| Copper | Power electronics, heat exchangers | Excellent conductivity | Susceptible to corrosion | High |

| Thermoplastics | Consumer electronics, automotive modules | Versatile and lightweight | Lower thermal stability | Low |

This analysis provides a comprehensive overview of material selection for module manufacturing, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for module manufacturer

What Are the Main Stages of Manufacturing Processes for Module Manufacturers?

Manufacturing modules involves several critical stages that ensure the final product meets quality standards and specifications. The primary stages include:

-

Material Preparation: This initial stage involves sourcing and preparing raw materials. For module manufacturers, materials like metals, plastics, and semiconductors are essential. Suppliers should provide Material Safety Data Sheets (MSDS) and certifications to verify the quality and origin of the materials. B2B buyers should assess the supplier’s ability to source high-grade materials, as this directly affects the end product’s reliability.

-

Forming: In this stage, raw materials are shaped into specific forms. Techniques such as extrusion, injection molding, and stamping are commonly used. For instance, extrusion is crucial for creating continuous profiles in plastic components, while stamping is essential for metal parts. Buyers should inquire about the machinery and technology used in this process, as advanced equipment often leads to higher precision and lower defect rates.

-

Assembly: After forming, the next step is assembly, where various components are put together to create the final module. This stage may involve manual or automated processes, including soldering, welding, and fastening. Buyers should look for suppliers that employ lean manufacturing principles to minimize waste and enhance efficiency. Understanding the assembly process helps buyers gauge how quickly and effectively their orders can be fulfilled.

-

Finishing: The finishing stage enhances the module’s aesthetic and functional properties. Techniques such as painting, coating, and polishing are applied to improve durability and appearance. B2B buyers should ask about the finishing processes used by suppliers to ensure they comply with environmental regulations and standards, particularly in regions with strict compliance requirements.

How Is Quality Assurance Implemented in Module Manufacturing?

Quality assurance (QA) is a critical aspect of the module manufacturing process, ensuring that products meet both international standards and customer expectations.

-

Relevant International Standards: Suppliers should adhere to international quality management standards such as ISO 9001. This certification demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets or API (American Petroleum Institute) standards for oil and gas applications are crucial. B2B buyers should verify these certifications during the supplier selection process to ensure compliance.

-

Quality Control Checkpoints: Effective quality control includes multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This step verifies the quality of raw materials before production begins. Buyers can request IQC reports to confirm that the materials meet specified standards.

– In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC ensures that each stage is performed correctly. B2B buyers should inquire about the frequency and type of inspections carried out during production.

– Final Quality Control (FQC): This is the last step before products are shipped. FQC checks the overall quality and performance of the final module. Buyers should request FQC reports or certificates of conformity to validate that the final product meets agreed specifications.

What Common Testing Methods Are Used in Module Manufacturing Quality Control?

To ensure the quality and reliability of manufactured modules, various testing methods are employed. These include:

-

Functional Testing: Verifies that the module operates according to its specifications. B2B buyers should ask suppliers for detailed reports on functional tests performed and the criteria used for acceptance.

-

Environmental Testing: Assesses the module’s performance under different environmental conditions, including temperature, humidity, and exposure to chemicals. Suppliers should provide testing results that demonstrate compliance with relevant environmental standards.

-

Electrical Testing: For electronic modules, electrical testing is crucial. It checks for short circuits, insulation resistance, and operational efficiency. Buyers should ensure that suppliers use standardized testing procedures and equipment.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is vital for B2B buyers, especially when sourcing from different regions. Here are effective methods:

-

Supplier Audits: Conducting a thorough audit of the supplier’s manufacturing and quality control processes is essential. This can be done by the buyer’s team or through third-party audit services. Audits should assess compliance with quality standards, production capabilities, and overall operational efficiency.

-

Quality Reports: Requesting regular quality reports, including IQC, IPQC, and FQC data, allows buyers to monitor the supplier’s quality performance over time. Buyers should analyze trends in defect rates and corrective actions taken by the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can be conducted at various stages, from raw material sourcing to final product delivery, ensuring comprehensive oversight.

What Are the Quality Control and Certification Nuances for International Buyers?

International B2B buyers must navigate various quality control and certification nuances that can differ by region:

-

Regional Regulations: Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with local regulations governing manufacturing and product safety. For example, EU regulations may require CE marking, while Middle Eastern countries may have specific compliance requirements for electrical products.

-

Cultural Differences: Understanding cultural nuances in communication and business practices is crucial when dealing with international suppliers. Clear communication regarding quality expectations and certifications can help bridge gaps.

-

Supply Chain Transparency: International buyers should prioritize suppliers that offer transparency in their supply chain practices. This includes providing traceability of materials and compliance documentation to ensure quality throughout the production process.

By focusing on these critical aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when selecting module manufacturers that meet their quality and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘module manufacturer’

The following is a practical sourcing checklist designed for international B2B buyers looking to procure modules from manufacturers. This guide will help ensure that your procurement process is efficient, effective, and tailored to your specific needs.

Step 1: Define Your Technical Specifications

Clearly outline your requirements before starting the procurement process. This includes understanding the specific type of module you need, such as size, material, capacity, and performance standards. Defining these specifications will help streamline your search and ensure that suppliers can meet your needs.

- Consider regulatory requirements: Check if there are any local or international standards that the modules must comply with, especially for specific markets like Europe or Africa.

- Assess compatibility: Ensure that the modules will integrate seamlessly with your existing systems or products.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential module manufacturers. Utilize online directories, trade shows, and industry associations to compile a list of suppliers.

- Look for industry reputation: Check reviews and testimonials from other buyers to gauge reliability.

- Evaluate geographical advantages: Consider suppliers located closer to your operations to reduce shipping costs and lead times.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Assess financial stability: Request financial reports to ensure the supplier can fulfill large orders over time.

- Inquire about production capacity: Make sure the supplier can handle your order volume within your required timeframe.

Step 4: Verify Supplier Certifications

Ensure that your suppliers have the necessary certifications and quality standards. This is particularly important for industries that require compliance with specific regulations.

- Check for ISO certifications: Look for ISO 9001 or other relevant quality management certifications.

- Confirm product-specific certifications: Depending on your industry, certifications like CE for Europe or UL for North America may be required.

Step 5: Request Samples and Prototypes

Before placing a large order, request samples or prototypes. This step allows you to evaluate the quality and functionality of the modules firsthand.

- Test for performance: Conduct necessary tests to ensure the modules meet your technical specifications.

- Assess packaging and delivery: Evaluate how the samples are packaged and delivered to ensure they will arrive safely.

Step 6: Negotiate Pricing and Terms

Engage in negotiations to secure the best pricing and contractual terms. This includes discussing payment terms, delivery schedules, and warranties.

- Consider bulk discounts: Ask if there are discounts available for larger orders.

- Discuss payment flexibility: Explore different payment methods and terms to ease cash flow concerns.

Step 7: Establish a Communication Plan

Develop a clear communication strategy with your chosen supplier. Regular communication can prevent misunderstandings and ensure that your project stays on track.

- Set up regular updates: Schedule weekly or bi-weekly check-ins to discuss progress and address any issues.

- Use project management tools: Consider utilizing tools like Trello or Asana for project tracking and updates.

Following this checklist can significantly enhance your sourcing process for module manufacturers, ensuring that you make informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for module manufacturer Sourcing

What Are the Key Cost Components in Module Manufacturing?

Understanding the cost structure of module manufacturing is crucial for international B2B buyers aiming to make informed sourcing decisions. The primary cost components include:

-

Materials: This is often the most significant expense, encompassing the raw materials required for module production, such as metals, plastics, and electronic components. Buyers should consider sourcing materials locally to mitigate costs, especially in regions like Africa and South America, where transportation can inflate expenses.

-

Labor: Labor costs vary significantly by region. For instance, labor in Europe may be more expensive than in parts of Africa or South America. Understanding local labor markets can provide insights into potential cost savings.

-

Manufacturing Overhead: This includes costs related to utilities, equipment depreciation, and maintenance. Efficient manufacturing processes can help reduce overhead costs, making it essential for buyers to evaluate a manufacturer’s operational efficiency.

-

Tooling: Tooling costs pertain to the creation of molds and dies necessary for manufacturing. Custom tooling can be a substantial upfront investment, so buyers should assess whether the manufacturer has existing tools or if new ones are needed.

-

Quality Control (QC): Implementing rigorous quality control measures is vital for ensuring product reliability. QC costs can vary based on the complexity of the modules and the certifications required, impacting the overall pricing.

-

Logistics: Transportation costs must be factored into the total cost of ownership. Buyers should consider Incoterms that define the responsibilities of sellers and buyers in shipping, as these can significantly influence logistics expenses.

-

Margin: Finally, manufacturers typically include a profit margin in their pricing. Understanding industry standards for margins can aid buyers in evaluating whether a price is fair.

How Do Price Influencers Impact Module Manufacturing Costs?

Several factors influence the pricing of modules, which international buyers should consider:

-

Volume and Minimum Order Quantities (MOQ): Ordering in larger volumes often leads to lower per-unit costs. Buyers should negotiate MOQs that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Highly specialized modules may incur additional costs due to custom manufacturing processes. Buyers must weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, CE) can elevate costs but may be necessary for compliance in certain markets. Buyers should assess the importance of these factors in relation to their end-user requirements.

-

Supplier Factors: The reputation, reliability, and production capabilities of suppliers can also impact pricing. Conducting due diligence on suppliers can help buyers identify the best value.

-

Incoterms: Understanding the chosen Incoterms is essential for determining who bears the cost and risk during transportation. This can impact overall pricing and should be a key consideration during negotiations.

What Negotiation Tips Can Help Buyers Achieve Cost Efficiency?

International B2B buyers can adopt several strategies to negotiate better pricing and improve cost efficiency:

-

Conduct Market Research: Understanding the average pricing in the market can empower buyers during negotiations. Research competitors and similar products to establish a baseline.

-

Leverage Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Consider long-term contracts that may offer discounts or preferential treatment.

-

Discuss Payment Terms: Negotiating favorable payment terms can improve cash flow. Consider options like partial payments upon order and the remainder upon delivery.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on initial purchase price, consider the TCO, which includes maintenance, operational costs, and logistics. This holistic view can lead to better purchasing decisions.

-

Seek Multiple Quotes: Request quotes from various manufacturers to compare prices and services. This competitive approach can highlight cost discrepancies and provide leverage in negotiations.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be mindful of specific pricing nuances:

-

Currency Fluctuations: Variations in currency exchange rates can significantly impact pricing. Buyers should consider hedging strategies to mitigate risks.

-

Import Duties and Taxes: Customs duties, tariffs, and taxes can add to the final cost of imported modules. Understanding local regulations can help buyers anticipate additional expenses.

-

Cultural Differences: Negotiation styles and business practices can vary by region. Being aware of these cultural nuances can facilitate smoother discussions and agreements.

-

Supply Chain Disruptions: Global events may impact supply chains, affecting prices and availability. Staying informed about current events can help buyers make proactive decisions.

In conclusion, a thorough understanding of cost components, price influencers, negotiation strategies, and pricing nuances is essential for international B2B buyers in the module manufacturing sector. This knowledge will enable them to make strategic sourcing decisions that optimize both cost and quality.

Alternatives Analysis: Comparing module manufacturer With Other Solutions

Exploring Alternatives to Module Manufacturers for B2B Buyers

When considering the procurement of module manufacturers, international B2B buyers should evaluate various alternatives that can fulfill their operational needs. Different solutions may offer distinct advantages in terms of performance, cost, and implementation. This analysis will compare module manufacturers against other viable options, helping buyers make informed decisions.

| Comparison Aspect | Module Manufacturer | Alternative 1: Integrated Circuit (IC) Design | Alternative 2: Custom PCB Solutions |

|---|---|---|---|

| Performance | High efficiency, tailored for specific applications | High performance for targeted applications | Flexible performance; can be optimized for specific uses |

| Cost | Generally higher due to specialized production | Moderate cost; dependent on complexity | Variable; can be high for low volumes but cheaper for mass production |

| Ease of Implementation | Requires specialized knowledge for integration | Easier for engineers familiar with ICs | Can be complex; requires design expertise |

| Maintenance | Requires manufacturer support for updates | Low maintenance; ICs are typically robust | Moderate maintenance; depends on design complexity |

| Best Use Case | Ideal for high-volume, specialized applications | Best for applications needing specific functionalities | Suitable for custom solutions in varying volumes |

What Are the Benefits and Drawbacks of Integrated Circuit (IC) Design?

IC design presents a compelling alternative to traditional module manufacturers. The primary advantage of ICs is their high performance for targeted applications. They often integrate multiple functions into a single chip, leading to reduced space and power consumption. However, the cost can be moderate, depending on the complexity of the design. One downside is that implementation may require specific engineering expertise, making it less accessible for teams without a strong background in electronics.

How Do Custom PCB Solutions Compare?

Custom PCB solutions offer flexibility and adaptability, making them a strong contender against module manufacturers. They can be tailored to meet specific design requirements, allowing businesses to innovate and create unique products. The cost structure can vary significantly; while low-volume production may be expensive, economies of scale can make mass production cost-effective. However, the design and implementation process can be complex, requiring skilled personnel. Maintenance can also be moderate, depending on the intricacies of the design.

How to Choose the Right Solution for Your Business Needs?

In conclusion, when selecting between module manufacturers and their alternatives, B2B buyers must consider their specific needs, including performance requirements, budget constraints, and implementation capabilities. If a business prioritizes high performance and has the resources for specialized integration, module manufacturers may be the best choice. Conversely, if flexibility and cost-effectiveness are paramount, integrated circuits or custom PCB solutions could be more suitable. Evaluating these factors will empower international buyers from Africa, South America, the Middle East, and Europe to make strategic decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for module manufacturer

What Are the Key Technical Properties for Module Manufacturing?

When evaluating module manufacturers, understanding critical technical specifications is essential for ensuring product quality and compatibility. Here are some key properties to consider:

1. Material Grade

Material grade refers to the quality and type of materials used in manufacturing modules. Common materials include aluminum, copper, and various polymers. The choice of material impacts durability, conductivity, and overall performance. For B2B buyers, selecting a manufacturer that uses high-grade materials can lead to longer-lasting products and reduced maintenance costs.

A stock image related to module manufacturer.

2. Tolerance

Tolerance is the permissible limit of variation in a physical dimension. It is crucial for ensuring that parts fit together correctly and function as intended. In module manufacturing, tighter tolerances typically indicate higher precision, which is vital in applications requiring exact specifications. B2B buyers should prioritize suppliers that can meet their tolerance requirements to avoid costly reworks or failures in the field.

3. Thermal Conductivity

Thermal conductivity measures a material’s ability to conduct heat. In module manufacturing, especially for electronics, materials with high thermal conductivity are necessary to manage heat dissipation effectively. This property is critical for maintaining performance and reliability, particularly in high-temperature environments. Buyers should assess thermal management capabilities when selecting a manufacturer.

4. Electrical Resistance

Electrical resistance quantifies how strongly a material opposes the flow of electric current. For modules that will be part of electrical systems, low electrical resistance is generally desired to minimize energy loss and enhance efficiency. Understanding the electrical properties of materials used in modules can guide buyers in selecting the right products for their applications.

5. Surface Finish

Surface finish refers to the texture and quality of a material’s surface. It can influence adhesion, corrosion resistance, and aesthetic appearance. Different applications may require specific surface finishes, such as polished or coated surfaces. Buyers should communicate their surface finish requirements clearly to ensure compatibility with their intended use.

What Are Common Trade Terminology and Concepts in Module Manufacturing?

Familiarity with industry terminology can greatly enhance communication and negotiation with suppliers. Here are several important terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for B2B buyers as it can affect product availability, compatibility, and warranty conditions. Buyers should clarify OEM partnerships when sourcing modules to ensure they receive authentic and reliable products.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of products that a supplier is willing to sell. This term is crucial for B2B buyers, especially small to medium enterprises, as it impacts inventory management and cash flow. Knowing the MOQ can help buyers plan their purchases and negotiate better terms with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and other details for specific products. Using RFQs helps buyers gather competitive quotes, making it easier to compare suppliers on price and terms. Crafting a detailed RFQ can lead to better negotiation outcomes and more favorable pricing.

4. Incoterms

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, which is essential for avoiding misunderstandings. B2B buyers should be familiar with relevant Incoterms to ensure smooth transactions and delivery processes.

5. Lead Time

Lead time is the duration from the initiation of an order until its fulfillment. Understanding lead times is crucial for supply chain management, as longer lead times can impact project schedules. B2B buyers should discuss lead times with manufacturers to align production schedules and avoid delays.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when selecting module manufacturers, ensuring that they choose partners who meet their specific requirements and expectations.

Navigating Market Dynamics and Sourcing Trends in the module manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Module Manufacturer Sector?

The module manufacturer sector is witnessing transformative changes driven by technological advancements and evolving global demands. Key market drivers include the increasing need for automation and smart technologies across industries, particularly in manufacturing and logistics. As businesses strive for efficiency, the adoption of modular systems—those that can be easily adapted and integrated—has surged. This trend is especially pronounced among international B2B buyers in Africa, South America, the Middle East, and Europe, where infrastructure development is rapidly progressing.

Emerging technologies such as the Internet of Things (IoT) and Industry 4.0 are reshaping sourcing strategies. Businesses are increasingly looking for suppliers that offer smart modules capable of real-time data integration and analytics. Additionally, the shift towards digital procurement platforms is streamlining sourcing processes, making it easier for international buyers to find and evaluate potential suppliers. This digital transformation is vital for companies in regions like France and Egypt, where competitive pressures demand efficiency and innovation.

Furthermore, the geopolitical landscape plays a significant role in market dynamics. Trade agreements and tariffs can influence sourcing decisions, making it crucial for buyers to stay informed about international trade policies. The rise of regional manufacturing hubs, particularly in Africa and South America, is another trend that offers opportunities for local sourcing, reducing lead times and transportation costs.

How Is Sustainability and Ethical Sourcing Shaping the Module Manufacturer Sector?

A stock image related to module manufacturer.

Sustainability is no longer just a buzzword; it has become a critical consideration in the module manufacturer sector. International B2B buyers are increasingly prioritizing suppliers who demonstrate environmental responsibility. The environmental impact of manufacturing processes, including waste generation and energy consumption, is under scrutiny. Companies that adopt sustainable practices not only enhance their brand reputation but also comply with stringent regulations in various markets.

Ethical sourcing is equally vital, as buyers seek suppliers who adhere to fair labor practices and transparency throughout their supply chains. Certifications such as ISO 14001 (Environmental Management) and ISO 26000 (Social Responsibility) are becoming essential for suppliers looking to establish credibility. These certifications signal to buyers that a manufacturer is committed to sustainability and ethical practices, which can be a decisive factor in supplier selection.

Moreover, the demand for ‘green’ materials—those that are recycled, biodegradable, or sustainably sourced—is increasing. Buyers are encouraged to engage with suppliers who offer eco-friendly modules that minimize environmental impact. This shift not only aligns with global sustainability goals but also meets the growing consumer demand for responsible products.

How Has the Module Manufacturer Sector Evolved Over Time?

The module manufacturer sector has evolved significantly over the past few decades, transitioning from traditional manufacturing practices to modern, technology-driven solutions. Initially, module manufacturing focused on standalone products, but the rise of modular design principles has led to an emphasis on flexibility and interoperability. This evolution has been fueled by the increasing complexity of industrial processes and the demand for customized solutions.

In recent years, advancements in manufacturing technologies, such as 3D printing and automation, have further transformed the sector. These innovations allow for rapid prototyping and production, enabling manufacturers to respond swiftly to changing market demands. As international B2B buyers seek efficient and adaptive solutions, the evolution of the module manufacturer sector continues to align with broader industry trends, positioning it as a vital component of global supply chains.

Frequently Asked Questions (FAQs) for B2B Buyers of module manufacturer

-

How do I choose the right module manufacturer for my business needs?

Choosing the right module manufacturer involves several key considerations. Start by assessing the manufacturer’s experience and reputation in your industry. Look for certifications, customer testimonials, and case studies that demonstrate their capability. Additionally, evaluate their manufacturing processes and technology used to ensure they align with your quality standards. For international buyers, consider the manufacturer’s ability to handle logistics and customs efficiently, especially if you are sourcing from regions like Asia or Europe. -

What are the typical minimum order quantities (MOQs) for module manufacturing?

Minimum order quantities can vary significantly among module manufacturers, often influenced by the type of modules and the complexity of customization. Generally, MOQs can range from 100 to several thousand units. It’s crucial to communicate your needs upfront and negotiate MOQs that fit your budget and inventory strategy. Many manufacturers may be willing to accommodate lower MOQs for first-time orders or long-term partnerships, particularly in regions like Africa and South America. -

What should I know about payment terms when sourcing from module manufacturers?

Payment terms can greatly impact your cash flow and project timeline. Common terms include upfront deposits (typically 30-50%), with the balance due upon delivery or before shipping. Ensure you understand the payment methods accepted, which may include bank transfers, letters of credit, or online payment platforms. For international transactions, consider the implications of currency exchange rates and transaction fees. Establishing clear payment terms can foster trust and transparency in your supplier relationship. -

How can I ensure the quality of modules from manufacturers?

To ensure quality, request detailed documentation of the manufacturer’s quality assurance processes. Look for ISO certifications or equivalent standards that indicate a commitment to quality control. Conducting factory audits or requesting samples before placing large orders can also mitigate risks. Additionally, establish a clear agreement on quality specifications and testing protocols to be adhered to during production, especially when dealing with manufacturers in diverse regions like the Middle East or Europe. -

What are the best practices for vetting module manufacturers?

Vetting manufacturers is essential to mitigate risks in your supply chain. Start by conducting thorough online research to check their business registration, industry reputation, and client reviews. Request references from previous clients and verify their production capabilities through site visits if possible. Utilize platforms like Alibaba or Global Sources, which often provide ratings and reviews. Engaging a local sourcing agent can also help navigate cultural and language barriers when dealing with manufacturers in Africa or South America. -

How do I handle logistics when sourcing modules internationally?

Managing logistics involves understanding shipping options, customs regulations, and potential tariffs in your country. Collaborate with your supplier to determine the best shipping methods, whether air freight for speed or sea freight for cost-effectiveness. Consider working with a freight forwarder who specializes in international trade to streamline the process. Ensure that all shipping documentation is accurate to avoid delays at customs, especially when importing modules from regions like Europe or Asia. -

What customization options should I consider when sourcing modules?

Customization can significantly enhance the functionality and appeal of your modules. Discuss options such as size, shape, material, and performance specifications with potential manufacturers. Many manufacturers offer design services to help tailor the product to your needs. Be clear about your requirements and ensure that the manufacturer has the capacity and expertise to deliver the desired customizations. This is particularly important for businesses in competitive markets in Africa or South America. -

What are the common pitfalls to avoid when sourcing from module manufacturers?

Avoiding common pitfalls requires due diligence and clear communication. One major pitfall is underestimating lead times; always confirm production and shipping timelines before placing orders. Another is neglecting to establish a clear contract that outlines quality standards, delivery schedules, and payment terms. Be wary of manufacturers that offer prices that seem too good to be true, as this may indicate compromised quality. Lastly, ensure you maintain open lines of communication throughout the process to address any issues promptly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for module manufacturer

In the dynamic landscape of module manufacturing, strategic sourcing emerges as a critical lever for international B2B buyers. By prioritizing supplier relationships, leveraging regional advantages, and embracing sustainability, buyers can enhance their competitive edge. Understanding the nuances of the supply chain—particularly in regions like Africa, South America, the Middle East, and Europe—allows for informed decision-making that aligns with both market demands and operational efficiencies.

What are the key benefits of strategic sourcing in module manufacturing? It not only reduces costs but also mitigates risks associated with supply disruptions. Additionally, fostering collaboration with suppliers can lead to innovation and improved product quality, which is vital for maintaining relevance in an increasingly competitive market.

As we look to the future, the importance of agility and responsiveness in sourcing strategies cannot be overstated. International B2B buyers are encouraged to continuously evaluate their sourcing practices, embrace technological advancements, and adapt to evolving market conditions. By doing so, they can position themselves for long-term success in the global module manufacturing sector. Engage proactively with suppliers today to unlock new opportunities and drive sustainable growth.