Discover Top Printed Circuit Board Suppliers: Save Costs Today (2025)

Introduction: Navigating the Global Market for printed circuit board supplier

As the demand for innovative electronic solutions continues to surge, sourcing a reliable printed circuit board (PCB) supplier has become a critical challenge for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, navigating the complexities of the global PCB market can be daunting. This guide aims to demystify the PCB sourcing process by providing a comprehensive overview of various types of printed circuit boards, their applications across industries, and essential criteria for vetting potential suppliers.

In this guide, you’ll discover actionable insights on how to assess suppliers based on quality standards, manufacturing capabilities, and cost-effectiveness. We will explore the latest trends in PCB technology, including advancements in materials and design methodologies that can enhance your product offerings. Additionally, we will address common pitfalls to avoid during the sourcing process, empowering you to make informed purchasing decisions.

Understanding the nuances of the PCB market is crucial for businesses looking to maintain a competitive edge. By leveraging the information in this guide, B2B buyers from regions like Germany and Brazil will be equipped to identify trustworthy suppliers, negotiate favorable terms, and ultimately enhance their product development processes. The right PCB supplier can not only provide quality components but also contribute to your overall business success by ensuring timely deliveries and responsive customer support.

Understanding printed circuit board supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PCB Suppliers | Mass production capabilities, standardized designs | Consumer electronics, automotive, industrial | Pros: Cost-effective, readily available; Cons: Limited customization options. |

| Custom PCB Manufacturers | Tailored designs, specialized materials | Aerospace, medical devices, high-tech industries | Pros: High flexibility, specific requirements met; Cons: Higher costs, longer lead times. |

| Prototype PCB Suppliers | Quick turnaround for initial designs, small batch sizes | R&D, product testing, startup projects | Pros: Rapid development, ideal for testing; Cons: Higher per-unit cost, less suitable for mass production. |

| Flexible PCB Suppliers | Bendable substrates, lightweight designs | Wearable technology, automotive applications | Pros: Space-saving, adaptable to various shapes; Cons: More expensive, can be complex to manufacture. |

| High-Frequency PCB Suppliers | Specialized for RF applications, advanced materials | Telecommunications, satellite technology | Pros: Optimized performance for high-frequency signals; Cons: Niche market, often higher prices. |

What Are the Characteristics of Standard PCB Suppliers?

Standard PCB suppliers are known for their ability to mass-produce printed circuit boards using established designs and processes. These suppliers typically focus on high-volume production runs, making them ideal for industries like consumer electronics and automotive sectors where cost efficiency is paramount. Buyers should consider the trade-off between price and customization; while these suppliers offer competitive pricing, they may not accommodate specific design needs.

How Do Custom PCB Manufacturers Stand Out?

Custom PCB manufacturers specialize in creating tailored solutions that meet specific client requirements. They work closely with businesses in sectors such as aerospace and medical devices, where precision and specialized materials are critical. When sourcing from custom manufacturers, B2B buyers should evaluate their design capabilities, material options, and lead times, as these factors can significantly impact project timelines and costs.

Why Choose Prototype PCB Suppliers for Your Projects?

Prototype PCB suppliers excel in producing small batches of printed circuit boards, making them an excellent choice for research and development or testing new products. These suppliers can quickly turn around initial designs, allowing businesses to refine their products before full-scale production. However, buyers should be aware that while the speed is a significant advantage, the per-unit cost can be higher compared to standard production runs.

What Are the Benefits of Flexible PCB Suppliers?

Flexible PCB suppliers provide circuit boards that can bend and twist, which is particularly beneficial for applications in wearable technology and automotive systems. These PCBs are designed to save space and fit into unconventional shapes, enhancing the overall product design. Despite their advantages, flexible PCBs often come with a higher price point and can be more challenging to manufacture, which buyers should factor into their purchasing decisions.

How Do High-Frequency PCB Suppliers Serve Niche Markets?

High-frequency PCB suppliers focus on producing circuit boards that operate effectively at radio frequencies, making them essential for telecommunications and satellite technologies. These suppliers utilize advanced materials and manufacturing techniques to ensure optimal performance. Buyers in this niche market should assess the supplier’s expertise in high-frequency applications, as well as their ability to meet stringent quality standards, which can often lead to higher costs.

Related Video: HOW TO UNDERSTAND A PRINTED CIRCUIT BOARD AND IT’S CONNECTIONS

Key Industrial Applications of printed circuit board supplier

| Industry/Sector | Specific Application of Printed Circuit Board Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Smart Appliances and IoT Devices | Enhanced functionality and connectivity | Quality assurance, compliance with international standards |

| Automotive | Electric Vehicle Control Systems | Improved efficiency and performance | Reliability, custom design capabilities |

| Telecommunications | Network Infrastructure Equipment | Increased data transmission speed and reliability | Scalability, support for diverse technologies |

| Healthcare | Medical Devices (e.g., diagnostic equipment) | Improved patient outcomes and operational efficiency | Regulatory compliance, precision in manufacturing |

| Industrial Automation | Robotics and Control Systems | Increased productivity and reduced operational costs | Customization options, durability under harsh conditions |

How are Printed Circuit Boards Used in Consumer Electronics?

In the consumer electronics sector, printed circuit boards (PCBs) are integral to smart appliances and IoT devices. These boards facilitate connectivity and control functions, enabling devices to communicate and operate efficiently. For international B2B buyers, sourcing high-quality PCBs that meet safety and performance standards is crucial. Additionally, understanding the supplier’s capacity for customization can enhance product differentiation in competitive markets, particularly in regions like Europe and South America.

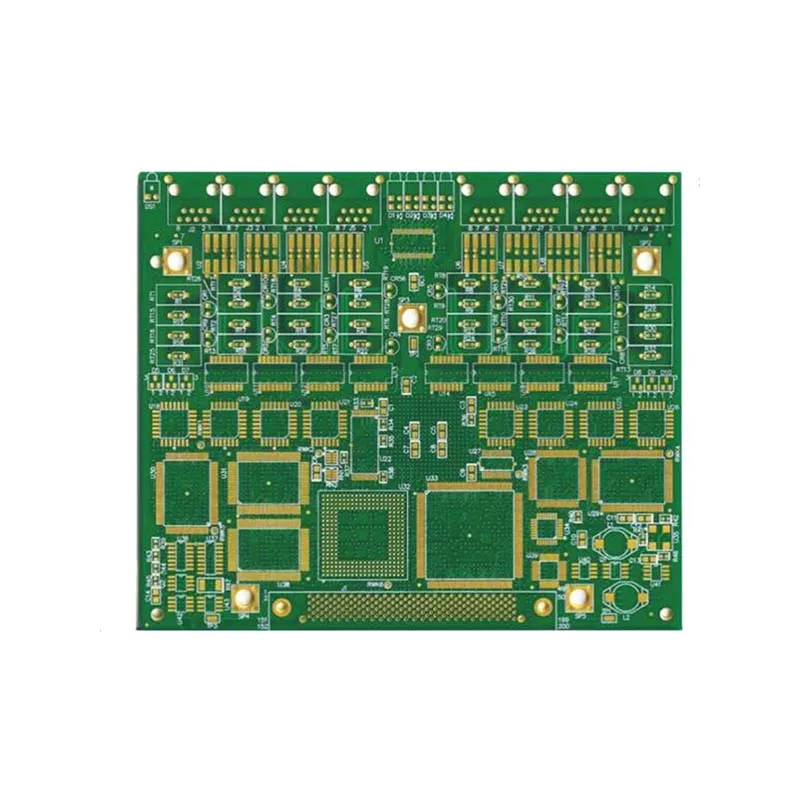

A stock image related to printed circuit board supplier.

What Role do Printed Circuit Boards Play in the Automotive Industry?

In the automotive industry, printed circuit boards are pivotal for electric vehicle (EV) control systems. They manage critical functions, such as battery management and energy distribution, which are essential for vehicle efficiency. B2B buyers from Africa and the Middle East should prioritize suppliers with proven reliability and the ability to design custom PCBs that meet stringent automotive standards. Ensuring compliance with global regulations can also mitigate risks associated with sourcing.

How are Printed Circuit Boards Essential for Telecommunications?

Telecommunications rely heavily on printed circuit boards for network infrastructure equipment. These PCBs help improve data transmission speeds and ensure reliable connections. B2B buyers in this sector, especially from Europe, should consider sourcing from suppliers that offer scalability and support for various technologies. This adaptability is vital in rapidly evolving markets where the demand for high-speed internet and connectivity solutions is increasing.

In What Ways are Printed Circuit Boards Used in Healthcare?

A stock image related to printed circuit board supplier.

In healthcare, printed circuit boards are crucial for medical devices, such as diagnostic equipment. They enhance the functionality of these devices, leading to improved patient outcomes and operational efficiency. B2B buyers must ensure that their suppliers comply with regulatory standards, as the healthcare sector is highly regulated. Precision in manufacturing is also essential, as even minor defects can have significant consequences in medical applications.

How do Printed Circuit Boards Contribute to Industrial Automation?

Printed circuit boards are central to robotics and control systems in industrial automation. They facilitate communication between various components, leading to increased productivity and reduced operational costs. For international buyers, especially from South America and Africa, sourcing durable PCBs that can withstand harsh industrial environments is critical. Customization options can further enhance the efficiency and effectiveness of automation solutions, making it a key consideration in the sourcing process.

Related Video: How to assemble a Printed Circuit Board – PCBWay PCB Assembly (PCBA)

3 Common User Pain Points for ‘printed circuit board supplier’ & Their Solutions

Scenario 1: Difficulty in Finding Reliable Printed Circuit Board Suppliers

The Problem:

International B2B buyers often face significant challenges in identifying reliable printed circuit board (PCB) suppliers, especially when sourcing from diverse regions like Africa, South America, the Middle East, and Europe. The lack of local suppliers can lead to long lead times, increased shipping costs, and potential quality issues. Buyers may also struggle with language barriers, cultural differences, and varying standards of quality and service, which can complicate the procurement process and lead to costly delays in product development.

The Solution:

To address this issue, B2B buyers should prioritize building a network of trusted suppliers through industry associations and trade shows relevant to their region. Engaging with platforms such as Alibaba or ThomasNet can also help in finding vetted suppliers with positive reviews. Before finalizing any supplier, conduct thorough due diligence, including requesting samples, checking certifications (like ISO 9001), and reviewing past client testimonials. Establishing clear communication channels and expectations from the outset can help mitigate misunderstandings and foster a reliable partnership. Additionally, consider engaging a local sourcing agent who understands the regional market dynamics, which can bridge the gap between buyers and suppliers.

Scenario 2: Managing Quality Control Issues with PCBs

The Problem:

Quality control is a critical concern for B2B buyers, particularly in sectors like automotive, aerospace, and medical devices where reliability is paramount. Many buyers report receiving PCBs that do not meet specifications or have defects, leading to production delays and increased costs. Such quality issues can stem from a lack of standardized processes at the supplier’s manufacturing facility, inadequate testing, or insufficient communication regarding design specifications.

The Solution:

To effectively manage quality control, buyers should implement a stringent quality assurance process that includes detailed specifications and testing requirements. It is essential to involve suppliers in the design phase to ensure that the PCBs are manufactured according to the intended use. Conducting pre-production inspections and utilizing third-party testing services can help identify potential defects before mass production begins. Additionally, establishing key performance indicators (KPIs) for quality and regular audits can help maintain high standards and accountability. Building a long-term relationship with a supplier that demonstrates a commitment to quality will further enhance product reliability.

Scenario 3: Navigating Complex Compliance Regulations for PCBs

The Problem:

B2B buyers often encounter challenges related to compliance with local and international regulations governing electronic components, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals). These regulations can vary significantly between regions, creating confusion and potential legal repercussions for companies that fail to comply. Navigating these complex requirements can be especially burdensome for international buyers unfamiliar with local laws.

The Solution:

To navigate compliance regulations effectively, buyers should invest in understanding the specific requirements relevant to their industry and regions of operation. Collaborating with legal experts or compliance consultants can provide clarity on the necessary certifications and documentation required for PCB imports. When selecting suppliers, prioritize those who have a proven track record of compliance with relevant regulations and who can provide necessary documentation upfront. Additionally, establishing a compliance checklist for each project can streamline the procurement process and ensure that all regulatory requirements are met. Regular training and updates on regulatory changes for the purchasing team can also foster a culture of compliance within the organization.

Strategic Material Selection Guide for printed circuit board supplier

What Are the Key Materials Used in Printed Circuit Boards?

When selecting materials for printed circuit boards (PCBs), international B2B buyers must consider several factors, including performance, cost, and compliance with regional standards. Here we analyze four common materials used in PCB manufacturing: FR-4, Polyimide, Rogers, and Aluminum. Each material has unique properties that influence its suitability for various applications.

How Does FR-4 Perform in PCB Applications?

FR-4 is the most widely used material for PCBs, primarily due to its excellent electrical insulation properties and mechanical strength. It is a composite material made from woven fiberglass cloth and epoxy resin.

Key Properties: FR-4 has a temperature rating of up to 130°C and offers good moisture resistance.

Pros & Cons: The advantages of FR-4 include its affordability and ease of manufacturing, making it suitable for high-volume production. However, it has limited thermal performance compared to specialized materials, which can be a drawback in high-temperature applications.

Impact on Application: FR-4 is compatible with a wide range of media, including water and various solvents, but it may not perform well in extreme environments.

Considerations for International Buyers: Buyers from regions like Europe and South America should ensure compliance with standards such as RoHS and IPC-6012, which govern material safety and performance.

What Are the Benefits of Polyimide for Flexible PCBs?

Polyimide is a high-performance polymer known for its flexibility and thermal stability, making it ideal for flexible PCBs.

Key Properties: Polyimide can withstand temperatures up to 260°C and offers excellent chemical resistance.

Pros & Cons: Its flexibility allows for intricate designs and applications in tight spaces. However, Polyimide is generally more expensive than FR-4 and can complicate manufacturing processes.

Impact on Application: Polyimide is particularly suited for applications requiring bending or twisting, such as in consumer electronics and medical devices.

Considerations for International Buyers: Compliance with international standards like IPC-6013 is crucial, especially in industries such as aerospace and automotive, where reliability is paramount.

Why Choose Rogers Materials for High-Frequency Applications?

Rogers materials are engineered for high-frequency applications, making them popular in telecommunications and RF (radio frequency) circuits.

Key Properties: These materials exhibit low dielectric loss and stable dielectric constant over a wide frequency range.

Pros & Cons: Rogers materials provide superior performance in high-frequency applications but are significantly more expensive than traditional materials like FR-4. Their manufacturing complexity can also lead to longer lead times.

Impact on Application: They are ideal for applications involving microwave and RF signals, ensuring minimal signal loss and interference.

Considerations for International Buyers: Buyers should be aware of the specific certifications required for Rogers materials, including compliance with ASTM standards, particularly in Europe.

What Advantages Does Aluminum Offer for Thermal Management?

Aluminum PCBs are becoming increasingly popular due to their excellent thermal conductivity, making them suitable for LED applications and power electronics.

Key Properties: Aluminum can dissipate heat effectively, with thermal conductivity ratings often exceeding 200 W/mK.

Pros & Cons: The primary advantage of aluminum PCBs is their ability to manage heat, enhancing the longevity of components. However, they are typically more expensive to manufacture and require specialized processes.

Impact on Application: Aluminum is particularly effective in applications where heat dissipation is critical, such as in LED lighting and power supply circuits.

Considerations for International Buyers: Buyers in the Middle East and Africa should consider local manufacturing capabilities and compliance with international standards like JIS and DIN, which may affect the choice of aluminum for specific applications.

Summary Table of Material Selection for PCBs

| Material | Typical Use Case for printed circuit board supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| FR-4 | General-purpose PCBs | Cost-effective and easy to manufacture | Limited thermal performance | Low |

| Polyimide | Flexible PCBs for consumer electronics | High flexibility and thermal stability | Higher cost and manufacturing complexity | High |

| Rogers | High-frequency RF applications | Low dielectric loss and stable performance | Expensive and complex to manufacture | High |

| Aluminum | LED and power electronics | Excellent thermal management | Higher manufacturing costs | Med |

This comprehensive analysis of materials used in PCB manufacturing provides international B2B buyers with actionable insights to make informed decisions based on application needs, cost considerations, and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for printed circuit board supplier

What Are the Main Stages of Printed Circuit Board Manufacturing?

The manufacturing process for printed circuit boards (PCBs) involves several critical stages, each essential to producing high-quality products. Understanding these stages can help B2B buyers from Africa, South America, the Middle East, and Europe evaluate potential suppliers effectively.

1. Material Preparation: What Materials Are Used in PCB Manufacturing?

The first stage in PCB manufacturing is material preparation. This involves selecting the right materials, typically fiberglass epoxy for the substrate, copper for conductive pathways, and various coatings for protection. The materials are carefully inspected for quality before proceeding. This stage is crucial because subpar materials can lead to failures in the final product.

2. Forming: How Are PCBs Formed?

Once the materials are prepared, the next step is forming. This includes processes like etching, where unwanted copper is removed to create the desired circuit pattern. Techniques such as photolithography are employed to transfer the design onto the copper layer using light-sensitive films. Understanding the forming techniques used can provide insight into the precision and reliability of the PCBs being produced.

3. Assembly: What Are the Key Techniques in PCB Assembly?

The assembly stage involves placing electronic components onto the PCB. This is often done using Surface Mount Technology (SMT) or Through-Hole Technology (THT). SMT allows for smaller components to be placed more densely, while THT is preferred for larger components. The assembly process typically includes soldering, which can be done using wave soldering or reflow soldering techniques. Each method has its advantages and can affect the PCB’s performance and durability.

4. Finishing: How Is the Final PCB Finished?

Finishing processes enhance the PCB’s durability and performance. This includes applying protective coatings, surface treatments, and final inspections. Common finishing methods include HASL (Hot Air Solder Leveling) and ENIG (Electroless Nickel Immersion Gold), which provide different levels of surface quality and oxidation resistance. The choice of finishing can significantly influence the PCB’s lifespan and reliability.

What Are the Key Quality Assurance Measures for PCBs?

Quality assurance (QA) in PCB manufacturing is critical to ensuring that the final products meet international standards and customer expectations. Various QA measures and international standards play a significant role in this process.

1. Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with several international standards that govern PCB quality. ISO 9001 is a widely recognized standard that focuses on quality management systems. Compliance with ISO 9001 indicates that a supplier has consistent quality control processes in place. Additionally, specific industry certifications such as CE (Conformité Européenne) for European markets and IPC standards (Institute of Printed Circuits) provide guidelines for PCB manufacturing quality.

2. What Are the Quality Control Checkpoints in PCB Manufacturing?

Quality control checkpoints are crucial for maintaining standards throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This step checks raw materials for defects before they enter production.

- In-Process Quality Control (IPQC): Ongoing checks during manufacturing ensure that processes remain within specified limits.

- Final Quality Control (FQC): This final inspection assesses the completed PCBs for functionality and compliance with specifications.

Understanding these checkpoints helps buyers gauge the thoroughness of a supplier’s quality assurance processes.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure they are partnering with reputable PCB suppliers, B2B buyers should take proactive steps to verify quality control measures.

1. What Are the Best Practices for Supplier Audits?

Conducting supplier audits is an effective way to assess a potential partner’s manufacturing processes and quality assurance practices. Buyers should request to review the supplier’s quality manuals, inspection reports, and compliance records. On-site visits can also provide valuable insights into the supplier’s operations.

2. How Can Buyers Leverage Third-Party Inspections?

Utilizing third-party inspection services can add an extra layer of assurance. Independent organizations can conduct inspections at various stages of the manufacturing process, providing unbiased reports on product quality. This is particularly valuable for international buyers, as it can help mitigate risks associated with overseas sourcing.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control in international procurement involves understanding specific nuances that vary by region.

1. How Do Regional Standards Affect PCB Quality?

Different regions may have varying standards and regulations that impact PCB quality. For example, European markets often require compliance with CE marking, while buyers in the Middle East might focus on local certifications. Buyers should ensure that their suppliers are well-versed in the regulatory requirements of the markets they serve.

2. What Should Buyers Consider Regarding Cultural and Communication Factors?

Cultural differences can influence quality control practices and communication styles. Buyers should prioritize suppliers that exhibit transparency in their processes and are willing to engage in open communication. Establishing a clear understanding of expectations can mitigate misunderstandings and ensure that quality standards are met consistently.

By gaining a comprehensive understanding of the manufacturing processes and quality assurance measures in PCB production, international B2B buyers can make informed decisions and build successful partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘printed circuit board supplier’

Introduction

Navigating the procurement process for printed circuit boards (PCBs) can be complex, especially for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This practical sourcing guide serves as a step-by-step checklist to help you identify, evaluate, and select the right PCB suppliers that meet your technical and business needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the foundation of a successful sourcing process. This step ensures that suppliers understand your exact requirements, including the type of PCB (e.g., single-sided, double-sided, or multi-layer), material specifications, and production volumes.

- Key Considerations:

- Consider the operational environment (temperature, humidity) the PCB will face.

- Specify any certifications required, such as RoHS compliance or ISO standards.

Step 2: Conduct Market Research

Before reaching out to suppliers, conduct thorough market research to identify potential candidates. This includes analyzing the competitive landscape and understanding regional strengths in PCB manufacturing.

- Key Considerations:

- Look for suppliers with a strong track record in your industry.

- Utilize platforms like industry forums, trade shows, and online marketplaces to gather insights.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Key Considerations:

- Assess their production capabilities and lead times.

- Check for customer reviews or testimonials to gauge reliability.

Step 4: Verify Supplier Certifications

Certifications are a critical aspect of supplier credibility. Ensure that your potential suppliers hold relevant industry certifications, such as ISO 9001 for quality management or IPC standards for PCB manufacturing.

- Key Considerations:

- Verify the authenticity of the certifications through the issuing bodies.

- Ensure that the certifications are up-to-date and relevant to your product requirements.

Step 5: Request Samples and Prototypes

Requesting samples or prototypes allows you to evaluate the quality of the supplier’s work firsthand. This step is essential to ensure that the PCBs meet your specifications and quality standards before placing a large order.

- Key Considerations:

- Assess the quality of materials, soldering, and overall finish.

- Test the prototype under operational conditions if possible.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, it’s time to negotiate terms and conditions. This should include pricing, payment terms, delivery schedules, and warranties.

- Key Considerations:

- Discuss bulk order discounts or long-term partnership agreements.

- Ensure clarity on the consequences of delays or quality issues.

Step 7: Establish Communication Protocols

Setting up clear communication protocols is vital for a smooth procurement process. Define how often you will check in with the supplier and through which channels (email, phone, etc.).

- Key Considerations:

- Establish point-of-contact individuals on both sides.

- Agree on a timeline for updates and progress reports throughout the production process.

By following this checklist, international B2B buyers can streamline their sourcing process for printed circuit boards, ensuring they partner with suppliers that align with their technical requirements and business objectives.

Comprehensive Cost and Pricing Analysis for printed circuit board supplier Sourcing

What Are the Key Cost Components in Printed Circuit Board (PCB) Sourcing?

When sourcing printed circuit boards (PCBs), understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The type and quality of materials significantly impact the overall cost. High-grade materials such as copper and FR-4 resin can increase expenses but may enhance performance and reliability.

-

Labor: Labor costs can vary dramatically based on the region and the complexity of the PCB design. For instance, sourcing from countries with lower labor costs might save money, but it’s essential to consider the skill level and expertise of the workforce.

-

Manufacturing Overhead: This encompasses the indirect costs of production, including utilities, facility maintenance, and depreciation of manufacturing equipment. Efficient production processes can lower these costs.

-

Tooling: Tooling costs are incurred during the setup of manufacturing processes. This includes the creation of molds and dies, which can be significant for custom designs.

-

Quality Control (QC): Implementing rigorous QC processes ensures the reliability of the PCBs. However, this can add to costs, especially if third-party inspections or certifications are needed.

-

Logistics: Shipping and handling costs are critical, particularly for international transactions. Factors such as distance, mode of transport, and customs duties can significantly influence logistics expenses.

-

Margin: Suppliers typically apply a profit margin to their costs. Understanding the margin can help buyers gauge the reasonableness of pricing.

How Do Volume and Specifications Affect PCB Pricing?

Several price influencers come into play when negotiating PCB costs:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should evaluate their needs carefully to optimize order sizes.

-

Specifications and Customization: Custom designs or specialized features will increase costs. Buyers should define their requirements clearly to avoid unnecessary expenses.

-

Materials and Quality Certifications: The choice of materials and the need for certifications (such as ISO or IPC standards) can impact pricing. High-quality materials and certifications often justify higher costs.

-

Supplier Factors: Supplier reputation, location, and production capabilities can also influence pricing. Established suppliers may charge more but often provide better reliability and support.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial as they define the responsibilities of buyers and sellers in shipping. Incorrect interpretations can lead to unexpected costs.

What Negotiation Strategies Can Help Lower PCB Costs?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Effectively: Always approach negotiations with a clear understanding of your budget and requirements. Presenting data on competitor pricing can strengthen your position.

-

Consider Total Cost of Ownership (TCO): Beyond just the purchase price, consider the TCO, which includes maintenance, logistics, and potential failures. A slightly higher upfront cost may lead to lower long-term expenses if the quality is superior.

-

Be Aware of Pricing Nuances: Different regions may have specific pricing norms based on local market conditions. Understanding these nuances can help avoid overpaying.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable conditions.

Disclaimer on Indicative Prices

It’s essential to note that prices for PCBs can vary widely based on the factors mentioned above. Buyers should seek multiple quotes and conduct thorough due diligence to ensure they receive competitive pricing tailored to their specific needs. Always request detailed breakdowns of costs to understand what you are paying for and to facilitate better negotiations.

Alternatives Analysis: Comparing printed circuit board supplier With Other Solutions

Understanding Alternatives in Printed Circuit Board Supply

When considering printed circuit board (PCB) suppliers, it’s essential to explore alternative solutions that can meet similar needs. Different approaches can offer unique advantages depending on your specific requirements, such as performance, cost, or ease of implementation. In this analysis, we will compare the traditional printed circuit board supplier against two viable alternatives: Flexible Printed Circuit Boards (FPCBs) and 3D-Printed Circuit Boards.

Comparison Table of PCB Solutions

| Comparison Aspect | Printed Circuit Board Supplier | Flexible Printed Circuit Boards (FPCBs) | 3D-Printed Circuit Boards |

|---|---|---|---|

| Performance | High durability and reliability | Lightweight and flexible, suitable for compact designs | Limited durability; still developing technology |

| Cost | Moderate to high, varies by complexity | Generally lower for high-volume production | Initially high setup cost, but potentially lower for custom runs |

| Ease of Implementation | Well-established processes, extensive supplier networks | Requires specialized manufacturing techniques | Emerging technology; may require additional training |

| Maintenance | Relatively low, established support | May need careful handling due to flexibility | Maintenance practices are still being defined |

| Best Use Case | High-reliability applications (e.g., automotive, aerospace) | Consumer electronics with space constraints (e.g., smartphones) | Prototyping and low-volume custom applications |

What Are the Advantages and Disadvantages of Flexible Printed Circuit Boards (FPCBs)?

Flexible printed circuit boards (FPCBs) offer a unique solution that can be particularly advantageous in applications where space and weight are critical. Their lightweight and flexible nature allows them to conform to various shapes, making them ideal for compact electronic devices. However, FPCBs may not be as durable as traditional rigid PCBs, which can be a concern in high-stress environments. Additionally, while they can reduce assembly costs in high-volume production, the initial setup may require specialized manufacturing techniques that could pose a challenge for some organizations.

How Do 3D-Printed Circuit Boards Compare?

3D-printed circuit boards represent an innovative approach to PCB manufacturing. They enable rapid prototyping and customization, allowing businesses to create unique designs without the need for extensive tooling. This can be particularly beneficial for startups or companies developing new products. However, the technology is still evolving, and 3D-printed boards may lack the durability and reliability of traditional PCBs. The initial investment in 3D printing technology can also be high, and maintenance practices for these boards are still being established.

How Can B2B Buyers Choose the Right PCB Solution?

In choosing the right PCB solution, B2B buyers should carefully assess their specific needs and project requirements. Factors such as the intended application, budget constraints, and production volume are critical in making an informed decision. For high-reliability applications, traditional PCB suppliers remain the best choice. Conversely, for projects requiring flexibility and space efficiency, FPCBs may provide significant advantages. Lastly, for innovative projects that prioritize customization, exploring 3D-printed circuit boards could yield promising results. By considering these alternatives, buyers can ensure they select the most suitable solution for their operational needs.

Essential Technical Properties and Trade Terminology for printed circuit board supplier

What Are the Essential Technical Properties of Printed Circuit Boards (PCBs)?

When sourcing printed circuit boards (PCBs) from suppliers, international B2B buyers should pay close attention to several key technical properties that can significantly influence the performance, reliability, and cost of their electronic products. Here are some critical specifications to consider:

1. Material Grade

The choice of material is paramount in PCB manufacturing. Common materials include FR-4 (a fiberglass epoxy laminate) and Rogers materials (for high-frequency applications). Each material has distinct thermal and electrical properties, affecting durability and performance. Selecting the appropriate material ensures the PCB meets the specific application requirements, enhancing product longevity and reliability.

2. Tolerance

Tolerance refers to the allowable deviation from specified dimensions in the PCB design. It is crucial for ensuring that components fit correctly and function as intended. A tighter tolerance can lead to higher manufacturing costs but is necessary for high-performance applications, such as in telecommunications or aerospace industries. Understanding tolerance requirements allows buyers to balance cost with performance needs.

3. Layer Count

PCBs can have multiple layers, with common configurations ranging from single-layer to multi-layer boards. The layer count impacts the complexity of the circuit design, the density of the components, and the overall size of the PCB. Buyers should determine the required layer count based on the application’s electrical performance and spatial constraints, ensuring that the supplier can accommodate these specifications.

4. Surface Finish

The surface finish of a PCB affects solderability and the overall quality of the electrical connections. Common finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative). Each type has its advantages, with some providing better corrosion resistance and others offering improved solderability. Choosing the right surface finish can enhance the reliability of connections and reduce manufacturing defects.

5. Thermal Management

Thermal management is vital for PCBs used in high-power applications. Specifications related to thermal conductivity and heat dissipation capabilities should be considered. Using materials with high thermal conductivity and incorporating design features like thermal vias can help manage heat effectively, preventing component failure and extending the lifespan of the PCB.

What Are Common Trade Terms Used in PCB Sourcing?

Familiarity with industry jargon can facilitate smoother negotiations and ensure clarity in communications with suppliers. Here are some common terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products or components that are sold under another company’s brand name. In PCB sourcing, understanding whether a supplier operates as an OEM can help buyers gauge product quality and reliability, as OEMs typically adhere to stringent manufacturing standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand, as it can affect inventory management and overall costs. Buyers should negotiate MOQs that align with their production needs to avoid overstocking or supply shortages.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. Crafting a detailed RFQ helps buyers receive accurate quotes, enabling them to compare suppliers effectively. Including detailed specifications in the RFQ can lead to more competitive pricing and better alignment with project requirements.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps buyers clarify shipping responsibilities, costs, and risks associated with transporting goods.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is crucial for planning production schedules and ensuring timely project completion. Buyers should communicate their timelines clearly to suppliers to avoid delays.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions when selecting printed circuit board suppliers, ultimately enhancing their product quality and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the printed circuit board supplier Sector

What Are the Current Market Dynamics and Key Trends in the Printed Circuit Board Supplier Sector?

The global printed circuit board (PCB) market is experiencing significant growth, driven by the increasing demand for electronics in various sectors, including automotive, consumer electronics, and telecommunications. Notably, the rise of electric vehicles and the Internet of Things (IoT) are propelling the demand for advanced PCBs with higher functionality and miniaturization. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging B2B tech trends include the adoption of Industry 4.0 principles, such as automation, artificial intelligence, and data analytics, which are transforming PCB manufacturing processes. These technologies enhance production efficiency, reduce lead times, and improve quality control, making suppliers more competitive. Furthermore, buyers are increasingly looking for suppliers who offer flexible and scalable solutions to meet fluctuating demand.

Another notable trend is the shift towards regional sourcing as companies seek to mitigate supply chain risks exacerbated by geopolitical tensions and the COVID-19 pandemic. Buyers are encouraged to evaluate suppliers based on their geographic location, reliability, and ability to adapt to changing market conditions. For instance, European buyers might prioritize suppliers within the EU to reduce logistics costs and lead times, while African and South American buyers could explore local suppliers to foster regional economic growth.

How Is Sustainability Shaping the Printed Circuit Board Supplier Industry?

Sustainability is becoming a pivotal concern in the PCB supplier sector, driven by environmental regulations and increasing consumer awareness. The environmental impact of PCB manufacturing, particularly concerning waste generation and toxic materials, has prompted buyers to prioritize ethical sourcing practices. B2B buyers must consider suppliers’ environmental policies and practices, ensuring they align with global sustainability goals.

Ethical supply chains are essential for fostering responsible consumption and production. Buyers should seek suppliers that utilize ‘green’ certifications, such as ISO 14001, and materials that minimize environmental harm. This includes the use of lead-free solder and recyclable materials, which not only reduce ecological footprints but also enhance brand reputation among environmentally conscious consumers.

Moreover, engaging with suppliers who prioritize transparency in their supply chains can help buyers mitigate risks associated with unethical practices. Establishing partnerships with suppliers committed to sustainability can also lead to innovation in product development, as these suppliers are often at the forefront of adopting new technologies and materials that meet green standards.

What Is the Historical Context of the Printed Circuit Board Supplier Sector?

The printed circuit board industry has evolved significantly since its inception in the mid-20th century. Initially, PCBs were simple and primarily used in military applications. However, with the advent of consumer electronics in the 1970s and 1980s, the demand for more complex and reliable PCBs surged. This evolution has been marked by technological advancements, including the introduction of surface mount technology (SMT) and multilayer boards, which allowed for the miniaturization of electronic components.

Today, the PCB sector is characterized by rapid innovation, with suppliers continually adapting to the changing needs of industries such as telecommunications, healthcare, and automotive. For international B2B buyers, understanding this historical context is crucial as it highlights the importance of partnering with suppliers who have a proven track record of adaptability and innovation in a fast-paced market.

Frequently Asked Questions (FAQs) for B2B Buyers of printed circuit board supplier

-

How do I choose the right printed circuit board supplier for my business needs?

Selecting the right printed circuit board (PCB) supplier involves assessing several factors. First, evaluate their experience in your industry and their ability to handle your specific requirements. Look for suppliers that offer customization options and have a robust quality assurance process. Additionally, check their production capabilities, lead times, and minimum order quantities (MOQs). Reading customer reviews and requesting samples can also provide insights into their reliability and product quality. -

What are the common customization options available for printed circuit boards?

Customization options for PCBs can vary widely among suppliers. Common options include different board materials (like FR-4 or polyimide), layer counts, thicknesses, and finishes (such as HASL or ENIG). Additionally, suppliers may offer various solder mask colors, silkscreen printing, and hole sizes. Discussing your specific design requirements with potential suppliers can help ensure they can meet your needs effectively. -

What should I know about minimum order quantities (MOQs) when sourcing PCBs?

Minimum order quantities (MOQs) can significantly impact your sourcing decisions. Many PCB suppliers set MOQs based on production efficiency and cost-effectiveness. For smaller businesses or startups, finding suppliers with lower MOQs can be beneficial. It’s essential to communicate your needs upfront, as some suppliers may be willing to negotiate MOQs or offer prototype runs for smaller batches, particularly for new projects. -

What are the typical payment terms offered by printed circuit board suppliers?

Payment terms can vary between suppliers, but common practices include upfront payments, net 30, or net 60 days. Some suppliers may require a deposit before starting production, especially for larger orders. It’s crucial to clarify payment terms during negotiations to avoid misunderstandings later. Additionally, consider suppliers that offer secure payment methods, which can provide added protection for international transactions. -

How do I assess the quality assurance practices of a PCB supplier?

To evaluate the quality assurance (QA) practices of a PCB supplier, inquire about their certifications (such as ISO 9001 or IPC standards) and quality control processes. A reputable supplier should have a documented QA process, including inspections at various production stages, testing protocols, and a clear return policy for defective products. Requesting sample products can also help assess their quality before placing a larger order. -

What logistics considerations should I be aware of when sourcing PCBs internationally?

When sourcing PCBs from international suppliers, consider shipping times, customs regulations, and potential tariffs. Understanding the logistics involved can prevent delays and unexpected costs. Collaborate with suppliers to determine the best shipping methods and ensure they have experience handling international orders. Additionally, ensure that your supply chain can accommodate lead times, especially if you require just-in-time delivery. -

What are the key factors influencing the cost of printed circuit boards?

The cost of PCBs is influenced by several factors, including the complexity of the design, the materials used, the number of layers, and the volume of the order. Customization options and additional features like surface treatments or specific testing can also add to the cost. When budgeting, consider both the unit price and any additional shipping or customs fees that may apply, especially for international orders. -

How can I ensure effective communication with my PCB supplier?

Effective communication with your PCB supplier is essential for a successful partnership. Establish clear points of contact and preferred communication methods early on. Utilize project management tools for tracking progress and changes. Be specific about your requirements and timelines, and encourage open dialogue to address any questions or concerns promptly. Regular updates can help maintain alignment and ensure that both parties are on the same page throughout the production process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for printed circuit board supplier

What Are the Key Takeaways for Strategic Sourcing in PCB Procurement?

In the dynamic landscape of printed circuit board (PCB) sourcing, strategic partnerships and informed decision-making stand out as critical components for international B2B buyers. By leveraging a comprehensive understanding of supplier capabilities, compliance standards, and regional market trends, businesses can not only mitigate risks but also optimize their supply chain efficiency. For buyers in Africa, South America, the Middle East, and Europe, particularly in robust markets like Germany and Brazil, it is essential to prioritize suppliers who demonstrate reliability, innovation, and responsiveness.

How Can Buyers Prepare for Future PCB Sourcing Challenges?

As the demand for sophisticated electronics continues to rise, so does the complexity of sourcing PCBs. Buyers should proactively seek suppliers who are not only well-versed in the latest technologies but also committed to sustainable practices. Engaging in direct communication and establishing clear expectations will foster stronger relationships and lead to better outcomes.

What Steps Should Buyers Take Moving Forward?

Looking ahead, international B2B buyers are encouraged to continuously evaluate their sourcing strategies and adapt to changing market conditions. By investing in strategic sourcing initiatives, businesses can enhance their competitive edge and ensure long-term success. Embrace collaboration with reliable PCB suppliers and leverage their expertise to drive innovation in your products. Now is the time to act—align your sourcing strategy with your business goals and unlock new opportunities in the global market.