Discover Top Printing Paper Suppliers: Your Ultimate Guide (2025)

Introduction: Navigating the Global Market for printing paper supplier

In today’s competitive landscape, sourcing reliable printing paper suppliers can pose a significant challenge for international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe. The diverse array of products available—from coated and uncoated papers to specialty options—demands a strategic approach to procurement that aligns with specific business needs. This guide aims to demystify the global market for printing paper by providing a comprehensive overview of different types of paper, their applications across various industries, and essential considerations for supplier vetting.

Navigating through supplier options can be overwhelming, particularly for businesses seeking quality materials at competitive prices. By leveraging the insights contained within this guide, buyers will be equipped to make informed purchasing decisions that not only meet their operational requirements but also enhance their overall supply chain efficiency. We will delve into key factors such as cost analysis, supplier reliability, and sustainability practices, ensuring that you are well-prepared to engage with potential partners.

Whether you are a print service provider in Kenya, a marketing agency in Turkey, or a manufacturer in Brazil, understanding the intricacies of the printing paper market is crucial. This guide serves as your roadmap, empowering you to forge partnerships that can elevate your business and drive success in the global marketplace.

Understanding printing paper supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Coated Paper | Smooth finish, ideal for high-quality images and colors | Magazines, brochures, marketing materials | Pros: High print quality, vibrant colors. Cons: More expensive, less eco-friendly. |

| Uncoated Paper | Natural texture, good for writing and general printing | Stationery, books, business documents | Pros: Cost-effective, writable. Cons: Lower print quality compared to coated paper. |

| Recycled Paper | Made from post-consumer waste, eco-friendly | Eco-conscious businesses, promotional materials | Pros: Sustainable, cost-effective. Cons: May have inconsistent quality. |

| Specialty Paper | Unique textures and finishes, custom options available | Invitations, high-end marketing materials | Pros: Distinctive appearance, customizable. Cons: Higher costs, longer lead times. |

| Digital Paper | Designed for digital printing, optimized for inkjet and laser | Short-run printing, on-demand printing | Pros: Quick turnaround, versatile. Cons: May not be suitable for large volumes. |

What Are the Characteristics of Coated Paper and Its B2B Suitability?

Coated paper features a smooth finish that enhances the quality of printed images and colors. This type of paper is particularly suitable for applications requiring high visual impact, such as magazines, brochures, and marketing materials. B2B buyers should consider the balance between print quality and cost, as coated paper tends to be more expensive than uncoated alternatives. Additionally, the environmental impact is a consideration, as many coated papers are not made from sustainable sources.

How Does Uncoated Paper Differ and Where Is It Best Used?

Uncoated paper is characterized by its natural texture, making it an excellent choice for writing and general printing tasks. It is widely used in stationery, books, and business documents. For B2B buyers, the main advantages include cost-effectiveness and the ability to write on the surface easily. However, the trade-off is a lower print quality compared to coated options, which may not be suitable for high-end marketing materials.

Why Choose Recycled Paper for Your B2B Needs?

Recycled paper is produced from post-consumer waste, making it an eco-friendly choice for businesses looking to enhance their sustainability credentials. It is commonly used for promotional materials and packaging by environmentally conscious companies. While recycled paper offers cost advantages and a lower carbon footprint, buyers should be aware that the quality can be inconsistent, which may affect print results.

What Makes Specialty Paper a Unique Option for Businesses?

Specialty paper includes a range of unique textures and finishes, allowing for customization in printing projects such as invitations and high-end marketing materials. This type of paper can create a distinctive appearance that sets a brand apart. B2B buyers should weigh the benefits of customization against the higher costs and longer lead times often associated with specialty papers, making it essential to plan ahead.

How Is Digital Paper Optimized for Modern Printing Needs?

Digital paper is specifically designed for use with digital printing technologies, including inkjet and laser printers. It is ideal for short-run and on-demand printing, which is increasingly important in fast-paced business environments. Buyers should consider the versatility and quick turnaround times offered by digital paper. However, it may not be suitable for high-volume printing, which could lead to increased costs per unit for large orders.

Related Video: 6 Different Types of Paper for Printing

Key Industrial Applications of printing paper supplier

| Industry/Sector | Specific Application of Printing Paper Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Publishing | High-quality book printing and magazines | Enhances brand image and reader engagement | Quality of paper, printing technology, and turnaround time |

| Advertising | Flyers, brochures, and promotional materials | Effective communication and increased sales potential | Customization options, print runs, and distribution capabilities |

| Education | Educational materials, textbooks, and workbooks | Supports learning and improves educational outcomes | Content accuracy, durability, and compliance with educational standards |

| Packaging | Printed packaging materials for products | Improves product visibility and consumer appeal | Sustainability of materials, design flexibility, and cost-effectiveness |

| Corporate | Business stationery, reports, and presentations | Professional appearance and effective communication | Brand alignment, paper quality, and delivery timelines |

How is Printing Paper Used in the Publishing Industry?

In the publishing industry, printing paper suppliers provide essential materials for producing high-quality books and magazines. This sector relies heavily on the aesthetics and feel of paper to enhance the reading experience and convey the brand’s identity. Buyers from Africa and South America should focus on sourcing papers that offer durability and vibrant color reproduction, as these factors contribute significantly to reader engagement and retention.

What are the Applications of Printing Paper in Advertising?

Advertising firms utilize printing paper for creating flyers, brochures, and other promotional materials. High-quality printed materials serve as a powerful tool for effective communication, helping businesses convey their messages clearly and attractively. B2B buyers in the Middle East and Europe must consider customization options and the ability to handle different print runs to meet varying marketing needs, ensuring their materials stand out in competitive markets.

Why is Printing Paper Important in Education?

In the education sector, printing paper suppliers are critical for producing textbooks, workbooks, and other educational materials. These products support learning by providing students with tangible resources that enhance comprehension and retention. Buyers from Turkey and Kenya should prioritize sourcing paper that meets educational standards for durability and content accuracy, as well as consider the environmental impact of their choices to align with sustainability goals.

How is Printing Paper Used in Packaging?

Printed packaging materials are crucial for product visibility and consumer appeal in various industries. Printing paper suppliers provide the necessary substrates for creating branded packaging that captures attention on retail shelves. Buyers should evaluate the sustainability of materials, design flexibility, and cost-effectiveness when sourcing packaging solutions, especially in regions like Africa and South America where eco-friendly practices are increasingly valued.

What Role Does Printing Paper Play in Corporate Communication?

In corporate settings, printing paper is used for business stationery, reports, and presentations. The quality of printed materials reflects the professionalism of the organization and enhances communication with clients and stakeholders. International B2B buyers must focus on paper quality and brand alignment to ensure that their printed materials convey the right message and uphold the company’s image, while also considering delivery timelines to meet business needs.

Related Video: The Printing Process – Sheet Offset Press – English

3 Common User Pain Points for ‘printing paper supplier’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Printing Paper

The Problem:

B2B buyers often struggle to find reliable suppliers of quality printing paper that meets their specific needs. This is particularly challenging in regions like Africa and South America, where local suppliers may not have the variety or quality standards required. Buyers may face issues such as inconsistent paper quality, limited options for sizes and finishes, and a lack of supplier transparency regarding sourcing and production practices. This can lead to delays in production schedules and dissatisfaction with the final printed products.

The Solution:

To overcome this sourcing challenge, B2B buyers should prioritize establishing relationships with reputable international printing paper suppliers who have a proven track record of quality and reliability. Start by conducting thorough research, utilizing platforms like Alibaba or industry-specific trade shows to identify potential suppliers. Request samples of different paper types to assess their quality firsthand before making larger orders. Additionally, consider suppliers that offer customizable options, allowing you to specify your required sizes and finishes. Building a strong communication channel with your chosen supplier can also enhance transparency and lead to better service and product quality.

Scenario 2: Managing Supply Chain Disruptions

The Problem:

Supply chain disruptions can severely impact the availability of printing paper, especially in regions prone to political instability or logistical challenges, such as the Middle East and parts of Africa. B2B buyers may find themselves facing unexpected delays, price hikes, or even complete shortages of essential materials. This unpredictability can disrupt production schedules and affect client relationships, leading to potential financial losses.

The Solution:

To mitigate the risks associated with supply chain disruptions, B2B buyers should adopt a proactive approach to inventory management. This includes maintaining a safety stock of essential paper types to buffer against unforeseen shortages. Additionally, diversifying your supplier base can be crucial; do not rely solely on one supplier or geographic region. Establish agreements with multiple suppliers across different regions to ensure continuity of supply. Leveraging technology such as supply chain management software can also help track inventory levels and forecast demand more accurately, allowing you to make informed purchasing decisions.

Scenario 3: Understanding Environmental Compliance and Sustainability

The Problem:

As global awareness of environmental issues increases, B2B buyers are increasingly pressured to source sustainable and environmentally friendly printing paper. However, navigating the various certifications and standards can be confusing. Buyers may encounter challenges in verifying a supplier’s claims about sustainability, such as whether the paper is sourced from responsibly managed forests or whether it meets specific environmental regulations. This uncertainty can lead to reputational risks and potential compliance issues.

The Solution:

To address these concerns, B2B buyers should prioritize suppliers who are transparent about their sustainability practices. Look for suppliers that provide certifications such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification). Request documentation that verifies the sustainability claims of the printing paper. Additionally, consider engaging in direct conversations with suppliers about their sourcing practices and environmental impact. Building partnerships with suppliers who prioritize sustainability not only helps you meet compliance requirements but also enhances your brand’s reputation among environmentally conscious clients.

Strategic Material Selection Guide for printing paper supplier

What Are the Key Properties of Common Printing Paper Materials?

When selecting printing paper, understanding the properties of various materials is crucial for ensuring optimal performance in specific applications. Here, we analyze four common types of printing paper materials: coated paper, uncoated paper, recycled paper, and specialty paper. Each material has distinct characteristics that affect durability, print quality, and cost.

Coated Paper: What Are Its Advantages and Disadvantages?

Coated paper is treated with a coating that enhances its smoothness and brightness, making it ideal for high-quality printing. Key properties include a high gloss finish, which improves color vibrancy and detail retention. Coated paper typically has a temperature tolerance that allows it to withstand various printing processes, including digital and offset printing.

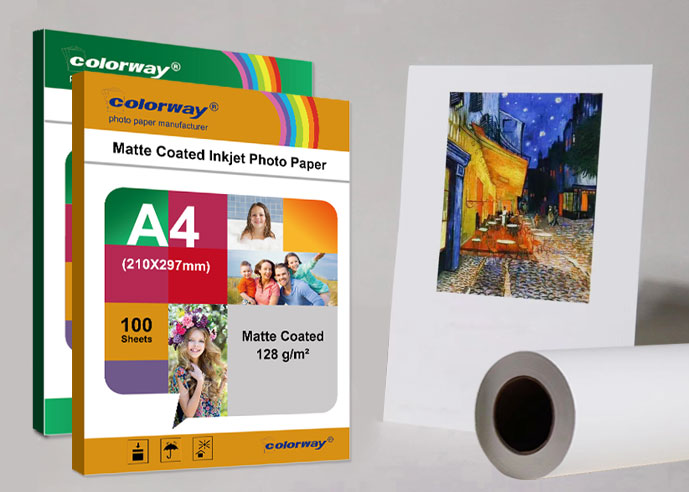

A stock image related to printing paper supplier.

Pros: The primary advantage of coated paper is its superior print quality, making it suitable for marketing materials, brochures, and high-end publications. However, it can be more expensive than uncoated options, and its manufacturing process can be complex, which may lead to longer lead times.

Cons: One limitation is its reduced durability in outdoor applications due to susceptibility to moisture. Coated paper may also not be suitable for applications requiring writing or direct contact with ink, as it can smudge.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local environmental regulations and standards, as coated papers may contain chemicals that are restricted in certain markets.

Uncoated Paper: When Should It Be Used?

Uncoated paper lacks the surface treatment of coated paper, offering a more natural feel and a matte finish. Its key properties include good ink absorption, which is beneficial for writing and printing applications.

Pros: Uncoated paper is often more affordable than coated options and is widely available. It is suitable for a variety of applications, including letterheads, envelopes, and books, where a more tactile experience is desired.

Cons: The downside is that uncoated paper may not produce as vibrant colors as coated paper, which can affect the overall aesthetic of printed materials. Additionally, it is less resistant to moisture and wear, making it less durable in demanding environments.

Considerations for International Buyers: In Europe and the Middle East, buyers should be aware of the varying quality standards for uncoated paper, such as ISO 9706, which ensures longevity and durability.

Recycled Paper: What Are Its Environmental Benefits?

Recycled paper is made from post-consumer waste, making it an environmentally friendly choice. Key properties include varying degrees of brightness and texture, depending on the recycling process.

Pros: The primary advantage of recycled paper is its reduced environmental impact, appealing to businesses focused on sustainability. It is often competitively priced and can be used for a wide range of applications, including everyday printing and packaging.

Cons: However, recycled paper may have inconsistent quality, which can affect print performance. It may also require specific inks or printing techniques to achieve desired results, potentially increasing production complexity.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider certifications such as FSC (Forest Stewardship Council) or SFI (Sustainable Forestry Initiative) to ensure the recycled paper meets sustainability standards.

Specialty Paper: When Is It the Right Choice?

Specialty paper encompasses a range of unique papers designed for specific applications, such as textured papers for invitations or synthetic papers for outdoor signage. Key properties vary widely but often include enhanced durability and unique finishes.

Pros: The key advantage of specialty paper is its versatility and ability to create distinctive printed materials that stand out. It can be tailored for specific uses, enhancing branding and customer engagement.

Cons: The main limitation is cost; specialty papers are generally more expensive than standard options and may have longer lead times due to specialized manufacturing processes.

Considerations for International Buyers: Buyers should be aware of local preferences and standards for specialty papers, as certain textures or finishes may be more desirable in specific markets, such as Turkey or Kenya.

Summary Table of Material Properties for Printing Paper Suppliers

| Material | Typical Use Case for printing paper supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Coated Paper | Marketing materials, brochures | Superior print quality | Reduced durability in outdoor applications | High |

| Uncoated Paper | Letterheads, envelopes | Affordable and widely available | Less vibrant colors | Medium |

| Recycled Paper | Everyday printing, packaging | Environmentally friendly | Inconsistent quality | Medium |

| Specialty Paper | Invitations, outdoor signage | Unique finishes and versatility | Higher cost and longer lead times | High |

This strategic material selection guide provides a comprehensive overview of the various printing paper options available to B2B buyers, helping them make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for printing paper supplier

What Are the Key Manufacturing Processes for Printing Paper Suppliers?

Manufacturing printing paper involves several critical stages that ensure the final product meets industry standards and customer expectations. Understanding these processes can empower international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, to make informed purchasing decisions.

Material Preparation: What Goes Into Printing Paper?

The first step in the manufacturing process is material preparation. This stage involves sourcing high-quality raw materials, primarily wood pulp. The pulp is processed to remove impurities and achieve the desired fiber length.

- Sourcing: Suppliers typically source wood from sustainably managed forests to meet environmental standards. Buyers should inquire about the origin of the pulp and whether it complies with sustainability certifications.

- Chemical Treatment: Chemicals are used to bleach the pulp, enhancing the brightness and ensuring uniformity. International buyers should confirm that suppliers use environmentally friendly chemicals to avoid issues with regulations in their respective countries.

Forming: How Is Printing Paper Shaped?

Once the pulp is prepared, it undergoes the forming process. This involves the following steps:

- Sheet Formation: The treated pulp is mixed with water and poured onto a moving screen. The water drains away, leaving behind a wet sheet of paper.

- Pressing: The wet sheet is passed through rollers that remove additional water and compress the fibers, increasing the paper’s density and strength.

- Drying: The pressed sheet is dried using heated rollers or air dryers. This process is crucial, as the moisture content directly affects the paper’s quality.

B2B buyers should assess the supplier’s technology and equipment used in these processes, as advanced machinery often results in higher quality output.

Assembly: How Are Various Paper Types Created?

In this stage, different types of printing paper can be produced based on specific requirements.

- Coating: Some papers undergo a coating process to improve printability. This may involve applying a layer of clay or polymer to enhance surface smoothness and brightness.

- Cutting and Trimming: The large sheets of paper are cut into specified sizes according to customer orders. Precision in this stage is vital to minimize waste and ensure consistency.

Understanding these assembly techniques helps buyers specify their needs accurately when placing orders.

Finishing: What Final Touches Are Applied?

The finishing process includes various treatments that enhance the paper’s properties:

- Calendering: This involves passing the paper through a series of rollers to smooth the surface and improve gloss.

- Packaging: Proper packaging is essential to protect the paper during transport. Buyers should consider the types of packaging materials used, as they can impact sustainability and waste management efforts.

Buyers should inquire about the finishing techniques employed by suppliers to ensure the final product meets their specific requirements.

What Quality Assurance Measures Should B2B Buyers Consider?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the paper meets both international and industry-specific standards. Understanding these QA measures can significantly influence purchasing decisions.

Which International Standards Should Buyers Look For?

International standards such as ISO 9001 are essential for ensuring quality management systems are in place. This certification indicates that a supplier adheres to global quality benchmarks, which is crucial for B2B buyers looking to mitigate risks.

- ISO 14001: This standard focuses on environmental management, ensuring that the supplier operates sustainably.

- FSC Certification: The Forest Stewardship Council (FSC) certification is vital for buyers concerned about sustainable sourcing.

B2B buyers should request documentation and certificates from suppliers to verify compliance with these standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival. Buyers should ensure that their suppliers have stringent IQC processes to prevent subpar materials from entering the production line.

-

In-Process Quality Control (IPQC): This step involves monitoring the manufacturing process itself. Regular checks during production help identify any deviations from quality standards.

-

Final Quality Control (FQC): Before packaging, the finished product undergoes rigorous testing to ensure it meets specifications. Common testing methods include:

- Physical Testing: Assessing the paper’s strength, thickness, and smoothness.

- Chemical Testing: Ensuring the paper’s pH levels and brightness conform to standards.

Buyers should inquire about the specific testing methods used and request access to QC reports.

How Can B2B Buyers Verify Supplier Quality Assurance?

Verifying a supplier’s quality assurance processes is crucial for international buyers. Here are actionable steps to ensure compliance:

-

Conduct Audits: Regular audits of suppliers can help assess their adherence to quality standards. Buyers should consider third-party audits for an unbiased evaluation.

-

Request QC Reports: Suppliers should provide detailed QC reports, showcasing their testing results and compliance with standards. This documentation is essential for transparency.

-

Third-Party Inspections: Engaging third-party inspection services can provide additional assurance regarding the quality of the paper. These services can evaluate both the manufacturing process and the final product.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Compliance: Different regions have varying regulations regarding paper products. Buyers should ensure that suppliers comply with local and international laws to avoid legal issues.

-

Cultural Expectations: Quality perceptions may vary across regions. Buyers should communicate their quality expectations clearly to suppliers to avoid misunderstandings.

By understanding the manufacturing processes and quality assurance measures in place, B2B buyers can make informed decisions, ensuring they partner with reliable printing paper suppliers that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘printing paper supplier’

To successfully source printing paper suppliers, international B2B buyers must follow a structured approach. This guide provides a step-by-step checklist to ensure you make informed decisions while navigating the complexities of the global supply chain.

Step 1: Define Your Technical Specifications

Clearly outline the type of printing paper you need. This includes weight, thickness, finish, and any environmental certifications such as FSC or PEFC. Having precise specifications helps in obtaining accurate quotes and ensures that the paper meets your production requirements.

- Considerations:

- What printing techniques will be used? (e.g., digital, offset)

- Are there specific industry standards your paper must comply with?

Step 2: Conduct Market Research

Explore the market landscape for printing paper suppliers within your regions of interest, such as Africa, South America, the Middle East, and Europe. Understanding regional suppliers can help you identify potential partners who are familiar with local regulations and market demands.

- Tips:

- Utilize online platforms and trade directories to find suppliers.

- Look for industry reports that highlight leading suppliers and emerging trends.

Step 3: Evaluate Potential Suppliers

Before making any commitments, thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from other businesses in your sector or region. This step is crucial to ensure reliability and quality.

- What to ask for:

- Past client testimonials and success stories.

- Information on production capacity and lead times.

Step 4: Verify Supplier Certifications

Ensure that your shortlisted suppliers hold relevant certifications that guarantee quality and compliance with international standards. Certifications can include ISO 9001 for quality management or environmental certifications.

- Why it matters:

- Certifications can indicate a supplier’s commitment to quality and sustainability.

- They may also affect your own compliance and branding.

Step 5: Request Samples

Before finalizing a supplier, always request samples of the printing paper you intend to purchase. This allows you to evaluate the paper’s quality, printability, and finish firsthand.

- Key points:

- Assess the samples against your defined specifications.

- Consider how the paper performs with your specific printing processes.

Step 6: Negotiate Terms and Pricing

Engage in discussions regarding pricing, payment terms, and delivery schedules. Transparent negotiations can prevent misunderstandings and build a solid foundation for your business relationship.

- Focus areas:

- Understand the supplier’s pricing structure (volume discounts, shipping costs).

- Clarify lead times and any penalties for late deliveries.

Step 7: Establish Clear Communication Channels

Once you select a supplier, establish clear communication protocols. Regular updates and feedback loops can help address any issues that may arise during the procurement process.

- Best practices:

- Use project management tools to track orders and communications.

- Schedule periodic reviews to assess the supplier’s performance and resolve any issues promptly.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing printing paper suppliers, ensuring they make informed decisions that align with their business needs.

Comprehensive Cost and Pricing Analysis for printing paper supplier Sourcing

What Are the Key Cost Components in Printing Paper Supplier Sourcing?

When sourcing printing paper, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of paper—be it coated, uncoated, recycled, or specialty grades—significantly influences material costs. Sourcing from local suppliers can reduce transportation costs, but international buyers should compare quality and price variations from different regions.

-

Labor: Labor costs vary widely across regions. Countries with higher labor costs may offer better-quality craftsmanship, while lower-cost labor markets might focus on volume production. Evaluating the balance between quality and cost is essential.

-

Manufacturing Overhead: This includes costs associated with running a manufacturing facility, such as utilities, equipment maintenance, and administrative expenses. Understanding how these overheads impact the final price can provide insights into supplier pricing strategies.

-

Tooling: Customization often requires specialized tools, which can add to upfront costs. Buyers should inquire about tooling costs for custom specifications and consider how these affect the overall pricing.

-

Quality Control (QC): Rigorous QC processes ensure that the final product meets quality standards, but they also add to costs. Buyers should assess whether the supplier’s QC measures justify the price, especially when sourcing internationally.

-

Logistics: Shipping and handling costs can be substantial, particularly for bulk orders. Buyers need to consider freight costs, customs duties, and delivery times, which can vary based on the supplier’s location and chosen Incoterms.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the typical margins in the industry can help buyers gauge whether a price is fair or inflated.

How Do Price Influencers Affect Printing Paper Sourcing Decisions?

Several factors can influence the pricing of printing paper, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for larger orders. Buyers should evaluate their needs against MOQs to optimize costs.

-

Specifications and Customization: Customization requests can increase costs significantly. Buyers should clearly define their specifications upfront to avoid unexpected price hikes.

-

Material Quality and Certifications: Higher-quality materials typically come at a premium. Buyers should consider the certifications (e.g., FSC, SFI) that may be required for their projects, as these can also affect pricing.

-

Supplier Factors: The supplier’s reputation, production capacity, and location can influence pricing. Established suppliers may charge more for their reliability, while emerging suppliers might offer competitive rates to build their clientele.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) can affect overall costs and responsibilities in the shipping process. Understanding these terms is vital for managing logistics expenses effectively.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

-

Negotiate Wisely: Leverage volume commitments to negotiate better pricing. Building long-term relationships with suppliers can also yield favorable terms.

-

Focus on Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs associated with quality, logistics, and potential wastage. A lower upfront cost may lead to higher TCO if quality is compromised.

-

Understand Pricing Nuances: International buyers should be aware of fluctuations in currency and regional market dynamics that can affect pricing. Engaging local experts or consultants can provide valuable insights.

-

Request Samples: Before placing large orders, request samples to evaluate quality. This can help prevent costly mistakes and ensure the product meets specifications.

-

Stay Informed on Market Trends: Keep abreast of market conditions, including raw material prices and environmental regulations, which can affect supplier pricing strategies.

Disclaimer on Indicative Prices

A stock image related to printing paper supplier.

Prices for printing paper can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough research and obtain quotes tailored to their specific needs and circumstances to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing printing paper supplier With Other Solutions

When evaluating the best solution for printing needs, international B2B buyers should consider various alternatives to traditional printing paper suppliers. Understanding the strengths and weaknesses of each option can help businesses make informed decisions that align with their operational goals and budget constraints.

| Comparison Aspect | Printing Paper Supplier | Digital Printing Solutions | Eco-friendly Alternatives |

|---|---|---|---|

| Performance | High-quality prints with various finishes and textures | Offers exceptional quality and speed for short runs | Varies; often good quality, but dependent on materials used |

| Cost | Generally moderate; costs can rise with specialty papers | Often more cost-effective for small runs, higher for large volumes | Typically higher initial costs but savings on disposal and long-term use |

| Ease of Implementation | Simple, straightforward; requires minimal training | Requires some technical knowledge; user-friendly platforms available | May need specialized training or knowledge of materials |

| Maintenance | Low maintenance; occasional supplier changes needed | Requires regular updates and maintenance of digital equipment | Minimal maintenance, but sourcing can be inconsistent |

| Best Use Case | Ideal for bulk orders and traditional printing needs | Best for on-demand printing and customization | Suitable for environmentally conscious companies and niche markets |

What Are the Advantages and Disadvantages of Digital Printing Solutions?

Digital printing solutions leverage technology to produce high-quality prints on demand. These solutions excel in speed and flexibility, allowing businesses to customize orders easily without the need for extensive setup. However, while they can be cost-effective for smaller batches, the expenses can escalate for larger volumes, making them less economical compared to traditional methods. Moreover, digital printing typically requires some technical expertise, which may necessitate training or hiring specialized staff.

How Do Eco-friendly Alternatives Compare?

Eco-friendly alternatives focus on sustainable materials and processes, such as recycled paper or biodegradable inks. These options appeal to businesses prioritizing sustainability and corporate social responsibility. While they can have higher initial costs due to the sourcing of specialized materials, they often lead to long-term savings, especially in waste disposal. The performance can vary significantly based on the materials used, and sourcing can sometimes be inconsistent, which may affect supply chain reliability.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Choosing the right printing solution depends on various factors, including budget, volume needs, and corporate values. B2B buyers should carefully assess their specific requirements, considering the long-term implications of each option. For companies focused on traditional printing needs and bulk orders, a printing paper supplier may be the best fit. Conversely, those looking for flexibility and customization might prefer digital printing solutions, while environmentally conscious businesses may lean toward eco-friendly alternatives. By weighing these factors, buyers can ensure they select a solution that not only meets their immediate needs but also aligns with their broader business objectives.

Essential Technical Properties and Trade Terminology for printing paper supplier

What Are the Key Technical Properties of Printing Paper?

When evaluating printing paper suppliers, understanding the technical properties of their products is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

-

Material Grade

Material grade refers to the quality of paper used, which can significantly affect printing performance. Common grades include uncoated, coated, and specialty papers. High-grade materials typically offer better print quality, durability, and finish. For international buyers, especially from regions like Africa and South America, selecting the right material grade can lead to better customer satisfaction and brand perception. -

Basis Weight

Basis weight is the weight of a standard ream (500 sheets) of paper, measured in pounds or grams. It influences the thickness and sturdiness of the paper. For example, a heavier basis weight often indicates better durability, making it suitable for brochures and business cards. Buyers should align their choice with the intended use to ensure optimal results. -

Opacity

Opacity measures how much light passes through the paper. High opacity is essential for double-sided printing as it prevents text and images from showing through. This property is especially critical for print products like magazines or flyers, where visual clarity is paramount. Understanding opacity can help buyers choose products that meet their visual requirements. -

Brightness

Brightness indicates how much light reflects off the paper’s surface. The higher the brightness, the more vibrant the colors will appear when printed. This property is vital for marketing materials, where color accuracy and vibrancy can influence purchasing decisions. Buyers should consider the brightness level based on the type of printing process and color fidelity desired. -

Finish

The finish of paper—such as gloss, matte, or silk—affects both the appearance and feel of the printed material. A gloss finish can enhance color vibrancy, while a matte finish offers a more subdued look, often preferred for professional documents. Understanding the desired finish helps buyers select products that align with their branding and communication goals.

What Are the Common Trade Terminology and Jargon in the Printing Industry?

Familiarity with industry terminology can streamline communications and negotiations with printing paper suppliers. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

In the printing industry, OEM refers to companies that produce paper for other brands to sell under their name. Understanding OEM relationships can help buyers find quality sources and negotiate better pricing structures. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for international buyers to plan their budgets and inventory effectively. It can also affect shipping costs and lead times, particularly for smaller companies. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from multiple suppliers. Providing detailed specifications in an RFQ can lead to more accurate pricing and better supplier comparisons. This is particularly useful for buyers from diverse regions seeking competitive rates. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms is vital for international buyers to avoid unexpected costs and ensure smooth logistics. -

Lead Time

Lead time is the period from placing an order to its delivery. Understanding lead times helps buyers plan their production schedules and avoid delays. For international buyers, lead times can vary significantly depending on shipping methods and customs clearance. -

Sustainability Certifications

Many suppliers now offer papers that meet sustainability certifications, such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification). Knowing about these certifications can help buyers make eco-friendly choices, which is increasingly important in global markets.

By grasping these technical properties and trade terms, international B2B buyers can engage more effectively with printing paper suppliers, ensuring they make well-informed decisions that align with their business needs and objectives.

Navigating Market Dynamics and Sourcing Trends in the printing paper supplier Sector

What are the Current Market Dynamics and Key Trends in the Printing Paper Supplier Sector?

The printing paper supplier sector is experiencing significant transformation driven by global market dynamics and technological advancements. One of the primary drivers is the growing demand for customized printing solutions across various industries, including advertising, publishing, and packaging. As businesses increasingly seek to enhance their branding efforts, there is a surge in demand for specialty papers that cater to specific needs, such as eco-friendly options or high-quality finishes.

Emerging technologies, such as digital printing and automation, are reshaping sourcing trends in this sector. Digital printing allows for shorter runs and quicker turnaround times, appealing to businesses that require flexibility and speed. Moreover, automation in production processes not only enhances efficiency but also reduces operational costs, making it a crucial consideration for international B2B buyers. In regions like Africa and South America, where local sourcing can be challenging, leveraging technology can facilitate smoother procurement processes and foster better supplier relationships.

Another important trend is the increasing globalization of supply chains. B2B buyers are now looking beyond their local markets to secure better pricing and quality. This trend is particularly evident in regions such as Turkey and Kenya, where buyers are sourcing printing paper from international suppliers to meet local demand. However, navigating these global supply chains requires a thorough understanding of international trade regulations, tariffs, and logistics, which can pose challenges for buyers unfamiliar with the complexities of global sourcing.

How is Sustainability Influencing Sourcing Decisions in the Printing Paper Sector?

Sustainability has become a critical consideration for B2B buyers in the printing paper supplier sector. With growing awareness of environmental issues, businesses are increasingly prioritizing ethical sourcing practices and sustainable materials. The impact of paper production on deforestation and waste has led many companies to seek suppliers who can provide certifications such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification). These certifications ensure that the paper products originate from responsibly managed forests.

Moreover, the demand for recycled paper has surged as businesses aim to reduce their carbon footprints. Buyers are encouraged to inquire about suppliers’ recycling processes and the percentage of recycled content in their products. This not only supports environmental sustainability but also aligns with corporate social responsibility goals, which are becoming essential for brand reputation, especially in markets like Europe and North America.

The shift towards sustainable materials also opens up new market opportunities for suppliers. As buyers increasingly seek green alternatives, suppliers who invest in eco-friendly production methods and materials can differentiate themselves in a competitive market. This trend is particularly relevant for B2B buyers in emerging markets, where sustainable practices can lead to long-term cost savings and improved brand loyalty.

What is the Historical Context Behind the Printing Paper Supplier Sector?

The printing paper supplier sector has evolved significantly over the past few decades. Initially dominated by traditional printing methods, the sector saw a major shift with the advent of digital technologies in the late 20th century. This transition not only changed the production processes but also altered consumer expectations regarding customization and speed.

As businesses began to embrace digital solutions, the demand for high-quality, versatile printing papers surged. This evolution has led to the diversification of product offerings, with suppliers now providing a range of specialty papers tailored to specific needs. The historical context is crucial for B2B buyers to understand current market dynamics, as it highlights the ongoing trends toward innovation and sustainability that continue to shape the sector.

In conclusion, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must stay informed about these market dynamics and trends to make strategic sourcing decisions that align with their business goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of printing paper supplier

-

How do I choose the right printing paper supplier for my business needs?

Selecting the right printing paper supplier requires a thorough understanding of your specific needs, including paper type, quality, and volume. Research potential suppliers by reviewing their product catalogs, certifications, and customer testimonials. It’s also essential to assess their ability to meet your deadlines and customization requests. Engage in direct communication with suppliers to discuss your requirements and request samples to evaluate the quality of their offerings before making a commitment. -

What are the key factors to consider when vetting a printing paper supplier?

When vetting a printing paper supplier, consider their reputation, production capacity, and reliability in fulfilling orders. Check for industry certifications that ensure quality standards, such as ISO certifications. Additionally, inquire about their sourcing practices, sustainability initiatives, and whether they provide transparent pricing models. Establishing a good rapport and clear communication channels with suppliers can also indicate their willingness to build a long-term partnership. -

What is the minimum order quantity (MOQ) for printing paper, and how does it vary by supplier?

The minimum order quantity (MOQ) for printing paper can vary significantly among suppliers, typically ranging from a few hundred to several thousand units. Factors influencing MOQ include the type of paper, customization options, and supplier policies. For international buyers, it’s advisable to discuss MOQ upfront and negotiate terms that align with your business needs. Some suppliers may offer flexibility for smaller orders, especially for new customers or trial runs. -

What payment terms should I expect when sourcing printing paper internationally?

Payment terms when sourcing printing paper internationally can vary by supplier and region. Common options include upfront payment, net 30 or 60 days, or payment upon delivery. It’s important to clarify these terms before placing an order to avoid misunderstandings. Consider using secure payment methods, such as letters of credit or escrow services, to protect your financial interests during international transactions. -

How can I ensure the quality of printing paper from international suppliers?

To ensure the quality of printing paper from international suppliers, request samples before finalizing any orders. Conduct quality assurance checks upon receipt of the products and establish clear specifications in your purchase agreements. Additionally, consider implementing a quality control process that includes regular audits of supplier practices. Building a strong relationship with your supplier can also facilitate open communication about quality expectations. -

What logistics considerations should I be aware of when importing printing paper?

Importing printing paper involves various logistics considerations, including shipping methods, customs regulations, and delivery timelines. Understand the shipping costs and choose a reliable freight forwarder familiar with importing paper products. Ensure that all necessary documentation, such as invoices and certificates of origin, are prepared to facilitate smooth customs clearance. Additionally, account for potential delays in shipping and plan your inventory accordingly. -

Are there customization options available for printing paper, and how do I request them?

Many printing paper suppliers offer customization options, such as specific sizes, weights, colors, and finishes. To request customization, clearly outline your requirements in your initial inquiry to the supplier. Provide detailed specifications, including intended usage, design elements, and any specific branding needs. Be prepared to discuss potential costs and lead times associated with customized orders. -

How do international trade regulations impact sourcing printing paper?

International trade regulations can significantly impact the sourcing of printing paper, affecting tariffs, duties, and import restrictions. Familiarize yourself with the regulations in both your country and the supplier’s country to ensure compliance. Utilize resources such as trade associations and government export/import agencies to stay informed about any changes in regulations. Understanding these factors will help you avoid unexpected costs and delays during the procurement process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for printing paper supplier

What Are the Key Takeaways for B2B Buyers in Printing Paper Sourcing?

In conclusion, strategic sourcing for printing paper suppliers is vital for international B2B buyers seeking to optimize their procurement processes. Buyers from Africa, South America, the Middle East, and Europe must prioritize suppliers that offer sustainable practices, competitive pricing, and reliable delivery. Establishing long-term relationships with suppliers can result in better negotiation terms and enhanced product quality.

Additionally, leveraging technology in sourcing can streamline operations and provide access to a broader range of suppliers. Buyers should consider incorporating a mix of local and international suppliers to mitigate risks associated with supply chain disruptions.

How Can B2B Buyers Prepare for the Future of Printing Paper Sourcing?

Looking ahead, the printing paper market is poised for innovation, driven by advancements in digital printing technologies and growing environmental consciousness. B2B buyers are encouraged to stay informed about market trends and emerging suppliers that align with their sustainability goals.

As you navigate your sourcing strategy, embrace flexibility and adaptability. This proactive approach will empower you to capitalize on opportunities and ensure a consistent supply of quality printing paper products. Engage with suppliers who share your vision for a sustainable future and drive your business forward in an increasingly competitive landscape.