Discover Top Pump Manufacturers in India: A Complete Guide (2025)

Introduction: Navigating the Global Market for Pump Manufacturers in India

In the competitive landscape of global sourcing, international B2B buyers face the critical challenge of identifying reliable pump manufacturers in India. The Indian pump manufacturing industry is recognized for its diverse offerings, catering to various applications from agriculture and construction to industrial processes and water treatment. This guide serves as a comprehensive resource, enabling buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like South Africa and Italy—to navigate the complexities of sourcing pumps effectively.

Within this guide, you will explore a wide range of topics, including the types of pumps available, their specific applications, supplier vetting processes, and cost considerations. Each section is designed to equip you with the necessary insights to make informed purchasing decisions, ensuring that you select the most suitable products for your operational needs. Additionally, we address common concerns such as quality assurance, compliance with international standards, and logistical considerations, which are vital for seamless procurement.

By leveraging the insights and strategies provided in this guide, you can streamline your sourcing process and build successful partnerships with Indian pump manufacturers. This resource empowers you to mitigate risks, enhance supply chain efficiency, and ultimately achieve your business objectives in a dynamic global market.

Understanding Pump Manufacturers in India Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Centrifugal Pumps | Utilizes rotational energy; high flow rates | Water supply, irrigation, chemical processing | Pros: Efficient for high volume; Cons: Not suitable for viscous fluids. |

| Positive Displacement Pumps | Delivers a fixed volume per cycle; suitable for viscous fluids | Oil & gas, food processing, pharmaceuticals | Pros: Consistent flow; Cons: Higher maintenance. |

| Submersible Pumps | Designed to operate underwater; space-saving design | Sewage and wastewater management | Pros: Effective for deep well applications; Cons: Requires specialized installation. |

| Diaphragm Pumps | Uses a diaphragm to create pressure; ideal for corrosive liquids | Chemical transfer, paint, and ink industries | Pros: Handles abrasive and corrosive materials; Cons: Limited flow rates. |

| Magnetic Drive Pumps | No mechanical seals; uses magnets for operation | Chemical processing, water treatment | Pros: Reduced risk of leaks; Cons: Higher initial cost. |

What are Centrifugal Pumps and Their B2B Applications?

Centrifugal pumps are the most common type of pumps used in various industries due to their ability to move large volumes of fluid efficiently. They operate by converting rotational energy, usually from an electric motor, into kinetic energy, which propels the fluid. These pumps are ideal for applications such as water supply, irrigation, and chemical processing. When considering a centrifugal pump, B2B buyers should evaluate the fluid characteristics, required flow rates, and the system’s pressure needs, as these factors influence performance and efficiency.

Why Choose Positive Displacement Pumps for Your Business?

Positive displacement pumps are unique in that they deliver a consistent volume of fluid with each cycle. This makes them particularly suitable for applications involving viscous fluids, such as oils and slurries. Industries like oil and gas, food processing, and pharmaceuticals often rely on these pumps for their reliability. Buyers should consider the specific viscosity of the fluid being pumped, as well as the pump’s maintenance requirements, which can be higher compared to other types.

How Do Submersible Pumps Function in Industrial Settings?

Submersible pumps are designed to operate submerged in fluid, making them ideal for applications like sewage and wastewater management. Their compact design allows for easy installation in confined spaces, such as deep wells or tanks. When selecting a submersible pump, B2B buyers must assess the depth of the installation site and the type of fluid being pumped, as these factors can significantly affect performance and longevity.

What Makes Diaphragm Pumps Suitable for Corrosive Liquids?

Diaphragm pumps utilize a flexible diaphragm to create pressure and move fluids, making them particularly effective for handling corrosive or abrasive materials. This feature makes them popular in chemical transfer, as well as in industries like paint and ink manufacturing. Buyers should evaluate the chemical compatibility of the materials used in the pump with the fluids to be handled, as well as the expected flow rates, to ensure optimal performance.

Are Magnetic Drive Pumps a Good Investment for Chemical Processing?

Magnetic drive pumps are notable for their leak-free operation, as they use magnets to transfer energy without mechanical seals. This makes them particularly suited for chemical processing and water treatment applications, where leakage could pose safety risks. When purchasing magnetic drive pumps, B2B buyers should consider the initial investment cost, as these pumps tend to be more expensive upfront, but they can result in lower operational costs over time due to reduced maintenance needs.

Related Video: Best Submersible Pump Manufacturers in India, Water Pumps & Motors Manufacturer #mascopumps

Key Industrial Applications of Pump Manufacturers in India

| Industry/Sector | Specific Application of Pump Manufacturers in India | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water and Wastewater | Sewage and Effluent Treatment Plants (ETPs) | Efficient removal of contaminants, compliance with regulations | Quality certifications, energy efficiency, maintenance support |

| Agriculture | Irrigation Systems | Enhanced crop yield, water conservation | Durability in harsh conditions, adaptability to local climates |

| Oil and Gas | Crude Oil and Natural Gas Extraction | Maximized resource recovery, reduced operational downtime | High-pressure tolerance, corrosion resistance, safety standards |

| Food and Beverage | Processing and Packaging of Liquid Foods | Improved hygiene, consistent flow rates | Food-grade materials, compliance with health regulations |

| Chemical Processing | Transfer of Chemicals and Petrochemicals | Safe handling of hazardous materials, increased productivity | Material compatibility, custom solutions, safety certifications |

How Are Pumps Used in Water and Wastewater Management?

In the water and wastewater sector, pump manufacturers in India supply critical systems for sewage and effluent treatment plants (ETPs). These pumps facilitate the efficient removal of contaminants, ensuring compliance with stringent environmental regulations. International buyers, particularly from regions like Africa and the Middle East, must consider the durability and energy efficiency of these pumps, as well as the manufacturer’s ability to provide ongoing maintenance support.

What Role Do Pumps Play in Agricultural Irrigation Systems?

Pump manufacturers in India are instrumental in developing advanced irrigation systems that enhance agricultural productivity. These pumps ensure consistent water supply, which is vital for maximizing crop yield and promoting water conservation practices. Buyers from South America and Europe should seek pumps that demonstrate durability in harsh conditions and adaptability to diverse local climates, ensuring long-term operational success.

How Are Pumps Essential in Oil and Gas Extraction?

In the oil and gas industry, pumps designed for crude oil and natural gas extraction are essential for maximizing resource recovery while minimizing operational downtime. Indian manufacturers provide specialized pumps that can withstand high pressures and corrosive environments. International B2B buyers must prioritize sourcing pumps that meet stringent safety standards, as well as those that can be customized for specific operational needs.

Why Are Pumps Important in the Food and Beverage Industry?

Pumps play a crucial role in the processing and packaging of liquid foods within the food and beverage sector. Indian pump manufacturers offer solutions that ensure improved hygiene and consistent flow rates during production. Buyers, especially from Europe, should consider pumps made from food-grade materials that comply with health regulations to ensure product safety and quality.

What Are the Applications of Pumps in Chemical Processing?

In chemical processing, pumps are vital for the safe transfer of chemicals and petrochemicals. Indian manufacturers provide pumps that handle hazardous materials, ensuring increased productivity while maintaining safety standards. B2B buyers should focus on sourcing pumps that are compatible with various materials and can be tailored to specific applications, ensuring reliability and efficiency in their operations.

Related Video: Diaphragm Type Metering PUMP Operation- HIGH FLOW EQUIPMENTS

3 Common User Pain Points for ‘Pump Manufacturers in India’ & Their Solutions

Scenario 1: Inconsistent Quality of Pump Products from Indian Manufacturers

The Problem: B2B buyers often encounter significant inconsistencies in the quality of pumps sourced from Indian manufacturers. This issue can stem from variations in manufacturing processes, quality control measures, and material sourcing. For buyers in regions like Africa or South America, where reliability is critical for industrial applications, receiving subpar products can lead to operational delays, increased maintenance costs, and even project failures.

The Solution: To mitigate quality inconsistencies, B2B buyers should implement a robust vendor evaluation process before finalizing partnerships with pump manufacturers in India. This process can include site visits to manufacturing facilities to assess production capabilities and quality assurance protocols. Additionally, buyers can request certifications and references from previous clients to verify the manufacturer’s reliability. Establishing clear quality expectations through detailed specifications in contracts can also help ensure that products meet the required standards. Regular audits and open lines of communication can facilitate ongoing quality assurance throughout the partnership.

Scenario 2: Lack of Customization Options for Specific Applications

The Problem: Many international buyers face challenges when sourcing pumps that meet specific application requirements, such as varying fluid types, pressures, and temperatures. Indian manufacturers often have standard product lines, which may not adequately cater to unique operational needs. This lack of customization can lead to inefficiencies and increased operational costs for businesses, particularly in sectors like mining or agriculture.

The Solution: To address the need for customized solutions, buyers should engage manufacturers early in the design process. Providing comprehensive specifications and application details can help manufacturers understand unique requirements. Buyers can also explore manufacturers that specialize in custom-engineered solutions, as they are more likely to offer tailored products. Leveraging technology, such as 3D modeling and simulation, can enhance collaboration between buyers and manufacturers, ensuring that the final product aligns closely with operational needs. Participating in industry trade shows and networking events can also help buyers discover manufacturers that offer the flexibility required for customized solutions.

Scenario 3: Complicated Import and Regulatory Compliance Processes

The Problem: B2B buyers often struggle with the complexities of importing pumps from India, including navigating various regulatory compliance requirements, tariffs, and shipping logistics. This can be particularly challenging for buyers in the Middle East and Europe, where stringent regulations govern the importation of industrial equipment. Missteps in compliance can lead to delays, additional costs, and even penalties.

The Solution: To streamline the import process, buyers should conduct thorough research on the regulatory landscape of their respective countries regarding imported pumps. Collaborating with local import/export experts or logistics companies can provide valuable insights into compliance requirements and help navigate tariffs. Establishing relationships with Indian manufacturers who have experience exporting to specific regions can also ease the process, as they are often familiar with the necessary documentation and compliance protocols. Utilizing technology platforms for tracking shipments and documentation can enhance transparency and efficiency in the supply chain, ultimately reducing the risk of delays and compliance issues.

Strategic Material Selection Guide for Pump Manufacturers in India

What Are the Key Properties of Common Materials Used in Pump Manufacturing?

In the pump manufacturing industry, the selection of materials is critical to ensuring product performance and longevity. Here, we analyze four common materials used by pump manufacturers in India, focusing on their key properties, advantages, disadvantages, and implications for international buyers.

1. Cast Iron

Key Properties: Cast iron is known for its excellent strength and durability, with a temperature rating typically up to 300°C and pressure ratings around 20 bar. It exhibits good wear resistance and has a natural ability to dampen vibrations.

Pros & Cons: The primary advantage of cast iron is its cost-effectiveness and durability, making it suitable for a variety of applications, especially in water and wastewater management. However, it is prone to corrosion, which can limit its use in aggressive environments. Manufacturing complexity is moderate, as it requires specific casting techniques.

Impact on Application: Cast iron is ideal for handling water and non-corrosive fluids. However, it is not suitable for applications involving aggressive chemicals or high-temperature fluids.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM A48 for cast iron. The availability of cast iron pumps in local markets can also influence procurement decisions.

2. Stainless Steel

Key Properties: Stainless steel offers excellent corrosion resistance, with temperature ratings often exceeding 500°C and pressure ratings up to 40 bar. Its composition includes chromium, which provides a protective layer against rust.

Pros & Cons: The key advantage of stainless steel is its versatility and ability to withstand harsh environments, making it suitable for food processing and chemical industries. However, it is more expensive than cast iron, and the manufacturing process can be complex due to its hardness.

Impact on Application: Stainless steel pumps are compatible with a wide range of media, including corrosive liquids and slurries. They are especially favored in applications where hygiene is paramount.

Considerations for International Buyers: Buyers from Europe, particularly Italy, should consider compliance with EN standards for stainless steel. The higher cost may be justified in applications requiring stringent hygiene and corrosion resistance.

3. Bronze

Key Properties: Bronze is known for its excellent corrosion resistance and high strength-to-weight ratio. It can typically handle temperatures up to 400°C and pressures around 30 bar.

Pros & Cons: The primary advantage of bronze is its resistance to seawater and other corrosive environments, making it ideal for marine applications. However, it can be more expensive than cast iron and is less common in standard pump applications.

Impact on Application: Bronze is particularly effective in applications involving saltwater or other corrosive fluids, making it suitable for marine and chemical processing industries.

Considerations for International Buyers: Buyers from the Middle East should be aware of the specific grades of bronze that meet ASTM B150 standards. The higher cost may be a barrier for some applications, but the longevity and performance can offset this.

4. Plastic (Polypropylene and PVC)

Key Properties: Plastic materials like polypropylene and PVC are lightweight and resistant to corrosion. They can handle temperatures up to 80°C and pressures around 10 bar.

Pros & Cons: The main advantage of plastic pumps is their cost-effectiveness and chemical resistance, making them suitable for a variety of applications. However, they are not as durable as metals and can be susceptible to UV degradation.

Impact on Application: Plastic pumps are ideal for handling corrosive chemicals and are commonly used in agricultural and chemical processing applications.

Considerations for International Buyers: Buyers from regions with high humidity or UV exposure, such as parts of Africa, should consider the long-term durability of plastic pumps. Compliance with local chemical handling standards is also essential.

Summary Table of Material Selection for Pump Manufacturers

| Material | Typical Use Case for Pump Manufacturers in India | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Water and wastewater management | Cost-effective and durable | Prone to corrosion | Low |

| Stainless Steel | Food processing and chemical industries | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Bronze | Marine and chemical processing applications | Corrosion resistant in seawater | More expensive and less common | Med |

| Plastic (PP/PVC) | Agricultural and chemical processing applications | Lightweight and cost-effective | Less durable and UV sensitive | Low |

This strategic material selection guide provides international B2B buyers with actionable insights into the materials used in pump manufacturing in India, helping to inform purchasing decisions based on specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for Pump Manufacturers in India

What Are the Main Stages in the Manufacturing Processes of Pump Manufacturers in India?

The manufacturing process for pumps in India typically involves several critical stages, each designed to ensure the final product meets stringent quality and performance standards. Understanding these stages can help international B2B buyers make informed decisions when sourcing pumps.

Material Preparation: How Do Pump Manufacturers Source and Prepare Materials?

The first stage in the manufacturing process is material preparation. Pump manufacturers primarily use metals like stainless steel, cast iron, and bronze for their products. The selection of material is crucial as it impacts the pump’s durability, efficiency, and resistance to corrosion.

Manufacturers often source raw materials from reputable suppliers who adhere to international quality standards. Once received, materials undergo inspection to verify their quality and compliance with specifications. Common preparation techniques include cutting, machining, and surface treatment, which are necessary to achieve the desired dimensions and surface finish.

What Key Techniques Are Used in Pump Manufacturing?

Forming: What Techniques Are Used to Shape Pump Components?

The forming stage is where raw materials are shaped into specific components through various techniques, including casting, forging, and machining.

-

Casting: This is a widely used technique where molten metal is poured into molds to create pump casings and impellers. It allows for complex shapes and is cost-effective for large-scale production.

-

Forging: This method involves shaping metal using compressive forces and is often used for components that require high strength, such as shafts and fittings.

-

Machining: After forming, components are precisely machined to meet tolerances and surface finish requirements. This is critical for ensuring proper fit and function during assembly.

How Is Assembly Conducted in Pump Manufacturing?

The assembly stage involves the integration of various components into a complete pump unit. Skilled technicians carry out this process, which often includes:

- Component Inspection: Before assembly, each component is inspected for defects to ensure quality.

- Sub-Assembly: Some components are pre-assembled into sub-units (like the motor assembly) before being integrated into the final product.

- Final Assembly: The complete pump is assembled, ensuring all components fit correctly and function as intended.

What Finishing Techniques Are Applied to Pump Products?

Finishing techniques are crucial for enhancing the aesthetic appeal and functional longevity of the pumps. Common processes include:

- Surface Treatment: Techniques like galvanizing, anodizing, or powder coating are used to protect against corrosion and wear.

- Quality Testing: After finishing, pumps undergo rigorous testing to ensure they meet performance specifications.

What Are the Quality Assurance Standards for Pump Manufacturers in India?

Which International Standards Are Relevant for Pump Manufacturers?

Quality assurance is paramount in the pump manufacturing process. Many Indian manufacturers adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. This certification ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

In addition to ISO 9001, industry-specific certifications may include:

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with safety and environmental standards.

- API Standards: The American Petroleum Institute standards apply to pumps used in the oil and gas industry, ensuring reliability and performance.

What Quality Control Checkpoints Are Implemented During Manufacturing?

Pump manufacturers typically establish several quality control (QC) checkpoints throughout the production process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor processes and detect defects early.

- Final Quality Control (FQC): After assembly, pumps undergo comprehensive testing, including pressure testing and performance evaluations, to ensure they function correctly.

What Common Testing Methods Are Utilized to Ensure Pump Quality?

To maintain high-quality standards, various testing methods are employed, including:

- Hydraulic Testing: Pumps are tested under pressure to verify their performance and leak integrity.

- Vibration Analysis: This technique assesses the operational stability of pumps, identifying potential issues that could lead to failure.

- Performance Testing: Pumps are evaluated for flow rates, efficiency, and power consumption to ensure they meet design specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure product reliability. Here are several approaches:

-

Supplier Audits: Conducting onsite audits allows buyers to evaluate the manufacturing processes and quality assurance systems firsthand. This can reveal adherence to international standards and best practices.

-

Requesting Quality Reports: Buyers can request documentation related to quality control, including test results and certification records, to assess the manufacturer’s compliance with standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control processes, ensuring transparency and reliability.

What Nuances Should International Buyers Consider Regarding Quality Control?

When sourcing pumps from India, international buyers should be aware of several nuances:

- Cultural Differences: Understanding the local business culture can help in negotiating terms and ensuring clear communication regarding quality expectations.

- Regulatory Compliance: Buyers must ensure that products comply with the regulations in their own countries, which may differ from Indian standards.

- Lead Times and Logistics: Quality assurance processes may extend lead times. Buyers should factor this into their procurement planning.

By understanding the manufacturing processes and quality assurance practices of pump manufacturers in India, international B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Pump Manufacturers in India’

In this practical sourcing guide, international B2B buyers looking to procure pumps from Indian manufacturers will find a step-by-step checklist designed to streamline the procurement process. This guide focuses on ensuring that buyers make informed decisions while navigating the complexities of sourcing in a diverse market like India.

Step 1: Define Your Technical Specifications

Before initiating contact with manufacturers, it’s essential to clearly outline your technical requirements. This includes the type of pump (centrifugal, positive displacement, etc.), capacity, pressure ratings, and materials needed. Having well-defined specifications helps prevent misunderstandings and ensures that suppliers can meet your specific needs.

- Consider operational conditions: Take into account factors such as temperature, fluid type, and viscosity.

- Document your requirements: Create a detailed specification sheet to share with potential suppliers.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify reputable pump manufacturers in India. Utilize online resources, industry directories, and trade shows to compile a list of potential suppliers.

- Check for industry experience: Look for manufacturers with a proven track record in producing the type of pump you require.

- Read reviews and testimonials: Seek feedback from other international buyers to gauge reliability and service quality.

Step 3: Evaluate Supplier Certifications and Compliance

Ensure that shortlisted suppliers hold relevant certifications, such as ISO 9001 for quality management systems. Compliance with international standards indicates a commitment to quality and safety.

- Request documentation: Ask for copies of certifications and any other compliance-related documents.

- Assess environmental and safety standards: Verify if the manufacturer adheres to environmental regulations relevant to your industry.

Step 4: Request Quotes and Compare Pricing

Once you have a shortlist of potential suppliers, request detailed quotes. Ensure that the quotes include all costs, including shipping, taxes, and duties, to avoid unexpected expenses.

- Analyze the breakdown of costs: Understand what each element of the quote entails.

- Compare not just on price: Factor in quality, delivery time, and after-sales support when evaluating offers.

Step 5: Conduct Factory Visits or Virtual Tours

If feasible, arrange to visit the manufacturing facilities or request a virtual tour. This step allows you to inspect the production processes, quality control measures, and overall operational capabilities of the supplier.

- Evaluate production capacity: Ensure the supplier can meet your volume requirements.

- Observe quality control procedures: Look for standards in place to maintain product quality.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations regarding payment terms, delivery schedules, and warranties. Clear agreements on these aspects can mitigate risks and foster a positive supplier relationship.

- Discuss payment methods: Consider options such as letters of credit or escrow services for added security.

- Set clear timelines: Ensure that both parties agree on delivery timelines and penalties for delays.

Step 7: Establish a Communication Plan

Effective communication is crucial throughout the procurement process. Establish regular check-ins and updates with your chosen supplier to ensure alignment on expectations and timelines.

- Designate points of contact: Identify key contacts on both sides for smooth communication.

- Utilize technology: Leverage tools like email, video calls, or project management software to facilitate ongoing dialogue.

By following this comprehensive sourcing checklist, international B2B buyers can enhance their procurement strategies and build fruitful partnerships with pump manufacturers in India.

Comprehensive Cost and Pricing Analysis for Pump Manufacturers in India Sourcing

What Are the Key Cost Components for Pump Manufacturers in India?

Understanding the cost structure of pump manufacturing in India is crucial for international B2B buyers. The primary cost components include:

-

Materials: This is the largest cost driver, often accounting for 40-60% of the total production cost. Common materials used in pump manufacturing include cast iron, stainless steel, and various polymers, which can fluctuate in price based on global market conditions.

-

Labor: Labor costs in India are generally lower than in many Western countries, but they can vary significantly by region and skill level. Skilled labor for assembly and quality control may demand higher wages.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and administrative expenses. Typically, overhead can contribute 10-20% to the total cost, depending on the efficiency of the manufacturing process.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs. These costs are amortized over the production volume, making them a critical factor in pricing for low-volume orders.

-

Quality Control (QC): Ensuring product quality is paramount, especially for international buyers. QC costs can range from 5-10% of total manufacturing costs, depending on the required certification standards (e.g., ISO, CE).

-

Logistics: Transportation and warehousing can add significant costs, especially for international shipments. These costs are influenced by the chosen Incoterms and shipping routes.

-

Margin: Manufacturers typically mark up prices to ensure profitability, which can vary based on competition and market demand.

How Do Price Influencers Impact Pump Manufacturing Costs?

Several factors influence the pricing of pumps manufactured in India, including:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their purchasing strategy to optimize costs.

-

Specifications and Customization: Customized pumps may incur higher costs due to specialized materials and additional labor. Buyers should clearly define specifications to avoid unexpected expenses.

-

Material Quality and Certifications: Pumps that require higher quality materials or specific certifications (e.g., API, ASME) will generally have higher costs. Understanding the required certifications for the intended market is essential for price negotiations.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established manufacturers with a proven track record may charge a premium, but they often provide better quality and service.

-

Incoterms: The chosen Incoterms can significantly impact total costs. For instance, FOB (Free on Board) may result in lower upfront costs but higher logistics responsibilities for the buyer.

What Are the Best Negotiation Tips for International B2B Buyers?

To achieve cost efficiencies when sourcing pumps from India, consider the following strategies:

-

Understand Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational costs, and logistics to understand the true cost of the product over its lifecycle.

-

Leverage Volume Discounts: If possible, consolidate orders to increase volumes, which can lead to better pricing and terms.

-

Be Transparent About Expectations: Clearly communicate your needs and expectations regarding quality, delivery timelines, and after-sales support to avoid misalignment and additional costs.

-

Research Market Trends: Stay informed about market trends in materials and manufacturing to negotiate from an informed position.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing, priority service, and potential discounts on future orders.

Disclaimer

The prices discussed in this analysis are indicative and can vary based on specific project requirements, market conditions, and supplier negotiations. International buyers should conduct thorough research and seek multiple quotations to ensure competitive pricing.

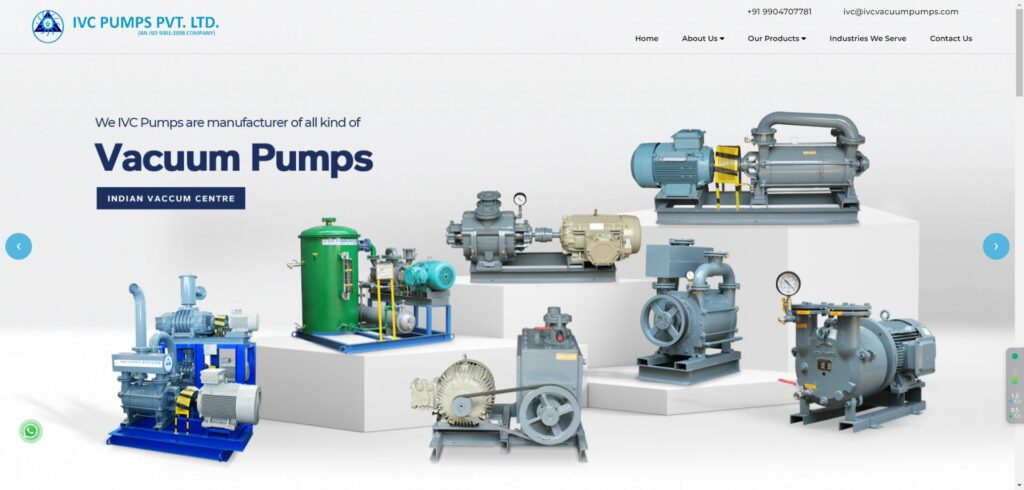

A stock image related to Pump Manufacturers in India.

Alternatives Analysis: Comparing Pump Manufacturers in India With Other Solutions

When evaluating options for sourcing pumps, international B2B buyers must consider various alternatives to Indian pump manufacturers. This section outlines viable alternatives that can meet specific operational needs, comparing them on key aspects to help buyers make informed decisions.

Comparison of Pump Solutions

| Comparison Aspect | Pump Manufacturers in India | Submersible Pumps | Centrifugal Pumps |

|---|---|---|---|

| Performance | High efficiency, suitable for diverse applications. | Effective in deep water applications. | Excellent for high flow rates and low viscosity fluids. |

| Cost | Competitive pricing, often lower than Western alternatives. | Higher upfront costs due to specialized design. | Moderate costs, widely available. |

| Ease of Implementation | Generally straightforward installation. | Requires expertise for installation in specific conditions. | Easy to install with standard fittings. |

| Maintenance | Moderate maintenance needs; local service support available. | Requires regular checks to prevent clogging. | Low maintenance; robust and durable. |

| Best Use Case | Agricultural, industrial, and municipal applications. | Ideal for drainage and sewage systems. | Suitable for water supply and chemical processing. |

What Are the Pros and Cons of Submersible Pumps?

Submersible pumps are designed to operate underwater, making them ideal for applications where water needs to be lifted from deep sources, such as wells or flooded areas.

Pros:

– High Efficiency: They can pump water at greater depths without losing efficiency.

– Space-Saving Design: Their compact design allows for installation in tight spaces.

Cons:

– Costly Installation: The need for specialized installation can drive up initial costs.

– Maintenance Challenges: They require periodic maintenance to avoid clogging and ensure longevity.

How Do Centrifugal Pumps Compare?

Centrifugal pumps are a popular choice for many industrial applications due to their design, which utilizes rotational energy to move fluids.

Pros:

– Versatility: They can handle a variety of fluids and flow rates, making them suitable for numerous applications.

– Low Maintenance: Their simple mechanical design requires less frequent servicing.

Cons:

– Performance Limitations: They may not perform well in high-viscosity fluids or at very low flow rates.

– Installation Requirements: Although they are generally easy to install, specific configurations may require additional considerations.

How to Choose the Right Pump Solution for Your Needs?

Selecting the right pump solution depends on several factors, including your specific application requirements, budget constraints, and maintenance capabilities. For buyers from Africa, South America, the Middle East, and Europe, understanding local conditions and sourcing options is crucial.

- Evaluate Performance Needs: Determine the required flow rate and head pressure for your application.

- Consider Total Cost of Ownership: Look beyond initial costs; consider maintenance, energy efficiency, and service availability.

- Assess Local Support: Ensure that the chosen solution has local support for installation and maintenance.

By thoroughly analyzing these alternatives, B2B buyers can make strategic decisions that align with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for Pump Manufacturers in India

What Are the Key Technical Properties for Pump Manufacturers in India?

When dealing with pump manufacturers in India, understanding specific technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that international B2B buyers should consider:

1. Material Grade

The material grade of a pump significantly impacts its durability and performance. Common materials include cast iron, stainless steel, and bronze. Each material has unique properties suited for different applications—stainless steel, for example, is ideal for corrosive environments. B2B buyers should assess the material grade based on the intended use to ensure longevity and reliability.

2. Tolerance

Tolerance refers to the allowable deviation from a specified dimension. It is critical in ensuring that pump components fit together correctly. Tight tolerances may be required in high-precision applications, while looser tolerances may suffice for general use. Understanding tolerance requirements helps buyers ensure compatibility and performance in their specific applications.

3. Flow Rate

Flow rate, typically measured in liters per minute (LPM) or gallons per minute (GPM), indicates the volume of fluid a pump can move within a certain time frame. This specification is vital for matching the pump to the operational requirements of the system. Buyers must consider the flow rate to ensure that the pump meets their production or process needs.

4. Power Consumption

Power consumption refers to the amount of energy a pump requires to operate. This metric is crucial for assessing operational costs and efficiency. B2B buyers should look for pumps that offer optimal power consumption without sacrificing performance to reduce long-term energy expenses.

5. Pressure Rating

The pressure rating indicates the maximum pressure a pump can handle safely. It is essential for applications where fluid dynamics play a critical role. Buyers must evaluate the pressure rating to ensure that the pump can withstand the demands of their specific system without risk of failure.

6. Efficiency Rating

Efficiency ratings provide insight into how effectively a pump converts electrical energy into hydraulic energy. Higher efficiency ratings not only reduce energy costs but also contribute to lower greenhouse gas emissions. B2B buyers should prioritize pumps with high-efficiency ratings to optimize operational performance and sustainability.

Which Trade Terminology Should B2B Buyers Understand?

Familiarity with trade terminology is essential for navigating the procurement process. Here are some common terms relevant to pump manufacturing:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, understanding OEM relationships can help ensure that they are sourcing high-quality components tailored for specific applications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is a critical factor for international buyers as it impacts inventory management and cost efficiency. Knowing the MOQ can help buyers plan their purchases effectively, especially in bulk ordering scenarios.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for a specific quantity of goods or services. B2B buyers should prepare a detailed RFQ to receive accurate quotes, ensuring they compare offerings effectively.

4. Incoterms

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping, risk, and cost responsibilities, which is essential for smooth cross-border transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. It is crucial for supply chain planning and inventory management. B2B buyers should consider lead times when making purchasing decisions to ensure timely project execution.

6. Certification

Certification indicates that a product meets specific industry standards and regulations. For pump manufacturers, certifications such as ISO, CE, or API can assure buyers of quality and compliance. Understanding certifications helps buyers select products that adhere to necessary safety and performance standards.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, ensuring they choose the right pumps for their applications while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the Pump Manufacturers in India Sector

What Are the Current Market Dynamics in the Pump Manufacturing Sector in India?

The pump manufacturing sector in India is experiencing significant growth driven by several global factors. Rapid industrialization, urbanization, and increasing demand for water management solutions are primary drivers behind this expansion. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for successful sourcing.

A notable trend is the integration of advanced technologies such as IoT and AI in pump systems, enhancing operational efficiency and predictive maintenance. This technological shift allows manufacturers to offer smarter, more reliable products that meet the evolving needs of industries ranging from agriculture to construction. Buyers are encouraged to seek manufacturers who invest in R&D to remain competitive and provide innovative solutions.

Additionally, the rise of e-commerce and digital platforms is transforming how international buyers interact with Indian pump manufacturers. These platforms facilitate smoother transactions, transparent pricing, and improved communication, enabling buyers to make informed decisions. However, navigating these platforms requires a keen understanding of local market practices and regulations, which can vary significantly across regions.

How Is Sustainability Impacting the Pump Manufacturing Industry in India?

Sustainability is becoming a cornerstone of B2B sourcing strategies, particularly in the pump manufacturing sector. The environmental impact of traditional manufacturing practices has prompted both buyers and manufacturers to prioritize sustainable methods. For international buyers, especially those in Europe and the Middle East, the demand for ethically sourced and environmentally friendly products is increasingly important.

Manufacturers in India are responding to this demand by adopting sustainable practices, such as utilizing recyclable materials and reducing energy consumption during production. Certifications like ISO 14001 and adherence to environmental regulations are becoming essential benchmarks for buyers evaluating potential suppliers.

Furthermore, the development of ‘green’ pumps, which consume less energy and are made from eco-friendly materials, is gaining traction. Buyers looking for sustainable solutions should inquire about a manufacturer’s commitment to sustainability, including their use of certified materials and their overall environmental impact.

What Is the Historical Context Behind India’s Pump Manufacturing Sector?

The pump manufacturing industry in India has evolved significantly over the past few decades. Initially dominated by a few local players, the sector has expanded with the entry of numerous domestic and international manufacturers. This growth has been fueled by increased investment in infrastructure and industrial projects, particularly since the liberalization of the Indian economy in the 1990s.

Historically, Indian manufacturers focused on producing basic pumps primarily for agricultural purposes. However, the demand for advanced pumping solutions across various sectors has led to diversification in product offerings. Today, the industry encompasses a wide range of pumps, including submersible, centrifugal, and diaphragm pumps, catering to sectors such as water supply, irrigation, and industrial processes.

This historical context is vital for international B2B buyers, as it highlights the industry’s adaptability and potential for innovation. Understanding the evolution of the sector can provide insights into current capabilities and future trends, aiding in the selection of reliable partners in India’s pump manufacturing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of Pump Manufacturers in India

-

How can I find reliable pump manufacturers in India?

To find reliable pump manufacturers in India, start by researching industry directories and trade associations, such as the Indian Pump Manufacturers Association (IPMA). Utilize platforms like Alibaba, IndiaMART, and TradeIndia for a wide selection of suppliers. Look for manufacturers with a proven track record, positive reviews, and certifications such as ISO 9001. Additionally, consider attending trade fairs like the India Water Week or the Pumps & Valves Expo to meet manufacturers in person and assess their products firsthand. -

What should I consider when evaluating pump manufacturers in India?

When evaluating pump manufacturers, assess their product range, technological capabilities, and customization options. Check for certifications that demonstrate quality assurance, such as CE and ISO standards. Examine their production capacity to ensure they can meet your demands. Additionally, consider their after-sales support, warranty terms, and responsiveness to inquiries. Establishing communication with previous clients can also provide insights into their reliability and service quality. -

What are the common payment terms for international B2B transactions with Indian pump manufacturers?

Payment terms can vary widely among manufacturers, but common practices include advance payments, letters of credit, and payment upon delivery. Many suppliers may request a 30% advance payment with the balance due upon shipment. It’s advisable to negotiate terms that align with your cash flow needs while ensuring the manufacturer’s security. Always ensure that terms are documented clearly in the purchase agreement to avoid misunderstandings. -

What is the minimum order quantity (MOQ) for pumps from Indian manufacturers?

The minimum order quantity (MOQ) for pumps can vary significantly based on the manufacturer and the type of pump. Generally, MOQs can range from 50 to 500 units for standard models. Custom pumps may have higher MOQs due to the specific requirements for production. It’s essential to discuss your needs directly with the manufacturer to understand their policies and potentially negotiate lower MOQs for initial orders or trials. -

How do I ensure quality assurance when sourcing pumps from India?

To ensure quality assurance, verify that the manufacturer adheres to international quality standards such as ISO 9001. Request detailed product specifications and quality control processes. Consider visiting the manufacturing facility to observe their production methods. Additionally, you can request sample products for testing before placing a bulk order. Utilizing third-party inspection services can also help validate the quality before shipment. -

What are the logistics considerations when importing pumps from India?

When importing pumps from India, consider shipping methods, lead times, and customs regulations. Sea freight is typically more cost-effective for large orders, while air freight is faster but more expensive. Ensure that you are familiar with the import duties and tariffs applicable in your country. Collaborating with a reliable freight forwarder can streamline the logistics process and help manage documentation, customs clearance, and delivery timelines. -

How can I customize pumps to meet specific industry requirements?

Most Indian pump manufacturers offer customization options for their products. Discuss your specific needs, such as flow rate, materials, and dimensions, with potential suppliers. Provide detailed specifications and application requirements to ensure the manufacturer can accommodate your requests. It’s advisable to confirm the timeline for customization and any additional costs involved. Request prototypes or samples to validate the design before full-scale production. -

What are the key factors influencing the cost of pumps sourced from India?

The cost of pumps sourced from India is influenced by various factors, including the type of pump, materials used, manufacturing processes, and order quantity. Additionally, fluctuations in raw material prices and labor costs can impact pricing. Customization and advanced features will also increase costs. To optimize your budget, compare quotes from multiple manufacturers and consider negotiating terms that align with your financial constraints while ensuring quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Pump Manufacturers in India

A stock image related to Pump Manufacturers in India.

In conclusion, strategic sourcing in the Indian pump manufacturing sector presents a wealth of opportunities for international buyers, particularly those from Africa, South America, the Middle East, and Europe. By leveraging India’s diverse manufacturing capabilities and competitive pricing, businesses can secure high-quality pumps that meet their specific operational needs. Emphasizing long-term partnerships with reliable manufacturers can enhance supply chain resilience and foster innovation.

International buyers should prioritize thorough due diligence, considering factors such as product certifications, after-sales support, and manufacturer reputation. Engaging with local trade associations and industry events can further facilitate connections with reputable suppliers.

Looking ahead, the Indian pump manufacturing industry is poised for growth, driven by advancements in technology and increasing demand across various sectors, including agriculture, construction, and water management. As global markets continue to evolve, now is the time for B2B buyers to explore the strategic sourcing options available in India. By investing in these partnerships, companies can position themselves favorably within their respective markets and capitalize on the dynamic potential of this thriving industry.