Discover Top Rubber Roller Manufacturers: Your Complete Guide (2025)

Introduction: Navigating the Global Market for Rubber Roller Manufacturers

Navigating the global market for rubber roller manufacturers can be daunting for international B2B buyers, especially when trying to identify reliable suppliers and assess product quality. The demand for high-quality rubber rollers is on the rise across various industries, including printing, packaging, and manufacturing. This guide aims to simplify the sourcing process by providing a comprehensive overview of rubber roller types, their applications, and key considerations for supplier vetting.

In this resource, you will find actionable insights into the diverse types of rubber rollers available, from standard rollers to specialized products designed for unique applications. We will also delve into essential factors such as cost considerations, material specifications, and performance standards, ensuring you make informed purchasing decisions.

For B2B buyers from Africa, South America, the Middle East, and Europe—regions that are increasingly engaging in global trade—this guide serves as an indispensable tool. It empowers you with the knowledge needed to evaluate potential suppliers effectively, understand market dynamics, and ultimately optimize your procurement strategy. Whether you are looking to enhance production efficiency or ensure product quality, our guide is designed to support you every step of the way.

By the end of this guide, you will be equipped with the expertise to navigate the complexities of sourcing rubber rollers, making confident decisions that align with your business needs.

Understanding Rubber Roller Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Rubber Rollers | Made from a variety of rubber compounds; versatile and cost-effective | Printing, packaging, and textiles | Pros: Cost-effective, widely available. Cons: May not withstand extreme conditions. |

| Silicone Rubber Rollers | High-temperature resistance and excellent durability | Food processing and pharmaceuticals | Pros: Durable and non-stick. Cons: Higher cost compared to standard rollers. |

| Polyurethane Rollers | Enhanced abrasion resistance and flexibility | Wood processing and metal fabrication | Pros: Long lifespan and superior performance. Cons: Can be more expensive upfront. |

| Metal-Covered Rollers | Metal core with rubber coating for added strength | Heavy-duty applications like steel mills | Pros: High durability and strength. Cons: Heavier, may require specialized handling. |

| Specialty Rollers | Custom-designed for specific applications, including anti-static and conductive options | Electronics and specialty manufacturing | Pros: Tailored solutions for unique needs. Cons: Longer lead times and potentially higher costs. |

What Are Standard Rubber Rollers and Their Applications?

Standard rubber rollers are the most commonly used type in various industries due to their versatility and cost-effectiveness. Typically made from a blend of rubber compounds, these rollers can be found in applications such as printing, packaging, and textiles. Buyers should consider the specific hardness and elasticity required for their applications, as these factors can influence performance and longevity.

Why Choose Silicone Rubber Rollers for High-Temperature Applications?

Silicone rubber rollers are distinguished by their ability to withstand high temperatures and maintain durability over time. This makes them ideal for industries such as food processing and pharmaceuticals, where hygiene and temperature control are critical. When purchasing, buyers should evaluate the specific temperature range and food safety certifications to ensure compliance with industry standards.

How Do Polyurethane Rollers Offer Enhanced Performance?

Polyurethane rollers are known for their enhanced abrasion resistance and flexibility, making them suitable for applications in wood processing and metal fabrication. Their ability to handle heavy loads without deforming is a significant advantage. Buyers should weigh the initial higher cost against the long-term benefits of reduced maintenance and replacement needs.

What Are the Advantages of Metal-Covered Rollers?

Metal-covered rollers consist of a robust metal core coated with rubber, providing exceptional strength for heavy-duty applications like steel mills. These rollers are designed to endure extreme conditions, making them a reliable choice for industries that require durability. However, their weight may necessitate specialized handling equipment, a consideration for buyers.

How Can Specialty Rollers Meet Unique Business Needs?

Specialty rollers are custom-designed to meet specific operational requirements, including anti-static or conductive properties for electronics manufacturing. While these tailored solutions can significantly enhance operational efficiency, buyers should be aware of the potential for longer lead times and higher costs associated with custom orders. This makes it essential to clearly define requirements before proceeding with a purchase.

Related Video: Rubber Roller Manufacturing Process.

Key Industrial Applications of Rubber Roller Manufacturers

| Industry/Sector | Specific Application of Rubber Roller Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Printing and Packaging | Printing Press Rollers | Ensures consistent ink transfer and print quality | Durability, surface finish, and compatibility with inks |

| Textile Manufacturing | Textile Processing Rollers | Enhances fabric handling and reduces defects | Material properties, temperature resistance, and custom sizes |

| Food Processing | Food Processing Rollers | Maintains hygiene standards and prevents contamination | FDA compliance, easy cleaning, and chemical resistance |

| Agriculture | Agricultural Equipment Rollers | Improves efficiency in harvesting and processing | Load capacity, weather resistance, and durability |

| Automotive | Automotive Assembly Line Rollers | Streamlines production and reduces downtime | Precision engineering, material strength, and customization options |

How Are Rubber Rollers Used in the Printing and Packaging Sector?

In the printing and packaging industry, rubber rollers play a crucial role in printing presses where they facilitate the transfer of ink onto substrates. These rollers ensure even ink distribution, which is vital for achieving high-quality prints. For B2B buyers in regions like South Africa and Spain, sourcing durable and resilient rubber rollers that can withstand various inks and solvents is essential. Buyers must consider factors such as the roller’s surface finish and compatibility with specific printing technologies to enhance operational efficiency.

What Role Do Rubber Rollers Play in Textile Manufacturing?

Rubber rollers are integral to textile manufacturing, particularly in processes such as dyeing and finishing. They help in handling fabrics smoothly, minimizing the risk of damage and defects during processing. International buyers from South America and the Middle East should prioritize rubber rollers that exhibit excellent temperature resistance and durability to cope with the demanding conditions of textile production. Custom sizes and specific material properties are also critical for meeting the unique requirements of different textile applications.

How Are Rubber Rollers Utilized in Food Processing?

In the food processing sector, rubber rollers are used in conveyor systems and processing machines to transport food products safely. These rollers must adhere to strict hygiene standards to prevent contamination. B2B buyers need to ensure that the rubber used is FDA-compliant, easy to clean, and resistant to various food processing chemicals. This is particularly important for businesses in Europe where food safety regulations are stringent, and sourcing high-quality rollers can significantly impact product safety and quality.

Why Are Rubber Rollers Important in Agriculture?

In agriculture, rubber rollers are utilized in various equipment such as harvesters and seeders to improve operational efficiency. They help in the smooth operation of machinery, ensuring that crops are harvested and processed without damage. Buyers in Africa and South America should consider the load capacity and weather resistance of these rollers, as agricultural conditions can vary significantly. Durability is key, as agricultural equipment often operates under challenging conditions, necessitating robust and reliable components.

How Do Rubber Rollers Enhance Automotive Manufacturing Processes?

Rubber rollers are essential in automotive assembly lines, where they facilitate the movement of parts and materials throughout the production process. They help streamline operations and reduce downtime, which is critical in the highly competitive automotive industry. Buyers from Europe and the Middle East should look for precision-engineered rubber rollers that offer high material strength and customization options to fit specific assembly line requirements. This ensures that the production flow remains uninterrupted, enhancing overall productivity and efficiency.

Related Video: A day in The rubber compounding Industry.

3 Common User Pain Points for ‘Rubber Roller Manufacturers’ & Their Solutions

Scenario 1: Quality Inconsistency in Rubber Roller Products

The Problem: One of the major pain points for B2B buyers sourcing rubber rollers is the inconsistency in product quality. This issue often arises when manufacturers do not adhere to stringent quality control measures. For businesses relying on rubber rollers in critical processes, such as printing or packaging, subpar products can lead to machinery malfunctions, increased downtime, and ultimately, financial losses. Buyers may face frustration when they receive products that do not meet the required specifications, leading to delays and potential damage to client relationships.

The Solution: To mitigate this risk, buyers should prioritize manufacturers with a solid reputation for quality assurance. Before placing an order, conduct thorough research into potential suppliers. This includes checking for certifications such as ISO 9001, which indicates a commitment to quality management systems. Additionally, request samples or prototypes to evaluate the material properties and durability of the rubber rollers. Establishing a clear specification document that outlines material requirements, tolerances, and performance metrics can also help ensure that the final product meets expectations. Building a collaborative relationship with the manufacturer, including regular communication and feedback loops, can further enhance product quality and consistency.

Scenario 2: Long Lead Times for Rubber Roller Production

The Problem: Another challenge faced by B2B buyers is the long lead times associated with rubber roller manufacturing. Buyers often require quick turnaround times to meet their production schedules. However, if a manufacturer has a backlog of orders or inefficient production processes, this can lead to delays that disrupt the buyer’s operations. Such scenarios can be particularly detrimental for businesses operating in fast-paced industries where time-to-market is crucial.

The Solution: To address lead time issues, buyers should consider partnering with manufacturers that offer flexible production capabilities and clear timelines. During the sourcing process, inquire about the manufacturer’s production capacity and their typical lead times for various orders. Establishing a just-in-time inventory system can also help manage these challenges by reducing the need for large stockpiles and allowing for quicker replenishment. Additionally, using manufacturers with local or regional facilities can significantly reduce shipping times and costs. Building a strategic partnership with key suppliers can facilitate better communication and more reliable delivery schedules, ensuring that production needs are met without unnecessary delays.

Scenario 3: Difficulty in Customizing Rubber Roller Specifications

The Problem: Many B2B buyers face difficulties when attempting to customize rubber roller specifications to meet unique operational requirements. This challenge can stem from limited options offered by manufacturers or a lack of technical expertise to navigate the customization process. Buyers may find themselves constrained by standard products that do not effectively solve their specific challenges, leading to inefficiencies and increased operational costs.

The Solution: To successfully navigate customization, buyers should seek out manufacturers known for their flexibility and willingness to collaborate on custom projects. Engage in detailed discussions about your specific requirements, including dimensions, hardness, surface finish, and material composition. Providing the manufacturer with detailed application data and performance expectations can aid in developing tailored solutions. Additionally, consider leveraging manufacturers with advanced engineering capabilities that can offer insights and recommendations based on their experience with similar applications. Utilizing CAD drawings and prototypes can also facilitate the customization process, allowing for iterative feedback and adjustments before final production. By fostering a strong partnership with the manufacturer, buyers can ensure that their unique specifications are met effectively.

Strategic Material Selection Guide for Rubber Roller Manufacturers

When selecting materials for rubber rollers, manufacturers must consider various factors that impact performance, durability, and cost. Below is an analysis of four common materials used in rubber roller manufacturing, providing actionable insights for international B2B buyers.

What Are the Key Properties of Natural Rubber for Rubber Rollers?

Natural rubber is known for its excellent elasticity and resilience, making it a popular choice for rubber rollers. It has a temperature rating of approximately -50°C to 80°C and displays good abrasion resistance. However, natural rubber is not inherently resistant to oils and solvents, which can limit its application in specific environments.

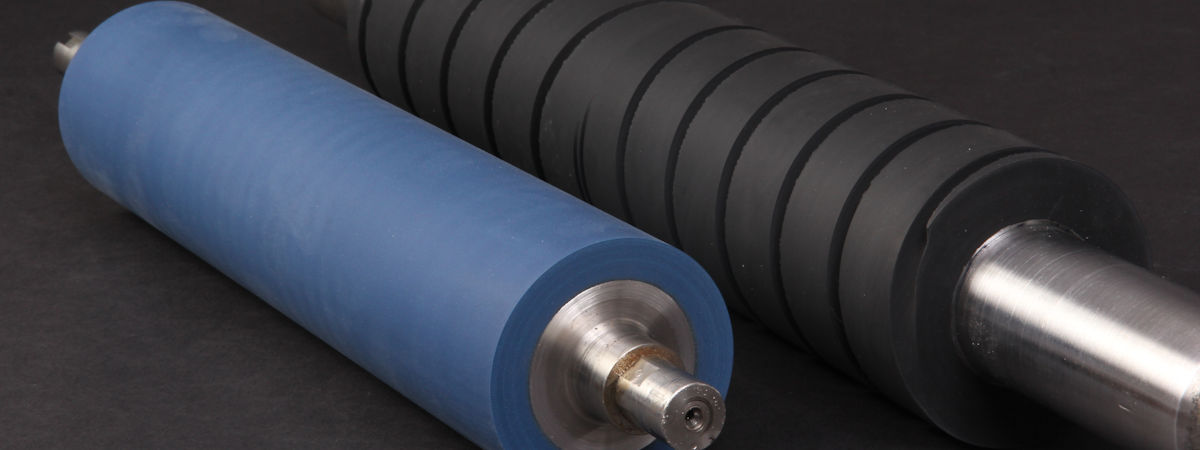

A stock image related to Rubber Roller Manufacturers.

Pros & Cons:

– Pros: High elasticity, good tensile strength, and excellent wear resistance.

– Cons: Limited chemical resistance and lower durability in high-temperature applications.

Impact on Application:

Natural rubber is ideal for applications involving light to moderate loads and where flexibility is crucial. However, its susceptibility to degradation in the presence of oils means that careful consideration must be given to the media it will encounter.

Considerations for International Buyers:

Buyers from regions such as Africa and South America should ensure compliance with local standards, as natural rubber may not meet specific industrial requirements. Familiarity with ASTM and DIN standards is essential when sourcing natural rubber rollers.

How Does Synthetic Rubber Compare in Performance for Rubber Rollers?

A stock image related to Rubber Roller Manufacturers.

Synthetic rubber, such as SBR (Styrene-Butadiene Rubber), offers enhanced durability and chemical resistance compared to natural rubber. With a temperature rating of -40°C to 100°C, synthetic rubber can perform well in more demanding environments.

Pros & Cons:

– Pros: Superior chemical resistance, better heat stability, and enhanced durability.

– Cons: Generally higher manufacturing costs and less elasticity compared to natural rubber.

Impact on Application:

Synthetic rubber is well-suited for heavy-duty applications and environments with exposure to oils, chemicals, and high temperatures. This makes it a preferred choice for industries such as automotive and manufacturing.

Considerations for International Buyers:

Buyers in Europe and the Middle East should consider the specific grades of synthetic rubber that comply with regional standards. Knowledge of JIS and ASTM specifications will aid in selecting the right synthetic rubber for their applications.

What Are the Advantages of Neoprene in Rubber Roller Manufacturing?

Neoprene is another synthetic rubber that provides excellent resistance to oils, chemicals, and weathering. It maintains its properties over a wide temperature range, typically from -40°C to 120°C.

Pros & Cons:

– Pros: Excellent chemical and weather resistance, good flexibility, and durability.

– Cons: Higher cost compared to natural rubber and potential for lower tensile strength.

Impact on Application:

Neoprene is ideal for applications requiring exposure to harsh chemicals or extreme weather conditions. Its versatility makes it suitable for various industries, including food processing and pharmaceuticals.

Considerations for International Buyers:

For buyers in regions like South Africa, understanding the specific grades of neoprene available and their compliance with local regulations is crucial. Ensuring that the neoprene meets international standards can prevent costly compliance issues.

Why Is EPDM Rubber a Preferred Choice for Certain Applications?

Ethylene Propylene Diene Monomer (EPDM) rubber is renowned for its excellent resistance to heat, ozone, and weathering. It operates effectively within a temperature range of -50°C to 150°C, making it suitable for outdoor applications.

Pros & Cons:

– Pros: Outstanding weather resistance, excellent aging properties, and good electrical insulation.

– Cons: Limited oil resistance and higher manufacturing complexity.

Impact on Application:

EPDM is particularly advantageous for outdoor applications, such as in agricultural machinery and construction equipment. Its durability in harsh environments makes it a reliable choice for long-term use.

Considerations for International Buyers:

Buyers from Europe and the Middle East should ensure that EPDM rubber meets the required industry standards, as this can vary significantly by region. Familiarity with the relevant compliance standards will help in making informed purchasing decisions.

Summary Table of Rubber Roller Materials

| Material | Typical Use Case for Rubber Roller Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Light to moderate load applications | High elasticity and wear resistance | Limited chemical resistance | Low |

| Synthetic Rubber (SBR) | Heavy-duty applications | Superior chemical resistance | Higher manufacturing costs | Medium |

| Neoprene | Harsh chemical environments | Excellent chemical and weather resistance | Higher cost than natural rubber | Medium |

| EPDM Rubber | Outdoor applications | Outstanding weather resistance | Limited oil resistance | Medium |

This strategic material selection guide provides essential insights for B2B buyers looking to optimize their rubber roller manufacturing processes while ensuring compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for Rubber Roller Manufacturers

What are the Key Stages in the Manufacturing Process of Rubber Rollers?

The manufacturing process for rubber rollers involves several critical stages that ensure the final product meets the required specifications and quality standards. Understanding these stages is essential for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, who are looking to source high-quality rubber rollers for their operations.

1. Material Preparation: What Raw Materials are Used?

The first stage in manufacturing rubber rollers involves the selection and preparation of raw materials. Common materials used include natural rubber, synthetic rubber (such as SBR and EPDM), and various additives like carbon black, accelerators, and curing agents. The quality of these materials directly impacts the performance of the rubber roller. Buyers should ensure that suppliers source materials from reputable vendors and that they meet international quality standards.

2. Forming: How are Rubber Rollers Shaped?

After material preparation, the next step is forming the rubber into the desired shape. This is typically done using molding techniques, such as compression or transfer molding. In compression molding, the rubber is placed into a heated mold and subjected to pressure, allowing it to take the shape of the mold. Transfer molding involves transferring the rubber into a closed mold, which allows for more intricate designs. Buyers should inquire about the molding techniques used by suppliers to ensure they can produce rollers with precise dimensions and surface finishes.

3. Assembly: What Processes are Involved?

Once the rubber has been formed, the rollers may require additional components, such as metal cores or bearings. The assembly process involves integrating these components with the rubber parts, often through methods like bonding or vulcanization, which enhances the durability and performance of the roller. For B2B buyers, understanding the assembly techniques employed can provide insights into the longevity and reliability of the rollers.

4. Finishing: How is the Final Product Prepared?

The finishing stage involves various processes, including trimming, grinding, and surface treatment. These processes ensure that the rubber rollers meet the specified tolerances and surface finishes required for their intended applications. For example, rollers used in printing may require a smooth finish, while those used in manufacturing may need a specific texture for better grip. Buyers should assess the finishing capabilities of potential suppliers to ensure their products meet specific application requirements.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is paramount in the manufacturing of rubber rollers, as it ensures the product’s performance, safety, and reliability. Buyers should familiarize themselves with relevant international and industry-specific standards.

International Standards: Which Certifications are Important?

One of the primary international standards is ISO 9001, which outlines the requirements for a quality management system. This certification indicates that the manufacturer has established processes to ensure consistent quality. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the end-use of the rubber rollers. Buyers from Europe, for example, should look for CE certification to ensure compliance with EU regulations.

What are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are essential in maintaining product quality throughout the manufacturing process. The following are critical checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production process. Buyers should ask suppliers for IQC reports to verify that materials meet specified standards.

-

In-Process Quality Control (IPQC): This is conducted during the manufacturing process to ensure that each stage meets quality standards. Regular checks at this stage can help identify potential issues early.

-

Final Quality Control (FQC): This involves inspecting the finished product before it is shipped. Buyers should request FQC reports, which should include details on dimensional checks, surface finish, and material properties.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure the reliability of their suppliers, B2B buyers should adopt a proactive approach to verify quality control processes.

1. Audits: What Should Buyers Look for?

Conducting supplier audits is an effective way to assess the quality management systems in place. During an audit, buyers should evaluate the supplier’s adherence to quality standards, their production processes, and their documentation practices. This hands-on approach can provide valuable insights into the supplier’s commitment to quality.

2. Reports: How Can Documentation Help?

Requesting documentation, such as quality control reports, test results, and compliance certificates, can help buyers gauge the reliability of their suppliers. Suppliers should be transparent about their quality assurance processes and willing to share relevant documentation.

3. Third-Party Inspections: Why are They Necessary?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can verify compliance with international standards and assess the quality of the products before shipment. For buyers in regions like Africa and South America, where access to certain suppliers may be limited, third-party inspections can be particularly valuable.

What Nuances Should International Buyers Consider in Quality Control?

International B2B buyers must be aware of the nuances in quality control that may vary by region. For instance, buyers from Europe may have stricter compliance requirements than those in Africa or South America. Understanding these differences can help buyers set appropriate expectations with suppliers and ensure that they receive products that meet their specific needs.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices is essential for B2B buyers sourcing rubber rollers. By focusing on material preparation, forming, assembly, and finishing stages, alongside robust quality assurance measures, buyers can ensure they partner with reliable manufacturers that meet their operational requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Rubber Roller Manufacturers’

This practical sourcing guide is designed to assist international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, in navigating the procurement process for rubber rollers. By following this step-by-step checklist, buyers can ensure they select the right manufacturers that meet their specific needs and industry standards.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is the first critical step in sourcing rubber rollers. Clearly outline the specifications, such as dimensions, material composition, hardness, and application. This will not only help in communicating effectively with suppliers but also in ensuring that the products meet your operational needs.

- Considerations:

- Identify the specific industry standards (e.g., FDA compliance for food processing).

- Determine the environmental conditions (temperature, humidity) the rollers will be exposed to.

Step 2: Research Potential Manufacturers

Once your specifications are clear, start researching manufacturers who specialize in rubber rollers. Utilize industry directories, trade shows, and online platforms to compile a list of potential suppliers.

- Tips:

- Look for manufacturers with a proven track record in your industry.

- Check online reviews and ratings to gauge reliability and quality.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify that the suppliers hold relevant certifications. Certifications such as ISO 9001, ISO 14001, or other industry-specific credentials are indicators of a manufacturer’s commitment to quality and environmental management.

- Why It Matters:

- Certifications provide assurance that the manufacturer adheres to international standards.

- They can also facilitate smoother regulatory compliance for your operations.

Step 4: Request Samples and Prototypes

Don’t hesitate to ask for samples of the rubber rollers that meet your specifications. Testing samples allows you to evaluate the quality and performance before making a bulk order.

- Action Items:

- Assess the durability, elasticity, and performance under expected operating conditions.

- Ensure the samples are representative of the final product quality.

Step 5: Understand Pricing Structures

Pricing can vary significantly among manufacturers. Request detailed quotations that outline not just the cost per unit, but also any additional fees such as shipping, customs, and taxes.

- Key Points:

- Clarify the terms of payment (e.g., deposits, payment methods).

- Be aware of potential discounts for bulk orders or long-term contracts.

Step 6: Check References and Client Feedback

Before finalizing your supplier, check references from other clients. Inquire about their experiences, delivery timelines, and how the manufacturer handled any issues.

- Questions to Ask:

- How responsive is the supplier to inquiries?

- Were there any significant delays or quality issues during previous orders?

Step 7: Negotiate Terms and Finalize the Agreement

Once you’ve selected a supplier, it’s time to negotiate the terms of the agreement. This should cover delivery schedules, payment terms, quality guarantees, and after-sales support.

- Important Aspects:

- Ensure that all terms are documented in the contract.

- Discuss options for recourse in case of non-compliance or defects.

By following these steps, B2B buyers can make informed decisions when sourcing rubber rollers, ultimately ensuring that they partner with manufacturers who can deliver quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for Rubber Roller Manufacturers Sourcing

What Are the Key Cost Components for Rubber Roller Manufacturing?

When sourcing rubber rollers, understanding the cost structure is crucial for B2B buyers. The primary components of manufacturing costs include:

- Materials: The quality and type of rubber used significantly influence the cost. Specialty rubbers, such as those resistant to heat or chemicals, command higher prices.

- Labor: Skilled labor is often necessary for both production and quality control processes. Labor costs can vary greatly by region, with developed countries typically facing higher wage standards.

- Manufacturing Overhead: This encompasses expenses such as utilities, rent, and equipment maintenance. Efficient production processes can help mitigate these costs.

- Tooling: Initial tooling costs for molds and machinery can be substantial, especially for custom rollers. It’s essential to consider these costs when calculating initial investment.

- Quality Control (QC): Implementing rigorous QC processes ensures that products meet specifications, but it adds to the overall cost.

- Logistics: Shipping costs can vary based on the distance from the manufacturer to the buyer and the chosen shipping method. Incoterms will play a critical role in determining who bears these costs.

- Margin: Manufacturers will typically add a profit margin to their costs, which can vary based on market conditions and competition.

How Do Price Influencers Affect Rubber Roller Sourcing?

Several factors can significantly affect the pricing of rubber rollers:

- Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate for favorable terms based on their projected needs.

- Specifications and Customization: Custom orders tailored to specific requirements can increase costs. Buyers must balance the need for customization against budget constraints.

- Materials: The choice of rubber type affects both durability and price. Buyers should assess the long-term performance against upfront costs.

- Quality and Certifications: Products meeting international quality standards may come at a premium. Certifications can assure buyers of product reliability and safety.

- Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established manufacturers with a track record may charge more due to perceived value.

- Incoterms: Understanding Incoterms is crucial for determining who is responsible for shipping, insurance, and tariffs, all of which can affect the total cost.

What Are Effective Buyer Tips for Negotiating Rubber Roller Prices?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency:

- Negotiate Terms: Always discuss payment terms, delivery timelines, and MOQ. Flexibility in these areas can lead to significant savings.

- Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and operational efficiency.

- Conduct Market Research: Understand the market landscape and average pricing to negotiate effectively. This knowledge can empower buyers during discussions.

- Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and service. Consistency in orders can also foster goodwill.

- Evaluate Alternatives: Don’t hesitate to explore multiple suppliers. Comparing quotes can reveal hidden cost advantages or better terms.

Conclusion: Navigating Pricing Nuances in International Sourcing

Understanding the cost structure and price influencers in rubber roller manufacturing is essential for making informed purchasing decisions. By being aware of these factors and employing strategic negotiation techniques, international B2B buyers can optimize their sourcing processes. Always remember that prices can fluctuate based on market conditions, so it’s prudent to obtain indicative quotes and assess them critically.

Alternatives Analysis: Comparing Rubber Roller Manufacturers With Other Solutions

When considering the procurement of industrial components, B2B buyers must evaluate various solutions that can fulfill their operational requirements. Rubber rollers are a popular choice due to their versatility and efficiency in various applications. However, it’s essential to compare them with other viable alternatives that may offer unique advantages depending on specific use cases. This analysis will focus on rubber roller manufacturers and two alternative solutions: polyurethane rollers and metal rollers.

Comparison Table: Rubber Roller Manufacturers vs. Alternatives

| Comparison Aspect | Rubber Roller Manufacturers | Polyurethane Rollers | Metal Rollers |

|---|---|---|---|

| Performance | Excellent grip and shock absorption; suitable for various surfaces. | High durability and abrasion resistance; ideal for high-speed applications. | Robust and long-lasting; ideal for heavy-duty applications but can be slippery. |

| Cost | Moderate initial investment with reasonable lifespan. | Generally higher initial costs but lower maintenance expenses. | Lower initial costs, but potentially higher long-term maintenance. |

| Ease of Implementation | Typically straightforward to install and replace. | Slightly more complex due to weight; may require specialized tools. | Installation can be labor-intensive and may need custom fittings. |

| Maintenance | Requires regular inspection for wear and tear; easy to maintain. | Low maintenance needs; may need replacement after prolonged use. | High maintenance; prone to rust and other forms of wear, requiring frequent checks. |

| Best Use Case | Ideal for applications requiring flexibility and noise dampening. | Best for applications with high-speed operations and increased load capacities. | Suitable for heavy industrial applications that require high strength. |

What Are the Advantages and Disadvantages of Polyurethane Rollers?

Polyurethane rollers are a robust alternative to rubber rollers, especially in environments where durability and abrasion resistance are paramount. These rollers are designed to withstand harsh conditions, making them suitable for high-speed applications such as conveyor systems. The primary advantage of polyurethane rollers is their long lifespan and reduced maintenance requirements, which can lead to lower total costs over time. However, the initial investment is typically higher than that for rubber rollers, which may deter some buyers, especially in regions with tight budgets.

How Do Metal Rollers Compare to Rubber Rollers?

Metal rollers are often used in heavy-duty industrial applications due to their strength and longevity. They are ideal for situations where high weight-bearing capacity is required, and they perform well in environments with extreme temperatures. The main advantage of metal rollers is their cost-effectiveness in terms of initial investment. However, they come with significant drawbacks, including high maintenance needs and the potential for rust and corrosion, which can increase long-term operational costs. Additionally, metal rollers can be slippery, leading to safety concerns in certain applications.

How Can B2B Buyers Choose the Right Solution for Their Needs?

In selecting the most appropriate solution, B2B buyers should consider several factors, including the specific application requirements, budget constraints, and long-term maintenance expectations. If flexibility and shock absorption are critical, rubber rollers may be the best choice. For high-speed applications where durability is essential, polyurethane rollers could be preferable. Conversely, if the application demands high strength and low initial costs, metal rollers might be the right fit, provided the buyer is prepared for the associated maintenance challenges. Ultimately, understanding the specific operational needs and the environments in which these rollers will be used is crucial for making an informed decision.

Essential Technical Properties and Trade Terminology for Rubber Roller Manufacturers

What Are the Essential Technical Properties of Rubber Rollers?

When considering rubber rollers for manufacturing processes, several key technical properties must be evaluated to ensure optimal performance and longevity. Here are critical specifications to keep in mind:

-

Material Grade

– The material used for rubber rollers significantly influences their durability and functionality. Common grades include natural rubber, nitrile, and polyurethane. Each material has unique properties, such as resistance to chemicals, temperature fluctuations, and wear. Selecting the appropriate material grade is vital for ensuring the roller meets the specific operational requirements of your machinery. -

Hardness (Durometer)

– Measured on the Shore A scale, hardness indicates the rubber’s resistance to indentation. A lower durometer signifies softer rubber, which is better for applications requiring flexibility and grip, while a higher durometer indicates firmer rubber, suitable for high-load applications. Understanding hardness helps in matching the roller to the intended application, impacting efficiency and product quality. -

Tolerance

– Tolerance refers to the permissible limit of variation in a roller’s dimensions. Tight tolerances are crucial in applications where precision is required, such as in printing and packaging. Maintaining strict tolerances ensures that the rollers fit perfectly into machinery, reducing the risk of mechanical failure and improving operational efficiency. -

Temperature Resistance

– Rubber rollers must withstand varying temperatures during operation. The ability to maintain performance at extreme temperatures, whether high or low, is essential for ensuring consistent production quality. Evaluating temperature resistance helps in selecting rollers that will not degrade or lose functionality under specific environmental conditions. -

Surface Finish

– The texture and finish of the roller’s surface impact its interaction with materials being processed. Smooth surfaces are typically used for applications requiring minimal friction, while textured surfaces can enhance grip. Understanding surface finish requirements is essential for optimizing the performance of the roller in its specific application.

What Trade Terms Should B2B Buyers Understand When Sourcing Rubber Rollers?

In the B2B landscape, familiarity with industry jargon is crucial for effective communication and negotiation. Here are some common trade terms relevant to rubber roller procurement:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of rubber rollers, buyers often seek OEMs to ensure compatibility with their existing machinery. Understanding OEM relationships can help buyers source quality products that meet specific operational standards. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers, especially when managing budgets and inventory levels. Suppliers may set MOQs to ensure profitability, and negotiating these terms can lead to cost savings for bulk orders. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers asking for price estimates for specified products. For rubber rollers, an RFQ should include detailed specifications, quantities, and delivery timelines. Understanding how to craft an effective RFQ can lead to better pricing and service agreements. -

Incoterms (International Commercial Terms)

– These are standardized trade terms used in international contracts to define responsibilities between buyers and sellers regarding shipping, risk, and costs. Familiarity with Incoterms is crucial for international buyers, as they dictate who pays for shipping, insurance, and tariffs, impacting overall costs and logistics planning. -

Lead Time

– Lead time refers to the time it takes from placing an order until the product is delivered. Understanding lead times is vital for planning production schedules and inventory management. Clear communication with suppliers about lead times can help avoid disruptions in the supply chain.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing rubber rollers, ensuring they select the right products for their manufacturing needs while navigating the complexities of global trade.

Navigating Market Dynamics and Sourcing Trends in the Rubber Roller Manufacturers Sector

What Are the Key Market Trends Affecting Rubber Roller Manufacturers?

The rubber roller manufacturing sector is experiencing significant shifts driven by global economic factors and technological advancements. Increasing automation in industries such as printing, textiles, and packaging has heightened the demand for high-performance rubber rollers. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers who can provide customized solutions to meet specific operational needs.

Emerging trends also include the integration of Industry 4.0 technologies, such as IoT and AI, which enhance production efficiency and product quality. These technologies allow manufacturers to monitor roller performance in real-time, leading to predictive maintenance and reduced downtime. Moreover, as businesses seek to optimize their supply chains, there is a growing emphasis on sourcing from suppliers who can demonstrate agility and responsiveness to changing market conditions.

The market dynamics are further influenced by geopolitical factors, trade policies, and economic fluctuations. Buyers must stay informed about these changes, as they can impact pricing and availability. For instance, fluctuations in raw material prices, especially natural rubber, can significantly affect manufacturing costs. Buyers are encouraged to conduct thorough market research and leverage relationships with suppliers who can navigate these complexities effectively.

How Can Sustainability and Ethical Sourcing Impact Rubber Roller Procurement?

Sustainability is becoming a cornerstone of procurement strategies across various industries, including rubber roller manufacturing. Buyers are increasingly aware of the environmental impact of their sourcing decisions and are seeking suppliers who prioritize sustainable practices. This includes the use of eco-friendly materials, efficient manufacturing processes, and waste reduction initiatives.

Ethical sourcing is also critical, as it ensures that the supply chain adheres to social and environmental standards. Buyers should look for manufacturers who hold certifications such as ISO 14001 for environmental management and FSC (Forest Stewardship Council) for responsible sourcing of rubber. These certifications not only enhance a company’s reputation but also align with the growing consumer preference for environmentally responsible products.

Moreover, incorporating sustainable practices can lead to cost savings in the long term. For example, using recycled materials in rubber production can reduce raw material costs and minimize waste. Buyers should engage with suppliers who are committed to sustainability, as this partnership can lead to innovative solutions that benefit both parties.

How Has the Rubber Roller Manufacturing Sector Evolved Over Time?

The rubber roller manufacturing industry has seen significant evolution over the past few decades, transitioning from traditional manufacturing processes to highly automated and technologically advanced operations. Initially dominated by manual labor, the sector has embraced machinery and robotics, allowing for increased precision and efficiency in production.

The introduction of synthetic rubber in the mid-20th century revolutionized the industry, offering greater durability and versatility compared to natural rubber. Today, manufacturers are not only focused on producing high-quality rollers but also on developing specialized products tailored to specific applications, such as heat-resistant rollers for the food processing industry or anti-static rollers for electronics manufacturing.

As global trade has expanded, international sourcing has become more prevalent, enabling buyers from regions such as Africa, South America, and Europe to access a wider range of products and suppliers. This evolution reflects the industry’s responsiveness to market demands and the continuous drive for innovation in manufacturing processes and materials.

Frequently Asked Questions (FAQs) for B2B Buyers of Rubber Roller Manufacturers

-

How do I choose the right rubber roller manufacturer for my business needs?

Selecting the right rubber roller manufacturer involves assessing their expertise in your specific industry, checking their production capabilities, and evaluating their product quality. Request samples to gauge the material and workmanship quality. Additionally, consider their certifications (like ISO) and customer reviews, which can provide insights into their reliability and customer service. For international buyers, ensure they can comply with your local regulations and standards. -

What are the key factors to consider when sourcing rubber rollers internationally?

When sourcing rubber rollers internationally, consider factors such as the manufacturer’s reputation, production capacity, lead times, and shipping logistics. It’s crucial to understand their compliance with international quality standards and environmental regulations. Additionally, assess the cost-effectiveness of their pricing, including shipping and tariffs, to ensure it aligns with your budget. Conducting due diligence through reference checks can also mitigate risks. -

What customization options are available for rubber rollers?

Many rubber roller manufacturers offer customization options tailored to specific applications. This can include variations in material hardness, surface finishes, dimensions, and coatings to enhance performance for specific tasks. Discuss your requirements with potential suppliers to explore available options. Additionally, inquire about their design capabilities and whether they can accommodate prototypes or small batch orders for testing purposes. -

What is the typical minimum order quantity (MOQ) for rubber rollers?

Minimum order quantities can vary significantly among manufacturers, often ranging from a few units to several hundred. Smaller manufacturers might offer more flexibility with lower MOQs, while larger companies may require higher quantities to justify production costs. When negotiating with suppliers, clarify the MOQ and explore options for bulk discounts or combining orders with other products to meet the minimum threshold. -

What payment terms should I expect when dealing with rubber roller suppliers?

Payment terms can vary by manufacturer and region. Common terms include a deposit upfront (typically 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or extended payment terms for established customers. Always clarify payment methods accepted, such as bank transfers or payment platforms, and ensure you understand any potential currency exchange implications if dealing internationally. -

How can I ensure quality assurance when sourcing rubber rollers?

Quality assurance can be ensured by requesting detailed quality control processes from manufacturers. Look for suppliers that implement rigorous testing protocols, including material inspections and performance testing of the rollers. Ask for certifications that demonstrate adherence to industry standards. Additionally, consider conducting factory visits or third-party inspections, especially for large orders, to verify that the production meets your quality expectations. -

What logistics considerations should I keep in mind when importing rubber rollers?

Logistics is a critical aspect of importing rubber rollers. Understand the shipping options available, including air freight for speed or sea freight for cost-effectiveness. Additionally, factor in customs clearance processes and potential tariffs that may apply. Work with a freight forwarder experienced in your target markets to streamline shipping logistics. Make sure to have a clear understanding of delivery timelines to align with your production schedules. -

What are common challenges faced when sourcing rubber rollers internationally, and how can I overcome them?

Common challenges include language barriers, cultural differences, and varying quality standards. To overcome these, consider working with a local representative or sourcing agent who understands the market dynamics and can facilitate communication. Establish clear specifications and expectations from the outset to minimize misunderstandings. Additionally, building strong relationships with suppliers can foster better collaboration and prompt resolution of any issues that arise during the sourcing process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Rubber Roller Manufacturers

As the global market for rubber rollers continues to evolve, strategic sourcing emerges as a critical factor for international B2B buyers, especially in Africa, South America, the Middle East, and Europe. Understanding the nuances of supplier relationships, quality assurance, and cost management can significantly enhance operational efficiency and competitiveness.

How Can International B2B Buyers Leverage Strategic Sourcing for Rubber Rollers?

By prioritizing strategic sourcing, buyers can unlock significant value through better supplier negotiations, risk mitigation, and access to innovative technologies. Establishing long-term partnerships with reliable rubber roller manufacturers not only ensures consistent quality but also fosters collaboration on product development and customization. Additionally, staying informed about regional market dynamics and sustainability practices can position buyers favorably in an increasingly eco-conscious marketplace.

What’s Next for Buyers in the Rubber Roller Industry?

Looking ahead, it is essential for international buyers to remain agile and proactive in their sourcing strategies. Engaging with manufacturers who prioritize technological advancements and sustainable practices will not only meet current demands but also prepare for future challenges. We encourage buyers to assess their sourcing strategies, explore diverse supplier options, and embrace innovation to stay ahead in this competitive landscape. The future of rubber roller manufacturing is bright, and the opportunities for growth and collaboration are vast.