Discover Top Strategies from Electric Car Manufacturers (2025)

Introduction: Navigating the Global Market for electric car manufacturer

As the global demand for sustainable transportation surges, international B2B buyers are increasingly focused on sourcing electric car manufacturers to meet evolving consumer expectations and regulatory pressures. Navigating the complex landscape of electric vehicle (EV) manufacturing can be challenging, especially for businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe. This guide provides a comprehensive overview of the electric car manufacturing sector, covering essential aspects such as types of electric vehicles, their applications, supplier vetting processes, and cost considerations.

In this resource, you will find actionable insights that empower you to make informed purchasing decisions tailored to your specific regional needs. Whether you are in Kenya, Colombia, or any other market, understanding the nuances of electric vehicle sourcing is crucial for gaining a competitive advantage. We will explore the various types of electric vehicles available, from battery electric vehicles (BEVs) to plug-in hybrids (PHEVs), and discuss their applicability in different business contexts.

Additionally, this guide will provide strategies for evaluating suppliers, ensuring compliance with international standards, and understanding the total cost of ownership associated with electric vehicles. By leveraging the information presented here, you can strategically position your business to capitalize on the electric vehicle revolution, ultimately driving growth and sustainability in your operations.

Understanding electric car manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Startups | Innovative designs, often focused on niche markets | Fleet solutions, ridesharing | Pros: Cutting-edge technology; Cons: Less established reliability. |

| Established Automakers | Legacy brands with extensive R&D and service networks | Corporate fleets, government contracts | Pros: Proven reliability; Cons: Slower innovation cycles. |

| Luxury Electric Vehicles | High-end features, advanced technology, premium pricing | Executive transport, luxury rentals | Pros: Brand prestige; Cons: High total cost of ownership. |

| Commercial Electric Vehicles | Focused on utility and efficiency for businesses | Delivery services, logistics | Pros: Lower operating costs; Cons: Limited range for some models. |

| Battery Manufacturers | Specialize in battery technology and development | Partnerships with automakers | Pros: Cutting-edge energy solutions; Cons: May lack complete vehicle offerings. |

What Are the Characteristics of Startups in Electric Vehicle Manufacturing?

Startups in the electric vehicle (EV) sector are often characterized by their innovative approaches and unique designs. They tend to focus on specific niches, such as compact city cars or specialized utility vehicles. For B2B buyers, particularly those in emerging markets like Kenya or Colombia, these manufacturers can offer cutting-edge technology and solutions tailored to local needs. However, buyers should be mindful of the potential risks associated with less established brands, including reliability and service support.

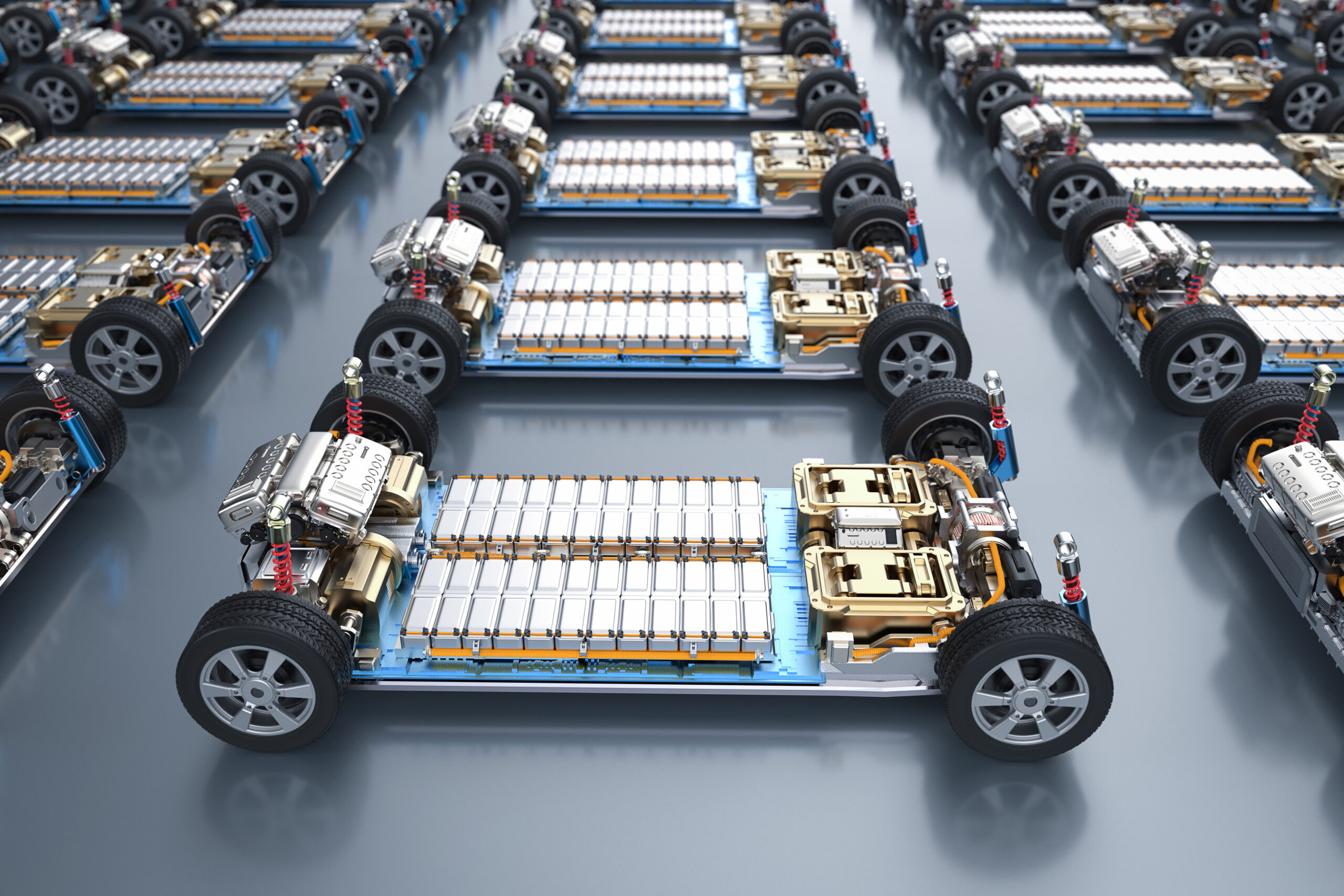

A stock image related to electric car manufacturer.

How Do Established Automakers Compare in the Electric Vehicle Market?

Established automakers have a significant advantage in terms of resources, research and development capabilities, and extensive service networks. They typically offer a range of electric vehicles that cater to corporate fleets and government contracts, ensuring reliability and support. B2B buyers can benefit from proven technology and established brand trust. However, these companies may be slower to innovate compared to startups, which could limit options for buyers seeking the latest technology advancements.

What Should Buyers Consider About Luxury Electric Vehicles?

Luxury electric vehicles (EVs) are designed with high-end features and advanced technology, appealing to businesses that prioritize brand prestige and comfort, such as executive transport or luxury rentals. While these vehicles provide a superior driving experience and cutting-edge technology, they come at a premium price point, which may not be suitable for all B2B buyers. It’s essential to weigh the total cost of ownership against the benefits of enhanced image and performance.

How Do Commercial Electric Vehicles Serve Business Needs?

Commercial electric vehicles are tailored for utility and efficiency, making them ideal for businesses in delivery services and logistics. These vehicles often feature larger cargo capacities and lower operating costs, which can significantly benefit companies looking to reduce their carbon footprint. However, some commercial models may have limited ranges, which can be a critical consideration for logistics businesses operating over long distances.

Why Are Battery Manufacturers Important for Electric Vehicle Development?

Battery manufacturers play a crucial role in the electric vehicle ecosystem by specializing in battery technology and development. They often partner with automakers to provide cutting-edge energy solutions that enhance vehicle performance and efficiency. For B2B buyers, collaborating with battery manufacturers can lead to innovative partnerships that improve vehicle capabilities. However, buyers should note that these manufacturers may not offer complete vehicle solutions, necessitating additional collaboration with automakers.

Related Video: NEW BYD Seal review – is this Chinese EV REALLY better than a Tesla? | What Car?

Key Industrial Applications of electric car manufacturer

| Industry/Sector | Specific Application of Electric Car Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Electric Buses and Shuttles | Reduced operational costs and environmental impact | Availability of charging infrastructure, maintenance support |

| Logistics and Delivery | Electric Delivery Vans | Lower fuel costs and enhanced sustainability | Range of vehicles, battery capacity, and payload capability |

| Tourism and Leisure | Electric Tour Vehicles | Unique customer experience and lower emissions | Vehicle customization options, safety features, and service support |

| Agriculture | Electric Utility Vehicles | Cost savings on fuel and maintenance | Adaptability to terrain, battery life, and support for attachments |

| Construction | Electric Construction Equipment | Decreased noise pollution and reduced emissions | Equipment durability, battery life, and service availability |

How are Electric Buses and Shuttles Transforming Public Transportation?

Electric buses and shuttles are pivotal in modernizing public transportation systems, particularly in urban areas across Africa and Europe. They offer a significant reduction in operational costs due to lower fuel expenses and maintenance needs. Additionally, these vehicles contribute to improved air quality and reduced noise pollution, aligning with global sustainability goals. For international B2B buyers, ensuring the availability of charging infrastructure and reliable maintenance support is crucial when considering electric bus procurement.

What Benefits Do Electric Delivery Vans Provide in Logistics?

A stock image related to electric car manufacturer.

Electric delivery vans are increasingly popular in the logistics sector, offering businesses a sustainable alternative to traditional fuel-powered vehicles. They help reduce operational costs significantly, especially in urban areas where congestion charges and low-emission zones are becoming more common. For buyers from South America and the Middle East, it is essential to evaluate the range of electric vans, battery capacity, and payload capabilities to meet specific delivery requirements while ensuring compliance with local regulations.

How Can Electric Tour Vehicles Enhance the Tourism Experience?

In the tourism and leisure industry, electric tour vehicles provide a unique and environmentally friendly experience for visitors. They allow tourists to explore attractions without contributing to air pollution, enhancing the overall enjoyment of the journey. B2B buyers in this sector should consider vehicle customization options, safety features, and the level of service support available to ensure a seamless experience for tourists, particularly in regions where eco-tourism is gaining traction.

What Role Do Electric Utility Vehicles Play in Agriculture?

Electric utility vehicles are revolutionizing agricultural practices by offering cost savings on fuel and maintenance. These vehicles are particularly beneficial in regions with vast farmlands, such as parts of Africa and South America, where traditional fuel costs can be high. Buyers should focus on the adaptability of electric utility vehicles to different terrains, battery life, and compatibility with various attachments to maximize their utility on farms.

How Are Electric Construction Equipment Reducing Environmental Impact?

Electric construction equipment is becoming a vital asset in the construction sector, providing a solution to reduce noise pollution and lower emissions on job sites. This is particularly important in urban areas where construction activities can disrupt communities. For B2B buyers, considerations should include the durability of equipment, battery life, and the availability of service and support to ensure efficient operations and compliance with increasingly stringent environmental regulations.

Related Video: Behind the scenes at BYD Auto: China’s biggest electric vehicle factory

3 Common User Pain Points for ‘electric car manufacturer’ & Their Solutions

Scenario 1: Navigating Supply Chain Disruptions in Electric Vehicle Manufacturing

The Problem: B2B buyers in regions like Africa and South America often face significant supply chain disruptions when sourcing components for electric vehicles (EVs). These disruptions can stem from political instability, inadequate infrastructure, or fluctuating trade policies. As a result, manufacturers may experience delays in production, increased costs, and ultimately, a negative impact on their market competitiveness. For instance, a company in Kenya trying to import battery components may encounter shipping delays that stall the entire production line.

The Solution: To mitigate supply chain risks, B2B buyers should establish strong relationships with multiple suppliers across different regions. This diversification strategy can help ensure a steady flow of components even if one supplier faces issues. Additionally, buyers should consider local sourcing options wherever possible. For instance, partnering with regional manufacturers in South America who produce EV components can reduce reliance on international logistics. Implementing a robust supply chain management system that utilizes real-time data analytics can also enhance visibility into the supply chain, allowing for proactive adjustments when disruptions occur.

Scenario 2: Addressing Concerns Over Electric Vehicle Range and Performance

The Problem: One of the primary concerns for B2B buyers, particularly fleet managers in Europe, is the range and performance of electric vehicles. Many businesses are hesitant to transition to EVs due to fears that the vehicles may not meet the operational demands of their fleets. For example, a delivery company may worry that the range of a particular electric van is insufficient for its daily routes, leading to operational inefficiencies and increased costs.

The Solution: B2B buyers should conduct thorough evaluations of electric vehicle specifications, focusing on real-world performance metrics rather than just manufacturer claims. Engaging in pilot programs or test drives can provide firsthand experience of the vehicle’s capabilities in actual working conditions. Furthermore, buyers should consider vehicles equipped with advanced battery technology that offers extended range and faster charging times. Collaborating with electric car manufacturers that provide comprehensive support, including charging infrastructure solutions and route optimization software, can also alleviate concerns about range and enhance overall operational efficiency.

Scenario 3: Understanding Regulatory Compliance and Incentives for Electric Vehicles

The Problem: In regions like the Middle East and Europe, navigating the complex landscape of regulations and incentives related to electric vehicles can be daunting for B2B buyers. Companies may struggle to understand what certifications are required for electric vehicles and how to take advantage of available subsidies or tax breaks. This lack of clarity can lead to costly delays in the procurement process and missed opportunities for financial incentives.

The Solution: B2B buyers should invest time in understanding the regulatory environment surrounding electric vehicles in their specific markets. This can be achieved by consulting with local regulatory bodies or industry associations that provide insights into compliance requirements. Additionally, buyers can benefit from partnering with electric car manufacturers that offer guidance on navigating these regulations, including assistance with paperwork and applications for incentives. Staying informed about upcoming regulations and changes in policy can also help buyers strategically plan their investments in electric vehicles, maximizing both compliance and cost savings.

Strategic Material Selection Guide for electric car manufacturer

What Are the Key Materials Used in Electric Car Manufacturing?

Electric vehicles (EVs) rely on a variety of materials that significantly influence their performance, safety, and sustainability. Understanding these materials is crucial for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. Here, we analyze four common materials used in electric car manufacturing: aluminum, steel, lithium-ion batteries, and carbon fiber.

How Does Aluminum Benefit Electric Vehicle Production?

Aluminum is a lightweight metal that offers excellent strength-to-weight ratios, making it a popular choice for electric vehicle manufacturers. Its key properties include high corrosion resistance and good thermal conductivity, which are essential for vehicle longevity and performance.

Pros: Aluminum’s lightweight nature contributes to improved energy efficiency and range in electric vehicles. It is also recyclable, aligning with sustainability goals.

Cons: The manufacturing process for aluminum can be complex and costly compared to traditional steel. Additionally, while aluminum has good tensile strength, it can be less impact-resistant than steel.

Impact on Application: Aluminum is particularly suitable for body panels and structural components, where weight reduction is critical for enhancing range and efficiency.

Considerations for International Buyers: Buyers in regions like Kenya and Colombia should consider local recycling capabilities and the availability of aluminum suppliers. Compliance with international standards such as ASTM and DIN can also affect procurement decisions.

What Role Does Steel Play in Electric Vehicle Manufacturing?

Steel remains a fundamental material in the automotive industry, including electric vehicles. Known for its durability and strength, steel is often used in the chassis and structural components of EVs.

Pros: Steel is cost-effective and widely available, making it a practical choice for many manufacturers. Its high strength offers excellent crash protection.

Cons: The weight of steel can negatively impact the vehicle’s range and efficiency. Additionally, steel is prone to corrosion unless treated, which may require additional manufacturing processes.

Impact on Application: Steel is typically used in areas where strength and safety are paramount, such as the vehicle frame and safety structures.

Considerations for International Buyers: Buyers should be aware of local steel standards and certifications, as well as the potential for import tariffs that could affect cost. In regions like Europe, adherence to environmental regulations is also crucial.

Why Are Lithium-Ion Batteries Essential for Electric Cars?

Lithium-ion batteries are the heart of electric vehicles, providing the necessary energy storage for propulsion. Their key properties include high energy density and a relatively low self-discharge rate.

Pros: Lithium-ion batteries offer long life cycles and fast charging capabilities, enhancing the user experience. They are also lightweight compared to other battery technologies.

Cons: The cost of lithium-ion batteries can be high, impacting the overall vehicle price. Additionally, concerns about resource sourcing and environmental impact are growing, especially regarding lithium extraction.

Impact on Application: These batteries are critical for the performance and range of electric vehicles, making them a focal point in EV design.

Considerations for International Buyers: Buyers should evaluate battery suppliers based on sustainability practices and compliance with international standards. In regions like the Middle East, supply chain logistics can also be a factor.

How Does Carbon Fiber Enhance Electric Vehicle Performance?

Carbon fiber is increasingly being used in high-performance electric vehicles due to its exceptional strength-to-weight ratio and stiffness.

Pros: Carbon fiber components can significantly reduce vehicle weight, improving acceleration and efficiency. They also offer excellent fatigue resistance.

Cons: The primary drawback of carbon fiber is its high cost and complex manufacturing processes, which can limit its use to premium vehicles.

Impact on Application: Carbon fiber is often used in performance components such as body panels and structural reinforcements, where weight savings are crucial.

Considerations for International Buyers: Buyers should assess the availability of carbon fiber manufacturers and the potential for local production. Compliance with international quality standards is also essential.

Summary Table of Material Selection for Electric Car Manufacturing

| Material | Typical Use Case for Electric Car Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Body panels and structural components | Lightweight and corrosion-resistant | Higher manufacturing complexity | Medium |

| Steel | Chassis and safety structures | Cost-effective and strong | Heavier, prone to corrosion | Low |

| Lithium-Ion Battery | Energy storage for propulsion | High energy density and lightweight | High cost and environmental concerns | High |

| Carbon Fiber | Performance components | Excellent strength-to-weight ratio | Expensive and complex to manufacture | High |

This guide provides a comprehensive overview of the strategic material selection process for electric car manufacturers, emphasizing the importance of understanding material properties, advantages, limitations, and regional considerations for international B2B buyers.

In-depth Look: Manufacturing Processes and Quality Assurance for electric car manufacturer

What Are the Main Stages of Electric Car Manufacturing?

The manufacturing process for electric cars is multifaceted, involving several critical stages that ensure efficiency and quality. Here’s a breakdown of the main stages:

-

Material Preparation: The first step involves sourcing and preparing raw materials. Manufacturers typically use advanced materials such as aluminum and high-strength steel for the chassis, as well as lithium-ion batteries for power. B2B buyers should inquire about the supplier’s sourcing practices, ensuring that materials meet international standards for sustainability and safety.

-

Forming: In this phase, raw materials are shaped into components through various techniques such as stamping, forging, and extrusion. These processes are vital for creating parts that meet precise specifications. Buyers should ensure that their suppliers utilize state-of-the-art technology to achieve high precision in component manufacturing.

-

Assembly: This stage involves the integration of different components into a complete vehicle. Automation plays a significant role here, with robotic systems performing tasks like welding and painting. B2B buyers should assess the supplier’s assembly line efficiency and the technologies employed, as this can impact lead times and overall production quality.

-

Finishing: The final stage of manufacturing includes painting, detailing, and quality checks. This not only enhances the vehicle’s aesthetics but also protects it from environmental factors. Buyers should ensure that suppliers follow stringent finishing processes to maintain the vehicle’s longevity and compliance with international aesthetic standards.

Which Key Techniques Are Used in Electric Car Manufacturing?

Electric car manufacturers employ various techniques to optimize production and ensure quality:

-

Lean Manufacturing: This technique focuses on minimizing waste while maximizing productivity. It is crucial for reducing costs and improving efficiency, especially for international buyers looking for competitive pricing.

-

Just-in-Time (JIT) Production: JIT reduces inventory costs by ensuring that parts arrive only when needed in the production process. This is particularly beneficial for B2B buyers who require flexibility in order fulfillment.

-

Modular Design: This approach allows for easier customization and scalability in production. By adopting modular designs, manufacturers can quickly adapt to changes in market demand, which is essential for international buyers looking to enter new markets.

What Are the Relevant International Standards for Quality Assurance?

Quality assurance is paramount in the manufacturing of electric vehicles, with several international standards guiding the processes:

-

ISO 9001: This standard focuses on quality management systems and is applicable across various industries, including automotive. B2B buyers should look for suppliers certified under ISO 9001, indicating a commitment to continuous improvement and customer satisfaction.

-

ISO 14001: This standard emphasizes environmental management, which is increasingly important for international buyers concerned about sustainability practices.

-

CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards. This is crucial for B2B buyers from Europe, ensuring that products meet regulatory requirements.

-

SAE Standards: The Society of Automotive Engineers (SAE) provides numerous standards that apply specifically to automotive manufacturing, including electric vehicles. Compliance with these standards can enhance product credibility.

How Are Quality Control Checkpoints Structured?

Quality control (QC) is implemented through several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step ensures that all incoming materials meet specified standards before they enter the production line. B2B buyers should request IQC reports to verify that materials from suppliers are consistently high-quality.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various checks are performed to ensure that components are being produced according to specifications. This can include dimensional checks, functional tests, and visual inspections.

-

Final Quality Control (FQC): Once the vehicle is assembled, final inspections are conducted to ensure overall quality and compliance with standards. This includes performance testing, safety checks, and aesthetic evaluations.

What Common Testing Methods Are Used in Electric Vehicle Quality Control?

Testing methods are critical to ensuring the safety and reliability of electric vehicles. Common methods include:

-

Durability Testing: This involves simulating extreme conditions to ensure that vehicles can withstand wear and tear over time. B2B buyers should inquire about the testing environments and protocols used by suppliers.

-

Safety Testing: This includes crash tests and safety feature evaluations to meet regulatory requirements and consumer expectations. Suppliers should provide certifications and results from recognized safety testing organizations.

-

Battery Testing: Given the importance of battery performance in electric vehicles, rigorous testing is essential. This includes assessments of battery life, efficiency, and safety under various conditions.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure quality assurance, B2B buyers should implement several verification methods:

-

Supplier Audits: Conducting regular audits allows buyers to evaluate the manufacturing processes and quality control measures in place. This can include visits to manufacturing facilities and reviews of QC documentation.

-

Quality Control Reports: Suppliers should provide comprehensive QC reports that outline testing results and compliance with relevant standards. Buyers should scrutinize these reports for thoroughness and transparency.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of supplier quality. This can be particularly beneficial for international buyers who may not have the resources to conduct on-site inspections.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, must navigate specific nuances in quality control and certification:

-

Cultural Differences: Understanding cultural approaches to manufacturing and quality assurance can improve communication and expectations between buyers and suppliers.

-

Regulatory Compliance: Different regions have varying regulations regarding vehicle standards. B2B buyers should familiarize themselves with local laws and ensure that suppliers can meet these requirements.

-

Logistics and Supply Chain: Quality control does not end at manufacturing. Buyers should evaluate the logistics and supply chain practices of their suppliers to ensure that quality is maintained throughout the distribution process.

In conclusion, B2B buyers looking to source electric vehicles must prioritize a thorough understanding of manufacturing processes and quality assurance practices. By focusing on these key aspects, buyers can make informed decisions that align with their business goals and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric car manufacturer’

This guide serves as a practical checklist for international B2B buyers interested in sourcing electric car manufacturers. With the global push towards sustainable transportation, understanding the procurement process can significantly impact the success of your business strategy. Here’s a step-by-step checklist to help you navigate the complexities of sourcing electric car manufacturers effectively.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the electric vehicles you wish to procure. This includes battery capacity, range, charging time, and any specific features such as autonomous driving capabilities.

– Importance: This step ensures that your needs align with what manufacturers offer, preventing costly mismatches later on.

– Tip: Engage with your engineering team to create a comprehensive list of specifications.

Step 2: Research and Identify Potential Manufacturers

Conduct thorough research to create a list of potential electric car manufacturers. Use industry directories, trade shows, and online platforms to find reputable suppliers.

– Importance: A well-curated list enables you to focus your efforts on manufacturers that meet your criteria.

– Tip: Look for manufacturers that specialize in the specific type of electric vehicle you require, such as passenger cars, buses, or trucks.

Step 3: Evaluate Supplier Credentials and Compliance

Assess the certifications and compliance of potential suppliers with international standards. Look for ISO certifications, safety standards, and environmental regulations.

– Importance: Ensuring that suppliers adhere to industry standards mitigates risks related to quality and safety.

– Tip: Request documentation of certifications and verify them through relevant industry bodies.

Step 4: Request and Analyze Proposals

Send out requests for proposals (RFPs) to shortlisted manufacturers and analyze their responses. Evaluate not only the pricing but also the terms of delivery, warranty, and after-sales service.

– Importance: A comprehensive analysis helps you identify the best value for your investment beyond just the cost.

– Tip: Use a scoring system to rank proposals based on critical criteria such as price, quality, and service.

Step 5: Conduct Site Visits and Assess Production Capabilities

If feasible, visit the manufacturing facilities of your top candidates. Observe their production processes, quality control measures, and overall operational capabilities.

– Importance: Site visits provide insight into the manufacturer’s capacity and commitment to quality.

– Tip: Prepare a checklist of key areas to assess during the visit, including workforce qualifications and equipment standards.

Step 6: Negotiate Terms and Finalize Agreements

Once you’ve selected a manufacturer, enter into negotiations to finalize terms. Discuss pricing, delivery schedules, payment terms, and service level agreements (SLAs).

– Importance: Clear agreements prevent misunderstandings and ensure a smooth procurement process.

– Tip: Involve legal counsel to review contracts to protect your interests.

Step 7: Establish a Communication and Monitoring Plan

Develop a communication strategy for ongoing interactions with the manufacturer post-agreement. Set up regular check-ins and performance reviews to monitor compliance with the agreed terms.

– Importance: Ongoing communication ensures that any issues are addressed promptly, maintaining a strong supplier relationship.

– Tip: Use project management tools to track progress and keep all stakeholders informed.

By following this checklist, B2B buyers can navigate the sourcing process for electric car manufacturers more effectively, ensuring that they make informed decisions that align with their business objectives.

Comprehensive Cost and Pricing Analysis for electric car manufacturer Sourcing

What Are the Key Cost Components in Electric Car Manufacturing?

Understanding the cost structure of electric car manufacturing is vital for international B2B buyers. The main cost components include:

-

Materials: The raw materials, such as lithium for batteries, steel, aluminum, and plastics, significantly impact the overall cost. Prices for these materials can fluctuate based on global supply and demand dynamics.

-

Labor: Skilled labor is essential in the manufacturing process, especially in assembly and quality control. Labor costs can vary significantly depending on the region, with countries like Kenya and Colombia offering competitive labor rates.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, impacting the final pricing.

-

Tooling: Initial tooling costs for production lines can be substantial, particularly for custom models. Buyers should consider these costs when negotiating pricing, as they can be amortized over larger production volumes.

-

Quality Control (QC): Ensuring high-quality standards is paramount in the automotive industry. Investment in QC processes can lead to higher upfront costs but can save on warranty claims and recalls later.

-

Logistics: Transportation and storage costs can vary widely, particularly for international shipments. Understanding Incoterms is crucial to determine who bears these costs and risks.

-

Margin: Manufacturers typically include a profit margin in their pricing structure. This margin can vary based on market competition and the uniqueness of the product.

How Do Price Influencers Impact Electric Car Manufacturer Costs?

Several factors can influence the pricing of electric cars, including:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes can lead to lower per-unit costs, allowing buyers to negotiate better pricing. Understanding the manufacturer’s capacity and willingness to scale production is key.

-

Specifications and Customization: Custom features or specifications can lead to increased costs. Buyers should clearly define their requirements upfront to avoid unexpected price hikes later in the process.

-

Material Choices: Selecting alternative materials can significantly impact the price. For instance, opting for a lower-cost battery technology can reduce initial costs but may affect performance and longevity.

-

Quality Certifications: Compliance with international quality standards may incur additional costs. Buyers should verify that manufacturers meet necessary certifications to ensure product reliability.

-

Supplier Factors: The financial stability and reputation of suppliers can influence pricing. Researching suppliers thoroughly can prevent issues related to quality and delivery timelines.

-

Incoterms: Understanding the terms of shipping and delivery is crucial. The choice of Incoterms affects who pays for shipping and insurance, impacting overall costs.

What Buyer Tips Can Enhance Cost-Efficiency in Electric Car Sourcing?

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Terms: Always negotiate pricing and payment terms. Establishing long-term partnerships can lead to better pricing structures and discounts.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the vehicle, including maintenance, fuel savings, and potential resale value. A lower upfront cost may not always equate to the best value.

-

Leverage Regional Advantages: Buyers in regions like Kenya or Colombia should leverage local manufacturing capabilities and incentives, which may provide cost benefits and tax advantages.

-

Stay Informed on Market Trends: Keeping abreast of market changes, such as fluctuations in raw material costs or advancements in battery technology, can help buyers make informed purchasing decisions.

-

Collaborate with Industry Experts: Engaging with industry analysts or consultants can provide insights into pricing trends and sourcing strategies tailored to specific markets.

Disclaimer on Pricing

Prices in the electric vehicle market can vary widely based on numerous factors. The information provided here serves as a guideline and is subject to change based on market conditions and individual negotiations. Buyers are encouraged to conduct thorough market research and consult with multiple manufacturers to obtain the best pricing for their specific needs.

Alternatives Analysis: Comparing electric car manufacturer With Other Solutions

Exploring Alternatives to Electric Car Manufacturers for B2B Buyers

As the automotive industry evolves, international B2B buyers must consider various solutions beyond traditional electric car manufacturers. With the increasing emphasis on sustainability and efficiency, exploring alternatives can help businesses optimize their transportation strategies. This analysis compares electric car manufacturing with alternative technologies such as hydrogen fuel cell vehicles and hybrid vehicles, providing actionable insights for buyers in Africa, South America, the Middle East, and Europe.

| Comparison Aspect | Electric Car Manufacturer | Hydrogen Fuel Cell Vehicles | Hybrid Vehicles |

|---|---|---|---|

| Performance | High torque, quiet operation | Fast refueling, long range | Good fuel economy, moderate range |

| Cost | Higher initial investment, lower running costs | High initial cost, moderate running costs | Moderate initial cost, variable running costs |

| Ease of Implementation | Requires charging infrastructure | Limited hydrogen stations; infrastructure investment needed | Easier integration with existing fuel systems |

| Maintenance | Lower maintenance costs due to fewer moving parts | Moderate maintenance, specialized repairs | Regular maintenance needed; more complex systems |

| Best Use Case | Urban commuting, fleet vehicles | Long-distance transport, remote areas | Mixed driving conditions, varied routes |

What Are the Advantages and Disadvantages of Hydrogen Fuel Cell Vehicles?

Hydrogen fuel cell vehicles (HFCVs) present a viable alternative to electric vehicles, particularly for businesses requiring long-distance transportation. One significant advantage of HFCVs is their fast refueling time, comparable to traditional gasoline vehicles, allowing for efficient logistics operations. Additionally, they offer a longer range, making them suitable for remote areas where charging infrastructure may be lacking. However, the initial investment for HFCVs is high, and the current hydrogen fueling infrastructure is limited, which could pose challenges for widespread adoption.

How Do Hybrid Vehicles Compare to Electric Cars?

Hybrid vehicles combine an internal combustion engine with an electric propulsion system, offering flexibility in fuel use. They generally have a lower initial cost than fully electric vehicles and can utilize existing fuel infrastructure, making them easier to implement for businesses not ready to fully commit to electric solutions. While hybrids provide good fuel economy and reduced emissions, they still rely on fossil fuels, which may not align with sustainability goals. Maintenance can also be more complex, as hybrids require regular servicing of both the electric and combustion systems.

How Can B2B Buyers Choose the Right Transportation Solution?

When selecting the ideal transportation solution, B2B buyers should carefully evaluate their specific operational needs, budget constraints, and long-term sustainability goals. Electric cars are ideal for urban environments with established charging infrastructure and businesses focused on reducing emissions. Hydrogen fuel cell vehicles are better suited for long-haul transport where refueling infrastructure can be developed. In contrast, hybrid vehicles offer flexibility and ease of integration for businesses transitioning to greener technologies. Ultimately, the right choice will depend on a thorough assessment of each alternative’s performance, cost implications, and alignment with the company’s strategic objectives.

Essential Technical Properties and Trade Terminology for electric car manufacturer

What Are the Critical Technical Properties for Electric Car Manufacturers?

When engaging in the electric vehicle (EV) manufacturing sector, understanding essential technical properties is crucial for ensuring product quality and performance. Here are some key specifications that B2B buyers should consider:

1. Material Grade

Material grade refers to the quality and composition of the materials used in manufacturing electric vehicles. Common materials include aluminum for lightweight structures, high-strength steel for safety, and lithium for batteries. The choice of material affects weight, durability, and overall performance, which are vital for energy efficiency and safety in electric cars.

2. Tolerance Levels

Tolerance levels define the acceptable limits of variation in manufacturing processes. In electric car manufacturing, precise tolerances are crucial for parts such as battery packs, motors, and chassis. Inaccuracies can lead to performance issues or safety risks. Understanding tolerance requirements can help buyers ensure that components meet necessary quality standards and function properly.

3. Battery Capacity and Range

Battery capacity is typically measured in kilowatt-hours (kWh) and indicates how much energy a battery can store. A higher capacity generally translates to a longer driving range, which is a significant selling point for consumers. For B2B buyers, evaluating battery specifications is essential for aligning product offerings with market expectations and regulatory requirements.

4. Charging Time

Charging time refers to the duration required to fully recharge an electric vehicle’s battery. It can vary significantly based on the charging infrastructure and technology used. Fast-charging capabilities are increasingly important in the competitive EV market, as they enhance user convenience. Buyers should consider the charging options available to meet consumer demands for efficiency.

5. Weight Distribution

Weight distribution is critical for vehicle stability and handling. Electric vehicles often have heavy batteries, which can influence their center of gravity. Proper weight distribution contributes to safety and performance, especially in diverse driving conditions. B2B buyers should assess how manufacturers optimize weight distribution to ensure vehicle performance.

What Are Common Trade Terms in Electric Car Manufacturing?

Familiarity with industry jargon is essential for effective communication and negotiations in the electric car manufacturing sector. Here are several common trade terms that international B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components that are used in another company’s products. In the EV industry, this could refer to battery manufacturers or parts suppliers. Understanding OEM relationships can help buyers identify reliable partners and ensure the quality of components.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is particularly relevant in the EV sector, where components can be expensive. Knowing the MOQ helps buyers plan their purchasing strategies and manage inventory effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This term is crucial for B2B buyers as it facilitates comparison among suppliers and aids in budget planning.

4. Incoterms (International Commercial Terms)

Incoterms are a series of international standards that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is essential for international trade, as they clarify costs and risks associated with transportation.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. In the electric vehicle industry, managing lead times effectively is vital for production schedules and inventory management. Buyers should inquire about lead times to align their production processes accordingly.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing components and partnering with manufacturers in the electric vehicle industry.

Navigating Market Dynamics and Sourcing Trends in the electric car manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Electric Car Manufacturing Sector?

The electric car manufacturing sector is experiencing transformative changes driven by several global factors. A significant driver is the increasing regulatory pressure to reduce carbon emissions, particularly in Europe and parts of South America, where governments are implementing stricter environmental policies. Additionally, the rise in consumer demand for sustainable transport options is reshaping market dynamics, encouraging manufacturers to innovate and diversify their product offerings.

Emerging technologies such as advanced battery systems, AI-driven manufacturing processes, and smart vehicle connectivity are becoming essential in the sourcing landscape. For B2B buyers, understanding these technological advancements is critical for making informed purchasing decisions. For instance, companies like Tesla and Rivian are not only focusing on electric vehicles (EVs) but also on integrating renewable energy solutions and autonomous driving technologies, which can influence procurement strategies.

Moreover, the shift towards localized supply chains is gaining momentum. International buyers, especially from Africa and the Middle East, are looking to source components closer to home to mitigate risks associated with global supply chain disruptions. This trend is particularly evident in the sourcing of critical materials such as lithium and cobalt, essential for battery production, where ethical sourcing practices are increasingly prioritized.

How Can Sustainability and Ethical Sourcing Influence B2B Decisions in Electric Car Manufacturing?

Sustainability is no longer a mere buzzword but a core component of business strategy in the electric car sector. B2B buyers must consider the environmental impact of their sourcing decisions. The lifecycle of electric vehicles, from raw material extraction to end-of-life disposal, poses significant environmental challenges. Companies are now prioritizing suppliers that adhere to sustainable practices, which can reduce their overall carbon footprint and enhance brand reputation.

Ethical supply chains are also becoming a focal point. Many manufacturers are seeking certifications such as ISO 14001 for environmental management and ISO 26000 for social responsibility. These certifications not only guarantee compliance with international standards but also foster trust among consumers and stakeholders. For international buyers, particularly in regions like Africa and South America, aligning with suppliers committed to ethical sourcing can open doors to new markets and partnerships.

Green materials, such as recycled aluminum and bio-based plastics, are gaining traction in the manufacturing process. B2B buyers should evaluate their suppliers’ commitment to using such materials, as they can significantly reduce the ecological impact of their products and appeal to environmentally conscious consumers.

What Is the Brief Evolution of the Electric Car Manufacturing Sector?

The electric car manufacturing sector has evolved remarkably over the past few decades. Initially viewed as a niche market, electric vehicles gained momentum in the early 2000s, largely due to technological advancements and growing environmental awareness. The introduction of government incentives and subsidies further accelerated adoption, particularly in Europe and North America.

By the 2010s, major automotive manufacturers began investing heavily in electric vehicle technology, leading to a surge in both competition and innovation. Today, the sector is characterized by a diverse range of players, from established car manufacturers pivoting towards electric models to new entrants focusing solely on EVs. This evolution presents both challenges and opportunities for international B2B buyers seeking to navigate the complexities of sourcing within the electric car manufacturing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of electric car manufacturer

- How do I evaluate the credibility of an electric car manufacturer?

To evaluate the credibility of an electric car manufacturer, conduct thorough research on their business history, market reputation, and customer reviews. Look for certifications and compliance with international quality standards, such as ISO certifications. Additionally, consider their production capacity, technology used, and after-sales support. Engaging with previous clients and checking their experiences can provide valuable insights. Utilizing platforms like LinkedIn can also help verify the manufacturer’s legitimacy and connections in the industry.

-

What is the best way to negotiate pricing with electric car manufacturers?

Negotiating pricing effectively involves understanding market trends, production costs, and the manufacturer’s pricing structure. Start by gathering quotes from multiple suppliers to establish a benchmark. Be clear about your requirements, including specifications and volumes, as larger orders may warrant discounts. Building a rapport with the manufacturer can facilitate negotiations, as trust often leads to better deals. Additionally, consider discussing long-term partnerships, which can benefit both parties through consistent business. -

What are the minimum order quantities (MOQs) for electric vehicles from manufacturers?

Minimum order quantities for electric vehicles can vary significantly between manufacturers. Some may have MOQs as low as 10 units for specific models, while others might require orders of 50 or more. Factors influencing MOQs include the model’s complexity, customization options, and production capacity. When negotiating with a manufacturer, clarify the MOQ and explore flexibility options, especially if you are a new buyer or looking for a trial order. -

How can I customize electric vehicles to meet my specific needs?

Customization options for electric vehicles often include modifications to battery capacity, software features, and design elements. To initiate customization, communicate your requirements clearly to the manufacturer. Most reputable manufacturers have dedicated teams to handle customization requests. It’s advisable to inquire about the costs and timelines associated with the customization process. Establishing a collaborative relationship with the manufacturer can also help ensure that your specific needs are met efficiently. -

What payment terms should I expect when sourcing electric cars?

Payment terms can vary widely among electric car manufacturers. Common terms include upfront payments, partial payments upon order confirmation, and balance upon delivery. Some manufacturers may offer financing options or payment plans, especially for larger orders. It’s crucial to discuss and agree upon payment terms before finalizing contracts to avoid misunderstandings. Ensure that the payment terms are documented clearly in the purchase agreement to protect both parties. -

How do I ensure quality assurance when purchasing electric vehicles?

To ensure quality assurance, request detailed information on the manufacturer’s quality control processes. This may include certifications such as ISO 9001, which indicates adherence to quality management standards. Conduct factory visits if possible, or request third-party inspections before shipment. Additionally, inquire about warranty options and after-sales support to address any potential issues post-purchase. Establishing a clear communication channel with the manufacturer can also facilitate prompt resolution of quality concerns. -

What logistics considerations should I keep in mind when importing electric cars?

Logistics play a critical role in the successful import of electric cars. Key considerations include shipping methods (e.g., container shipping vs. roll-on/roll-off), customs regulations, and import tariffs specific to your country. Collaborate with a logistics provider experienced in automotive shipping to navigate these complexities. Ensure that all necessary documentation, such as bills of lading and customs declarations, is in order to avoid delays at the port. Planning for potential delays and understanding the timeline for delivery is also essential. -

What are the common challenges faced when sourcing electric vehicles internationally?

Common challenges include navigating different regulatory environments, fluctuating currency exchange rates, and varying quality standards across countries. Additionally, cultural differences can affect communication and negotiations. To mitigate these challenges, conduct in-depth market research and establish a strong network of local contacts. Utilizing professional intermediaries or consultants can also ease the sourcing process, ensuring compliance with local laws and facilitating smoother transactions. Building relationships with multiple suppliers can further reduce risks associated with reliance on a single source.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electric car manufacturer

What Are the Key Takeaways for Strategic Sourcing in Electric Car Manufacturing?

In the rapidly evolving landscape of electric vehicle (EV) manufacturing, strategic sourcing emerges as a pivotal factor for international B2B buyers. Engaging in strategic sourcing enables companies to secure a reliable supply chain, optimize costs, and enhance innovation. As electric car manufacturers focus on sustainable materials and advanced technologies, understanding local market dynamics becomes crucial, especially for buyers in regions like Africa, South America, the Middle East, and Europe.

How Can International Buyers Leverage Strategic Sourcing?

For B2B buyers, leveraging strategic sourcing not only ensures access to high-quality components but also fosters partnerships that can lead to shared technological advancements. This is particularly relevant in emerging markets where infrastructure and regulatory frameworks may differ significantly. By prioritizing relationships with local suppliers and manufacturers, buyers can navigate these complexities more effectively.

What’s Next for B2B Buyers in the Electric Vehicle Sector?

Looking ahead, the demand for electric vehicles is set to increase, driven by a global push for sustainability and reduced carbon emissions. International buyers are encouraged to stay ahead of the curve by investing in strategic sourcing initiatives that align with their long-term business goals. Embrace opportunities to collaborate with innovative manufacturers and suppliers to not only enhance your product offerings but also contribute to a greener future. The time to act is now—seize the opportunity to lead in the electric vehicle revolution.