Discover Top Strategies from Leading Bathroom Manufacturers (2025)

Introduction: Navigating the Global Market for bathroom manufacturer

Navigating the global market for bathroom manufacturers presents a significant challenge for B2B buyers, particularly in sourcing high-quality fixtures and fittings that meet diverse regional standards. As businesses expand across borders, understanding the nuances of product specifications, compliance regulations, and supplier reliability becomes critical. This guide is designed to equip international B2B buyers—especially those in Africa, South America, the Middle East, and Europe (including Poland and the UK)—with the knowledge necessary to make informed purchasing decisions.

Throughout this comprehensive resource, we will explore various types of bathroom products, from eco-friendly fixtures to luxury fittings, and discuss their applications in residential and commercial settings. Additionally, we will delve into essential topics such as supplier vetting processes, cost considerations, and market trends, enabling buyers to assess and select the best options for their specific needs.

By leveraging the insights provided in this guide, international B2B buyers will be empowered to navigate the complexities of the bathroom manufacturing landscape. This will not only enhance their procurement strategies but also ensure that they secure products that align with their quality standards and budgetary constraints.

Understanding bathroom manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Bathroom Manufacturers | Focus on classic designs and materials like porcelain and ceramic; often customizable. | Residential projects, hotels, and restaurants. | Pros: Timeless aesthetics, high durability. Cons: Longer lead times for custom orders. |

| Modern Bathroom Manufacturers | Emphasis on sleek, minimalist designs; often use innovative materials like glass and composites. | Urban apartments, modern hotels, and corporate offices. | Pros: Contemporary appeal, often easier maintenance. Cons: May lack the warmth of traditional designs. |

| Eco-friendly Bathroom Manufacturers | Use sustainable materials and water-saving technologies; certifications like LEED. | Green buildings, eco-conscious developments. | Pros: Reduces environmental impact, potential cost savings on utilities. Cons: Higher upfront costs. |

| Luxury Bathroom Manufacturers | High-end materials and bespoke services; often include smart technology integration. | Luxury residences, high-end hotels, spas. | Pros: Exceptional quality and exclusivity. Cons: Significant investment required. |

| Modular Bathroom Manufacturers | Pre-fabricated units that can be easily assembled on-site; customizable layouts. | Commercial projects, rapid construction sites. | Pros: Faster installation, cost-effective for large projects. Cons: Limited customization compared to traditional manufacturing. |

What Are the Characteristics of Traditional Bathroom Manufacturers?

Traditional bathroom manufacturers are known for their focus on classic designs and materials, such as porcelain and ceramic. They often provide customization options, allowing buyers to tailor products to specific project needs. This type is particularly suitable for residential projects, hotels, and restaurants where timeless aesthetics are desired. When purchasing, buyers should consider lead times for custom orders, as they may take longer compared to off-the-shelf options.

How Do Modern Bathroom Manufacturers Differ?

Modern bathroom manufacturers emphasize sleek, minimalist designs and often utilize innovative materials like glass and composites. Their products are ideal for urban apartments, modern hotels, and corporate offices where a contemporary appeal is essential. Buyers should consider ease of maintenance and aesthetic compatibility with the overall design of the space, while being aware that these products may lack the warmth found in traditional styles.

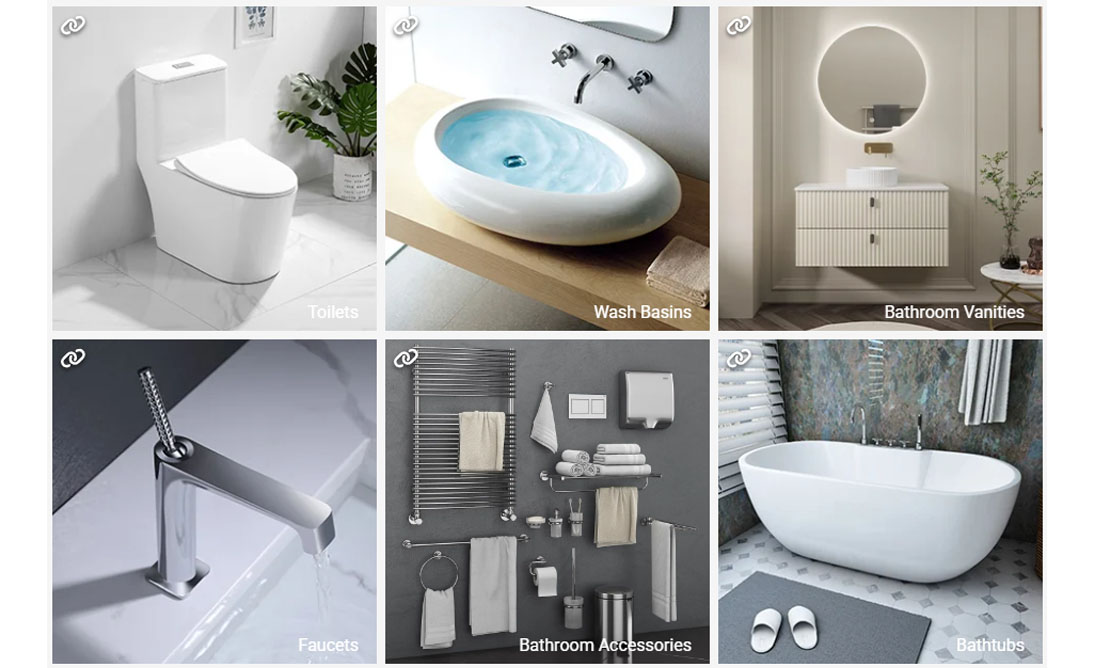

A stock image related to bathroom manufacturer.

What Makes Eco-friendly Bathroom Manufacturers Unique?

Eco-friendly bathroom manufacturers prioritize sustainable materials and water-saving technologies, often holding certifications such as LEED. They are best suited for green buildings and eco-conscious developments, appealing to buyers looking to reduce environmental impacts. While these products can lead to long-term cost savings on utilities, buyers should be prepared for potentially higher upfront costs associated with sustainable materials and technologies.

What Are the Benefits of Luxury Bathroom Manufacturers?

A stock image related to bathroom manufacturer.

Luxury bathroom manufacturers offer high-end materials and bespoke services, frequently integrating smart technology into their designs. They cater to luxury residences, high-end hotels, and spas, providing exceptional quality and exclusivity. Buyers should be ready for significant investments, as the cost of luxury products can be substantial, but the payoff is often seen in the enhanced experience and aesthetic value they bring to a space.

How Do Modular Bathroom Manufacturers Operate?

Modular bathroom manufacturers specialize in pre-fabricated units that can be easily assembled on-site. This approach is particularly beneficial for commercial projects and rapid construction sites, allowing for faster installation and cost-effectiveness. Buyers should weigh the benefits of quick deployment against the limited customization options available compared to traditional manufacturing methods.

Related Video: Quick Ways to Identify the Brand and Manufacturer for Faucet Repair

Key Industrial Applications of bathroom manufacturer

| Industry/Sector | Specific Application of Bathroom Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Custom bathroom fixtures and fittings for hotels | Enhances guest experience, boosts brand reputation | Quality assurance, design flexibility, compliance with local regulations |

| Healthcare | Sanitary ware for hospitals and clinics | Promotes hygiene, reduces infection rates | Durability, ease of cleaning, adherence to health standards |

| Real Estate Development | Bathroom installations in residential projects | Increases property value, attracts buyers | Cost-effectiveness, trend alignment, availability of materials |

| Education | Bathroom solutions for schools and universities | Ensures student comfort, supports health initiatives | Safety standards, accessibility features, maintenance support |

| Retail | Showroom displays and customer bathrooms | Enhances customer experience, drives sales | Design aesthetics, integration with existing layouts, scalability |

How are Bathroom Manufacturers Used in Hospitality Settings?

In the hospitality sector, bathroom manufacturers provide custom fixtures and fittings that enhance the guest experience. Hotels require high-quality, aesthetically pleasing bathrooms that reflect their brand identity. By sourcing durable materials that are easy to maintain, hotel operators can ensure that their facilities remain attractive and functional. International buyers should consider local regulations regarding water usage and accessibility to ensure compliance and appeal to diverse clientele.

What Role Do Bathroom Manufacturers Play in Healthcare Facilities?

In healthcare, bathroom manufacturers supply sanitary ware designed to promote hygiene and reduce the risk of infections. Hospitals and clinics require fixtures that are not only durable but also easy to clean and maintain. Buyers in this sector must prioritize products that meet stringent health standards and regulations. Additionally, features such as touchless faucets and anti-bacterial materials are increasingly important in promoting patient safety.

How Do Bathroom Manufacturers Contribute to Real Estate Development?

Bathroom manufacturers play a crucial role in real estate development by providing installations that significantly increase property value. Well-designed bathrooms can attract potential buyers and renters, making them a focal point in residential projects. Developers should focus on cost-effective solutions that align with current design trends. International buyers must also consider the availability of materials and local construction practices to ensure a seamless integration into their projects.

Why Are Bathroom Solutions Important for Educational Institutions?

In educational settings, bathroom manufacturers supply solutions that ensure student comfort and support health initiatives. Schools and universities need to provide accessible and safe bathrooms to accommodate a diverse student body. Buyers in this sector should prioritize safety standards, such as non-slip flooring and appropriate fixtures for children. Additionally, maintenance support and the ability to handle high traffic are critical factors for decision-makers in educational institutions.

How Can Bathroom Manufacturers Enhance Retail Experiences?

In the retail sector, bathroom manufacturers contribute by designing showroom displays and customer bathrooms that enhance the shopping experience. A well-designed retail bathroom can create a positive impression and encourage customers to spend more time in the store. Retailers should focus on design aesthetics that align with their brand image while ensuring that the facilities are scalable to accommodate varying customer volumes. Integration with existing layouts is also a key consideration for effective space management.

Related Video: Bathroom Waterproofing

3 Common User Pain Points for ‘bathroom manufacturer’ & Their Solutions

Scenario 1: Sourcing Quality Materials at Competitive Prices

The Problem: International B2B buyers often face challenges in sourcing high-quality materials from bathroom manufacturers at competitive prices. This is particularly true for buyers in emerging markets like Africa and South America, where quality assurance standards may vary. Buyers may receive subpar materials that do not meet their specifications, leading to dissatisfaction among end-users and potential reputational damage.

The Solution: To overcome this challenge, buyers should implement a rigorous supplier evaluation process. Start by conducting comprehensive market research to identify reputable bathroom manufacturers who have a proven track record in your target market. Utilize platforms like Alibaba or global trade shows to connect with manufacturers. When evaluating potential suppliers, request samples of their materials and conduct quality testing to ensure they meet your specifications. Additionally, consider forming partnerships with manufacturers who offer transparency regarding their sourcing and production processes, which can help you secure better pricing while maintaining quality standards.

Scenario 2: Navigating Regulatory Compliance Challenges

The Problem: Compliance with local and international regulations is a significant pain point for B2B buyers in the bathroom manufacturing sector. Buyers in regions such as Europe and the Middle East must adhere to stringent building codes and environmental regulations, which can complicate procurement processes. Failure to comply can result in costly fines, project delays, and damage to brand reputation.

The Solution: To navigate these regulatory challenges, B2B buyers should invest in understanding the regulatory landscape of their target markets. This involves engaging with local legal experts who specialize in construction and manufacturing regulations. Moreover, buyers should work closely with bathroom manufacturers who are knowledgeable about compliance issues and can provide certifications and documentation for their products. Establishing a checklist of relevant regulations and ensuring that your suppliers can meet these requirements will streamline your procurement process and mitigate compliance risks.

Scenario 3: Addressing Design and Customization Needs

The Problem: Many B2B buyers require customized bathroom solutions to meet specific project requirements, such as unique design aesthetics or functional specifications. However, bathroom manufacturers may not always be flexible or responsive to these needs, leading to frustration and delays in project timelines.

The Solution: To effectively address design and customization challenges, buyers should prioritize working with manufacturers known for their flexibility and ability to collaborate on bespoke solutions. Engage in detailed discussions with potential suppliers about your specific design needs and request portfolios of past custom projects. Utilize digital design tools or 3D modeling software to create prototypes that can be shared with manufacturers, ensuring that everyone is aligned on expectations. Establishing clear communication channels and timelines for feedback will facilitate a smoother design process. Additionally, consider setting up a pilot project with the manufacturer to test the viability of the proposed solutions before committing to larger orders. This approach helps to foster a collaborative relationship, ultimately leading to successful project outcomes.

Strategic Material Selection Guide for bathroom manufacturer

When selecting materials for bathroom manufacturing, international B2B buyers must consider several factors, including performance characteristics, cost-effectiveness, and regulatory compliance. Below, we analyze four common materials used in bathroom manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Ceramic in Bathroom Manufacturing?

Ceramic is a widely used material in bathroom fixtures such as sinks, toilets, and tiles. Its key properties include high temperature resistance, low water absorption, and excellent durability. Ceramics are also resistant to corrosion and chemical damage, making them suitable for various cleaning agents commonly used in bathrooms.

Pros: Ceramic is highly durable and can withstand significant wear and tear, making it ideal for high-traffic areas. Additionally, it is relatively low in cost and easy to manufacture into complex shapes.

Cons: However, ceramics can be brittle and prone to cracking under sudden impact. They also require careful handling during installation to avoid damage.

Impact on Application: Ceramic’s compatibility with water makes it an ideal choice for wet environments. However, it is essential to ensure that the ceramic used meets local standards for safety and durability.

Considerations for International Buyers: Buyers should verify that the ceramics comply with ASTM or DIN standards, particularly regarding lead content and surface finish quality. Preferences for color and design may vary significantly across regions, influencing the choice of ceramic products.

How Does Acrylic Compare as a Material for Bathroom Fixtures?

Acrylic is another popular material for bathtubs and shower enclosures. It is lightweight, easy to mold, and offers good thermal insulation, helping to maintain water temperature.

Pros: Acrylic is less prone to chipping or cracking compared to ceramic, making it a safer option for families. It is also available in a wide range of colors and finishes.

Cons: On the downside, acrylic can be more susceptible to scratches and UV degradation over time, which may affect its appearance and longevity.

Impact on Application: Acrylic is compatible with various cleaning agents, but care must be taken to avoid abrasive cleaners that can scratch the surface.

Considerations for International Buyers: Buyers should consider the UV stability of acrylic products, especially in regions with high sun exposure. Compliance with local health and safety regulations is also crucial.

What are the Advantages and Disadvantages of Stainless Steel in Bathrooms?

Stainless steel is commonly used for sinks and fixtures due to its strength and resistance to corrosion. Its key properties include high temperature and pressure resistance, making it suitable for various applications.

Pros: Stainless steel is incredibly durable and easy to clean, providing a hygienic surface that resists bacteria growth. It also offers a modern aesthetic that appeals to many consumers.

Cons: However, stainless steel can be more expensive than other materials, and it may be prone to scratching and denting.

Impact on Application: Stainless steel is compatible with a wide range of media, including hot and cold water. It is essential to ensure that the grade of stainless steel used is appropriate for the specific application to prevent corrosion.

Considerations for International Buyers: Buyers should look for products that meet international standards, such as JIS for Japan or EN for Europe, to ensure quality and durability.

Why is Glass a Unique Choice for Bathroom Applications?

Glass is increasingly popular for shower doors and partitions due to its aesthetic appeal and ability to create a sense of space.

Pros: Glass is non-porous and easy to clean, making it a hygienic choice. It also allows for natural light to flow, enhancing the bathroom’s ambiance.

Cons: The primary drawback is its fragility; glass can shatter upon impact and requires careful handling during installation.

Impact on Application: Glass is compatible with water but must be treated to resist staining and scratching.

Considerations for International Buyers: Buyers should ensure that the glass meets safety standards, such as tempered or laminated glass requirements, to prevent accidents.

Summary Table of Material Selection for Bathroom Manufacturing

| Material | Typical Use Case for bathroom manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ceramic | Sinks, toilets, tiles | Durable and resistant to chemicals | Brittle and prone to cracking | Low |

| Acrylic | Bathtubs, shower enclosures | Lightweight and easy to mold | Susceptible to scratches and UV damage | Medium |

| Stainless Steel | Sinks, fixtures | Hygienic and modern aesthetic | Higher cost and prone to scratching | High |

| Glass | Shower doors, partitions | Aesthetic appeal and space-enhancing | Fragile and requires careful handling | Medium |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for bathroom manufacturing, helping them make informed decisions that align with their specific regional needs and standards.

In-depth Look: Manufacturing Processes and Quality Assurance for bathroom manufacturer

What Are the Main Stages of the Manufacturing Process for Bathroom Products?

The manufacturing process for bathroom products involves several key stages that ensure high-quality output. Understanding these stages is essential for B2B buyers looking to source reliable products.

1. Material Preparation

The first step in the manufacturing process involves sourcing and preparing raw materials. Common materials used in bathroom manufacturing include ceramic, acrylic, metal, and various plastics. Quality assurance starts here, as the selection of materials significantly impacts the final product’s durability and finish. Buyers should inquire about the suppliers’ sourcing practices and material certifications to ensure compliance with international standards.

2. Forming

Once materials are prepared, they undergo various forming techniques. For ceramics, this may involve pressing or casting, while acrylic products often require thermoforming. Metal components might be stamped or extruded. Understanding the forming techniques used can provide insight into product quality and durability. Buyers should ask for technical specifications and process descriptions to assess whether the techniques align with their quality expectations.

3. Assembly

After individual components are formed, they are assembled into final products. This stage may involve manual labor or automated processes, depending on the manufacturer’s capabilities. Effective assembly is crucial for ensuring that products meet design specifications and function correctly. B2B buyers should evaluate the manufacturer’s assembly techniques and workforce qualifications, as this can significantly affect the product’s quality.

4. Finishing

The final stage involves applying finishes to enhance aesthetics and protect surfaces. Finishing processes can include glazing for ceramics, polishing for metals, and surface treatments for plastics. Quality control during finishing is vital to ensure uniformity and adherence to specifications. Buyers should request information on the finishing processes employed and any protective coatings used, as these can impact product longevity.

How Is Quality Assurance Implemented in Bathroom Manufacturing?

Quality assurance (QA) is critical in bathroom manufacturing to ensure that products meet both customer expectations and regulatory requirements. International buyers should be aware of the quality standards and practices in place at their chosen manufacturers.

Relevant International Standards for Quality Assurance

Many bathroom manufacturers adhere to international quality standards, such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards can assure buyers of a manufacturer’s commitment to quality and continuous improvement. Additionally, specific industry standards, such as CE marking in Europe or API specifications for plumbing products, may also apply. Understanding these certifications can help buyers gauge the reliability of potential suppliers.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integral to the manufacturing process, providing systematic evaluations at various stages.

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials upon arrival at the manufacturing facility. It ensures that materials meet specified standards before they enter the production line.

-

In-Process Quality Control (IPQC): This stage involves monitoring production processes to detect and rectify issues in real-time. Regular inspections and testing during manufacturing can prevent defects from progressing to the final stages.

-

Final Quality Control (FQC): The last checkpoint occurs before products are packaged and shipped. This comprehensive inspection verifies that finished goods meet quality standards and specifications.

What Common Testing Methods Are Used in Bathroom Manufacturing?

Testing methods play a crucial role in quality assurance, ensuring that products are safe, functional, and durable. Some common testing methods include:

-

Dimensional Testing: This ensures that products meet specified measurements and tolerances.

-

Material Testing: Conducted to assess the strength, durability, and chemical resistance of materials used in production.

-

Functional Testing: Verifying that products operate as intended, particularly for plumbing fixtures and electronic components.

-

Environmental Testing: Assessing the product’s performance under various conditions, such as humidity or temperature changes, which is critical for bathroom environments.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are several methods to conduct due diligence:

1. Supplier Audits

Conducting on-site audits allows buyers to assess a manufacturer’s processes, facilities, and quality management systems firsthand. An audit can reveal insights into the supplier’s operational capabilities and adherence to quality standards.

2. Quality Reports

Requesting detailed quality reports can provide transparency regarding a manufacturer’s production processes and quality outcomes. These reports should include information on past inspections, testing results, and compliance with relevant standards.

3. Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of a manufacturer’s quality control processes. These inspections can be particularly valuable for buyers in Africa, South America, the Middle East, and Europe, ensuring that products meet both local and international quality standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers should be aware of specific quality control nuances that may affect their purchasing decisions. For instance:

-

Regulatory Compliance: Different regions may have varying regulations and standards for bathroom products. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Cultural Differences in Quality Expectations: Quality perceptions can vary across cultures. Understanding local preferences and standards can help buyers set realistic expectations and avoid miscommunication.

-

Logistical Considerations: Transportation and storage conditions can impact product quality. Buyers should consider how products will be handled during shipping and whether the manufacturer has protocols in place to mitigate potential damage.

By understanding the manufacturing processes and quality assurance practices in bathroom manufacturing, B2B buyers can make informed decisions that align with their quality expectations and regulatory requirements. This knowledge is essential for establishing successful partnerships with suppliers across different regions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bathroom manufacturer’

Introduction

Sourcing a reliable bathroom manufacturer is a critical step for B2B buyers looking to enhance their product offerings. This guide provides a structured checklist to streamline your procurement process, ensuring that you select a supplier that meets your quality, compliance, and business needs. Whether you’re based in Africa, South America, the Middle East, or Europe, these steps will help you make informed decisions.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is essential to ensure that the manufacturer can meet your product requirements. This includes dimensions, materials, and design features. A well-defined specification document will not only guide your discussions with potential suppliers but also help in obtaining accurate quotes.

- Detail your requirements: Include specifics like water resistance, durability, and aesthetic preferences.

- Consider compliance: Ensure your specifications adhere to local regulations and standards relevant to your target market.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential bathroom manufacturers that align with your business goals. Utilize industry directories, trade shows, and online platforms to compile a list of candidates.

- Evaluate online presence: Look for manufacturers with a professional website and active social media profiles, as these often indicate credibility.

- Check reviews and ratings: Seek feedback from other businesses that have worked with these suppliers to gauge their reliability.

Step 3: Verify Supplier Certifications

Before engaging in any negotiations, it’s crucial to verify the certifications and compliance of your shortlisted manufacturers. This step ensures that they meet industry standards for quality and safety.

- Request documentation: Ask for ISO certifications, product safety certifications, and any other relevant compliance documents.

- Evaluate manufacturing practices: Ensure that their manufacturing processes align with international standards, particularly if you are importing products.

Step 4: Request Samples and Conduct Quality Checks

Requesting samples is a vital step in assessing the quality of a manufacturer’s products. This allows you to evaluate materials, craftsmanship, and functionality firsthand.

- Assess sample quality: Look for any defects or inconsistencies that could indicate manufacturing issues.

- Conduct performance tests: If applicable, test the samples in real-world scenarios to ensure they meet your expectations.

Step 5: Negotiate Terms and Pricing

Once you’ve selected a potential manufacturer, it’s time to negotiate terms and pricing. This step is crucial to ensure that you get the best value for your investment.

- Discuss payment terms: Clarify payment schedules, upfront deposits, and any financing options available.

- Negotiate delivery timelines: Ensure that the manufacturer can meet your deadlines without compromising quality.

Step 6: Establish Clear Communication Channels

Effective communication is key to a successful supplier relationship. Establishing clear communication channels can prevent misunderstandings and ensure that both parties are aligned throughout the manufacturing process.

- Define points of contact: Assign specific individuals from both sides to handle communications.

- Use project management tools: Consider using digital tools to track progress, manage timelines, and facilitate updates.

Step 7: Evaluate Post-Delivery Support

Finally, assess the level of post-delivery support the manufacturer offers. This includes warranty terms, return policies, and customer service availability.

- Inquire about warranty coverage: Understand what is covered and for how long.

- Assess customer service responsiveness: A manufacturer that provides excellent support can save you time and resources in the long run.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing bathroom manufacturers, ensuring a successful partnership that meets their business objectives.

Comprehensive Cost and Pricing Analysis for bathroom manufacturer Sourcing

What Are the Key Cost Components in Bathroom Manufacturing?

When sourcing from bathroom manufacturers, understanding the cost structure is crucial. The main components include:

-

Materials: The choice of materials significantly impacts costs. Common materials include ceramics, acrylics, and metals, each with varying price points. For example, high-quality ceramics might be more expensive but offer better durability and aesthetics.

-

Labor: Labor costs can vary widely depending on the region and skill level required for production. In countries with lower labor costs, such as some in Africa or South America, manufacturers can offer competitive pricing. However, it’s essential to consider the implications of labor quality on the final product.

-

Manufacturing Overhead: This includes costs related to factory operations such as utilities, rent, and administrative expenses. Efficient manufacturers often have lower overhead costs, which can be passed on to buyers.

-

Tooling: Specialized tools for manufacturing custom designs can lead to significant upfront costs. Buyers should inquire about tooling costs if they require bespoke products, as these can affect overall pricing.

-

Quality Control (QC): Effective quality control processes ensure product reliability and compliance with standards. While this adds to the cost, it is essential for minimizing returns and enhancing customer satisfaction.

-

Logistics: Transportation costs can be considerable, especially for international shipments. Factors such as shipping distance, mode of transport, and Incoterms can all influence logistics expenses.

-

Margin: Manufacturers typically mark up prices to ensure profitability. Understanding the markup percentage can aid in evaluating the reasonableness of quoted prices.

How Do Price Influencers Affect Bathroom Manufacturing Costs?

Several factors can influence pricing strategies in bathroom manufacturing:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their purchasing needs and negotiate MOQ terms that align with their business strategy.

-

Specifications and Customization: Customized products usually incur additional costs. Be clear about your specifications upfront to avoid unexpected charges.

-

Materials and Quality Certifications: Premium materials and certifications (like ISO or environmental standards) can elevate costs. Ensure that the quality aligns with your brand’s requirements to justify higher expenditures.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can significantly impact pricing. Engage with suppliers who have a proven track record in quality and timely delivery.

-

Incoterms: Understanding the agreed Incoterms is vital. They dictate who bears the cost and risk at various stages of transportation, influencing overall pricing.

What Negotiation Tips Can Help Buyers Achieve Cost-Efficiency?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings:

-

Research and Benchmarking: Conduct thorough market research to understand typical pricing and terms within your industry. This knowledge empowers you during negotiations.

-

Build Relationships: Establishing a strong rapport with suppliers can lead to better pricing and terms. Long-term relationships often yield favorable conditions.

-

Focus on Total Cost of Ownership (TCO): Evaluate all costs associated with the product, including maintenance, shipping, and potential returns. A lower initial price may not always equate to better value.

-

Be Prepared to Walk Away: If the terms are not favorable, be willing to explore alternatives. This stance can often prompt suppliers to reconsider their offers.

What Should Buyers Know About Pricing Nuances in International Markets?

Pricing structures can vary significantly across regions, influenced by local economic conditions, currency fluctuations, and trade regulations. Buyers from Europe, for instance, may encounter higher prices due to stringent quality standards compared to those sourcing from developing markets.

Understanding these nuances helps buyers anticipate costs and negotiate more effectively. Always request indicative pricing and be aware that quotes may change based on market conditions or additional requests.

Disclaimer on Indicative Prices

Prices mentioned in discussions or negotiations are often indicative and subject to change based on a multitude of factors. Always confirm final pricing and terms in writing to avoid misunderstandings.

Alternatives Analysis: Comparing bathroom manufacturer With Other Solutions

Understanding Alternatives to Bathroom Manufacturers

In the global marketplace, B2B buyers are often faced with a variety of solutions when it comes to sourcing bathroom fixtures and installations. While traditional bathroom manufacturers provide a comprehensive range of products, exploring alternative solutions can lead to cost savings, enhanced performance, and improved customization options. This section compares bathroom manufacturers with prefabricated bathroom units and modular bathroom solutions, highlighting their respective advantages and disadvantages.

| Comparison Aspect | Bathroom Manufacturer | Prefabricated Bathroom Units | Modular Bathroom Solutions |

|---|---|---|---|

| Performance | High-quality, customized products tailored to specific needs | Quick installation with decent quality | Flexible design options with good quality |

| Cost | Higher upfront costs, potential for bulk discounts | Generally lower due to mass production | Mid-range costs, depending on customization |

| Ease of Implementation | Time-consuming due to custom orders and installations | Quick setup, often pre-assembled | Requires planning but can be installed quickly |

| Maintenance | Variable based on product quality | Low maintenance, factory-finished | Moderate, depending on materials used |

| Best Use Case | High-end projects requiring unique designs | Budget projects needing speed | Projects requiring flexibility and adaptability |

What Are the Advantages and Disadvantages of Prefabricated Bathroom Units?

Prefabricated bathroom units are manufactured off-site and delivered ready for installation. This solution is ideal for projects that prioritize speed and cost-effectiveness. The main advantage of prefabricated units is their quick installation time, which can significantly reduce labor costs. However, these units may offer less customization compared to traditional bathroom manufacturers, and their design may not suit every aesthetic preference.

How Do Modular Bathroom Solutions Compare?

Modular bathroom solutions offer a flexible alternative, allowing B2B buyers to customize layouts while benefiting from quicker assembly times. These systems can be tailored to specific needs, making them suitable for various environments, from residential to commercial spaces. The main disadvantage lies in the planning required for installation, which may add time upfront, but the long-term benefits of adaptability often outweigh this initial investment.

How to Choose the Right Solution for Your Bathroom Needs

When selecting the most suitable solution for bathroom installations, B2B buyers should consider factors such as project scope, budget, and design requirements. If a project demands high-quality, bespoke solutions, traditional bathroom manufacturers may be the best choice despite the higher costs. Conversely, for those needing rapid deployment and cost efficiency, prefabricated units or modular solutions may be more appropriate. Ultimately, understanding the specific needs of the project will guide buyers towards the ideal solution, ensuring that they make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for bathroom manufacturer

What Are the Essential Technical Properties for Bathroom Manufacturing?

Understanding the technical properties of bathroom manufacturing is crucial for B2B buyers seeking quality and compliance. Here are several key specifications that should be considered:

1. Material Grade

Material grade refers to the classification of materials based on their composition and properties. Common materials used in bathroom manufacturing include ceramics, stainless steel, and acrylic. For instance, high-grade stainless steel (such as 304 or 316) is often preferred for fixtures due to its corrosion resistance and durability. Buyers should prioritize suppliers that use high-grade materials to ensure longevity and performance.

2. Tolerance Levels

Tolerance levels indicate the acceptable limits of variation in a manufactured product’s dimensions. This specification is vital in ensuring that components fit together correctly, especially in plumbing and fixtures. For example, a tolerance of ±0.5 mm may be acceptable for certain fittings, while others may require tighter tolerances. Understanding these levels helps buyers avoid costly installation errors and ensures compatibility with existing systems.

3. Water Absorption Rate

The water absorption rate measures how much water a material can absorb over a specified period. This property is particularly important for ceramics and tiles used in bathrooms. A lower absorption rate (typically less than 0.5%) indicates better resistance to moisture and, consequently, mold and mildew growth. Buyers should seek products with low water absorption to maintain hygiene and reduce maintenance needs.

4. Finish Quality

Finish quality refers to the surface treatment of bathroom products, impacting aesthetics and durability. Options may include gloss, matte, or textured finishes. High-quality finishes can enhance corrosion resistance and ease of cleaning, making them more appealing to customers. Buyers should assess finish quality to ensure they meet both functional and aesthetic requirements.

5. Load-Bearing Capacity

Load-bearing capacity indicates the maximum load a product can withstand without failure. This property is essential for items like bathtubs and shower trays, which must support significant weight. Buyers should inquire about load-bearing specifications to ensure safety and compliance with local building codes.

What Are Common Trade Terms in Bathroom Manufacturing?

Navigating the complex landscape of bathroom manufacturing involves familiarizing oneself with industry terminology. Here are some common trade terms that international B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In bathroom manufacturing, OEMs often provide components like faucets or toilet tanks. Understanding OEM relationships can help buyers source high-quality parts while ensuring brand consistency.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers looking to manage inventory costs effectively. Understanding MOQ helps buyers negotiate better terms and assess whether a supplier aligns with their purchasing strategy.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to solicit price quotes for specific products or services. It is a critical step in the procurement process, allowing buyers to compare pricing and terms from multiple suppliers. Crafting a clear RFQ can lead to better deals and informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms used in international shipping to define responsibilities between buyers and sellers. They clarify who is responsible for shipping costs, insurance, and risk management during transit. Familiarity with Incoterms can help buyers avoid misunderstandings and ensure smooth transactions across borders.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. It is an essential consideration for planning and inventory management. Understanding lead times can help buyers align their procurement strategies with project timelines and customer demands.

These essential properties and terms equip international B2B buyers with the knowledge necessary to make informed decisions in the bathroom manufacturing sector. By focusing on these aspects, buyers can enhance their purchasing strategies and ensure they receive quality products that meet their needs.

Navigating Market Dynamics and Sourcing Trends in the bathroom manufacturer Sector

What Are the Key Market Dynamics and Sourcing Trends for International Bathroom Manufacturers?

The global bathroom manufacturing sector is experiencing a significant transformation driven by various factors. Emerging markets in Africa, South America, the Middle East, and Europe are reshaping demand dynamics as urbanization and infrastructure development accelerate. As international B2B buyers seek reliable suppliers, understanding these market dynamics is crucial. Key trends include the adoption of advanced manufacturing technologies, such as automation and IoT, enhancing production efficiency and product customization. Furthermore, the shift towards digital platforms for sourcing and procurement is streamlining the buying process, allowing buyers to access a wider range of products and suppliers with ease.

Sustainability has also become a primary driver in the bathroom industry. Buyers are increasingly prioritizing eco-friendly products and sourcing practices, pushing manufacturers to innovate in their materials and processes. The rise of smart bathrooms, integrating technology for enhanced user experience, is another trend reshaping the market. As a B2B buyer, staying informed about these trends is essential for making strategic sourcing decisions that align with market demands and consumer preferences.

How Is Sustainability Shaping Sourcing Decisions in the Bathroom Manufacturing Sector?

Sustainability is no longer just a buzzword; it is a critical component of business strategy for bathroom manufacturers. International B2B buyers are increasingly aware of the environmental impacts of their purchases and are seeking suppliers committed to ethical sourcing practices. This includes the use of sustainable materials, such as recycled plastics and responsibly sourced wood, which reduce the overall carbon footprint of products.

Moreover, obtaining certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) can enhance a manufacturer’s credibility in the eyes of buyers. These certifications assure buyers that the products meet strict environmental standards. Additionally, transparency in supply chains is becoming a non-negotiable requirement, as buyers demand visibility into the sourcing of materials and labor practices. By prioritizing sustainability, buyers can not only contribute to environmental conservation but also enhance their brand reputation and customer loyalty.

What Historical Developments Have Influenced the Bathroom Manufacturing Sector?

The bathroom manufacturing sector has evolved significantly over the decades. Historically, the industry was characterized by traditional craftsmanship, with products being handmade and customized for each client. The post-World War II era saw a surge in mass production techniques, driven by industrialization and the need for affordable housing. This led to standardized products, making bathrooms more accessible to the general population.

In recent years, technological advancements have further transformed the sector. The introduction of computer-aided design (CAD) and 3D printing has enabled manufacturers to innovate rapidly and respond to market demands effectively. As consumer preferences shift towards personalized and smart solutions, the industry continues to adapt, blending tradition with modern technology to meet the evolving needs of international B2B buyers. Understanding this evolution can provide valuable context for making informed sourcing decisions in today’s dynamic market.

Frequently Asked Questions (FAQs) for B2B Buyers of bathroom manufacturer

- How do I evaluate potential bathroom manufacturers for international sourcing?

Evaluating potential bathroom manufacturers involves several critical steps. Start by assessing their production capacity and capabilities to meet your specific requirements, including design and material preferences. Verify their certifications (e.g., ISO, CE) to ensure compliance with international standards. Additionally, seek out reviews or testimonials from previous clients to gauge reliability and quality. It’s beneficial to request samples of their products, as this allows you to evaluate craftsmanship and materials firsthand before committing to a larger order.

-

What are the key factors to consider when negotiating payment terms with bathroom manufacturers?

When negotiating payment terms, consider factors such as the total order value, your relationship with the supplier, and their payment history. Common terms include a percentage upfront (typically 30-50%), with the balance due upon completion or delivery. Ensure you clarify any potential additional costs, such as shipping and customs duties. It’s wise to explore options like letters of credit or escrow services for larger transactions, providing security for both parties. Clear communication about timelines and penalties for late payments is also essential. -

What minimum order quantities (MOQs) should I expect from bathroom manufacturers?

Minimum order quantities (MOQs) can vary significantly among bathroom manufacturers, typically ranging from 100 to 1,000 units depending on the product type and manufacturer. High-quality, specialized products may have higher MOQs due to the costs associated with production. It’s advisable to discuss your specific needs with the manufacturer to negotiate MOQs that align with your business model. Some manufacturers may offer flexibility for initial orders, especially if you establish a strong business relationship. -

How can I ensure quality assurance (QA) in my orders from bathroom manufacturers?

To ensure quality assurance, start by defining clear product specifications and quality standards in your purchase agreement. Request the manufacturer’s quality control processes and certifications, such as ISO 9001. Consider conducting third-party inspections during production and before shipment to verify compliance with your quality standards. Additionally, establishing a return policy for defective products can safeguard your investment and enhance accountability on the manufacturer’s part. -

What logistics considerations should I keep in mind when importing bathroom products?

Logistics plays a crucial role in importing bathroom products. First, understand the shipping options available (air freight vs. sea freight) and choose based on your budget and timeline. Be aware of customs regulations and tariffs in your destination country, as these can significantly impact costs and delivery times. Partnering with a reliable freight forwarder can streamline the logistics process, helping you navigate documentation and compliance. Always plan for potential delays, especially in peak shipping seasons. -

How do customization options affect pricing and lead times for bathroom products?

Customization options, such as unique designs, materials, or finishes, can increase both pricing and lead times. Manufacturers often charge premium rates for custom work due to the additional resources required for design and production adjustments. Lead times may extend significantly, particularly if the manufacturer needs to source specific materials or components. To mitigate costs, consider bulk ordering customized items or discussing flexible design options that maintain your brand identity without substantial price increases. -

What are the common challenges faced when sourcing bathroom manufacturers internationally?

Common challenges include language barriers, differences in time zones, and varying business practices. Additionally, navigating customs regulations and ensuring compliance with local laws can complicate the sourcing process. Quality control can also be a concern, as it may be difficult to assess product quality without an on-site presence. To overcome these challenges, build strong relationships with suppliers, utilize technology for communication, and consider hiring local experts who understand the market dynamics. -

How can I effectively communicate my requirements to a bathroom manufacturer?

Effective communication with a bathroom manufacturer begins with clear, detailed specifications. Provide comprehensive documentation, including drawings, dimensions, and material samples. Using visual aids, such as photos or prototypes, can help convey your design vision more effectively. Establish regular check-ins to discuss progress and address any issues promptly. Utilizing project management tools can enhance collaboration and ensure that all parties are aligned throughout the production process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for bathroom manufacturer

What Are the Key Takeaways for International B2B Buyers in Bathroom Manufacturing?

In conclusion, strategic sourcing remains a crucial component for international B2B buyers in the bathroom manufacturing sector. By leveraging data-driven insights, buyers can identify reliable suppliers who offer high-quality products at competitive prices. This approach not only enhances supply chain efficiency but also fosters long-term partnerships that can lead to innovation and sustainability in product offerings.

How Can Buyers Navigate Global Markets Effectively?

As buyers from Africa, South America, the Middle East, and Europe explore global markets, it is vital to consider regional preferences and compliance standards. Understanding local regulations and cultural nuances can significantly impact procurement decisions and customer satisfaction. Additionally, engaging with suppliers who prioritize ethical sourcing practices can enhance brand reputation and consumer trust.

What’s Next for the Bathroom Manufacturing Industry?

Looking ahead, the bathroom manufacturing industry is poised for growth, driven by trends such as smart technology integration and eco-friendly materials. Buyers are encouraged to stay informed about emerging trends and invest in suppliers who are adaptable and innovative. By doing so, they not only secure a competitive edge but also contribute to a more sustainable and technologically advanced industry.

Take action now to evaluate your sourcing strategies and embrace the opportunities that lie ahead in the evolving bathroom manufacturing landscape.